Page 1

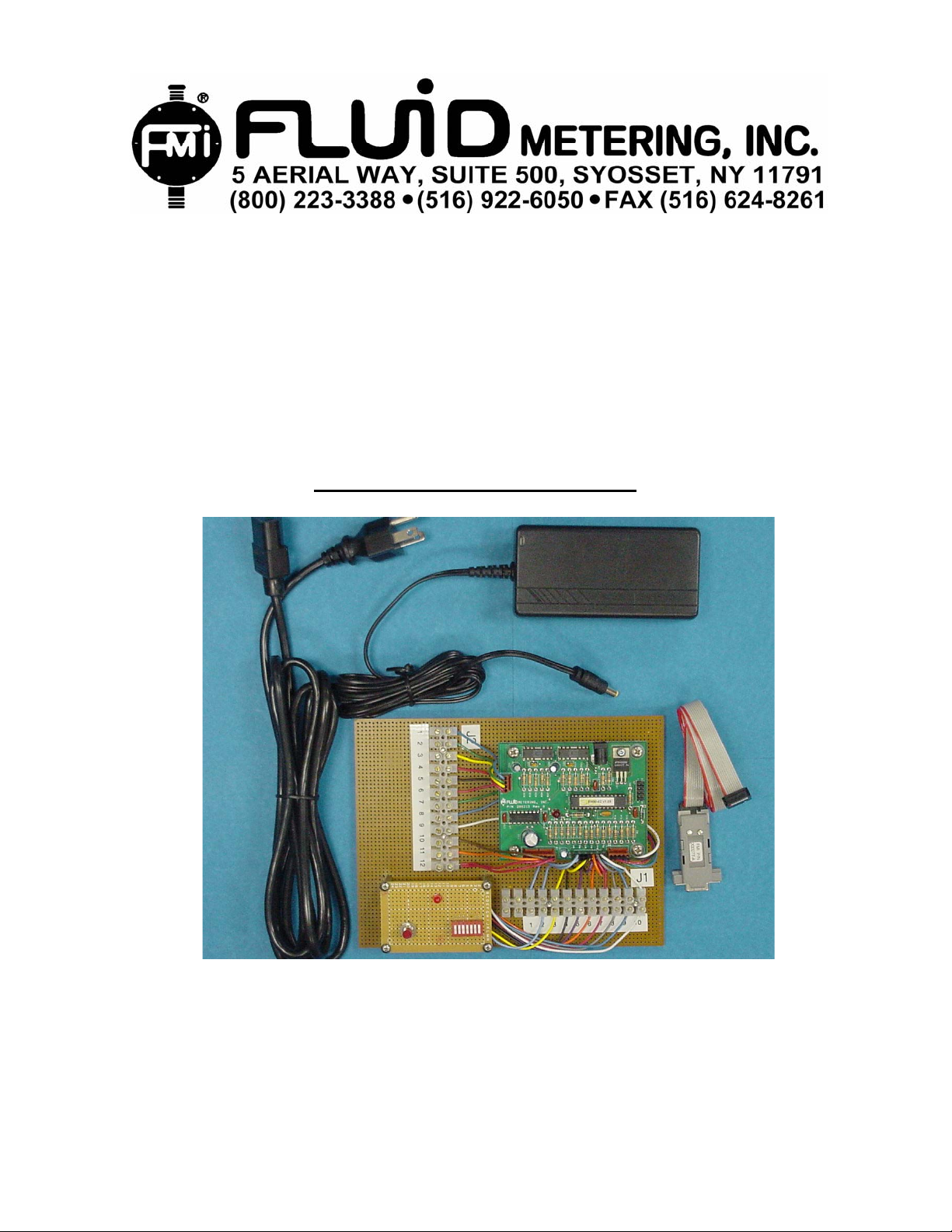

ICST-01

INTELLIGENT

STEP MOTOR DRIVE SYSTEM

INSTALLATION --- OPERATION

DEVELOPMENT KIT P/N ICST-01

SHOWN ABOVE

This kit is intended for help in setting up your required protocol for your FMI pump /

dispenser functions.

