Page 1

Electric utility plays

it safe with Fluke T+

Electrical Tester

Application Note

Testing

Functions

Case

Study

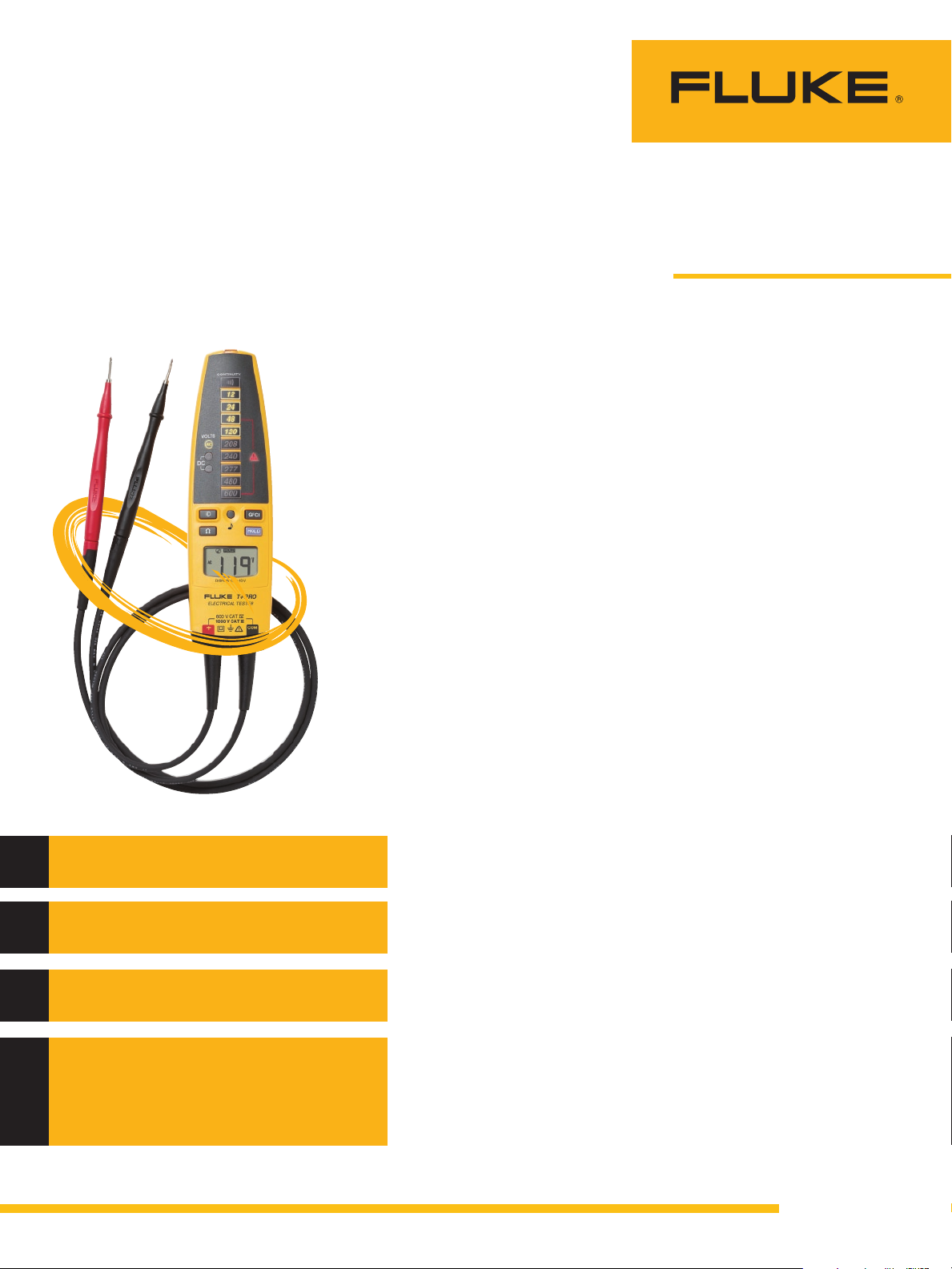

Measuring tools: Fluke T+PRO

Electrical Tester

Operator: Electrical utility field

service team

Tests conducted: Voltage, load,

continuity, tampering

Quote: “Our safety department got

involved,” the supervisor said, “and

they told us the solenoid-based tester

was old technology and not reliable.”

There’s a lot at stake when

electric utility field service

representatives turn the electric

power on or off. Their safety,

and that of their customers,

comes first.

So each time they remove

or install an electric meter for

one of 300,000 customers, field

reps for this Electric Co. test the

meter socket for voltage.

“My guys aren’t electricians,

they are strictly field service

employees,” said the supervisor

of field service and collections.

“They use a tester to determine

if voltages are correct, and if

there’s load being drawn from

inside the house when they

restore service. They’re also

trying to determine if there’s

tampering.”

The company won’t activate service if a device in the

home is drawing current. The

load could be an appliance,

such as a hair dryer, heater or

power tool, that would cause a

hazard or even start a fire if left

on unattended. Another problem is tampering with electric

service, which involves rewiring to bypass the meter and get

power for free. Of course that’s

illegal, but a greater concern

is the fire and shock hazard

tampering with circuitry can

cause for residents and utility

workers.

