T+ and T+ PRO

Electrical Tester

Instruction Sheet

Introduction

The Fluke T+ and T+ PRO Electrical Testers (the “Tester”) have the

following features:

• AC and dc voltage measurement, 12 V to 600 V, with or without

batteries

• LED bar voltage and hazardous voltage indicators function with or

without batteries

• Vibration and beeper indicators for ac and dc voltages

• Beeper and LED continuity indication

• Backlit LCD displays measured voltage (T+ PRO only)

• Rotary field direction indicators (T+ PRO only)

• Resistance measurement up to 9.99 kΩ (T+ PRO only)

• Flashlight

• GFCI trip

Additional languages of this instruction sheet (Brazilian Portuguese,

Simplified Chinese, Japanese, Korean, and Thai) are available for

download at www.fluke.com.

Contacting Fluke

To contact Fluke, call one of the following telephone numbers:

• Technical Support USA: 1-800-44-FLUKE (1-800-443-5853)

• Calibration/Repair USA: 1-888-99-FLUKE (1-888-993-5853)

• Canada: 1-800-36-FLUKE (1-800-363-5853)

• Europe: +31 402-675-200

• Japan: +81-3-6714-3114

• Singapore: +65-6799-5566

• China: +86-400-921-0835

• Anywhere in the world: +1-425-446-5500

Or, visit Fluke's website at www.fluke.com.

To register your product, visit http://register.fluke.com.

To view, print, or download the latest manual supplement, visit

http://us.fluke.com/usen/support/manuals.

PN 2559547 November 2006 Rev. 2, 9/17

© 2006 - 2017 Fluke Corporation. All rights reserved.

Safety Information

To avoid possible electric shock or personal injury, follow

these guidelines:

• Use the Tester only as specified in this instruction

sheet, otherwise the protection provided by the Tester

may be impaired.

• The Tester is to be used only by qualified personnel.

• Do not use the Tester if it is damaged. Inspect the case

before use. Look for cracks or missing plastic. Pay

particular attention to the insulation surrounding the

connectors.

• Inspect the test leads for damaged insulation or

exposed metal. Check the test leads for continuity.

Replace damaged test leads before using the Tester.

• Do not use the Tester if it operates abnormally.

Protection may be impaired. When in doubt, have the

Tester serviced.

• Do not operate the Tester around explosive gas, vapor,

or dust.

• Do not apply more than the rated voltage, as marked

on the Tester, between terminals or between any

terminal and earth ground.

• When measuring hazardous voltage, verify the Tester’s

operation by measuring a known voltage.

• Only the test probes and batteries are serviceable.

When servicing, use only specified replacement parts.

• To determine the LEDs and beeper are working

correctly, short the test leads together. The beeper

sounds (if enabled) and all LEDs and display segments

(T+ PRO) switch on briefly indicating correct operation.

• Comply with local and national safety requirements

when working in hazardous locations.

• Use proper protective equipment, as required by local

or national authorities when working in hazardous

areas.

• Use caution when working above 30 V ac rms, 42 V

peak, or 60 V dc. Such voltages pose a shock hazard.

• When using the probes, keep fingers away from the

ends of the probe tips.

• Connect the common test lead before connecting the

live test lead. When disconnecting the test leads,

disconnect the live test lead first.

• Do not operate the Tester with the battery door or

portions of the cover removed or loosened.

• When the batteries are depleted, self test will not

function.

• When the beeper is disabled, it will not sound until the

beeper is reactivated.

XWWarning

• For voltages above 240 V, you must only

connect to a voltage source for a MAXIMUM of

30s and then disconnect for a MINIMUM of 300s.

• Perform a self test before any measurements are taken

for voltage, continuity, resistance, or rotary field. See

“Self Test”.

• Exercise caution when performing measurements on

PLC (Programmable Logical Controller) inputs. When

measuring relay control voltages on PLCs, be aware

that this may open or close the relay/switch.

• All appliances or equipment on the circuit being tested

should be unplugged to help avoid erroneous

readings.

