Page 1

GE

Sensing

Pressurements

Deadweight Testers

Pressurements is a Druck product.

Druck has joined other GE

high-technology sensing businesses

under a new name

_

GE Industrial, Sensing.

Features

• The most comprehensive range

• Gauge pressure

• Absolute pressure

• Vacuum

• Separators and comparison test pumps

Deadweight testers are the basic primary standard used

world-wide for the accurate measurement of pressure.

No other piece of equipment can match the stability,

repeatability and accuracy of the deadweight tester. It is

ideal for calibrating pressure gauges, transducers,

transfer standards, recorders, digital calibrators, etc. and

can also be used to directly measure the pressure in

systems and processes where precise readings are

important.

g

Page 2

Standard with Every Deadweight

Tester

• One year guarantee against normal operating failure

• 1/8, 1/4, 3/8, 1/2 NPT or BSP female adaptors

• Calibrated weight set in carrying case

• Traceable certificate of overall accuracy

• Individual piston certificate

• Operating fluid (where applicable)

• Spare seals

GE

Sensing

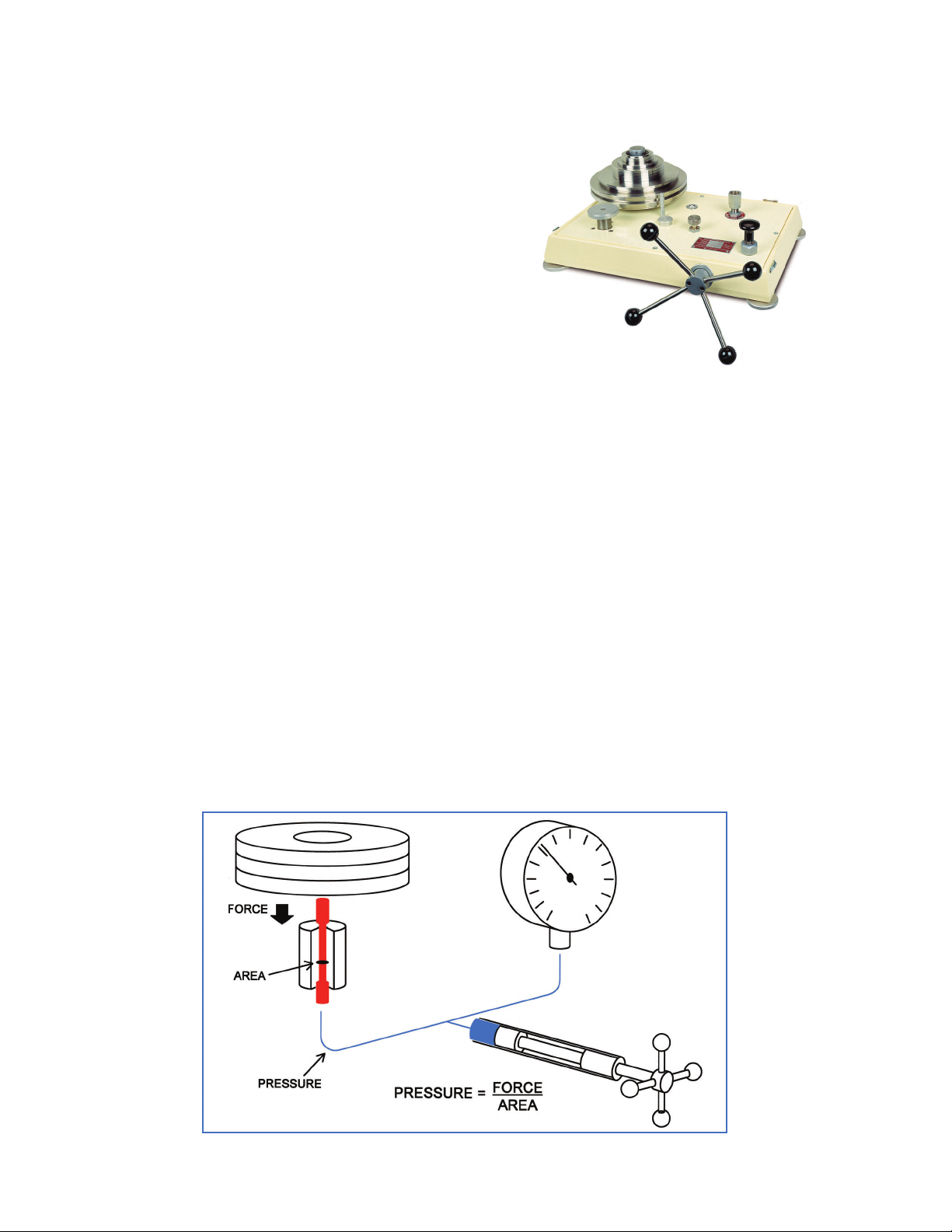

Using the well proven piston gauge system, which

consists of a vertically mounted precision lapped piston

and cylinder assembly, accurately calibrated masses are

loaded onto the piston, which rises freely within its

cylinder. These weights balance the upward force

created by the application of pressure within the system.

