Flycolor RAPTOR BLS-Mini User Manual

多旋翼飞行器

无刷电子调速器说明书

● 采用功 能强大EF M8BB 21F1 6G MCU ,8位C8051核 心,工作频 率高达50M Hz;

● 专用三 合一驱动I C,反应速度 更快。电调 最高支持50万 转速。

● 超小尺 寸,更适合 小型多旋翼 。

● BL Heli- S 固件,专为 多旋翼提升 优越的性能 ,硬件产生 的电机PW M可提升平 滑的油门响 应和降低噪 音。

● Dam ped lig ht 会产生再 生制动,使 得效率更高 ,油门从大 到小变化时 电机减速响 应更加迅速 ,多旋翼稳 定

性和灵 活性得到显 著加强。

● 多种参 数可设置, 使得电调能 够在最暴力 的配置下运 行,即使默 认设置也能 在正常配置 下出色的运 行。

● 电调上 电自动检测 油门信号, 支持普通PW M油门模式1- 2ms的脉宽 输入、One shot和 Mu ltish ot。

● 支持Ds hot15 0、Dshot 300和Dsh ot600。D shot为数 字信号,抗 干扰能力强 ,而且电调 不需要校准 油门行程。

● 信号线 为双绞硅胶 线, 增加其使用 寿命同时更 有效降低信 号在铜线内 传输所产生 的干扰,使飞行 更稳定。

*为避免短 路和漏电, 请确保连接 处绝缘良好

01 主 要特性

02 产 品规格

03 连 线示意图

*图片仅供 参考,产品 以实物为准

1. 启动 功率 (Sta rtup po wer):

启动功 率可以设置 从0.031到1. 5的一个值。 它是启动过 程中允许的 最大功率, 实际应用的 功率取决于 油门的输入 值。

启动功 率也会影响 双向操作, 因为启动功 率也是用来 限制在反向 时一个施加 的功率。对 于低转速电 机,最大功 率是有限的 ,为了便于 低反电动势 的电

压检测 ,允许的最 大功率可以 通过启动功 率这个参数 来设置。

(Co mmuta tion ti ming) : 2. 进角

进角可 设置为 低/中低/中/中高/高 ,分别对应0°/ 7.5°/15°/ 22.5°/3 0°进角。

通常设 置中进角即 适用于大部 分电机,但 如果电机运 转不顺畅时,可 以尝试改变 进角。

对于一 些高感电机 ,其换向退 磁时间较长 ,尤其在低 速运转的时 候,电机会 在油门快速 增加的情况 下停转或者 不顺畅。将 进角改高点 会有有助于 改善

这个现 象,因为高 进角允许更 长的换向退 磁时间。

(De mag com pensa tion):3. De mag补偿

Dema g补偿是防 止电机由于 换向引起停 转的一个功 能,典型的 现象是在快 速增加油门 时电机停转 或不顺畅, 尤其在低转 速运行时。 如前面所述 ,设置

高进角 可以帮助改 善,但有可能降 低效率。一 般情况下,D emag补偿 参数的值越 高,保护越 好。如果补 偿值设置得 太高,最大 功率将有所 降低。

转向 (R otati on dire ction ):4.

电机转 向可以设置 为正转/反转/双向 。

在双向 模式下,油 门中点为零 点,中点以 上为正转,中点 以下为反转 ;当选择双 向操作时, 油门编程被 禁用。

(Be ep stre ngth):5. 鸣叫声强 度

设置正 常运行下鸣 叫声强度。

(Be acon st rengt h):6. 警报 音强度

设置警 报音响起时 的强度。如 果油门信号 在零点位置 的时间超过 一个设定的 时间,电调 将开始报警 。请注意如 果设置一个 高的警报强 度将会导致 电机

或电调 发热。

(Be acon de lay):7.警报 音延迟

设置报 警音开始之 前的延时。

以下的 参数需 要通过B LH eliS uite编 程

04 编 程参数值

持续电 流

瞬时电 流(10S)

BE C

尺寸(供参 考)重量(供参 考)

锂电池 节数

典型应 用(供参考)