Although the Tester may be used with depleted batteries,

replace depleted batteries immediately to avoid Tester

damage from battery acid leakage.

WCaution

Symbols

The following symbols appear on the Tester or in this instruction sheet.

Table 1. Symbols

Symbol Explanation Symbol Explanation

W

T

)

~

WARNING - RISK OF

DANGER. Consult user

documentation.

Double insulated

Certified by CSA Group

to North American

safety standards.

Measurement Category

III is applicable to test

and measuring circuits

connected to the

distribution part of the

building’s low-voltage

MAINS installation.

This product complies with the WEEE Directive marking

requirements. The affixed label indicates that you must not

discard this electrical/electronic product in domestic

household waste. Product Category: With reference to the

equipment types in the WEEE Directive Annex I, this product

is classed as category 9 "Monitoring and Control

Instrumentation" product. Do not dispose of this product as

unsorted municipal waste.

X

R

WARNING.

HAZARDOUS

VOLTAGE. Risk of

electric shock.

Earth

Continuity beeper

Measurement Category

IV is applicable to test

and measuring circuits

connected at the source

of the building’s lowvoltage MAINS

installation.

Optional Accessories

Accessories are available for the T+/T+ PRO Electrical Tester. See Table

2.

Table 2. Accessories

Item Item Number

Belt Holster H3

Replaceable Test Probes (1 red and 1 black) TP2

Pushbuttons

Use the pushbuttons to toggle switchable functions of the Tester on or off.

The pushbuttons are shown and described in Table 3.

Table 3. Pushbuttons

Pushbutton Description

Press to turn the flashlight on, release to turn it off.

C

O

Performs Ground Fault and trips the GFCI.

The flashlight will turn off 5 seconds after release of the

pushbutton. Batteries are required for this feature.

Toggles the ohms function on or off. T+PRO only. See

“Measuring Resistance (T+ PRO Only)”.

Batteries are required for this feature.

Toggles the HOLD function on or off. T+PRO only. See

“HOLD”. Batteries are required for this feature.

Turns beeper on or off. When the beeper is turned off, it

will not sound until it is reactivated. Batteries are

required for this feature.

Understanding the Display (T+ PRO Only)

Display indicators are shown and described in Figure 1.

3 4

2

1

8

5

7

6

eqc001f.emf

Item Description

Low battery icon. If the battery is depleted the voltage will

still be displayed by the LED stack but the beeper and

vibration will not operate, continuity and resistance

measurements cannot be made, and the LCD will not

switch on.

WCaution

Replace depleted batteries immediately to avoid

damage to the Tester from battery acid leakage.

All audible signals are disabled

HOLD function is selected

Measurement units

Numeric display

AC or dc volts

Continuity test function is selected

Indicates phase rotation for a right or left-hand turning field

from one phase to the next in a three-phase system

Figure 1. Display Indicators

Beeper

When the Tester detects a voltage, the LEDs light to indicate the voltage

level, the Tester vibrates, and a beeper sounds (the T+ PRO also shows

the voltage on the display). The beeper tones are different depending on

what is being measured:

• AC voltage - the beeper is a chirping tone

• DC voltage - the beeper is a steady tone

• Continuity - the beeper is a steady tone for resistances less than 20

kΩ

If any voltage is present, the Tester automatically switches to

voltage mode.

To turn the beeper on or off, press for more than 3 seconds. Each time

the beeper is activated or deactivated, the Tester emits 3 short beeps.

Batteries are required for this feature.

Note

Vibration Voltage Indication

The Tester vibrates when voltages 40 V and higher are measured.

Batteries are required for vibration to function.

Automatic Operation

The Tester automatically turns on when the probes are placed across a

complete circuit. The Tester selects continuity, ac or dc voltage modes

based on the resistance or voltage between the probes. The tester

switches off immediately after the test probes are removed from the circuit

under test or after 5 seconds if C is released when the probes are not

attached to a test circuit. If the HOLD function is activated, this switches off

after 1 minute if a voltage is not detected.

