Page 1

High resolution

infrared inspection for

oil and gas applications

Unscheduled downtime can cost millions. Professionals who

work in the oil and gas industry know it is critical to maintain

stable, continuous operations without sacrificing safety. They

also know that regular maintenance, quick diagnosis of potential

problems, and clear documentation are key to keeping produc-

tion going smoothly and meeting regulatory requirements.

A multipurpose monitoring

and troubleshooting tool for

oil and gas applications

Infrared cameras offer the versatility, accuracy, and usability

to address a wide variety of

inspection and troubleshooting

activities in the oil and gas

industry. Whether used onshore

or offshore, upstream or downstream, infrared cameras allow

you to capture two-dimensional

representations of the apparent

surface temperatures of a wide

variety of equipment and processes. You can collect heat

signatures for process equipment,

as well as for leaks in pipes and

tanks, without touching those

surfaces and without interfering

with the process. The images and

measurements from that inspection can help you quickly identify

problems at an early stage.

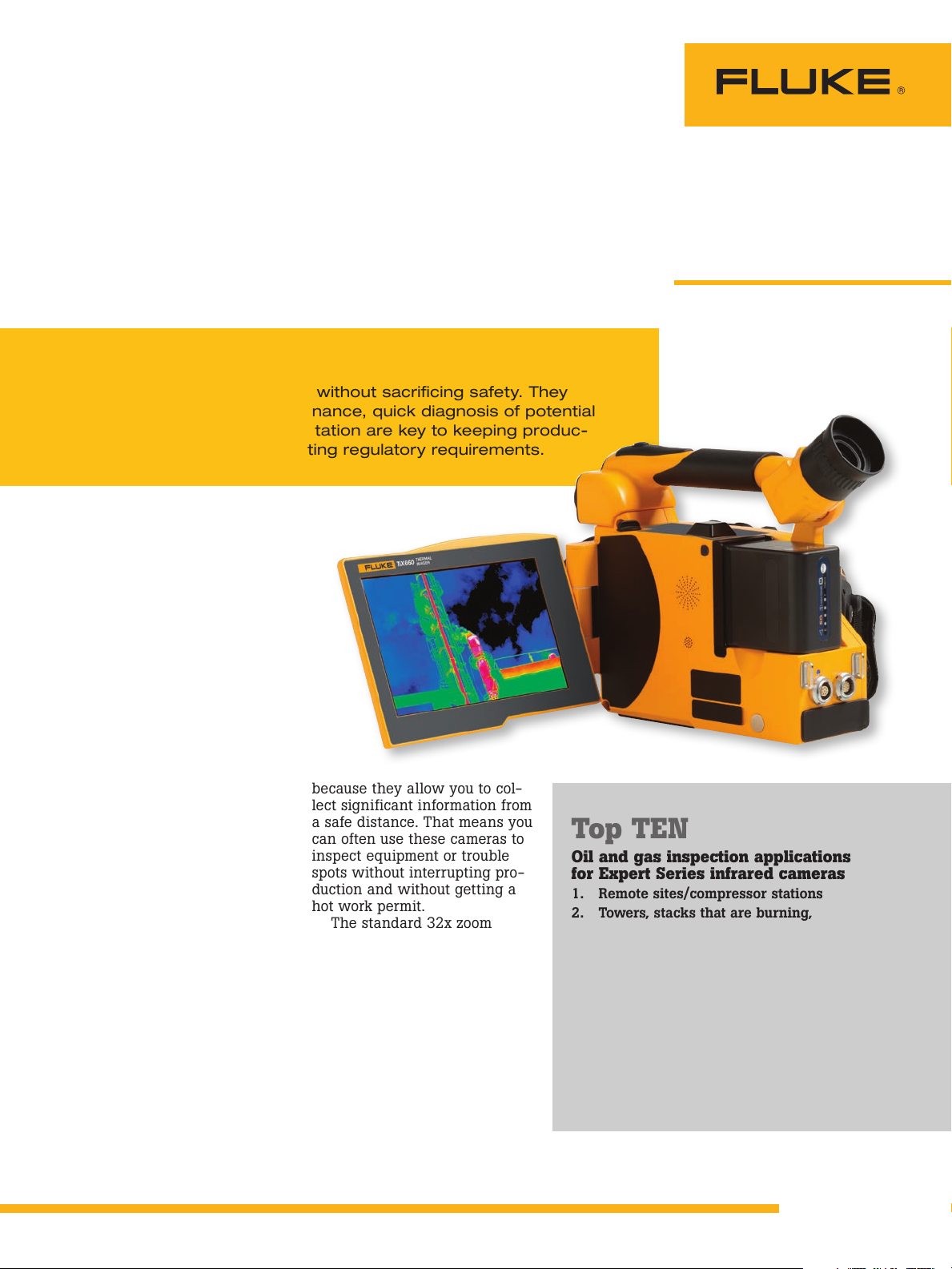

However, not all thermal

imagers are created equal. The

new Fluke TiX1000, TiX660 and

TiX640 infrared cameras—part of

the Fluke Expert Series line—are

ideal for oil and gas applications

because they allow you to col-

lect significant information from

a safe distance. That means you

can often use these cameras to

inspect equipment or trouble

spots without interrupting pro-

duction and without getting a

hot work permit.

