Page 1

Before using any Fluid Metering, Inc. product read the following safety instructions

as well as specific product specifications and operating instructions.

Warning!

Fire, electrical shock or explosion may occur if used near combustibles

explosive atmosphere, corrosive air, wet environment or submerged in fluid.

!

Caution! Fire, electrical shock, injury and damage may

occur if not used in accordance with Fluid Metering, Inc.

specifications and operation instructions.

Do not put wet fingers into power outlet of unit.

Do not operate with wet hands.

Do not operate drive assemblies that require a hard mount

(to be bolted down) unless they are mounted per Fluid Metering, Inc.

specifications, if not injury may occur and/or damage to unit.

Do not touch any rotating pump or motor components: injury may

occur.

Do not run pump dry, unless designed for that service.

Running dry is harmful to the pump, and will cause excessive heating

due to internal friction.

Check pump rotation and inlet/outlet pump port orientation before

connecting power to pump. If not injury may occur.

When pulling out cords from outlets do not pull cord, grasp plug to

prevent plug damage or electrical shock.

Fluid Metering, Inc. Drive Motors become HOT and can cause

a burn

. DO NOT TOUCH!

Turn off the electrical power before checking pump for any problems.

Connect motor, speed controllers, or any other electrical devices

based on Fluid Metering Inc. specifications. Any unauthorized work

performed on the product by the purchaser or by third parties can impair product functionality and thereby relieves Fluid Metering, Inc.

of all warranty claims or liability for any misuse that will cause

damage to product and/or injury to the individual.

Power cables and leads should not be bent, pulled or inserted by excessive force. Otherwise there is a threat of electrical shock or fire.

Replace any inline fuses only with fuse rating as specified by Fluid Metering, Inc.

When pump/drive is under operation, never point discharge tubing into

face or touch any rotating components of pump.

In a power down thermal overload cut-in condition, unplug or turn off

power to pump. Always allow a cool down period before restarting:

otherwise, injury or damage may occur.

For 30 seconds after power is removed from pump/drive: do not

touch any output terminals. Electrical shock may occur because of

residual voltage.

!

SAFETY INSTRUCTIONS

General Instructions

Congratulations! You are about to install the newest technology from FMI, designed specifically

for industrial dispense applications, where long-term trouble-free performance is expected. If

you have any questions during any stage of your installation please don't hesitate to give us a

call. Our technical staff is ready with answers. Call us at 1-800-223-3388. LET'S GET

STARTED!

Your controller is initially set to provide one dispense per signal at 320 strokes per minute.* Dispense signal, other speed settings, and dispense values are easily set by following the detailed

instructions on the following pages. * Best speed for most dispense applications.

