Page 1

Instructions

ReportNo. 08-154

Masonry Firebox

Model MMST43

THIS WOOD-BURNING FIREPLACE COMPLIES WITH UL127 STANDARD AS A FACTORY-BUILT APPLIANCE.

WARNING: THIS FIREPLACE IS APPROVED FOR USE AS A WOOD BURNING FIREPLACE.

IT HAS NOT BEEN TESTED OR APPROVED FOR UNVENTED GAS LOGS.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE INJURY, PROPERTY DAMAGE OR LOSS OF LIFE. REFER TO THIS MANUAL FOR ASSISTANCE OR

ADDITIONAL INFORMATION. CONSULT A QUALIFIED INSTALLER OR LOCAL DISTRIBUTOR.

SAVE THIS BOOK

This book is valuable. In addition to instructing you on how to install and maintain your appliance, it also contains

information that will enable you to obtain replacement parts or accessory items when needed. Keep with your other

important papers.

Installer: Leave these instructions with the consumer.

Consumer: Retain for future reference.

Do not store gasoline or other ammable vapors and

liquids in the vicinity of this or any other appliance.

ICC Evaluation Services

Report No. 2401

Page 2

This page has been left intentionally blank.

Page 3

CONTENTS

2701 S. Harbor Blvd.

SANTA ANA, CA 92704

DATE OF MFG.

SERIAL No.

LISTED MASONRY FIREPLACE SYSTEM COMPLIES WITH APPLICABLE REQUIREMENTS OF UL127

Fireplace is designed for installation per the National Fire Protection Association Standard

for Chimneys, Fireplaces, Vents and Solid Fuel-Burning Appliances (NFPA 211).

MODEL

No.:

MMST43

DO NOT REMOVE THIS LABEL

See FMI’s installation and operating instructions for

this model. Contact local building officials about

restrictions and installation specifications in your area.

WARNING:

FOR USE ONLY WITH

12

" I.D.

FMI PRODUCTS, LLC LISTED

FIREPLACE COMPONENTS: PIPE

SECTIONS, FIRESTOP SPACERS,

OFFSET AND RETURN ELBOWS,

FLASHINGS, STORM COLLARS,

TERMINATIONS AND WALL SHIELDS.

!

THIS APPLIANCE NEEDS FRESH AIR FOR SAFE OPERATION AND MUST BE INSTALLED

SO THERE ARE PROVISIONS FOR ADEQUATE COMBUSTION AND VENTILATION AIR.

MANTEL CLEARANCES

0" - 3" : 1½" MAX. PROJ.

3" - 12" : 1½" - 8" MAX. PROJ.

MANTEL ABOVE OPENING:

MIN. - 3" SHEATHING OR

TRIM TO OPENING SIDES 8"

FIREPLACE CLEARANCES TO COMBUSTIBLES:

UNIT FRONT, SIDES, REAR.............................................. 2" (51 mm)

COMBUSTIBLE FLOOR ............................................ 6

"

(152 mm)

COMBUSTIBLE SHEATHING ABOVE OPENING TOP.... 8

"

(203 mm)

SHEATHING OR TRIM TO OPENING SIDES.................. 8

"

(203 mm)

MANTLE ABOVE OPENING...........................................12

"

(305 mm)

OPENING TO SIDE WALL............................................. 24

"

(610 mm)

HEARTH EXTENSION BEYOND FRONT...................... 20

"

(508 mm)

HEARTH EXTENSION BEYOND SIDES........................12

"

(305 mm)

INSULATION FROM FIREBOX........................................... 2

"

(51 mm)

!

WARNING

:

THIS FIREPLACE

HAS BEEN TESTED FOR USE ONLY

WITH APPROVED GLASS DOORS.

TO REDUCE THE RISK OF FIRE OR

INJURY, CONSULT OWNER’S MANUAL.

THIS FIREPLACE IS DESIGNED

FOR USE ONLY WITH SOLID

WOOD LOGS, PLUMBED LPG

OR NG LOG LIGHTERS OR

PLUMBED ANSI Z21.60

DECORATIVE GAS LOGS.

Consult instructions included with

this firebox for further information.

PFS

®

US

CHIMNEY HEIGHT:

Max.: 40 ft.

Min.: 14 ft.

(17 ft. with 1 or 2 offset

sections maximum)

6.5”

6.25

Report No.

08-154

ICC Evaluation

Services Report

No. 2401

Parts Lists ...............................................................................................................Pg. 2

Fireplace Overall & Framing Dimensions ................................................................Pg. 4

Fireplace Framing Dimensions (Combustible Floor Systems) ................................ Pg. 5

Safety Information ................................................................................................... Pg. 6

Product Overview ....................................................................................................Pg. 7

Clearance To Combustibles ....................................................................................Pg. 8

Fireplace & Chimney System ..................................................................................Pg. 8

Supporting Floor Systems .......................................................................................Pg. 9,10

Weight Determination ..............................................................................................Pg. 10

Component for combustible oors: 8” Metal Base .................................................. Pg. 11

Fireplace Assembly Procedures .............................................................................. Pg. 12 ~ 14

Firestop Radiation Shield ........................................................................................ Pg. 14

Firebrick Liners ........................................................................................................ Pg. 15

Electrical Line Feed ................................................................................................. Pg. 15

Fireplace Finishes and Combustible Trim Clearances ............................................ Pg. 16

Mantle and Mantle Shelf Clearances ...................................................................... Pg. 16

Installing Outside Air ............................................................................................... Pg. 16

Adding a Gas Pipe .................................................................................................. Pg. 16

Adding Electrical Connection .................................................................................. Pg. 16

Chimney Systems ................................................................................................... Pg. 17

Installing Damper and Chimney System ................................................................. Pg. 17

Fireplace Door Accessory ....................................................................................... Pg. 17

Owner’s Operation & Precautions ...........................................................................Pg. 18

Starting A Fire and Basic Operation ........................................................................ Pg. 18

Annual Fireplace Maintenance ................................................................................ Pg. 19

Technical Service ....................................................................................................Pg. 19

Replacement Parts .................................................................................................. Pg. 19

Appendix I ............................................................................................................... Pg. 20

Appendix II .............................................................................................................. Pg. 21

Warranty Information ............................................................................................... Pg. 22

Below is a sample picture of the rating plate that is located inside the lower dome side of your replace. Serial number and date

code should be stamped on the plate where required.