GE offers one of the most comprehensive series of

deadweight testers available, covering a wide variety of

applications and ranges of pressure and vacuum. The

piston assemblies are manufactured to the very highest

standards with certified accuracies traceable to

international standards laboratories such as the National

Institute of Standards and Technology (NIST).

Gravity varies significantly with geographical location

and this variation has a direct effect on the force of the

weights and the accuracy of the deadweight tester. Each

instrument can be calibrated to local gravity at no extra

cost. If unspecified, instruments will be supplied

calibrated to standard gravity 980.665 cm/s2.

Instruments are supplied with an integral carrying case,

making them neat, compact and easily portable.

Components are stored in the detachable lid, which also

provides excellent protection from dirt and damage

when the tester is in transit or storage. Unique test

station connections allow quick hand-tight sealing, no

need for polytetrafluoroethylene (PTFE) tape and

wrenches. A spirit level and adjustable feet are provided

to enable the operator to level the instrument. A flotation

indicator is mounted on the top plate, removing

guesswork when floating the piston. Weights are stored

in a separate box.

Page 3

Hydraulic Deadweight Testers

• *Accuracy better than 0.015% of reading. 0.008%

optional

• Dual piston models allow calibration over a wide

range. Piston automatically selected without valving or

piston exchange

• Overhanging weight carrier protects carbide piston,

improves rotational spin, sensitivity and stability.

• Water models eliminate oil contamination.

• Pressure is generated by a ram screw.

Oil Operated Models

Dual Piston Series

Model Range

M2000 10 to 5000 psi (1 to 350 bar)

M2200 10 to 10,000 psi (1 to 700 bar)

M2800 10 to 16,000 psi (1 to 1100 bar)

Single Piston Series

Model Range

M1800 10 to 500 psi (1 to 35 bar)

M4000 40 to 2000 psi (4 to 140 bar)

M2000/H 100 to 5000 psi (10 to 350 bar)

M2200/H 200 to 10,000 psi (20 to 700 bar)

M2800/H 200 to 16,000 psi (20 to 1100 bar)

M3830 500 to 30,000 psi (40 to 2000 bar)

M3840 500 to 40,000 psi (40 to 2600 bar)

M3860 500 to 60,000 psi (40 to 4000 bar)

Water Operated Models

Dual Piston Series

Model Range

W2000 10 to 5000 psi (1 to 350 bar)

W2200 10 to 10,000 psi (1 to 700 bar)

Single Piston Series

Model Range

W1800 10 to 500 psi (1 to 35 bar)

W2000/H 100 to 5000 psi (10 to 350 bar)

W2200/H 200 to 10,000 psi (20 to 700 bar)