The standard 32x zoom

and optional telephoto lenses

on these Fluke Expert Series

infrared cameras are powerful

enough to produce high resolution images of targets over 100

feet away with a crisp level of

detail so you can quickly pinpoint temperature anomalies.

Top TEN

Oil and gas inspection applications

for Expert Series infrared cameras

1. Remote sites/compressor stations

2. Towers, stacks that are burning,

3. Steam traps, leaks, cat cracker degradation

4. Horizontal flares on offshore rigs

5. Top drives

6. Tank level

7. Electrical systems

8. Equipment monitoring

9. Motors and drives

10. Bearings

Application Note

and air scrubbers

From the Fluke Digital Library @ www.fluke.com/library

Page 2

Expedite inspection and

troubleshooting

Oil and gas production environments can be extremely

challenging. The hazardous

nature of the products, the hot,

moist, dusty and corrosive conditions, and less than optimal

lighting, drive inspectors to

complete their tasks quickly and

leave the area. You need to have

confidence that the infrared

camera you’re using can identify

potential problems at an early

stage, because you don’t want

to have to make a second trip, or

deal with the fallout of imprecise

imaging.

That’s why the new Fluke

Expert Series infrared cameras with their high resolution

imaging, long distance accuracy,

thermal sensitivity, advanced

focus systems, flexible viewing

options, and other innovative

features are so well suited to

this environment. They let you

work from a safe distance and

still get ultra-high resolution

images that provide detailed

temperature information.

Because they deliver this performance at such a long distance,

they save a lot of climbing and

allow you to inspect areas you

wouldn’t be able to get close

enough to see otherwise without

shutting down production.

Here are just some of the

inspection areas where these

cameras can save you time,

energy, and downtime:

Gain inspection accuracy, versatility, and speed with the

new Fluke Expert Series infrared cameras

• More diagnostic informa-

tion. The more detail you can

see in an infrared image, the

more information you have

to work with. These Fluke

Expert Series infrared cameras give you both detail and

information.

• Super high resolution

images. Get four times the

standard mode resolution

and pixels (up to 3.1 million

pixels on the TiX1000 and up

to 1.2 million pixels with the

TiX660) with Super Resolution

mode for crisp images that

deliver maximum detail.

• Large 5.6 inch rotatable

LCD display lets you more

easily inspect over, under, and

around difficult-to-navigate

equipment.

2 Fluke Corporation High resolution thermal imaging for oil and gas applications

• A tiltable LCoS color view-

finder display with 800 x

600 pixel resolution provides

great visibility in daylight

applications.

• Advanced focus systems

offer a choice of manual, auto

focus and LaserSharp

Focus and EverSharp multifocal recording features,

for quick, accurate, in-focus

image capture.

• Maximum lens flexibility

with field replaceable optional

lenses (2x and 4x telephoto

lenses and two wide-angle

lenses gives you the ability to capture high-resolution

images close up or at a distance, eliminating the need in

many cases to climb a tower

or stack.

®

Auto

• Gray scale and full color

imaging serve a variety of

applications.

• Video capture with voice

and text annotations makes

it easier to document trouble

points.

• Fluke Connect™ wireless

compatibility allows inspec-

tors to send images and

measurements to smartphones

and iPads with the Fluke

Connect

®

mobile app for team

collaboration*.

• Handheld versatility and the

included neck strap make it

easy to carry if you do have to

climb a ladder.

*Within providers wireless service area.

Page 3

Evaluate corrosion or str uctural integ rity of

storage tanks.

Easily inspect stacks and flares from the

ground.

Monitor ing of large electrical inf rastructures that support oil and gas facilit ies.

• Remote sites/compressor

stations. These remote sites

are linked to regional operational centers via freeway

and cellular towers that constantly transmit data on their

operating conditions. Rather

than having to climb 180feet towers to check for loose

connections and other weak

links, technicians can use the

32x zoom on these TiX Series

infrared cameras or a telephoto or super telephoto lens

to examine these areas from

the ground, quickly, safely,

and accurately.

• Towers, stacks that are

burning or steaming, and

air scrubbers can be easily

scanned from the ground to

evaluate their performance.

• Steam traps, leaks in

hard-to-reach areas such

as cement kilns, or degradation of fluid catalytic

crackers “cat crackers”.