1

Page 4

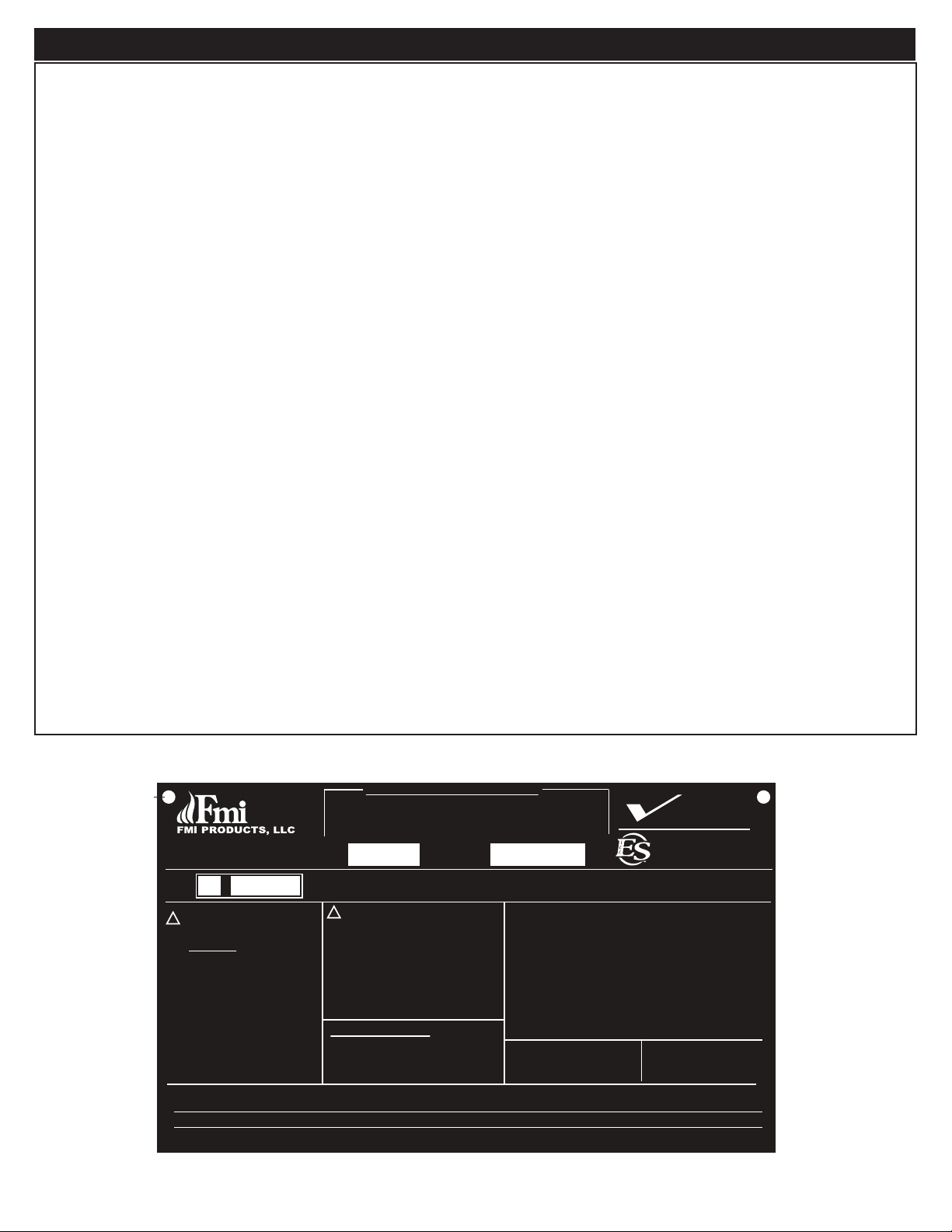

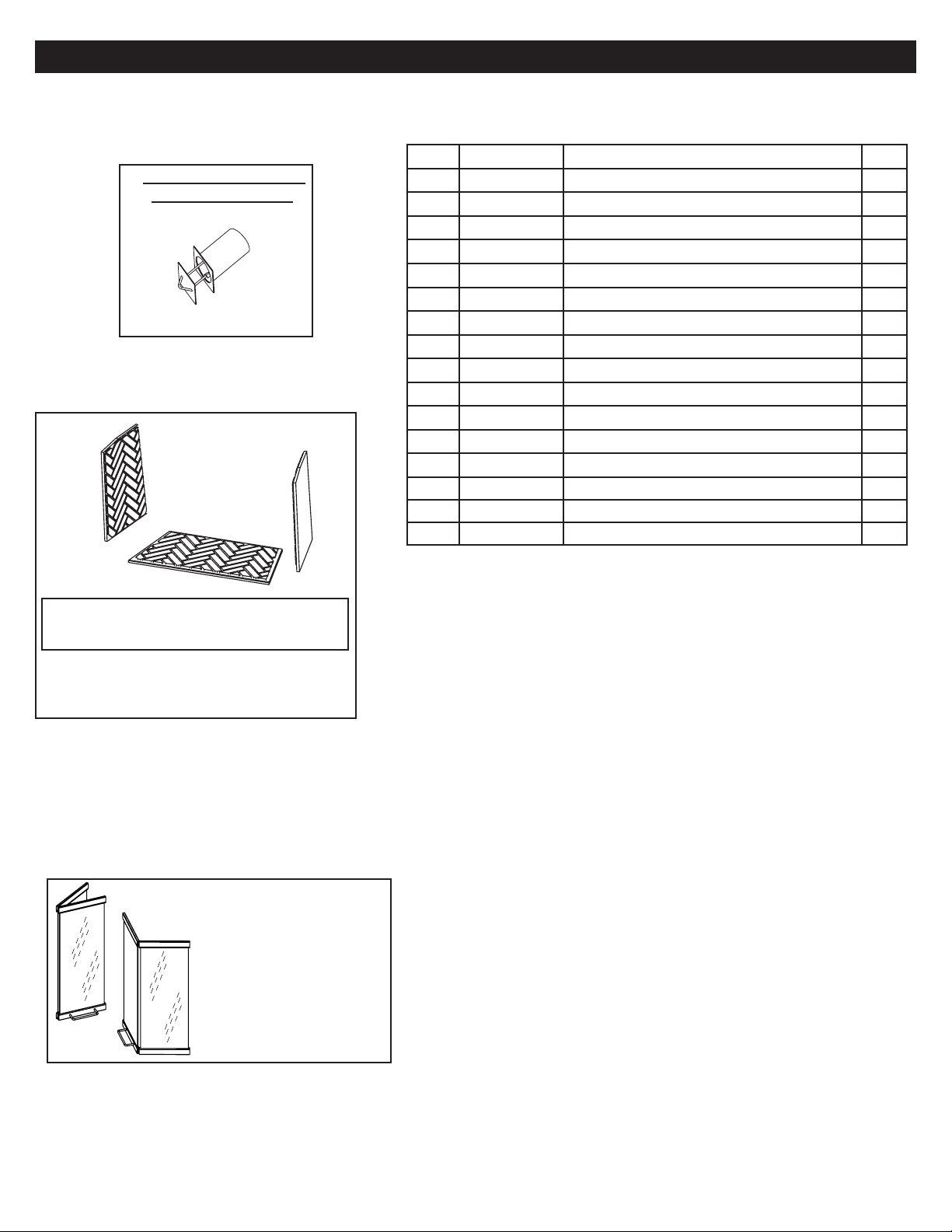

MMST43 Fireplace Parts Diagrams

Figure 1

13

14

8

7

12

6

20

Combustible Floor Systems

9

10

Non-Combustible Floor Systems

Figure 2

13

14

8

7

12

6

20

9

10

19

17

1

19

3

3A

16

18

1

3

3A

2

Page 5

Optional Outside Ø4”

Combustion Air Kit

Model No.: MM4-AK

(Ø4” Ducting not included)

MMST43 Fireplace Parts List

ITEM P/N DESCRIPTION QTY

1 MFPST-43-1 HEARTH (Left or Right) 2

3 MFPST-43-3 SIDE WALL 5

3A MFPST-43-3A SIDE WALL W/4” KNOCKOUT 1

6 MFPST-43-6 LINTEL 1

7 MFPST-43-7 DOME SIDE - LOWER 2

8 MFPST-43-8 DOME SIDE - UPPER 2

9 MFPST-43-9 DOME TOP FOR 16” CLASS A CHIMNEY 1

10 MFPST-43-10 DOME FRONT/REAR - UPPER 2

12 125122-01 RATING PLATE, MM43ST 1

MM12AP

13

**

14

16 MMB43 STEEL SUPPORT PLATFORM 8 INCH HIGH 1

**

17

18 ** ASSY, FLOOR JOIST BRACE 4

19 ** #3 REBAR (Ø3/8”) x 36” 8

20 MMARC LINTEL TRIM (OPTIONAL) 2

Ø12” DAMPER / ANCHOR PLATE ---

INSULATION BLANKET ---

CEMENT BOARD ---

MM43STSHBL- Herringbone

MM43STFRBL- Running Bond

Refractory Firebrick Liners

(Herringbone Pattern shown, also available

in Running Bond - see Pg.27)

Only the following

doors have been tested

and approved for use

with this fireplace:

Crown-Breckinridge

or

McKenzie-Pendelton

3

Page 6

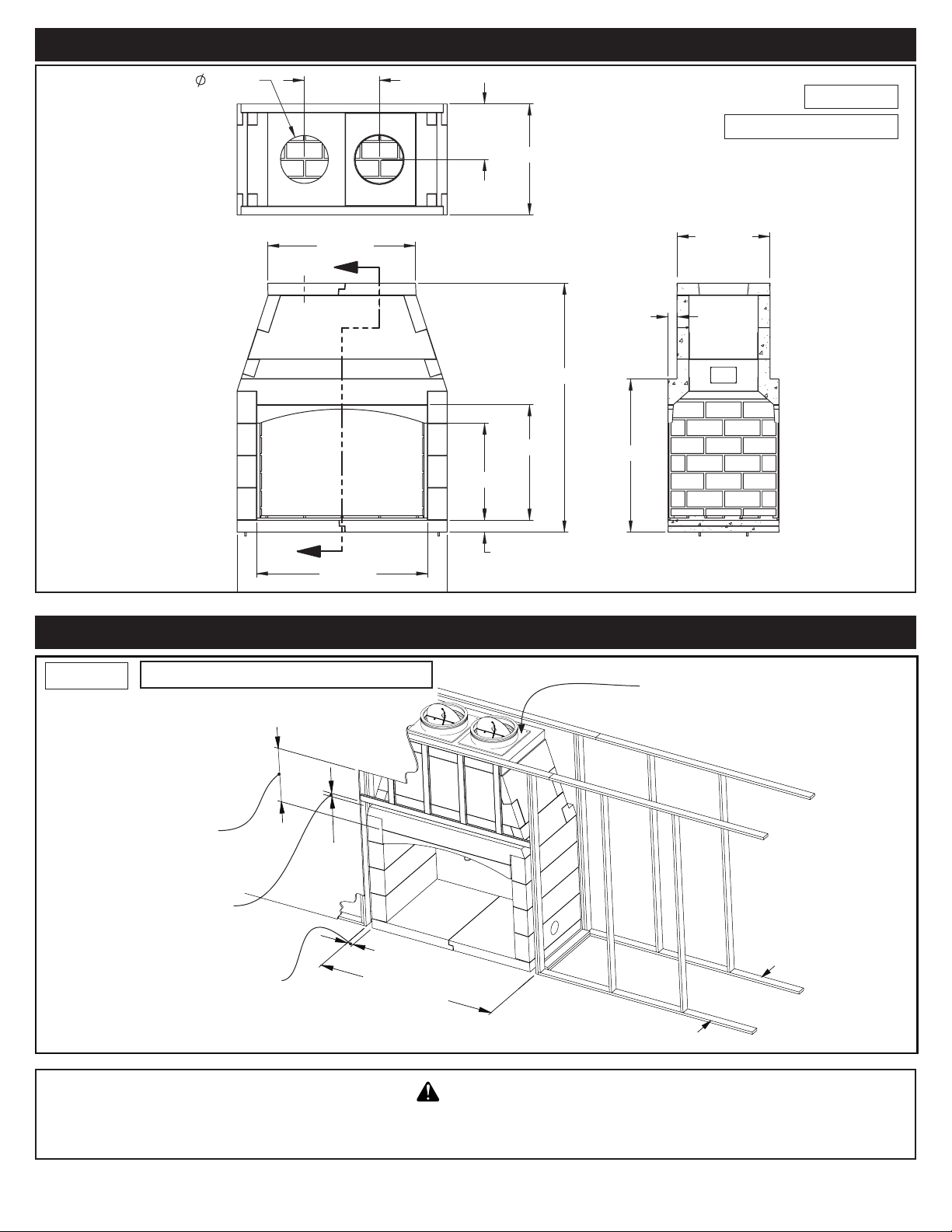

MMST43 Fireplace Overall Dimensions

62 7/8"

43 1/4"

29 1/8"

24 1/2"

3"

37 3/8"

A

A

18 7/8"12 1/8"

28"

14"

SECTION A-A

23 1/2"

38 5/8"

2 1/4"

Figure 3

Overall Dimensions

Figure 4

IF WOOD FRAMING IS UTILIZED

IT MUST BE HELD 18 INCHES

MIN. FROM TOP OF LINTEL AND

2 INCHES MIN.CLEARANCE

MUST BE MAINTAINED ALL

AROUND FIREPLACE DOME.

IF METAL FRAMING IS USED

MAINTAIN A 1/2 INCH MIN. AIR

SPACE FROM TOP OF LINTEL.

2” MIN. CLEARANCE TO

COMBUSTIBLES AROUND SIDES,

REAR AND TOP OF FIREPLACE DOME.

Non-Combustible Floor Systems

Fireplace Framing Dimensions

57” I.D.

FRAMING

MAINTAIN THE 2” CLEARANCE TO

COMBUSTIBLES ABOVE THE DOME. DO

NOT ATTACH COMBUSTIBLE MATERIALS

ON TOP OF THE DOME.

28” O.D.

WARNING

Failure to position the parts in accordance with these diagrams or failure to use only parts specically

approved with this appliance may result in property damage or personal injury.

4

Page 7

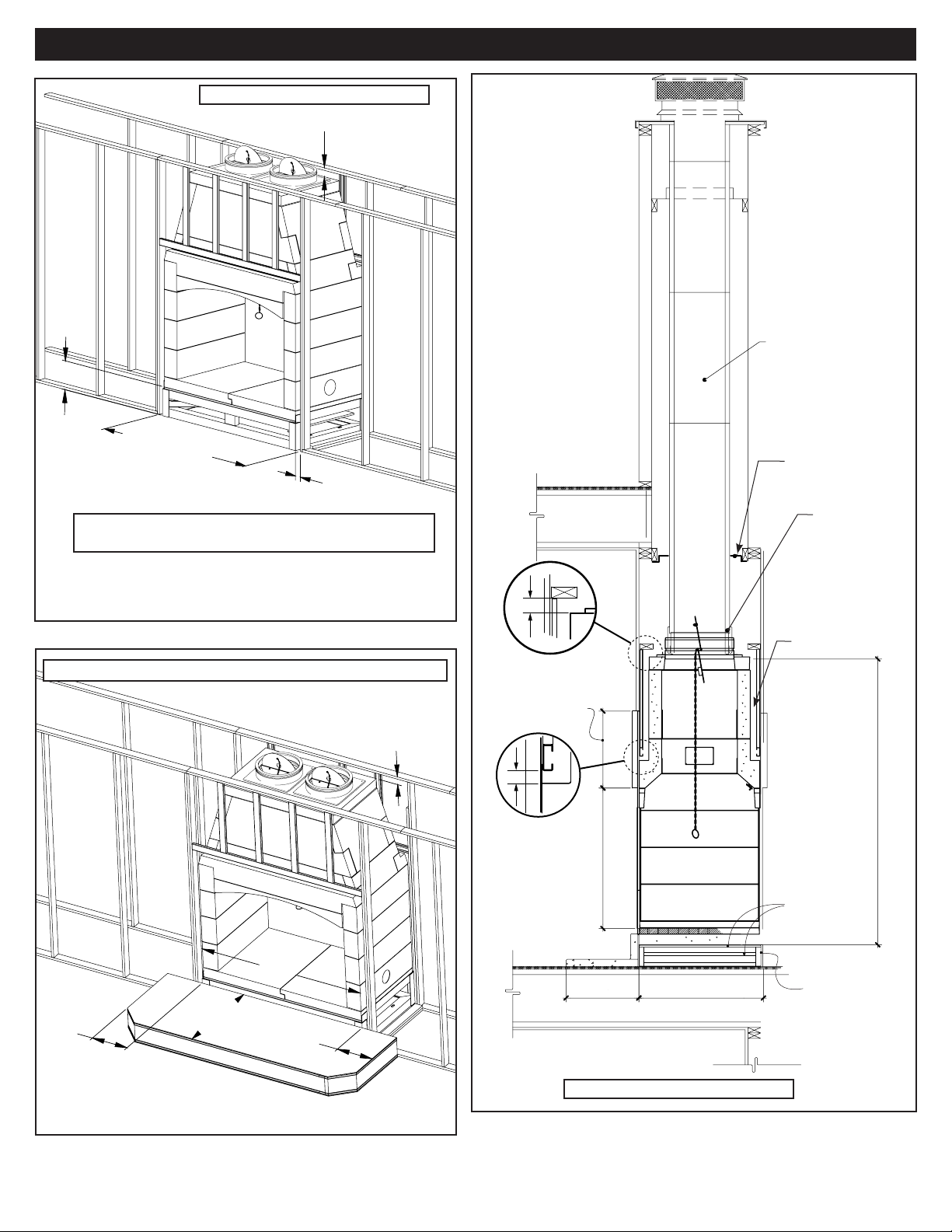

30 5/8"

65"

28”

1/2”

2”

Fireplace Framing Dimensions (Combustible Floor Systems)

20"

MIN

12"

MIN

12"

MIN

2" MIN

53"

Figure 5 - Combustible Floor

2” MIN**

8-1/2”

57” I.D.

FRAMING

2” MIN*

* 2 INCH CLEARANCE TO COMBUSTIBLES BOTH

SIDES OF FIREPLACE

CLASS “A”

CHIMNEY

SEE FIG. 27

AND 28

SEE FIG. 26

** If using a raised hearth or metal base plate, note that a

combustible wood header must be no closer than 2” to the

top of the dome top.

Figure 6 - Non-Combustible Hearth Extension (by others*)

2” MIN*

53”

12”

MIN

20”

MIN

12”

MIN

* Not provided as part of replace

ONLY NON-COMBUSTIBLE

MATERIAL WITHIN 18” OF

TOP OF OPENING.

20”

Figure 7 - Combustible Floor

2” AIRSPACE

CLEARANCE TO

COMBUSTIBLES

FROM REAR

AND SIDES

1/2” THICK

CONCRETE

BOARD

8” METAL

PLATFORM

5

Page 8

Safety Information

WARNING: THIS FIREPLACE HAS NOT BEEN

TESTED FOR USE WITH AN UNVENTED GAS LOG SET.

TO REDUCE THE RISK OF FIRE OR INJURY, DO NOT

INSTALL AN UNVENTED GAS LOG SET INTO FIREPLACE.

WARNING: THIS FIREPLACE HAS BEEN TESTED

FOR USE WITH OPTIONAL GLASS DOORS: CROWN-

BRECKINRIDGE OR MCKENZIE-PENDELTON ONLY.

WARNING:

Install only approved, listed UL 103-16” I.D. Class A

Chimney System.

Chimney maximum height: 40 feet

Chimney minimum height: 14 feet (with offset = 17 feet)

2 offsets maximum.

Important: Follow the chimney pipe manufacturer’s

instructions on the installation of their specic ue system.

GUIDELINES FOR USE:

All current and future users of FMI Products, LLC Fireplaces

are charged with the responsibility for full knowledge of the

information contained within this manual which includes:

Strict requirements for assembly.

Detailed instructions for installation.

Cautionary guidelines for use.

On-going maintenance instructions.