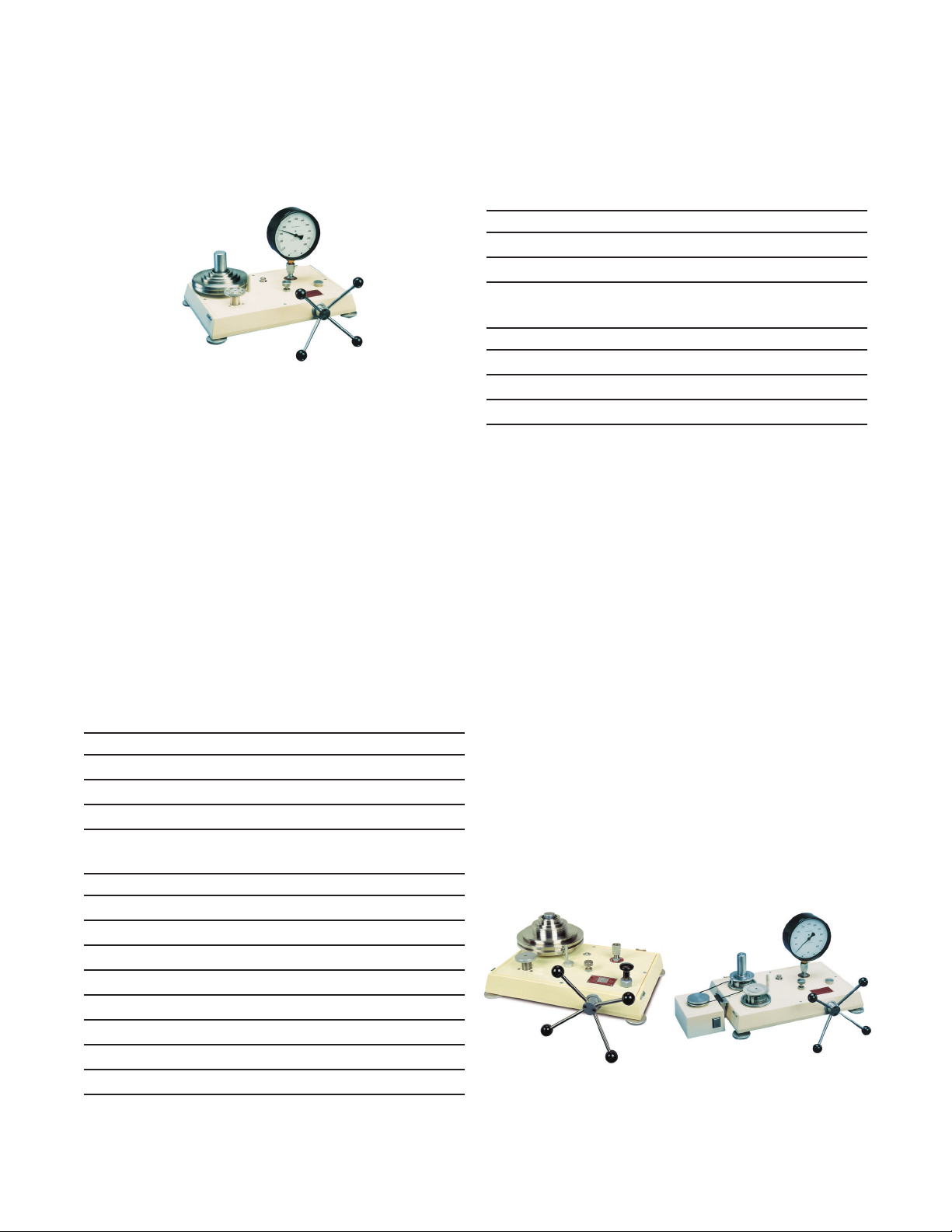

Built-In Hand Pump

• Large volume systems are easily primed

• Greatly speeds up priming and pressure generation

• Enables an effortless, small bore, high pressure ram

screw to be fitted

• There is no additional valve operation involved.

• Standard on M2800, not available on M3800 Series

Motor Drive

If a continuous pressure is required, a motor drive can be

provided to rotate the weights. Rotating the weights by

hand is satisfactory for standard calibrations.

The motor is isolated from the deadweight tester by a

thermal barrier, preventing warming of the measuring

piston. The motor is suitable for 210/250, 105/125 volts

at 50/60 Hz, please specify requirements at time of

order.

Not available on models M2800, M2800/H and M3800

Series

Other units available including Kgf/cm

2

and kPa

Built-in hand pump Motor drive

GE

Sensing

Page 4

Pneumatic Deadweight Testers

Model Range

T5100 5 to 100 in H20 (15 to 300 mbar)

T5250 5 to 250 in H20 (15 to 600 mbar)

T5400 5 to 400 in H20 (15 to 1000 mbar)

T5800 12 to 800 in H20 (30 to 2000 mbar)

• *Accuracy better than 0.015% of reading. 0.008%

available

• Instruments to 150 psi (10 bar) are supplied with

built-in hand pumps.

• Instruments up to 2000 psi (140 bar) and vacuum

operate from an external air supply. Hand pumps can

be supplied for both pressure and vacuum.

• T2700, T2900 are fitted with a ram screw for fine

control.

Optional Extras

• Built-in hand pumps to generate pressure

(up to 150 psi/10 bar) and/or vacuum (up to 80%)

• Fitted as standard on models T1150, T1100 and T2500

Lightweight Pressure Models

Pressure Models

Model Range

T1150 5 to 400 in H20 (15 to 1000 mbar)

T1100 12 to 800 in H20 (30 to 2000 mbar)

T2500 3 to 150 psi (0.2 to 10 bar)

T2300 3 to 500 psi (0.2 to 35 bar)

T2700 10 to 1000 psi (4 to 70 bar)

T2900 10 to 2000 psi (4 to 140 bar)

Model Range

T2700/L 10 to 1000 psi (1 to 140 bar)

T2900/L 10 to 2000 psi (1 to 140 bar)

These instruments are fitted with liquid lubricated piston assemblies where cleanliness and

environmental control cannot be assured.

All the above models are available in other pressure units.