HOLD

Press to freeze the display reading. Press again to release HOLD.

HOLD does not interfere with the voltage LED function.

Removing the Probe Tips

To remove the probe tips:

1. Grasp the probe firmly in one hand.

2.

Hold the test lead jack firmly in the other hand.

3. Pull to disengage the test lead probe from the test lead jack.

LED Display Voltages

Table 4 shows the differences in the displayed voltages on the LEDs on

the Canadian and USA versions of the Tester.

Table 4. LED Display Voltages

USA Canada

Q Q

R R

S S

T T

U U

V V

W

X X

Y Y

Self Test

To avoid possible electric shock or personal injury:

• Perform a self test before any measurements are taken for

voltage, continuity, resistance, or rotary field.

• When the batteries are depleted, self test will not function.

Replace the batteries.

Although the Tester may be used with depleted batteries,

replace depleted batteries immediately to avoid Tester

damage from battery acid leakage.

To perform the self test, short the two probes. The self test lights all LEDs,

and all LCD segments (T+ PRO). The beeper sounds (unless disabled)

and the Tester switches to continuity mode. The self test will then be deactivated for 30 seconds. If the self test needs to be repeated, wait 30

seconds.

To complete the check procedure, always measure a known voltage

before use. If the Tester fails self test or voltage check, it must not be used

and requires service. See “Contacting Fluke”.

XWWarning

WCaution

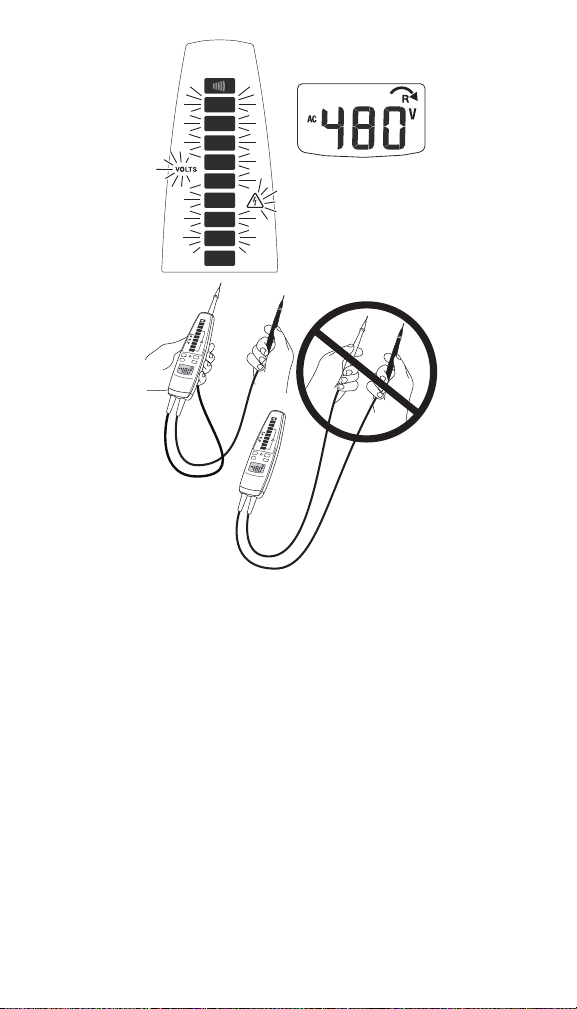

Measuring Voltage

To measure voltage, connect the probes to the circuit under test. The

voltage is indicated by the voltage LED stack and beeper (if enabled). The

T+PRO will show the measurement on the LCD for voltages > 10 V; < 10

V the LCD remains blank. The AC, DC+ and DC- LEDs will only operate

for voltages greater than 24 V. Refer to Figure 2.

DC Voltage

600 V dc maximum

AC Voltage

600 V rms maximum

45 Hz to 66 Hz

CONTINUITY

12

24

48

120

208

240

277

480

600

CONTINUITY

12

24

48

120

208

240

277

480

600

12 V dc

Figure 2. Measuring Voltage

Note

Maximum measurable voltage is 600 V ac or dc. This will be

indicated on the LED and LCD (T+ PRO).