It is the responsibility of the distributor, subcontractor and/or

the general contractor – whoever shoulders the liability for

installation of this product – to see to it that the work is in

complete compliance with the guidelines and instructions

in this manual. Note that the general contractor is the party

accountable for seeing that adequate clearances are provided

from all rebox surfaces per specications in this manual.

DO NOT USE A FIREPLACE INSERT OR OTHER

PRODUCTS NOT SPECIFIED FOR USE WITH THIS

FIREPLACE.

The Grand Meridian is Designed for Use Only with:

- Solid Wood Logs

- Plumbed LPG or Natural Gas Log Lighter.

- Plumbed ANSI Z21.60 Decorative Gas Log.

DO NOT USE OR STORE GASOLINE OR OTHER

FLAMMABLE LIQUIDS OR GASES IN OR NEAR THE

FIREPLACE!

ATTENTION: A re or an explosion could occur causing

property damage, injury or loss of life if you do not follow the

information in this manual!

NOTE: THIS MANUAL MUST BE REPRODUCED ONLY

IN ITS ENTIRETY.

Before Beginning the Installation

Read these instructions carefully before beginning the

installation of this replace. Also, if installing an ANSI Z21.60

Decorative Gas Log, read the gas log appliance manufacturer’s

literature regarding sizing and suitability for the installation into

this Enclosure prior to installation.

Statement of Intended Use:

The Grand Meridian Fireplace is a modular refractory

masonry unit designed for eld assembly. The rebox is

constructed using pre-cast, interlocking refractory blocks.

The blocks are then secured to each other using Mortar. The

system includes all parts necessary for the assembly of a

complete masonry replace. In addition to the basic enclosure,

a standard 1-1/8” thick, high temperature refractory brick is

required to line the interior of the rebox.

These replaces are not intended to serve as a primary

heat source, rather, the replace was expressly created as a

supplemental source of heat. The unit is designed for use with

solid fuels such as cord wood.

WARNING:

Any application other than the “Intended Use” as stated above

is in violation of the manufacturer’s instructions and is hereby

prohibited. Such violation may cause immediate hazard,

property damage or loss of life and will void all liabilities to the

manufacturer and will void all warranties explicit or implied.

6

Page 9

Product Overview

Introduction

We extend a warm welcome from all of us at FMI

PRODUCTS, LLC.

You may have thought long and hard before you chose the

replace which would grace your home. Rest assured that

every component of the Fireplace has been tested to ensure

long-term durability.

Product Overview

FMI Products, LLC Fireplaces are designed as factory-

built blocks to be assembled on-site. These replaces may

be installed on either combustible or non-combustible oors.

In order for the replace to be installed on a combustible oor

though, it is necessary that the replace be supported on a

platform or sub-oor that is non-combustible.

The Four Components of the Grand Meridian Fireplace:

Combustible or Non-Combustible Floor•

Non-Combustible Raised Platform•

Grand MeridianFirebox and Smoke Dome•

UL103-16” class A listed chimney system required. •

Important: Follow the chimney pipe manufacturer’s

instructions on the installation of their specic ue system.

Figure 8 - Typical Installations

Internal

Wall

Installation

Island

Installation

Careful step-by-step instructions for each phase of the

installation procedure will be given for the Grand Meridian

conventional radiant heat replaces. Those instructions

generally fall into the following categories:

Spacing and clearance as it relates to combustible •

materials.

Familiarity of installation for all components.•

The strength of the oor on which it rests.•

Chimney system measurements.•

Choice of materials and craftsmanship in replace and •

hearth nishing.

Note that each of these topics will be covered in detail and that

the installer is expected to understand each phase completely

before going on to subsequent instructions.

Attention: Be advised that all the illustrations in this manual

are for general reference only. Do not scale drawings. Actual

design elements will vary from case to case. Pay attention to

specied minimum clearances to combustibles.

Testing and listing for the Grand Meridian Fireplace has been

undertaken by PFS Inc. (Report No. 08-154) to UL 127.

Attention: You may need a residential building permit to install

a Grand Meridian Fireplace. Consult local jurisdictions before

you get started!

If asked, advise the local authorities that the Grand Meridian Fireplace is designed for installation per the National Fire

Protection Association Standard for Chimneys, Fireplaces,

Vents and Solid Fuel-Burning Appliances (NFPA211).

When choosing the location of your Grand Meridian Fireplace,

keep in mind you must maintain 2” (two inches) minimum

clearance from left, right and rear of Fireplace to surrounding

structure. Also, when choosing a location, consider outside air

requirements to determine if it will be on the left or right side

of the Fireplace. In the case of an island installation, outside

air accessibility may be obtained through sub-ooring. See

section on Installing Outside Air on page 17.

7

Page 10

Clearances to Combustibles

The distance to be maintained from the surfaces of the

replace to combustibles must be observed. Below is a list of

the most common combustible materials to name a few:

Drywall Wood ooring Plywood

Sub-ooring Wood Framing Particle board

Mill board Plywood paneling

Grand Meridian Fireplace & Chimney System

Prior to starting the installation, check with local, regional or

state codes for any restrictions or required permits regarding

your replace installation.

The Grand Meridian is designed to be installed with a 1)

listed UL-103-16” I.D. Class A, Metal Chimney System.

Maintain the following clearances:

Unit front, sides, rear: 2” (50 mm)•

Combustible Floor: 8” (150 mm)•

Combustible Sheathing above opening top: 8” (200 mm)•

Sheathing or trim to opening sides: 8” (200 mm)•

Mantel above opening: (refer to • Fig.9)

Opening to sidewall: 24” (500 mm)•

Hearth extension beyond front: 20” (500 mm)•

Hearth extension beyond sides: 12” (300 mm)•

Insulation from rebox: 2” (50 mm)•

Figure 9

Understanding Clearance to Combustibles

There is a build-up of considerable amount of radiant heat

on the outer surfaces of the Grand Meridian Fireplace. It’s

critical that proper clearances to combustibles be maintained

so that this radiant heat is maintained to safe limits.

MMST43 Grand Meridian Fireplaces have been designed

with clearance to combustible oors at a minimum of 8-1/2”

(eight and one half inches) as provided by the 8” metal base

and 1/2” concrete board. Cover any part of the combustible

oor system left exposed with 1” (one inch) thick ceramic ber

insulation rated up to 2,100°F.

This Grand Meridian replace is intended as a supplemental 2)

heat source only. It is not intended as a primary heat

source.

It is the responsibility of the contractor installer (not the 3)

manufacturer) to ensure that adequate combustion air is

provided for proper function of this replace. Fireplaces

take up a large volume of replacement air from outside the

house and if the house is of airtight construction, smoke

spillage may occur if proper draft is not achieved.

There are many conditions beyond a manufacturer’s 4)

control regarding improper replace operation. The

manufacturer cannot ensure “smoke free” operation,

nor can the manufacturer take on the responsibility for

problems with surrounding construction; chimneys that

have not been built at the right heights; system drafts

caused by faulty mechanical systems; adverse weather

conditions or any other inclement environmental situations

over which the manufacturer has no control.

Inspect all replace & chimney components for evidence 5)

of damage prior to starting installation. Consult your local

distributor for replacement parts if necessary.

Under no circumstances should you make any adjustments 6)

or modications to the chimney system during the

installation procedure. If you do, you are not only liable

for negating the warranty, but you could very well cause a

serious malfunction of the replace. You must follow your

chimney manufacturer’s instructions.

Caution is urged if it is decided to add insulation material 7)

to any part of the Grand Meridian Fireplace or Chimney

system, be certain that the insulation material is kept at

least 2” (two inches) away from any part of the system.

When using insulation or vapor barrier materials, cover

with a layer of plywood, particle board or gypsum board to

maintain the specied 2” (two inch) clearance.

Air spaces around rebox must remain open. DO NOT ll 8)

these open spaces with insulation or packing material of

any kind.

The Grand Meridian Steel Platform , the 1/2” concrete

board

above, the 1” ceramic ber blanket or board within the

platform (Fig.15) and the 2” clearance for dome front, and unit

sides provide the temperature safety margin to combustible

materials.

Chimney System Heights

When installed, the maximum overall height of the chimney

system from bottom of replace to the top/termination chimney

is 40 feet. The minimum installed height of the completed

Chimney System is 14 feet with a straight ue stack, 17 feet if

the chimney includes one or two offset sections.

8

Page 11

Supporting Floor Systems

I-JOISTS

Anchor

Brackets

I-Joist

It is the ultimate responsibility of the installer to ensure that

proper concrete slab supports are used.

Attach the rebox side wall anchors to steel support frame

by inserting all-thread rods through holes on the bottom ange

on the steel support frame as shown in Figure 14. Secure with

two Ø 2” o.d. x Ø 9/16” i.d. x 0.10” Washers and two 1/2-13

UNC Nuts.

WARNING to the licensed design professional and/or building

contractor: It is your responsibility to be certain that the Grand

Meridian can be properly supported by the combustible oor

system on which the replace will rest.