Vacuum Models

Model Range

T2600 1 to 30 in Hg (0.03 to 1 bar) vacuum

Combined Pressure and Vacuum Models

Two instruments in one, with a selector valve for pressure (P) or vacuum (V).

Model Range

T3550 V_1 to 30 in Hg (0.03 to 1 bar)

P_5 to 400 in H

2

O (15 to 1000 mbar)

T3580 V_1 to 30 in Hg (0.03 to 1 bar)

P_12 to 800 in H

2

O (30 to 2000 mbar)

T3500 V_1 to 30 in Hg (0.03 to 1 bar)

P_3 to 500 psi (0.2 to 35 bar)

Vacuum model Pressure and vacuum model

GE

Sensing

Page 5

Hydraulic

Specifications

*Accuracy

M & W ±0.015% of reading (±0.008% when specified)

M3800 Series 0.02% of reading (±0.015% when specified)

L Series ±0.05% of reading (±0.025% when specified)

P7000 Series ±0.005% of reading

Total Instrument Weight 24.6 lb (12 kg)

M3800 Series 70 lb (32 kg)

Total Boxed Weight Set

Up to 10,000 psi (700 bar) 66 lb (30 kg)

M2800 106 lb (48 kg)

M3830 264 lb (120 kg)

M3860 396 lb (180 kg)

Instrument Size (l x d x h)

M3800 Series 18.5 x 12.5 x 8 in (47 x 32 x 20 cm)

*Accuracy based on % of reading from 10% to 100% of the piston range when used in

accordance with the corrections found on the calibration certificate. Below 10%, ± (accuracy

class) x 10% of the piston range.

Weight Material Series 3 non-magnetic stainless steel

Weight Density 7.9 g/cm

3

Piston Material

Oil Operated Tungsten carbide

Water Operated Stellite; up to 500 psi (35 bar)

Above 500 psi (35 bar) Tungsten Carbide

Cylinder Material Hardened martensitic steel

Water above 500 psi (35 bar) Tungsten Carbide

Minimum Standard Weight Increment

Low Pressure Piston 1 psi (0.05 bar)

High Pressure Piston x10 or 20; models above 5000 psi (350 bar)

M3800 Series 20 psi (1 bar)

Optional Fractional Weights (Aluminum)

Low Pressure Piston 0.1 psi (0.01 bar)

High Pressure Piston x10 or 20; models above 5000 psi (350 bar)

General

Material of Construction

Weight Increment

Pneumatic

Specifications

*Accuracy

T Series ±0.015% of reading (±0.008% when specified)

6100 Series ±0.015% of reading (±0.008% when specified)

P7000 Series ±0.005% of reading

Total Instrument Weight 22 lb (10 kg)

T5000 Series 10 to 66 lb (4.7 to 8 kg)

Total Weight Set Variable from 10 to 66 lb (4.5 to 30 kg)

Instrument Size (l x d x h); including lid

11.8 x 12.5 x 8 in (47 x 32 x 20 cm)

T5000 Series 12 x 10 x 5 in (30 x 25 x 13 cm)

*Accuracy based on % of reading from 10% to 100% of the piston range when used in

accordance with the corrections found on the calibration certificate. Below 10%, ± (accuracy

class) x 10% of the piston range.

Weight Material Series 3 non-magnetic stainless steel

Weight Density 7.9 g/cm

3

Piston Material

Oil Operated Tungsten carbide

Water Operated Stellite; up to 500 psi (35 bar)

above 500 psi (35 bar) Tungsten Carbide

Cylinder Material Hardened martensitic steel

Water above 500 psi (35 bar) Tungsten Carbide

Minimum Standard Weight Increment

T2500, T2300, T3500(P) 1 psi (0.05 bar)

T5100, T5250, T5400, 1 in H20 (5 mbar)

T1150, T3550(P)

T5800, T1100, T3580(P) 2 in H20 (10 mbar)

T2700, T2900 1 psi (0.2 bar)

T2600, T3500(V) 0.2 in Hg (0.01 bar)

Optional Fractional Weights (Aluminum)

T2500, T2300, T3500(P) 0.1 psi (0.01 bar)

T5100, T5250, T5400, 0.5 in H20 (1 mbar)

T1150, T3550(P)

T5800, T1100, T3580(P) 1 in H20 (5 mbar)

T2700, T2900 0.5 psi (0.05 bar)

General

Material of Construction

Weight Increment

GE

Sensing

Page 6

Model Range

T1300 and T1301 0 to 20,000 psi (0 to 1400 bar)

Model T1300

Liquid

Tested with water and suitable for use with:

• Water

• Mineral/vegetable oil

• Alcohol

Supplied with a reservoir and valve, pressure is quickly

generated with the ram screw.

