Page 1

T3

®

Tester

Calibration Manual

PN 1599206

February 2001

© 2001 Fluke Corporation, All rights reserved. Printed in USA

All product names are trademarks of their r espective comp ani es.

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and

service. The warranty period is one year and begins on the date of shipment. Parts, product repairs, and

services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of

a Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in

Fluke’s opinion, has been misused, altered, neglected, contaminated, or damaged by accident or abnormal

conditions of operation or handling. Fluke warrants that software will operate substantially in accordance

with its functional specifications for 90 days and that it has been properly recorded on non-defective media.

Fluke does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers

only but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is

available only if product is purchased through a Fluke authorized sales outlet or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for importation costs of

repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke’s warranty obligation is limited, at Fluke’s option, to refund of the purchase price, free of charge repair,

or replacement of a defective product which is returned to a Fluke authorized service center within the

warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that service center, with a description of the difficulty,

postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following

warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination, alteration, accident, or abnormal

condition of operation or handling, including overvoltage failures caused by use outside the product’s

specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair

costs and obtain authorization before commencing the work. Following repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or

limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not

apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court or other

decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any other

provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

Page 3

Table of Contents

Title Page

Introduction........................................................................................................ 1

Definition Symbols Used in this Manual........................................................... 1

Safety Information............................................................................................. 2

Parts and Service................................................................................................ 3

Specifications..................................................................................................... 3

Cleaning the Tester............................................................................................ 4

Required Equipment.......................................................................................... 4

Performance Tests.............................................................................................. 4

Testing the Voltage Function........................................................................ 4

Continuity Function Tests............................................................................. 5

Calibration Adjustment...................................................................................... 5

Battery Replacement.......................................................................................... 7

Parts and Accessories......................................................................................... 8

i

Page 4

T3

Calibration Manual

ii

Page 5

List of Tables

Table Title Page

1. Symbols .................................................................................................................. 1

2. DC and AC Voltage Tests...................................................................................... 4

3. Replacement Parts and Accessories....................................................................... 8

List of Figures

Figure Title Page

1. Calibration Adjustment Point................................................................................. 6

2. Replacing the Batteries........................................................................................... 7

iii

Page 6

T3

Calibration Manual

iv

Page 7

T3

Introduction

This calibration information sheet provides the following information for the T3 Tester (hereafter

referred to as "the tester"):

• Safety information

• Parts and service information

• Specifications

• Cleaning procedure

• Required equipment

• Performance tests

• Calibration adjustment

• Battery replacement procedure

• Parts and accessories list

For operating instructions, refer to the T3 Tester Instruction Sheet.

Definition Symbols Used in this Manual

Table 1. Symbols

B

F

W

J

N10140

AC (alternating current)

DC (direct current)

Important information

On light

Earth ground Underwriters Laboratories

Conforms to CSA C22.2 No 1010-1-92 + Amendment 2 1997

Conforms to relevant Australian standards

X

T

P

R

Hazardous Voltage

Double insulated

Conforms to European Union

Directives

Beeper

Certification

1

Page 8

T3

Calibration Manual

Safety Information

Warning

To avoid possible electric shock or personal injury, follow these

guidelines:

• Do not use the tester if it is damaged. Before you use the

tester, inspect the case. Look for cracks or missing plastic.

Pay particular attention to the insulation surrounding the

connectors.

• Inspect the test leads for damaged insulation or exposed

metal. Check the test leads for continuity. Replace damaged

test leads before you use the tester.

• Do not use the tester if it operates abnormally. Protection

may be impaired. When in doubt, have the tester serviced.

• Do not operate the tester around explosive gas, vapor, or

dust.

• Do not apply more than the rated voltage, as marked on the

tester, between terminals or between any terminal and earth

ground.

• Before use, verify the tester’s operation by measuring a

known voltage.

• When servicing the tester, use only specified replacement

parts.

• If the auto-on light does not come on when the test leads are

shorted together, do not use the tester.

• Use caution when working above 30 V ac rms, 42 V peak, or

60 V dc. Such voltages pose a shock hazard.

• When using the probes, keep your fingers behind the finger

guards on the probes.