For replace support foundations installed on concrete refer to

Appendix I and II (pages 20 & 21 ) for specic instructions.

Rebar locations

Lay-out the position of the replace and drill holes where

the rebar will be located. Secure eight #3 rebar 4 inches into

concrete foundation with ITW Epoxy or Simpson Epoxy.

Follow manufacturer’s instructions for installation of rebar into

slab.

Wood Floor

Anchorage of replace to wood oor construction is required.

Refer to Figure 10 for anchorage locations. Four anchors are

required to attach to the sub-ooring framing.

Crawl Space or Upper Floor:

For installation of rebox over combustible crawl spaces or

upper oors, anchorage of the rebox is required. Illustrations

of examples of possible anchorage methods are shown in

Figures 10 thru 13 depending upon the type of oor framing.

Final method of anchorage to be determined by licensed

design professional.

Figure 10

Metal Base

Assembly

2X FLOOR JOIST

EXAMPLE ONLY

Floor Sheathing

not shown for

clarity

A35 Brackets

(16 required)

2X FLOOR JOIST

For conventional framing where the oor joists are parallel

with the sides of the rebox, the addition of oor joists to align

with the anchor brackets allows the brackets to be directly

connected to the oor joists.

Note that additional oor joists may be required to support

the weight of the rebox and chimney. Where the oor joists

run parallel to the front of the rebox, anchorage can be

accomplished in like manner as shown in Figure 12 using

blocking between the oor joist.

For oors supported by I-Joists, the method of anchorage

is illustrated in Figures 10 and 11. Figure 12 illustrates the

general arrangement of anchorage to oor framing.

It is important to take into consideration that the load for the

Grand Meridian Fireplace must be considered as additional

dead load that will have to be supported by the oor framing.

Additional oor joists or I-joists may be required as determined

by the licensed design professional.

The weights to be considered are noted in Table I. It is the

task and responsibility of the general contractor/installer to see

that the proper reinforcement for weight loads are made by a

licensed design professional prior to the replace installation.

As stated above, it is desirable to place additional framing

for alignment of anchor rods. Refer to Figure 14 for anchor

rod locations.

Figure 11

I-Joist Anchoring

Top View

Simpson

Strong-Tie

A-35 or

equivalent

Figure 12

I-Joist

Anchoring

Bottom

View

9

Example Only

Example Only

Page 12

Grand Meridian Weight Determination

48 3/4"

8"

12"

2” min

clearance

Fireplace

outline

10”

The following are dead load weight estimates for the

Grand Meridian Fireplace.

Table I

Model: MMST43

Fireplace 835 lb..

Damper/Anchor

Plate, Firebrick &

Mortar

Steel Platform 70 lb..

Floor Area

Other Weight Considerations:

Fireplace nished facing (surround): This information needs to be obtained from the contractor.1)

Weight of metal ue: See chimney manufacturer’s weight specications. Some chimney systems can weigh up to 50 lb. per 2)

linear foot.

350 lb..

53” x 28”

(10.3 square feet)

Table II - Deection Limits

Construction L S or W D +L1

Floor Members

1

For wood structural members having a moisture content of less than 16 per cent at time of installation and used under dry

conditions, the deection resulting from L + 0.5D is permitted to be substituted for the deection resulting from L + D.

Note that Grand Meridian cannot accept responsibility for structural oor support details. All drawings are presented as mere

illustrations to indicate the presence of the underlying oor system. It is the responsibility of the general contractor/installer to

consult with a local licensed design professional for guidance in building a proper oor support system.

Figure 14

Floor framing anchor rods see Figure 15 for support of

anchor rods by the steel support frames.

Figure 16

Typical Anchorage

Layout

I/360 --- I/240

Figure 15

EXAMPLE ONLY

SECTION VIEW

ROTATED 90CW

10

Page 13

Combustible Floor Installations

8” Metal Base

The Grand Meridian Metal Base ensures the minimum

8” (eight inch) clearance above combustible ooring is

maintained.

A layer of 1/2” minimum Concrete Board is required on

the top and mid section below as shown in Figure 17. The

required sizes are shown in the table below.

1/2” Thick Cement Board Dimensions

Model A1 A2 B1 B2

MMST43 53” 28” 48” 23”

Figure 17

Place Cement Board

on top rails of platform.

Place Cement Board on

top of cross-members.

26 ga. galv.

Hearth Ember Shields

Eight (8) All-Thread Rods are secured to the top ange

of the Metal Base with sixteen (16) at washers (2”OD x

9/16”ID x 0.10”) and sixteen (16) 1/2”-13 UNC Nuts.

Anchor Bracket All-Thread Rods are secured to the bottom ange

of the Metal Base with eight (8) at washers (2”OD x 9/16”ID x

0.10”) and eight (8) 1/2-13 UNC Nuts.

Remember to tighten up nuts below the oor after replace

installation in order to take up any slack in the threads.

Metal Base Assembly

A1

A2

B2

B1

IMPORTANT:

What You Will Need

You will nd that the Grand Meridian Fireplace is designed

to be completely assembled on-site, consisting of interlocking

precast parts. You will need a thin-set type mortar for bonding.

The parts of the replace are made of incredibly strong blend

of specialty cement and a light weight aggregate.

IMPORTANT! When applying mortar, it is imperative that the

concrete blocks be maintained moist (not soaking) so they

don’t absorb the water out of the mortar and cause adhesion

to fail. Frequently run a damp sponge to the parts before

mortar is applied!

The installation of an anchor plate/damper is required but

not supplied. You may purchase it from FMI PRODUCTS,

LLC. Also, an optional combustion air inlet MM4-AK can be

obtained from FMI PRODUCTS, LLC.

Refractory Firebrick Liners also need to be installed. These

should be a minimum of 1-1/8” (one and one-eight inches)

thick. The liner will be applied within the walls and hearth area

of the rebox.

TOOLS NEEDED FOR INSTALLATION:

One 4 ft. level•

Roto-hammer with ½” drill bit•

Drill motor with mixer blade to mix Mortar•

Two empty 5 gallon buckets to mix Mortar•

One wheelbarrow• and shovel to mix concrete

Grout bag•

Triangular masonry trowel•

Rubber hammer•

Sponge and 2 water buckets to wipe down and moisten •

parts prior to applying mortar

MATERIALS NEEDED FOR INSTALLATION:

Epoxy for securing rebar in footing / foundation•

Three (3) - 90 lb. bags of ready mix concrete with ¼” or •

smaller aggregate

MATERIALS INCLUDED:

8 - ⅜” Rebar x 28” Long•

8 - ⅜” Rebar x 12” Long•

1 - 50 lb. bucket Mortar•

20 - Small Wood Shims •

Hearth Ember Shield:

Metal safety stripping is required between the front of the

Fireplace Hearth and Hearth Extension (not supplied). A 26

gauge galvanized 4” wide metal strip can be used. The length

needs to extend 2 inches beyond each side of the replace

opening. If two strips are used, make sure they overlap at

least two inches in the middle. The strip is placed about 2” into

the underside of the platform at the front of both openings on

the replace.

Note: When using an on-site-constructed hearth extension,

you may use a sand-cement grout between the hearth and

extension instead.

11

Page 14

Fireplace Assembly Procedures

MMST43 Fireplace Assembly

Mixing the mortar – The mortar comes premixed and a)

should be dry. Be sure to use clean water and work it up

into a mixture that is pasty but not lumpy. If it’s too thin

and the surfaces don’t stay moist, the components will not

adhere. Load the mixture into a standard grout bag.

Apply about ½” (one-half inch) thread of mortar. The mortar b)

bead should be approximately ½” (one-half inch) away

from all edges. The mortar has a considerable amount of

holding power so do not overload the components with too

much mortar. Keep the components moist at all times!

Some mortar will “ooze out” when placing components c)

together, this is normal. Wipe excess away with a trowel. Do

not cover component surfaces completely with mortar. Do

not apply the mortar in thick bands even if the component

you are working with is larger than the rest. You will want

to apply “stripes” of mortar in these situations.

Make sure components are level. It’s extremely important d)

that you pay careful attention to how you are assembling

the Grand Meridian Fireplace since every component builds

on the next. If you have to make any kind of an adjustment,

do not try to do it “by loading an opening” with mortar, this

will only result in a replace that will not be plumb or level.

Use wood shims instead. You will nd these small wood

shims supplied with the Grand Meridian Fireplace and

you can nudge them in between openings to achieve the

precision you need in making component adjustments.

Once you have inserted any shims, you will want to

cover any gaps that may have resulted with the mortar.

1) Place the Grand Meridian Fireplace hearth base on top

of your non-combustible oor or metal base. For concrete

slabs, supporting oor needs to be rated at ASTM 90.

a) 2) Combustible Floor Installations:

Mix up a batch of mortar and place hearth slabs on

top of cement board which sits on top of the Raised

Metal Platform (see Figure 15). All-thread rods should

stick up through the holes on the hearth slabs.

b) Non-combustible Floor Installations:

Draw an outline of the hearth area based on the

dimensions shown in Figure 18. Position Hearth slabs

and mark rebar center locations (see Pg. 10, Fig.14).

