Page 1

TiX620, TiX640, TiX660,

TiX1000

Thermal Imager

September 2014, Rev.1, 9/16

© 2014, 2016 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

This Fluke product will be free from defects in material and workmanship for two years from the date of purchase. This

warranty does not cover fuses, disposable batteries, or damage from accident, neglect, misuse, alteration, contamination, or

abnormal conditions of operation or handling. Resellers are not authorized to extend any other warranty on Fluke’s behalf.

To obtain service during the warranty period, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that Service Center with a description of the problem.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER WARRANTIES, SUCH AS FITNESS FOR A PARTICULAR

PURPOSE, ARE EXPRESSED OR IMPLIED. FLUKE IS NOT LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES, ARISING FROM ANY CAUSE OR THEORY. Since some states or countries

do not allow the exclusion or limitation of an implied warranty or of incidental or consequential damages, this limitation of

liability may not apply to you.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

11/99

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

Page 3

Table of Contents

Chapter Title Page

1 Before You Start ........................................................................................................... 1-1

Introduction .................................................................................................................... 1-1

How to Contact Fluke ..................................................................................................... 1-2

Safety Information .......................................................................................................... 1-3

Optional Accessories ...................................................................................................... 1-7

Technical Description ..................................................................................................... 1-7

Functional Principle ................................................................................................... 1-7

Description of the Functional Units ............................................................................ 1-7

Lens ...................................................................................................................... 1-7

Detector ................................................................................................................ 1-10

Detector Electronics .............................................................................................. 1-10

Image Processing Electronics ............................................................................... 1-10

Optomechanics ..................................................................................................... 1-11

Controls ................................................................................................................ 1-11

Power Supply ........................................................................................................ 1-11

Interfaces .............................................................................................................. 1-12

Technical Data........................................................................................................... 1-12

Unpacking and Control ................................................................................................... 1-15

i

Page 4

TiX620, TiX640, TiX660, TiX1000

Users Manual

Parts of the Thermal Imager .......................................................................................... 1-16

Quick Guide ................................................................................................................... 1-18

Preparation ............................................................................................................... 1-19

Start .......................................................................................................................... 1-19

Display ...................................................................................................................... 1-20

Setting the Focus ...................................................................................................... 1-21

Setting the Temperature Range ................................................................................ 1-21

Saving Images .......................................................................................................... 1-24

Menu Functions ........................................................................................................ 1-25

Shut-Down ................................................................................................................ 1-25

Data Transmission to the Computer .............................................................................. 1-26

Start-Up ......................................................................................................................... 1-26

Hand Strap ................................................................................................................ 1-26

Tripod ........................................................................................................................ 1-26

Power Supply ............................................................................................................ 1-26

Memory Card ............................................................................................................ 1-26

Lens Replacement .................................................................................................... 1-27

Operation using the Gigabit Ethernet (GigE) Interface .............................................. 1-27

Operation with Breakout Box .................................................................................... 1-28

2 Elements of the User Interface ................................................................................... 2-1

Introduction .................................................................................................................... 2-1

Button Functions ............................................................................................................ 2-3

Image Elements ............................................................................................................. 2-5

Setting the Temperature Scale ...................................................................................... 2-7

Focus ............................................................................................................................. 2-7

Saving with "Check" ............................................................................................. 1-24

Quick Saving ........................................................................................................ 1-24

Ethernet Cable and AC Adapter ........................................................................... 1-28

AC Adapter Connection ....................................................................................... 1-28

ii

Page 5

Contents (continued)

LaserSharp® Auto Focus ........................................................................................... 2-8

Permanent LaserSharp® Auto Focus ......................................................................... 2-8

EverSharp Multifocal Recording ................................................................................ 2-8

Spot Editor ..................................................................................................................... 2-9

Saving ............................................................................................................................ 2-9

Saving with Check .......................................................................................................... 2-10

Quick Saving .................................................................................................................. 2-10

3 Display Menus .............................................................................................................. 3-1

Introduction .................................................................................................................... 3-1

Image Submenu ............................................................................................................. 3-2

Manual Submenu ...................................................................................................... 3-3

Mode Submenu ......................................................................................................... 3-5

Zoom Submenu ......................................................................................................... 3-8

Palette Submenu ....................................................................................................... 3-9

Elements Submenu ................................................................................................... 3-12

Isotherms Submenu .................................................................................................. 3-13

Filter Mode Submenu ................................................................................................ 3-15

Format (Subwindowing) Submenu ............................................................................ 3-15

File Menu ....................................................................................................................... 3-16

Directory Structure ..................................................................................................... 3-16

Load Submenu .......................................................................................................... 3-16

Save Submenu .......................................................................................................... 3-19

IR Photonotes Submenu ........................................................................................... 3-22

Format SD Submenu ................................................................................................. 3-23

Saving Format Submenu ........................................................................................... 3-23

Measure Menu ............................................................................................................... 3-25

Spot Temperature Submenu ..................................................................................... 3-25

Measurement Definitions Submenu ........................................................................... 3-26

Correction Submenu .................................................................................................. 3-31

iii

Page 6

TiX620, TiX640, TiX660, TiX1000

Users Manual

GPS Submenu .......................................................................................................... 3-35

Laser Submenu ......................................................................................................... 3-35

Settings Menu ................................................................................................................ 3-36

Calibration Submenu ................................................................................................ 3-36

Extras Submenu ....................................................................................................... 3-37

Automatic Submenu .................................................................................................. 3-38

Compensation Submenu .......................................................................................... 3-39

Buttons Submenu ..................................................................................................... 3-40

Digital Alarm Output Submenu.................................................................................. 3-43

Configuration Submenu ............................................................................................ 3-44

System Menu ................................................................................................................. 3-46

Display Submenu ...................................................................................................... 3-47

Regional Submenu ................................................................................................... 3-48

Date and Time Submenu .......................................................................................... 3-48

Menu Layout Submenu ............................................................................................. 3-49

Menu Control Submenu ............................................................................................ 3-50

Info Submenu............................................................................................................ 3-51

4 Maintenance ................................................................................................................. 4-1

Introduction .................................................................................................................... 4-1

How to Clean ................................................................................................................. 4-1

Calibration ..................................................................................................................... 4-2

Environmental ................................................................................................................ 4-2

Service ........................................................................................................................... 4-2

Battery ........................................................................................................................... 4-3

iv

Page 7

Chapter 1

Before You Start

Introduction

The TiX620, TiX640, TiX660, and TiX1000 Thermal

Imagers (the Product) are state-of-the-art thermography

systems for precise, quick, and non-contact measurement

of the surface temperature of objects.

These thermal imagers are designed for universal

application and can be used both as a mobile and as a

stationary device for measuring and storing temperature

values. The compact and resilient design and a high

degree of protection allow for industrial application even

in unfavorable external conditions. The low weight of the

device, as well as the long operating time of the

rechargeable battery allow for efficient use in this.

High measurement accuracy, precision optics with

extraordinary image quality, as well as the universal

interface concept for digital real-time thermography data

collection using GigE-Vision allow for using the thermal

imager in a wide variety of applications.

The thermal imager is equipped with a digital color video

camera in order to document the measuring situation on

photos. Infrared (IR) and visual light images, as well as

image sequences can be saved to SD and SDHC

(Secure Digital High Capacity) cards. For the purposes of

visualization, the thermography system is equipped with a

swivel-mounted color thin film transistor (TFT) viewfinder

and a pivot and swivel-mounted active color TFT display.

Diverse accessories and different software packages for

pre- and post-processing of the recordings turn the

product into a universal thermography system for a broad

range of applications.

1-1

Page 8

TiX620, TiX640, TiX660, TiX1000

Users Manual

Typical fields of application of the thermography system

are:

• thermographic inspection of electrical and

mechanical systems

• optimization of components and assemblies

• material inspections

• control of process temperatures

• quality assurance

• building inspection and diagnostics

• research and development

How to Contact Fluke

To contact Fluke, call one of the following telephone

numbers:

• Technical Support USA: 1-800-44-FLUKE

(1-800-443-5853)

• Calibration/Repair USA: 1-888-99-FLUKE

(1-888-993-5853)

• Canada: 1-800-36-FLUKE (1-800-363-5853)

• Europe: +31 402-675-200

• Japan: +81-3-6714-3114

• Singapore: +65-6799-5566

• Anywhere in the world: +1-425-446-5500

Go to www.fluke.com to register your product, download

manuals, and find more information.

To view, print, or download the latest manual supplement,

visit http://us.fluke.com/usen/support/manuals.

1-2

Page 9

Before You Start

Safety Information

1

Safety Information

A Warning identifies conditions and procedures that are

dangerous to the user. A Caution identifies conditions

and procedures that can cause damage to the Product or

the equipment under test.

Warning

To prevent eye damage and personal injury:

• Do not look into the laser. Do not point

laser directly at persons or animals or

indirectly off reflective surfaces.

• Do not open the Product. The laser beam

is dangerous to eyes. Have the Product

repaired only through an approved

technical site.

• Do not locate the laser beam so that it is

at eye level when you install the

thermography system.

• The Product is equipped with an LED

light to illuminate the image. Avoid any

direct eye contact and do not point the

LED light at people, animals, or reflective

surfaces.

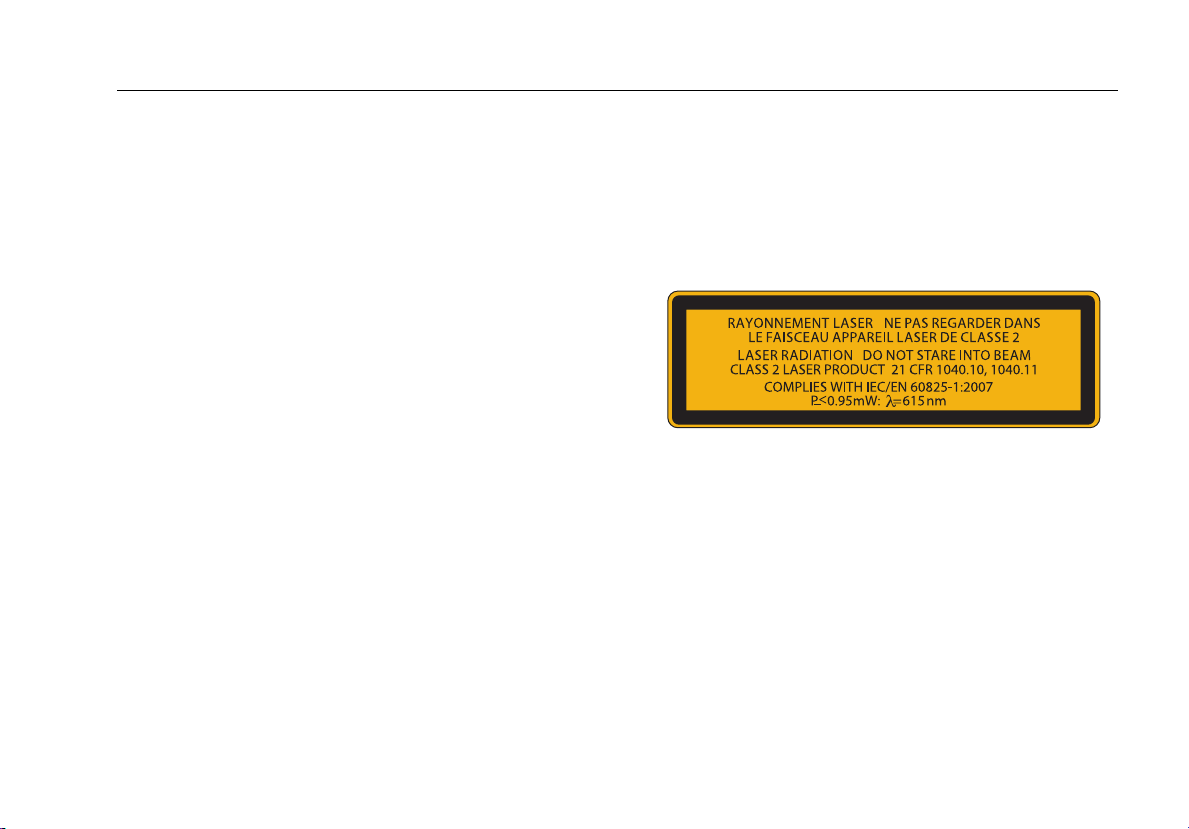

Additional laser warning information is on the case of the

Product, see Figure 1-1.

hvh300.eps

Figure 1-1. Lens Cover Laser Warning

Warning

To prevent possible electrical shock, fire, or

personal injury:

• Carefully read all instructions.