型号

Rap tor BL S-Min i-15A

15A 20A

2-3 S

5g

90- 150 多旋翼

No

15x 11.5x4. 2mm

RA PT OR B LS -M in i

*Ra ptor B LS-M ini 使用的B LHe li-S固件 为 ;请联 系Flycol or以获取 更多信息。 G-H- 30

感谢您购 买本产品! 本产品功率 强大,错误 的使用可能 导致人身伤 害和设备损 坏,强烈建 议您在使用 设备前仔细

阅读本说 明书并保存 ,严格遵守 规定的操作 程序。我们 不承担因使 用本产品或 擅自对产品 进行改造所 引起的任何

责任,包 括但不限于 对附带损失 或间接损失 的赔偿责任 。我们有权 在不经通知 的情况下变 更产品的设 计、外观、

性能及使 用要求。

ATTENTION

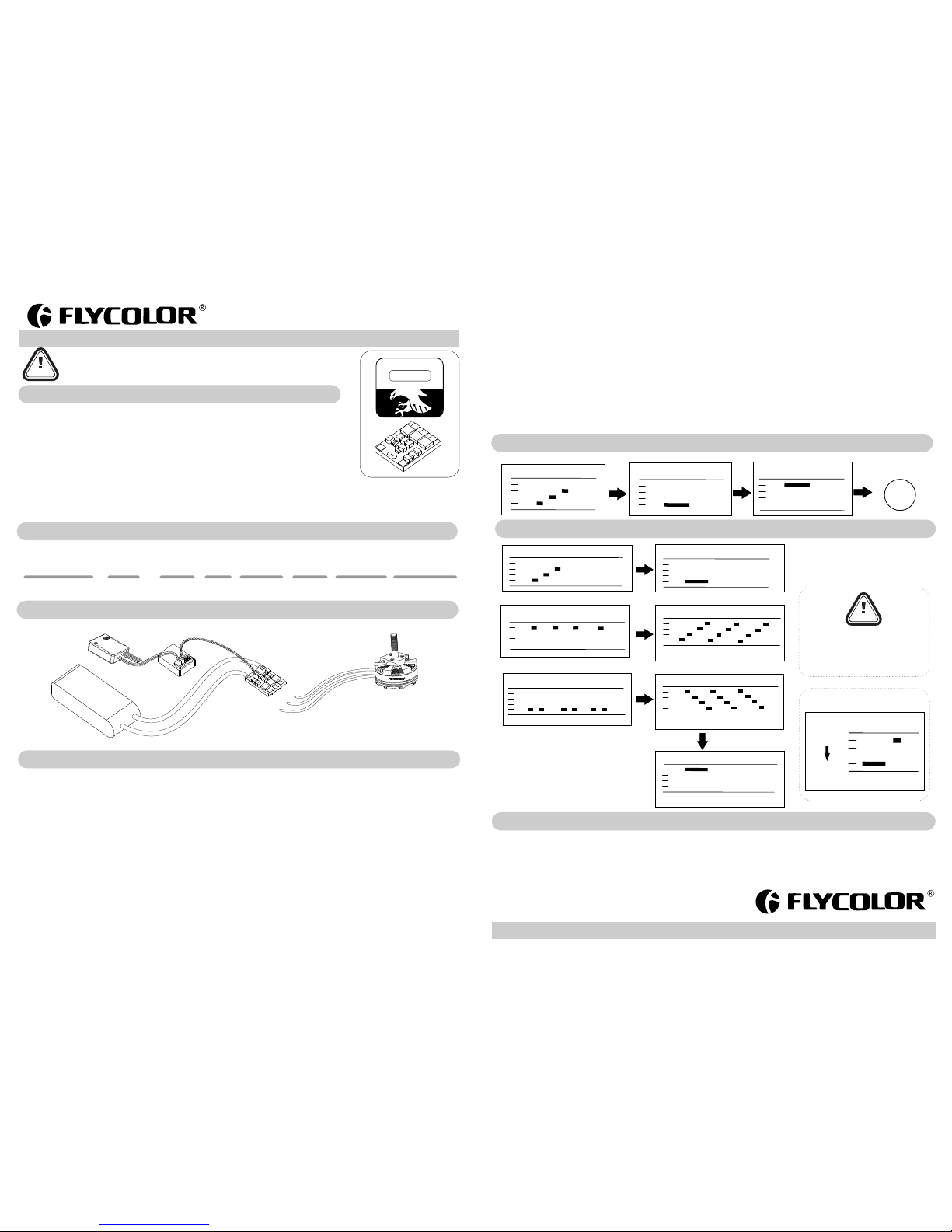

05 正 常工作及提 示音

06 油 门校准

● 电调接 入飞行系统 后,每次上电会 自动检测输 入的油门信 号,然后执行相 应的油门模 式;

● 首次使 用无刷电调 或更换遥控 设备后需要 进行油门行 程校准 ;;Dsh ot 模式时, 将不再需要 校准油门

● 使用BL Heli- S开源程序,当 电机出现异 常或者要求 达到更高转 速时,可尝 试更改进角 参数;