Drill 4 inches into concrete slab and secure the four

pieces of rebar with epoxy.

Figure 18

Apply mortar

between joints

28”

53”

LH Hearth 2nd

RH Hearth 1st

Four 26ga.galv. 4” wide

Hearth Ember Shields

required (not supplied)

2” min

overlap typ.

Before installing the side walls, conrm placement of 3)

outside combustion air side block (if required), this can

be installed either side depending on which side is

accessible to outside combustion air. Prepare side wall

footprint with the prepared mortar.

Figure 19

Setting Firebox Sides

Keep the assembly of the next sections of the rebox 4)

side walls moving up, keeping components moist,

mixing mortar as you need it and threading the mortar

appropriately as you stack each section, one onto the

next. Constantly check for squareness and levelness

while building each course of block. As you complete

each section, make certain that you adhere the mortar at

each and every joint.

12

Page 15

After the last side walls are in place it is time to install the 5)

rebar. Mix approx. 2 cu. ft. of Ready-Mix Concrete. Insert

the 36” rebar vertically through the cells, into the holes in

the hearth, adjacent to the rebar and/or all-thread sticking

up from the hearth. Fill all cells with Ready-Mix Concrete

mix.

Figure 20

Keep damp at all

times while applying

mortar.

IMPORTANT! Keep in mind that, when applying the

mortar, you must frequently run a damp sponge to the

parts before mortar is applied!

Set the lintel in place as shown in 6) Figure 21. Check that

all is level. If you need to make adjustments, use shims.

Place one or more of these shims between the lowest

wall component and the top surface of the base plate.

Once you are satised with the degree of levelness, you

can address any gap that may have occurred with an

appropriate amount of mortar.

Figure 22

Lintel Assembly

Lintel

As you are connecting each Grand Meridian component, 10)

be certain you are following the instructions given

previously for using mortar. Stop to look at the smoke

dome side, front and rear walls to see that they are

aligning correctly and that the surfaces be smooth and

uniform. Make sure connections are covered with an

adequate amount of mortar. Remember that you have

the option of using shims and covering them with mortar

if you need to. Make any adjustments to the replace

alignment before continuing to the next step.

Figure 23

Lower Side

Dome Assembly

Lintel

Figure 21

Building

Lower

Firebox

Note: Although you are cautioned to use mortar

sparingly because it does have such holding power, you

should look over the rebox assembly at the end and ll

in any gaps, especially joint connections, with the mortar.

Needless to say, you must make adjustments to be sure

the replace is level and square while the mortar is still

wet.

Set the remaining lintel as shown in 7) Figure 22.

Now you are ready to start the smoke dome assembly. 8)

Take the lower side dome positioned so that the beveled

face lines up with the inward angles of the lintel sides

(see Figure 23). Top surfaces should be level.

Now position the front/rear smoke dome parts on top of 9)

dome. These parts require care in leveling, noting the

parts have a slight bevel. Check for vertical with level

(Figure 24).

Figure 24

Lower Dome

Assembly

Check your assembly here. If things are proceeding as 11)

they should be, the nished top surface should be at

and level.

Now you can set the smoke dome top plate into position. 12)

Be sure that it is ush in every direction as you place it

on the crest of the smoke dome wall assembly.

13

Page 16

Figure 25

Completed

Firebox

Firestop Radiation Shield

A Firestop Radiation Shield is required in multistory installations

at each oor penetration above that where the Support Box is

located.

Seal Anchor Plate using a 1” thick ceramic ber blanket. 13)

Complete the Anchor Plate assembly by securing with (4)

1/4-inch masonry anchors as shown in Figure 26.

Figure 26

Chimney Anchor Plate Installation

Place 1” Ceramic Fiber

Blanket under Anchor

Plates and secure with

eight 1/4-inch masonry

anchors.

Figure 27

Firestop Spacer with Living

Space Above Ceiling

E x i s t i n g

C e i l i n g

Frame

Firestop

Spacer

eight

#8 x 3/4

Screws

Firestop Radiation Shields also provide complete separation

from one oor space to another or attic space as required

by most codes. When the double wall pipe passes through

a framed opening into an attic space, the restop must be

placed into an attic oor as shown in Figure 28.

Figure 28

Firestop Spacer with Attic

Space Above Ceiling

eight

#8 x 3/4

Screws

Now that you have completed the smoke dome 14)

assembly, all the components should stack up for a

smooth transition into the ue components. Setting the

smoke dome completes the Grand Meridian Firebox and

Smoke Dome assembly. You are now ready to begin the

installation of the necessary rebrick lining and the ue

components.

WARNING: DO NOT PACK REQUIRED AIR SPACES WITH

INSULATION OR OTHER MATERIALS.

Firestop

Spacer

E x i s t i n g

C e i l i n g

Frame

Follow your chimney manufacturer’s instructions on specic

guidelines pertaining to their chimney and Firestop Radiation

Shield installation instructions.

14

Page 17

Grand Meridian Firebrick Liners

Custom Firebrick Lining

Custom Firebrick lining is not included with the replace. There

is, however, the option of modular pre-fabricated panels that

can be obtained from FMI PRODUCTS, LLC. See exploded

parts page for details.

If custom rebrick lining is desired, 1-1/8” inch thick liners will

be required. The pattern for the rebrick lining is exclusively

your choice. Before you install the lining, remember to consider

any holes your contractor may need to drill for gas, electrical

or combustion air kit access holes.

Please use a certied mason to lay-in the brick. He will follow

the proper instructions from the replace liner manufacturer

and also understand the type of adhesive or cement he is to

use.

Make sure the replace is installed with the nished rebrick

oor of the replace so that it is at least 11” (eleven inches)

above the combustible oor system.

Figure 30

Sectioned Side View

If Optional Arches

are used, corner

notching will be

required on all

four places.

Figure 29

FINISHED

FIREBRICK

HEARTH

LINER

11 INCHES

MINIMUM TO

COMBUSTIBLE

FLOOR

Finished Height to Combustible Floor

Disclaimer: FMI PRODUCTS, LLC wishes to express that

as the manufacturer of the Grand Meridian Fireplaces, they

cannot take any liability or responsibility for they way the

firebrick or the firebrick mortar performs. It is not unusual in

the course of the life of the firebrick, or the firebrick mortar, for

heat stress cracks to appear. FMI PRODUCTS, LLC cannot

be responsible for this and other wear and tear to the firebrick

and mortar.

The following Firebrick Liners are available from FMI

PRODUCTS, LLC:

Figure 31

Herringbone Brick Pattern

MMST43SHBL- Herringbone

MMST43FRBL- Running Bond

Modular Firebrick Lining

If using our Firebrick Liners, simply use an extra bucket of the

mortar we supply. Install Hearth Liner rst, then continue with

sides. Consider if brackets for grates will be required also if

pre-drilling is required for gaslines, electrical or if the outside

combustion air kit is to be installed. If the optional Arch is

used, the top corners of the rebrick side liners will need to be

notched (see Figure 30).

15

Figure 32

Running Bond Brick Pattern

Page 18

Fireplace Finishes & Combustible Trim

Clearances

Hearth Material & Dimensions – Codes are strict regarding the

use of proper materials for hearth extensions and the proper

dimensional characteristics.

All hearth extensions must be made of code-rated,

noncombustible materials such as tile, brick, concrete or

stone. Grand Meridian Fireplaces usually have an opening of

approximately 8 sq. ft. (eight square feet) that translates to a

hearth extension of about 20” (twenty inches) at the replace’s

opening and about 12” (twelve inches) extension at each side.

These relative dimensions are also covered by code. Note

that it is required that metal safety strips must be laid on the

oor of the non-combustible raised platform. These should be

26 gauge and measure 4” (four inches) wide. They need to

extend half way under the platform and half way under the

hearth extension material (see Figure 18).

Attention: You will note that there will be a gap between the

replace front and the extension of the non-combustible hearth

material. Be certain that you seal this with non-combustible

material.

Mantle and Mantle Shelf Clearances

As with any radiant heat replace, all Grand Meridian Fireplaces

must comply with building code safety clearances, for units

that have openings of 6 sq. ft. (six square feet) or greater.

For Mantel clearances see Figure 9.

Walls that Adjoin – your replace cannot be installed closer

than 2 ft. (two feet) to any adjoining walls in the room where

the replace is.

Caution in Regards to Combustibles – If any part of the replace

or objects in the room (curtains, rugs, paint, cushions, etc.) start

to show warping or discoloration due to heat from the replace,

it is time to take immediate action. Do not use the replace

until you have gured out how to address the problem. You are

facing a potential re hazard. FMI PRODUCTS, LLC cannot

be responsible for the make-up of material on the exterior of

the replace you have chosen, nor can FMI PRODUCTS, LLC

be held responsible for the materials in a room that may be

responding negatively to heat. However, in almost all cases,

there is a solution to the problem, either by making adjustments

to airow or the modications to the room itself.