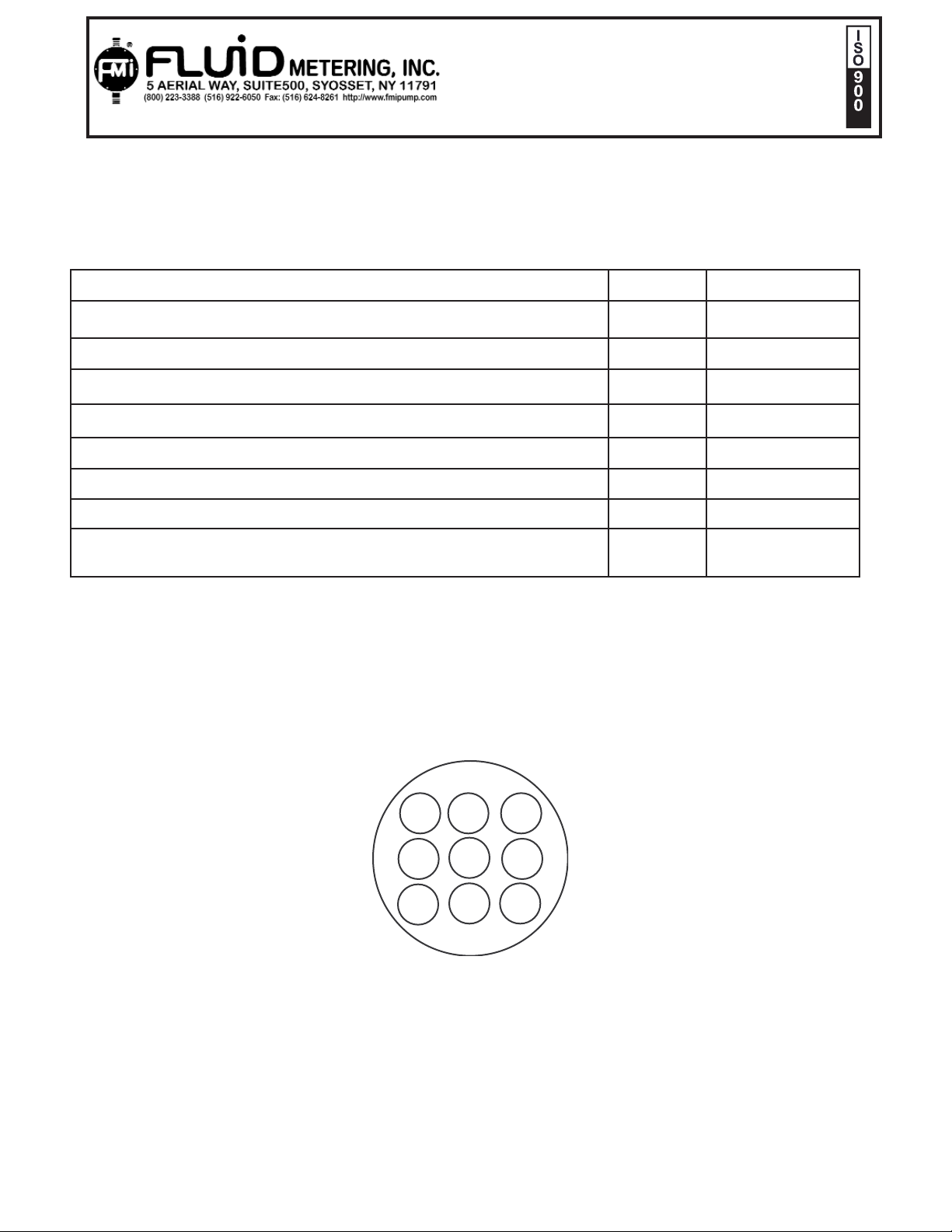

Connect cable from CONNECTOR P1 on the housing to your PLC or controller and power supply as per the following pin connections. NOTE: Not all the available functions may be suitable

for your application; therefore some wires may not need to be connected.

1

IN-IDS-08

IDS INDUSTRIAL DISPENSER

INSTRUCTIONS

1

!

Page 2

IN-IDS-08IN-IDS-08

2

The following connections are made through the 6' cable provided. It has a nine-pin Amp Series 1, Circular Connector, shell size 13, arrangement 13-9, standard sex (Plug/Socket). This connector is P1 on

Figure 1

.

1. Power positive (+24-30VDC Max) Fused 2.5 Amp Time Lag Pin #1

Red

2. Power Ground Pin #2 Black

3. Flag Verify, (+Side Sinking Open Collector) 12-30 V Max @ 20mA max Pin #3 Blue

4. Safety Ground Pin #4 Green/Yellow

5. Flag Verify, Return, Emitter

Pin #5

Orange

6. Start (+Side Sinking Opto-Isolator LED Input) 12-30 V Max @ 20mA Pin #6

Yellow

7.Start Return - Signal Common Pin #7 White

8. Analog Volts Input, 0.1-5.0 V Max (Optional) Pin #8

Brown

9. Dispense/Run (+Side Sinking Opto-Isolator Input) 12-30 V Max @ 20mA Pin #9 Violet

FMI provides a 6' (2 meters) shielded 9-pin hook up cable, Part No. 200204.

P1 INPUT CONNETOR VIEWED

FROM OUT SIDE BOX

FIGURE 1

IDS INDUSTRIAL DISPENSER

INSTRUCTIONS

1

1

4

7

2

5

8

3

6

9

Page 3

IDS INDUSTRIAL DISPENSER

INSTRUCTIONS

3

1.0 Description

The IDS Industrial Dispenser has a stepper motor and a self-contained step motor controller specifically

designed for use with Fluid Metering valveless pumps. It contains its own step output drivers and can be

set to several run modes utilizing either internal or external controls. This system is designed for maximum performance in all industrial situations. If you have any questions at all, please don't hesitate to call

our technical hot line at 1-800-223-3388.

1.1 Features

• Pre-set Run Modes.

• Multiple Control Methods: PLC *, Relay, 0-5 VDC, or manually by internal switches.

• Dispense Run, Purge, etc.

• Variable speeds.

• Verification of dispense cycle and rotation.

• Opto-isolated inputs.

• Auto-Current reduction, when not in a running mode.

• Internally fused at 2.5 A via a plug-in fuse socket.

• Automatic over temperature shutdown of drive current output if driver devices reach 70 º C internal

temper atures. Note: This does not prevent motor overheating!

• Rugged 304 Stainless Steel, NEMA type 12, IP 65 enclosure.

• Forward/Reverse Function Default SW 12 Open is clockwise direction

*Typical compatible PLC's are: Texas instruments Ti 305, SIMATIC, GE Fanuc OCS stations, Crouzet

Type RPX and DIAL 5, DIAL 10 systems, IDEC's series of Micro 3 or Micro 3 C and PLC Direct DL105

through DL 405. PLCs require opto-isolated or relay outputs for start, run or dispense functions and an

opto-isolated current loop input.