1

Page 2

Contents

1. SYSTEM SAFETY........................................................................... 3

2.

SYSTEM DESCRIPTION ................................................................ 3

2.1 FUNCTIONS

2.2 FEATURES

3. SYSTEM INSTALLATION.............................................................. 4

4.

WIRING SPECIFICATIONS ........................................................... 5

4.1 P/N ICST-01 Page 5

4.2 P/N ICST-01 OEM Page 6

5. PROGRAMS AND PROGRAMING.................................................7

5.1 Program Installation

5.2 Program Operation

6. SPECIFICATIONS........................................................................ 13

7.

TROUBLE SHOOTING................................................................. 14

TECHNICAL ASSISTANCE.......................................................... 14

8.

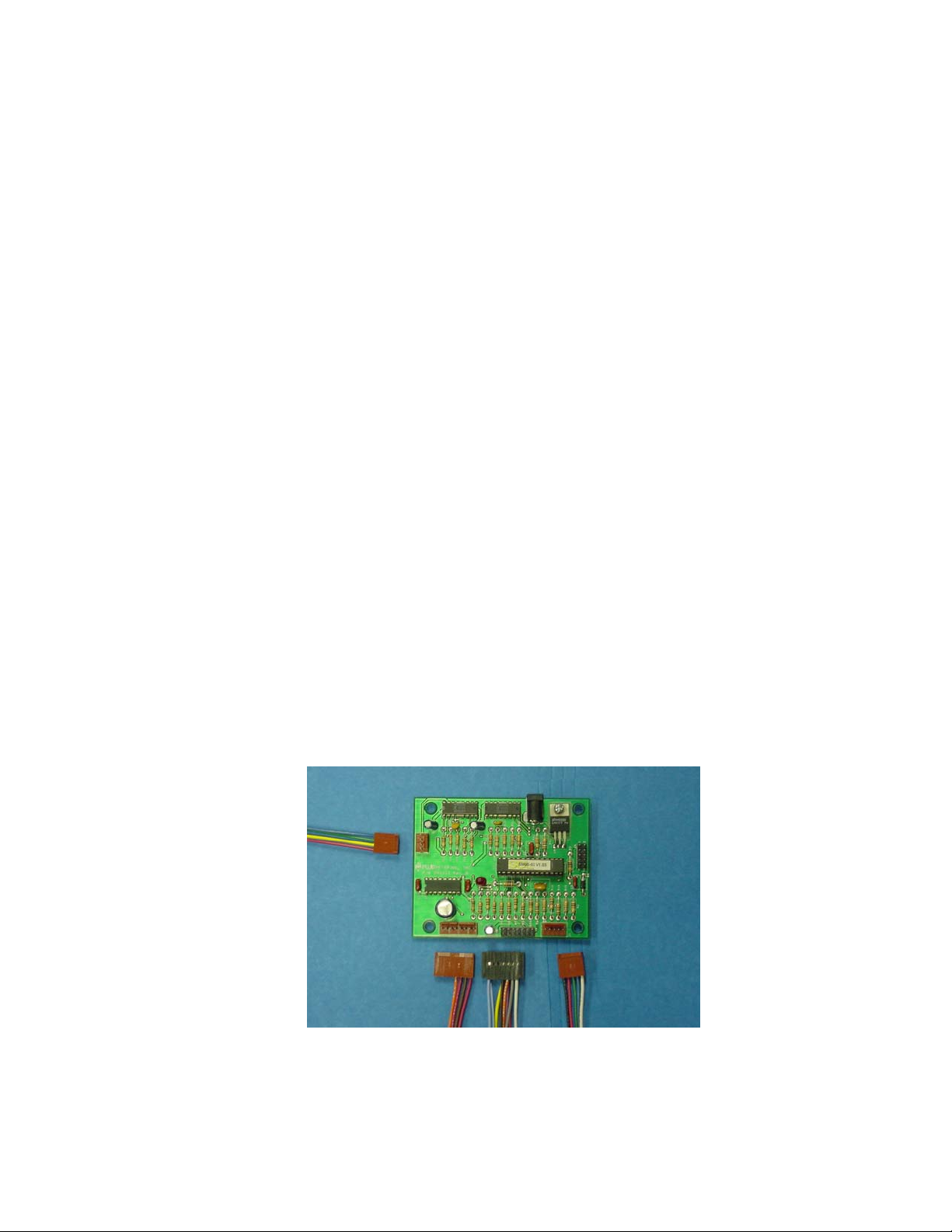

BOARD ALONE P/N ICST-01 OEM

SHOWN ABOVE

IN-ICST-01-07 2

Page 3

1. System Safety

CAUTION : To prevent power surge and damage to the board, apply and remove power by

the AC source of the power supply. DO NOT PLUG AND UNPLUG AT THE

BOARD.

CAUTION : To insure proper operation of the board be sure all wiring and connections are

correct and secure.

CAUTION : Keep fluids away from the electronics.

CAUTION : To prevent heat buildup in the motor, current to the motor should be reduced to

holding current or turned off between cycles.

2. System Description

The “ICST” is a programmable step motor control intended for use with FMI step motor

equipped pumps and dispensers. Using a computer programming adapter and exclusive ICSTPLE (program loader and editor) CD for Windows®, the operator can program the pump /

dispenser protocol that fits his application.

2.1 Functions

Fluid Metering Inc. can supply custom programs for the driver to fit most expected conditions.

Listed are a few of the functions of the driver boards programming.

Run: Clockwise or counter clockwise at fixed rate or through a profile table. The motor can be

accelerated and decelerated through a variable number of steps.

Stop: Stop can be programmed to actuate on either the leading or the trailing edge of the pumps

rotational flag. The stop can be also set to go any number of steps past the trip point. For

example if the program is set to stop on the trailing edge of the flag, going clockwise this would

