Page 1

VT305

Gas Flow Analyzer

Users Manual

FBC-0034

January 2013, Rev. 1

© 2013 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

Page 2

Warranty and Product Support

Fluke Biomedical warrants this instrument against defects in materials and workmanship for one full year from the date of original purchase.

During the warranty period, we will repair or, at our option, replace at no charge a product that proves to be defective, provided you return

the product, shipping prepaid, to Fluke Biomedical. This warranty does not apply if the product has been damaged by accident or misuse or

as the result of service or modification by other than Fluke Biomedical. IN NO EVENT SHALL FLUKE BIOMEDICAL BE LIABLE FOR

CONSEQUENTIAL DAMAGES.

Only serialized products and their accessory items (those products and items bearing a distinct serial number tag) are covered under this

one-year warranty. PHYSICAL DAMAGE CAUSED BY MISUSE OR PHYSICAL ABUSE IS NOT COVERED UNDER THE WARRANTY.

Items such as cables and nonserialized modules are not covered under this warranty.

Recalibration of instruments is not covered under the warranty.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state, province to province, or

country to country. This warranty is limited to repairing the instrument to Fluke Biomedical’s specifications.

Page 3

Notices

All Rights Reserved

Copyright 2013, Fluke Biomedical. No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any

language without the written permission of Fluke Biomedical.

Copyright Release

Fluke Biomedical agrees to a limited copyright release that allows you to reproduce manuals and other printed materials for use in service training programs and

other technical publications. If you would like other reproductions or distributions, submit a written request to Fluke Biomedical.

Unpacking and Inspection

Follow standard receiving practices upon receipt of the instrument. Check the shipping carton for damage. If damage is found, stop unpacking the instrument.

Notify the carrier and ask for an agent to be present while the instrument is unpacked. There are no special unpacking instructions, but be careful not to damage

the instrument when unpacking it. Inspect the instrument for physical damage such as bent or broken parts, dents, or scratches.

Technical Support

For application support or answers to technical questions, either email techservices@flukebiomedical.com or call 1-800- 850-4608 or 1-440-248-9300. In Europe,

email techsupport.emea@flukebiomedical.com or call +31-40-2965314.

Claims

Our routine method of shipment is via common carrier, FOB origin. Upon delivery, if physical damage is found, retain all packing materials in their original

condition and contact the carrier immediately to file a claim. If the instrument is delivered in good physical condition but does not operate within specifications, or

if there are any other problems not caused by shipping damage, please contact Fluke Biomedical or your local sales representative.

Returns and Repairs

Return Procedure

All items being returned (including all warranty-claim shipments) must be sent freight-prepaid to our factory location. When you return an instrument to Fluke

Biomedical, we recommend using United Parcel Service, Federal Express, or Air Parcel Post. We also recommend that you insure your shipment for its actual

replacement cost. Fluke Biomedical will not be responsible for lost shipments or instruments that are received in damaged condition due to improper packaging

or handling.

Use the original carton and packaging material for shipment. If they are not available, we recommend the following guide for repackaging:

Use a double–walled carton of sufficient strength for the weight being shipped.

Use heavy paper or cardboard to protect all instrument surfaces. Use nonabrasive material around all projecting parts.

Use at least four inches of tightly packed, industry-approved, shock-absorbent material around the instrument.

Page 4

Returns for partial refund/credit:

Every product returned for refund/credit must be accompanied by a Return Material Authorization (RMA) number, obtained from our Order Entry Group at 1440-498-2560.

Repair and calibration:

To find the nearest service center, go to www.flukebiomedical.com/service or

In the U.S.A.:

Cleveland Calibration Lab

Tel: 1-800-850-4608 x2564

Email: globalcal@flukebiomedical.com

Everett Calibration Lab

Tel: 1-888-99 FLUKE (1-888-993-5853)

Email: service.status@fluke.com

In Europe, Middle East, and Africa:

Eindhoven Calibration Lab

Tel: +31-40-2675300

Email: ServiceDesk@fluke.com

In Asia:

Everett Calibration Lab

Tel: +425-446-6945

Email: service.international@fluke.com

To ensure the accuracy of the Product is maintained at a high level, Fluke Biomedical recommends the product be calibrated at least once every

12 months. Calibration must be done by qualified personnel. Contact your local Fluke Biomedical representative for calibration.

Certification

This instrument was thoroughly tested and inspected. It was found to meet Fluke Biomedical’s manufacturing specifications when it was shipped from the

factory. Calibration measurements are traceable to the National Institute of Standards and Technology (NIST). Devices for which there are no NIST calibration

standards are measured against in-house performance standards using accepted test procedures.

WARNING

Unauthorized user modifications or application beyond the published specifications may result in electrical shock hazards or improper operation. Fluke

Biomedical will not be responsible for any injuries sustained due to unauthorized equipment modifications.

Restrictions and Liabilities

Page 5

Information in this document is subject to change and does not represent a commitment by Fluke Biomedical. Changes made to the information in

this document will be incorporated in new editions of the publication. No responsibility is assumed by Fluke Biomedical for the use or reliability of

software or equipment that is not supplied by Fluke Biomedical, or by its affiliated dealers.

Manufacturing Location

The VT305 Gas Flow Analyzer is manufactured in Switzerland for Fluke Biomedical, 6920 Seaway Blvd., Everett, WA, U.S.A.

Page 6

Page 7

Table of Contents

Title Page

Introduction .................................................................................................................... 1

Safety Information .......................................................................................................... 1

Responsibility and Warranty .......................................................................................... 3

Intended Use ................................................................................................................. 3

Software and Firmware versions ................................................................................... 4

System Requirements ................................................................................................... 4

Female Users ................................................................................................................ 4

Start Up ......................................................................................................................... 4

Power Supply ............................................................................................................ 5

Filter .......................................................................................................................... 5

Flow Channel ............................................................................................................ 6

Differential Pressure ................................................................................................. 6

High Pressure ........................................................................................................... 7

O2 Measurement Cell ................................................................................................ 7

Controls .................................................................................................................... 7

Electrical Interfaces ....................................................................................................... 9

Operation ....................................................................................................................... 10

How to Turn On and Turn Off the Product ................................................................ 10

The Start Screen ....................................................................................................... 10

Settings ..................................................................................................................... 11

i

Page 8

VT305

Users Manual

Numerical Values ...................................................................................................... 13

Graphical Values ....................................................................................................... 13

Filter .......................................................................................................................... 13

How to Save Data ..................................................................................................... 14

Zero-Point Calibration ............................................................................................... 14

Connect the Product ...................................................................................................... 15

Setup for Ventilator Measurements ........................................................................... 16

Setup for Precise Flow Measurements ..................................................................... 17

Setup for Dusty or Contaminated Gases ................................................................... 18

Setup for High Pressure Gases ................................................................................ 19

Measurement Data ........................................................................................................ 20

Store Measurement Data on the Micro-SD Card ...................................................... 20

How to Connect to the Computer .............................................................................. 20

How to Read the Data on the Computer ................................................................... 21

To Make an Excel File with Saved Values ................................................................ 22

Product Configuration .................................................................................................... 24

Values Configuration ................................................................................................. 26

Curves Configuration ................................................................................................ 27

Interface Configuration .............................................................................................. 28

Trigger Configuration ................................................................................................ 29

Miscellaneous Configuration ..................................................................................... 30

How to Setup an Ethernet Connection ...................................................................... 31

Default Ethernet Setup ......................................................................................... 31

Configured and DCHP Ethernet Setup ................................................................. 34

O2 Sensor ...................................................................................................................... 34

Activation .................................................................................................................. 34

Installation ................................................................................................................. 34

Oxygen Sensor Calibration – Air Only ....................................................................... 34

Oxygen Sensor Calibration – O2 and Air ................................................................... 35

Measure Respiratory Data ............................................................................................. 37

General ..................................................................................................................... 37

Connection to the Respiratory Apparatus ................................................................. 39

Standard Trigger Values ........................................................................................... 39

Baseflow ................................................................................................................... 39

ii

Page 9

Contents (continued)

Find the Correct Trigger Setting ................................................................................ 40

Flow Curve Downstream of the Y-Piece .............................................................. 40

Flow Curve Upstream of the Y-Piece ................................................................... 40

Pressure Curve Upstream of the Y-Piece ............................................................ 41

Special Cases ........................................................................................................... 41

Inspiration Volume Vti ............................................................................................... 41

Expiration Volume Vte .............................................................................................. 43

Care and Maintenance .................................................................................................. 44

Guidelines for Care and Maintenance ....................................................................... 44

Preventive Cleaning and Maintenance ..................................................................... 44

Accessories and Spare Parts ........................................................................................ 45

Ordering Address ...................................................................................................... 45

Disposal ......................................................................................................................... 46

Specifications ................................................................................................................ 47

Operation Principle of Flow Measurement ..................................................................... 51

Dynamic viscosity ..................................................................................................... 51

Density ...................................................................................................................... 51

Gas Standard ................................................................................................................ 52

Abbreviations and Glossary ........................................................................................... 52

Measured Values and Units ........................................................................................... 56

Conversion Factors ........................................................................................................ 58

iii

Page 10

VT305

Users Manual

iv

Page 11

List of Tables

Table Title Page

1. Symbols ................................................................................................................................ 3

2. Product Parts ........................................................................................................................ 4

3. Front-Panel Controls ............................................................................................................. 8

4. Electrical Interfaces .............................................................................................................. 10

5. Settings Screens ................................................................................................................... 11

6. Maintenance Tasks ............................................................................................................... 45

7. Standard Accessories ........................................................................................................... 46

8. Optional Accessories ............................................................................................................ 46

9. Measured Values and Units .................................................................................................. 56

10. Conversion Factors ............................................................................................................... 58

v

Page 12

VT305

Users Manual

vi

Page 13

List of Figures

Figure Title Page

1. Ports for Power Connection .................................................................................................. 5

2. Flow Channel ........................................................................................................................ 6

3. Differential Pressure Ports .................................................................................................... 6

4. High Pressure Ports .............................................................................................................. 7

5. O2 Cell .................................................................................................................................. 7

6. Electrical Interfaces .............................................................................................................. 9

7. Start-Up Screen .................................................................................................................... 10

8. Numerical Values Screens .................................................................................................... 13

9. Measured Curves Screens ................................................................................................... 13

10. Saving Data Screen .............................................................................................................. 14

11. Zero Calibration Screen ........................................................................................................ 14

12. Product to Breathing Apparatus Connections ....................................................................... 15

13. Ventilator Connections .......................................................................................................... 16

14. Precise Flow Measurement Connections .............................................................................. 17

15. Filter Use .............................................................................................................................. 18

16. High Pressure Connections .................................................................................................. 19

17. Mass Storage Message ........................................................................................................ 20

18. Micro-SD Card ...................................................................................................................... 20

