Fluke PG7202 V2.03, PG7102 V2.03, PG7302 V2.03, PG7601 V2.03 Operation and Maintenance Manual

Page 1

PG7000™ PISTON GAUGES

PG7102™, PG7202™,

PG7302™, PG7601™

(Ver. 2.03 and Higher)

Operation and Maintenance Manual

©1998-2002 DH Instruments, Inc.

Page 2

PG7000™ OPERATION AND MAINTENANCE MANUAL

High pressure liquids and gases are potentially hazardous. Energy stored in these liquids and gases

can be released unexpectedly and with extreme force. High pressure systems should be assembled

and operated only by personnel who have been instructed in proper safety practices.

© 1998 - 2002 DH Instruments, Inc. All rights reserved.

Information in this document is subject to change without notice. No part of this document may be reproduced or transmitted in any

form or by any means, electronic or mechanical, for any purpose, without the express written permission of DH Instruments, Inc.

4765 East Beautiful Lane Phoenix Arizona 85044-5318 USA.

DH Instruments makes sincere efforts to ensure the accuracy and quality of its published materials; however, no warranty,

expressed or implied, is provided. DH Instruments disclaims any responsibility or liability for any direct or indirect damages

resulting from the use of the information in this manual or products described in it. Mention of any product or brand does not

constitute an endorsement by DH Instruments of that product or brand. This manual was originally composed in English and was

subsequently translated into other languages. The fidelity of the translation cannot be guaranteed. In case of conflict between the

English version and other language versions, the English version predominates.

DH Instruments, DH, DHI, PG7000, PG7102, PG7202, PG7302, PG7601, CalTool and COMPASS are trademarks, registered and

otherwise, of DH Instruments, Inc.

Swagelok is a registered trademark of the Swagelok Company.

Krytox is a registered trademark of the Dupont de Nemours Company.

Products described in this manual are manufactured under international patents and one or more of the following U.S.

patents: 5,142,483, 5,257,640, 5,331,838, 5,445,035. Other U.S. and international patents pending.

Document No. 550099k

020612

Printed in the USA

© 1998-2002 DH Instruments, Inc

Page 3

TABLE OF CONTENTS

T

AABBLLEE OOFF

T

C

OONNTTEENNTTS

C

S

TABLE OF CONTENTS ...............................................................I

TABLES..................................................................................V

FIGURES................................................................................ VI

ABOUT THIS MANUAL............................................................VII

ABOUT THIS MANUAL............................................................VII

1. INTRODUCTION ................................................................. 1

1.1 PRODUCT OVERVIEW ...........................................................................................................................1

1.2 SPECIFICATIONS ...................................................................................................................................2

1.2.1 GENERAL SPECIFICATIONS.......................................................................................................................2

1.2.1.1 EMBEDDED FEATURES...........................................................................................................................3

1.2.1.2 AMBIENT AND INSTRUMENT CONDITION MEASUREMENTS..............................................................4

1.2.2 PISTON-CYLINDER MODULES....................................................................................................................5

1.2.2.1 PC-7100/7600............................................................................................................................................5

1.2.2.2 PC-7200.....................................................................................................................................................6

1.2.2.3 PC-7300.....................................................................................................................................................7

1.2.3 MASS SETS...................................................................................................................................................8

1.2.4 PRESSURE MEASUREMENTS....................................................................................................................8

1.2.4.1 PC-7100/7600............................................................................................................................................8

1.2.4.2 PC-7200.....................................................................................................................................................9

1.2.4.3 PC-7300...................................................................................................................................................10

1.3 TERMINAL AND PLATFORM FRONT AND REAR PANELS...............................................................11

1.3.1 TERMINAL FRONT AND REAR PANELS ..................................................................................................11

1.3.1.1 PG TERMINAL FRONT PANEL...............................................................................................................11

1.3.1.2 PG TERMINAL REAR PANEL.................................................................................................................12

1.3.2 PLATFORM REAR PANELS.......................................................................................................................12

2. INSTALLATION ................................................................ 13

2.1 UNPACKING AND INSPECTION..........................................................................................................13

2.1.1 REMOVING FROM PACKAGING................................................................................................................13

2.1.1.1 PLATFORM..............................................................................................................................................13

2.1.1.2 MASS SET...............................................................................................................................................14

2.1.1.3 PISTON-CYLINDER MODULE(S)............................................................................................................14

2.1.2 INSPECTING CONTENTS...........................................................................................................................14

2.1.2.1 PLATFORM..............................................................................................................................................14

2.1.2.2 MASS SET...............................................................................................................................................19

2.1.2.3 PISTON-CYLINDER MODULE(S)............................................................................................................21

2.2 SITE REQUIREMENTS..........................................................................................................................22

2.3 SETUP ...................................................................................................................................................23

2.3.1 PREPARING FOR OPERATION.................................................................................................................23

2.3.1.1 SETTING UP THE PLATFORM...............................................................................................................23

2.3.1.2 SYSTEM PRESSURE INTERCONNECTIONS........................................................................................24

2.3.1.3 SETTING UP THE MASS SET.................................................................................................................24

2.3.2 INSTALLING A PISTON-CYLINDER MODULE INTO THE PLATFORM....................................................25

2.3.3 SWITCHING A PG7202 BETWEEN GAS OPERATION AND OIL OPERATION .......................................27

Page I © 1998-2002 DH Instruments, Inc.

Page 4

PG7000™ OPERATION AND MAINTENANCE MANUAL

2.4 POWER UP AND VERIFICATION.........................................................................................................28

2.4.1 POWER UP..................................................................................................................................................28

2.4.2 CHECK THAT ON-BOARD PISTON-CYLINDER MODULE AND MASS SET INFORMATION

ARE CORRECT...........................................................................................................................................28

2.4.3 SET LOCAL GRAVITY VALUE ...................................................................................................................29

2.4.4 SETUP PRESSURE EQUATION VARIABLE INPUT SOURCES.....................................................29

2.4.5 CHECK PROPER OPERATION OF AMBIENT CONDITION MEASUREMENTS ......................................29

2.4.6 APPLY PRESSURE TO THE PISTON-CYLINDER MODULE....................................................................30

2.4.7 CHECK PROPER BEHAVIOR OF MOTORIZED PISTON ROTATION (IF PRESENT)..............................30

2.4.8 CHECK PROPER OPERATION OF PISTON BEHAVIOR MEASUREMENTS...........................................31

2.4.8.1 VERIFY VACUUM REFERENCE (PG7601 ONLY).................................................................................31

2.4.9 CHECK AUTOMATED PRESSURE GENERATION (IF PRESENT) ....................................................32

2.4.10 CHECK/SET SECURITY LEVEL.................................................................................................................32

2.4.11 ADDITIONAL PRECAUTIONS TO TAKE BEFORE MAKING PRESSURE MEASUREMENTS................32

2.5 SHORT TERM STORAGE.....................................................................................................................33

3. GENERAL OPERATION ..................................................... 35

3.1 FUNDAMENTAL OPERATING PRINCIPLES .......................................................................................35

3.1.1 GAS OPERATED, LIQUID LUBRICATED PISTON-CYLINDER OPERATING PRINCIPLE

(PG7202) ....................................................................................................................................................36

3.2 KEYPAD LAYOUT AND PROTOCOL...................................................................................................37

3.3 SOUNDS................................................................................................................................................38

3.4 PRESSURE READY/NOT READY INDICATION...................................................................................38

3.4.1 PISTON POSITION READY/NOT READY..................................................................................................39

3.4.2 PISTON ROTATION READY/NOT READY.................................................................................................39

3.4.3 VACUUM REFERENCE READY/NOT READY (PG7601 ONLY) .....................................................40

3.5 PISTON POSITION................................................................................................................................41

3.6 MASS LOADING PROTOCOL..............................................................................................................42

3.7 MAIN RUN SCREEN..............................................................................................................................45

3.8 GENERAL FUNCTION/MENU FLOW CHART......................................................................................46

3.9 DIRECT FUNCTION KEYS....................................................................................................................47

3.9.1 DIRECT FUNCTION KEYS SUMMARY......................................................................................................47

3.9.2 [P-C].............................................................................................................................................................48

3.9.3 [UNIT]...........................................................................................................................................................49

3.9.3.1 CUSTOMIZING PRESSURE UNITS AVAILABLE UNDER THE UNIT FUNCTION ................................51

3.9.4 [MODE] ........................................................................................................................................................52

3.9.4.1 DIFFERENTIAL MEASUREMENT MODE (PG7601 ONLY) ........................................................54

3.9.4.2 HIGH LINE DIFFERENTIAL MEASUREMENT MODE (PG7102 AND PG7202 ONLY)..........................61

3.9.5 [SYSTEM] ....................................................................................................................................................73

3.9.5.1 FIRST SYSTEM RUN SCREEN...............................................................................................................74

3.9.5.2 SECOND SYSTEM RUN SCREEN..........................................................................................................75

3.9.6 [AMBIENT]...................................................................................................................................................76

3.9.7 [HEAD].........................................................................................................................................................77

3.9.8 [ROTATE] (OPTIONAL ON PG7102, PG7202 AND PG7302)....................................................................79

3.9.9 [GEN] (OPTIONAL)......................................................................................................................................80

3.9.10 [RES]............................................................................................................................................................81

3.9.11 [ENTER] FROM RUN SCREEN...................................................................................................................82

3.9.11.1 [ENTER] IN PRESSURE TO MASS MODE.............................................................................................83

3.9.11.2 [ENT] IN MASS TO PRESSURE MODE..................................................................................................85

3.9.12 [P OR M] ......................................................................................................................................................86

3.9.13 [ ] .............................................................................................................................................................86

3.10 [SETUP] MENU......................................................................................................................................87

3.10.1 <1SELECT>.................................................................................................................................................89

3.10.2 <2VIEW>......................................................................................................................................................89

3.10.3 <3EDIT>.......................................................................................................................................................90

3.11 [SPECIAL] MENU..................................................................................................................................92

3.11.1 <1PC/MS>....................................................................................................................................................93

3.11.1.1 CREATE PISTON-CYLINDER MODULE.................................................................................................94

3.11.1.2 EDIT PISTON-CYLINDER MODULE INFORMATION.............................................................................97

3.11.1.3 VIEW PISTON-CYLINDER MODULE......................................................................................................97

3.11.1.4 DELETE PISTON-CYLINDER MODULE .................................................................................................98

3.11.1.5 SELECT THE ACTIVE PISTON-CYLINDER MODULE...........................................................................98

3.11.1.6 ADD MASS SET.......................................................................................................................................98

3.11.1.7 EDIT MASS SET....................................................................................................................................102

3.11.1.8 VIEW MASS SET...................................................................................................................................103

© 1998-2002 DH Instruments, Inc. Page II

Page 5

TABLE OF CONTENTS

3.11.1.9 DELETE MASS SET ..............................................................................................................................103

3.11.1.10 SELECT MASS SET..............................................................................................................................103

3.11.1.11 ADD MASS LOADING BELL..................................................................................................................103

3.11.1.12 EDIT MASS LOADING BELL INFORMATION.......................................................................................105

3.11.1.13 VIEW MASS LOADING BELL................................................................................................................105

3.11.1.14 DELETE MASS LOADING BELL ...........................................................................................................105

3.11.1.15 SELECT MASS LOADING BELL ...........................................................................................................106

3.11.2 <2PRESU>.................................................................................................................................................106

3.11.3 <3HEAD>...................................................................................................................................................106