• Read all safety information before you

use the Product.

• Do not alter the Product and use only as

specified or the protection supplied by

the Product can be compromised.

1-3

Page 10

TiX620, TiX640, TiX660, TiX1000

Users Manual

• Do not use the Product around explosive

gas, vapor, or in damp or wet

environments.

• Use this Product indoors only.

• Examine the case before you use the

Product. Look for cracks or missing

plastic. Carefully look at the insulation

around the terminals.

• Do not use the Product if it is altered or

damaged.

• Do not use the Product if it operates

incorrectly.

• Replace the batteries when the low

battery indicator shows to prevent

incorrect measurements.

• Remove the batteries if the Product is

not used for an extended period of time,

or if stored in temperatures above 50 °C.

If the batteries are not removed, battery

leakage can damage the Product.

• Batteries contain hazardous chemicals

that can cause burns or explode. If

exposure to chemicals occurs, clean

with water and get medical aid.

• Do not disassemble the battery.

• Do not short the battery terminals

together.

• Do not disassemble or crush battery

cells and battery packs.

1-4

Page 11

Before You Start

Safety Information

• Do not keep cells or batteries in a

container where the terminals can be

shorted.

• Do not put battery cells and battery

packs near heat or fire. Do not put in

sunlight.

Warning

For safe operation and maintenance of the

Product:

• Repair the Product before use if the

battery leaks.

• Be sure that the battery polarity is

correct to prevent battery leakage.

• Use only Fluke approved power adapters

to charge the battery.

1

1-5

Page 12

TiX620, TiX640, TiX660, TiX1000

Users Manual

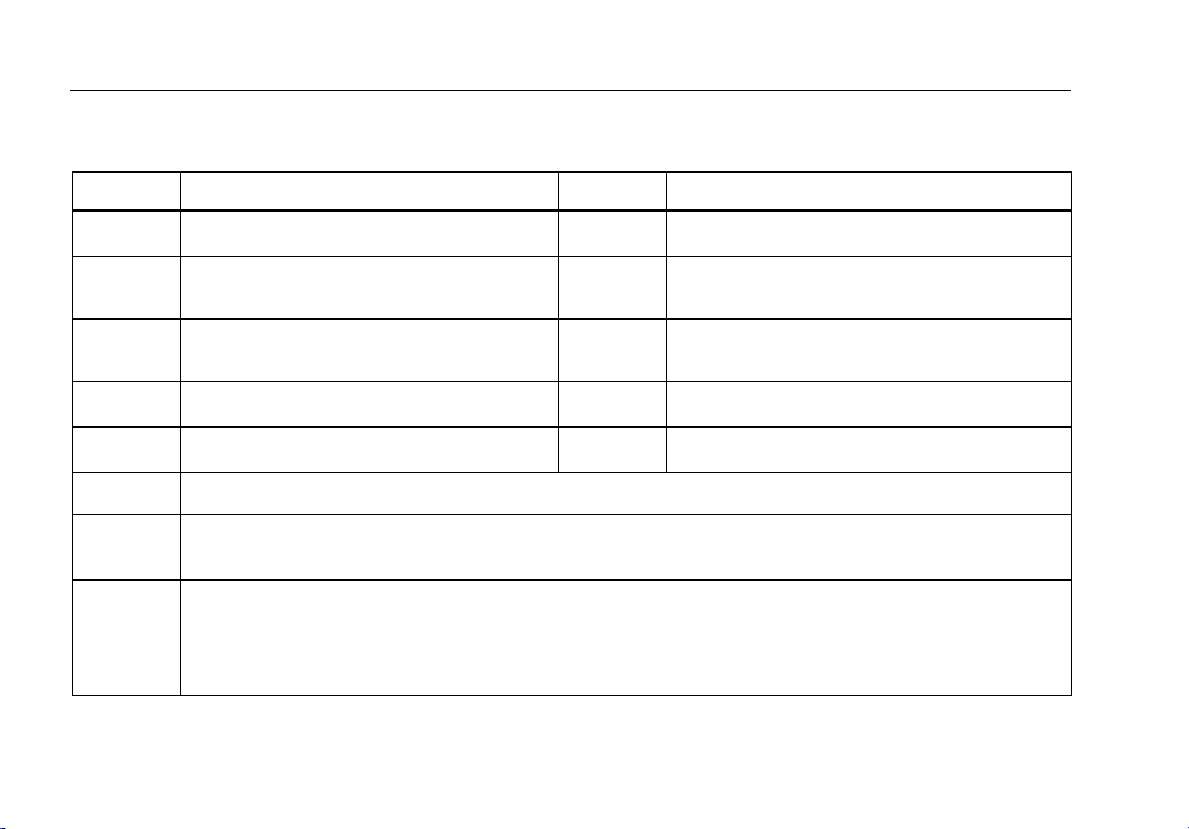

Table 1-1 is a list of symbols used on the Imager and in

this manual.

Table 1-1. Symbols

Symbol Description Symbol Description

WARNING. RISK OF DANGER.

WARNING. HAZARDOUS VOLTAGE. Risk

of electric shock.

On/Off Symbol.

Conforms to relevant South Korean EMC

standards.

Conforms to relevant Australian Safety and

EMC standards.

Consult user documentation.

This Product contains a lithium-ion battery. Do not mix with the solid waste stream. Spent batteries should be

disposed of by a qualified recycler or hazardous materials handler per local regulations. Contact your

authorized Fluke Service Center for recycling information.

This product complies with the WEEE Directive marking requirements. The affixed label indicates that you

must not discard this electrical/electronic product in domestic household waste. Product Category: With

reference to the equipment types in the WEEE Directive Annex I, this product is classed as category 9

"Monitoring and Control Instrumentation" product. Do not dispose of this product as unsorted municipal

waste.

WARNING. LASER RADIATION. Risk of eye

damage.

Battery status.

Battery charging when animated.

Conforms to relevant North American Safety

Standards.

Conforms to requirements of European Union

and European Free Trade Association.

1-6

Page 13

Before You Start

Optional Accessories

1

Optional Accessories

• ac adapter with 14-pin LEMO connector

• replacement lenses, macro attachments

• protective window for lenses, laser protection filter

• Bluetooth headset

• gigabit Ethernet

• Ethernet cable with 8-pin LEMO connector

• device tripod

• spare batteries

Technical Description

Functional Principle

The Product is a thermography system designed for the

long-wave infrared spectral range (LWIR) of 7.5 μm to

14 μm. The lens reproduces the object scene to a

microbolometer array with 1024 x 768 and/or 640 x 480

pixels. The electrical signal of the detector array is

processed further by the internal electronics. In this, the

electronics comprise all functions required for camera

operation, such as actuation of the microbolometer array,

A/D conversion, offset and gain correction, pixel

correction, as well as actuation of the different interfaces.

Operation is optionally performed directly using the

integrated keyboard (joystick, focus rocker switch,

function buttons) or using optional interfaces. RS232,

Ethernet (GigE Vision), or USB2.0 are available as

interfaces. Specific software packages are required in

order to use these interfaces.

Description of the Functional Units

Lens

The camera lens collects the IR radiation in the field of

view emitted by the measuring object and reproduces this

IR radiation on the detector array. Field of view (FOV)

and resolution/measuring spot size (IFOV, Instantaneous

Field of View) are determined at the same distance to the

focal distance f of the used lens.

1-7

Page 14

TiX620, TiX640, TiX660, TiX1000

Users Manual

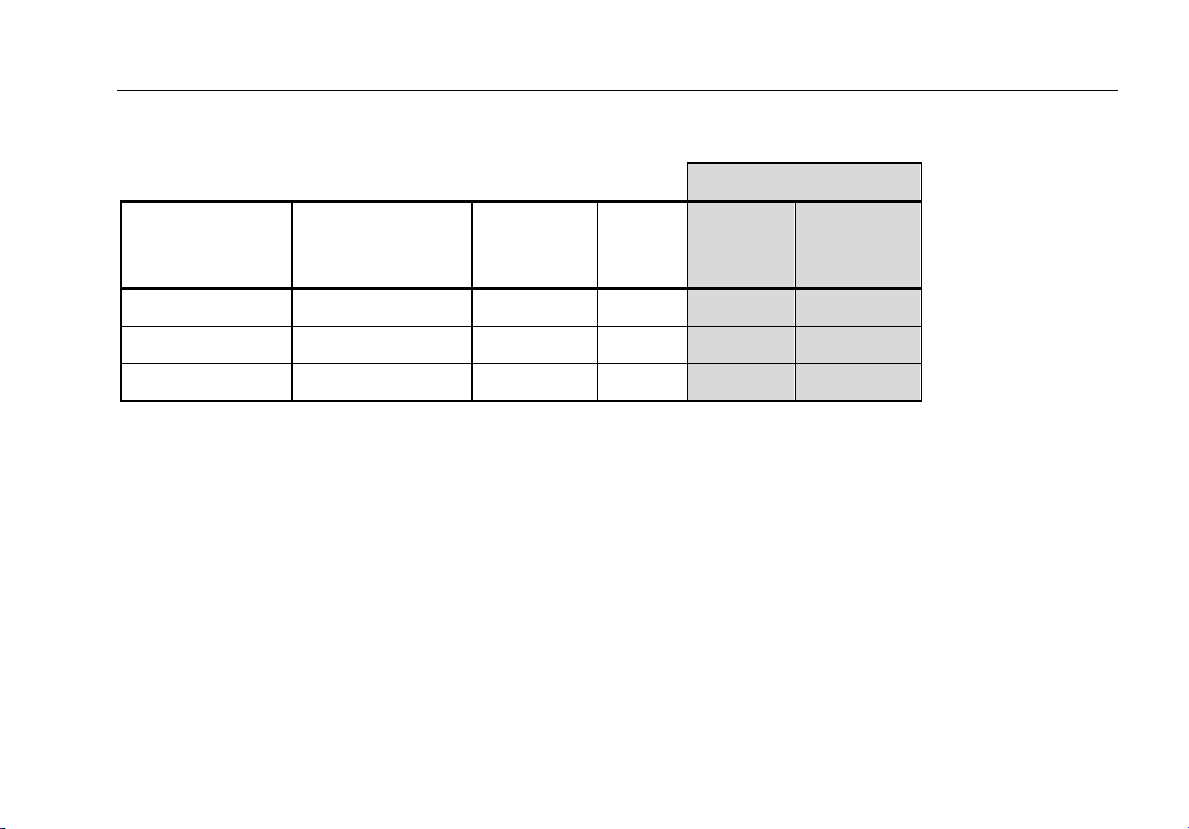

Table 1-2 is a list the optional lenses that are available for

TiX640, TiX660, and TiX1000:

Table 1-2. Thermography System Lenses

1024 x 768 640 x 480

Focal

Model Lens

FLK-Xlens/Sup-Wide Super wide-angle lens 7.5 0.17 2.3 135.8 x 104.4 3.3 128.9 x 92.7

FLK-Xlens/Wide Wide-angle lens 15 0.47 1.1 68.7 x 50.7 1.7 62.3 x 46.4

FLK-Xlens/Stan Standard lens 30 0.72 0.6 32.4 x 24.7 0.8 30.9 x 23.1

FLK-Xlens/Tele Telephoto lens 60 1.99 0.3 16.4 x 12.4 0.4 14.9 x 11.3

FLK-Xlen/SupTele Super telephoto lens 120 6.58 0.1 8.1 x 6.2 0.2 7.5 x 5.7

Model Lens

FLK-Xlens/Macro1 Close-up 0.2x for 30 137.4 85.5 x 63.2 81 78.1 x 57.9 119

FLK-Xlens/Macro2 Close-up 0.5x for 30 47.4 34.3 x 25.3 32 31.3 x 23.2 47

FLK-Xlens/Macro3 Close-up 0.5x for 60 100 35.1 x 26.5 35 32.3 x 24.4 50

distance

(mm)

Focal

distance

(mm)

Focus (m)

Focus

(mm)

IFOV

(mrad)

IFOV

(mrad)

FOV (°) IFOV (mrad) FOV (°)

Resolution

(μm)

IFOV (mrad)

Resolution

(μm)

1-8

Page 15

Before You Start

Technical Description

Table 1-2 is a list the optional lenses that are available for the TiX620:

Table 1-3. Thermography System Lenses - TiX620

1

Minimum

Model Lens

IR 1/10 Wide angle 250 1.0/10 1.70 57.1 × 44.4

IR 1/20 LW Standard 500 1.0/20 0.85 32.7 × 24.0

IR 1/40 LW Telephoto lens 1300 1.0/40 0.43 15.5 × 11.6

Focal distance

(mm)

Focus

(mm)

IFOV (mrad) FOV (°)

640 x 480

1-9

Page 16

TiX620, TiX640, TiX660, TiX1000

Users Manual

Detector

The thermal imager is equipped with an uncooled

microbolometer FPA detector (uncooled Focal Plane

Array) with a resolution of (1024 x 768) or (640 x 480) IR

pixels. The individual elements of the detector are

microscopically small thin-film resistors on extremely thin

diaphragms arranged a few micrometers above the

silicon read-out circuit in an unsupported manner. The

lens of the thermography system reproduces the thermal

radiation from the scene onto these detector elements

and these detector elements absorb this radiation. The

temperature change of the detector elements results in

signals that can be analyzed electronically, read-out lineby-line and column-by-column using a read-out circuit.

Use of an uncooled detector ensures the quick availability

of the camera function at start-up (starting time

<30 seconds) and a long mean time to failure (MTTF) in

continuous operation.

Detector Electronics

Detector electronics supply the BIAS voltages and further

actuation signals required for detector operation to ensure

that the analog output signal of the detector is

preprocessed and digitalized.

Image Processing Electronics

With the help of an FPGA (Field Programmable Gate

Array) and up to two processors, real-time image

processing with the following essential functions

(depending on the equipment) is implemented:

• detector electronics interface

• gain and offset correction

• defect pixel treatment

• low-pass filtration

• zoom generator

• graphics overlay

• VIS/IR/graphics mixer

• GigE-Vision interface

• PC interfaces (Wi-Fi SD Card/USB2.0)

• video image interfaces (DVI-D, FBAS)

1-10

Page 17

Before You Start

Technical Description

1

Optomechanics

With the help of an optomechanic assembly, the following

functions are implemented:

• LaserSharp

• measuring range switch-over (apertures)

• internal NUC (Non Uniformity Correction) with shutter

Furthermore, this assembly optionally comprises a

module for hardware-based increase of the geometric

resolution of the thermography system to 2048 x 1536 IR

pixels (detector with 1024 x 768 pixels) and

1280 x 960 IR pixels (detector with 640 x 480 pixels) in

SuperResolution mode.

®

Auto Focus

Controls

The thermal imager is controlled by means of a focus

rocker switch with center function for autofocus, the

function buttons Automatic, Temperature,

Start/Stop/Save, and the multi-function buttons and

at the right top. On the backside of the camera, a power

button for right-thumb operation, a joystick

center function (Enter), and the button (Cancel) can be

found. The controls of the thermal imager are arranged

for single-hand operation with the right hand. Another

multi-function button can be found at the top of the

handle. When carrying the camera on its handle, it can be

operated using the thumb of your right hand.

with

Specific modes of camera operation and presettings can

be configured using menus. Chapter 2 contains a detailed

description of how to operate the thermography system,

as well as a detailed description of the menu structure.

Power Supply

Optionally, an external 15 V ac adapter (accessories) or a

rechargeable lithium-ion battery 7.2 V (accessories) can

be used to supply the thermal imager with power.

The ac adapter is connected to the 14-pin (right-hand

side) LEMO socket on the backside of the housing. The

rechargeable battery is inserted vertically into the

designated position on the backside of the thermography

system (see Chapter 3).

1-11

Page 18

TiX620, TiX640, TiX660, TiX1000

Users Manual

Interfaces

The Product is equipped with the following interfaces:

• drive for SD/SDHC card (behind the cover on the left

side of the camera, unfold the display)

• DVI-D (HDMI socket) behind the cover on the

backside of the camera, composite video (LEMO

14-pin)

• 2 x digital E/A for external trigger input/trigger output

(TTL level, LEMO 14-pin)

• 2 x analog output 0-5V (LEMO 14-pin)

• RS232 (LEMO 14-pin)

• GigE-Vision (LEMO 8-pin)

Simultaneously using several interfaces on the 14-pin

LEMO socket is allowed for by means of a breakout box.

The breakout box is also used for external power supply.

As an alternative to the digital high-resolution DVI-D

image data on the HDMI socket, the analog image data

(4:3 PAL/NTSC) is available as FBAS signal (composite)

on the 14-pin LEMO socket. The HDMI socket can be

used to connect screens processing a resolution of

1280 x 768 or 1280 x 800 in accordance with the VESA

standard.

In connection with the provided software, the GigE-Vision

interface allows for remotely controlling the thermography

system, as well as for transmitting digital image

information to a PC in real time.

Technical Data

Spectral range ................................ 7.5 μm to 14 μm

Temperature measurement range

TiX1000, TiX660 ......................... -40 °C to +1200 °C

(-40 °F to +2192 °F)

with high temperature option:

up to 2000 °C (3632 °F)

TiX640 ........................................ -40 °C to +1200 °C

(-40 °F to +2192 °F)

TiX620 ........................................ -40 °C to +600 °C

(-40 °F to +1112 °F

Measurement accuracy

TiX640, TiX660, TiX1000 ............ ±1.5 K or ±1.5 %

TiX620 ........................................ ±2.0 K or ±2 %

Image resolution (pixels)

TiX1000 ...................................... 1024 x 768

2048 x 1536 (SuperResolution)

TiX660 ........................................ 640 x 480

1280 x 960 (SuperResolution)

TiX640, TiX620 ........................... 640 x 480

1-12

Page 19

Before You Start

Technical Description

Frame rate (@ max. image resolution)

TiX1000 ...................................... 30 Hz

TiX660, TiX640, TiX620 ............. 60 Hz

Field of view (FOV) standard 30 mm lens

TiX1000 ...................................... 32.4° x 24.7°

TiX660, TiX640, TiX620 ............. 30.9° x 23.1°

Thermal sensitivity [NETD]

TiX1000 ...................................... ≤0.05 °C at 30 °C target

temperature (50 mK)

TiX660, TiX640 .......................... ≤0.03 °C at 30 °C target

temperature (30 mK)

TiX620 ........................................ ≤0.04 °C at 30 °C target

temperature (40 mK)

Digital zoom .................................... up to 32x

A/D conversion ............................... 16-bit

Power supply

External ...................................... 12 V dc to 24 V dc

Battery ........................................ Standard lithium-ion video

camera battery

Operating temperature

with external power .................... -25 °C to +55 °C

(-13 °F to +131 °F)

with battery power ...................... -25 °C to +40 °C

(-13 °F to +104 °F)

Storage temperature ....................... -40 °C to +70 °C

(-40 °F to +158 °F)

Operating altitude ............................ <2000 m

Humidity .......................................... relative humidity 10 % to

95 %, non-condensing

Shock .............................................. Operational: 25G, IEC 68-2-29

Vibration .......................................... Operational: 25G, IEC 68-2-6

Protection class ............................... IP54

Safety .............................................. meets IEC 60825-1: class 2

Electromagnetic Compatibility (EMC)

International ................................ IEC 61326-1: Portable

Korea. ......................................... Class A Equipment (Industrial

Broadcasting &

Communication Equipment)

Class A: Equipment meets requirements for industrial

electromagnetic wave equipment and the seller or user

should take notice of it. This equipment is intended for use

in business environments and not to be used in homes.