In the past, the service representatives used a solenoid-based

electrical tester or “Wiggy

device to detect voltage and load

(see sidebar). But recently, the

supervisor had them try a new

™”

tool for the job, the safety-rated

Fluke T+PRO Electrical Tester. It

all started with an incident that

could have had tragic consequences: A service rep tested a

meter socket, but the solenoid

tester in use did not detect that

there was continuity present.

Someone had tampered with

the service. The continuity

caused a short.

“Our safety department got

involved,” the supervisor said,

“and they told us the solenoidbased tester was old technology and not reliable.” As they

looked for a replacement tool,

the team determined that the

digital multimeters used elsewhere in the company were too

sensitive and had more features

than the service reps needed.

Then they heard about a new

device, the safety-rated Fluke

T+PRO Electrical Tester, that

was specifically designed to

do the job of the old solenoidbased testers, but more accurately and safely.

The Fluke T+PRO tester is

safety rated for use in IEC CAT

IV 600 V (including outside

facilities, service entrance and

electric meters) and CAT III

1000 V settings and complies

with the National Fire Protection Association (NFPA) standard 70E when used properly

per Article 110.9. It looked like

it could meet the team’s need

for a safety-rated test tool of

compact size, capable of testing

meter sockets without picking

up stray or “ghost” voltage.

From the Fluke Digital Library @ www.fluke.com/library

Page 2

When they tested the Fluke

T+PRO on the job, the field service team liked its ease of use

and multiple signaling methods

(LCD, LED, sound and vibration)

and its built-in flashlight, and

felt the unit was built tough

enough for daily industrial use.

They also appreciated its added

features for resistance, continuity and GFCI testing. One rep

commented that the Fluke tool

detected a small load—a transistor radio left on—that the

solenoid tester did not pick up.

Another group of employees,

the meter electricians who

actually test electric meter

function, liked the tool’s ability

to test all three power phases

and determine the phase rotation between any two phases.

The team also had suggestions for the Fluke design

engineers, such as larger

buttons for gloved hands

and a battery life indicator.

They noted that the unit was

designed to measure voltage

even if the batteries for the unit

were depleted or missing. The

T+PRO test leads took some

getting used to, but the unit

does come with velcro wraps

and on-unit probe storage to

help keep them under control.

Solenoid-based Testers: What’s the Buzz?

The Fluke T+PRO passed

the field tests, and the utility

is adding the tool as a standard to replace all of the old

solenoid-based testers. “These

devices worked perfectly,” the

supervisor said. “They do what

they are intended to do and

they have very nice features.

We’re going to bring them in

as a regular stock item in our

warehouse,” he said. And, in

addition to the 25 field service

representatives, and the meter

electricians, they anticipate that

the overhead and underground

crews too will adopt the Fluke

T+PRO.

Their compact size and ruggedness have made solenoid-based

electrical testers a traditional

favorite for electrical industry

professionals, but advancing

safety standards are leaving

these devices behind. These

classic testers are no longer

safe to use by NFPA electrical

measurement standards and not

CAT rated by the International

Electrotechnical Commission

(IEC). Many companies have

outright barred them from use.

A solenoid depends on the

movement of a ferrite slug in

response to the energization

and de-energization of an electromagnetic coil. The indication function of these testers

depends on a spring, which

drives a mechanical pointer.

The spring restrains the slug,

which slides to one end of its

chamber or the other, depending on whether the coil has

enough energy to cause the

slug to overcome the opposing

force of the spring. Unfortunately, solenoid-based testers

have several shortcomings:

The amount of energy

•

required restricts their

sensitivity. In the US, a

useful solenoid-based tester

will measure voltages up

to 480 V or more. But the

poor dynamic range of the

magnetics limits the ability of

such a device to detect voltages below about 100 V.

Solenoid-based testers have

•

relatively low input impedance—10 kilohms at the

upper end, but often as low

as 1 kilohm. So solenoidbased testers can easily

make their presence felt in a

circuit as loads and interfere

with the operation of that

circuit. The relatively high

current draw also creates

enough heat that the testers

can quickly overheat, even

to the point of damaging the

tester.

These testers are gener-

•

ally unable to comply to

IEC 61010 due to excessive

current draw, poor dielectric

withstand performance and

impulse destruction due to

transients originating from

the mains. This is one reason

many companies forbid the

use of voltage testers on

anything but 24 V control

circuits, and some forbid

them altogether.

The high current flowing

•

through solenoid-based

testers has another downside. You can easily carry a

lethal current through the

tester. Wearing insulated

gloves can reduce the shock

hazard, but you’ll also be

risking an arc hazard with

each use.

Fluke. Keeping your world

up and running.

Fluke Corporation

PO Box 9090, Everett, WA 98206 U.S.A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2007-2009 Fluke Corporation.

Specifications subject to change without notice.

Printed in U.S.A. 3/2009 3057495 A-EN-N Rev C

Modification of this document is not permitted

without written permission from Fluke Corporation.

®

2 Fluke Corporation Electric utility plays it safe with Fluke T+ Electrical Tester

Loading...

Loading...