120 V ac

eqc03f.eps

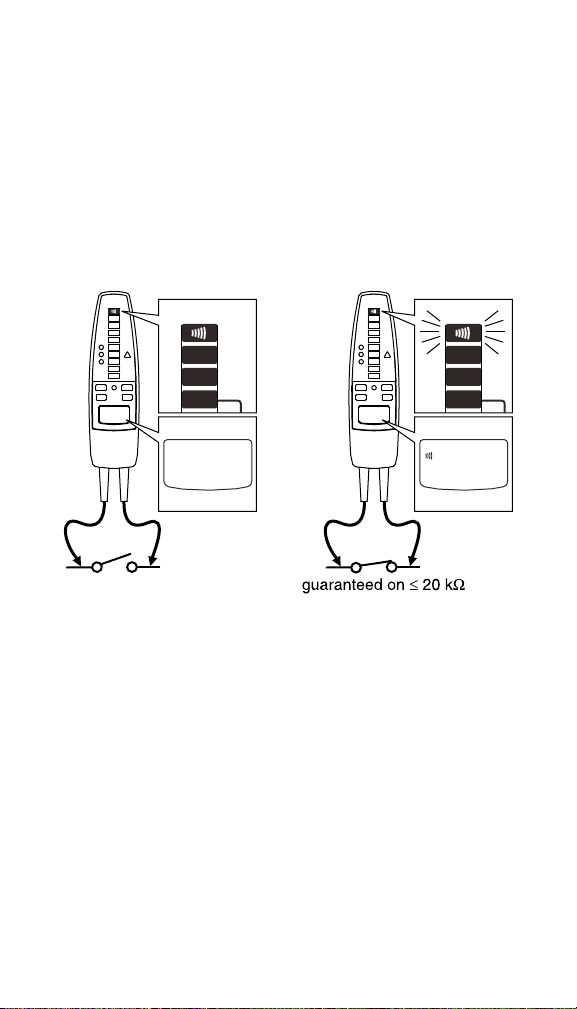

Testing for Continuity

To avoid electrical shock:

• Make sure the power to the circuit is turned off and all

capacitors are discharged.

• If the beeper is disabled, the Tester will not beep and only

P will light. On the T+ PRO, the display will also show .

To measure continuity, turn off circuit power and connect the probes to the

circuit under test. Continuity (a resistance less than 20 kΩ) is indicated by

the beeper and a lighted P. If the beeper is disabled, it will not sound

during this test. The T+PRO shows on the LCD. If the resistance is

greater than 20 kΩ, the beeper will not sound and P will not light. Refer

to Figure 3.

CONTINUITY

XW Warning

CONTINUITY

CONTINUITY

CONTINUITY

open

12

24

48

Figure 3. Continuity Test

12

24

48

eqc02f.emf

Measuring Resistance (T+ PRO Only)

To avoid electrical shock when measuring resistance in a

circuit, make sure the power to the circuit is turned off and

all capacitors are discharged.

To measure resistance, turn off the circuit power, press O, and place

the test probes across the resistance under test. For resistances less than

9.99 kΩ, the T+PRO display shows the resistance value. For greater

resistances, the display shows OL. See Figure 4.

XWWarning

DISPLAY ON >10V

Figure 4. Measuring Resistance

eqc04f.eps

GFCI Test

To avoid electrical shock, do not touch any exposed

metalwork during the test.

This test will switch off the power to the circuit.

To test a GFCI receptacle, do the following:

1. Insert the Tester probes into the GFCI receptacle under test.

2. Connect probes to the phase (hot) and ground (PE-protective earth)

of the GFCI receptacle.

3. Press for 1 second. The DC+ and DC- LEDs will alternately

switch on and off and, if activated, the beeper will sound indicating

that a test is in progress. The test may last up to 7 seconds.