• Connect the common test lead before you connect the live

test lead. When you disconnect test leads, disconnect the

live test lead first.

• Do not operate the tester with the battery door or portions of

the cover removed or loosened.

• Before each use, perform the Battery Test to avoid false

readings due to a low battery. Replace the batteries as soon

as the tester fails the Battery Test.

2

Page 9

Parts and Serv ice

The tester is warranted to be free from defects in material and workmanship for 1 year, while

under normal use. Parts and repairs are warranted for 90 days. For the complete warranty

statement, refer to the T3 Tester Instruction Sheet.

To order parts, or for warranty service, contact Fluke as follows:

USA: 1-888-99-FLUKE (1-888-993-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-678-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

Or, visit Fluke’s Web site at www.fluke.com.

Specifications

Display Accuracy The LED for each range turns on by 95 % of the nominal range value.

Tester

Parts and Service

Maximum Voltage

Between any Terminal

and Earth Ground

Input Impedance ~750 kΩ

Temperature Operating: -10 °C to +50 °C (14 °F to 122 °F) Storage: -30 °C to +60 °C

Altitude Operating: 3000 m (9843 ft); Storage: 10,000 m (32808 ft)

Relative Humidity 0 °C to 30 °C (32 °F to 86 °F): 90 %; 30 °C to 40 °C (86 °F to 104 °F): 75 %;

Battery Type and Life AA (2); 250 hours with NEDA 15F or IEC R6

Shock, Vibration 1 m drop at 15 °C to 35 °C (59 °F to 95 °F). Sinusoidal vibration per MIL-

Environmental Seal IP 52 per IEC 529, no vacuum applied

Safety This tester complies with IEC 1010-1 to 1000V OVERVOLTAGE Category III,

1000 V dc; 1000 V ac rms (sine wave), Overvoltage Category III; Tester

meets requirements for CAT IV 600 V, allowing use on outdoor/direct burial

wiring or utility-side measurements.

(-22 °F to +140 °F)

40 °C to 50 °C

(104 °F to 122 °F): 45 %

PRF-28800F for a Class 2 instrument (5 Hz to 55 Hz, 3 g maximum)

Pollution Degree 2, and with IEC 664-1 to 600 V OVERVOLTAGE Category

IV, Pollution Degree 2.*

*OVERVOLTAGE (Installation) Categories refer to the level of Impulse

Withstand Voltage protection provided at the specified Pollution Degree.

Equipment of OVERVOLTAGE CATEGORY III is equipment in fixed

installations. Examples include switchgear and polyphase motors.

Equipment of OVERVOLTAGE CATEGORY IV is for use at the origin of the

installation. Examples include electricity meter and primary over-current

protection equipment.

EMC Regulations EN61326

Certifications

, , Listed 950Z N10140, VDE (Pending),

3

Page 10

T3

Calibration Manual

Cleaning the Tester

If the tester requires cleaning, wipe it down with a cloth that is lightly dampened with water or a

mild detergent. Do not use aromatic hydrocarbons, chlorinated solvents, or methanol-based fluids

when wiping down the tester.

Required Equipment

The following equipment is required for performance tests and calibration adjustments:

Warning

To avoid electrical shock or damage to the tester, never allow

water inside the case. To avoid damaging the tester’s case,

never use solvents on the tester.

• Fluke 5500A Multi-Product Calibrator, or equivalent (DC voltage range: 0 to ±1020 V,

AC voltage range: 1 mV to 1020V 10 Hz to 500 kHz, sine)

• Small, insulated, Phillips screwdriver

• Fluke 87 Digital Multimeter (maximum DC voltage = 1000 V ± (0.05%+1), maximum

AC voltage= 1000 V ±(0.7%+2) )

Performance Tests

Use the following procedures to verify the tester’s performance.

Testing the Voltage Function

If the tester fails the voltage test, perform the calibration adjustment described under "Calibration

Adjustment"; then retest all of the voltage functions. If the tester continues to fail, return it to

Fluke for service.

Test the voltage function as follows:

1. Set the calibrator to 199 V dc. Apply this voltage to the tester to verify that the 220 V dc

range LED is on.