19. Micro SD Card Files .............................................................................................................. 21

20. Report Data Files .................................................................................................................. 22

vii

Page 14

VT305

Users Manual

21. Formatted Excel File of Measurement Data .......................................................................... 23

22. Configuration Utility Web Page ............................................................................................. 25

23. Trigger Values Web Page ..................................................................................................... 26

24. Graphical Screen Configuration Web Page .......................................................................... 27

25. Create Configuration File Web Page .................................................................................... 29

26. Configure Triggers Screen .................................................................................................... 29

27. Miscellaneous Configuration Window ................................................................................... 30

28. Ethernet Connection Screen ................................................................................................. 31

29. Computer Ethernet Setup Windows ...................................................................................... 32

30. Ethernet IP Address Properties Form ................................................................................... 33

31. O2 Calibration - Apply Air ...................................................................................................... 34

32. O2 Calibration Successful Screen ......................................................................................... 35

33. O2 Calibration - Apply Oxygen .............................................................................................. 35

34. O2 Calibration - Apply Air ...................................................................................................... 35

35. O2 Calibration Successful Screen ......................................................................................... 36

36. Protective Cap Removal ....................................................................................................... 36

37. O2 Sensor Installation ........................................................................................................... 37

38. Breath Cycle ......................................................................................................................... 38

39. Downstream Flow Curve ....................................................................................................... 40

40. Inspiration Duct Upstream Curve .......................................................................................... 40

41. Upstream Pressure Curve..................................................................................................... 41

42. Inspiration Volume ................................................................................................................ 42

43. Expiration Volume ................................................................................................................. 43

44. Linear Flow Element ............................................................................................................. 51

viii

Page 15

Introduction

Warning

To prevent the possibility of personal injury,

read all safety information before you use the

Product.

This manual is applicable for the VT305 (the Product). It is

a compact, portable and easy-to-use measurement

instrument. The Product measures or calculates:

• Flow

• Volume

• Pressure differences

• High pressure

• Barometric pressure

• Oxygen

• Temperature of gas in the measurement chamber

• Breathing rate

• Inspiratory and expiratory time

• Ratios

• Ti/Tcyc

• Breathing volume

• Volumes per minute

• Peak flow

• Pressure

• Static Compliance (Cstat)

• Triggers (used to separate inspiration time from

expiratory time within each breath).

The Product measures and calibrates parameters on

breathing apparatuses.

Safety Information

A Warning identifies conditions and procedures that are

dangerous to the user. A Caution identifies conditions and

procedures that can cause damage to the Product or the

equipment under test.

1

Page 16

VT305

Users Manual

Warning

To prevent possible electrical shock, fire, or

personal injury:

• Read all safety Information before you use

the Product.

• Use the Product only as specified, or the

protection supplied by the Product can be

compromised.

• Do not connect the Product to a patient or

equipment connected to a patient. The

Product is intended for equipment analysis

only.

• Do not use the Product for diagnosis,

treatment, or other capacity where the

Product touches a patient.

• Remove the batteries if the Product is not

used for an extended period of time, or if

stored in temperatures above 50 °C. If the

batteries are not removed, battery leakage

can damage the Product.

• Recharge the batteries when the low

battery indicator shows to prevent

incorrect measurements.

• Do not use and disable the Product if it is

damaged.

• Do not use the Product if it operates

incorrectly.

• Examine the case before you use the

Product. Look for cracks or missing

plastic. Carefully look at the insulation

around the terminals.

• Use this Product indoors only.

• Carefully read all instructions.

• Do not touch voltages > 30 V ac rms, 42 V

ac peak, or 60 V dc.

2

Page 17

Gas Flow Analyzer

Responsibility and Warranty

Table 1 is a list of symbols used in this manual and on the

Product.

Table 1. Symbols

Symbol Definition

Risk of Danger. Important information. See

Manual.

Hazardous voltage

Conforms to relevant North American Safety

Standards.

Conforms to European Union directives

This product complies with the WEEE Directive

(2002/96/EC) marking requirements. The

affixed label indicates that you must not

discard this electrical/electronic product in

domestic household waste. Product Category:

With reference to the equipment types in the

WEEE Directive Annex I, this product is

classed as category 9 "Monitoring and Control

Instrumentation" product. Do not dispose of

this product as unsorted municipal waste. Go

to Fluke’s website for recycling information.

Responsibility and Warranty

The manufacturer assumes no responsibility or warranty,

nor accept liability if the user or third parties:

• Do not use the Product as intended.

• Violates the technical specifications.

• Changes the Product (through unauthorized

modifications, changes, etc.)

• Uses the Product with accessories other than those

shown in the related Product documentation.

Intended Use

This Product is intended to do tests on medical devices or

systems that deliver gas flow and pressure. This includes

ventilators and anesthesia systems.

The intended user is a trained biomedical equipment

technician who does preventative maintenance on medical

equipment. Users are associated with hospitals, clinics,

original equipment manufacturers, and independent

service companies. The end user is an individual, trained

in medical instrumentation technology.

This Product is intended to be used in a laboratory

environment, outside of patient care areas. It is not

intended for use on patients or on equipment connected to

patients. It is intended for over-the-counter use. This

Product is not intended to be used to calibrate medical

equipment.

3

Page 18

VT305

Users Manual

Software and Firmware versions

This manual is applicable for the Product with software

version 3.1 or higher and hardware version 1.0 or higher.

A product with different versions can operate differently

from this manual.

System Requirements

Your computer must have the minimum requirements

below:

• Microsoft Windows x86 or x64 (64-bit mode support for

IE only)

• 1.6 GHz or higher

• 512 Mb RAM

• Microsoft Windows, Vista, 7, 7 SP1, Windows Server

2008 SP2, Windows Server 2008 R2 SP1, Windows

Server 2003, XP SP2 and SP3

Female Users

This manual uses the male pronoun “he” for simplicity and

better understanding. This notwithstanding expressly

includes female users as well.

Start Up

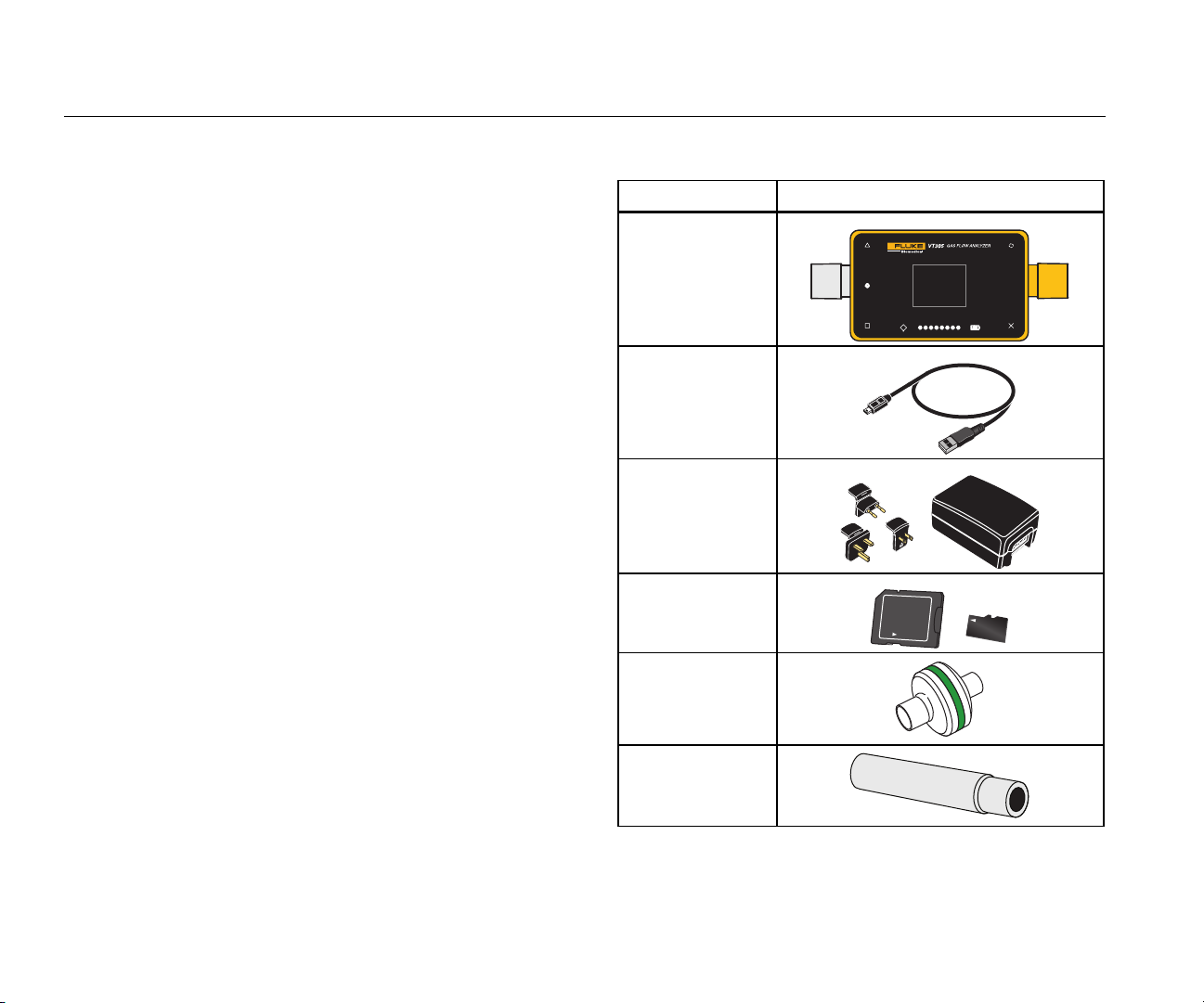

Table 2 is a list of parts included with the Product.