Dimensions with standard 30 mm lens

TiX1000, TiX660 ......................... 210 mm x 125 mm x 155 mm

(8.25 in x 4.9 in x 6.1 in)

TiX640, TiX620 ........................... 206 mm x 125 mm x 139 mm

(8.1 in x 4.9 in x 5.5 in)

1

1-13

Page 20

TiX620, TiX640, TiX660, TiX1000

Users Manual

Weight with standard 30 mm lens

TiX1000, TiX660 ......................... 1.95 kg (4.3 lb)

TiX640 ......................................... 1.4 kg (3.1 lb)

TiX620 ......................................... 1.5 kg (3.3 lb)

Display ............................................ Extra-large 5.6 in color TFT

Viewfinder

TiX1000, TiX660 ......................... Tilt-able LCoS color

TiX640, TiX620 ........................... none

Digital visible light camera .............. up to 8 Megapixel resolution

Image/video storage ....................... SDHC memory card

Interfaces

Supported in camera

data ports (image transfer) .......... SD card, USB 2.0, video

Supported in SmartView

®

software ...................................... SD card

display, 1280 x 800 pixel

resolution, Suitable for

daylight operation

viewfinder display, 800 x 600

pixel resolution

for image and video

recording

output DVI-D HDMI

(GigE vision, RS232

available in 2015)

(USB 2.0, GigE Vision,

RS232 available in 2015)

Features:

• Fluke Connect

• AutoBlend™ mode

• LaserSharp

®

compatible

®

Auto Focus (TiX660, TiX1000 only)

• Auto Focus

• Manual Focus

• EverSharp multifocal recording

• SuperResolution

• Dynamic SuperResolution

• Laser pointer

• Laser distance meter (TiX660, TiX1000 only)

• GPS

• Text and voice annotation

• Audio

• Replaceable Smart Batteries with LED level indicator (2

with TiX660, TiX1000; 1 with TiX640, TiX620)

• SmartView

®

software compatible

1-14

Page 21

Before You Start

Unpacking and Control

1

Unpacking and Control

When you receive your Product, check the components

for completeness and integrity. Possible damages must

be reported to the supplier immediately.

The Product is delivered in a transport box.

The basic package contains the following components:

• thermography camera with lens and 5.6” TFT display

• integrated digital color video camera

• depending on the equipment, Laser Distance

Meter/laser pointer, GPS

• rechargeable lithium-ion battery NP-QM91D (Sony)

(2 with TiX660, TiX1000; 1 with TiX640, TiX620)

• battery charger

• SDHC card

• card adapter for SD card

• protective lens cap

• shoulder strap

• Users Manual (go to www.fluke.com to download the

Users Manual for this Product)

• Safety Information

• transport box/transport packaging

• ac adapter

1-15

Page 22

TiX620, TiX640, TiX660, TiX1000

Users Manual

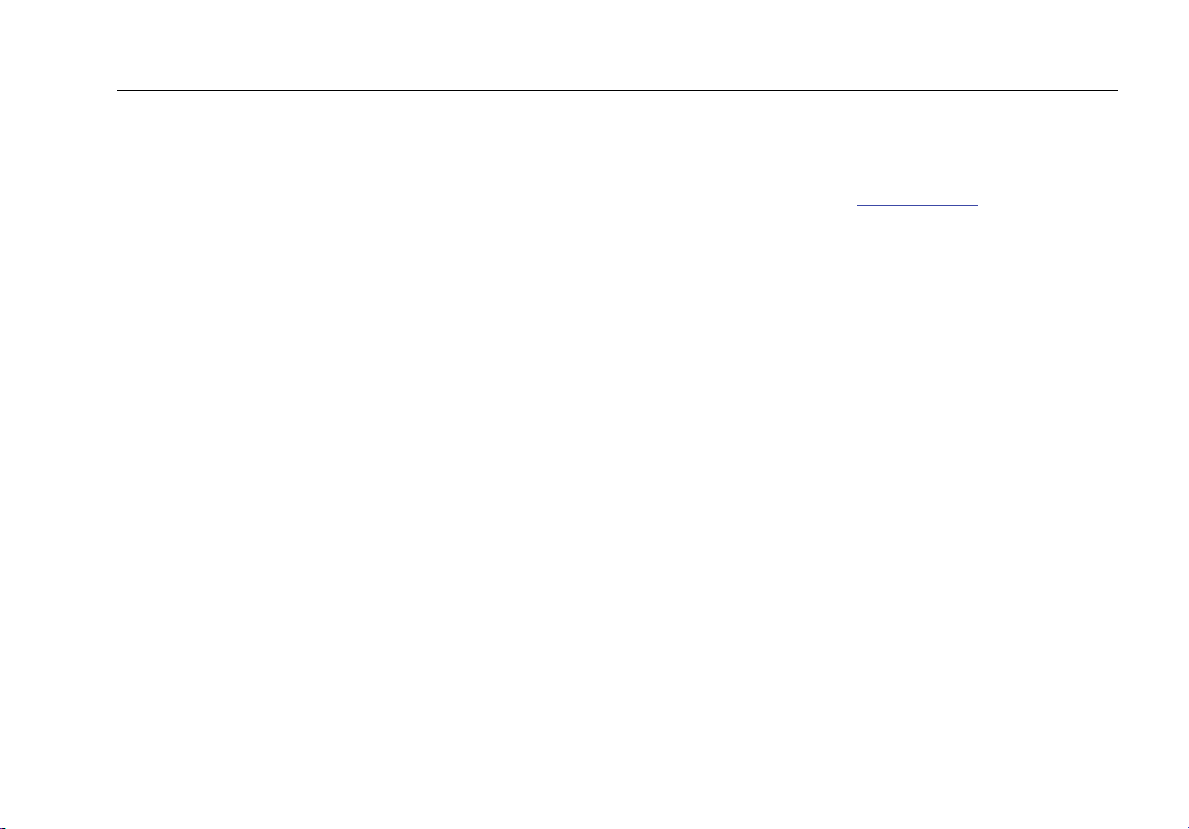

Parts of the Thermal Imager

See Table 1-4 and Table 1-5 for a general overview of the thermal imager components.

Table 1-4. Thermal Imager Components

1

L

MA

R

THE

IMAGER

0

64

TiX

7

Item Description Item Description

Multifunction button Connection for power supply, trigger, FBAS

Handle SD card slot

Color TFT viewfinder (TiX660, Tix1000 only) USB port

Lithium-ion battery DVI port

Connection for GigE-Vision, RS232

2

3

4

5

6

8 9

hvh013.eps

1-16

Page 23

Before You Start

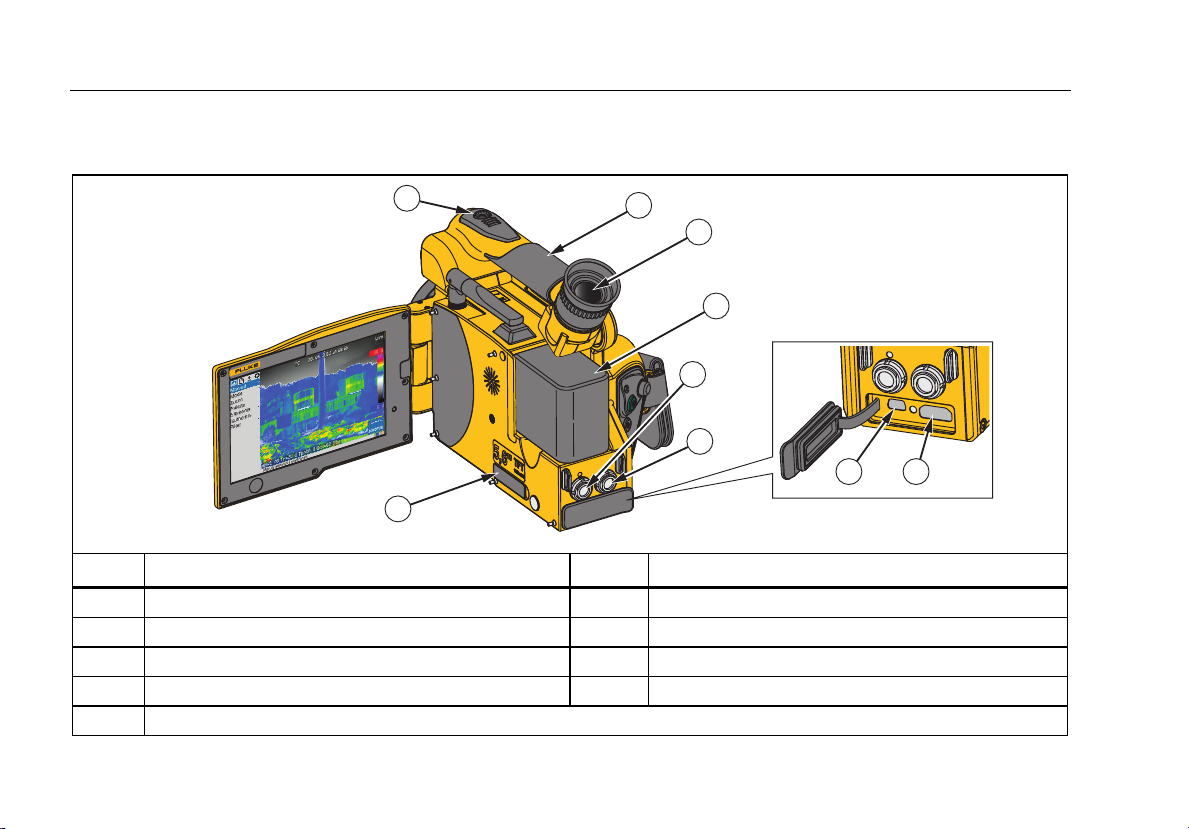

Table 1-5. Front View of Thermal Imager

1

3

1

4

5

Color Video Camera

Lens

Item Description

2

Laser Range Finder

LED Video Light

IMAGER

TiX640

THERMAL

hvh014.eps

Color TFT Display

1-17

Page 24

TiX620, TiX640, TiX660, TiX1000

Users Manual

Quick Guide

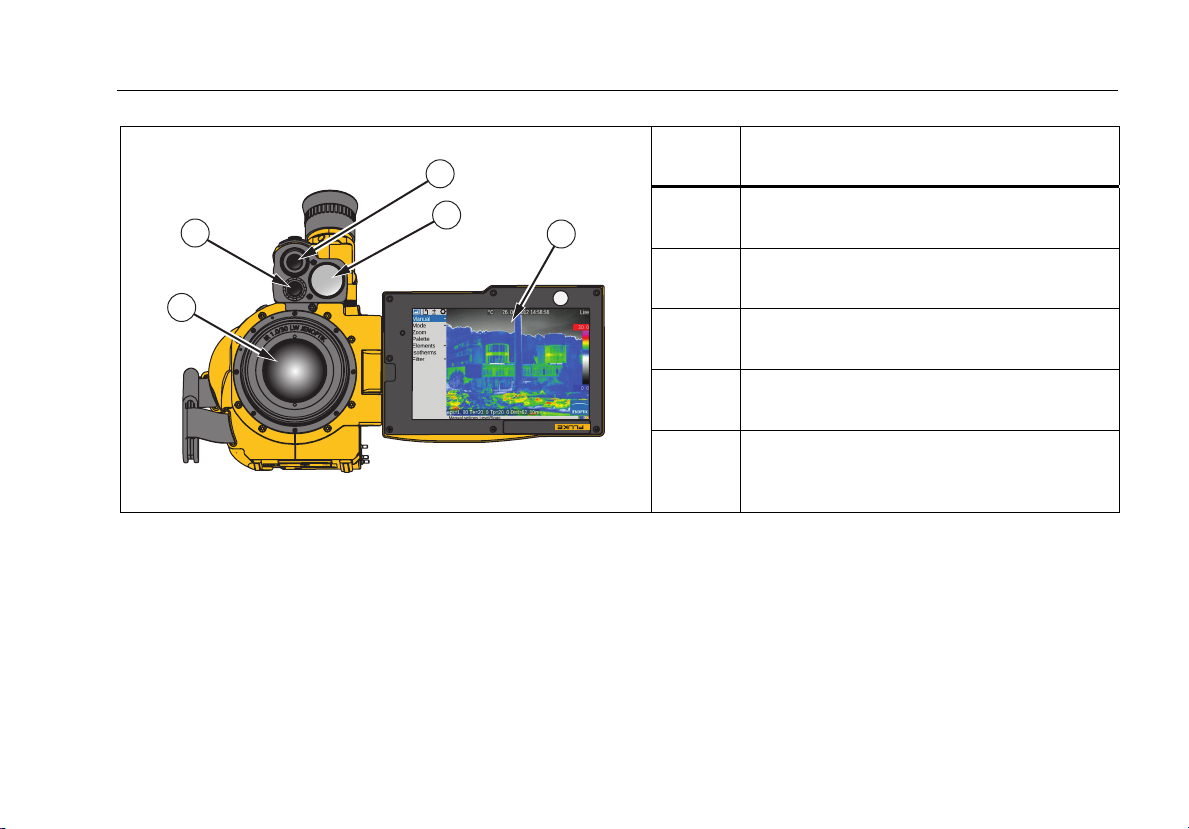

Table 1-6 shows the location of the controls on your

thermal imager. In order to achieve professional results,

we recommend thoroughly reading the entire manual.