3.11.3.1 <3HEAD>, <1FLUID>.............................................................................................................................107

3.11.3.2 <3HEAD>, <2UNIT>...............................................................................................................................107

3.11.3.3 <3HEAD>, <3ATM> ...............................................................................................................................108

3.11.3.4 <3HEAD>, <4PISTON>..........................................................................................................................108

3.11.4 <4PREFS> .................................................................................................................................................109

3.11.4.1 <4PREFS>, <1SCRSVR>......................................................................................................................109

3.11.4.2 <4PREFS>, <2SOUND>........................................................................................................................109

3.11.4.3 <4PREFS>, <3TIME> ............................................................................................................................110

3.11.4.4 <4PREFS>, <4ID> .................................................................................................................................110

3.11.5 <5REMOTE>..............................................................................................................................................111

3.11.5.1 COM1, COM2 AND COM3 (RS232) ......................................................................................................111

3.11.5.2 IEEE-488................................................................................................................................................112

3.11.5.3 RS232 SELF TEST ................................................................................................................................112

3.11.5.4 EXTERNAL BAROMETER (RPM) COMMUNICATIONS (COM2).........................................................113

3.11.6 <6GL> ........................................................................................................................................................115

3.11.7 <7CAL>......................................................................................................................................................115

3.11.8 <8LEVEL>..................................................................................................................................................115

3.11.8.1 SECURITY LEVELS...............................................................................................................................116

3.11.9 <9RESET> .................................................................................................................................................119

3.11.9.1 <9RESET>, <1SETS>............................................................................................................................119

3.11.9.2 <9RESET>, <2UNITS> ..........................................................................................................................120

3.11.9.3 <9RESET>, <3COM>.............................................................................................................................120

3.11.9.4 <9RESET>, <4CAL>..............................................................................................................................120

3.11.9.5 <9RESET>, <5SETUPS>.......................................................................................................................121

3.11.9.6 <9RESET>, <6ALL>...............................................................................................................................121

4. REMOTE OPERATION ......................................................123

4.1 OVERVIEW..........................................................................................................................................123

4.2 INTERFACING.....................................................................................................................................123

4.2.1 RS232 INTERFACE...................................................................................................................................123

4.2.1.1 COM1.....................................................................................................................................................123

4.2.1.2 COM2 AND COM3.................................................................................................................................124

4.2.2 IEEE-488 (GPIB)........................................................................................................................................124

4.3 COMMANDS........................................................................................................................................125

4.3.1 COMMAND SYNTAX.................................................................................................................................125

4.3.2 COMMAND SUMMARY.............................................................................................................................126

4.3.3 ERROR MESSAGES.................................................................................................................................128

4.3.4 COMMAND DESCRIPTIONS.....................................................................................................................129

4.3.4.1 IEEE STD. 488.2 COMMON AND STATUS COMMANDS .....................................................129

4.3.4.2 PG7000 COMMANDS............................................................................................................................131

4.4 STATUS SYSTEM ...............................................................................................................................152

4.4.1 STATUS REPORTING SYSTEM...............................................................................................................152

4.4.1.1 STATUS BYTE REGISTER....................................................................................................................153

4.4.1.2 STANDARD EVENT REGISTER...........................................................................................................154

4.5 HIGH LINE DIFFERENTIAL MODE PROGRAMMING EXAMPLES ...................................................155

4.5.1 RECOMMENDED SEQUENCE FOR A HOST PROGRAM TO REMOTELY SET A NEW

HIGH LINE PRESSURE AND ENABLE HIGH LINE DIFFERENTIAL MODE ..........................................155

4.5.2 RECOMMENDED SEQUENCE FOR A HOST PROGRAM TO REMOTELY ENABLE

HIGH LINE DIFFERENTIAL MODE USING THE LAST LINE PRESSURE SETTING.............................157

Page III © 1998-2002 DH Instruments, Inc.

Page 6

PG7000™ OPERATION AND MAINTENANCE MANUAL

5. MAINTENANCE, ADJUSTMENTS AND CALIBRATION ........... 159

5.1 INTRODUCTION..................................................................................................................................159

5.2 PLATFORM .........................................................................................................................................160

5.2.1 CALIBRATION/ADJUSTMENT OF ON-BOARD MEASUREMENT FUNCTIONS....................................160

5.2.1.1 PRINCIPLES..........................................................................................................................................160

5.2.1.2 BAROMETRIC PRESSURE SENSOR...................................................................................................161

5.2.1.3 AMBIENT TEMPERATURE SENSOR...................................................................................................161

5.2.1.4 RELATIVE HUMIDITY SENSOR............................................................................................................162

5.2.1.5 PI S T O N - C Y L I N D E R M O D U L E T E M P E R A T U R E S E N S O R ..................................................... 162

5.2.1.6 REFERENCE VACUUM GAUGE (PG7601 ONLY)...............................................................................164

5.2.2 PISTON POSITION DETECTION ADJUSTMENT.....................................................................................165

5.2.3 EMPTYING OIL RUN-OFF TRAY (PG7202 AND PG7302 ONLY).................................................165

5.2.4 PURGE MOUNTING POST LIQUID RUN OFF (PG7202 ONLY) ..............................................166

5.2.5 DRIVE BELT REPLACEMENT..................................................................................................................166

5.3 PISTON-CYLINDER MODULES..........................................................................................................167

5.3.1 DISASSEMBLY, CLEANING AND MAINTENANCE.................................................................................167

5.3.2 DISASSEMBLY AND REASSEMBLY.......................................................................................................168

5.3.2.1 DISASSEMBLY AND REASSEMBLY OF GAS OPERATED, GAS LUBRICATED

PISTON-CYLINDER MODULES (PC-7100/7600).......................................................................168

5.3.2.2 DISASSEMBLY AND REASSEMBLY OF GAS OPERATED, LIQUID LUBRICATED PISTON-CYLINDER

MODULES (PC-7200)............................................................................................................................172

5.3.2.3 DISASSEMBLY AND REASSEMBLY OF OIL OPERATED, OIL LUBRICATED

PISTON-CYLINDER MODULES (PC-7300) ..........................................................................................174

5.3.3 FILLING OR EMPTYING GAS OPERATED, LIQUID LUBRICATED PISTON-CYLINDER

MODULE RESERVOIR WITH LIQUID ......................................................................................................176

5.3.4 CLEANING PISTON-CYLINDERS.............................................................................................................177

5.3.5 RECALIBRATION......................................................................................................................................179

5.3.5.1 UPDATING PISTON-CYLINDER MODULE FILES................................................................................179

5.4 MASS SETS.........................................................................................................................................179

5.4.1 CLEANING.................................................................................................................................................179

5.4.2 RECALIBRATION......................................................................................................................................179

5.4.2.1 UPDATING ON-BOARD MASS SET FILES..........................................................................................179

5.5 RELOADING EMBEDDED SOFTWARE INTO PG7000 FLASH MEMORY........................................180

5.6 DISASSEMBLY AND REASSEMBLY OF PG7000.............................................................................180

5.6.1 PLATFORM................................................................................................................................................180

5.6.2 TERMINAL.................................................................................................................................................180

6. TROUBLESHOOTING .......................................................181

6.1 OVERVIEW..........................................................................................................................................181

7. APPENDIX ...................................................................... 183

7.1 CONVERSION OF NUMERICAL VALUES..........................................................................................183

7.1.1 PRESSURE................................................................................................................................................183

7.2 DEFINED PRESSURE CALCULATIONS............................................................................................183

7.2.1 PG7102, PG7202 AND PG7302................................................................................................................185

7.2.2 PG7601 ......................................................................................................................................................186

7.2.3 FLUID HEADS ...........................................................................................................................................187

7.2.3.1 FLUID HEAD COMPONENTS...............................................................................................................187

7.2.3.2 OVERALL FLUID HEAD CORRECTION...............................................................................................188

7.3 GLOSSARY.........................................................................................................................................189

7.4 WARRANTY STATEMENT..................................................................................................................191