Table 2. Product Parts

Name Item

VT305

USB Cable

Power Supply

(power adapter)

Micro-SD 2GB

multi kit

Bacteria/Dust

Filter

Lock

4

Intlet Pipe

Page 19

Gas Flow Analyzer

Start Up

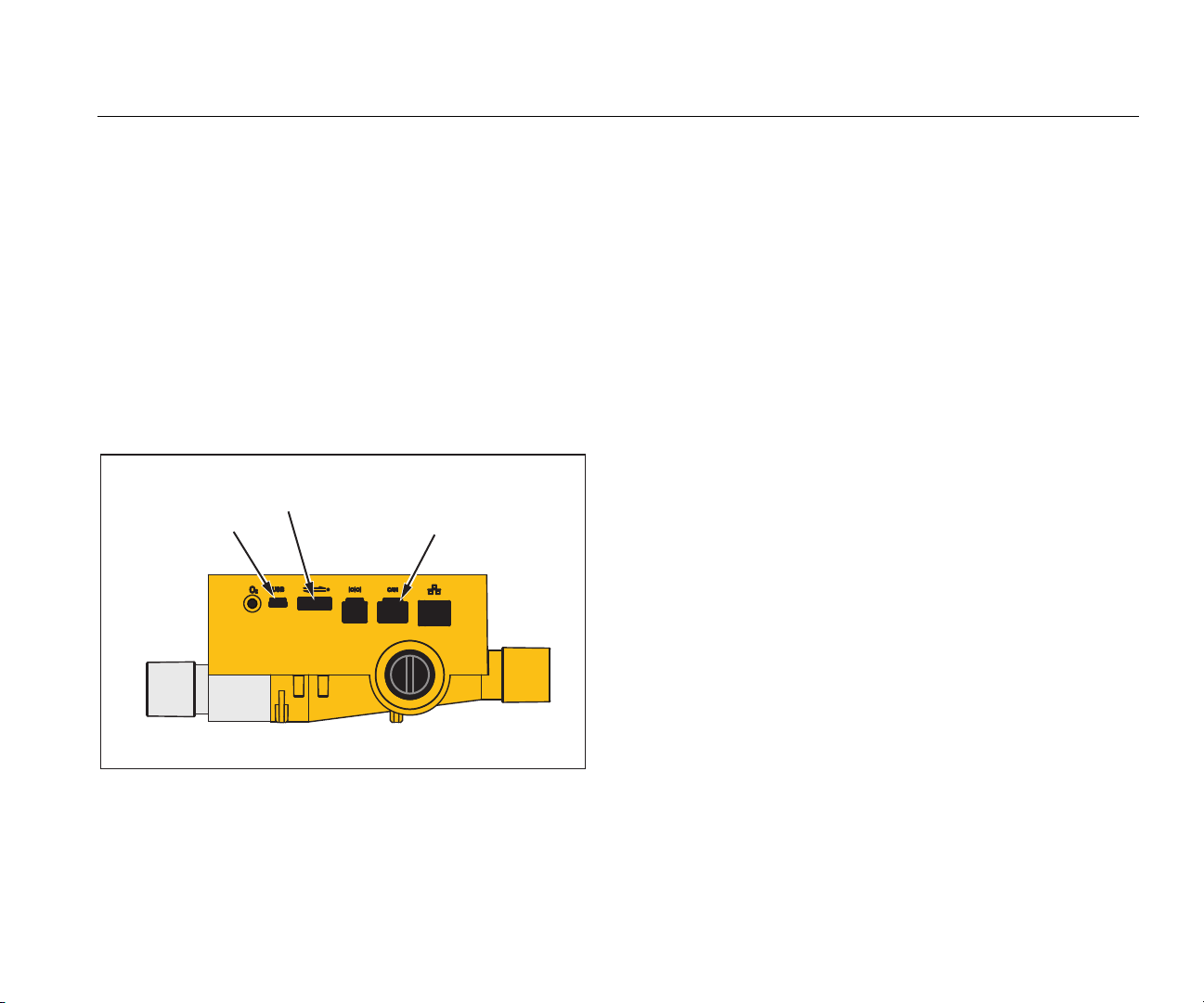

Power Supply

The Product can be operated from the power supply or the

built-in rechargeable battery.

Use the USB cable to connect the Product to a computer

or the included power supply. The USB port is shown in

Figure 1. You can power the Product through the analog,

USB, and CAN interfaces when you use the appropriate

optional adapters.

A battery symbol shows in the display when the battery

charges. The charge level of the battery is shown in the

battery display screen. A red LED shows in the left side of

the display when the battery is low.

Analog

Interface

USB Port

CAN interface

Connect the power adapter into a mains socket with a

voltage of 100 V ac to 240 V ac at 50 Hz or 60 Hz.

Caution

To prevent damage to the Product, make sure

the mains voltage is in the range specified on

the power adapter nameplate. Use the Product

only with the power adapter supplied with the

Product.

Filter

To prevent damage to the Product from dirt and particles

in the air, use the supplied filters for all flow

measurements. Use the filter to ensure laminar flow.

Laminar flow is necessary to make accurate flow

measurements.

Note

Particles in the air can clog the measurement

system, and cause an error message. Examine

the filter regularly.

Figure 1. Ports for Power Connection

gyo006.eps

5

Page 20

VT305

Users Manual

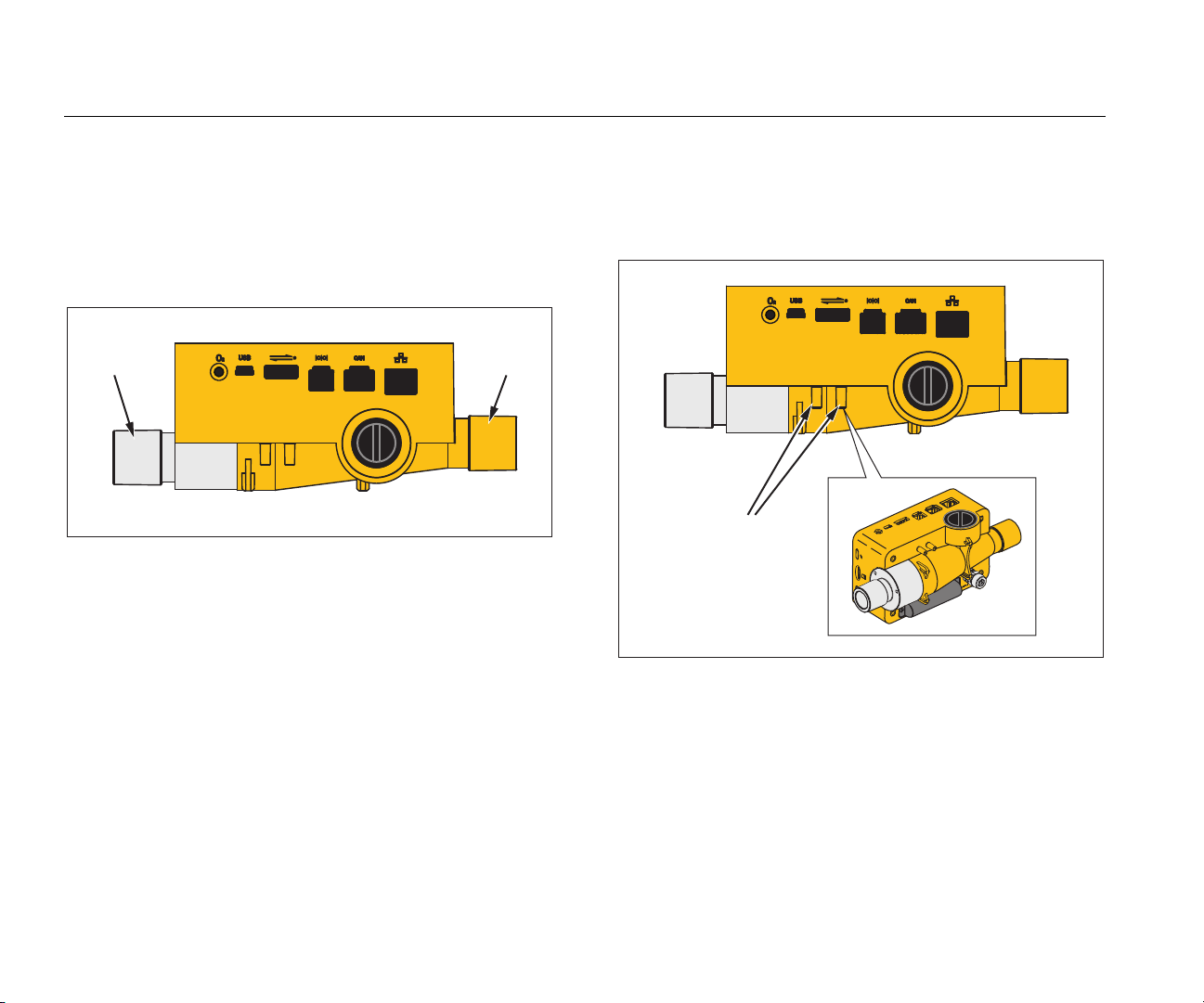

Flow Channel

The flow port can be used bidirectionally to measure flow,

volume, chamber gas temperature, oxygen, and pressure

in the flow channel. See the specifications for these

measurement ranges and accuracies. Figure 2 shows the

flow channel on the Product.

Flow

Channel

Figure 2. Flow Channel

Flow

Channel

gyo007.eps

Differential Pressure

The differential pressure connections are used to measure

differential pressure. Figure 3 shows the differential

pressure connections.