2.0 Run Modes

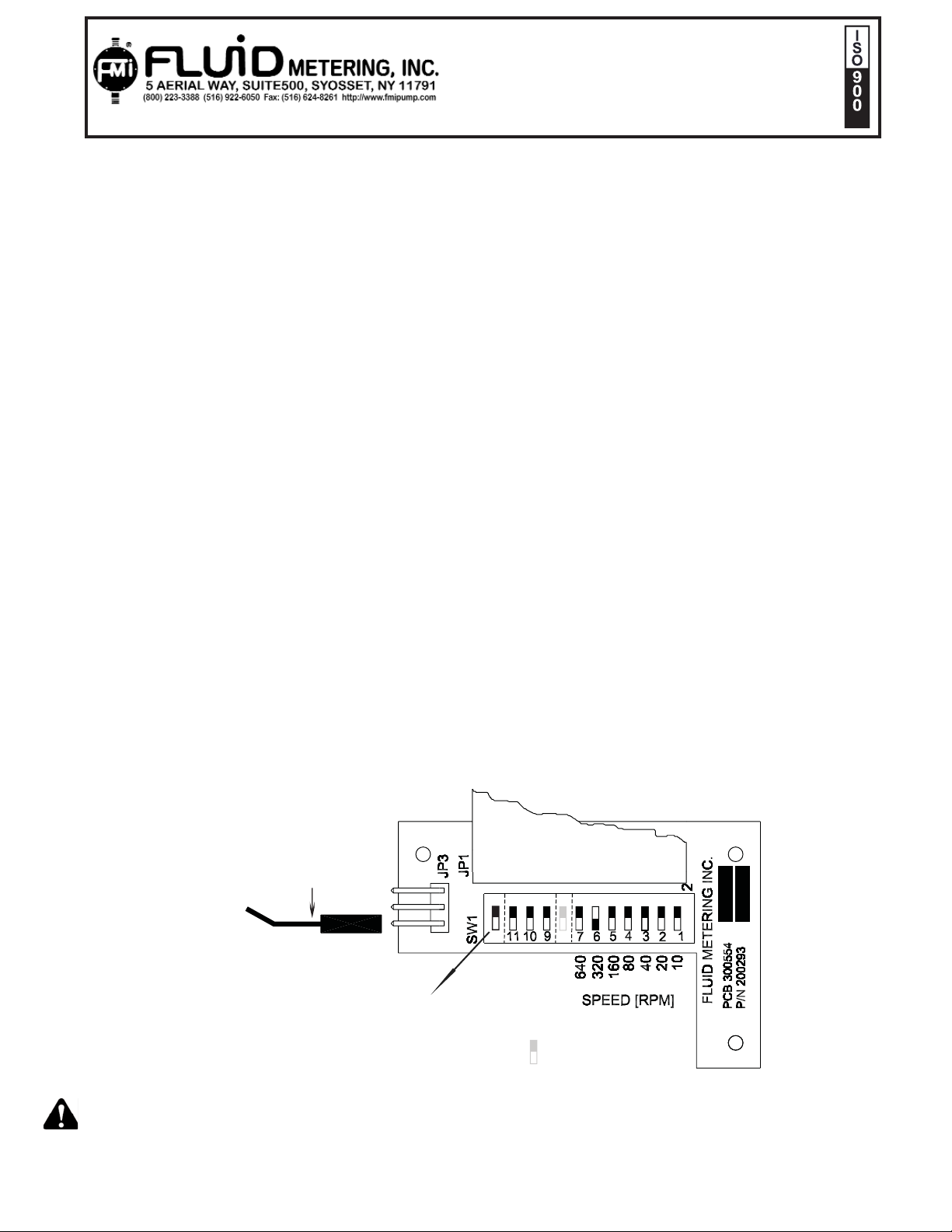

The step motor controller board housed in the IDS can drive pumps in any of the following modes by

changing switches on the Switchboard 200293 as shown below.

8

OFFOFF

ENCLOSURE FASTENERS MUST BE TORQUED TO 6 INCH POUNDS ± 10% TO ASSURE PROPER SEALING.

1

'RED' Jumper

Dispense control

11

10

9

switchboard #200293

OPEN

*

12

124

Dispense

FWD/REV

Switches

*#8 Always off

Page 4

IN-IDS-08

4

OPEN

8

0

60

0

OFF

S

U

G

C.