stop the pump ½ way into the discharge stroke, the program can be instructed to go 100 steps

past the flag sense and stop at the bottom of the discharge stroke; without interrupting the

rotation. FMI standard (best) stop point is ½ way into the inlet stroke

Flow control: Program flow control includes the following; call, if, else, loop, goto, set, clear,

waitfor, repeat, run, halt, stop.

2.2 Features

Designed for maximum performance when mated to FMI 23 and 17 frame 1.8º step motors.

Most FMI step motor pumps come standard with a sensor and rotational flag that is aligned to the

pump piston. The rotational flag sensor outputs motor and or piston position to the driver.

All external connections to the driver board are via standard Waldom/Molex straight headers,

except the power input witch is a standard modular DC center positive receptacle. Development

kit has connections via barrier terminal blocks, except power input.

MOTOR OUTPUT POWER: Has three states, full power (1 Amp/Phase), low power (300

ma/Phase), or off. Power settings can be programmed to any state at any time. Ratings are ±

10%.

IN-ICST-01-07 3

Page 4

ACCESSORY OUTPUTS: Two dedicated power level outputs rated at supply voltage (24VDC)

and 150 milliamps each are available to drive external solenoids or relays.

TTL LEVEL INPUTS: Two dedicated TTL compatible high impedance, single ended, nonisolated, ground referenced, 5V inputs are provided. One is for Fluid Metering Inc. 5-wire optical

sensor. The other is high speed input capable recognizing an input pulse with a duration as little

as 4 Microseconds.

TTL LEVEL CONTROL: Seven TTL compatible I/O lines are available. These lines are current

limited to 5 milliamps each. All I/O lines are fully programmable.

3. System Installation

CAUTION : To insure proper operation of the board be sure all wiring and connection s are

correct and secure.

The “ICST” is a bi-polar driver only, set up to work half stepping only

stepping motor, this equals 400 steps per revolution. Speed and rotational calculations need to be

made from the 400 steps per revolution.

Stepping motors are made with different numbers of leads, there are 4, 6 and 8 lead motors. The

23 frame motor used on our general product line is an (8) eight lead motor. This motor, for the

best performance, works most efficiently when wired bipolar–series. The 17 frame motor is a (6)

six lead, and works most efficiently when wired half coil.