Differential

Pressure

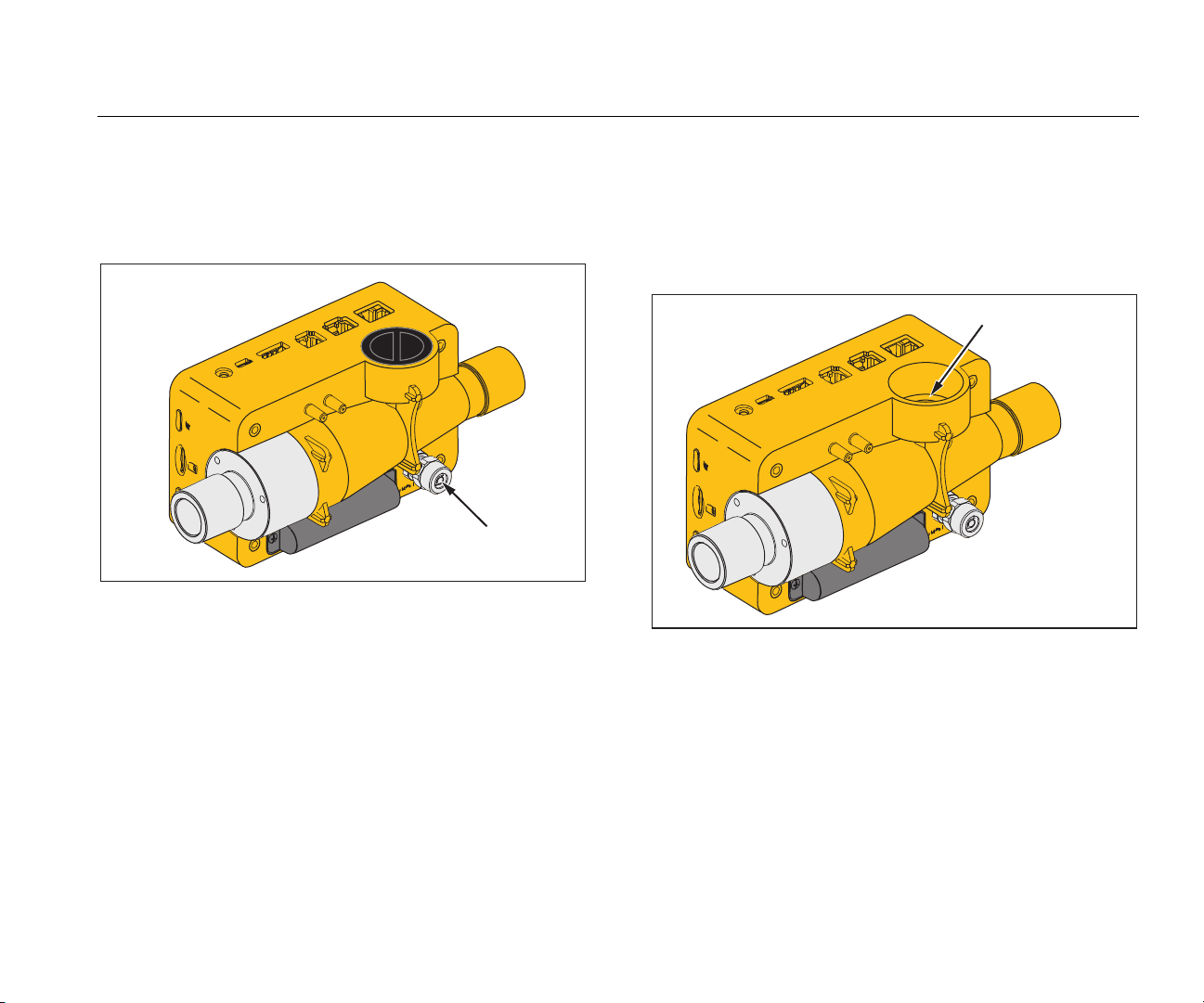

Figure 3. Differential Pressure Ports

gyo008.eps

6

Page 21

Gas Flow Analyzer

Start Up

High Pressure

The high pressure port is used to measure pressure more

than 200 mbars. Figure 4 shows the high pressure port on

the Product.

High

Pressure

gyo009.eps

Figure 4. High Pressure Port

Note

For measurements to a maximum of 200 mbar,

Fluke Biomedical recommends you use the

differential pressure port. Accuracy is 100 times

higher.

O2 Measurement Cell

The Product has an interface for an O2 measurement cell.

See Figure 5. For more information, see the O

Sensor

2

section in this manual.

O2 – Measuring Cell

gyo010.eps

Figure 5. O2 Cell

Controls

Table 3 is a list of the front-panel controls.

Caution

To prevent damage to the high-pressure

sensor, do not measure pressure more than

15 bar.

7

Page 22

VT305

Users Manual

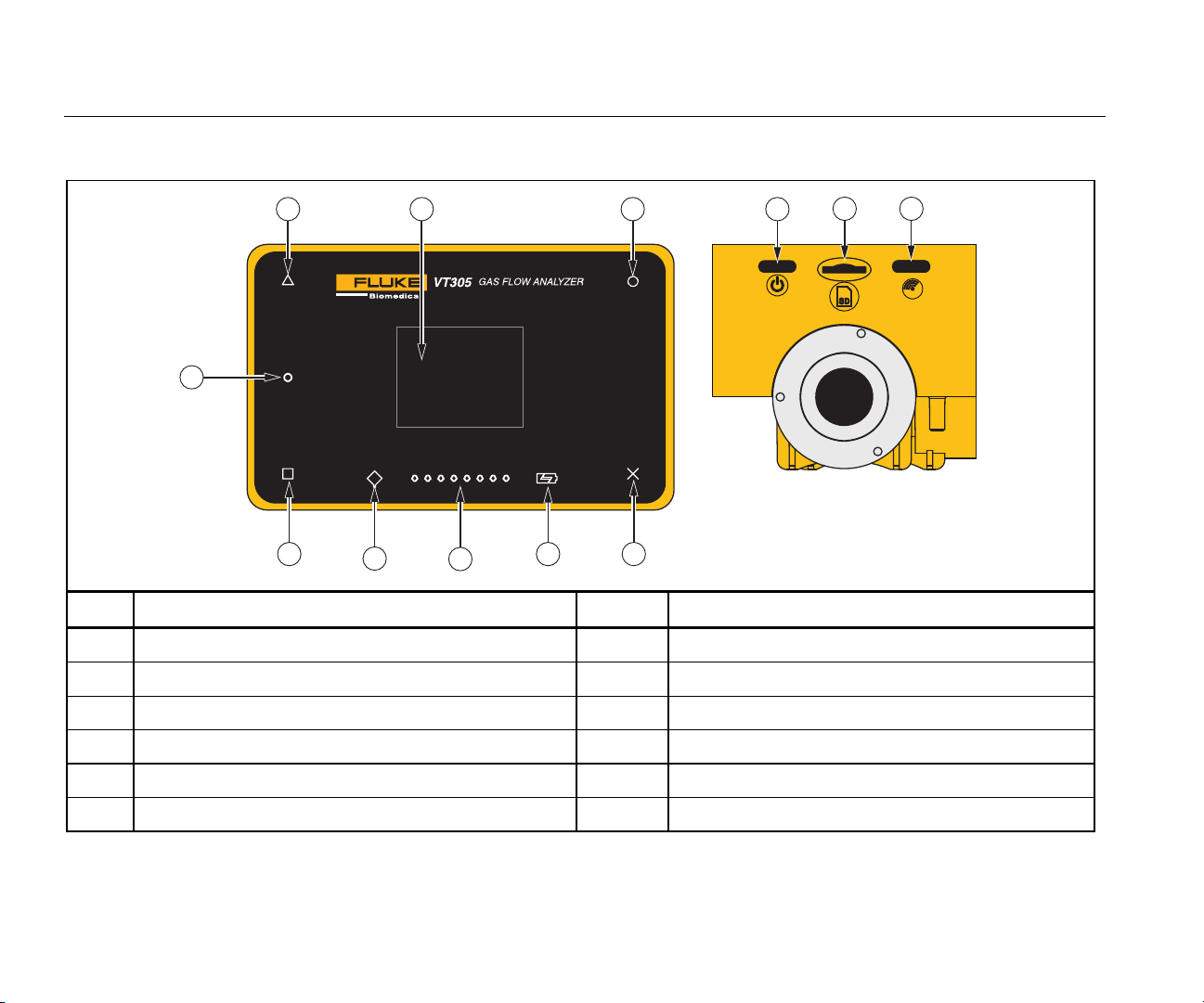

Table 3. Front-Panel Controls

1 311

12

2

10

9

8

4

5

6

7

gyo012.epx

Item Description Item Description

1 Display/Change measurement curves 7 Future use

2 Show/Change numerical measurement values 8 Battery on charge

3 Change settings/save data 9 Flow direction LEDs

4 Show menu/change menu/zero calibration 10 Function error LED

5 On/Off 11 Screen

6 Micro SD card slot 12 Low battery warning

8

Page 23

Gas Flow Analyzer

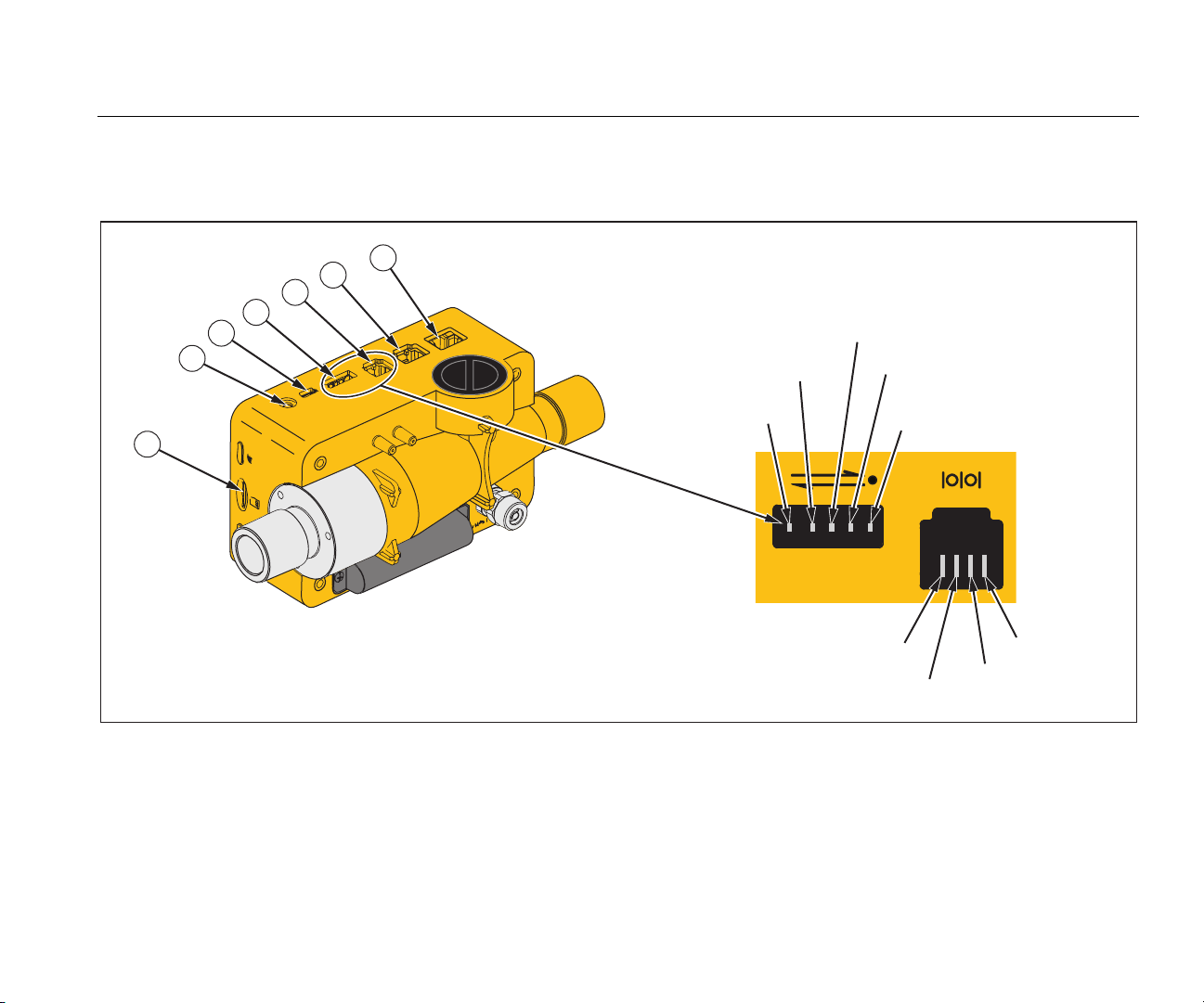

Electrical Interfaces

Electrical Interfaces

The Product has six electrical interfaces. Table 4 is a list of the electrical interfaces and references Figure 6.