4

7 6 5 4

3

Fig 2A

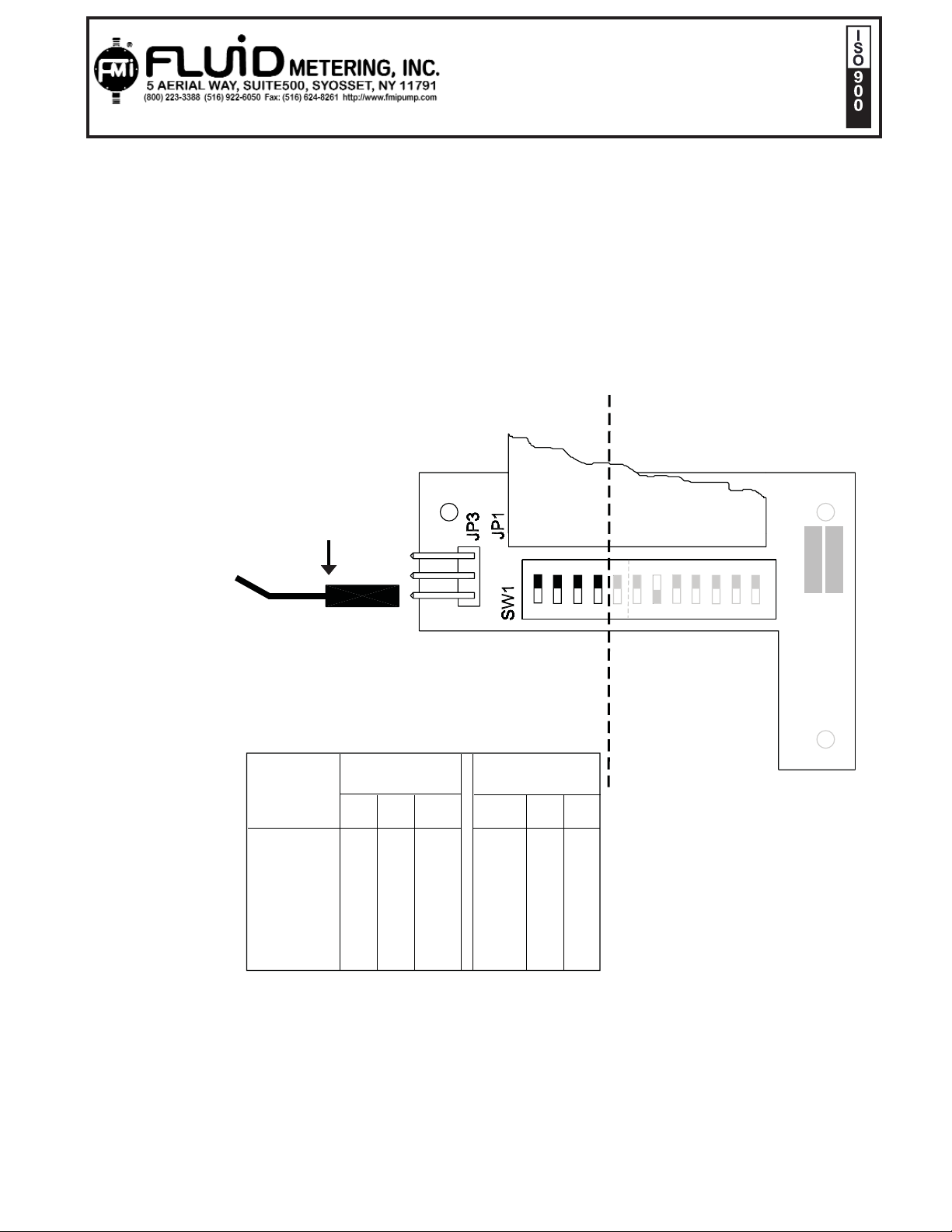

2.1 Dispense Mode:

The IDS comes factory set for one dispense revolution** per signal at 320 rpm* Dispense start actuation

is handled by pins 6 (YELLOW) and return pin 7 (WHITE) of the external connector, P1. The minimum

signal input time that this function can respond to is .030 milliseconds (0.020 sec) to a maximum of 100

milliseconds, or less than the time it takes to make one revolution.

You can, have up to seven shots per signal if desired. The number of shots per Start signal is set by

switches 9, 10, 11 and Red Jumper on Switchboard # 200293. See Matrix below (Figure 2A) **( FMI has

determined that 320 RPM is best speed for a single revolution dispense, this may vary depending on the

hydraulics of your system.)

IDS INDUSTRIAL DISPENSER

INSTRUCTIONS

1

'RED' Jumper

Dispense control

11

10

9

Dispense Matrix

Red Jumper and Switch Settings / Dispense

Dispense /

start

1

2

3

4

5

6

7

Red Jumper

Location

9 10 11

1

0

0

1

1

0

0

0

1

0

0

1

1

0

0

0

0

1

0

0

0

Dispense

switch

9 10 11

0

0

0

0

0

0

0

switchboard

#200293

OFF

12

11 10 9

124

Dispense

Switches

0

0

0

0

1

0

0

0

0

1

0

1

1

1

2

4

0

1

4

PEED[RPM]