© 1998-2002 DH Instruments, Inc. Page IV

Page 7

TABLES AND FIGURES

T

AABBLLEES

T

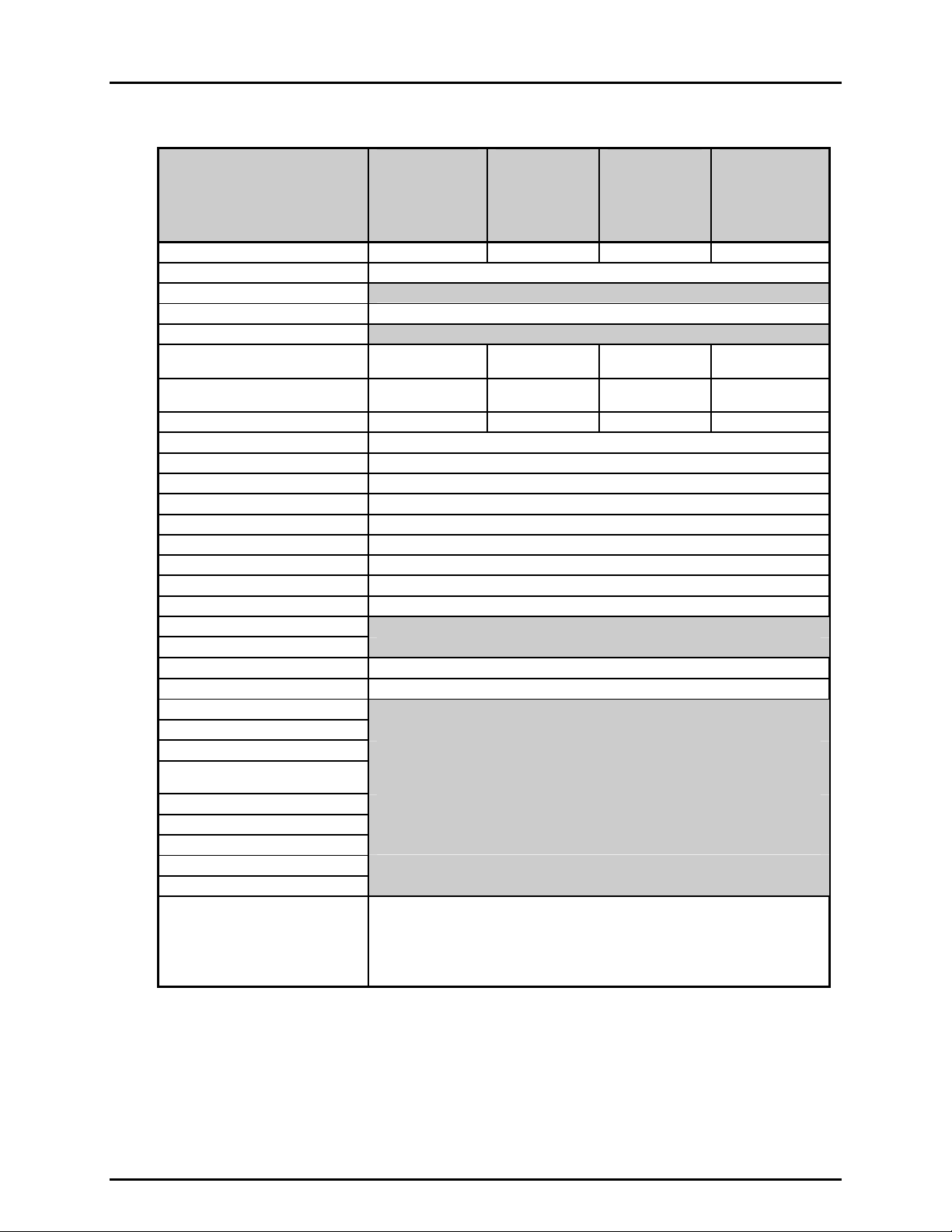

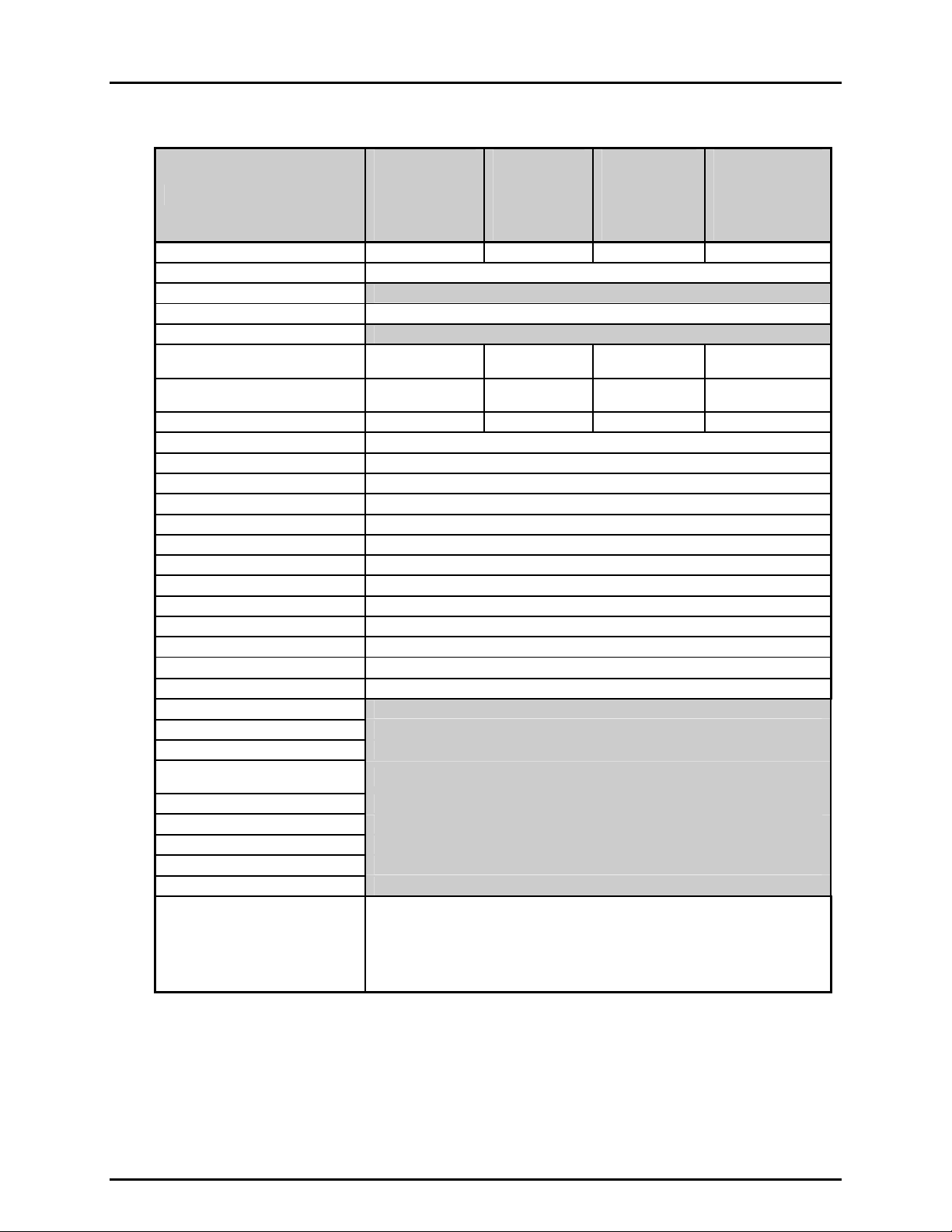

Table 1. PG7102 Parts List........................................................................................................................15

Table 2. PG7202 Parts List........................................................................................................................16

Table 3. PG7302 Parts List........................................................................................................................17

Table 4. PG7601 Parts List........................................................................................................................18

Table 5. Mass Parts List (excluding 80 and 100 kg)..................................................................................19

Table 6. Mass Parts List (80 and 100 kg)..................................................................................................19

Table 7. Mass Set Definitions ....................................................................................................................20

Table 8. Mass Set Compatibility ................................................................................................................20

Table 9. PC-7100/7600 Piston-Cylinder Modules Parts List .....................................................................21

Table 10. PC-7200 Piston-Cylinder Modules Parts List ............................................................................21

Table 11. PC-7300 Piston-Cylinder Modules Parts List ...........................................................................21

Table 12. Summary of PG7000 Direct Function Key Operations..............................................................47

Table 13. Pressure Units of Measure Available.........................................................................................51

Table 14. Valve Settings for Setting Differential Mode Static Pressure.....................................................57

Table 15. Valve Settings to Apply PG7000 Pressure to the RPM for Differential Mode Offsetting...........57

Table 16. Valve Settings for Operating in Differential Mode......................................................................59

Table 17. SETUP File Choices, Factory Preferred Choice and Normal Value..........................................88

Table 18. COM1, COM2 and COM3 Available Settings.......................................................................... 111

Table 19. Security Levels - Functions NOT Executed Per Function/Level.............................................. 117

Table 20. COM1 DB-9F Pin Designation.................................................................................................124

Table 21. COM2 and COM3 DB-9M Pin Designation .............................................................................124

Table 22. Command Summary................................................................................................................126

Table 23. Error Messages........................................................................................................................128

Table 24. Status Byte Register ................................................................................................................153

Table 25. Standard Event Register..........................................................................................................154

Table 26. Mounting Post Wire Colors, Description and Location............................................................164

Table 27. PG7000 Troubleshooting Checklist.........................................................................................181

Table 28. Pressure Unit of Measure Conversions...................................................................................183

Table 29. PG7000 Defined Pressure Calculation Variables....................................................................184

Table 30. DHI Authorized Service Providers ...........................................................................................191

S

Page V © 1998-2002 DH Instruments, Inc.

Page 8

PG7000™ OPERATION AND MAINTENANCE MANUAL

F

IIGGUURREES

F

Figure 1. PG Terminal Front Panel............................................................................................................ 11

Figure 2. PG Terminal Rear Panel.............................................................................................................12

Figure 3. PG Platform Rear Panel.............................................................................................................12

Figure 4. Piston-Cylinder Module Installation............................................................................................26

Figure 5. Piston Gauge Operating Principle..............................................................................................35

Figure 6. Gas Operated, Liquid Lubricated Piston-Cylinder (PC-7200) Operating Principle ...................37

Figure 7. PG7000 Keypad Layout..............................................................................................................37

Figure 8. Piston Stroke and Zones ............................................................................................................41

Figure 9. Run Screen Flow Chart ..............................................................................................................46

Figure 10. Differential Mode Controller Schematic....................................................................................55

Figure 11. High Line Differential Mode Schematic ....................................................................................64

Figure 12. Status Byte Register...............................................................................................................153

Figure 13. PG7202 Mounting Post Drain.................................................................................................166

Figure 14. 10 kPa/kg Gas Piston-Cylinder Module (Expanded View).....................................................169

Figure 15. 10 kPa/kg Piston Insertion Tool..............................................................................................170

Figure 16. Gas Piston-Cylinder Module Sleeve Nut Tool........................................................................170

Figure 17. 50 and 200 kPa/kg Gas Piston-Cylinder Modules (Expanded View).....................................171

Figure 18. Gas Operated, Liquid Lubricated Piston-Cylinder Module (Expanded View) .......................173

Figure 19. Oil Piston-Cylinder Module (Expanded View) ........................................................................175

Figure 20. Filling Gas Operated, Liquid Lubricated Piston-Cylinder Module Reservoir (PC-7200).......177

S

© 1998-2002 DH Instruments, Inc. Page VI

Page 9

ABOUT THIS MANUAL

A

BBOOUUTT

A

This manual provides the user with the information necessary to operate various PG7000 Piston Gauges.

It also includes a great deal of additional information provided to help you optimize PG7000 use and take

full advantage of its many features and functions.

This manual covers four PG7000 models: PG7102, PG7202, PG7302 and PG7601. The four models

have many features and characteristics in common as well as individual differences. When discussing

features that are common to all four models, they are referred to collectively as PG7000. When providing

information pertaining to a specific model, that model is referred to by its specific model number.

Before using the manual, take a moment to familiarize yourself with the Table of Contents structure.

All first time PG7000 users should read Sections 1 and 2. Section 3 provides a comprehensive

description of general PG7000 operating principles. Section 4 covers remote communication with an

external computer. Section 5 provides maintenance and calibration information. Section 6 is a quick

troubleshooting guide. Use the information in Section 6 to troubleshoot unexpected PG7000 behavior

based on the symptoms of that behavior.

Certain words and expressions have specific meaning as they pertain to PG7000s. The Glossary

(see Section 7) is useful as a quick reference for the definition of specific words and expressions as they

are used in this manual.

FOR THOSE OF YOU WHO “DON’T READ MANUALS”, GO DIRECTLY TO SECTION 2.3 TO SET UP

YOUR PG7000. THEN GO TO SECTION 2.4. THIS WILL GET YOU RUNNING QUICKLY WITH MINIMAL

RISK OF CAUSING DAMAGE TO YOURSELF OR YOUR PG7000. THEN… WHEN YOU HAVE

QUESTIONS OR START TO WONDER ABOUT ALL THE GREAT FEATURES YOU MIGHT BE MISSING,

GET INTO THE MANUAL!

T

T

HHIISS

M

AANNUUAAL

M

L

Manual Conventions

(CAUTION) is used throughout the manual to identify user warnings and cautions.

(NOTE) is used throughout the manual to identify operating and applications advice and

additional explanations.

[ ] indicates direct function keys (e.g., [RANGE]).

< > indicates PG7000 screen displays (e.g., <1yes>)

Page VII © 1998-2002 DH Instruments, Inc.

Page 10

PG7000™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 1998-2002 DH Instruments, Inc. Page VIII

Page 11

1. INTRODUCTION

11..

I

NNTTRROODDUUCCTTIIOON

I

N

1.1 PRODUCT OVERVIEW

PG7000 Piston Gauges are reference level pressure standards that operate on the piston

gauge principle. Pressure is defined by balancing it against the force exerted by a known mass

accelerated by gravity on the effective area of a piston-cylinder.

A PG7000 piston gauge consists of the PG7000 Platform, one or several piston-cylinder modules and a

mass set. A PG7000 system also includes the means to generate and adjust pressures and to

interconnect the system components and a device being calibrated or tested. The system may also

include COMPASS

test reports.

There are four PG7000 Platforms: Model PG7102, PG7202, PG7302 and PG7601. These have

common PG7000 presentation and features. They are distinguished by their normal operating medium

(oil or gas) and the capability to define pressures relative to a vacuum reference.