23 Frame Stepper.

FMI P/N 110746 (8lead)

Connector

Pin 6 RED wire is A Phase

Pin 1 YELLOW wire is A bar

Phase

Pin 8 GREEN wire is B Phase

Pin 3 BLUE wire is B bar Phase

Pins 2 & 5 BLACK & WHITE

terminated pair.

Pins 4 & 7 ORANGE & BROWN

terminated pair.

See Section 4, P/N ICST-01 or P/N ICST-01 OEM for the correct wiring, phase relationship, of the

motor to the driver. Motors shown are standard FMI pump drive motors.

For other motor wiring contact Fluid Metering.

FMI Sensor (STD. Optical Sensor) P/N 110569

This is a 5 lead inverted open collector output sensor. Signal goes high when the light source is

blocked. The pull-up and load resistors are built into the driver, so that the sensor can be directly

wired to the driver board.

RED wire is + V for the Ired LED.

BLACK wire is the ground for the Ired LED.

WHITE wire is the + V for the output.

GREEN wire is the ground for the output.

BLUE wire is the inverted open collector output to the controller.

17 Frame Stepper.

FMI P/N 110745 (6lead)

Connector

Pin 3 RED wire is A Phase

Pin 2 BLACK wire is A bar Phase

Pin 4 BLUE wire is B Phase

Pin 5 WHITE wire is B bar Phase

Pin 1 YELLOW wire is not used

Pin 6 ORANGE wire is not used

. For a standard FMI 1.8º

23 Frame Stepper (STRH).

FMI P/N 300615 (8 lead)

Used with FMI cable assembly

P/N 110711

Pin 1 ORANGE wire is A bar Phase.

Pin 2 & 5 WHITE/BLACK &

WHITE/ORANGE terminated pair.

Pin 3 YELLOW wire is B bar Phase.

Pin 4 & 7 WHITE/RED &

WHITE/YELLOW terminated pair.

Pin 6 BLACK wire is A Phase.

Pin 8 RED wire is B Phase.