2. Apply 190 V dc to the tester. Verify that the tester’s 220 V dc range LED is off.

3. Apply each nominal voltage and frequency as listed in Table 2. Verify that each

corresponding LED turns on.

Table 2. DC and AC Voltage Tests

DC Voltages for All

Models

-6 V dc

(verify that -VDC LED is on)

12 V dc 48 V ac 24 V ac 48 V ac

24 V dc 120 V ac 48 V ac 120 V ac

36 V dc 208 V ac 110 V ac 208 V ac

48 V dc 240 V ac 230 V ac 240 V ac

110 V dc 277 V ac 400 V ac 347 V ac

220 V dc 480 V ac 690 V ac 600 V ac

AC Voltages for

Model T3US (60 Hz)

24 V ac 12 V ac 24 V ac

AC Voltages for Models

T3WF/T3WR (50 Hz)

AC Voltages for Model

T3CAN (60 Hz)

4

Page 11

Calibration Adjustment

Continuity Function Tests

The following tests verify correct operation of the continuity beeper and LED.

1. Set the calibrator to 20 kΩ. Apply the 20 kΩ to the tester and verify that the tester’s beeper

and continuity LED are ON.

2. Set the calibrator to 200 kΩ. Apply the 200 kΩ to the tester and verify that the tester’s beeper

and continuity LED are OFF.

Calibration Adjustment

If the tester fails a voltage test, perform the following calibration adjustment.

1. Verify that the tester’s batteries are good: replace the batterie s if touch ing the leads to geth er

does not turn on the continuity LED.

2. Remove the tester’s battery door and batteries.

3. Remove the two screws that hold the tester’s case together.

4. Remove the top case.

5. Place the tester’s batteries in the battery compartment. Temporarily install the battery door to

hold the batteries in place during calibration.

Tester

WWarning

It is not necessary to remove the two screws that hold the circuit board

in the bottom case; however, if the screws are removed for any reason,

they must be secured with Loctite™ or equivalent when reinstalled to

prevent them from coming loose.

6. Turn the tester on by touching the test leads together.

7. Using a calibrated meter, measure the voltage across the voltage divider with the positive lead

near R4 and the negative lead at the other end of the divider. Refer to Figure 1.

8. Adjust R4 until the voltage across the divider is as follows:

• T3USA = 605 - 615 mV

• T3CAN = 759 - 765 mV

• T3W = 873 - 883 mV

9. Secure R4 with Loctite or equivalent.

10. Reassemble the tester; then perform the voltage test s as given under "Tes ti ng the Vol tag e

Functions".

5

Page 12

T3

Calibration Manual

87

TRUE RMS MULTIMETER

MIN MAX RANGE HOLD

PEAK MIN MAX

41/2 DIGITS

1 Second

mV

V

V

OFF

mA µA

A COM

400mA MAX

FUSED

10A MAX

FUSED

!

LS1

R26

Q5

CR2

R19

R20

R17

Q6

R27

H

HzREL

mA

A

µA

V

!

CAT II

1000V MAX

+

R23

Q4

+

C10

DS8DS9

DS10

DS7

R22

Q3

R21

Q1

Q2

R25

R12

DS0 DS1

R10

C6

C7

R14

DS2

C3

C1

+

+

R8

DS3 DS4

R18

+

U4

R6 R13

DS5 DS6

C8

C9C2

+

U3R4

R15

R6 R13

R11

C11

DS3

DS4

R15

U3R4

R16

DS5 DS6

R7

R11

R7

C11

R16

+

C5

C12

C4

R1

R9

50-1406A

Lo

Hi

akm1f.eps

Figure 1. Calibration Adjustment Point

6

Page 13

Battery Replacement

Battery Replacement

Replace the batteries when touching the leads together no longer turns on the continuity LED.