• PG7102 - Gas operated with gas lubricated piston-cylinder modules (PC-7100/7600

modules)

- Maximum pressure is 11 MPa (1 600 psi)

- Does not support definition of pressure against a vacuum reference

®

software to assist in executing test sequences, acquiring test data and producing

• PG7202 - Gas operated, liquid lubricated piston-cylinder modules (PC-7200 modules)

- Oil operated piston-cylinder modules (PC-7300 modules)

- Its maximum pressure is 110 MPa (16 000 psi) when operated with a PC-7200 module

- Its maximum pressure is 200 MPa (30 000 psi) when operated with a PC-7300 module

- Does not support definition of pressure against a vacuum reference

• PG7302 - Oil operated (PC-7300 modules)

- Maximum pressure is 500 MPa (72 500 psi)

• PG7601 - Gas operated, gas lubricated piston-cylinder modules (PC-7100/7600 modules)

- Maximum pressure is 11 MPa (1 600 psi)

- Supports definition of pressure against a vacuum reference

PG7000 platforms, piston-cylinder modules and mass sets are designed to maximize metrological

performance and ease of operation. They include many features that enhance the fundamental precision

and stability of pressure measurements as well as simplifying use and reducing the operator influence on

the measurements. Extensive monitoring and controlling capability and advanced local and remote user

interfaces are integrated into PG7000 Platforms.

Operator interaction with PG7000 and its extensive capabilities is accomplished through the display and

keypad of the PG Terminal or from a computer via a standard RS232 or IEEE-488 interface.

Page 1 © 1998-2002 DH Instruments, Inc.

Page 12

PG7000™ OPERATION AND MAINTENANCE MANUAL

1.2 SPECIFICATIONS

1.2.1 GENERAL SPECIFICATIONS

Power Requirements

Operating Temperature Range

Weight

Instrument platform with no mass loaded.

PG7102

PG7202

PG7302

PG7601

PG Terminal

Dimensions

Instrument Platform

PG Terminal

Microprocessors

Instrument Platform

PG Terminal

Communication Ports

RS232

IEEE-488

Overall Pressure Ranges

Actual range depends on piston-cylinder

and mass set selection

PG7102 Gauge: 5 kPa to 11 MPa (0.7 to 1 600 psi)

PG7202 Gauge: 100 kPa to 110 MPa (15 to 16 000 psi)

85 to 264 VAC, 50/60 Hz, 22 VA max. consumption.

15 to 35 °C

13 kg (29 lb)

13 kg (29 lb)

13 kg (29 lb)

17 kg (37 lb)

1.4 kg (3 lb)

36 cm H x 40 cm W x 35 cm D (14.5 in. x 15.8 in. x 13.8 in.)

(Height: Top of mounting post with piston-cylinder module installed

for PG7102/PG7202/PG7302; top of bell jar for PG7601.)

12 cm H x 15 cm W x 20 cm D (4.7 in. H x 5.9 in. W x 7.9 in. D)

Motorola 68302

Hitachi 64180

COM1: Host computer

COM2: External barometer and pass through communications

COM3: Automated pressure generator/controller Host computer

Absolute: 105 kPa to 11 MPa (15 to 1 600 psi)

Differential: DP + static pressure < 11 MPa (1 600 psi)

Absolute: 200 kPa to 110 MPa (30 to 16 000 psi)

Differential: DP + static pressure < 110 MPa (16 000 psi)

PC-7200 can be operated in oil up to 200 MPa (30 000 psi)

PG7302 Gauge: 20 kPa to 500 MPa (3 to 75 000 psi)

PG7601 Gauge: 5 kPa to 7 MPa (0.7 to 1 000 psi)

Operating Media

PG7102

PG7202

PG7302

PG7601

Maximum Mass Load

PG7102

PG7102

PG7302

PG7601

© 1998-2002 DH Instruments, Inc. Page 2

Absolute: 120 kPa to 500 MPa (20 to 75 000 psi)

Absolute: 5 kPa to 7 MPa (0.7 to 1 000 psi)

Differential: 90 to 350 kPa (-12 to 50 psi) at

15 to 200 kPaa (2 to 30 psia) static pressure

Gas: air, helium, nitrogen

Gas: any non-corrosive

Oil: Di2-EthylHexyl Sebacate (synthetic oil)

Oil: Di2-EthylHexyl Sebacate (synthetic oil)

Gas: air, helium, nitrogen

100 kg, while not exceeding 11 MPa (1 600 psi)

100 kg, while not exceeding 110 MPa (16 000 psi) when operated

with PC-7200 piston-cylinder modules or 200 MPa (30 000 psi) when

operated with PC-7300 piston-cylinder modules

100 kg

35 kg

when used with PC-7300 oil operated piston-cylinders.

Page 13

1. INTRODUCTION

Pressure Connections

PG7102

PG7202

PG7302

PG7601

CE Conformance

Test port: DH200

Test port: DH500

Drain port: DH500

Test port: DH500

Test port: DH200

Bell Jar Vent Port: DH200

Vacuum Reference

Pump Down Port: KF25

DH200 and DH500 are gland and collar type fittings for

1/4 in. (6 mm) coned and left hand threaded tubes.

DH200 is equivalent to AE SF250C, HIP LF4, etc.

DH500 is equivalent to AE F250C, HIP HF4, etc.

Available, must be specified.

1.2.1.1 EMBEDDED FEATURES

• Local control with 2 x 20 vacuum fluorescent display and 4 x 4 function

driven keypad.

• Real time (1 second update rate) display and measurement of ambient

(pressure, temperature, humidity) and instrument (piston-cylinder

temperature, piston position, piston drop rate, piston rotation rate, piston

rotation decay rate, reference vacuum) conditions.

• Real time (1 second update rate) mass-to-pressure and pressure-to-mass

calculations taking into consideration all environmental and operational

variables.

• Full gas and liquid fluid head corrections including DUT head correction and

piston position head correction.

• Adjustable mass loading resolution (0.01 g to 0.1 kg).

• Audible prompts of instrument status (piston movement, Ready/Not Ready indication)

with override capability.

• Interfacing and automatic exploitation of any external barometer (RS232).

• Automated differential mode to define low differential pressures at various

static pressures between vacuum and two atmospheres.

• Automated high line differential mode to define differential pressure at high

line pressure.

• Storage and one step activation of metrological data on up to 18 piston-cylinder

modules, (3) mass sets and (3) mass loading bells.

• Continuous pressure Ready/Not Ready indication based on measured

conditions.

• Motorized, intelligent piston drive system based measured rotation rate with

operator alert and manual override (motorization optional on PG7102 and

PG7302).

• Built-in drivers for automated pressure control components and piston

floating with override capability.

• Full RS232 and IEEE-488 communications with multi-level commands to set

and read all instrument functions.

Page 3 © 1998-2002 DH Instruments, Inc.

Page 14

PG7000™ OPERATION AND MAINTENANCE MANUAL

1.2.1.2 AMBIENT AND INSTRUMENT CONDITION

MEASUREMENTS

Temperature

Range

Resolution

Measurement Uncertainty

Barometric Pressure

with Internal Sensor

Range

Resolution

Measurement Uncertainty

Relative Humidity

Range

Resolution

Measurement Uncertainty

Piston Position

Range

Resolution

Measurement Uncertainty

Piston Rotation

(Rate and deceleration)

Range

Resolution

Ambient

0 to 40

0.1 0.01

± 1 ± 0.1

70 to 110 kPa

10 Pa

± 140 Pa

Barometric pressure can also be read automatically with any

RS232 device such as a DHI RPM.

5 to 95 % RH

1 % RH

± 10 % RH

± 4.5 mm

0.1 mm

± 0.2 mm

2 to 99 rpm

1 rpm

Piston Cylinder Module

o

C 0 to 40 oC

Vacuum

(PG7601 only)

Range

Resolution

Measurement Uncertainty

0 to 20 Pa

0.01 Pa

± 0.1 Pa or 10 % of reading, whichever is greater

© 1998-2002 DH Instruments, Inc. Page 4

Page 15

1. INTRODUCTION

1.2.2 PISTON-CYLINDER MODULES

All piston-cylinders are integrated modules including mounting hardware delivered in individual

shipping and storage bullet cases.

1.2.2.1 PC-7100/7600

Gas operated, gas lubricated piston-cylinder characteristics.

PC-7100/7600-10

Operation

Piston Material

Cylinder Material

Nominal Diameter

Nominal Area

Mounting System

PC-7100/7600-50

Operation

Piston Material

Cylinder Material

Nominal Diameter

Nominal Area

Mounting system

PC-7100/7600-200

Operation

Piston Material

Cylinder Material

Nominal Diameter

Nominal Area

Mounting System

Gas operated, gas lubricated

Ceramic (tungsten carbide available, higher mass)

Tungsten carbide

35 mm

1 000 mm

Simple free deformation

Gas operated, gas lubricated

Tungsten carbide

Tungsten carbide

16 mm

200 mm

Negative free deformation

Gas operated, gas lubricated

Tungsten Carbide

Tungsten carbide

8 mm

50 mm

Negative free deformation

2

2

2

Page 5 © 1998-2002 DH Instruments, Inc.

Page 16

PG7000™ OPERATION AND MAINTENANCE MANUAL

1.2.2.2 PC-7200

Gas operated, liquid lubricated piston-cylinder module characteristics.

Though not recommended for day to day operation, PC-7200 modules can

also be filled completely with oil and operated with oil as the test medium

(see Section 2.3.3).

PC-7200-100

Operation

Lubricating Liquid

Piston Material

Cylinder Material

Nominal Diameter

Nominal Area

Mounting System

PC-7200-200

Operation

Lubricating Liquid

Piston Material

Cylinder Material

Nominal Diameter

Nominal Area

Mounting System

PC-7200-500

Operation

Lubricating Liquid

Piston Material

Cylinder Material

Nominal Diameter

Nominal Area

Mounting System

PC-7200-1

Operation

Lubricating Liquid

Piston Material

Cylinder Material

Nominal Diameter

Nominal Area

Mounting System

PC-7200-2

Operation

Lubricating Liquid

Piston Material

Cylinder Material

Nominal Diameter

Nominal Area

Mounting System

Gas operated, liquid lubricated

Synturion 6 (Krytox

®

optional)

Tungsten carbide

Tungsten carbide

11.2 mm

98.1 mm

2

Negative free deformation

Gas operated, liquid lubricated

Synturion 6 (Krytox

®

optional)

Tungsten carbide

Tungsten carbide

7.9 mm

49.0 mm

2

Negative free deformation

Gas operated, liquid lubricated

Di-2-ethylhexyl Sebacate (Krytox

Tungsten carbide

Tungsten carbide

5.0 mm

19.6 mm

2

Negative free deformation

Gas operated, liquid lubricated

Di-2-ethylhexyl Sebacate (Krytox

Tungsten carbide

Tungsten carbide

3.5 mm

2

9.8 mm

Negative free deformation

Gas operated, liquid lubricated

Di-2-ethylhexyl Sebacate (Krytox

Tungsten carbide

Tungsten carbide

2.5 mm

2

4.9 mm

Negative free deformation

®

optional)

®

optional)

®

optional)

© 1998-2002 DH Instruments, Inc. Page 6

Page 17

1. INTRODUCTION

1.2.2.3 PC-7300

PC-7300 modules PC-7300-1, -2 and -5 may also be used in a PG7202 platform.

Oil operated, oil lubricated piston-cylinder module characteristics.