Model Range

T1200 0 to 10,000 psi (0 to 700 bar)

Model T1200

Air

Pressure is generated with the sensitive hand pump and

is vented with a fine control needle valve.

Model Range

T4100 0 to 300 psi (0 to 20 bar)

Model T4100

Vacuum

Vacuum is generated quickly and easily with the hand

pump and vented with a fine control needle valve.

Model Range

T4200 0 to 20 inHg (0 to 800 mbar)

Model T4200

These test pumps are used for checking pressure

measuring instruments against master test gauges or

transducers. All are portable or can be bench mounted.

Supplied with NPT or BSP quick hand-tight sealing gauge

adaptors.

Liquid

This is the most portable and versatile version of our

comparison test pumps. These units are based on our

standard deadweight tester system. The piston and

weights are replaced by a second test station to which

either a test gauge, transducer or transfer standard is

connected for comparison against the instrument under

test. A built-in hand pump is supplied offering the

following benefits:

• Large volume systems are easily primed

• A small bore high pressure ram screw is provided

offering quick and effortless pressure generation

without additional valve operation

Model T1300 for oil applications

Model T1301 for water applications

Comparison Test Pumps

GE

Sensing

Page 7

Liquid to Air

For high pressure pneumatic calibration, this unit

interfaces with hydraulic deadweight testers, giving a

rateless liquid to air separation. A series of fluid traps

ensures that instrument under test remains dry.

Needle valves control the pressure, and the deadweight

tester ram screw controls the fluid level.

Please specify if interface is for oil or water application.

Separators

Model Range

API5000/1 0 to 4000 psi (0 to 300 bar)

Model API5000

Liquid to Liquid

This unit has a flexible Viton®diaphragm, separating the

deadweight tester fluid and a non-contaminating liquid.

Any liquid can be used that is compatible with Viton and

aluminum bronze. The unit also protects the deadweight

tester from contamination.

Model Range

T3600 0 to 8000 psi (0 to 600 bar)

T3601 0 to 10,000 psi (0 to 700 bar)

Dirt/Moisture Trap

Protects pneumatic deadweight testers, when the

cleanliness of the instrument under test cannot be

guaranteed. The unit is mounted directly onto the test

station. Particles and moisture are trapped within the

body, which are visible on Model T4400.

Model Range

T4400 0 to 500 psi (0 to 35 bar)

T4401 0 to 10,000 psi (0 to 700 bar)

Model T3600 Model T4400

Two Gauge Adaptor

To calibrate two instruments at the same time. This

adaptor is mounted directly onto the test station.

Model Range

T4500 0 to 10,000 psi (0 to 700 bar)

Ancillary Equipment

Angle Adaptor

To calibrate back connection gauges, the angle adaptor

fits directly onto the test station, converting it to 90°,

allowing the same adaptors to be used.

Model Range

T3700 0 to 10,000 psi (0 to 700 bar)

Pointer Remover/Punch

To remove and refit the pointer of a pressure gauge. This

two in one tool has a spring loaded plunger to quickly

and consistently refit the pointer.

Model T3700 Pointer remover/punch

Gas

GE

Sensing

Page 8

©2005 GE. All rights reserved.

BR-006B

All specifications are subject to change for product improvement without notice. GE

®

is a registered trademark of General Electric Co. Other company or product names

mentioned in this document may be trademarks or registered trademarks of their

respective companies, which are not affiliated with GE.

g

Low (L) Range 0.5 to 30 psi (30 to 2000 mbar)

Mid (M) Range 3 to 300 psi (0.2 to 20 bar)

High (H) Range 300 to 1000 psi (20 to 70 bar)

Further information available

• *Accuracy 0.015% pr 0.008% of reading

Pressure Model 6100 operates over an extremely wide

pressure range. Three standard ranges (piston and

weight set) are available to fit into the instrument base:

Combined Absolute and Gauge

Pressure Standard Model 6100

Ranges To 20,000 psi (1400 bar)

Further information available

• *Accuracy better than 0.005% of reading

• Integrated hardware and software systems

• Special dual-based deadweight tester calibrating

option

The P7000 has been designed for pressure

measurements to the highest level of accuracy. The wide

range of options ensures maximum flexibility.

High Accuracy Pressure

Standards P700

Ranges To 10,000 psi (700 bar)

Further information available

• *Accuracy 0.05% or 0.025% of reading

Low Cost Hydraulic Deadweight

Tester L Series

Model 6100

P7000

www.gesensing.com

GE

Sensing

Loading...

Loading...