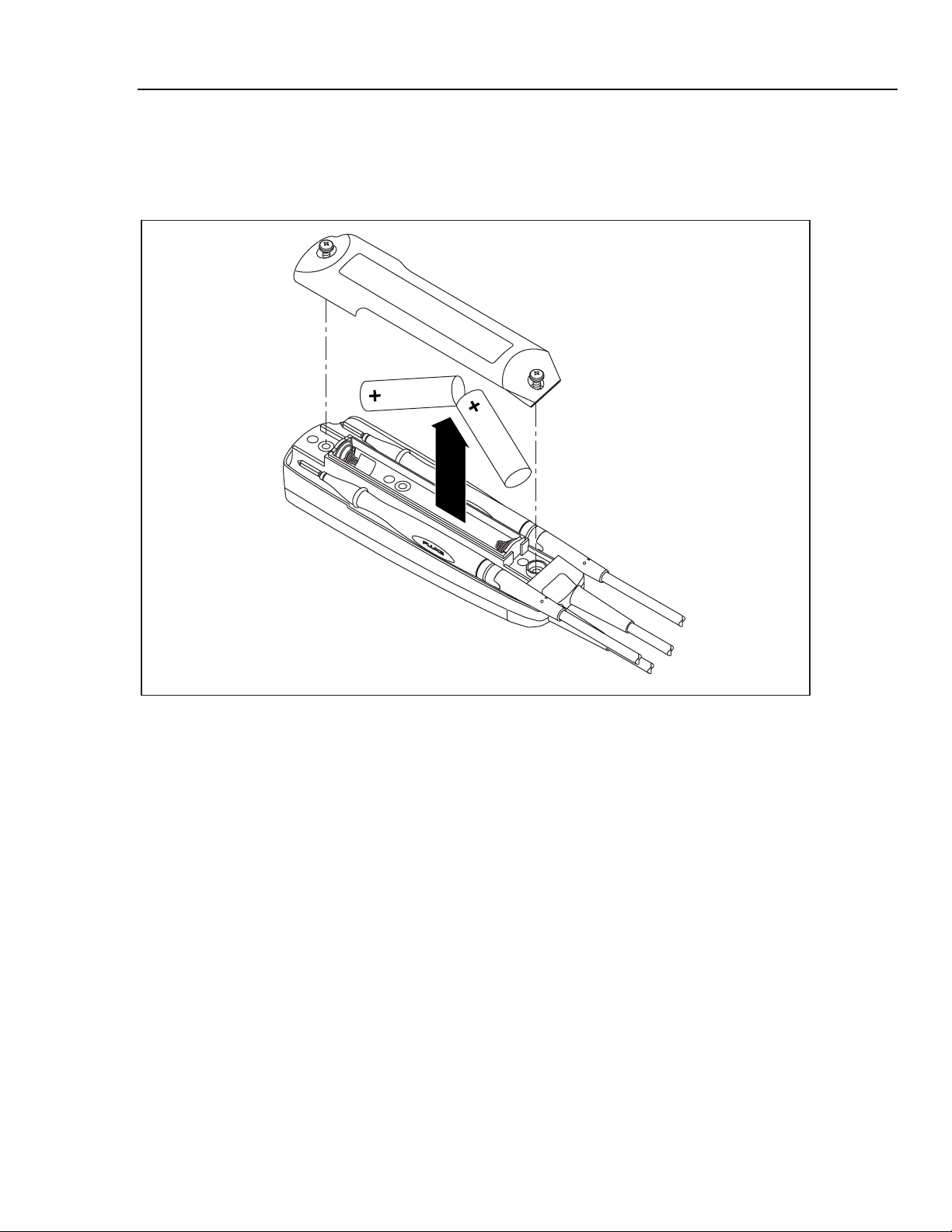

Figure 2 shows how to replace the batteries.