PC-7300-100

Operation

Piston and Cylinder Material

Nominal Diameter

Nominal Area

Mounting System

PC-7300-200

Operation

Piston Material

Nominal Diameter

Nominal Area

Mounting System

PC-7300-500

Operation

Piston Material

Nominal Diameter

Nominal Area

Mounting System

PC-7300-1

Operation

Piston Material

Nominal Diameter

Nominal Area

Mounting System

PC-7300-2

Operation

Piston Material

Nominal Diameter

Nominal Area

Mounting System

PC-7300-5

Operation

Piston Material

Nominal Diameter

Nominal Area

Mounting System

Oil operated, oil lubricated

Tungsten carbide

11.2 mm

98.1 mm

2

Simple free deformation

Oil operated, oil lubricated

Tungsten carbide

7.9 mm

49.0 mm

2

Simple free deformation

Oil operated, oil lubricated

Tungsten carbide

5.0 mm

19.6 mm

2

Simple free deformation

Oil operated, oil lubricated

Tungsten carbide

3.5 mm

2

9.8 mm

Simple free deformation

Oil operated, oil lubricated

Tungsten carbide

2.5 mm

2

4.9 mm

Simple free deformation

Oil operated, oil lubricated

Tungsten carbide

2.0 mm

2

2.0 mm

Simple free deformation

Page 7 © 1998-2002 DH Instruments, Inc.

Page 18

PG7000™ OPERATION AND MAINTENANCE MANUAL

1.2.3 MASS SETS

Masses > 50g

Material

Finish

Adjustment Tolerance

Uncertainty of Measured Values

Masses < 50g

304L non-magnetic stainless steel

Electropolished

± 20 ppm of nominal value

± 5 ppm or 1 mg, whichever is greater

Conform to NIST S1

Masses designated “tare” are delivered without reported measured values and are intended

only for use on the “tare” PG7000 in high line differential pressure measurement mode.

1.2.4 PRESSURE MEASUREMENTS

1.2.4.1 PC-7100/7600

For uncertainty in piston-cylinder effective area and typical measurement

uncertainty in pressure defined by the piston gauge, see the piston-cylinder

calibration report and DHI Technical Note 7920TN01.

All masses are delivered in molded, reusable, transit cases with custom inserts.

PC-7100/7600-10

Sensitivity

Reproducibility

Typical Drop Rate (35 kg)

1

0.02 Pa + 0.5 ppm

2

± 2 ppm

0.2 mm/min

PC-7100/7600-50

Sensitivity

Reproducibility

Typical Drop Rate (35 kg)

PC-7100/7600-200

Sensitivity

Reproducibility

Typical Drop Rate (35 kg)

1

0.1 Pa + 0.5 ppm

2

± 3 ppm

0.5 mm/min

1

0.4 Pa + 0.5 ppm

2

± 5 ppm

1.0 mm/min

Piston-cylinder modules designated “tare” are delivered without reported

values and are intended only for use on the “tare” PG7000 in high line

differential pressure measurement mode.

1 Sensitivity: The smallest variation in input detectable in output.

2 Reproducibility: Combined long term stability of piston-cylinder effective area and masses.

© 1998-2002 DH Instruments, Inc. Page 8

Page 19

1. INTRODUCTION

1.2.4.2 PC-7200

For uncertainty in piston-cylinder effective area and typical measurement

uncertainty in pressure defined by the piston gauge, see the piston-cylinder

calibration report and DHI Technical Note 7920TN01.

PC-7200-100

Sensitivity

Reproducibility

Typical Drop Rate (50 kg)

1

2 Pa + 1 ppm

2

± 5 ppm

0.10 mm/min

PC-7200-200

Sensitivity

Reproducibility

Typical Drop Rate (50 kg)

PC-7200-500

Sensitivity

Reproducibility

Typical Drop Rate (50 kg)

PC-7200-1

Sensitivity

Reproducibility

Typical Drop Rate (50 kg)

PC-7200-2

Sensitivity

Reproducibility

Typical Drop Rate (50 kg)

1 Sensitivity: The smallest variation in input detectable in output.

2 Reproducibility: Combined long term stability of piston-cylinder effective area and masses.

1

4 Pa + 1 ppm

2

± 5 ppm

0.15 mm/min

1

10 Pa + 1 ppm

2

± 5 ppm

0.20 mm/min

1

20 Pa + 1 ppm

2

± 5 ppm

0.25 mm/min

1

40 Pa + 1 ppm

2

± 5 ppm

0.50 mm/min

Page 9 © 1998-2002 DH Instruments, Inc.

Page 20

PG7000™ OPERATION AND MAINTENANCE MANUAL

1.2.4.3 PC-7300

For uncertainty in piston-cylinder effective area and typical measurement

uncertainty in pressure defined by the piston gauge, see the piston-cylinder

calibration report and DHI Technical Note 7920TN01.

PC-7300-100

Sensitivity

Reproducibility

Typical Drop Rate (50 kg)

1

2 Pa + 1 ppm

2

± 5 ppm

0.02 mm/min

PC-7300-200

Sensitivity

Reproducibility

Typical Drop Rate (50 kg)

PC-7300-500

Sensitivity

Reproducibility

Typical Drop Rate (50 kg)

PC-7300-1

Sensitivity

Reproducibility

Typical Drop Rate (50 kg)

PC-7300-2

Sensitivity

Reproducibility

Typical Drop Rate (50 kg)

PC-7300-5

Sensitivity

Reproducibility

Typical Drop Rate (50 kg)

1 Sensitivity: The smallest variation in input detectable in output.

2 Reproducibility: Combined long term stability of piston-cylinder effective area and masses.

1

4 Pa + 1 ppm

2

± 5 ppm

0.04 mm/min

1

10 Pa + 1 ppm

2

± 5 ppm

0.10 mm/min

1

20 Pa + 1 ppm

2

± 5 ppm

0.20 mm/min

1

40 Pa + 1 ppm

2

± 5 ppm

0.40 mm/min

1

100 Pa + 1 ppm

2

± 5 ppm

1.00 mm/min

© 1998-2002 DH Instruments, Inc. Page 10

Page 21

1. INTRODUCTION

1.3 TERMINAL AND PLATFORM FRONT AND REAR PANELS

1.3.1 TERMINAL FRONT AND REAR PANELS

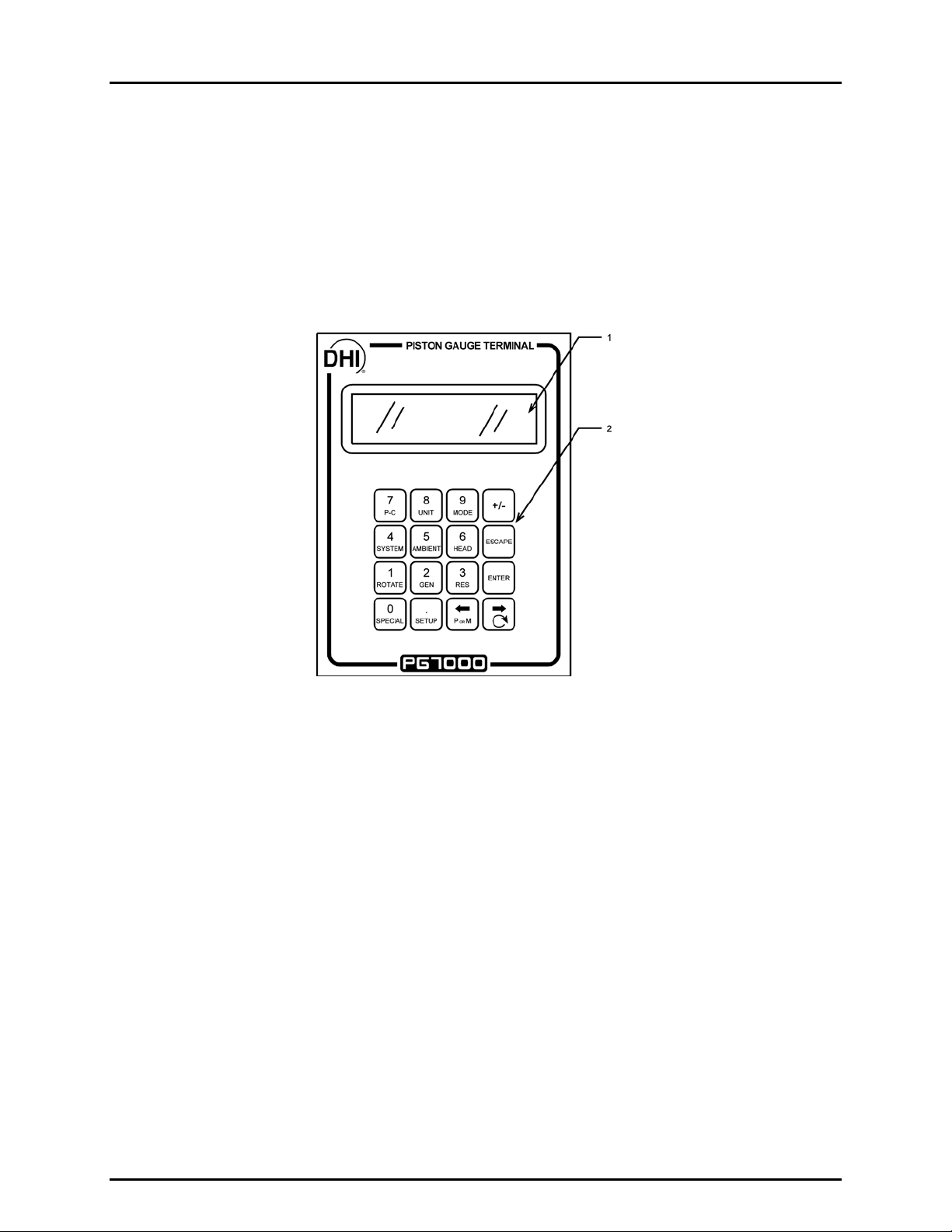

1.3.1.1 PG TERMINAL FRONT PANEL

The front panel assembly provides a 2 x 20 vacuum fluorescent display and a

4 x 4 membrane keypad for local user interface. The terminal front panel assembly

is the same for all PG7000 models (i.e., PG7102, PG7202, PG7302, PG7601).

1. Fluorescent display

2. Keypad

Figure 1. PG Terminal Front Panel

Page 11 © 1998-2002 DH Instruments, Inc.

