Page 1

PG7601-SYS-AF™

Gas Operated Piston Gauge

Pressure Calibration System

Operation and Maintenance Manual

NSN 6695-01-551-5125

Consists of Base System and Exchange Pack

© 2007 DH Instruments, a Fluke Company

Page 2

PG7601-SYS-AF™ OPERATION AND MAINTENANCE MANUAL

High-pressure liquids and gases are potentially hazardous. Energy stored in these liquids and gases

can be released unexpectedly and with extreme force. High-pressure systems should be assembled and

operated only by personnel who have been instructed in proper safety practices.

© 2007 DH Instruments, a Fluke Company All rights reserved.

Information in this document is subject to change without notice. No part of this document may be reproduced or transmitted in any

form or by any means, electronic or mechanical, for any purpose, without the express written permission of DH Instruments, a

Fluke Company. 4765 East Beautiful Lane Phoenix Arizona 85044-5318 USA.

DH Instruments makes sincere efforts to ensure the accuracy and quality of its published materials; however, no warranty,

expressed or implied, is provided. DH Instruments disclaims any responsibility or liability for any direct or indirect damages

resulting from the use of the information in this manual or products described in it. Mention of any product or brand does not

constitute an endorsement by DH Instruments of that product or brand. This manual was originally composed in English and was

subsequently translated into other languages. The fidelity of the translation cannot be guaranteed. In case of conflict between the

English version and other language versions, the English version predominates.

DH Instruments, DH, DHI, PG7601-AF, PG7601, PPPC3, CalTool and COMPASS are trademarks, registered and otherwise, of

DH Instruments, a Fluke Company.

Swagelok is a registered trademark of the Swagelok Company.

Krytox is a registered trademark of the Dupont de Nemours Company.

Products described in this manual are manufactured under international patents and one or more of the following U.S.

patents: 6,701,791, 5,142,483, 5,257,640, 5,331,838, 5,445,035. Other U.S. and international patents pending.

Document No. 550152a-01

071001

Printed in the USA

© 2007 DH Instruments, a Fluke Company

Page 3

TABLE OF CONTENTS

T

AABBLLEE OOFF

T

C

OONNTTEENNTTS

C

S

TABLE OF CONTENTS ...............................................................I

TABLES................................................................................VII

FIGURES................................................................................IX

ABOUT THIS MANUAL............................................................. XI

1. INTRODUCTION ................................................................. 1

1.1 SPECIFICATIONS....................................................................................................................................1

1.1.1 OVERALL SYSTEM SPECIFICATIONS........................................................................................................1

1.1.1.1 PRESSURE MEASUREMENTS................................................................................................................2

1.1.2 PISTON GAUGE PLATFORM (PG7601-AF).................................................................................................2

1.1.2.1 EMBEDDED FEATURES...........................................................................................................................3

1.1.2.2 MEASUREMENT OF AMBIENT AND INSTRUMENT CONDITIONS........................................................4

1.1.3 PISTON-CYLINDER MODULES (PC-7100/7600-10-L, -50, -200)............................................................5

1.1.4 MASS SET (MS-7001-35-AF)........................................................................................................................6

1.1.5 PRESSURE CONTROLLER (PPC3-7M-AF).................................................................................................7

1.1.6 REFERENCE VACUUM PUMP (D16B).........................................................................................................7

2. SYSTEM AND COMPONENT OVERVIEW AND DESCRIPTION .... 9

2.1 SYSTEM OVERVIEW (PG7601-SYS-AF)................................................................................................9

2.2 PISTON GAUGE PLATFORM AND TERMINAL (PG7601-AF).............................................................12

2.2.1 PLATFORM..................................................................................................................................................13

2.2.2 PG TERMINAL.............................................................................................................................................14

2.3 PISTON-CYLINDER MODULES (PC-7100/7600-10-L, -50, -200)...............................................15

2.4 MASS SET (MS-7001-35-AF).................................................................................................................16

2.5 PRESSURE CONTROLLER (PPC3-7M-AF).........................................................................................16

2.6 REFERENCE VACUUM PUMP (D16B).................................................................................................18

3. INSTALLATION ................................................................ 19

3.1 UNPACKING AND INSPECTION...........................................................................................................19