IN-ICST-01-07 4

Page 5

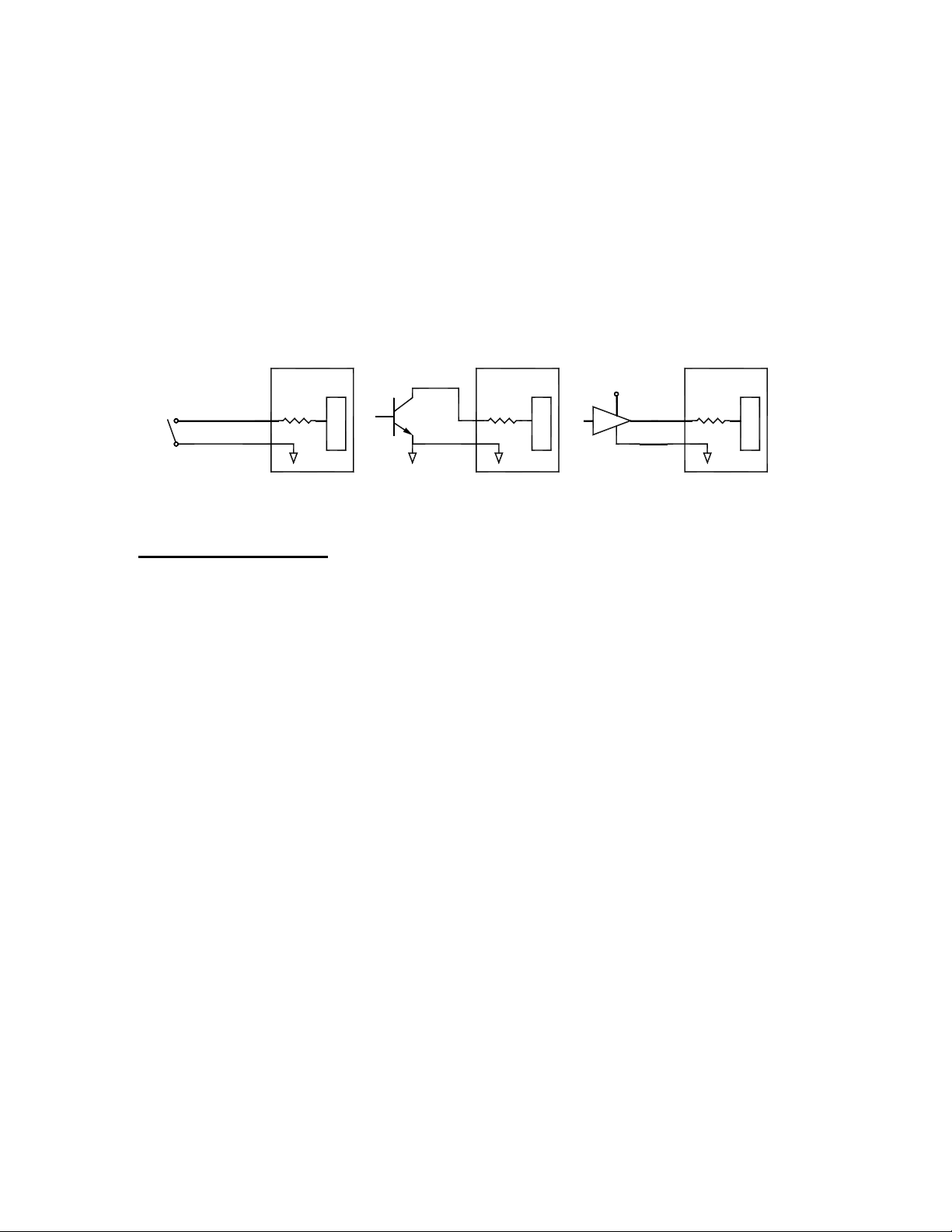

NOTES ON TTL LOGIC: For interface to PLC or other type of control.

TTL (Logic High) ≥ 2.0 Vdc

TTL ( logic Low) ≤ 0.6 Vdc

Vin ( Absolute Maximum) = 5Vdc

Vin ( Absolute Mininum) = 0.0Vdc

Vin ( Logical High) = ≥ 3.5 Vdc.

Vin ( Logical Low) = ≤ 1.0 Vdc.

ACCEPTABLE INPUTS

5 Vdc

DRY CONTACT

4. Wiring Specifications

4.1 P/N ICST-01

Wiring for terminal strip marked J12:

Number 1 is the B bar phase to the motor.

Number 2 is the B phase to the motor. Note: See section 3 system

Number 3 is the A bar phase to the motor installation for motor wiring.

Number 4 is the A phase to the motor.

Number 5 is the Black wire from the sensor.

Number 6 is the Red wire from the sensor.

Number 7 is the Green wire from the sensor.

Number 8 is the Blue wire from the sensor.

Number 9 is the White wire from the sensor.

Number 10 is the Brown wire for Relay 1 (- side activated).

Number 11 is the Orange wire for Relay 2 (- side activated).

Number 12 is the 2 Red wires (+24 Vdc) for Relay power.

Wiring for terminal strip marked J11:

Numbers 1 and 2 are Ground, the Lt Blue wire two places.

Number 3 is the Push Button Switch (Activation Switch), the Yellow wire.

Number 4 is the Dip Switch 1 (I/O1), the Black wire.

Number 5 is the Dip Switch 2 (I/O2), the Purple wire.

Number 6 is the Dip Switch 3 (I/O3), the Orange wire.

Number 7 is the Dip Switch 4 (I/O4), the Red wire.

Number 8 is the Dip Switch 5 (I/O5, the Gray wire.

OPEN COLLECTOR

(OPEN DRAIN)

TTL or CMOS LOGIC

IN-ICST-01-07 5

Page 6

Number 9 is the Dip Switch 6 (I/O6), the Blue wire.

Number 10 is the Dip Switch 7 (I/O7), the White wire.

4.1 P/N ICST-01/ OEM

J1 I/O Connector

PIN # FUNCTION

Pin 1 Ground the Lt Blue wire.

Pin 2 Ground the Lt Blue wire.