4. Keep the probes connected while the LEDs are switching on and off.

If the GFCI trips, power to the circuit will be interrupted and the Tester

will stop indicating voltage. If the GFCI does not trip after

approximately 7 seconds, the GFCI test stops, indicated by no

switching of the DC+ and DC- LEDs but the tester will continue to

indicate the presence of voltage.

When testing and verifying GFCI circuits or components, do the following:

• Consult the GFCI manufacturer’s installation instructions to determine

that the GFCI is installed in accordance with its specifications.

• Check for correct wiring of receptacles and all remotely-connected

receptacles on branch circuits.

• Operate the pushbutton on the GFCI receptacle installed in the

circuit. The GFCI must trip. If it does not, the GFCI receptacle is not

operating properly. DO NOT use the circuit. Consult an electrician or

properly certified personnel.

If the GFCI does trip, retest the receptacle as explained above.

If the Tester fails to trip the GFCI, consider either of the following:

• The GFCI is fully functional but a wiring problem exists within the

installation or receptacle.

• The GFCI is faulty and the installation wiring is correct.

Consult an electrician to check the wiring and GFCI.

• After a GFCI test, further GFCI tests will be inhibited for 0.5

seconds.

• It is not possible to switch the beeper off during a GFCI test.

To avoid possible electric shock or personal injury, follow

these guidelines:

• When testing GFCIs installed in 2-wire systems,

(systems where no ground wire is available at the

receptacle) the Tester may give a false indication that

the GFCI is not functioning properly. If this occurs,

recheck the operation of the GFCI using the test and

reset button.

XWWarning

Note

XWWarning

• The GFCI button test function should demonstrate

proper operations. However, if there is cause to verify

proper operation of the GFCI receptacle in a 2-wire

system, apply one test probe of the Tester to the

energized input of the GFCI receptacle while applying

the alternates test probe to a known external neutral or

ground reference location external to the GFCI

receptacle. Operate the GFCI button on the Tester as

described in the Instruction Sheet to verify the GFCI

receptacle is operating properly.

Rotary Field Direction (T+ PRO Only)

This test shows the direction of a rotary field in a three-phase system

when measured phase to phase. The LCD indicates phase rotation for a

right or left-hand turning field from one phase to the next in a three-phase

system.

If measuring from phase to neutral at a panel or single-phase

outlet, the Tester may indicate or . However, this is not a

valid reading. A valid reading can only come from a phase to

phase circuit. The rotary field function is specified for use on line

(mains) systems only.

To perform a rotary field direction test, see Figure 5:

1. Attach one probe to the center probe holder on the back of the Tester

and grip the main body with one hand.

2. Attach both probes to the test points. If the red lead is 120 degrees

ahead of the black lead, is displayed. If the red lead lags the

black lead by 120 degrees, is displayed. In both situations the

voltage is shown on the display. If a phase rotation measurement is

not possible, no arrows will light but the voltage appears on the

display.

You can verify the rotary field direction by reversing the two

probes and watching for an indication of a change in the field

direction.

Note

Note

CONTINUITY

12

24

48

120

208

240

277

480

600

C

O

N

T

IN

U

I

T

Y

12

24

4

8

1

20

20

8

2

40

2

77

4

8

0

6

00

C

O

N

T

I

N

U

I

T

Y

1

2

24

4

8

12

0

20

8

240

2

77

4

8

0

600

Figure 5. Rotary Field Measurement

eqc05f.emf

Maintenance

WCaution

Do not use abrasives or solvents on the Tester.

Clean the case with a damp cloth and mild detergent.

Replacing the Batteries

Perform a self test to determine the charge state of the batteries on T+

Testers. The self test will not work with dead batteries. On T+ PRO

Testers, the low battery icon (B) on the LCD indicates that the batteries

need to be replaced.

XWWarning

To avoid possible electric shock or personal injury:

• Disconnect test leads from any electrical source before

opening the battery compartment.