1

0 = OFF

1 = ON

IN

ID METERIN

B 30055

/N 200293

FL

Page 5

IN-IDS-08

5

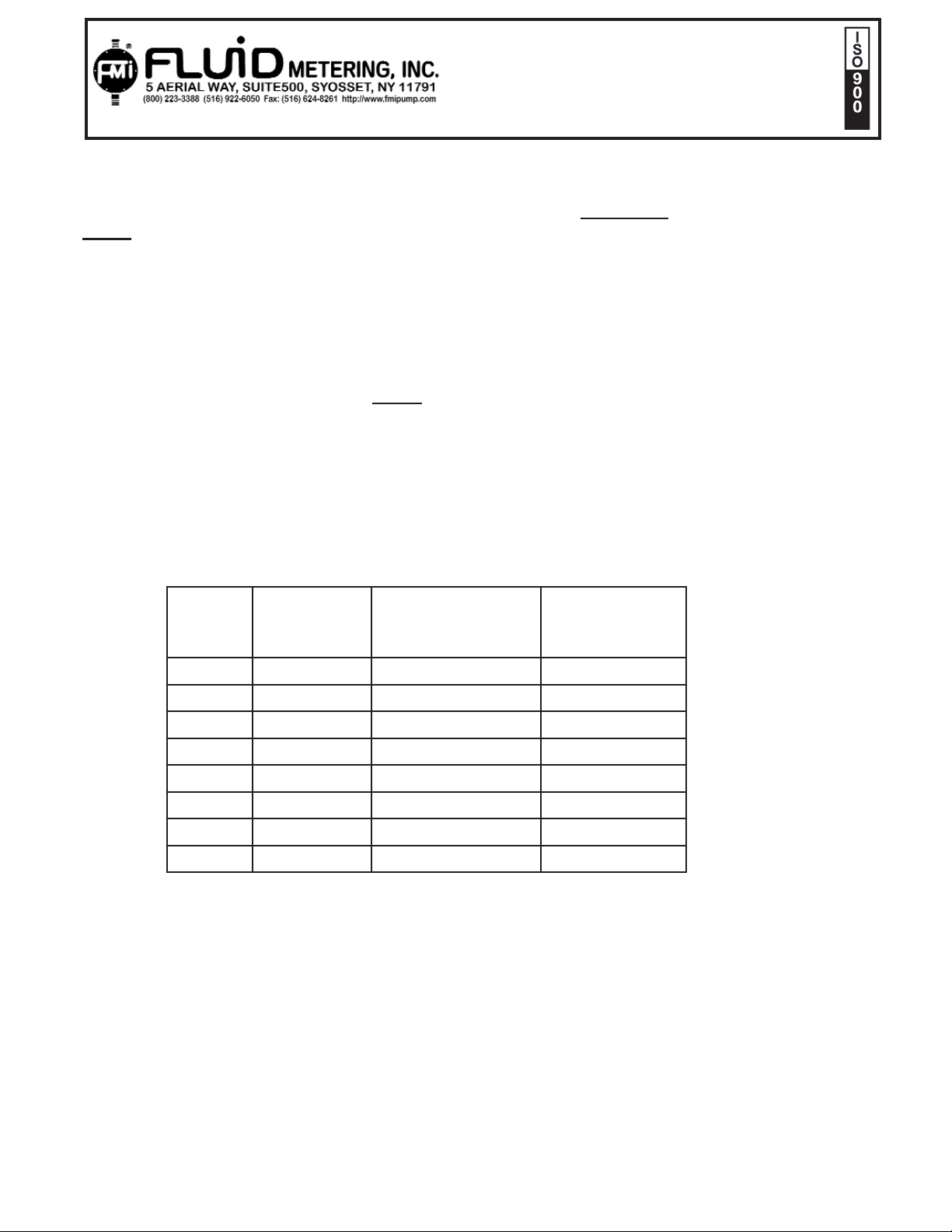

VOLTS OPTO-OUTPUT

OHMS

TRANSISTOR OUTPUT

OHMS

RELAY OUTPUT,

OHMS

6 220 220 270

9 390 390 470

12 620 620 680

15 820 820 820

18 1000 1000 1000

24 1300 1300 1500

28 1600 1600 1800

30 2000 2000 2000

NOTE: These are the closest values of current limiting 5%, ¼ watt resistors for the applied voltages. Voltage control sources must have series resistors as shown in Table above, to limit control signal currents to

the input opto-isolators, Pins 3, 6, 9, on P1.

2.2 RUN / PURGE MODE

A current of 6 to 20mA must be supplied continuously throughout the signal current input at P1, Pin 9

(VIOLET) to keep the dispenser in a continuous run mode. THE ABSENCE

OF THIS SIGNAL WILL

HOLD THE PUMP IN A DISPENSE MODE ONLY. Run / Purge Actuation is handled by Pin 9 (VIOLET)

(+ side sinking) and 7 (WHITE) (return) on the input connector P1 (see Figure 1, Page 1), by providing a

current of 6 to 20mA through a switch closure, PLC, Relay, Mechanical Timer/Counter or transistor output

2.3 Timed/Count Dispense/Continuous Run Mode

To activate this mode for a timed dispense system, the closing of dispense switch 9 is done externally

using a control signal current input at P1 Pin 9 (VIOLET) for one dispense per signal. The pump will

begin running when this connection is closed

, and rotation will cease when the control current is turned

off from Pin 9 of P1. The current must be provided through a resistor (the typical values are shown

on Table 2 below) from a counter or timer that can control a SPST relay or switch closure. External

counters and PLCs can use the VERIFY SIGNAL OUTPUT (P1 Pin 3 (BLUE), verify return common Pin 5

(ORANGE)) to sense and count each revolution pulse. If no PLC is used, a standard industrial counter

such as OMRON H7CR can be set to count up to 9999999 revolutions, and then stop.