Pin 3 + 24 V (From input power supply) NC

Pin 4 + 24 V (From input power supply) NC

Pin 5 +5 V (Do not recommend using this, loads the voltage regulator) NC

Pin 6 +5 V (Do not recommend using this, loads the voltage regulator) NC

Pin 7 Input 1 (Used as start signal) Yellow wire.

Pin 8 I/O 1 = Program PIN1 the Black wire.

Pin 9 I/O 2 = Program PIN2 the Purple wire.

Pin 10 I/O 3 = Program PIN3 the Orange wire.

Pin 11 I/O 4 = Program PIN4 the Red wire.

Pin 12 I/O 5 = Program PIN5 the Gray wire.

Pin 13 I/O 6 = Program PIN6 the Blue wire.

Pin 14 I/O 7 = Program PIN7 the White wire.

J2 Sensor Connector (STD. Optical Sensor) P/N 110569

PIN # FUNCTION

Pin 1 +5 V cc the White wire.

Pin 2 Signal from sensor to board the Blue wire.

Pin 3 Ground the Green wire.

Pin 4 +5 V ir the Red wire.

Pin 5 Ground the Black wire.

J3 Motor Connector

PIN # FUNCTION

Pin 1 A Phase the Red wire. Note: See section 3 system

Pin 2 A bar Phase the Yellow wire. installation for motor wiring.

Pin 3 B Phase the Green wire.

Pin 4 B bar Phase the Blue wire.

J4 Programming Connector

For use with the programming cable only. See pages 12 and 13 for details.

J5 Relay output Connector

PIN # FUNCTION

Pin 1 + 24 Vdc the Red wire.

Pin 2 Control to ground for RELAY1 the Brown wire.

Pin 3 + 24 Vdc the Red wire.

Pin 4 Control to ground for RELAY2 the Orange wire.

Pin 5 Not used + 24 Vdc NC

Pin 6 Not implemented NC

Pin 7 Not used + 24 Vdc NC

Pin 8 Not implemented NC

IN-ICST-01-07 6

Page 7

5. Programs and Programming

The “ICST” driver board is fully programmable and is designed to drive a low power stepper

motor through a pre-configured profile while exercising discrete outputs and responding to inputs

as necessary. The SCL (“Simplified Control Logic”) is a set of commands that allow stepper motor

position and timing control to be preset into a non-volatile memory. Board retains program in

memory after the board is powered down. Reapply power to the board and start the program.

Restart is usually through dedicated input. Note: If power is removed during a single revolution, a

partial revolution must be made to return to start “HOME” position. Fluid Metering Inc. can supply

custom programs for the driver to fit most expected conditions. More information about the

programming is available in the “PROGRAMMERS MANUAL” supplied on the CD in PDF format.

File names for the programs may not have more than eight (8) characters before the .SCL

extension.

The FMI “ICST-01” comes with ”ICST-PLE” Windows® multi-platform loading and editing

program CD, and programming adapter. Included are 4 general use programs to help you get

started. These programs are basic yet offer quick solutions to many simple dispensing/pump

application. These basic programs while fixed do offer some mods and tweaking functions.

A look at the basic programs:

900000 Test program to check board functions.

900000_1 Continuous in either direction at 300, 400, 450 or 500 spm

Purge and or Back flush at 500 spm

Single dispense with or without Suckback

Stall detect

900000_2 Dispensing – single or Multiple (continuous) by count

1 shot or multiple (2 to 6000)

Purge or Back flush at 500 spm

900000_3 Dispensing

Purge and or Back flush at 500 spm

1 shot aspirate

900000_4 Dispensing with output signal / Revolution

1,2 or 4 Dispenses / switch closure at 240 or 300 spm

Purge and or Back flush at 500 spm

1 shot aspirate

5.1 Program Installation

The “ICST-PLE” CD is setup to auto start. If your cdrom is not setup to auto start go to START

then RUN, Browse to the cdrom the CD is in click on setup then click open, click on OK to start

setup. Follow the on screen instructions. If the install did not place an icon on the desktop, go to

start menu, go to run, browse to Program Files/FirstStep/FirstStep.exe, click open then ok.