● 如需更 多信息,请 联系飞盈佳 乐售后或者 技术支持。

07 注 意事项

1. 上电:

2. 油门 信号检测:

一次

一次

一次

3. 零点 油门检测 :

4. 此时 电机准备

就绪, 可以启动。

OK

ww w.fl ycolo r.ne t

电池

Bat tery

接收机

Rec eiver

BEC

无刷电子 调速器

ESC

马达

Mot or

多旋翼飞行器

无刷电子调速器说明书

5. 当油 门摇杆低于 中间位置 (检测 最小油门):

正在检 测

1. 上电:

一次

完成

3. 当油 门摇杆高于 中间位置 (检测 最大油门):

正在检 测

2. 油门 信号检测 :

一次

7. 油门 校准已经完 成。

此鸣叫 音表示油门 校准完成, 可以正常工 作。

一次

1.使用 飞控调参软 件校准油门 将更简便;

2.当输 入信号为Ds hot 模式时 ,将不再

需要校 准油门,请 忽略此步骤 。

ATTENTION

6. 当油 门摇杆低于 中间位置:

此鸣叫 顺序表示最 小油门已经 被存储

一次

4. 当油 门摇杆高于 中间位置超 过3秒

此鸣叫 顺序表示最 大油门已经 被存储

一次

图示举 例:

短音

长音

音调最 高

音调最 低

(Pr ogram ming by T X):8. 油门 编程

如果禁 用,油门行程校 准将被禁用

注意:B LHe li-S 只能 用遥控器油 门进行油门 行程校准, 不能使用油 门来编程。

9. 最小 油门,最大 油门和中心 油门 (Min th rottl e, max th rottl e and cen ter thr ottle ):

设置电 调的油门范 围;中点油 门只用于双 向操作;设 置值正常的 为1000us 到 2 000us的 输入信号。 对于其他输 入信号,该 值必须按比 例设置。

(Th ermal p rotec tion ):10.温 度保护保护

可以启 用或禁用。 温度保护阀 值可以设置 为80℃-140℃( 从16.3版本 开始),当 温度高于阀 值时,电机功率 降低到75%; 当温度高于 阀值5℃,电机功率 降

低到50 %;当温度高 于阀值10℃时,电 机功率

降低到2 5%;当温度 高于阀值15℃ 时,电机功率降 低到0%。

(Lo w RPM po wer pro tect):11.低转速 功率保护

低转速 功率限制可 以启用或禁 用。

禁用它 可以以保证 低KV电机在 低电压运行 时实现全功 率。然而禁 用它将增加 同步丢失的 风险,伴随 着电机或E SC发热的 可能性。

(Br ake on st op):12.停车制 动

可以启 用或禁用制 动。当设置 启用时,在 通电状态, 油门在零点 位置电机将 会有拖刹, 阻止电机转 动。如果油 门没有零点 ,此项设置 无效。

(L ED cont rol):13. LED控制

对于支 持的ESC, 可以控制发 光二极管。 多达4个LE D可以打开或 关闭。

RA PT OR

DS HOT

BL S-M ini

01 M ain f eatur es

02 S pec ificat ion s

03 W iri ng diag ram

04 P rog rammi ng pa ram ete r

BE C

Rap tor BL S-Min i-15A

15A 20A

2-3 S

5g

90- 150 Mul ti

No

15x 11.5x4. 2mm

RA PT OR B LS -M in i

ATTENTION

05 B eep s-Nor mal o per ati on

06 B eep s - Thr ott le cali bra tio n

07 O the rs

ww w.fl ycolo r.ne t

RA PT OR

DS HOT

BL S-M ini

Batt ery

Rece iver

BEC

ESC

Moto r

● EF M8BB 21F1 6G MCU , pipe lined 8 -bit C8 051 cor e with 50 M Hz max imum op erati ng freq uency.

● Ded icate d 3in1 dr iver, f aster r espon se.ES C maxi mum spe ed is lim ited to 500k e RPM.

● Ult ra smal l size, mo re sui table fo r small m ulti rotor.

● BL Heli- S firmwa re is des igned f or supe rior pe rform ance in m ultir otors , and use s hardw are gen erate d motor

pwm fo r smoot h throt tle res ponse a nd sile nt oper ation .

● Dam ped lig ht does r egene rativ e braki ng, cau sing ve ry fast m otor re tarda tion, a nd inhe rentl y also do es acti ve

free wheel ing.