Installing Outside Combustion (make-up) Air

1) The Grand Meridian Fireplace needs enough make-up air to

function properly and some local building codes may require

outside combustion air to be provided. If no make-up air is

provided, improper ue drafting may occur, creating negative

pressure whereby smoke may enter the home, especially in

homes that are very well insulated and tightly sealed. Check

local building codes for specic requirements.

2) Install Combustion Air Kit MM4-AK into the Grand Meridian

Firebox through the side wall opening provided. The tubing

that goes out of the rebox wall must feed into a exible

metal conduit as the source for outside combustible air. It can

go straight out through an outside wall or into a ventilated

crawl space. If crawl space is used, check codes for proper

termination.

3) Be sure that you carefully check the source of the outside air

before you choose the site for your air intake. You don’t want

a place where snow will collect, where bushes or trees will be

growing or a location that is too close to any other structure.

4) Install a screened termination cap to keep out animals.

Adding a Gas Pipe

You may elect to add a vented decorative gas appliance

(gas log) to your Grand Meridian Fireplace. If so, follow the

installation instructions from the Decorative Gas Appliance

manufacturer. Familiarize yourself with requirements for

installation as outlined by the National Fuel Gas Code, ANSI

Z223.1. This gas pipe provision should only be used on a

decorative gas appliance.

1) You can route the gas piping practically anywhere in the

rebox – the oor, back wall or side walls. You will just need

a masonry drill; the instructions from the gas appliance

manufacturer will be very straightforward.

2) Fill in the holes you have drilled around the gas piping with

the regular mortar.

3) Follow the Gas Log manufacturer’s instructions.

Adding Electrical Connection

Like the gas line, electrical feed lines can be run through

the oor, back wall, or side walls. Follow local building and

electrical code requirements.Grand Meridian Chimney

Systems:

The Grand Meridian Fireplace requires the following chimney

systems:

All chimney systems must be installed with an integrated

damper/base plate installed on top of unit. Installers are

cautioned to put the chimney system together exactly as

instructed and shown in chimney manufacturer’s guide. Any

variations may have serious consequences resulting in an

accident or malfunction. If instructions are not followed, the

warranty on the product will become null and void.

Note that the most important aspect of the installation is

maintaining the minimum required clearances to combustible

16

Page 19

materials according to the chimney pipe manufacturer’s

recommendations, otherwise a potential re hazard may

occur.

Warning: do not interchange chimney manufacturer’s parts

with any other parts except those specically required by

the chimney manufacturer’s recommendations otherwise a

potential hazardous condition may be created.

Attention: When choosing a Chimney System it must meet the

following requirements:

Designed for installation in accordance with the National •

Fire Protection Standard and UL 103.

Meets the requirements of NFPA 211.•

Designed in accordance with ICC Codes.•

Figure 33

Elbow

Return

Elbow

Elbow

6' Max.

6' Max.

Return

Elbow

Elbow

A

Elbow

Return

Elbow

6' Max.

Ceiling

B

Support Pipe

12S-12DM

Return

Elbow

6' Max.

Return

Elbow

6' Max.

Assuming you have sections of vertical pipe that are more than

10’ (ten feet) measuring between elbows, you must insert – at

midpoint – a chimney stabilizer. When installing the stabilizer,

pull out the support straps with a good amount of tension and

hammer to the frame.

Installing Damper and Chimney System

The Damper System/Anchor Plate assembly is required

for the installation of these chimney systems. Consult the

Chimney System manufacturer’s instructions.

Using the Damper/Anchor Plate Assembly, apply a 1/4” 1.

(one-quarter inch) bead of gasket cement around the

base of the Anchor Plate. Apply ceramic blanket gasket to

the gasket cement.

Apply balance of gasket cement in a 1/4” (one-quarter 2.

inch) bead on top of smoke dome top approx. 3” (3 inches)

outside of outlet hole. Install damper on top of unit pressing

damper into cement.

Place chimney adapter onto top of damper plate and 3.

center in opening using gasket supplied with adapter.

Attach adapter with (12) #8 cement fasteners supplied, 4.

carefully drilling holes into damper plate.

Attach damper chain stop on center rear of lintel 3” 5.

(three inch) vertical from opening using (3) #8 cement

fasteners.

Fireplace

MMST43

Elbow

Chimney System

UL103-16” I.D. Class A

6' Max.

C

Attention: Clearance to combustible construction cannot be

reduced during course of construction. For the safe operation

of the nished replace, these clearances must be followed

when building the framework for the chimney system.

Finishing Your Installation

To complete your replace installation, a replace grate will

be required for safe operation. The replace grate must be

sized to 50% of the hearth maximum. Additionally, a replace

screen must be installed for safety.

Fireplace Door Accessory

IMPORTANT: Only Crown-Breckinridge or McKenziePendelton Doors are approved for use with this replace.

For installation Instructions, see separate instructions included

with doors.

17

Page 20

Grand Meridian Owner’s Operation &

Precautions

Installers of the Grand Meridian are urged to leave the owner’s

manual with the unit after installation is complete.

WARNING: Do not attempt to operate your replace

without a re safety screen installed.

CAUTION: The manufacturer cautions against using chemical

chimney cleaners. Never use charcoal or coal in the replace

under any circumstances.

First Lighting of the Grand Meridian – After construction 1)

is completed, all elements of the replace and chimney

system must be completely dry. This means that the unit

must stand without any ring for a minimum of 28 days.

Only after that period of time can a rst lighting take place.

The rst re must be small and well-controlled, started

with a small amount of kindling. Add no more than eight

pounds of wood, preferably small logs not more than 3”

(three inches) in diameter. You will probably burn no more

than three to four of these small logs. Do not let the re

burn for more than one hour. After this rst lighting – when

the replace has started to “cure” Do not set another re

for at least 24 hours.

Starting a Fire and Basic Operation

Before starting a re in your replace, open the damper to

its’ fully open position. Crumple some paper and place it on

the log grate. Use some soft, dry wood as kindling and put it

on top of the paper. Place some small logs or split logs atop

the paper and kindling.

Finish off the fuel load with a couple of hardwood logs or

split logs – oak or hickory. Check to see that you’re stacking

the logs so that they will fall inside the grate as they burn.

To get the most out of your wood, it is recommended

that you let it set and completely dry out for nine months to a

year.

When you are satised with the arrangement of your wood

load, light the paper which in turn will ignite the kindling, then

the softer wood and nally, the harder wood logs. As the re

burns, you can carefully lay additional logs on the ame, but

make sure you place them gently without forcing them into the

opening.

Second Lighting – Start the re slowly and gradually as 2)

you did with the rst lighting, but this time you can burn up

to ten pounds of rewood, probably four to ve logs that

are 3” (three inches) in diameter. With the second lighting

you can let the re burn two hours – no more.

After First and Second Lightings – When the replace 3)

has been properly cured with 1st and 2nd lightings, you

will be able to add a full fuel load to the Grand Meridian

which is about 10 to 15 pounds of rewood at any given

time. Consider that this typical fuel load is three to four dry

hardwood logs that are about 6” (six inches) to 8” (eight

inches) in diameter.

Without a grate for your rewood to rest on, you cannot 4)

get the air ow you need under the re which makes for a

hotter, more satisfying re.

Don’t “over burn” – Always remember, your Grand

Meridian Fireplace is an elegant addition to your home.

It is not an indoor incinerator! If you start to use the

replace and begin a routine of “over burning,” you

can permanently and unalterably damage the unit.

Under no circumstances should you be burning

household trash, including chemicals and combustibles,

cardboard boxes, your ofce papers, scrap lumber

or stray branches from your yard, particularly pine.

WARNING: Burning of above mentioned materials will

cause an unsafe condition and will void your warranty!

18

Page 21

ANNUAL FIREPLACE MAINTENANCE

Your replace and chimney require seasonal and

monthly tune-ups”. Like any piece of well-built equipment,

the Grand Meridian Fireplace and chimney needs routine

maintenance.

The manufacturer recommends that inspection of the

replace and chimney take place on a monthly basis during the

heating season.

Start at the top, looking for birds’ nests, leaves or any

other obstructions. Also check the spark arrestor, for creosote

or soot build-up. Twice a year, you will want to clean the rebox

and chimney yourself or hire a professional chimney sweep to

do the job for you. If you elect to do it yourself, use a plastic,

wood or steel brush for the inside of the chimney.

For the spark arrestor, scrub with a wire brush. To

dismantle the chimney cap for cleaning of the ue, unscrew

the four screws that hold it in place. For cleaning access from

below, open the damper in the rebox. It is best to use a exible

handle chimney cleaning brush made especially for the job.

If your replace system has any offset chimney sections,

start cleaning with the exible brush from the top of the section

downward to the elbow. Then clean from the rebox up to the

offset/return section.

