Page 1

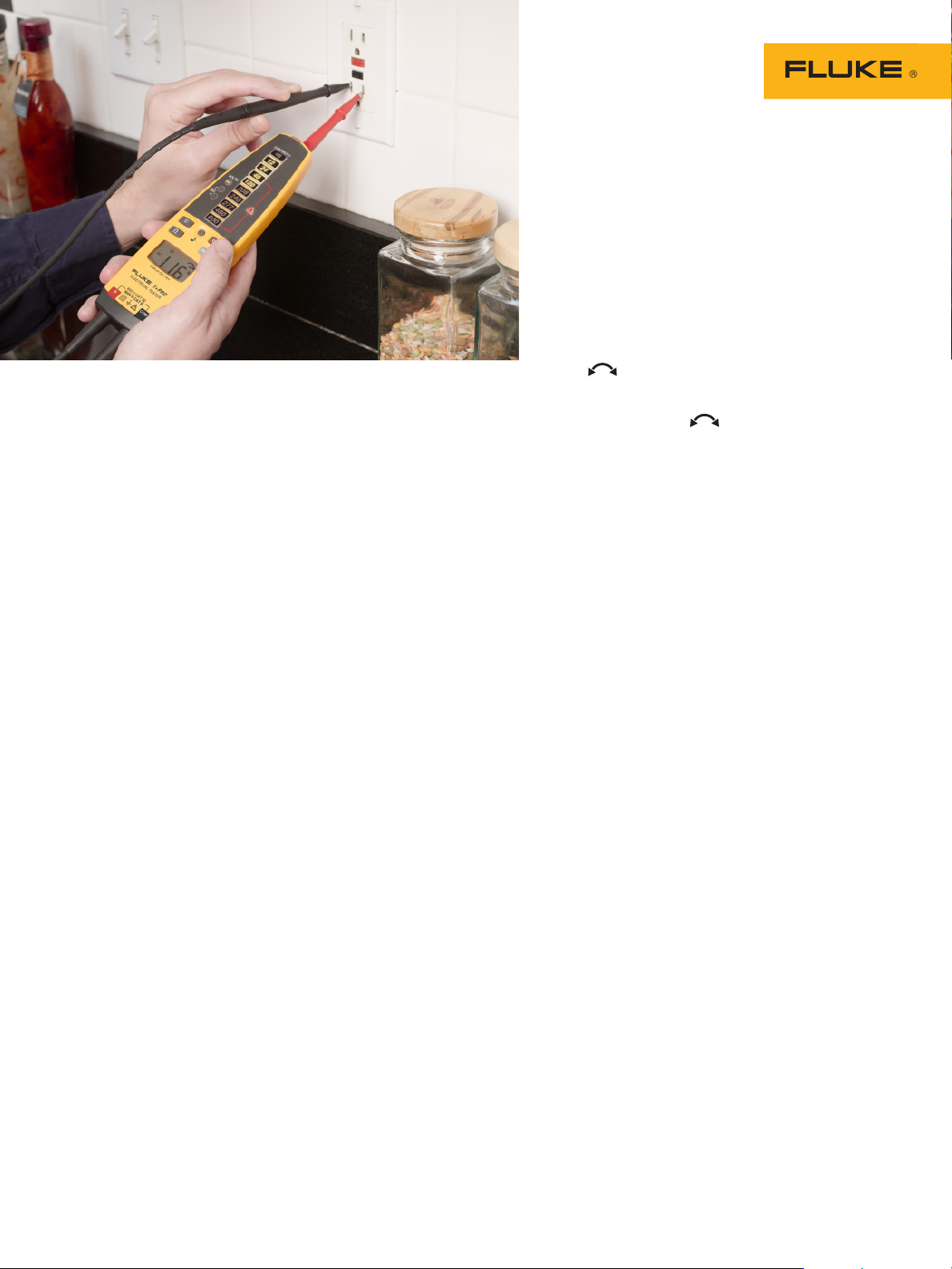

The NEW Fluke

T+ and T+PRO

Electrical Testers

The first electrical tester had a simple solenoid that

pulled an indicator attached to a spring across a special voltage scale. The higher the voltage applied to

the solenoid, the further the indicator would be pulled

against the spring.