● Sup ports fe ature s to prev ent syn c loss. T here ar e tunea ble par amete rs that c an make t he code r un well e ven in

the mo st dema nding s ituat ions, a lthou gh defa ult set tings w ill wo rk excel lentl y in nor mal ope ratin g envir onmen ts.

● The c ode sup ports r egula r 1-2ms p ulse wi dth PW Minpu t, as wel l as Ones hot and M ultsh ot . The in put sig nal is

auto matic ally de tecte d by the E SC upo n power u p.

● Sup ports D shot1 50, Dsh ot300 a nd Dsho t600. Dshot i s digit al sign al, ant i-int erfer ence ab ility i s stron ger, and d o not nee d throt tle cal ibrat ion.

● The si lico ne twis ted-p air of the t hrott le sign al cabl e incr ease the servic e life, and effe ctive ly redu ces the c rosst alk cau sed by si gnal tr ansmi ssion ,

and ma kes flig ht more s table .

Thank yo u for using o ur produc t. A ny Imprope r operati on may cause person al injury d amage to the

produc t and rela ted e quipment s. Th is hi gh po wer s ystem for RC model can be d angerous ,we stron gly

recomm end readin g the user manu al careful ly and compl etely. We will no t assume any re sponsibi lity for any

losses ca used by unauthor ized modifica tions to our produ ct. We h ave the right to chang e t he d esign,

appear ance, perf ormance and u sage requi rements of t he product wi thout noti ce.

Con. Curre nt

Bur st Curre nt

(10 S)

Size

(For reference)

Weight

(For refer ence)

LiP o cells

Typical Applications

(For reference)

Mod el

*Ra ptor B LS-M ini is us ing the BL Heli -S firmw are; Pl ease co ntact F lycol or for mo re info rmati on.G-H -30

User Manual

Multi-Rotor Brushless ESC

*All p ictur es are fo r refer ence on ly

*Plea se ensure a ll solde r joints ar e insulat ed with he at shrink w here nece ssary.

1. Sta rtup po wer:

Star tup pow er can be s et to rel ative v alues f rom 0.0 31 to 1.5 . This is t he maxi mum pow er that i s allow ed duri ng star tup. Act ual app lied po wer

depe nds on th rottl e input , and can b e lower, b ut the mi nimu m level i s a quart er of the ma ximum l evel . Startu p power a lso aff ects bid irec tiona l

oper ation , as the pa ramet er is use d to limi t the pow er appl ied du ring di recti on reve rsal. F or low rp ms, the ma ximum p ower to t he moto r is limi ted,

in ord er to fac ilita te dete ction o f low BE MF vo ltage s. The ma ximum p ower al lowed c an be set v ia the st artup p ower pa ramet er.

2. Co mmutat ion tim ing:

Comm utati on timi ng can be s et to low /medi umlow /medi um/me diumh igh/ high, th at corr espon d to 0°/7.5°/ 15°/22. 5°/30° tim ing adv ance.

Typic ally a me dium se tting w ill wor k fine, bu t if the mo tor stu tters i t can be be nefici al to cha nge tim ing. So me moto rs with h igh ind uctan ce can ha ve

a very l ong com mutat ion dem agnet izati on time . This ca n resul t in moto r stop or s tutte r upon qu ick thr ottle i ncrea se, par ticul arly wh en runn ing at a

low rp m. Sett ing tim ing to hi gh will a llow m ore tim e for dem agnet izati on, and o ften he lps.

3. De mag comp ensa tion:

Dema g compe nsati on is a fea ture to p rotec t from mo tor sta lls cau sed by lo ng wind ing dem agnet izati on time a fter co mmuta tion. T he typi cal

symp tom is mo tor sto p or stut ter upo n quick t hrott le incr ease, p artic ularl y when ru nning a t a low rpm . As menti oned ab ove, se tting h igh

comm utati on timi ng norm ally he lps, bu t at the co st of effic iency. Gener ally, a hi gher va lue of th e compe nsati on para meter g ives be tter pr otect ion.

If dem ag comp ensat ion is se t too hig h, maxi mum pow er can be s omewh at redu ced.

4. Di rectio n:

Rota tion di recti on can be s et to fwd /rev/ bidir ectio nal fwd /bidi recti onal re v. In bidi recti onal mo de, cen ter thr ottle i s zero an d above i s fwd rot ation

and be low is re verse r otati on. Whe n bidir ectio nal op erati on is sel ected , progra mmin g by TX is di sable d.

5. Bee p stren gth:

Sets t he stre ngth of b eeps un der nor mal ope ratio n.