7

6

5

4

3

2

V

IN

Trigger Input

Analog OUT 2

GND

1

TxD (output)

Analog OUT 1

GND

RxD (Input)

N.C.

gyo011.eps

Figure 6. Electrical Interfaces

9

Page 24

VT305

Users Manual

Table 4. Electrical Interfaces

Item Description

1

2 The O2 interface is used to connect the O2 sensor to the Product.

3

4

5 The RS-232 interface is used as a data interface. See the Specifications section for more data.

6 The CAN interface – future use.

7 The Ethernet interface is used to configure the Product and save the file to the SD card.

The Micro-SD card is used for software updates and Product configurations. Measurement data can be output

through the micro SD card. See the Measurement Data section.

The USB port is a data interface. It can also be used to operate with the mains power supply and to charge the

battery.

The Analog OUT port is used to output analog signals, connect to an external trigger, operate with the optional

mains power supply, and charge the battery of the Product. See the Specifications section for more data.

Operation

The sections that follow tell how to use the Product.

How to Turn On and Turn Off the Product

The Product is turned on and turned off when you push the

power button ().

The Start Screen

When the Product is turned on, the start-up screen in

Figure 7 shows in the display. After approximately

3 seconds the numerical measurement values show in the

display.

Settings

Push X on the front panel to show the information screen.

This shows the device data. Push X again to show more

menu items to make adjustments. Push O to change

Figure 7. Start-Up Screen

gyo076.eps

10

Page 25

Gas Flow Analyzer

Operation

individual settings. Table 5 is a list of screens that show in

the display.

Table 5. Settings Screens

Screen Description

Information

VT305

Owner:

Company:

Next Calib:

Last Calib:

Software:

Hardware:

Shows device data. You can

set Owner and Company data

fields with the browser-based

configurator. See the Product

Configuration section.

Battery

Shows the current charge of

the battery.

Table 5. Settings Screens (cont.)

Screen Description

Ethernet

Ethernet

Default

IP: 192.168.1.1

Subnet: 255.255.255..0

The Ethernet screen is used to

set the Ethernet communication

parameters.

Set Trigger

Trigger

Adult

Start: 60ms

Flow: >3.0 l/min

End: 60ms

Flow: >3.0 l/min

The Trigger events screen is

used to set when the Product

calculates volume, and

respiratory parameters. The

factory defaults show adult,

pediatric, and high frequency

trigger configuration. See the

Measure Key Respiratory Data

section.

Set Gas Standard

Standard

ATP

Amb. Temperature/Pressure

The Product calculates the

measured flow and volume

values for the set standard. See

the Gas Standard after the

Specifications section.

11

Page 26

VT305

Users Manual

Table 5. Settings Screens (cont.)

Screen Description

Set Gas Types

Gas Type

Air

Sets the gas type for the gas

to be measured. See the

Measurement Variables

section.

Set the X-Axis

X-Axis

0…2 sec

Sets the time base line for the

graphic/waveform displays (2,

4, 6, 8, and 10 seconds).

Humidity

Humidity

50.0%

Sets the percent (%) of relative

humidity in the gas flow (0 %

to 100 % in 10 % steps).

Table 5. Settings Screens (cont.)

Screen Description

O2 Calibration

O2 Calibr.

Used to calibrate the O

See the O

Sensor section.

2

cell.

2

12

Page 27

Gas Flow Analyzer

Operation

Numerical Values

Push on the display to show the numerical values screen

in the display. See Figure 8. You can change one, two,

four, or six numerical values on each screen. You

configure individual values and units through the web

browser-based configurator. See the Product

Configuration section.

ATP Air

ATP Air

0.0

Flow

l/min

Figure 8. Numerical Values Screens

The Product measures the temperature of the gas in the

measurement chamber inside the Product. This

temperature is not the same as the gas temperature that

enters the Product. The heat of the gas changes due to

the heat inside the Product.

The Product calculates static compliance (Cstat) with this

formula:

Cstat =

ATP Air

0.0

Flow

l/min

ATP Air

0.0

0.0

Flow

Flow

l/min

l/min

plateau – PEEP

P

gyo020.eps

V

t

When no plateau pressure is available, the formula has a

divisor of zero. The Product will show “---“ in the display

when this happens.

Graphical Values

Push Δ on the display to show the measured curves in the

display. See Figure 9. You can change one or two

measured curves each screen. You configure individual

values and units through the online application. See the

Product Configuration section.

Flow l/min

Flow l/min

Flow l/min

Flow l/min

gyo021.eps

Figure 9. Measured Curves Screens

Filter

The display update period is 500 ms or two times each

second. The acquisition time of new measurements is

5 ms to 8 ms. Without the filter, the latest measured value

is shown in the display when the screen updates. Because

each measurement has some noise, use the filter to

average the values equally for a specified period of time.

13

Page 28

VT305

Users Manual

The available filter selections are as follows:

• None (Display of the latest measured value without

thresholds)

• Low (Mean value over 240 ms)

• Medium (Mean value over 480 ms)

• High (Mean value over 960 ms)

The factory default for the filter is high.

You can change the filter selection in the browser-based

Product configuration tool. To learn more, see the Product

Configuration section.

How to Save Data

Push and hold O for 5 seconds to store data on the microSD card. The screen in Figure 10 shows in the display

while the Product saves the data. See the How to Read

Out Measurement Data section.

Data saved to

DATAxx.CSV

gyo022.eps

Figure 10. Saving Data Screen

Zero-Point Calibration

Push and hold X for 5 seconds to start the zero calibration

of the pressure and flow sensors. While the Product does

the calibration procedure, the screen in Figure 11 shows in

the display.

Zero- Calibration

Running

gyo023.eps

Figure 11. Zero Calibration Screen

It is important to do a zero calibration periodically to

remove off-sets in the flow measurement.

Caution

To make accurate measurements, do not apply

pressure to the Product when you do a zero

calibration. This caution is not shown in the

display when you use the X symbol.

It is very important to do the zero calibration while the

airway pressure transducer stabilizes and before a

measurement is made.

14

Page 29

Gas Flow Analyzer

Connect the Product

Connect the Product

Refer to Figure 12 when you do the subsequent steps.

1. Always use the dust filter.

2. Connect the tube system.

Note

Avoid tight bends, kinks, or dents in the tubing.

Good Setup

Flow

Direction

3. Connect the test lung.

4. Connect the breathing apparatus.

For more information on how to connect the breathing

apparatus, see the How to Measure Respiratory Data

section.

Figure 12. Product to Breathing Apparatus Connections

gyo053.eps

15

Page 30

VT305

Users Manual

Setup for Ventilator Measurements

To test and calibrate ventilators, use the inlet pipe between

the breathing circuit and the Product, as shown in

Figure 13. Use the filter to improve laminarity of the flow.

This improves measurement accuracy.

Breathing circuit Inlet Pipe Fluke VT305 Testlung

Positive flow direction

Figure 13. Ventilator Connections

gyo052.eps

16

Page 31

Gas Flow Analyzer

Connect the Product

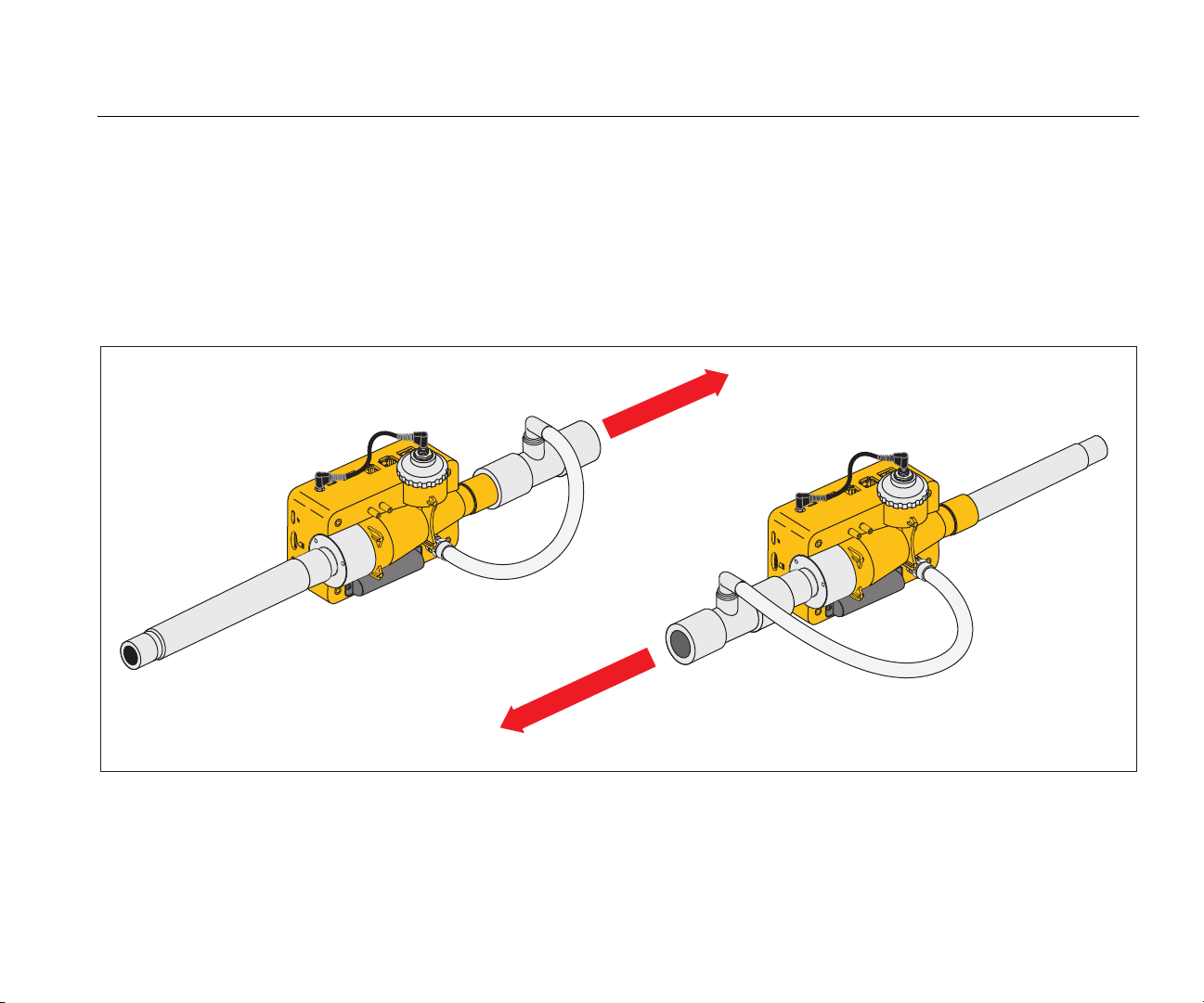

Setup for Precise Flow Measurements

Note

The measured gas must be free of oil, grease, and

dust. For best measurement results, set the trigger

to “adult.”