Tester

Figure 2. Replacing the Batteries

il2f.eps

7

Page 14

T3

Calibration Manual

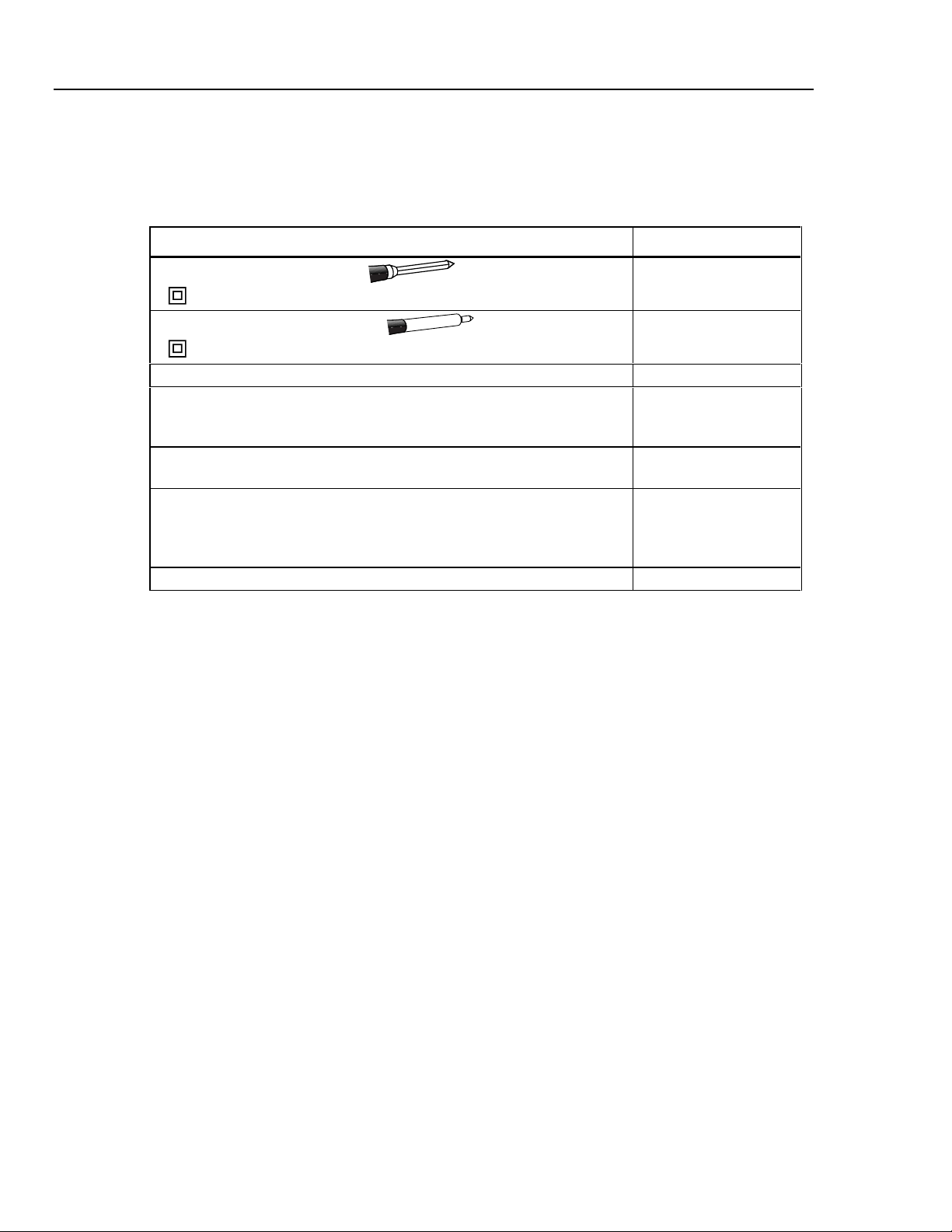

Parts and Accessories

Table 3 shows the replacement parts and accessories available from Fluke for the T3 Tester.

Table 3. Replacement Parts and Accessories

Description Fluke Part Number

Test lead assembly, flat blade

Replace only with Fluke double-insulated leads.

Test lead assembly, 4 mm round

Replace only with Fluke double-insulated leads.

Battery door 1576525

AA battery, 1.5 V, carbon-zinc (2 required)

or

AA battery, 1.5 V, alkaline (2 required)

T3 Tester Instruction Sheet Packages (Americas)

English, French, Spanish

T3 Tester Instruction Sheet Packages (International)

English, French, German, Italian, Finnish, Dutch, Danish, Norwegian,

Swedish, Spanish, Portuguese, Korean, Thai, Simplified Chinese,

Traditional Chinese

H5 Belt Holster Accessory

686733

688165

650181

376756

1562069

1562078

8

Loading...

Loading...