3.1.1 UNPACKING AND INSPECTION OF PG7601-BAS-AF BASE SYSTEM...................................................19

3.1.1.1 PLATFORM, TERMINAL AND BELL JAR (PG7601-AF)........................................................19

3.1.1.2 PRESSURE CONTROLLER (PPC3-7M-AF)...........................................................................................20

3.1.1.3 REFERENCE VACUUM PUMP (D16B)...................................................................................................20

3.1.1.4 PRESSURE INTERCONNECTIONS KIT (PK-7601-P-AF) ......................................................20

3.1.1.5 VACUUM INTERCONNECTIONS KIT (PK-7601-V-AF)..........................................................................21

3.1.1.6 DOCUMENTATION AND ACCESSORIES..............................................................................................21

3.1.2 UNPACKING AND INSPECTION OF PG7601-EXC-AF EXCHANGE PACKAGE......................................21

3.1.2.1 PISTON-CYLINDER MODULES (PC-7100/7600-10-L, PC-7100/7600-50, PC-7100/7600-200) AND

ACCESSORIES .......................................................................................................................................22

3.1.2.2 MASS SET (MS-7001-35-AF)..................................................................................................................22

3.1.2.3 DOCUMENTATION AND ACCESSORIES..............................................................................................23

3.2 SITE REQUIREMENTS..........................................................................................................................23

3.3 PHYSICAL SETUP.................................................................................................................................25

3.3.1 SETTING UP THE PLATFORM...................................................................................................................25

3.3.2 SETTING UP THE PRESSURE CONTROLLER.........................................................................................26

3.3.3 SYSTEM PRESSURE INTERCONNECTIONS............................................................................................26

3.3.4 SETTING UP THE MASS SET ....................................................................................................................27

3.3.5 INSTALLING A PISTON-CYLINDER MODULE INTO THE PLATFORM....................................................28

Page I © 2007 DH Instruments, a Fluke Company

Page 4

PG7601-SYS-AF™ OPERATION AND MAINTENANCE MANUAL

3.3.6 SETTING UP THE REFERENCE VACUUM PUMP AND VACUUM INTERCONNECTIONS.....................29

3.3.7 CONNECTING TEST GAS SUPPLY...........................................................................................................29

3.3.8 CONNECTING CONTROL VACUUM SUPPLY...........................................................................................30

3.4 POWER UP AND VERIFICATION .........................................................................................................30

3.4.1 POWER UP PLATFORM AND PRESSURE CONTROLLER......................................................................30

3.4.2 CHECK THAT ON-BOARD PISTON-CYLINDER MODULE AND MASS SET DIGITAL IDS ARE

CORRECT....................................................................................................................................................31

3.4.3 SET LOCAL GRAVITY VALUE ...................................................................................................................31

3.4.4 CHECK/SET SECURITY LEVEL.................................................................................................................31

3.4.5 CHECK PROPER OPERATION OF AMBIENT CONDITION MEASUREMENTS ......................................31

3.4.6 TURN ON AUTOGEN AND AUTOROTATE................................................................................................32

3.4.7 APPLY SUPPLY PRESSURE .....................................................................................................................32

3.4.8 APPLY CONTROL VACUUM......................................................................................................................32

3.4.9 APPLY REFERENCE VACUUM..................................................................................................................32

3.4.10 SET A GAUGE MODE PRESSURE, CHECK AUTOGEN AND AUTOROTATE FUNCTIONS..................32

3.4.11 CHECK PISTON BEHAVIOR MEASUREMENTS.......................................................................................34

3.4.12 CHECK REFERENCE VACUUM SYSTEM AND ABSOLUTE MODE OPERATION..................................34

3.5 ADDITIONAL PRECAUTIONS TO TAKE TO MAKE GOOD PRESSURE MEASUREMENTS.............36

4. GENERAL OPERATION ..................................................... 37

4.1 OPERATING PRINCIPLES....................................................................................................................37

4.1.1 FUNDAMENTAL OPERATING PRINCIPLE................................................................................................37

4.1.2 PRESSURE CONTROL, MANUAL AND AUTOMATED.............................................................................38

4.1.3 PRESSURE READY/NOT READY INDICATION........................................................................................39

4.1.3.1 PISTON POSITION READY/NOT READY ..............................................................................................39

4.1.3.2 PISTON ROTATION READY/NOT READY.............................................................................................40

4.1.3.3 VACUUM REFERENCE READY/NOT READY.......................................................................................40

4.1.4 PISTON POSITION......................................................................................................................................41