Table 2

IDS INDUSTRIAL DISPENSER

INSTRUCTIONS

1

Page 6

IN-IDS-08

6

2.4 External Control 0-5 VDC - Voltage Following Input Mode

In order for the stepper controller board to recognize and accept a 0-5 VDC control input, all speed

switches 1-7 (Switchboard #200293, Figure 2,) must be turned off. The board will not respond to a

voltage input unless all speed switches are off. Once off, a DC voltage (5.0 volts max.) signal may be applied via the input cable (P1) Pin 8 (RED) (+ voltage) and Pin 7 common returns. A variation of that voltage will linearly vary the motor speed. Maximum speed using a 0-5 volt DC input signal is limited to

approximately 2000 rpm. (The smallest increment is about 6 rpm.)

2.5 Continuous (Constant Run) Mode

By turning off the Dispense switches 9, 10, 11 on the Switchboard, and having a current signal at P1 Pin

9 (VIOLET), the motor will run at a continuous pre- set speed. This condition is useful for priming the

system.

Speed (factory set at 320rpm) may be changed according to section 5.0

3.0 Motor Direction

Factory preset to CLOCKWISE looking into the pump head. Suction is on the RIGHT, discharge on the

LEFT, when the pump head is facing you. Counter Clockwise rotation is settable by closing SW12 on

Switchboard # 200293 inside of the box. See section 5.0 * This Function is not Accessible on Connector

P1.

4.0 Power Supply requirements

A single 24 VDC power supply delivering 2.0 amps (minimum) of current is required for driving the

IDS 2000A. Connect positive (+) to P1 Pin 1 (RED) and negative (-) to P1 Pin 2 (BLACK). An addi-

tional power supply may be needed to provide input currents to the control inputs, if they are not internally

sourced from your controller.

IDS INDUSTRIAL DISPENSER

INSTRUCTIONS

1

Page 7

IDS INDUSTRIAL DISPENSER

INSTRUCTIONS

IN-IDS-08

7

O

9

board

s

OFF

OFF

U

G

C.

C

/

4

3

2

200293

9

3

The switches are set up as a binary system. This means that multiple switches will add their values together. For example, to set the motor to run at 500 rpm you must turn on switch 6, 5 and 2 (320+160+20

= 500 rpm). The switches can give a maximum speed of 1000rpm.

The controller will run at a constant pre-set speed via switches 1 through 7, until control current to P1 Pin

9 (VIOLET). is removed. When the current is removed the unit returns to “one cycle per start signal”. At

the first cycle of the dispense mode the pump will “home” itself to the proper starting point. All following

dispense cycles will then home to the proper start position.

Fig 2B

5.0 Speed switches –Switchboard # 200293

The SPEED switches 1 -7 are used for changing the speed settings.

1

'RED' Jumper

Dispense control

JP

witch

P1

W1

Dispense

Switche

10

#

PEN

7 6

640

PEED[RPM]

160

80

20

IN

10

ID METERIN

FL

B 300554

N 200293

P

P

Page 8

IN-IDS-08

8

FIGURE 4 (200145)

IDS INDUSTRIAL DISPENSER

INSTRUCTIONS

1

Page 9

IDS INDUSTRIAL DISPENSER

INSTRUCTIONS

9

Interchangeable pumphead modules permit this industrial dispenser to be

FLOW RANGE

IDS FLOW INFORMATION

Interchangeable pumphead modules permit this industrial dispenser to be

60

100

100

100

5

15

(PSIG) MAX

PRESSURE

60

0 - 320

10000.32Q1 (1/4)

Q2 (3/8)

Q3 (1/2)

operated in any of four flow rate ranges.

RH00 (1/8)

RH1 (1/4)

RH0 (3/16)

operated in any of three flow rate ranges.

900

800

0 - 100

0 - 25

0 - 50

1000

1000

1000

0 - 1000

0 - 650

0.025

0.100

0.050

0.72

1.28

Q0 (1/8)

PISTON

MAXIMUM

1000

RPM

mL/MIN

0 - 80

STROKE

0.08

MAX mL PER

SIZE

If a TIMED/COUNTED dispense is run, the pump will stop at the point of signal turn off. It will NOT

continue to complete the interrupted revolution. The pump will only complete the cycle if a single Start

command is given or as part of the next TIMED /COUNTED cycle.

6.0 Dispense / Flow Rates

To avoid cavitation at maximum speed use maximum internal diameter tubing at the suction side. Cavitation produces noise and inaccuracies of flow.