You can point these infrared

cameras at a hard-to-reach

targets and swivel the large

5.6 inch articulating LCD display into a position where you

can see the image.

• Horizontal flare inspection

on an offshore rig. With the

high resolution and zooming

capabilities at long distances,

you can inspect an offshore

flare either from the rig or

from a helicopter. The high

frame-refresh capabilities,

helps you spot sudden rapid

temperature changes, that

might indicate that the flare

is about to burn out.

• Top drive inspection.

Rather than have to climb up

an oil drilling rig, you can

inspect the top drive from the

ground using the 32x zoom

capability. The tiltable color

viewfinder provides a clear

view of the image even in

sunlight.

• Tank level inspection. Using

a wide angle lens with the

high definition capabilities of

the Fluke TiX1000 infrared

camera, you can quickly scan

tank levels from a distance.

Offloading or onloading fuel.

You can use these Expert

Series cameras at a distance

to scan the pipes.

In addition to long distance

exterior inspections, you can use

these Fluke TiX series infrared

cameras to troubleshoot the

standard equipment in a refinery

from a safe distance so you may

not have to secure a hot work

permit or get closer to high

voltage.

• Inspecting electrical sys-

tems. These infrared cameras

help pinpoint potential problems with loose and corroded

connections, electrical imbalance, failing transformers

and switchgear and faults in

motor control centers. You can

clearly view the image in less

than optimal light conditions

on the large 5.6-inch backlit

display.

• Monitoring. Helps identify

problems in refractory-lined

equipment, heaters, boilers,

furnaces, heat exchangers,

steam lines and traps, process and safety valves, steam

turbines, process lines and

mechanical rotating equipment—both in the plant and

in the field.

• Checking motors and

drives. You can use these

Fluke TiX infrared cameras

for regular inspections to:

– See if the motors and asso-

ciated panels and controls

are operating too hot

– Track down specific failed

components

– Check for phase imbal-

ance, bad connections, and

abnormal heating on the

electrical supply

• Inspecting bearings.

Capture two-dimensional

high resolution infrared

images of bearing and housing temperatures, to compare

current operating temperatures to benchmarks and

detect potential failures in

time to prevent them.

3 Fluke Corporation High resolution thermal imaging for oil and gas applications

Page 4

Multiply your resources with

Fluke Connect® wireless capabilities

With the Fluke Connect mobile app you can

transmit images and measurements from Fluke

Expert Series infrared cameras in real-time to

any smart phone that has the Fluke Connect

mobile app. That makes it easy to share results

with team members because everybody on the

ShareLive

and measurements remotely that you’re seeing on

site. That can help you get questions answered or

get approvals on the spot and expedite repairs.

from your smart phone to EquipmentLog

in secure Fluke Cloud

all authorized users. In that way you can compare

real time measurements to baseline data to identify problems and make better decisions faster.

™ video call can see the same images

You can also save images and measurements

™

storage for easy access by

™* history

See what you’re missing

The common requirements for all of

these applications are clear image resolution, temperature detail and accuracy,

speed, and flexibility to get images in

areas that may be hard to reach. Those

are the very capabilities that set these

Fluke infrared cameras apart.

To find out more about how these

versatile, high resolution, high accuracy cameras can help you keep your

production processes moving smoothly,

consult your Fluke sales representative

or visit www.fluke.com/TiX1000 for

more information.

You can also use SmartView

®

software

included with all Fluke infrared cameras to

document your findings in a report that includes

thermal images, visible light images, and blended

images to communicate problems you find and to

suggest repairs.

Fluke Connect™ is not available in all countries.

*Within providers wireless service area.

4 Fluke Corporation High resolution thermal imaging for oil and gas applications

Fluke. Keeping your world

up and running.

Fluke Corporation

PO Box 9090, Everett, WA 98206 U.S. A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0)40 267 5100 or

Fax +31 (0)40 267 5222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

© 2014 Fluke Corporation. All trademarks are t he prop erty of their respective owners. Smart phone, wi reles s

serv ice and data plan not included with purch ase. F irst

5 GB of storage is free. Compatible wit h iPhone 4x and

up run ning iOS 7 or higher, iPad (in an i Phone f rame

on iPad) a nd Galaxy S 4, Nexus 5, HT C One running

Andr oid™ 4.4. x or higher. Apple and the Apple logo

are tr ademarks of Apple Inc. r egistered in the U. S. and

other countries. App Store is a ser vice mark of Apple

Inc. Google Play is a trademark of Google Inc.

Specifi cations su bjec t to change wit hout notice.

Printed in U. S.A . 11/2014 6003832b-en

Modificat ion of th is doc ument is not permit ted

without written permission f rom Flu ke Corporation.

®

Loading...

Loading...