Table 1-6. Control Locations

2

1

10

9

8

3

7

4

5

6

hvh015.eps

Item Description

Focus rocker switch with autofocus

Temperature

Auto

Multifunction 2

Multifunction 1

Save

Joystick

Power

Escape

Power LED

1-18

Page 25

Before You Start

Quick Guide

1

Note

All buttons can be used for multiple functions

triggered either by:

• half or full pressing: and and/or

• short or long press: , , , and .

The button function can be changed by changing

the settings in menu "Settings"

"Buttons".

Preparation

You will need the following equipment:

• thermal imager

• rechargeable lithium-ion battery or ac adapter with

LEMO connector

• SmartView

• SD card

• card reader for SD-/SDHC cards

®

software

Start

To get started:

1. Provide for power supply by inserting the charged

rechargeable lithium-ion battery or by connecting the

ac adapter to the thermal imager (plug the 14-pin

connector into the right LEMO socket with the red dot

pointing to the top).

2. Remove the cover of the SD card slot, insert the SD

card into the card slot, and replace the cover.

3. Remove the protective cap from the lens.

4. Push . The imager turns on and the Fluke logo

displays during the boot process. At system

initialization the power-on LED initially flashes green

and then illuminates as steady green to indicate that

the thermal imager is ready-to-operate in Live mode.

1-19

Page 26

TiX620, TiX640, TiX660, TiX1000

Users Manual

Display

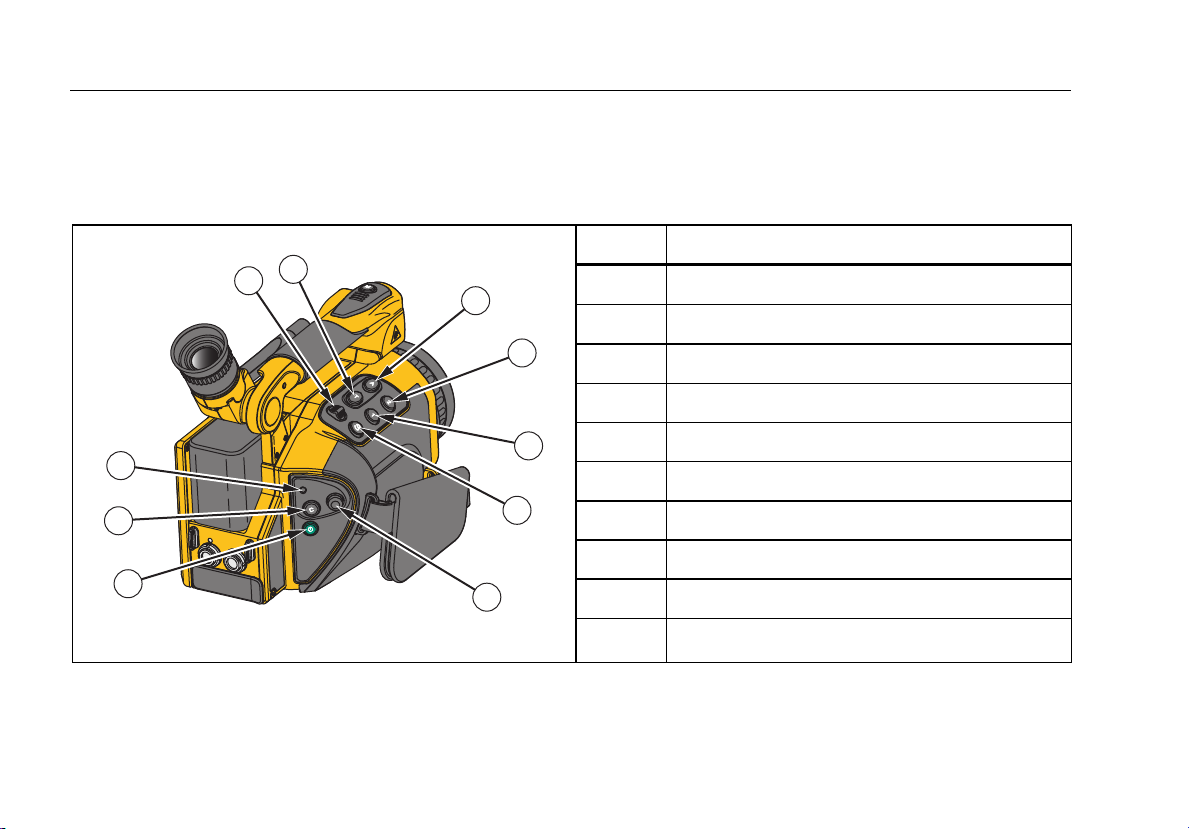

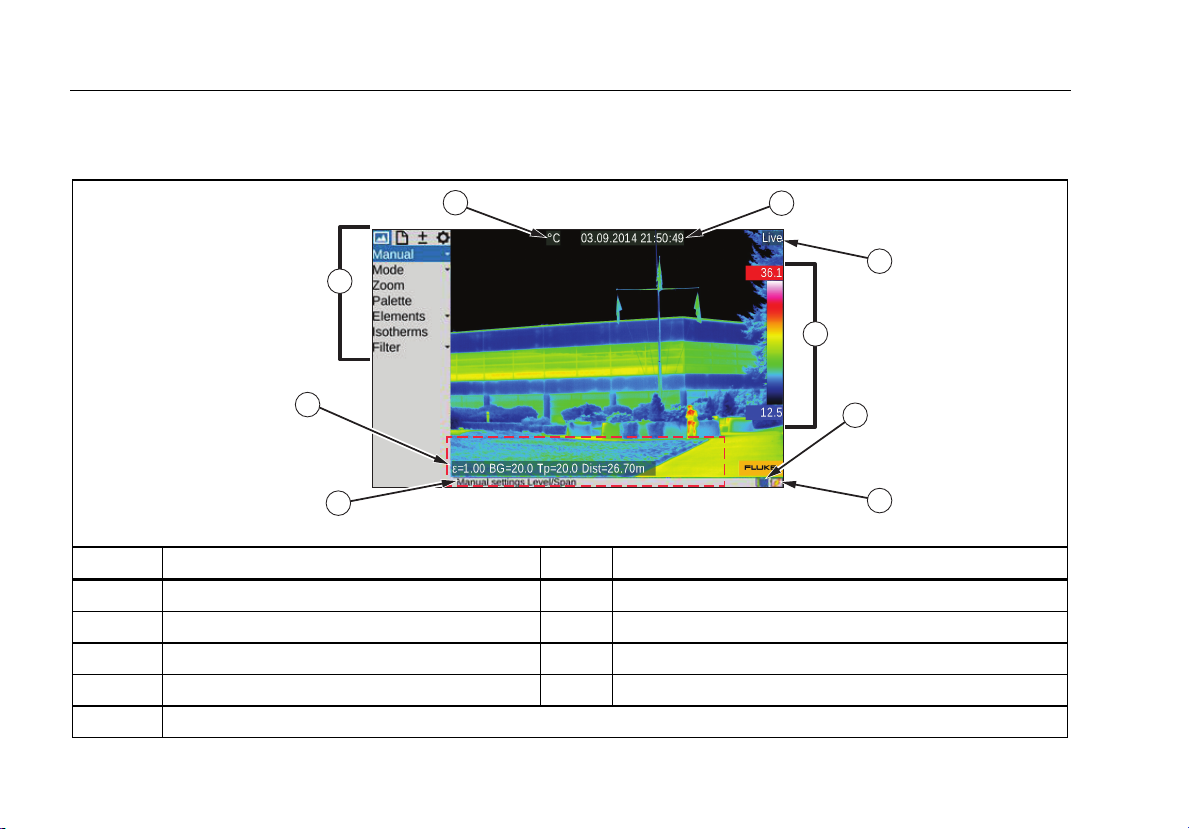

Table 1-7 shows the location of the display elements.

Table 1-7. Arrangement of the Image Elements

2

1

9

8

3

4

5

6

7

Item Description Item Description

Camera menu Rechargeable battery, SDHC card

Temperature unit Status indications

Date/time Help line

Camera status (mode) System information field

Color scale with upper and lower limits

1-20

hvh022.eps

Page 27

Before You Start

Quick Guide

1

Initially, you must view a scene that contains a thermal

contrast, for example, an active electrical device. Then

point the thermal imager at this scene.

To use the viewfinder, fold the display to the side of the

camera. This turns on the viewfinder. You must initially

adapt the viewfinder to your eye using the diopter

compensation. Rotate the eyecup on the viewfinder. To

find the ideal setting, use the sharpness of an edge in the

scene.

Setting the Focus

Push : middle button for autofocus or to the left or to

the right in order to set the focus for longer or shorter

distances to the measuring object. If the autofocus

function is used, a rectangle will be displayed in the

center of the screen. The distance setting is optimized

taking the distance of the objects contained in the

rectangle.

Setting the Temperature Range

Push with a short press. The thermography system

automatically sets a temperature scale of the false color

image corresponding to the current scene:

The required temperature scale can also be set by means

of the joystick

"Manual".