Positive Flow Direction

For precise flow measurements, put the inlet pipe and filter

on the Product as shown in Figure 14.

Negative Flow Direction

Figure 14. Precise Flow Measurement Connections

gyo049.eps

17

Page 32

VT305

Users Manual

Setup for Dusty or Contaminated Gases

When you use the Product to measure gas that contains

dust or other contaminants, use the filter as shown in

Figure 15.

Flow

Direction

Figure 15. Filter Use

Note

The gas must not contain oil or grease.

Distance tube from

filter to inlet Pipe:

minimum 1 meter.

gyo050.eps

18

Page 33

Gas Flow Analyzer

Connect the Product

Setup for High Pressure Gases

The Product automatically compensates for the gas

pressure in the flow channel up to 150 mbar. Use the high

pressure port as shown in Figure 16 for pressures greater

than 150 mbar.

Caution

To prevent damage to the Product, do not

apply more than 800 mbars to the airway

channel port of the Product.

In the flow channel, the Product adjusts for pressures to a

maximum of 150 mbars. When the high pressure port is

used, the Product adjusts for pressures up to a maximum

of 300 mbars.

Flow Direction

Flow Direction

Figure 16. High Pressure Connections

gyo051.eps

19

Page 34

VT305

Users Manual

Measurement Data

Product measurements can be exported on the micro-SD

card, analog out interface, or the RS-232 interface.

Store Measurement Data on the Micro-SD Card

Push and hold O for 5 seconds. This stores the

measurement data on the Micro-SD card. A message that

shows the filename that contains the measured data

shows in the display. The filename format is DataXX.csv.

See Figure 10.

There are two ways to get to the data on the Micro-SD

card. Use the USB port of the Product or put the Micro-SD

card into a computer.

To access data through the USB port, connect the USB

port of the Product to a computer.

Note

To communicate with the Product from a

computer, you must install a device driver. The

driver file “usb_cdc_ser.inf” is stored on the

Micro-SD card. Call or email technical support for

help.

When the Product senses USB communications, the

message in Figure 17 shows in this display. If you do not

make a choice in 5 seconds, the Product will not become a

USB mass storage device

Use as USB

mass storage?

YES NO

gyo063.eps

Figure 17. Mass Storage Message

When you use the Product as a USB mass storage device,

you cannot use the configuration tool to configure the

Product.

How to Connect to the Computer

Push the Micro-SD card to release it from the Product. You

can connect the Micro-SD card to your computer through a

USB port or SD-card socket. See Figure 18.

Micro-SD Card Micro-SD Card

gyo025.eps

Figure 18. Micro-SD Card

20

Page 35

Gas Flow Analyzer

Measurement Data

How to Read the Data on the Computer

Figure 19 shows the files and directory structure on the Micro-SD card used by the Product.

Figure 19. Micro SD Card Files

gyo073.jpg

21

Page 36

VT305

Users Manual

To Make an Excel File with Saved Values

1. Open the SetupReportFormatter.bat file. This file

installs ReportFormatter.xlsb in the Report/XLSTART

folder. This causes the ReportFormatter file to open

when Microsoft Excel is started. A list of files in the

Excel file open dialog box. See Figure 20. Double click

on a .csv file in the DATA folder to open it.

When you open a .csv file, a dialog box shows in the

computer display where you can set whether the

report data is formatted or not.

22

Figure 20. Report Data Files

gyo072.jpg

Page 37

Gas Flow Analyzer

Measurement Data

2. Click Yes to make a formatted file. The Product test

report like that shown in Figure 21 is made.

3. You can change the Excel file as necessary.

Note

Files on the Micro-SD card cannot be renamed.

Figure 21. Formatted Excel File of Measurement Data

gyo028.jpg

23

Page 38

VT305

Users Manual

Product Configuration

You can configure the Product through the Ethernet

interface. When a configuration parameter is changed, the

change will be made in the Product and saved on the

micro SD card immediately.

Note

You must install Microsoft Silverlight 5 on Internet

Explorer 7+, Safari 4+, Chrome 12+, or

Firefox 3.6+ to configure the Product through the

internet.

1. Insert a micro SD card that contains the necessary

files into the Product. The SD card must contain the

ClientBin folder that includes ConfigurationWeb.asp

file, the clientaccesspolicy.xml file, and the index.html

file.

Note

The micro SD card must be installed in the

Product if you want to save the configuration. If

you cannot find the micro SD card, talk to your

Fluke Biomedical distributor or call Fluke

Biomedical technical support. See Technical

Support in the front of this manual.

2. Connect the Ethernet port of the Product to a network

or directly to a computer.

The Default selection is the recommended method

when you connect the Product directly to a computer.

The Configured and DHCP-Client selection should

be used when you connect to an existing network.

See the How to Setup an Ethernet Connection section

for instructions to set an IP Address and subnet mask.

The browser-based configuration page in Figure 22

shows in the computer display when an Ethernet

connection is made.

5. To personalize the Product, type a name in the owner

field and a name in the company name field of the web

page.

6. In the upper-left corner of the web page, there are

main menu and submenu hyperlinks that you use to

navigate in the configuration tool.

7. To change Product configuration parameter values,

click on the configuration hyperlink. The configuration

page in Figure 23 shows in the computer display.

The submenu selections are VALUES, CURVES,

TRIGGERS, INTERFACE, and MISC. You click on these

submenu hyperlinks to open the configuration page that

will show the parameters for the selected parameter group.

3. Push X on the Product to show the Ethernet screen.

4. Push O to select one of the three internet connection

methods: Default, Configured, and DHCP-Client.

24

Page 39

Gas Flow Analyzer

Product Configuration

Figure 22. Configuration Utility Web Page

gyo030.jpg

25

Page 40

VT305

Users Manual

Values Configuration

gyo031.jpg

Figure 23. Trigger Values Web Page

The values configuration screen lets you set the value parameters in the Product. Click on the down arrow in each combo box

to show a list of parameters or values that you click on to set. To switch between Value 1, Value 2, and Value 3, click on the

grey banner of the window that shows the values you want to change. The Value 2 window is selected in Figure 23. To select

the Value 1 window shown on the left, click the grey Value 1 banner at the top of that window.

26

Page 41

Gas Flow Analyzer

Product Configuration

Curves Configuration

Change the displayed curves or associated units on the Product with the drop down combo boxes shown in Figure 24.

Figure 24. Graphical Screen Configuration Web Page

Note

The gas temperature shown on the display is the temperature of the gas in the measurement chamber and not the

temperature of the gas that flows into the Product. The temperature of the Product will change the temperature of the

gas that flows into the Product.

gyo032.jpg

27

Page 42

VT305

Users Manual

Interface Configuration

Use the Configure interfaces screen to setup the Ethernet connection and analog output channels. Use the drop-down

lists to set the IP configuration and analog outputs. See Figure 25.

28

Figure 25. Create Configuration File Web Page

gyo034.jpg

Page 43

Gas Flow Analyzer

Product Configuration

Trigger Configuration

Use the Configure triggers screen sown in Figure 26 to set one of the three preconfigured triggers.

Figure 26. Configure Triggers Screen

Click on the active button in one of the three windows to select the trigger you want to use in the Product. Some

parameters are set with the drop-down lists. Click on the Reset to Defaults button to set all trigger parameters to their

factory default values.

gyo064.jpg

29

Page 44

VT305

Users Manual

Miscellaneous Configuration

Change the miscellaneous parameters on the Product with the drop down combo boxes shown in Figure 27.

30

Figure 27. Miscellaneous Configuration Window

gyo054.jpg

Page 45

Gas Flow Analyzer

Product Configuration

How to Setup an Ethernet Connection

There are three Ethernet setup procedures: Default,

Configured, and DHCP-Client.

Default Ethernet Setup

The default setup is used when no network exists and you

connect the Product directly to the computer.

1. Use an Ethernet cable to connect the Ethernet port on

the computer to the Product.

2. Push X on the Product until the Ethernet screen shows

in the display. See Figure 28.

Ethernet

Default

IP: 192.168.1.1

Subnet: 255.255.255..0

Figure 28. Ethernet Connection Screen

3. If Default does not already show in the display, push

O until it does.

gyo062.eps

6. Click on Change adapter settings.

7. Double click on the Local Area Network. See

Figure 29.

8. Highlight Internet Protocol Version 4 (TCP/Pv4).

9. Click the Properties button. See Figure 30.

10. Set the IP Address to 192.168.1.2 (or any IP address

between 192.168.1.2 through 192.168.1.255) and the

subnet mask to 255.255.255.0.

11. Click the OK button.

12. Close all the windows you opened through the control

panel.

13. Open an Internet Browser.

14. In the address line, type the IP address shown in the

display of the Product and push Enter on the

computer keyboard.

The default configuration sets the IP Address of the

Product to 192.168.1.1 and the subnet mask to

255.255.255.0.

4. Open the Control Panel on the computer.

5. Click on Network and Internet in the control panel

window.

31

Page 46

VT305

Users Manual

32

Figure 29. Computer Ethernet Setup Windows

gyo074.eps

Page 47

Gas Flow Analyzer

Product Configuration

Figure 30. Ethernet IP Address Properties Form

gyo075.eps

33

Page 48

VT305

Users Manual

Configured and DCHP Ethernet Setup

The configured setup is used when a network that does

not have a DCHP server exists. The DCHP-Client setup is

used when you connect to networks that have a DCHP

server.

1. Use an Ethernet cable to connect the Ethernet port on

the Product to the network.

2. Push X on the Product until the Ethernet Configured

or Ethernet DCHP – Client screen shows in the

Product display.

3. Open an Internet Browser.

4. In the address line, type the IP address shown in the

display of the Product and push Enter on the

computer keyboard.

Note

There can only be one connection to the

configuration tool for a single Product. With the

configuration tool open, the Product cannot be

configured from another computer.

The configuration tool will download to the computer and

establish a connection.

O2 Sensor

Activation

The Product has an interface for an oxygen sensor. The

oxygen sensor must be calibrated with air and 100 % O

.

2

Installation

A kit that has the oxygen sensor and connection cable

comes with the oxygen option.

Remove the protective cap (rubber stopper) from the

sensor.

Oxygen Sensor Calibration – Air Only

Note

Fluke Biomedical does not recommend you

calibrate the oxygen sensor with air.

To calibrate the oxygen sensor with air:

1. Push X on the front panel until O2 Calibration with Air

shows in the display.

2. Push O to start the calibration process.

3. Apply 25 l/min of air to the flow channel of the Product

when the instruction shows in the display. See

Figure 31.