See 7.0 Calibration

IN-IDS-08

1

Page 10

IDS INDUSTRIAL DISPENSER

INSTRUCTIONS

IN-IDS-08

10

IDS-“Q” Pumphead

direction <right to left

Displacement is adjusted by

changing Angle of pumphead.

Loosen 11/32 hex nut and move

pumphead “left to increase” and

“right to decrease”.

Now recalibrate. Lock hex nut set

and lock Displacement adjust

stop screw.

The Knurled ADJUSTMENT NUT on the

pumphead controls stroke to stroke

Piston displacement. Turning clockwise

to zero stops displacement. Turning the ADJUSTMENT-NUT counterclockwise four and one half turns

from zero (450 on scale) (fig.5) causes maximum

pump reciprocation, e.g., 50 µl per stroke for the H-0

or 100 µ for H-1 unit.

Thus each 1-1/8 turn (112.5 on scale) of the ADJUSTMENT NUT Represents 25% of maximum

(12.5µl for H-0 and 25µl for H-1) and each graduation

on the ring represents an adjustment of 1/450th of

maximum (0.111 µl for H-0, 0.222 µl for H-1).

IDS-“RH” Pumphead

Flow direction> left to right

7.0 Calibration and Displacement

Your IDS comes factory calibrated to maximum displacement of the installed pumphead unless ordered

with specific displacement and calibration.

Recalibration and changes of displacement are relatively easy.

7.1 Calibration for Dispensing

FMI calibrates by weighing 3 or more dispenses on an analytical balance. It then finds the average. The

pumphead displacement is then adjusted as required up or down accordingly. See Fig

1

FIXED CALIBRATION LINE

CALIBRATION RING

Page 11

IDS INDUSTRIAL DISPENSER

INSTRUCTIONS

IN-IDS-08

ALL OIL S AND PART ICLES. BE SURE THE SURFACE

INSTALLATI ON INSTRUCTIONS FOR MOUNTING

8. REPLACE WITH A NEW 300598 PAD IF THE UNIT IS REMOVED.

THERMAL PAD, FMI P/N 300598

1. CLEAN THE MACHINE MOUNTING SURFACE OF

IS FREE OF RAISED GOUGES OR BURRS.

2. CAREFULLY REMOVE T HE BLUE SHEET FROM THE PAD.

3. THE EXPOSED WHIT E SURF ACE IS "TACKY" AND

WILL STICK T O T HE BACK OF THE PUMP ENCLOSURE.

4. ALIGN THE HOLES IN T HE PAD AND MOUNTI NG

6. REMOVE ANY AIR BULGES FROM UNDER THE PAD.

7. BOLT THE DISPENSER IN PL ACE.

SURFACE.

5. PRESS THE PAD INTO PLACE.

FINISH

SURFACE

FINISH

Chemical Metering Pumps

TOLERANCES

UNLESS OTHERW ISE

SPECIFIED

.X = ±.0 15

.XX = ±.010

.XXX = ±.005

MAT'L

DRAWN

BY

CHECKED

APPVD

BY

BY

TITLE

SCALE DWG NO. REV

DATE

DATE

FILEN AM E

APVD

DATEDESCRIP TIONSYM

REVISIONS

DATE

DATE

DWG BY

ORIG.

BY

NOTE : FMI TO B E NOTIF IED IN WRITING P RIOR TO ANY

CHANGES IN MATERIALS, PROCESSES OR CONSTRUCTION.

ANG = ±1°

700023

THERMAL PAD

MOUNTING

LABEL

8/16/02

A

8/16/02

8/16/02

8/16/02

Sht 1 of 1

FMI P/N 700023

1

Page 12

IDS INDUSTRIAL DISPENSER

INSTRUCTIONS

IN-IDS-08

SHT 2 OF 2

G

REV

Syosset,NY 11791

ENCLOSURE

IDS A SERIES,

5 Aerial Way, Suite 500

OUTLINE DRAWING,

Fluid Metering Inc.

R

WITH CSC-TC

OVERALL DIMENSIONS

1

PUMP HEAD MODULE

WITH CSC-WT

OVERALL DIMENSIONS

PUMP HEAD MODULE

TITLE

600059

DWG NO

FMI P/N IDS2000A / IDS2000AGM

CONNECTOR

OUTLINE

IDS2000A / IDS2000AGM

6.0 [152.4]

COVER

4.9 [125]

3.4 [86.4]

1.25" [31.8]

RADIUS =

MIN. BEND

Ø0.30

[7.6](8X)

CABLE

11.8 [300]

TYP

R.50 [12.7]

CABLE

CONNECTOR

OUTLINE

RADIUS =

1.25" [31.8]

MIN. BEND

3.4 [86.4]

6.0 [152.4]

15.8 [401] APPROX.

16.0 [406] APPROX.