. For this, select Menu "Image"

1-21

Page 28

TiX620, TiX640, TiX660, TiX1000

Users Manual

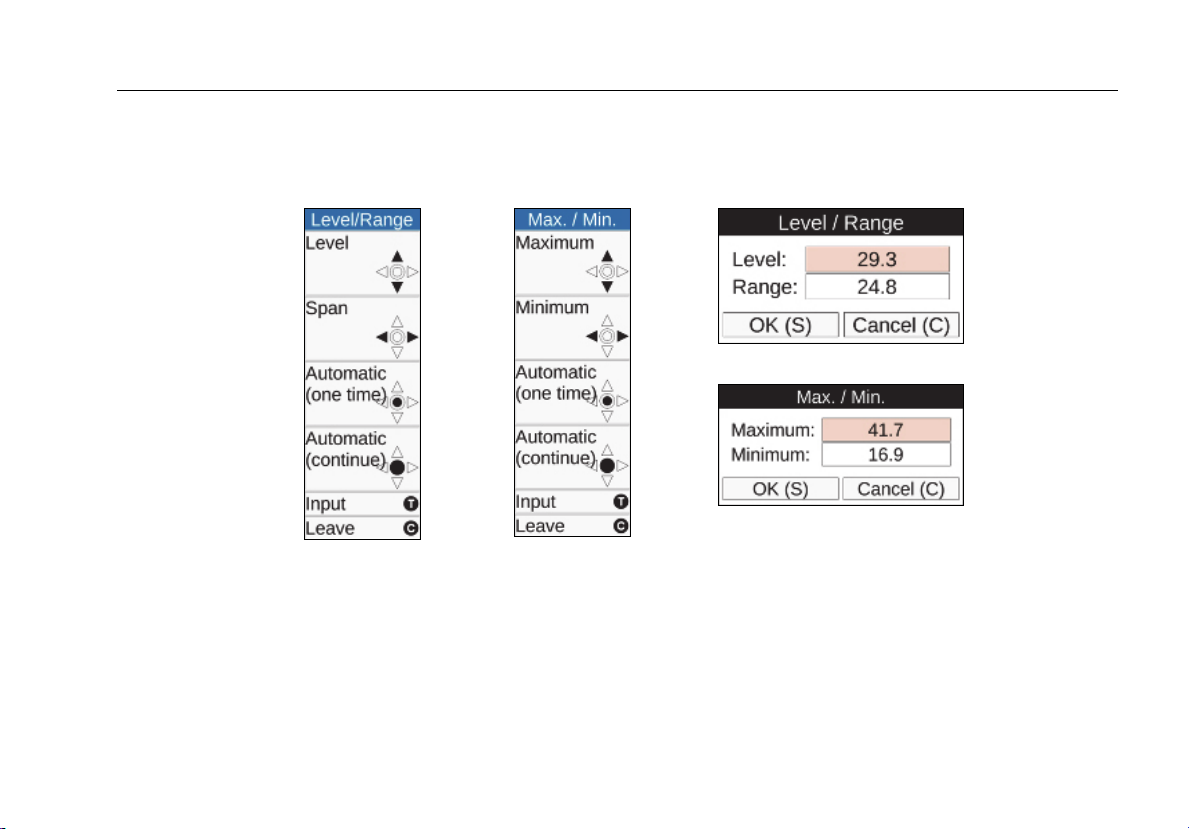

Depending on the selected input variant, the joystick

can be used in order to set the temperature level and the

temperature range (Level/Range) or the upper and lower

limits (Max/Min) and the values can be input numerically

hvh030.jpg

hvh031.jpg

as well. In this, the respective joystick and button

functions are displayed to the left of the thermal image.

The respective input dialog for numerical input is

displayed in the center of the field of view:

hvh032.jpg

1-22

Page 29

Before You Start

Quick Guide

1

If you manually set the options Level/Range and

Maximum/Minimum, you can set the temperature scale

one time, automatically, with a short push of Enter

Use a long push of Enter , to continuously change the

hvh033.jpg

.

hvh034.jpg

temperature scale automatically (AUTO mode). In AUTO

mode, shows on the right side of the image above

the color palette. The AUTO mode is terminated by any

manual setting of Level/Range/Max/Min.

hvh036.jpg

hvh035.jpg

1-23

Page 30

TiX620, TiX640, TiX660, TiX1000

Users Manual

Saving Images

In order to save the thermal image, the button is

required. The following variants are possible:

Saving with "Check"

1. Push the button halfway down.

The live image is frozen:

• The frozen image can initially be "checked" on

the display or viewfinder.

• If the image is not to be saved, push the

button: .

2. Push the button completely.

The image is saved.

The process of writing the data is indicated by the

changing color of the map symbol (in the line below the

image, right-hand side):

camera control automatically activates the Live mode:

.

.

. When saving, the

Quick Saving

Immediately push the button completely. The image is

saved immediately: , the camera control then

automatically re-activates the Live mode: .

Note

Deviating from the factory setting described

above, the button can be used to trigger

further functions such as shutter activation,

autofocus, VIS-LED, Laser Distance Meter/laser

pointer before saving the image.

1-24

Page 31

Before You Start

Quick Guide

1

Menu Functions

The thermal imager offers a large number of analysis and

automatic functions and can be configured individually for

the respective use case. The settings and functions are

selected in the camera menu, which is arranged at the

left-hand side of the image area.

Use the joystick

and select the functions using the Enter button.

The four main menus can be selected by means of tabs

located on the upper margin of the menu and identified

with the corresponding symbols:

Image Menu

File Menu

Measure Menu

Settings Menu

(↑, ↓, ←, →) to navigate the menu

Sub-menus can be opened by using the button (Enter)

on the respective menu item, for example, push the

button in order to open the sub-menu for

manually setting the temperature range.

Settings made can be accepted using the buttons Enter

or or discarded using the button.

Shut-Down

Use to open the shut-down dialog, and or

(Enter) to confirm the selection.

1-25

Page 32

TiX620, TiX640, TiX660, TiX1000

Users Manual

Data Transmission to the Computer

Use the SmartView® software to enable the transmission

of data via the GigE Vision communications protocol.

Another data transmission method is to read out the

SDHC card by means of a card reader.

Set-Up

Hand Strap

The thermal imager is designed as highly portable system

for single-hand operation. Initially, adjust the hand strap

attached to the handle piece as required. For this, open

the loop of the hand strap and adjust the length of the belt

strap in such a way that you can comfortably access the

controls with your fingers. Then, close the hook and loop

fastener of the loop.

Tripod

The thermography camera is equipped with a 4.5 mm

(1/4") tripod thread (DIN 4503) on the bottom of the

housing. To achieve rigid camera images, particularly for

the SuperResolution mode, Fluke recommends that you

attach the thermal imager to a tripod.

Caution

Do not exceed the maximum penetration

depth of the tripod thread: 4.5 mm (DIN

4503).

Power Supply

When using a rechargeable battery, you must place the

battery on the included adapter plate. Push down the

rechargeable battery until it engages. Push the

rechargeable battery slightly to the front, towards the

lens. Please only use the genuine SONY® rechargeable

batteries NP-QM91D and the included charger.

The ac adapter is connected to the 14-pin socket on the

right-hand side of the backside of the thermography

system.

Memory Card

The SD card slot is located on the left-hand side of the

camera. In order to guarantee the degree of protection

IP54, the slot is protected by a cover. Pull off the cover to

insert a memory card and insert the SD card into the card

slot. Please observe the proper orientation of the card (▲

to the top). Afterwards, the cover must be re-closed. This

is the only way to ensure the complete degree of

protection of the device.

1-26

Page 33

Before You Start

Set-Up

1

Lens Replacement

Only replace the lenses in dry and low-dust conditions.

When the lens is removed, the degree of protection

of the system is no longer guaranteed!

Position the thermal imager on a solid, level plane so that

the lens is pointed towards you. Rotate the lens on the

thermography system counterclockwise as far as it will go

and/or until the two red dots are aligned. Then, remove

the lens to the front.

In order to attach the lens, the red marking spots on lens

and camera must be aligned. In this position, the lens

must be pressed slightly against the camera corpus and

turned clockwise until the red dot of the lens is aligned

with the white dot of the camera.

IP 54

Operation using the Gigabit Ethernet (GigE) Interface

Please proceed as follows in order to connect the thermal

imager to a PC/notebook. The accessories described are

contained in the scope of delivery as an option.

• The Ethernet cable is used in order to establish a

connection to the Ethernet interface of the PC (RJ45

connector).

• The 8-pin LEMO connector (blue mark) is connected

to the left 8-pin LEMO socket (Figure 1-2, blue mark)

on the camera.

Caution

Make sure you establish the connection to

the correct LEMO socket. Plug the LEMO

connector into the socket with the red dot

directed to the top. Do not force the

connector in.

1-27

Page 34

TiX620, TiX640, TiX660, TiX1000

Users Manual

Ethernet Cable and AC Adapter

The Ethernet cable is used in order to connect the

thermography camera to the 8-pin LEMO socket (lefthand side, blue mark).

The 14-pin connector of the ac adapter is plugged into the

right-hand side LEMO socket with the red mark pointing

to the top. See Figure 1-2.

Ethernet

AC Adapter

hvh057.eps

Figure 1-2. Ethernet Cable and AC Adapter

AC Adapter Connection

To operate while permanently connected to a notebook or

PC, the power should be supplied using the ac adapter

(see Figure 1-3) with the 14-pin LEMO connector on

right-hand side socket.

hvh058.eps

Figure 1-3. AC Adapter

When the ac adapter is connected, the camera is

automatically supplied by the ac adapter and no longer by

the rechargeable battery. However, the rechargeable

battery is not charged at the same time.

Operation with Breakout Box

Using the breakout box will expand the connection

options of the thermal imager, see Table 1-8. The

interfaces 2 x analog output, 2 x trigger E/A, PAL/NTSCFBAS, as well as the digital RS232 interface are

accessible via the breakout box.

1-28

Page 35

Before You Start

Set-Up

1

Caution

Follow the specified steps on how to

establish the required connections.

1. Connect the thermography camera to the breakout

box. For this, the 14-pin connecting cable of the

breakout box must be used. It is connected to the

right-hand side 14-pin LEMO socket on the backside

of the thermal imager.

Table 1-8. Breakout Box

2

1

6 5 4

3

hvh061.eps

2. Connect the breakout box to the COM interface of

the host computer with a commercially available

cable.

3. Connect the supplied ac adapter to the breakout box.

4. Push the Power button on the backside of the

camera to turn on the thermography system.

Item Description

Connecting cable for thermal imager

14-pin LEMO socket for ac adapter

Terminal strip

Trigger T1, T2 (configurable)

BNC video port (PAL/NTSC-FBAS)

Serial interface (RS232)

1-29

Page 36

TiX620, TiX640, TiX660, TiX1000

Users Manual

1-30

Page 37

Chapter 2

Elements of the User Interface

Introduction

The thermal imager has these controls (see Table 2-1):

• keyboard on the right top camera side (focus rocker

switch , buttons , , , as well as and )

• keyboard on the right of the backside (ESC button

and power button )

• multi-function joystick

right of the backside

• multi-function button on the top of the front

camera handle

with Enter function on the

Note

All buttons can be used for multiple functions

triggered either by:

• half or full pressing: and and/or

• short or long pressing: , , and .

The functions of the buttons , , , and can be

changed by setting the buttons (see Chapter 3, Menus).

Furthermore, the function of the buttons depends on the

current mode of operation and, depending on the

aforementioned, is displayed in the menu and the help

line at the lower margin of the screen.