SURFACE CRACKS

The Grand Meridian FIREPLACES are manufactured

using high quality materials. During the drying process, surface

cracking may occur. These small cracks (under 1/16” will not

effect the replace safety or performance). During the assembly

process, ll surface cracks with thin-set mortar and brush when

drying for a smooth surface nish.

Removal of Creosote and Soot Formation – Creosote

vapors are known to form in the relatively cool chimney ues of

slow burning res, hence, creosote residue collects on the ue

lining. Because of soot and creosote build-up, it is recommended

that the replace and chimney cleaning be done twice a year. In

colder climates, cleaning should be done more often.

Always allow the replace to completely cool before

you work on it, which means, of course, shutting off all gas and

electrical connections, also.

Be certain that you use only solid fuel in your replace.

You may use a natural or LP gas log lighter as a method to start

your wood re.

The ue damper must be in the OPEN position whenever

there is heat in the replace.

Technical Service

Be sure that you have covered the oor of the replace

and out to the hearth with a damp sheet that has been taped

securely in place. When all the soot has settled, remove the

sheet and vacuum up – don’t sweep the excess soot.

Good old-fashioned “elbow grease” is enough to

remove the extraneous matter from the inside of the rebox

and chimney. Never use any chemical cleaners as their residue

could introduce a re hazard after the task is completed.

Outside Inspection – During your once a month

inspection of the rebox and chimney, make it a point to also

check the outside of the chimney, the metal ashing and weather

seals that surround it. If you nd any cracks or openings around

screws or nails, seal them to avoid any roof or chimney chase

leaks.

You may have further questions about installation, operation, or troubleshooting. If so, contact FMI PRODUCTS, LLC at 1-866-328-4537.

When calling please have your model and serial num-

bers of your replace ready.

You can also visit our web site at

www.fmiproducts.com.

Replacement Parts

If this product is missing a part or has a broken component, please do not return it to the store. Call FMI

PRODUCTS, LLC at 1-866-328-4537 to answer

questions and replace parts under warranty.

Note: Use only original replacement parts. This will

protect your warranty coverage for parts replaced

under warranty.

When calling, have ready:

• your name

• your address

• model and serial numbers of your replace

• how replace was malfunctioning

• purchase date

19

Page 22

AppendixI

For installations regulated by the International Residential Code, the

support foundation for the fireplace installed on concrete shall

consist of aminimum of6inchesthick reinforced concrete slab. The minimum specified compressive strength of

f’

c

,shall be as

required in Table R402.2 of the International Residential Code (IRC). Concrete subject to moderate or severe weathering as indicated

in Figure R301.2(3) of the International Residential Code (IRC) shall be air entrained as specified in TableR402.2ofthe International

Residential Code (IRC). The maximum weight of fly ash, other pozzolans, silica fume, slag or blended cements that is included in

concrete mixtures for garage floor slabs and for exterior porches, carport slabs and steps that will be exposed to deicingchemicals

shall not exceed the percentages of the total weight of cementitious materials specified in Section 4.2.3 of ACI 318. Materials

used to

produceconcrete and testingthereofshall comply with theapplicable standards listed in Chapter 3 of ACI 318.

For installations regulated by the International Building Code (IBC), the support foundation for the fireplace installed on concrete

shall consist of a minimum of 6 inches thick reinforced concrete slab. The concrete strength and durability shall comply with Sections

1903, 1904 and 1905 of the International Building Code (IBC).

TABLE R402.2 MINIMUM SPECIFIED COMPRESSIVE STRENGTH OF CONCRETE

MINIMUM SPECIFIED COMPRESSIVE STRENGTH

a

(f’

c

)

Weathering Potential

b

TYPE OR LOCATION OF CONCRETE CONSTRUCTION

Negligible Moderate Severe

Basement walls, foundations and other concrete not exposed to theweather 2,500 2,500 2,500

c

Basement slabs and interior slabs on grade, except garage floor slabs 2,500 2,500 2,500

c

Basement walls, foundationwalls, exterior walls and other vertical concrete

work exposed to the weather

2,500 3,000

d

3,000

d

Porches, carport slabs and steps exposed to the weather, and garage floor slabs2,500 3,000

d,e,f

3,500

d,e,f

a. Strengthat28dayspsi.

b. SeeFigureR301.2(3) forweathering potential.

c. Concrete in these locationsthatmay be subject to freezing and thawing during construction shall be air-entrained concrete in

accordance with Footnote d.

d. Concrete shall be air-entrained.Total air content(percent by volume of concrete) shall be not less than 5 percent or more than

7 percent.

e. See Section R402.2 for maximumcementitious materials content.

f. For garagefloorswith a steel troweled finish, reduction of thetotal air content (percent by volume of concrete) to not less than

3 percentis permitted if the specified compressive strength of the concrete is increased to not less than 4,000 psi.

20

Page 23

AppendixII

FIGURE R301.2(3) WEATHERING PROBABILITY MAPFOR CONCRETE

a. Alaskaand Hawaii are classified as severe and negligible, respectively.

b. Lines defining areas are approximate only. Local conditions may be more or less severe than indicated by region classification. A

severe classificationiswhere weather conditions result in significant snowfall combined with extended periods during which there is

little or no natural thawing causing deicing salts to be used extensively.

21

Page 24

WARRANTY

KEEP THIS WARRANTY

Model (

Serial No. (

located on product or identication tag

located on product or identication tag

Date Purchased __________________

Keep receipt for warranty verication.

) _________________

) ______________

FMI PRODUCTS, LLC LIMITED WARRANTIES

New Products

FMI PRODUCTS, LLC warrants all Grand Meridian Fireplaces to be free from defects in materials that adversely affect replace

performance for a period of ten (10) years from the date of purchase, subject to the terms and conditions of this limited warranty.

FMI PRODUCTS, LLC does not warrant accessory chimney, outside air ducts, gas control or burner system, ceramic logs, and

devices not manufactured by FMI PRODUCTS, LLC. Valves and electronic parts are only covered for one year parts and labor per

the log set manufacturer’s warranty.

This warranty covers only products manufactured by FMI PRODUCTS, LLC, specically the modular concrete rebox, and NO

WARRANTY, EXPRESS OR IMPLIED, EXTENDS TO ANY OF THE HARDWARE, FOUNDATION, VENTING, DUCTS, OR

ACCESSORIES. THIS WARRANTY DOES NOT COVER DRAFTING, SMOKING, OR SOOTING OF THE FIREPLACE SYSTEM.

Factors beyond the manufacturer’s control may affect drafting, smoking, and sooting, FMI PRODUCTS, LLC cannot guarantee

these aspects of performance.

If a component is found to be defective under the terms of this warranty, the party this warranty is extended to shall notify FMI

PRODUCTS, LLC, 2701 S. Harbor Blvd. Santa Ana, CA 92704 in writing, by registered mail, within thirty (30) days following the

discovery of the defect within the warranty period. The letter shall contain (1) the date of purchase; (2) place of purchase; (3)

address of installation; (4) name, address and phone number of the homeowner; and (5) a brief description of the defect.

FMI PRODUCTS, LLC, or any entity thereof, is not responsible for any labor costs or indirect costs incurred for the replacement

of defective components.

FMI PRODUCTS, LLC is not responsible for misuse or mishandling of component parts. Nothing in this warranty makes FMI

PRODUCTS, LLC, or any entity thereof, liable in any respect for any injury or damage to the building or structure in which

the replace has been installed or to the persons or property therein arising out of the use, misuse, or installation of properly

manufactured FMI PRODUCTS, LLC product.

FMI PRODUCTS, LLC, OR ANY ENTITY THEREOF, SHALL NOT BE HELD LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES OR EXPENSES ARISING OUT OF THE USE OF THE FIREPLACE. ALL SUCH DAMAGES AND EXPENSES ARE

HEREBY EXCLUDED.

This warranty is null and void when the replaces are not installed pursuant to the installation instructions provided by FMI

PRODUCTS, LLC and local building codes have not been followed completely.

This warranty applies only to those replaces installed in the continental United States, Hawaii, Alaska and Canada. If any part of

this warranty is found to be unenforceable,, the remaining parts shall remain in force and effect.

FMI PRODUCTS, LLC HEREBY DISCLAIMS ALL GUARANTEES AND WARRANTIES, EXPRESS OR IMPLIED, BEYOND THE

WARRANTIES SET FORTH HEREIN.

CUSTOMER SERVICE & PARTS REPLACEMENT:

Parts and accessories may be purchased from your local dealer. Additional information is available from FMI PRODUCTS, LLC.

Accessory orders will be accepted by mail, or you may call to order Monday through Friday from 8:00 a.m. to 5:00 p.m. (Central

Standard Time) at: (800) 328-4537.

Please complete the following information for future reference and warranty verication:

2701 S. Harbor Blvd.

Santa Ana, CA 92704

1-866-328-4537

www.fmiproducts.com

125161-01

Rev. A

12/09

Loading...

Loading...