High accuracy is not a big concern when installing

lighting, switches, and other common electrical wiring

and equipment. Often, you just need to differentiate

common voltages from one another.

The problem is, these classic testers are no longer

safe to use by NFPA electrical measurement standards. Many companies have outright barred them

from the field and floor.

Since the basic measurement need was still there,

Fluke developed two new testers that did what electricians needed them to do. The new T+ and T+PRO

ac/dc electrical testers are rated to CAT IV 600 V

and CAT III 1000 V and use light, sound, and vibration

to indicate voltage. They also test for continuity and

GFCI and are low impedance. Additionally, the T+PRO

model has a LCD digital readout screen, a rotary

phase indicator, and resistance.

Application Note

Basic voltage

applications

Before starting any test, touch

the two leads of the T+PRO or

T+ together. All of the LEDs

should light up. That means the

tester is working and has battery

power.

These testers have nine LEDs,

each of which indicates a specific voltage, that illuminate

when the test leads contact

voltage. At the same time, the

testers beep and vibrate strongly

enough that you can feel it when

voltage is detected. For ac voltage, the ac LED lights up and the

beeper makes a chirping sound.

For dc voltage, the dc positive

or negative LED lights up and

the beeper makes a steady tone.

F r o m t h e F l u k e D i g i t a l L i b r a r y @ w w w . f l u k e . c o m / l i b r a r y

And, on the T+PRO, a digital

readout of either measurement

will appear on the LCD. If the

batteries fail, the LEDs will still

light up, so that the user always

has voltage detection capability.

Both testers measure ac and dc

voltage from 12 to 600 volts (the

T+PRO measures down to 10.2 V

on the LCD). For the residential

electrician, the T+ model covers

all of the basic electrical measurements, from voltage entering

the house at the power panel,

to the output of the transformer

powering the doorbell.

One typical use is checking

a 240 V ac outlet for a dryer or

range for correct wiring. Place

the tester’s probes between the

two hot sockets of the outlet. The

tester will automatically come

on, illuminate the LEDs to indicate 240 V ac, beep, vibrate, and

illuminate the hazardous voltage

LED. Next, check for 120 V ac

between each hot and neutral

socket of the outlet.

For industrial techs, check voltage balance between phases—is

it within 2 %—and for voltage

drop across motor contactors

or relays, where voltage drop

should be negligible. Also check

control circuit voltage. To eliminate measurement errors from

ghost or stray voltages, these

testers’ low input impedance

loads the circuit and absorbs any

ghost voltage energy. That gives

you a reliable indication that the

circuit you are testing is truly

dead.

Page 2

Continuity

One common continuity application is checking switches or

breakers for continuity when they

are closed. With power removed

from the switch, place the tester

probes on the two switch contacts. If the switch is working

properly, the tester will illuminate

the continuity LED and sound

the beeper continuously when

the switch is closed. No need to

power the tester on or select a

function. As long as there is no

voltage present, the tester automatically comes on and selects

the continuity function.

GFCI testing

Both the T+ and the T+PRO

have a GFCI test function. After

installing a GFI protected circuit,

say a kitchen outlet branch circuit for example, apply power to

the circuit by closing the breaker

at the power panel. Go to one

of the kitchen outlets and place

the tester’s black lead into the

ground (not neutral) socket and

the red lead into the hot (small

slot) socket. If the branch circuit

is wired properly, the tester will

immediately illuminate the LEDs

to indicate normal voltage. Next,

press the tester’s GFCI button

and leave tester connected for

seven seconds. While testing, the

dc (+) and dc (-) LEDs will blink

to indicate the GFCI test is active.

If the GFI circuit is operating normally, the GFCI should trip and

remove power from the circuit.

With no power, the tester’s LEDs

should extinguish. Reset the GFCI

circuit and repeat the test from

the next outlet.

Nice-to-haves

When working in dimly-lit locations, use the LED flashlight built

in to the tester to illuminate the

connections and guide your measurement. The light stays on for

five seconds or as long as the

flashlight button is pressed. With

one probe locked into the builtin probe holder, the tester’s light

will illuminate the area where

the probe is pointing.