12.0 [305]

Ø0.30

COVER

4.9 [125]

[7.6](8X)

TYP

R.50 [12.7]

4.12 [105]

3.5 [88.9]

3.7 [94.0]

TOLERANCES UNLESS OTHERWISE SPECIFIED:

.X = ±.04 [1.0]

NOTE: DIMENSIONS ARE IN INCHES [MILLIMETERS]

DIMENSIONS REPRESENT MAXIMUM VALUES OF PUMP HEAD EXTREMETIES.

.XXX = ±.010 [.25]

.XX = ±.02 [.50]

Page 13

IDS INDUSTRIAL DISPENSER

INSTRUCTIONS

IN-IDS-08

SHT 1 OF 2

2.0 [50.8]

CAUTION

RISK OF DAMAGE TO

9

6

3

7

8

5

4

1

2

ELECTRONICS! TURN

POWER OFF BEFORE

INSTALLING OR REMOVING

POWER CONNECTOR

300598

THERMO PAD

SHELL SIZE 13

ARRANGEMENT 13-9

AMP CIRCULAR CONNECTOR

STANDARD SEX

WITH CSC

OVERALL DIMENSIONS

PUMP HEAD MODULE

1

2.9 [73.7]

4.3 [109.2]

Syosset,NY 11791

5 Aerial Way, Suite 500

Fluid Metering Inc.

R

OUTLINE DRAWING,

TITLE

IDS A SERIES,

G

REV

ENCLOSURE

600059

DWG NO

OUTLINE

CONNECTOR

IDS2000A / IDS2000AGM

6.0 [152.4]

5.4 [137.2]

3.4 [86.4]

1.25" [31.8]

RADIUS =

MIN. BEND

CABLE

11.7 [297.8]

15.7 [398.8] APPROX.

7.50 [190.5]

6.75 [171.5]

0.38 [9.7]

BASE AND THERMO PAD MOUNTING

1.0 [25.4]

2.0 [50.8]

R.50 [12.7]

FMI P/N IDS2000A / IDS2000AGM

TYP

COVER

4.8 [121.9]

3.5 [88.9]

3.7 [94.0]

Ø0.30

[7.6](8X)

TYP

R.50 [12.7]

AMBIENT TEMPERATURE; 41°F - 104°F [ 5°C - 40°C ] IN STILL AIR, MOUNTED

OPERATING CONDITIONS:

GENERAL SPECIFICATIONS:

VERTICALLY, WITH AT LEAST 1 INCH OF CLEAR AIR SPACE ON ALL SIDES. MOUNTING

MAY BE BY 1 INCH WIDE BARS OR CHANNELS. FOR HIGHER TEMPERATURE AMBIENT,

ADDITIONAL HEAT SINKS AND FORCED AIR WILL BE REQUIRED TO KEEP THE

HOUSING OUTSIDE TEMPERATURE TO A MAXIMUM OF 125°F [52°C] ON ANY SURFACE.

RELATIVE HUMIDITY; 30% TO 80% NON-CONDENSING.

ATMOSPHERIC PRESSURE; 10.5 PSI [700 MILLIBARS] TO 15.4 PSI

[1060 MILLIBARS].

AMBIENT TEMPERATURE; 0°F [-18°C] TO 158°F [70°C].

NON-OPERATIONAL CONDITIONS:

RELATIVE HUMIDITY; 30% TO 85% NON-CONDENSING.

ATMOSPHERIC PRESSURE; 7.5 PSI [500 MILLIBARS] TO 15.4 PSI

1060 MILLIBARS].

TOLERANCES UNLESS OTHERWISE SPECIFIED:

.X = ±.04 [1.0]

NOTE: DIMENSIONS ARE IN INCHES [MILLIMETERS]

.XX = ±.02 [.50]

.XXX = ±.010 [.25]

DIMENSIONS REPRESENT MAXIMUM VALUES OF PUMP HEAD EXTREMETIES.

Page 14

IDS INDUSTRIAL DISPENSER

INSTRUCTIONS

IN-IDS-08

FINISH

SURFACE

FINISH

Chemical Metering Pumps

TOLERANCES

UNLESS OT HER WISE

SPECIFIED

.X = ±.015

.XX = ±.010

.XXX = ±.005

MAT'L

DRAWN

BY

CHECKED

APPVD

BY

BY

TITLE

SCALE DWG N O. REV

DATE

DATE

FILENAME

APVD

DATEDESCRIPTIONSYM

REVISI ONS

DATE

DATE

DWG BY

ORIG.

BY

NOTE : FMI TO BE NOT IFIED IN WRITIN G PRIOR TO ANY

CHANG ES IN MATERIALS, PROC ESSES OR CON STRUCTION.

ANG = ±1°

700021

EXAMPLE

IDS 2000A

START SIGNALS

2/5/04

D

6/6/02

2/19/04

2/19/04

Sht 1 of 1

FMI P/N IDS2000A SERIES

1

Loading...

Loading...