For specifications and attachment of the serial communications program adapter; FMI P/N

200277 refer to page 13.

Note: If for any reason the program becomes corrupt or non functional insert the CD, if the CD

auto starts say no to the installation, go to RUN browse to the disk and click on uninstall to

remove the program. After the program is removed browse to the setup and reinstall. CAUTION,

if you modified or are using a custom program you should move the files to another folder, the

uninstall will delete all the information in the current folder.

1,2 or 4 Dispenses / switch closure at 240 or 300 spm

IN-ICST-01-07 7

Page 8

Quick Start Screens:

Level 1, called “Pick and Run”, is designed to allow the least experienced user to select a

program from a list of documented programs, load that program into the hardware, and enable

program execution. Some operational parameters may be optionally adjusted at this level.

Level 2 – The “Target Inspector”, is designed for hardware checkout. On this level, an

engineer can see the target hardware the way the SCL controller sees it. Input lines can be

observed dynamically, output lines can be exercised individually and bi-directional signals

can be tested in both directions

IN-ICST-01-07 8

Page 9

Level 3 – This level “Building Blocks” is currently being developed.

Level 4 – This area is reserved for the advanced SCL programmer. Full control over all

features in the target is available to the user at this level. While SCL is considerably less

demanding than other micro-controller programming languages, it still requires a level of

“Logical” expertise that is better suited to someone with a programming background.

Main Screen:

Pull down menus: Files

Home

View

Toolbox menu is not functional for this

application.

Status bar shows target, program loaded

onto the board, status of the driver.

N = not connected

H = halted

R = running

Up arrow loads the programs.

Square halts the program execution

Right arrow starts the program

IN-ICST-01-07 9

Page 10

Pick and Run Screen:

Single click on a program in list brings the

program description into the description

window for review prior to loading.

Double click will auto load the program into the

board processor.

The program controls “Tweakable

parameters”associated with the program are

also shown.

Target Inspector Screen:

This screen shows boards I/O’s ,

This screen allows operator to check

And verify the operation of the boards

I/O functions.

Use in conjunction with supplied program

900000 to check the functionality of the

of the board. This program is loaded onto

the driver when shipped.

IN-ICST-01-07 10

Page 11

Advance Program Screen:

This screen by default opens with Project

Description, Program List and Program

Controls. Program List and Program controls

can be closed by clicking on the “X” button.

Use the mouse pointer to check the definitions

of the icons each has a pop up definition.

Two icons of note are the check and the bug.

The check icon: Checks the program for errors.

The bug icon: This brings up the Simulator/

Debugger screen. SEE THE NEXT SCREEN.

DEBUG/Simulation screen:

Open the Project Code screen by clicking

on the icon.

When using the step command the

program will highlite each command as it

steps through the program.

NOTE:

This is not a real time display. The

debugger is running in the computer

program not in the drivers on board chip.

The next step is to just push the buttons to see what happens. If the program stops running close it

and reopen it. The worst case is to crash the program, in this case use the CD and say no to the load

program prompt. Run the uninstall from the CD to remove the program from the drive and reinstall it.

When running the debugger This array shows the I/O’s

in step mode this bar will and the inputs as well as

advance through the timer the relays as they change

if a WAIT is in the program. States.

Click on this at a WAIT state

to go to the next line of code.

IN-ICST-01-07 11

Page 12

ICST Driver Board

Location of Headers and Location of Pin 1 on the Header

J4

Programing

Pin 1

Interface

Pin 1

J2

Sensor Input

J6

2

POWER INPUT

1

J4

J6

10

9

J2

J1

I/O Header

13114

Pin1

12

J1

J5

1

1

J3

Pin 1

J5

J3

Pin 1

Motor Output

IN-ICST-01-07 12

Relay Output

Page 13

6. Specifications

DRIVER BOARD

Electrical:

Input Voltage: 24 VDC at 2 Amps Min. ( J6 Power Jack Center Positive)

Mating Power Plug: 5.54mm OD 2.54mm ID 9.53mm Long

Output current: 1 Amp/Phase Max.