O2 Calibration

Air

Apply 25 I/min (0)

Press o to start

Figure 31. O2 Calibration - Apply Air

gyo066.eps

34

4. Push O to continue.

Page 49

Gas Flow Analyzer

O2 Sensor

Note

To stop the calibration procedure, push X.

Air calibration starts and will take 114 seconds to

complete. Under no circumstances interrupt the flow of

air through the flow channel. The screen in Figure 32

shows in the display when the calibration is done.

O2 Calibration

Air successful

Press any key to exit

gyo067.eps

Figure 32. O2 Calibration Successful Screen

Oxygen Sensor Calibration – O2 and Air

To calibrate the oxygen sensor with air and oxygen:

1. Push X on the front panel until O2 Calibration with O2

and Air shows on the display.

2. Push O to start the calibration process.

3. Apply 25 l/min of 100 % oxygen to the flow channel of

the Product when the instruction shows in the display.

See Figure 33.

O2 Calibration

100% O2

Apply 25 I/min (0)

Press o to contiue

gyo070.eps

Figure 33. O2 Calibration - Apply Oxygen

4. Push O to continue.

Note

To stop the calibration procedure, push X.

Oxygen calibration starts and will take 114 seconds to

complete. Under no circumstances interrupt the flow of

gas through the flow channel.

5. Apply 25 l/min of air to the flow channel of the Product

when the instruction shows in the display. See

Figure 31.

O2 Calibration

Air

Apply 25 I/min (0)

Press o to start

gyo066.eps

Figure 34. O2 Calibration - Apply Air

Air calibration starts and will take 114 seconds to

complete. Under no circumstances interrupt the flow of

air through the flow channel.

35

Page 50

VT305

Users Manual

The screen in Figure 35 shows in the display when the

calibration is done.

O2 Calibration

O2 and Air

successful

Press any key to exit

Figure 35. O2 Calibration Successful Screen

gyo069.eps

gyo035.eps

Figure 36. Protective Cap Removal

Turn the O

sensor clockwise to attach it to the Product.

2

Use the sensor cable to connect it to the Product. See

Figure 37.

36

Page 51

Gas Flow Analyzer

Measure Respiratory Data

Measure Respiratory Data

General

To measure key respiratory data, the Product must read

out a breath cycle from the measured pressure and/or flow

chart curves. This is controlled through the triggers shown

in Figure 38.

Figure 37. O2 Sensor Installation

gyo036.eps

37

Page 52

VT305

Users Manual

V

Breath Cycle

ExpirationInspiration

S

Start Trigger

V

0

End Trigger

Figure 38. Breath Cycle

It is very important to set the start and stop triggers

correctly. These triggers significantly influence the

measurement results because they trigger the breath

cycles. Make sure these triggers are set correctly before

you start respiratory data measurement.

E

S

Note

The start trigger is interpreted as the start of the

inspiration phase. The stop trigger is interpreted

as the end of the inspiration phase and the start of

the expiration phase. The expiration continues

until the subsequent start trigger.

gyo037.eps

38

Page 53

Gas Flow Analyzer

Measure Respiratory Data

Connection to the Respiratory Apparatus

There are three different methods to connect the Product

to the respiratory apparatus:

• Downstream of the Y-piece

Fluke VT305

Ventilator

• In the inspiration duct upstream of the Y-piece

Fluke VT305

Ventilator

• In the expiration duct upstream of the Y-piece

Test Lung

gyo038.eps

Test Lung

gyo039.eps

Test Lung

Ventilator

Fluke VT305

gyo040.eps

Standard Trigger Values

Because the Product can measure flow in each direction, it

makes sense to use the first connection method. In this

measurement setup, flow is usually chosen as the trigger

value. Flow triggers are stored as standard values in the

device and can be reset when necessary. The standard

trigger values for the flow trigger for adult breathing, for

example, are:

Starttrigger: Flow > 3 l/min

Endtrigger: Flow < -3 l/min

With the second and third connection methods, pressure is

usually chosen as the trigger signal. In this case the

standard values are as follows:

Starttrigger: Pressure > 1 mbar

Endtrigger: Pressure < 1 mbar

Baseflow

The base flow is the constant flow that must be ignored

when you calculate volume. If there is an identified

leakage in the system, like a constant discharge of 3 l/min

39

Page 54

VT305

Users Manual

of air, the 3 l/min is not counted as inspiration volume.

When you type in:

Base flow: on 3.0 l/min

the volume calculation in our example could be corrected.

Type the base flow parameter value in the configurator

base flow section.

Find the Correct Trigger Setting

When you set a trigger for the first time, it is important to

know the curve of the signal for the trigger (flow or

pressure). Here are some examples that also show

possible problems.

Flow Curve Downstream of the Y-Piece

Figure 39 is an example of a flow curve downstream of the

Y-piece. The standard triggers (> 3 l/min/< –3 l/min) can

be used without a problem.

Note

In such situations it is important to keep in mind that the

trigger is significantly higher than the noise of the base

line. Incorrect triggers can be released.

Flow Curve Upstream of the Y-Piece

The curve in Figure 40 shows the flow curve in the

inspiration duct upstream of the Y-piece. The first two

circles show the triggers that must be used here. The top

figure shows a small incorrect signal at the measurement

point after the inspiration. This is caused by switching the

valves. This results in faulty triggering.

Faulty triggering!

40

Figure 39. Downstream Flow Curve

gyo041.jpg

Time [S]

Figure 40. Inspiration Duct Upstream Curve

gyo042.eps

Page 55

Gas Flow Analyzer

Measure Respiratory Data

Note

Flow cannot be used here as a trigger. The

pressure curve must be used.

Pressure Curve Upstream of the Y-Piece

For the pressure curve shown in Figure 41, the standard

triggers can be used: (> 1 mbar / < 1 mbar).

gyo043.jpg

Figure 41. Upstream Pressure Curve

Note

The trigger is significantly higher than the noise of

the base line. If not, the trigger value must be

increased.

Special Cases

In measurement technology there can always be a

deviation from the standard variants to get a more

accurate result. You can get very accurate results with the

settings shown in this manual, which is better than the

accuracy of all respiratory equipment.

Measurement errors inherent in the overall system occur in

the respiratory apparatus and in the Product. The values

shown in the display can be different because not the

same thing was measured and compared.

Inspiration Volume Vti

If the breath curve shows a plateau or a break, a tiny flow

can be measured during this time. A lot of breathing

equipment does not include these tiny flows when they

calculate Vti. You can match this behavior in the Product

when you use the trigger values that follow:

In Figure 42, S shows the start trigger and E the end

trigger.

41

Page 56

VT305

Users Manual

Start and

End Trigger

V

V

Breath Cycle

Inspiration

Expiration

Vti

E

0

S S

t

gyo044.eps

Figure 42. Inspiration Volume

42

Page 57

Gas Flow Analyzer

Measure Respiratory Data

Expiration Volume Vte

Figure 43 shows the optimal trigger values to measure Vte.

Breath Cycle

Inspiration

Start Trigger

End Trigger

V

S

V

0

Figure 43. Expiration Volume

The start trigger must be set to S and the end trigger to E.

Vte

E

Expiration

S

t

gyo045.eps

43

Page 58

VT305

Users Manual

Care and Maintenance

Warning

To prevent possible electrical shock, fire, or

personal injury:

• Batteries contain hazardous chemicals that

can cause burns or explode. If exposure to

chemicals occurs, clean with water and get

medical aid.

• Do not disassemble the battery.

• Do not disassemble or crush battery cells

and battery packs.

• Do not put battery cells and battery packs

near heat or fire. Do not put in sunlight.

• Do not operate the Product with covers

removed or the case open. Hazardous

voltage exposure is possible.

• Use only specified replacement parts.

• Have an approved technician repair the

Product.

For safe operation and maintenance of the

product:

• Keep cells and battery packs clean and

dry. Clean dirty connectors with a dry,

clean cloth.

• Do not keep cells or batteries in a

container where the terminals can be

shorted.

Guidelines for Care and Maintenance

For safe and reliable operation of the Product, follow these

maintenance guidelines. Use only components

recommended by the manufacturer.

Note

You must use the guidelines and maintenance

instructions supplied by the manufacturer.

Preventive Cleaning and Maintenance

Note

The maintenance tasks shown below must only be

done by personnel that know the Product. All other

repairs must be done by approved personnel.

To keep the Product accurate and reliable in the long term,

follow the maintenance tasks in Table 6 on a regular basis:

• Repair the Product before use if the battery

leaks.

• Do not short the battery terminals together.

44

Page 59

Gas Flow Analyzer

Accessories and Spare Parts

Table 6. Maintenance Tasks

Interval Task

While in

operation

4 weeks Examine the filter for contamination.

12 Months Factory calibration to make sure the

Use the supplied filter.

To do this, connect the filter inlet

and outlet to the differential

pressure connection with two Tpieces. Measure the pressure loss

across the filter with this

connection. The pressure loss for a

flow of 60 l/min cannot be more

than 2 mbar. If the pressure is more

than 2 mbar, the filter must be

replaced.

Product gives reliable

measurements.

Accessories and Spare Parts

Ordering Address

Fluke Biomedical

6045 Cochran Rd.

Cleveland, OH 44139

USA

Telephone: +1 440-248-9300

Toll-free: (800) 850-4608

Fax: +1 440-349-2307

E-Mail: sales@flukebiomedical.com

Or

Fluke Biomedical Europe

Science Park Eindhoven 5110

5692EC Son

The Netherlands

Telephone: +31 40 267 5436

Fax: +31 40 267 5436

E-Mail: ordersupport.emea@flukebiomedical.com

45

Page 60

VT305

Users Manual

Table 7. Standard Accessories

Item Part No.

O2 SENSOR ASSEMBLY 4281611

ACCULUNG II PORTABLE PRECISION

TEST LUNG

PROTECTION FILTER 4294528

ADAPTER SET 4294537

O2 SNR CABLE 4296104

O2 HIGH PRESSURE ADAPTER 4294543

PWR ADAPTER SET 4308219

SD CARD 2GB 4296162

INLET PIPE 4296170

CARRY CASE 4296181

Table 8. Optional Accessories

Item Part No.

AIR HIGH PRESSURE ADAPTER 4294555

4281291

Disposal

The manufacturer is responsible for disposal of this

Product. The device must be shipped (free and with duty

paid) to the manufacturer for disposal.

• A licensed private or public collection company can

take this Product for disposal.

• The Product can be disassembled into individual

components and then recycled or discarded in the

correct manner.

• If disposal is done by the manufacturer, the regulations

for disposal are contingent on the country and are

subject to its laws and legal requirements. You can get

the applicable rules and regulations from the

responsible authority.

In this regard, the Product is to be recycled or discarded:

• Without effect on human health.

• Without the use of procedures or methods that cause

damage to the environment (water, air, soil, flora, and

fauna).