6. Bea con str ength :

Sets t he stre ngth of b eeps wh en beep ing bea con bee ps. The E SC wi ll star t beepi ng beac on beep s if the th rottl e signa l has bee n zero fo r a given

time . Note th at sett ing a hig h beaco n stren gth can c ause ho t motor s or ES Cs!

Pro gramm ing par amete rs belo w can be ac cesse d from th e config urati on soft ware (B LHe liSui te):

7. Bea con de lay:

Beac on dela y sets th e delay b efore b eacon b eepi ng star ts.

: If dis abled , throt tle cal ibrat ion is di sable d. 8. Pro gramm ing by T X

Plea se noti ce that t hrott le stic k can cal ibrat e throt tle ran ge only, a nd can no t progr ammin g param enter v ia thro ttle st ick .

9. Min t hrott le, max t hrott le and ce nter th rottl e:

Thes e setti ngs set t he thro ttle ra nge of th e ESC . Cente r throt tle is on ly used f or bidi recti onal op erati on. The v alues g iven fo r these s ettin gs are fo r

a norm al 1000 us to 200 0us in put sig nal, an d for the ot her inp ut sign als, th e value s must be s caled .

10. Therma l prote ction :

Ther mal pro tecti on can be e nable d or disa bled. An d the tem perat ure thr eshol d can be pr ogram med bet ween 80°C a nd 140°C(fr om rev1 6.3).

The E SC mea sures t emper ature w ithin t he MC U and lim its mot or powe r if the te mpera ture is t oo high . Motor p ower is l imite d in four s teps:

- If the t emper ature i s above t hresh old , mot or powe r is limi ted to 75 %.

- If the t emper ature i s above t hresh old 5°C, mo tor pow er is lim ited to 5 0%.

- If the t emper ature i s above t hresh old 10°C, m otor po wer is li mited t o 25%.

- If the t emper ature i s above t hresh old 15°C, m otor po wer is li mited t o 0%.

11.Lo w RPM p ower pr otect :

Powe r limit ing for l ow RP Ms can be e nable d or disa bled. D isabl ing it ca n be nece ssary i n order t o achie ve full p ower on s ome low k V motor s

runn ing on a l ow supp ly volt age. Ho wever, d isabl ing it in creas es the ri sk of syn c loss, w ith the p ossib ility o f toasti ng moto r or ES C.

12. Brake o n stop:

Brak e on stop c an be ena bled o r disab led. Wh en enab led, br ake wil l be appl ied whe n throt tle is ze ro. For n onzer o throt tle, th is setti ng has no e ffect.

1. Po wer up:

2.T hrott le sign al dete cted

(arm ing se quenc e start ):

OK

Once

Once

3.Z ero thr ottle d etect ed

(arm ing se quenc e end):

Once

4.A fter th is, the

moto r will ru n.

ATTENTION

1.P ower up :

2.T hrott le sign al dete cted

(arm ing se quenc e start ):

Once

3.Wh en thro ttle is a bove mi dstic k

(me asuri ng max th rottle ):

4.If th rottle is abo ve midstic k for 3 seconds :

Thi s beep se quenc e indic ates th at max

thro ttle ha s been st ored

Once

While

measuring

5.W hen thr ottle i s below m idsti ck

(me asuri ng min th rottle ):

While

measuring

6.If th rottle is be low midsti ck for 3 secon ds:

Thi s beep se quenc e indic ates th at min

thro ttle ha s been st ored.

Once

Com plete

7.T hrott le cali brati on is com plete .

Afte r this, t he moto r will ru n.

Once

Exam ple:

Hig hest to ne

Low est ton e

Sho rt beep

Lon g beep

1.T hrott le cali brati on will b e more si mple if

usin g Fligh t Contr oller C onfig urator.

2.W hen the i nput si gnal is D shot, t hrott le

cali brati on is dis abled , and the t hrott le

cali brati on valu es are ig nored .

● Afte r the ES C conn ected t o the flig ht syst em, it wi ll auto matic ally de tect th e input t hrott le sign als eve ry time i t power ed on, an d then ex ecute t he

corr espon ding si gnal -rece iving m ode.

● Use r need to c alibr ate the t hrottl e rang e when st artin g to use a ne w ESC or a nothe r trans mitte r. When th e input s ignal i s Dshot , throt tle cal ibrat ion

is dis able d

● Whe n some ab norma lity oc curs in E SC dri ving th e motor o r need th e motor t o reach a h igher RPM, u ser can t ry to cha nge the t iming .

● Ple ase con tact Fly color s ales or t echni cal sup port fo r more in forma tion.

User Manual

Multi-Rotor Brushless ESC

251 400-1 073, V 1. 0

Loading...

Loading...