2-1

Page 38

TiX620, TiX640, TiX660, TiX1000

Users Manual

2

1

Table 2-1. Control Locations

Item Description

3

Focus rocker switch with autofocus

Temperature

4

Auto

Multifunction 2

2-2

10

5

Multifunction 1

Save

9

6

Joystick

Power

8

7

hvh015.eps

Escape

Power LED

Page 39

Elements of the User Interface

Button Functions

Button Functions

The functions are assigned (factory defaults) to the

function buttons in such a way that functions required

frequently can be executed quickly:

Table 2-2. Shortcuts

Button Type Function Explanation

2

short Auto Mode (Span) Automatic adaptation temperature scale

long NUC Non-uniformity correction (compensation)

long

short Spot ON/OFF If no AOI was created yet create spot 1

long Spot editor AOI settings

short Laser ON/OFF Mark and laser distance meter

long Max/Min ON/OFF Global max/min measurement On/Off

short IR Visual Light Image Switch-over image mode

long Color SW For manually setting Max/Min

halfway LED ON/OFF Photo lamp

complete FREEZE Subsequent image saving possible using

Menu

Level/Range

For manually setting Level/Range

2-3

Page 40

TiX620, TiX640, TiX660, TiX1000

Users Manual

The function of the save button when saving images is

defined in the Saving Format Submenu (see Chapter 3,

Menus).

The save button

accept inputs in many menus. This function shortens the

navigation and is activated by the factory, but can also be

deactivated (see Chapter 3, Menus).

The multi-function joystick

and to select functions, to input using the arrow buttons ↑,

↓, ←, →, as well as the function (Enter, push the

center).

The focus rocker switch can be used in order to

manually focus the infrared image:

← change the focus to longer distance push left

→ change the focus to shorter distance push right

or to focus automatically:

center function of the focus rocker switch.

can be used in order to immediately

can be used to navigate

The Power button is used to turn on the thermal

imager. Initially, the status LED on the left-hand side

above the button will start to flash green and the logo

of the camera manufacturer is displayed on the camera

display. Upon successful system initialization, the status

LED will be illuminated permanently green: the thermal

imager is now ready to operate. The system start takes

about 30 seconds.

hvh066.jpg

Use the power button to turn off the thermal imager.

2-4

Page 41

Elements of the User Interface

Image Elements

2

Image Elements

The image elements have the following functions:

Table 2-3. Image Elements

Image Element Location Function

Image Central display area Display of the current thermal image, visual light image or of a

superimposition of both images, display of saved images

Menu Left from screen area Adjustment of the camera functions

Help Lower screen area, left Display of the current function

Logo Lower right corner of the

screen

Date, time Screen center, upper edge of

screen

Camera status Upper right corner of the

screen

Temperature scale Right edge of the screen Assignment of the colors/shades of gray of the image to the

Measured values table Left screen area Display of temperature values

Manufacturer's logo

Date and system time

Current mode of operation

temperature range shown

2-5

Page 42

TiX620, TiX640, TiX660, TiX1000

Users Manual

Table 2-3. Image Elements (cont.)

Image Element Location Function

Status symbols Lower screen area, right Status indicators for:

• power supply (ac adapter/status rechargeable battery)

• SDHC card

• laser distance meter/laser pointer

• photo LED

GPS reception

Information Screen area bottom left

st

1

line

nd

line and 3rd line

2

2-6

Information indicators for

• GPS data: latitude, longitude, satellites

• (global) emissivity

• ambient temperature

• path temperature

• relative humidity

• distance

• calibration range

• lens information

• zoom

eps

Te

Tp

rH

Dist

Cal

FOV

z

Page 43

Elements of the User Interface

Setting the Temperature Scale

2

In addition to the current temperature scene in false color

representation, different image elements are used in

order to show information about the camera status and

operation. The displayed image elements can be

changed and adapted with the individual requirements in

the "Image" menu using the "Elements" menu item (see

Chapter 3, Menus).

Along with the (normally always displayed) main image

elements, further system messages are displayed

depending on the current function, providing information

about the system status and intended to facilitate

operation, for example, autofocus, temperature indicators

for isotherms, temperature alarm indicators, messages

regarding critical status of the rechargeable battery, and

"Please wait…".

The thermal imager can be operated both by the control

directly attached to the camera and, depending on the

equipment, remotely using GigE or RS232.

Setting the Temperature Scale

At system start (pushing the power button ), the

camera is in Live mode. This mode is shown on the righthand side at the top of the screen: . In Live mode, the

current scene is shown as a false color representation of

the temperature distribution (IR image), as a video image

(visible, visible light image), or as a superimposition of IR

and visible light image (IR Fusion

temperature scale of the false color representation of the

IR image can be set automatically or manually.

To automatically adapt the temperature scale to the

current scene, push the button. Factory setting for

button sets the scale to the highest (= upper limit) and

lowest temperature (= lower limit) of the current scene. If

the temperature scale was set before the focus was

changed, then reset the temperature scale.

Observe the calibration range limit of the currently used

measuring range. If the temperature of the current scene

is outside of the set range, an appropriate calibration

range must be selected (see Chapter 3, Menus).

The manual setting options for the ideal adjustment of the

temperature scale are described in detail in Chapter 3,

Menus.

®

technology). The

Focus

Carefully setting the focus is important to achieve a

precise temperature measurement with the thermography

system.

2-7

Page 44

TiX620, TiX640, TiX660, TiX1000

Users Manual

Use the focus rocker switch to:

• Manual focus

o push the left side of the focus rocker switch in

order to change the focus to longer distances

and/or

o push the right side of the focus rocker switch in

order to change the focus to shorter distances.

• Auto focus

o push the center function of the focus rocker

switch.

Note

The zoom setting can be used to manually focus

for measurements of small objects.

It is not necessary to change the visible light image focus.

LaserSharp® Auto Focus

To setup:

1. Go to Laser menu and select LaserSharp Auto

Focus.

2. Push the center function of the focus rocker switch.

Warning

To prevent eye damage and personal injury:

• Do not look into the laser. Do not point

laser directly at persons or animals or

indirectly off reflective surfaces.

• Use caution when the laser is on

continuously. Turn off the laser when it

is not in use.

Permanent LaserSharp® Auto Focus

Go to the Laser menu and select LaserSharp Auto

Focus.

Laser will continuously display and will automatically

focus when the distance to target changes.

EverSharp Multifocal Recording

1. Go to the “Extras submenu” in the “Settings Menu”.

2. Select “EverSharp” within this menu

Once selected, the camera takes all images in the

EverSharp mode.

Note

You can see images taken with EverSharp in

SmartView

®

software.

2-8

Page 45

Elements of the User Interface

Spot Editor

2

Spot Editor

By pushing the button, a temperature measuring point

is created in the center of the image. Pushing the

button with the spot turned on will turn off the measuring

point.

The spot editor can be started by pushing the button

for a long period of time. The editor can be used to define

measuring objects with different shapes and properties

(Areas of Interest, AOIs), as well as to set the way the

measuring objects are displayed. After having defined the

AOIs, these regions and their measured values can be

activated and deactivated using the button. The

particular description of the spot editor's function can be

found in Measurement Definitions menu starting in

Chapter 3, Menus.

Saving

Thermography images and photographic pictures are

saved to the SC card inserted into the camera. The

thermal imager supports commercially available SD

and/or SDHC cards up to a capacity of 32GB. Depending

on the detector format and the set memory format, up to

25,000 IR images can be saved to one SDHC card this

way. Along with individual IR image, thermal image

sequences can be saved as digital raw data and video

sequences. The particular description of the camera

settings for data storage can be found in Chapter 3,

Menus.

Depending on the equipment, the thermography and

video data can be transmitted using the GigE interface so

that transmitted data can also be stored on the used

control units.

Before saving to the SD card, check that the SD card

inserted into the camera has sufficient memory space

available. The free memory space can be displayed in

menu "Settings" "System" "Info" (see System

Submenu in Chapter 3, Menus. A writable memory card is

indicated by means of a blue card symbol

right area of the field of view. A non-writable or read-only

memory card is indicated by means of a grayed-out card

symbol

.

in the lower

2-9

Page 46

TiX620, TiX640, TiX660, TiX1000

Users Manual

Saving with Check

To check the image to be recorded before saving it, the

Live mode should be stopped:

1. Push the button halfway down.

The live image is frozen:

• The frozen image can initially be "checked" on

the display or viewfinder.

• If the image is not to be saved, push the

button: .

2. Push the button completely.

The image is saved.

The process of writing the data is indicated by the

changing color of the map symbol (in the line below the

image, right-hand side):

camera control automatically activates the Live mode:

.

.

. When saving, the

Quick Saving

Using the thermal imager, you can immediately save

images in the Live mode or directly from the motion:

• Immediately push the button completely. The

image is saved immediately: , the

camera control then automatically re-activates

the Live mode: .

Note

Deviating from the factory setting described in

Table 2-3, the button can be used to trigger

further functions such as shutter activation,

autofocus, visible light image-LED, laser

distance meter/laser pointer before saving the

image.

2-10

Page 47

Chapter 3

Display Menus

Introduction

The main menu is designed to select and set the different

functions of the thermal imager. It is arranged to the left of

the image section.

hvh079.jpg

hvh078.jpg

The menu can be navigated using the joystick

settings are accepted using the joystick center button

(Enter). The four main menus are located on the upper

margin of the menu and can be selected by means of the

corresponding symbols of the tabs:

hvh080.jpg

hvh081.jpg

,

Page 48

TiX620, TiX640, TiX660, TiX1000

Users Manual

Within the menus, the joystick is used to navigate to

the top ↑ and/or to be bottom ↓. The main menus can be

switched using the buttons ← and →. Depending on the

settings for "Menu control" made in the "Settings" menu in

the "System" menu item at the "Menu control" function

(see System Menu on page 3-46), the lower menu in

each case can be accessed directly by pushing ↑ from the

very top and/or the upper menu in each case can be

accessed directly by pushing ↓ from the very bottom

and/or "Image" can be selected directly by → from

"Settings" and/or vice versa by ←.

Submenus can be opened by pushing the Enter button

on the respective menu item, for example,

to open the submenu for manual

temperature range setting. Changes performed to setting

dialogs can be accepted using the joystick Enter button or

or can be discarded using .