The Fluke T+ and T+PRO come

with special, extra-heavy-duty

test leads that hold up longer against the wear and tear

of normal use than standard

leads. Both test leads also have

removable probe tips for easy

tip replacement and to allow

alternate probe tip styles. The

test leads themselves can also

be replaced without having to

replace the entire tester.

Additional features of the

T+PRO

The T+PRO Electrical Tester has

additional features tailored to the

electrician working in commercial and industrial installations.

These features include a digital

display with a resolution up to

0.1 volts for readings between

10 V and 50 V, a resistance

function, and a Rotary Field

Direction function.

When measuring ac voltage

between phases of a threephase circuit, the T+PRO tester

indicates the phase relationship between the two test

leads as well as the voltage.

A typical application is connecting a three-phase motor

and testing for proper rotation

direction. Connect the tester’s

leads between two of the phase

conductors. The tester’s display

will indicate a clockwise rotation ( ) when the red test

lead voltage is 120° ahead of the

black lead. You’ll see a counterclockwise indicator ( ) when

the phase between the leads is

reversed. Next, move the red test

lead to the third phase conductor

to see its phase relationship to

the other two conductors. Now

you can connect the conductors to

the motor for the desired rotation.

Press the ohms Ω button to

switch the tester to resistance

mode. Now, you can check resistors in motors, fuses, switches,

relays, or other general resistance applications on dead circuits, up to 9.99 kΩ.

Last but not least, because the

T+PRO can measure down to

10 V with three digits of accuracy, it’s a far more accurate tool

for low-voltage lighting applications. Most standard electrical

testers (solenoid and solid-state)

only measure down to 12 V and

may not be able to see that a

step-down lighting transformer

is only putting out 10.8 volts.

(That’s a 10 % variance from

what the voltage should be.)

Depending upon the set up, the

bulbs may not function properly

(or at all). The farther down the

line you go from the transformer,

the greater the possible voltage

drop—but a standard voltage tester may still read 12 V, leading

you to believe that everything is

fine.

For more information on industrial and HVAC applications, read

the Fluke application note “HVAC

applications for the Fluke T+ and

T+PRO Electrical Testers.”

2 Fluke Corporation The NEW Fluke T+ and T+PRO Electrical Testers

Page 3

Five reasons to give up

your old solenoid tester

1. In the US, a useful solenoid tester can measure

up to 480 V or more. Having the ability to measure higher voltages limits the tool’s ability to

detect voltages below 100 V, due to the poor

dynamic range of its magnetics. Try using one

on 24 V or 48 V control circuits, and you may as

well be using a stick of wood.

2. Solenoid-based testers can appear on the circuit

under test as a load and interfere with its operation. The T+ and T+PRO testers have higher

input impedance than traditional solenoid-type

testers, but not so high that they have problems

with ghost voltages.

3. The relatively high current draw of solenoidbased testers means significantly more heat—

enough that the testers can quickly overheat

and even become damaged if you measure voltage too long. If you use a solenoid-based tester,

allow for half-minute cool-downs. The T+ and

T+PRO testers can measure voltage under 240 V

indefinitely.

4. Solenoid-based testers generally don’t comply

with the IEC 61010 electrical safety standard

due to excessive current draw, poor dielectric

withstand performance, and impulse destruction

from transients. When they fail, it can be catastrophic. Without IEC 61010 compliance, these

testers also miss compliance with NFPA 70E

(article 110.9) and other standards that require

environmental ratings.

5. Applying Ohm’s Law to the low-impedance

solenoid-based tester shows that you can easily carry a lethal current through the tester.

Wearing insulated gloves can reduce the shock

hazard, but you’ll also be risking an arc hazard each time. Solid-state testers, on the other

hand, provide additional protection against this

type of occurance.

Fluke. Keeping your world

up and running.

®

3 Fluke Corporation The NEW Fluke T+ and T+PRO Electrical Testers

Fluke Corporation

PO Box 9090, Everett, WA USA 98206

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2007 Fluke Corporation. All rights reserved.

Specifications subject to change without notice.

Printed in U.S.A. 4/2007 2825353 A-EN-N Rev A

Loading...

Loading...