Page 22

PG7000™ OPERATION AND MAINTENANCE MANUAL

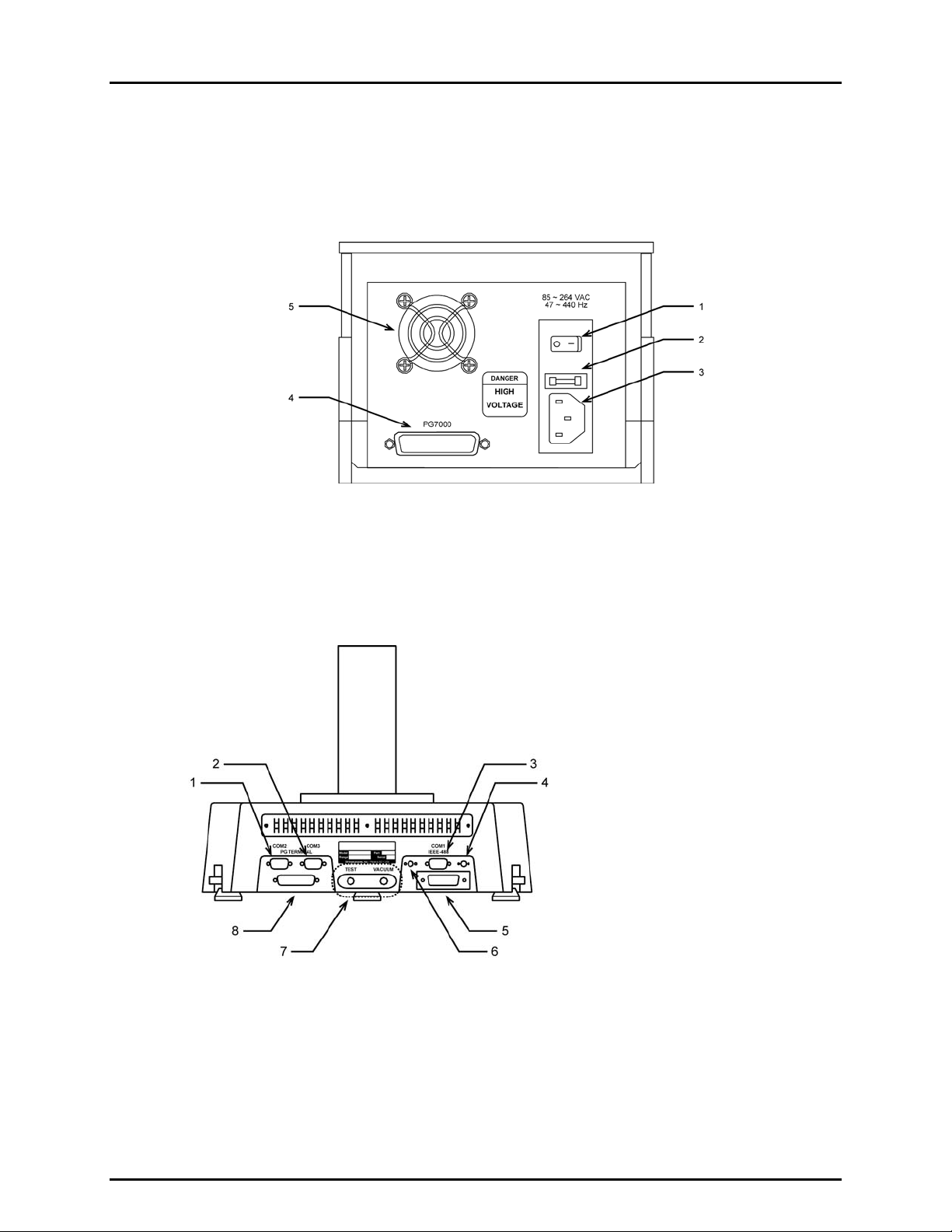

1.3.1.2 PG TERMINAL REAR PANEL

The rear panel assembly provides the communications connection to the

PG7000 Platform and the power connection module. The terminal rear panel

assembly is the same for all PG7000 models.

Figure 2. PG Terminal Rear Panel

1. Power Switch

2. Fuse (25-pin)

3. Power

Receptacle

4. Connector for

Cable to

PG7000

5. Cooling Fan

1.3.2 PLATFORM REAR PANELS

The PG7000 Platform rear panels provide the connection to the PG Terminal, remote

communication connections and pressure connection ports. The rear panels of all PG7000

models are identical except for the pressure connections (see Figure 3, # 6).

1. COM2 (RS232) - External Barometer and

Pass Through Communications

2. COM3 (RS232) - Automated Pressure

Generation/Control Component

3. COM1 (RS232) - Remote Host

Communications

4. Ambient Temperature Sensor

5. IEEE-488 - Remote Host Communications

6. Ambient Relative Humidity Sensor

7. Pressure Ports:

PG7102 - TEST port: DH200

PG7202 - TEST and DRAIN ports: DH500

PG7302 - TEST port: DH500

PG7601 - TEST and VACUUM vent ports: DH200

Vacuum pull down port on front

left side: KF25

8. PG7000 Terminal Port

Figure 3. PG Platform Rear Panel

© 1998-2002 DH Instruments, Inc. Page 12

Page 23

2. INSTALLATION

22..

I

NNSSTTAALLLLAATTIIOON

I

N

2.1 UNPACKING AND INSPECTION

2.1.1 REMOVING FROM PACKAGING

A typical PG7000 system includes the PG7000 Platform (see Section 2.1.1.1), a mass set,

(see Section 2.1.1.2), one or more piston-cylinder modules (see Section 2.1.1.3) and other

accessories (see the accessory Operation and Maintenance Manual or Instruction Sheet).

2.1.1.1 PLATFORM

The mass loading bell is a metrological element that is part of the mass set.

Like all of the masses, it is preferable not to handle it with bare hands.

Protective gloves are provided in the accessory kit of each PG7000 Platform.

The PG7000 Platform is shipped in a reusable, molded shipping and storage case.

Open the PG7000 shipping and storage case (it is the large, 66 cm x 53 cm

x 47 cm case).

Remove the PG Terminal and accessories from upper packing insert.

Inspect and inventory the accessories (see Section 2.1.2).

Remove the upper packing insert.

Carefully lift the PG7000 Platform from its position in the lower packing

insert. Note the orientation so that the same orientation will be used when

PG7000 is repacked.

Reinstall the upper packing insert into the shipping and storage case and

store in a safe place.

Page 13 ©1998-2002 DH Instruments, Inc.

Page 24

PG7000™ OPERATION AND MAINTENANCE MANUAL

2.1.1.2 MASS SET

The stability over time of PG7000 pressure measurements is a function of

the stability of the masses loaded on the piston. Precautions should be

taken in handling the masses to minimize influences that may change their

mass. This includes always wearing protective gloves when handling the

masses to avoid contaminating them with body oils and perspiration.

Protective gloves are provided in the accessory kits of PG7000 Platforms.

The mass set accessories are shipped in a separate corrugated container.

Open the corrugated container and inspect and inventory the accessories.

The PG7000 masses are shipped in reusable, molded shipping and

storage cases. The PG7000 masses should be removed from their shipping

cases and inventoried when actually setting up the PG7000 system.

2.1.1.3 PISTON-CYLINDER MODULE(S)

The piston-cylinder modules are shipped in PVC bullet cases that are packed in

corrugated containers with custom foam inserts.

Open the corrugated containers and remove the piston-cylinder modules

and accessories.

The bullet cases screw open by turning the lid counterclockwise.

When reinstalling an oil (PC-7300) or liquid lubricated (PC-7200) piston-cylinder

module in its bullet case, be sure to empty out any liquid that may have

collected in the hole in the bottom of the case. Excess liquid will not

compress, making it difficult to fully close the case and could result in

damaging it.

2.1.2 INSPECTING CONTENTS

Check that all items are present and have NO visible signs of damage. A parts list of items

supplied is provided in Section 2.1.2.1 for PG7000, Section 2.1.2.2 for mass sets, and

Section 2.1.2.3 for piston-cylinder modules.

2.1.2.1 PLATFORM

Each PG7000 Platform is delivered complete with accessories as listed by part

number in Tables 1 through 4.

© 1998-2002 DH Instruments, Inc. Page 14

Page 25

2. INSTALLATION

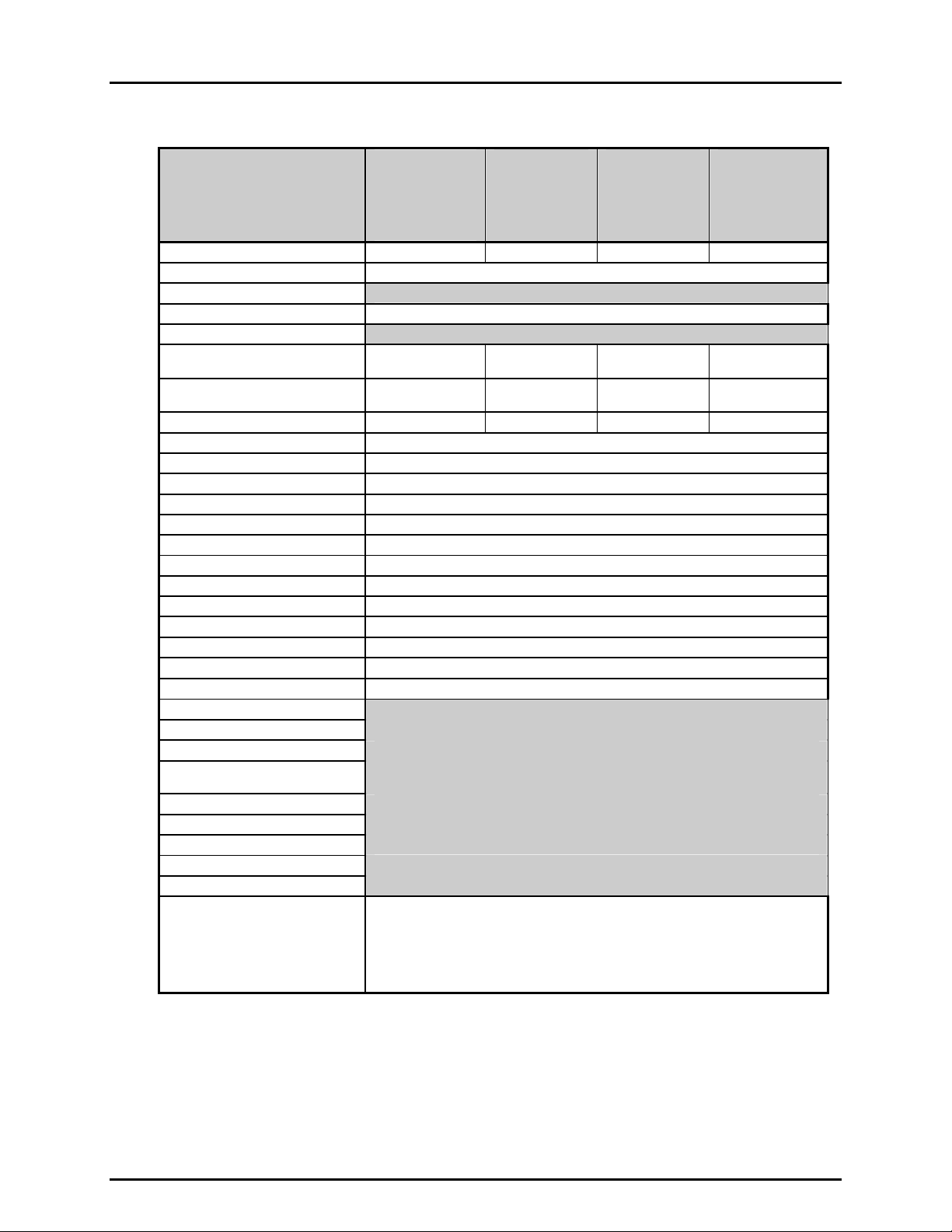

Table 1. PG7102 Parts List

PG7102

P/N 401141

DESCRIPTION

Platform 401294 401294-CE 401293 401293-CE

Mass Bell 401132

Bell Jar and Seal

Terminal 401284

PG Terminal to Platform Cable

Non-CE (DB25M - DB25F,

≈ 1.8 meters)

CE (DB25M - DB25F,

≈ 1.5 meters)

Power Cable 100770 (Black) 100770-CE (Gray) 100770 (Black) 100770-CE (Gray)

Accessory Kit 401560

NIP, SS, DH200, 2.75 in. 100204

ADPT, SS, DH200 F x 2 NPT F 100299

O-ring, Buna 2-242 (2 ea.) 101976

Storage Cover, 7600 Type 102132

Allen Wrench, 2.5 mm 102257

Allen Wrench, 3 mm 102168

Allen Wrench, 5 mm 102262

Spanner Wrench (Metrological) 122568

Wrench, 5/8 in.

Collar, SS, DH500

Krytox GPL205/6 0.5 oz.