ANSUR VT PLUG-IN LICENSE 4296065

For more accessories and spare parts, go to

www.FlukeBiomedical.com

46

Page 61

Gas Flow Analyzer

Specifications

Specifications

Display ................................................................... 26 mm x 33 mm

Real time curves ................................................... Flow, Pressure, Volume, temperature of gas inside the measurement chamber, oxygen, respiratory

Interfaces ............................................................... RS-232, USB, Ethernet, CAN, Analog Out, TTL

Temperature (gas in measurement chamber)

Operating ............................................................ 15 °C to 40 °C (59 °F to 104 °F)

Storage ............................................................... -10 °C to 60 °C

Relative humidity

Operating ............................................................ 10 % to 90 % RH

Storage/Transportation ....................................... 5 % to 95 % RH

Ambient pressure ................................................. 500 mbar to 1150 mbar

Power

AC adapter

Voltage input ................................................... 100 V ac to 240 V ac, 50 Hz to 60 Hz

Supply voltage ................................................ 5 V dc

Power consumption ........................................ 2.5 W to 6 W

Battery

Battery life ....................................................... 4 hours. Operation time will be reached in standalone operation (without use of interfaces)

Recharge time ................................................ 5 to 8 hours (varies with port used)

Dimensions (W x L x H) ........................................ 16.5 cm x 10.8 cm x 6.4 cm (6.5 in x 4.25 in x2.5 in)

Weight .................................................................... 0.4 kg

Safety ..................................................................... IEC 61010-1: Pollution Degree 2

Electromagnetic Environment ............................. IEC 61326-1: Portable

Calibration interval ............................................... annually

Memory Card ......................................................... yes

Data Interfaces

Analog port

Analog Output 1 .............................................. 0 Vdc to 5 Vdc ±1.8 %, load ≥5 kΩ

Analog Output 2 .............................................. 0 Vdc to 5 Vdc ±1.8 %, load ≥5 kΩ

parameters

47

Page 62

VT305

Users Manual

Trigger Input ................................................... 5 Vdc to 24 Vdc

V

IN .................................................................. 9 Vdc to 29 Vdc

RS-232 Port

Baud Rate ........................................................... 19200, 8 bits, no Parity, 1 stop bit

Measurement Variables

Air and N2

Flow Measurements

Range ......................................................... ±300 sl/min

Accuracy ..................................................... ±1.9 %* or ±0.1 l/min

Ambient pressure compensated ..................... yes

Temperature compensated ............................ yes

O2/Air Mixtures

Flow Measurements

Range ......................................................... ±300 sl/min

Accuracy ..................................................... ±1.9 %* or ±0.1 l/min

Ambient pressure compensated ..................... yes

Temperature compensated ............................ yes

CO2

Flow Measurements

Range ......................................................... ±140 sl/min

Accuracy ..................................................... ±3.0 %* or ±0.1 l/min

Ambient pressure compensation accuracy ..... 25 °C to 30 °C

Temperature compensated ............................ yes

Channel pressure compensation accuracy .... -50 to +600 mbar

Heliox (21 % O2/ 79 % He)

Flow Measurements

Range ......................................................... ±300 sl/min

Accuracy ..................................................... ±4.0 %* or ±0.3 l/min

Ambient pressure compensation accuracy ..... 25 °C to 30 °C

Temperature compensated ............................ yes

48

Page 63

Gas Flow Analyzer

Specifications

N2O/O2 Mixtures

Flow Measurements

Range ......................................................... ±80 sl/min

Accuracy ..................................................... ±4.0 %* or ±0.3 l/min

Ambient pressure compensation accuracy ..... 25 °C to 30 °C

Temperature compensated ............................ yes

Pressure

High

Range ......................................................... 0 to 10 bar

Accuracy ..................................................... ±1 %* or ±10 mbar**

Difference

Range ......................................................... ±200 mbar

Accuracy ..................................................... ±0.75 %* or ±0.1 mbar

In the flow channel

Range ......................................................... -50 to 150 mbar

Accuracy ..................................................... ±0.75 %* or ±0.1 mbar

Barometer

Range ......................................................... 500 to 1150 mbar

Accuracy ..................................................... ±1.0 %* or ±5.0 mbar

Variables

Flow ................................................................ l/min, l/s, cfm, ml/min, ml/s

Pressure ......................................................... bar, mbar, cmH

Oxygen concentration (pressure compensated ≤150 mbar)

Range ......................................................... 0 % to 100 %

Accuracy ..................................................... ±1 % O

2

Gas Temperature

Range ......................................................... 0 °C to 50 °C

Accuracy ..................................................... ±1.75 %* or ±0.5 °C

Type of gas ..................................................... Air, Air/O

Gas Standard ................................................. ATP, ATPD, ATPS, AP21, STP, STPH, BTPS, BTPD, 0/1013, 20/981, 15/1013, 25/991, 20/1013

O, inH2O, Torr, inHg, hPa, kPa, mmHg, PSI

2

**

, N2O/O2, Heliox (21 % O2), He/O2, N2, CO

2

2

49

Page 64

VT305

Users Manual

Respiratory Parameters

Breathing Rate (BR/min)

Range ......................................................... 1 bpm to 1000 bpm

Accuracy ..................................................... ±1 bpm or ±2.5 % **

Time (Ti, Te)

Range ......................................................... 0.05 s to 60 s

Accuracy ..................................................... ±0.02 s

Ratio (I:E)

Range ......................................................... 1:300 to 300:1

Accuracy ..................................................... ±2.5 %*

Ratio (Ti/Tcyc)

Range ......................................................... 0 % to 100 %

Accuracy ..................................................... ±5 %*

Breathing Volume (Vti, Vte)

Range ......................................................... ±10 l

Accuracy ..................................................... ±2 %* or ±20 ml

Volume per minute (Vi, Ve)

Range ......................................................... 0 l/min to 300 l/min

Accuracy ..................................................... ±2.5 %*

Peakflow

Range ......................................................... ±300 l/min

Accuracy ..................................................... ±1.9 %* or ±0.1 l/min

Pressure (Ppeak, Pmean, PEEP, Pplateau)

Range ......................................................... 0 mbar to 150 mbar

Accuracy ..................................................... ±0.75 %* or ±0.1 l/min

Compliance (Cstat)

Range ......................................................... 0 ml/mbar to 1000 ml/mbar

Accuracy ..................................................... ±3 %* or ±1 ml/mbar

Trigger Range (Adult, Pediatric, HFO) ........... Flow and volume (from default settings and adjustable levels) the greater tolerance is valid

* Tolerance related to the measured value.

** Absolute tolerance.

*** sl/min is based on ambient conditions of 0° C and 1013 mbar (DIN 1343)

50

Page 65

Gas Flow Analyzer

Operation Principle of Flow Measurement

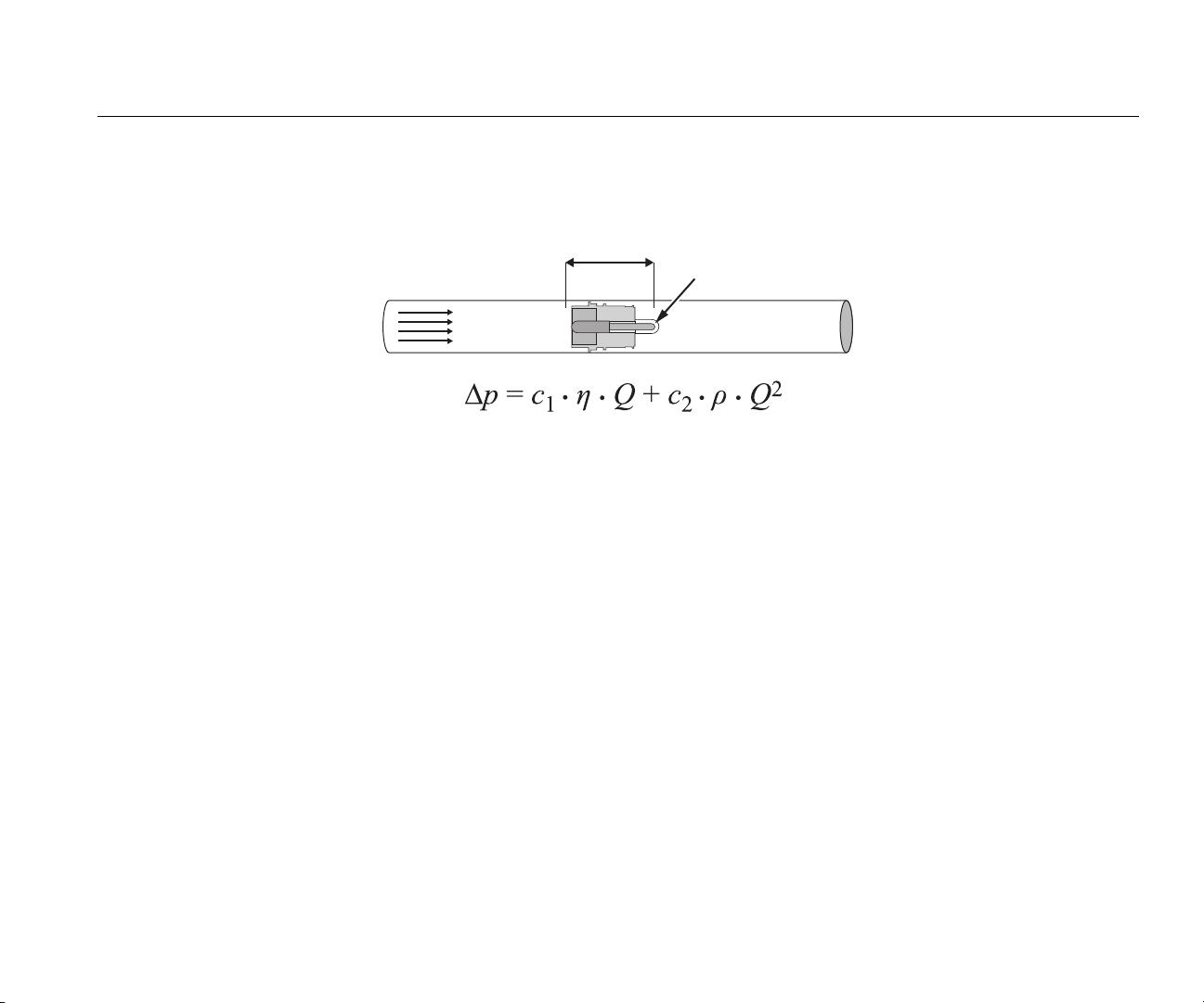

Operation Principle of Flow Measurement

A differential pressure measurement is used to find the flow in the flow channel. To make the pressure difference, a linear flow element is used as a flow

resistance. See Figure 44.

Pressure Difference ∆p

Linear flow element

Gas Flow Q

Figure 44. Linear Flow Element