Image Submenu

The Image menu constitutes a summary of the settings

relevant for the representation of the thermal image.

hvh083.jpg

3-2

Page 49

Display Menus

Image Submenu

3

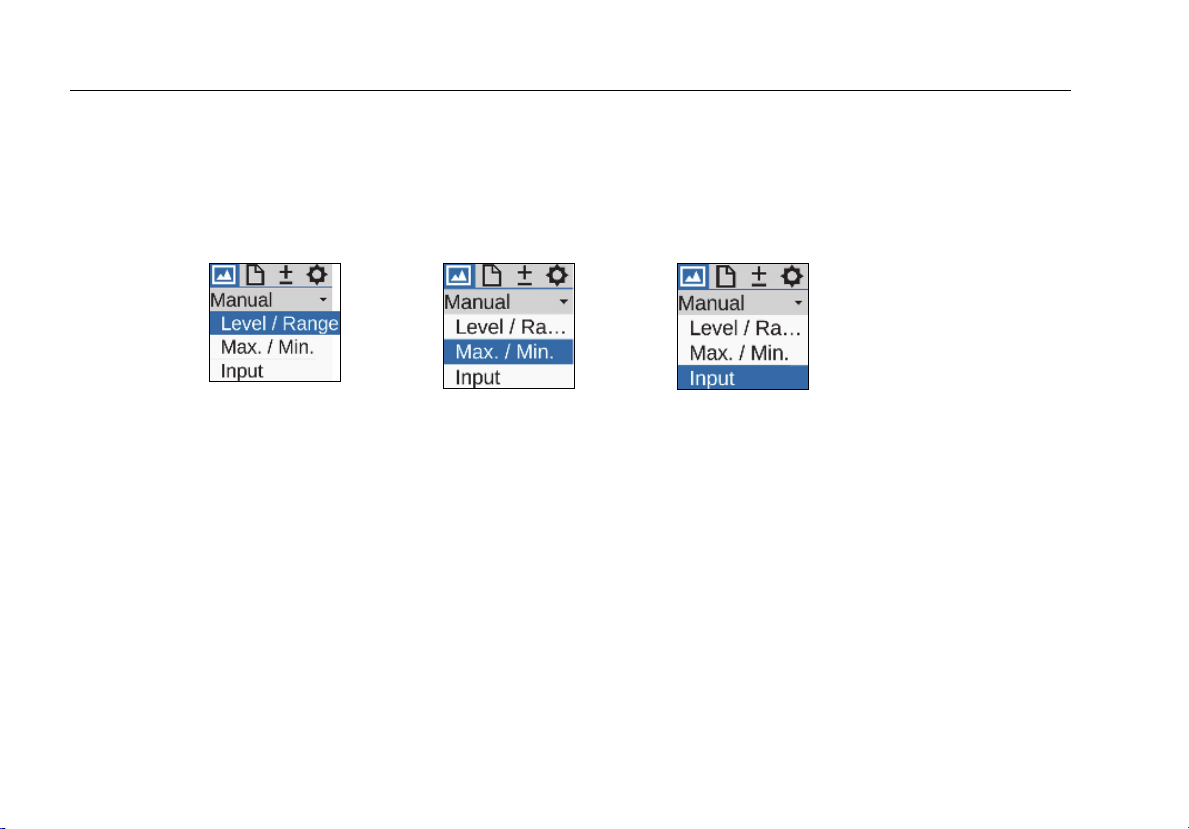

Manual Submenu

The option of manually setting the temperature scale is a

central function of each thermography camera. Therefore,

this function is arranged in a quickly accessible menu in

the left top area of the main menu of the thermal imager.

Set the temperature scale to allow for a visual allocation

of temperatures to the displayed scene by means of the

false color representation of the thermal image. Maximum

and minimum values of the currently set temperature

range are indicated by the corresponding figures above

and below the arranged color palette.

hvh084.jpg

Different modes can be selected for manually setting the

temperature range in the "Manual" menu item:

• Level/Range

• Max./Min.

• Input

hvh085.jpg

hvh086.jpg

3-3

Page 50

TiX620, TiX640, TiX660, TiX1000

Users Manual

Depending on the selected input variant, the joystick

can be used in order to set the temperature level and the

temperature range (Level/Range) or the upper and lower

limits (Max/Min) and the values can be input numerically

hvh087.jpg hvh088.jpg

as well. In this, the respective joystick and button

functions are displayed to the left of the thermal image.

The respective input dialog for numerical input is

displayed in the center of the field of view:

hvh089.jpg

hvh090.jpg

3-4

Page 51

Display Menus

Image Submenu

3

Along with the option of manually setting the temperature

scale, the temperature scale can be set once by pushing

the joystick Enter button shortly, or permanently active, by

pushing the joystick Enter button longer. The permanent

setting of the temperature range, known as Auto Mode

(Span), is indicated by in the right top corner of the

screen. The Auto Mode (Span) is deactivated by any

manual change to the temperature scale or non-recurrent

triggering of the Auto Mode (Span) function.

Note

The setting menus Level/Range and

Maximum/Minimum can be accessed directly by

the button functions Long and Long, as set

from the factory.

hvh093.jpg

hvh092.jpg

Mode Submenu

In Live mode, the thermal imager displays thermal images

(infrared images), video images (Digital images), or the

superimposition of both (IR Fusion

options can be selected in the "Mode" menu, which must

be dropped down for this. If an infrared image is currently

displayed, you can switch to Digital image or IR Fusion

From the Digital image mode you can switch to infrared

image or IR Fusion

®

. From the IR Fusion® mode you can

switch to infrared image or Digital image. The different

representation variants in the IR Fusion

set after the submenu dropped down.

hvh094.jpg

®

technology). The

®

mode can be

hvh095.jpg

®

.

3-5

Page 52

TiX620, TiX640, TiX660, TiX1000

Users Manual

Infrared Image Mode

In the Infrared Image mode, the thermal image is shown

in false color representation. Depending on the

equipment, the live image displays (1024 x 768) or

(640 x 480) IR pixels with the digital zoom switched off.

While saving, the geometric resolution can be increased

to (2048 x 1536) and/or (1280 x 960) IR pixels by means

of the optomechanic MicroScan functions,

SuperResolution and Dynamic SuperResolution. These

modes must be activated in the "Settings" menu using the

"Extras" menu item.

hvh096.jpg

hvh097.jpg hvh098.jpg hvh099.jpg

Digital image mode

In the Digital image mode, the camera-internal digital

photo channel is operated in video mode and displayed

with a geometric resolution of (1024 x 720) pixels. The

option of saving photos with the available pixel resolution

of (3264 x 2448) pixels (8 megapixels) is set in the "File"

menu using the "Saving format" menu item (see Saving

Format Submenu on page 3-23).

IR Fusion® Technology

In the IR Fusion® mode, 4 different modes can be

selected. To select these options, the IR Fusion

®

submenu must be dropped down:

3-6

Page 53

Display Menus

Image Submenu

3

IR Fusion® with Autoblend® Technology

(Picture-in-Picture)

In the Picture-in-Picture mode, a part of the infrared

image is superimposed over the digital image, regardless

of the temperature of the current scene. The size and the

position of the displayed infrared section can be changed

by using the joystick

wider using → and narrower using ←. The joystick Enter

button can be used to toggle between the options Resize

and Move. The merged image section can be moved to

the top ↑, to the bottom ↓, to the right → and to the left ←

In the IR Fusion

temperatures of the current scene are displayed in the

selected partial area in accordance with the set

temperature scale. Blending refers to the surface area. In

the color alarm, high alarm, and low alarm modes, the

displayed temperature range can be restricted: blending

depends on the temperature in the entire infrared image.

: higher using ↑, lower using ↓,

®

with Autoblend® Technology mode, all

Color Alarm

In the Color Alarm mode, a (partial) temperature interval

is defined within the set temperature range. Partial areas,

the temperatures of which are within this interval, are

displayed as an infrared image in false color

representation. Partial areas, the temperatures of which

are outside of this interval, are displayed as a digital

image (visible light image).

Upper and lower limits of the superimposed temperature

range are displayed to the left of the palette on top and at

the bottom and can be changed by using the joystick

↑ increase the temperature level of the IR Fusion

interval

↓ decrease the temperature level of the IR Fusion®

interval

→ increase the temperature interval

← decrease the temperature interval

:

®

3-7

Page 54

TiX620, TiX640, TiX660, TiX1000

Users Manual

High Alarm, Low Alarm

Just as in Interval, a (partial) temperature interval is

defined in the High Alarm and Low Alarm modes, not only

the upper and/or lower limits are defined for the partial

areas at this point. For the Above option, all areas above,

and for the Below option, all areas below the adjustable

temperature limit are displayed. The upper limit for the

Above option corresponds to the upper limit of the set

total range. The lower limit for the Below option

corresponds to the lower limit of the total range.

Continual Blend

In all IR Fusion

®

modes, the transparency of the continual

blend area can be selected. The degree of continual

blend (Alpha blending) can be set in the "Blending"

submenu in an infinitely variable manner.

hvh107.jpg

Zoom Submenu

Depending on the equipment, the thermal imager

supports digital magnification of the infrared image and

the Digital image (visible light image) up to 32-fold. The

setting is made in the "Setting" menu using the "Zoom"

menu item and is applicable to the currently displayed

image in each case (infrared image or visible light image).

A set magnification is indicated as the corresponding

status symbol to the right below the image. If the

image was enlarged digitally, the enlarged section of the

image (initially located in the center of the image) can be

moved. By shortly pushing the joystick Enter button, you

can toggle between the options enlargement (zoom) and

Move. The function active in each case is indicated by

blackened joystick symbols in the upper part of the menu.

The zoom level and the position of the enlarged section of

the image are indicated in the left bottom area of the total

image. After the enlarged section of the image has been

moved from the center of the image, the joystick Enter

button must be pushed longer to center the section of the

image.

3-8

hvh106.jpg

Page 55

Display Menus

Image Submenu

Palette Submenu

The current allocation of the individual colors/shades of

gray of the false color representation to the corresponding

temperatures is performed by using the palette shown on

the right-hand side margin of the screen. In this, the

maximum value of the image area above and its minimum

value below the palette serve the purpose of orientation

for the temperature level.

The "Image" "Palette" menu item is used to open a

dialog for selecting and setting predefined palettes, see

Table 3-1.

3

hvh110.jpg hvh111.jpg

Regardless of any set digital magnification of the infrared

or visible light images, the total image is always saved

when saving digital raw data in the irb format.

hvh112.jpg

hvh113.jpg

3-9

Page 56

TiX620, TiX640, TiX660, TiX1000

Users Manual

Table 3-1. Palettes

Rainbow

Grayscale palette (left) and

inverted representation (right)

Grayscale

3-10

Ironbow

Blue Red

Marked

High

Contrast

Palette containing 256 colors

(left) and 16 colors (right)

Steps

Black Red

Hot Metal

Menthol

Sepia

Grayscale/

Grayscale/Rainbow palette with

temperature-linear (left) and Ultra

Rainbow

Contrast representation

Page 57

Display Menus

Image Submenu

3

The "Inverse" function can be used to invert the current

palette. For example, if the grayscale palette is set, the

low temperatures are indicated in darker colors when

compared to the higher temperatures by default. If the

"Inverse" function is activated for the grayscale palette,

the representation is inverted: The low temperatures are

now indicated in lighter colors and the higher

temperatures are now indicated in darker colors.

The "16 steps" function can be used to set the

representation of the palette from 256 color steps to 16

steps. Accordingly, only 16 temperature levels can be

indicated instead of 256, which is why differentiations

exceeding the 16 steps are no longer displayed on the

screen. Therefore, the scene is "summarized" to 16

"classes" of the same temperature levels.

The "Logarithmic" function can be used to toggle the

representation of the temperature values between a linear

and a logarithmic curve. By default, a linear curve is

selected to represent the temperatures. By activating this

function, it is possible to use a more differentiated

resolution for the low temperature range when compared

to the high temperature range. The effects of the