Gift Kit with Gloves 400511

Valve, Vacuum Relief

Union, SS, 2P

Valve, Toggle 2T,OGS2

Instruction Sheet,

PG7600 Vac Relief

ADPT, DH200 M x 2T

ADPT, SS, DH200M x 2T

Frl, SS, Front, Gyr 2T

Frl, SS, Rear, Gyr, 2T

Nut, SS, Gyr, 2T

Documentation

Calibration Report (PG Platform)

Calibration Report (Mass Bell)

Technical Data

PG7000 Operation &

Maintenance Manual

Documentation CD

MOTORIZED

ROTATION

NON-CE

102227 102227

102227-CE 102227-CE

PG7102

P/N 401141-CE

MOTORIZED

ROTATION

CE

PG7102

P/N 401140

NON-MOTORIZED

ROTATION

NON-CE

102496

550100

550100

550101

550099

102987

PG7102

P/N 401140-CE

NON-MOTORIZED

ROTATION

CE

Page 15 © 1998-2002 DH Instruments, Inc.

Page 26

PG7000™ OPERATION AND MAINTENANCE MANUAL

Table 2. PG7202 Parts List

PG7202

#401722

DESCRIPTION

Platform 401725 401725-CE 401724 401724-CE

Mass Bell 401132

Bell Jar and Seal

Terminal 401284

PG Terminal to Platform Cable

Non-CE (DB25M - DB25F,

≈ 1.8 meters)

CE (DB25M - DB25F,

≈ 1.5 meters)

Power Cable 100770 (Black) 100770-CE (Gray) 100770 (Black) 100770-CE (Gray)

Accessory Kit 401134

NIP, SS, DH200, 2.75 in. 100204

ADPT, SS, DH200 F x 2 NPT F 100299

O-ring, Buna 2-242 (2 ea.) 101976

Storage Cover, 7600 Type 102132

Allen Wrench, 2.5 mm 102257

Allen Wrench, 3 mm 102168

Allen Wrench, 5 mm 102262

Spanner Wrench (Metrological) 122568

Wrench, 5/8 in. 103044

Collar, SS, DH500 101201

Krytox GPL205/6 0.5 oz.

Gift Kit with Gloves 400511

Valve, Vacuum Relief

Union, SS, 2P

Valve, Toggle 2T,OGS2

Instruction Sheet, PG7600

Vac Relief

ADPT, DH200 M x 2T

ADPT, SS, DH200M x 2T

Frl, SS, Front, Gyr 2T

Frl, SS, Rear, Gyr, 2T

Nut, SS, Gyr, 2T

Documentation

Calibration Report (PG)

Calibration Report (Mass Bell)

Technical Data

PG7000 Operation &

Maintenance Manual

Documentation CD

MOTORIZED

ROTATION

NON-CE

102227 102227

102227-CE 102227-CE

PG7202

#401722-CE

MOTORIZED

ROTATION

CE

PG7202

#401721

NON-MOTORIZED

ROTATION

NON-CE

102496

550100

550100

550101

550099

102987

PG7202

#401721-CE

NON-MOTORIZED

ROTATION

CE

© 1998-2002 DH Instruments, Inc. Page 16

Page 27

2. INSTALLATION

Table 3. PG7302 Parts List

PG7302

DESCRIPTION

Platform 401292 401292-CE 401291 401291-CE

Mass Bell 401132

Bell Jar and Seal

Terminal 401284

PG Terminal to Platform Cable

Non-CE (DB25M -DB25F,

≈ 1.8 meters)

CE (DB25M - DB25F,

≈ 1.5 meters)

Power Cable 100770 (Black) 100770-CE (Gray) 100770 (Black) 100770-CE (Gray)

Accessory Kit 401134

NIP, SS, DH200, 2.75 in. 100204

ADPT, SS, DH200 F x 2 NPT F 100299

O-ring, Buna 2-242 (2 ea.) 101976

Storage Cover, 7600 Type 102132

Allen Wrench, 2.5 mm 102257

Allen Wrench, 3 mm 102168

Allen Wrench, 5 mm 102262

Spanner Wrench (Metrological) 122568

Wrench, 5/8 in. 103044

Collar, SS, DH500 101201

Krytox GPL205/6 0.5 oz.

Gift Kit with Gloves 400511

Valve, Vacuum Relief

Union, SS, 2P

Valve, Toggle 2T,OGS2

Instruction Sheet, PG7600

Vac Relief

ADPT, DH200 M x 2T

ADPT, SS, DH200M x 2T

Frl, SS, Front, Gyr 2T

Frl, SS, Rear, Gyr, 2T

Nut, SS, Gyr, 2T

Documentation

Calibration Report (PG)

Calibration Report (Mass Bell)

Technical Data

PG7000 Operation &

Maintenance Manual

Documentation CD

P/N 401298

MOTORIZED

ROTATION

NON-CE

102227

PG7302

P/N 401298-CE

MOTORIZED

ROTATION

CE

102227

102227-CE 102227-CE

102496

550100

550100

550101

550099

102987

PG7302

P/N 401297

NON-MOTORIZED

ROTATION

NON-CE

PG7302

P/N 401297-CE

NON-MOTORIZED

ROTATION

CE

Page 17 © 1998-2002 DH Instruments, Inc.

Page 28

PG7000™ OPERATION AND MAINTENANCE MANUAL

Table 4. PG7601 Parts List

PG7601

P/N 400480

DESCRIPTION

Platform 401290 401290-CE

Mass Bell 400578

Bell Jar and Seal 122106 and 101546

Terminal 401284

PG Terminal to Platform Cable

Non-CE (DB25M -DB25F,

≈ 1.8 meters)

CE (DB25M - DB25F,

≈ 1.5 meters)

Power Cable 100770 (Black) 100770-CE (Gray)

Accessory Kit 400987

NIP, SS, DH200, 2.75 in. 100204

ADPT, SS, DH200 F x 2 NPT F 100299

O-ring, Buna 2-242 (2 ea.) 101976

Storage Cover, 7600 Type 102132

Allen Wrench, 2.5 mm 102257

Allen Wrench, 3 mm 102168

Allen Wrench, 5 mm 102262

Spanner Wrench (Metrological) 122568

Wrench, 5/8”

Collar, SS, DH500

Krytox GPL205/6 .5 oz.

Gift Kit with Gloves 400511

Valve, Vacuum Relief 401050

Union, SS, 2P 101980

Valve, Toggle 2T,OGS2 102119

Instruction Sheet, PG7600

Vac Relief

ADPT, DH200 M x 2T 400518

ADPT, SS, DH200M x 2T 121692

Frl, SS, Front, Gyr 2T 100179

Frl, SS, Rear, Gyr, 2T 100181

Nut, SS, Gyr, 2T 100183

Documentation

Calibration Report (PG)

Calibration Report (Mass Bell)

Technical Data

PG7000 Operation &

Maintenance Manual

Documentation CD

MOTORIZED

ROTATION

NON-CE

102227

102227-CE

102496

560002

550100

550100

550101

550099

102987

PG7601

P/N 400480-CE

MOTORIZED

ROTATION

CE

© 1998-2002 DH Instruments, Inc. Page 18

Page 29

2. INSTALLATION

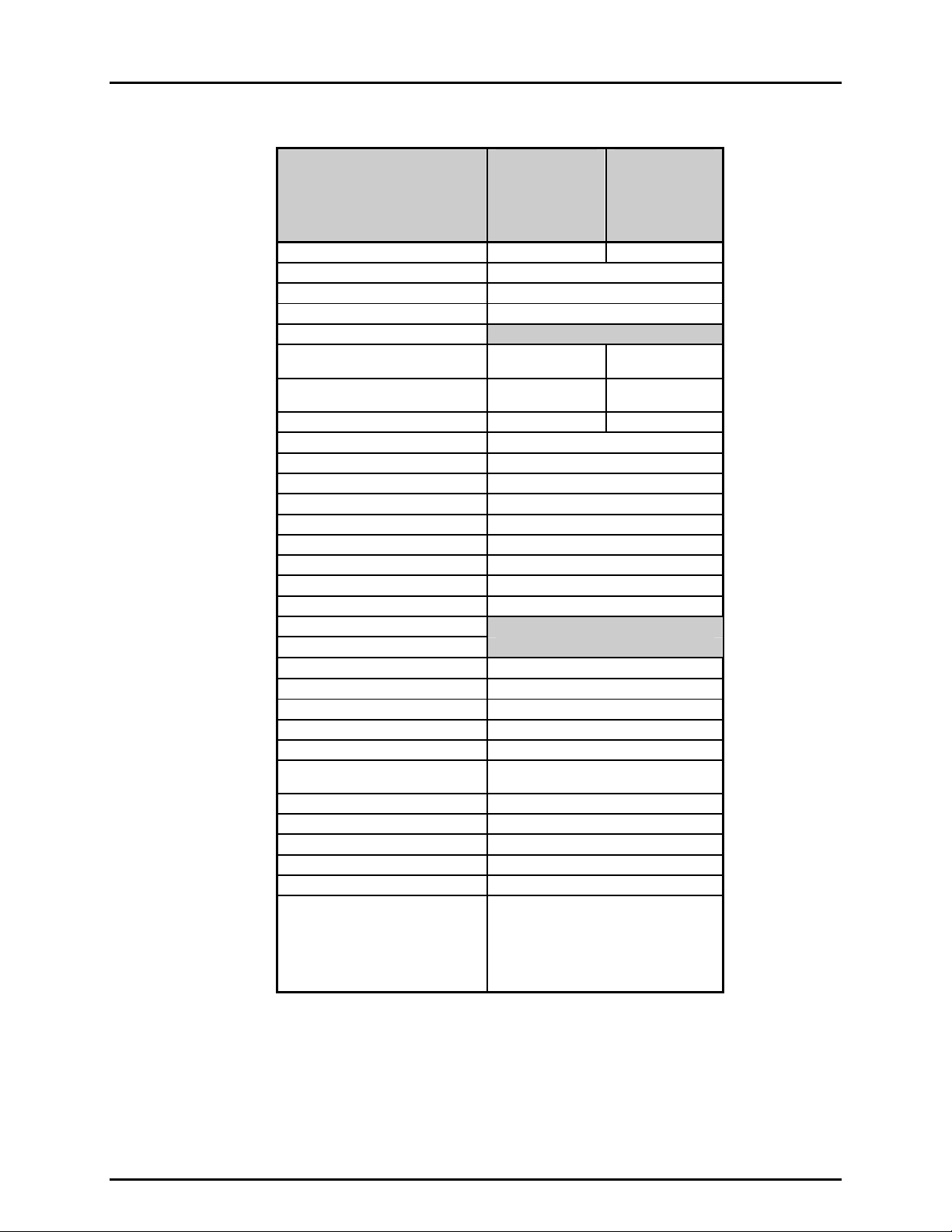

2.1.2.2 MASS SET

PG7000 mass sets are composed of different combinations of individual masses

and accessories depending on the specific mass set ordered (see Tables 5, 6, 7).

Table 5. Mass Parts List (excluding 80 and 100 kg)

DESCRIPTION PART NO.

Mass Set Refer to Table 7 Reusable Molded Transit Case with Foam Inserts

35 kg set

40 kg set

45 kg set

55 kg set

Mass Set Tray and Spindle 123050 and 123051

Dust Covers 102814 and 102847

Calibration Report 550100

Table 6. Mass Parts List (80 and 100 kg)

DESCRIPTION PART NO.

Mass Set Refer to Table 7

Reusable Molded Transit Case with Foam Inserts

80 kg set

100 kg set

Dust Covers 102846 and 102847

Calibration Report 550100

122577

1 ea.