Stroke Rate: 500 RPM Max

. Drive mode is bi-polar for 2 phase stepping motors and is half stepped.

Duty Cycle: Intermittent and Continuous Duty.

Storage: -40º c to +125º c.

Operational: +20º c to +60º c.

Mechanical:

Circuit Board: Dimension: 3” [76,2 mm} X 3.75” [95,3 mm] X 1” [25,4 mm]

Mounting: 4 Holes: Ø 0.18 [4,57 mm]

2.50” [63,5 mm] X 3.13” [79,4] Pattern

DEVELOPMENT SYSTEM REQUIREMENTS:

100mhz Pentium or better

Windows 95, 98, ME, 2000

VGA monitor or better

10 megabytes of available disk space

8 megabytes of RAM

CD ROM drive

1 RS232 communications port: Standard 9 pin “D”

SERIAL COMMUNICATIONS WITH THE TARGET DRIVER:

RS232-C specification

9600 Baud

1 stop bit

No parity

1 Serial communications adapter cable, FMI P/N 200277

Ribbon cable orientation: Looking at the adapter so that the two LED’s are facing up the red wire

of the ribbon cable on the connector goes to pin 1 (indicated by arrow on the adapters’ mating

connector, the arrow is just outside of being in line with the LED).

Adapter cable attaches to J4 on the driver board. Red wire of the ribbon cable on the connector

goes to Pin 1 of J4; see page 12 for view of J4.

To verify port settings in “Windows” enable a session of “Terminal” or “Hyper-terminal”. Set the

communications settings to Parity-None, Flow control-none, Baud-9600, Data bits-8, Stop bits-1.

Select the appropriate COM port. With the terminal window selected, press the enter key and

verify that one of the LED’s on the programming adapter flashes. This indicates proper

connection and selection of the COM port.

NOTE: The program is by default setup to look for serial COM 1 if you do not have that COM port

available the port can be changed by clicking on the VIEW pull down and click on

Communications. Set the COM port to be used close the window and the program restart the

program.

IN-ICST-01-07 13

Page 14

7. Trouble Shooting

1. Be sure all connections are tight and secure.

2. Be sure all wiring is to the wiring specifications.

3. Be sure power is applied, typical 24 Vdc @ 2 A, 30 Vdc max.

4. Board fails to respond, chips on the board get hot: The major cause for total board failure

is hot swapping the power connector at the driver board this causes a power serge and may

also cause static discharge. The board is static sensitive.

5. Motor fails to rotate: Check motor wiring, check the program being run to be sure there is the

proper current setting, and check the program to be sure there sufficient acceleration ramp to

obtain the speed required.

6. Pump fails to stop: If the program is set up to stop the pump at a prescribed location and it

fails to stop at all. The most probable cause is a failure of the board seeing the flag signal. See

(Pump fails to stop in the correct location) for more information.

7. Pump fails to stop in the correct location: Check the program being run for programming

errors if the pump is programmed to stop at a place other the leading edge of the flag. Check

the sensor for function. This can be done with the ICST-PLE using the target inspector (Page

10), click select all than auto read. The sensor is INPUT 2 and should change state while

rotating the pump drive by hand. Checking the sensor itself is more difficult. If the sensor can

be removed from the pump body a volt meter across the blue wire connection and the green

wire connection will show the change in state if the light source is blocked and unblocked.

8. Failure to communicate with the driver board: Make sure the interface cable is installed

correctly, see page 13.

9. Program seems not to load properly: Loading a program repeatedly, making numerous

changes may cause the loader to fail to operate correctly. This is not usual case, but is a

software generated situation. To fix this, just go in the installed file directory (the place where

the program being loaded is located) and delete the files with the programs name with the file

extensions .LST and .BIN. Reload the program.

8. Technical Assistance

Please contact:

Fluid Metering Inc

Tel: 800-223-3388

5 Aerial Way, Suit 500

Syosset NY 11791 Tel: 516-922-6050

Email: pumps@fmipump.com Fax: 516-624-8261

IN-ICST-01-07 14

Loading...

Loading...