• Do not operate the Tester with the battery door or

1. Turn the Tester over and use a flat-head screwdriver to loosen the

2. Replace the batteries with two new AAA alkaline batteries.

3. Reattach the battery compartment door and reinstall the screw.

portions of the cover removed or loosened.

battery door screw and remove the door.

Specifications

Temperature: Operating: -10 °C to +55 °C (14 °F to 131 °F)

Relative Humidity: 0 °C to 30 °C (32 °F to 86 °F) 90 %

Altitude: Operating: 2,000 m

Battery Type/Life: AAA (2); 40 hours

Shock, Vibration: Sinusoidal vibration per MIL-PRF-28800F for a

Safety: ANSI/ISA S82.02.01, CSA C22.2-1010.1, IEC 61010-

AC Bandwidth: 45 Hz to 66 Hz

Maximum Input

Voltage Between

Terminal and

Earth Ground: Maximum working voltage 1000 V ac or dc.

Duty Cycle:

Voltage

Hazard LED: LEDs turn on @ voltages > 30 V ac/dc ± 35 %

Storage: -30 °C to +60 °C (-22 °F to +140 °F)

30 °C to 40 °C (86 °F to 104 °F) 75 %

40 °C to 50 °C (104 °F to 122 °F): 45 %

Storage: 10,000 m

Class 2 instrument

1 to 1000 V CAT III/600 V CAT IV; Pollution Degree II

Maximum measurable voltage 600 V ac or dc. This

will be displayed on the LED and the LCD (T+ PRO).

Indefinitely for voltages up to 240 V.

For voltages between 240 V to 600 V the duty cycle is

30 seconds on / 300 seconds off. For voltages above

240 V the Tester must connect to a voltage source

only for a MAXIMUM of 30 seconds and then

disconnect for a MINIMUM of 300 seconds.

LEDs: LEDs turn on @ between 70 % and 100 % of the

Fluke C

Fluke E

indicated voltage on the LED, except for the 12 V LED

which turns on @ between 50 % and 100 %.

EMC Compliance: EN61326-1:2005 Class B emissions and immunity in

field strengths between 1 V/m and 3 V/m add

8 % of range.

Accuracy:

AC voltage: ± (3 % rdg. + 2 digits)

DC voltage: ± (2 % rdg + 2 digits)

Resistance: ± (5 % rdg + 3 digits)

LCD Resolution: 0.1 V for voltages < 50 V, 1 V for voltages ≥ 50 V,

0.01 kΩ at resistance measurement

GFCI Test

Current: 100 V to 150 V @ 6 mA to 9 mA ac

150 V to 240 V < 12 mA

Standard Input

Test Current: < 5 mA

Size (HxWxL): 1.3 in x 2.15 in x 7.6 in

Weight: 9.9 oz

LIMITED WARRANTY & LIMITATION OF LIABILITY

This Fluke product will be free from defects in material and workmanship

for two years from the date of purchase. This warranty does not cover

fuses, disposable batteries, or damage from accident, neglect, misuse,

alteration, contamination, or abnormal conditions of operation or handling.

Resellers are not authorized to extend any other warranty on Fluke’s

behalf. To obtain service during the warranty period, contact your nearest

Fluke authorized service center to obtain return authorization information,

then send your defective Tester to that Service Center with a description of

the problem. Replace depleted batteries immediately to avoid Tester

damage from battery leakage.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER

WARRANTIES, SUCH AS FITNESS FOR A PARTICULAR PURPOSE,

ARE EXPRESSED OR IMPLIED. FLUKE IS NOT LIABLE FOR ANY

SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES

OR LOSSES, ARISING FROM ANY CAUSE OR THEORY. Since some

states or countries do not allow the exclusion or limitation of an implied

warranty or of incidental or consequential damages, this limitation of

liability may not apply to you.

11/99

orporation

P.O. Box 9090

Everett WA

98206-9090

urope B.V.

P.O. Box 1186

5602 B.D. Eindhoven

The Netherlands

Loading...

Loading...