1 ea.

1 ea.

1 ea.

122577

1 ea.

1 ea.

123057

1 ea.

1 ea.

1 ea.

2 ea.

123035

2 ea.

3 ea.

Page 19 © 1998-2002 DH Instruments, Inc.

Page 30

PG7000™ OPERATION AND MAINTENANCE MANUAL

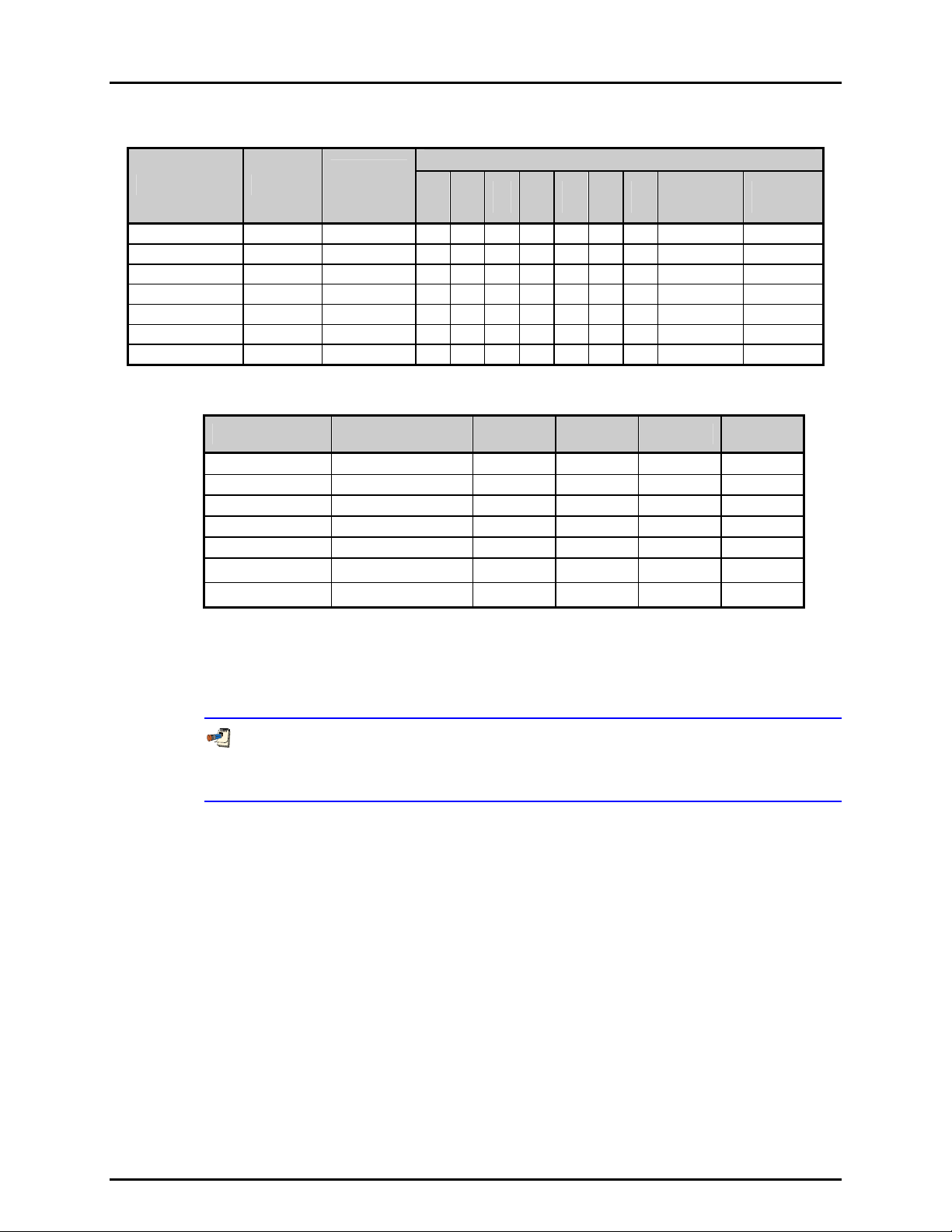

Table 7. Mass Set Definitions

DESIGNATION PART #

MS-7001-35 401425 35 - 5 2 1 1 2 1 1 1 (4.5)

MS-7002-35 401426 35 - 5 2 1 1 2 1 1 1 (4)

MS-7002-40 401522 40 - 6 2 1 1 2 1 1 1 (4)

MS-7002-45 401496 45 - 7 2 1 1 2 1 1 1 (4)

MS-7002-55 401427 55 - 9 2 1 1 2 1 1 1 (4)

MS-7002-80 401518 80 6 1 2 1 1 2 1 1 1 (9)

MS-7002-100 401519 100 8 1 2 1 1 2 1 1 1 (9)

TOTAL

MASS (KG)

10

KG 5 KG 2 KG 1 KG

NOMINAL

MASS SET COMPOSITION

0.5

0.2

0.1

KG

KG

KG

TRIM SET

50 TO 0.1 G

Table 8. Mass Set Compatibility

DESIGNATOR

MS-7001-35 35

MS-7002-35 35

MS-7002-40 40

MS-7002-45 45

MS-7002-55 55

MS-7002-80 80 •1

MS-7002-100 100 •1

1

: These mass sets, on certain piston-cylinder sizes, can cause the maximum working pressure of the PG Platform to be

exceeded. Do not exceed the following maximum working pressures:

• PG7201: 11 MPa (1 600 psi)

• PG7202: When using PC-7200 piston-cylinder modules: 110 MPa (16 000 psi)

When using PC-7300 piston-cylinder modules: 200 MPa (30 000 psi)

• PG7302: 500 MPa (72 500 psi)

NOMINAL

TOTAL MASS (KG)

PG7102 PG7202 PG7302 PG7601

• • •

• • •

• • •

• • •

•1

•1

•

•

MAKE-UP

MASS (KG)

•

The mass loading bell and piston make up part of the total mass load but are not

included with the mass set. Piston-cylinder modules are purchased and delivered

separately. The mass loading bell is delivered with the PG7000 Platform.

© 1998-2002 DH Instruments, Inc. Page 20

Page 31

2. INSTALLATION

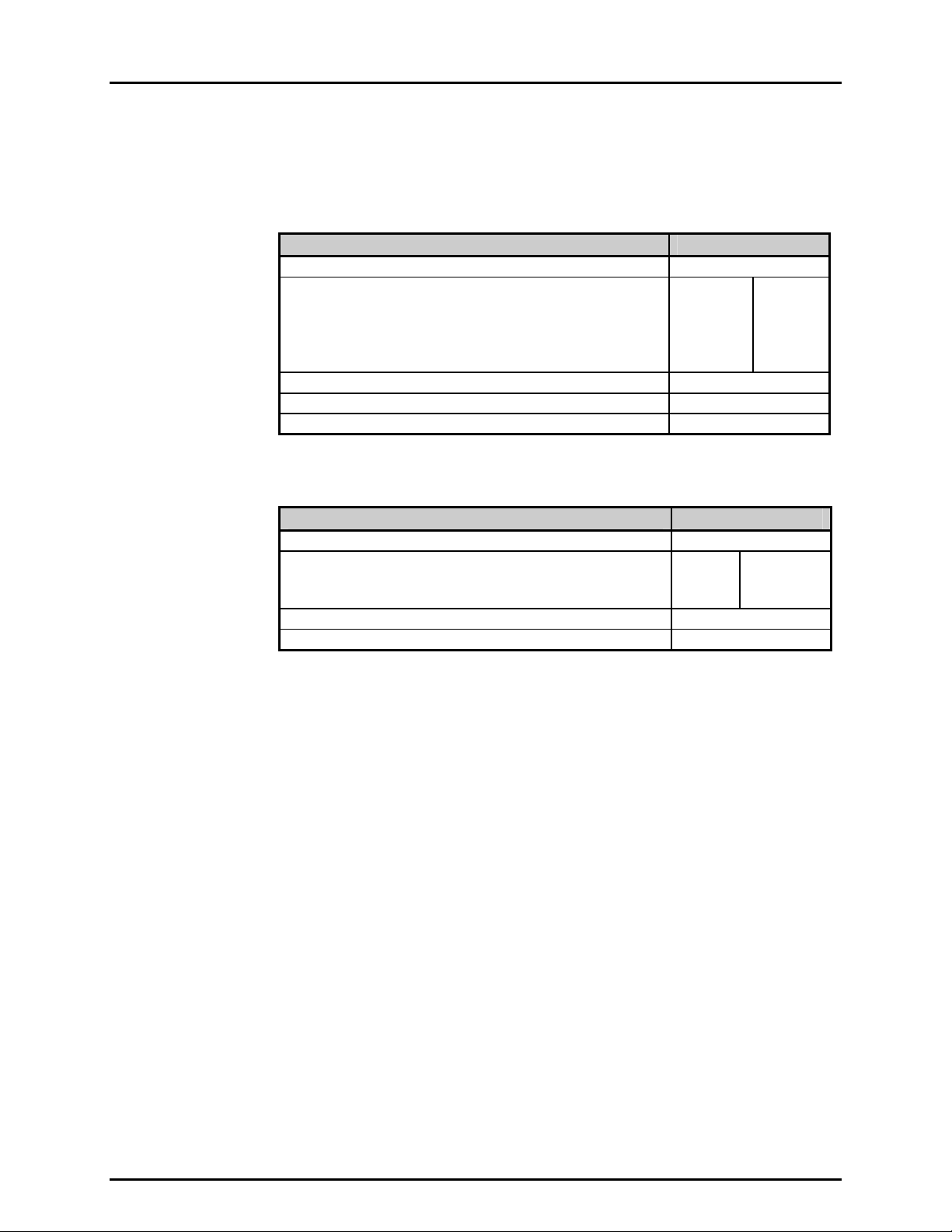

2.1.2.3 PISTON-CYLINDER MODULE(S)

Table 9. PC-7100/7600 Piston-Cylinder Modules Parts List

Piston-Cylinder Kit 401561 401562 401563 401564

Piston-Cylinder Module 400580 401418 401332 401021

Hermetic PVC Bullet

Case

Accessory Kit 401243 401243 401242 401242

O-rings

Insertion Tool 122186 122186 N/A N/A

Calibration Report 550100 550100 550100 550100

10 kPa

PC-7100/7600-10

401642 401642 401642 401642

101918

102380

10 kPa

PC-7100/7600-10 TC

101918

102380

50 kPa

PC-7100/7600-50

101921

102380

200 kPa

PC-7100/7600-200

101921

102380

Table 10. PC-7200 Piston-Cylinder Modules Parts List

Piston-Cylinder Kit 401738 401739 401740 401741 401742

Piston-Cylinder

Module

Hermetic PVC

Bullet Case

Accessory Kit 401743 401743 401723 401723 401723

O-rings

Anti-Extrusion Ring N/A N/A 123444 123444 123444

Syringe 103046 103046 103046 103046 103046

Syringe tips (3) 103046 (3) 103046 (3) 103046 (3) 103046 (3) 103046

Synturion 6 fluid 401794 401794 - - Sebacate fluid - - 401793 401793 401793

Calibration Report 550100 550100 550100 550100 550100

100 kPa

PC-7200-100

401728 401729 401730 401731 401732

401733 401733 401733 401733 401733

(2) 101295

101102

102109

200 kPa

PC-7200-200

(2) 101295

101102

102109

500 kPa

PC-7200-500

(2) 101295

101102

102109