4.1.5 MASS LOADING PROTOCOL ....................................................................................................................42

4.2 USER INTERFACE................................................................................................................................45

4.2.1 PISTON GAUGE (SYSTEM INTERFACE)..................................................................................................45

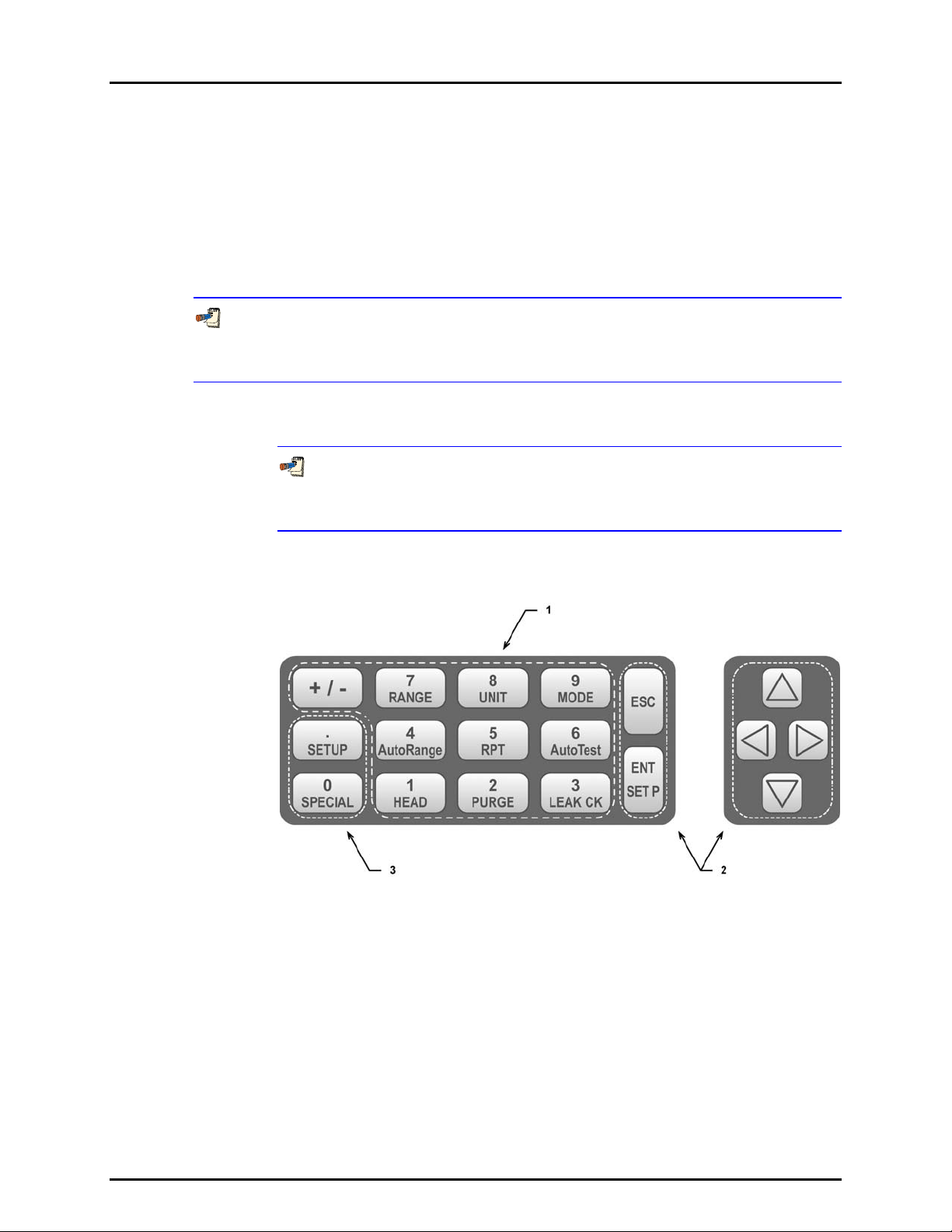

4.2.1.1 KEYPAD LAYOUT AND PROTOCOL......................................................................................................45

4.2.1.2 MAIN RUN SCREEN................................................................................................................................46

4.2.1.3 GENERAL FUNCTION/MENU FLOW CHART........................................................................................48

4.2.1.4 SOUNDS..................................................................................................................................................48

4.2.2 PRESSURE CONTROLLER........................................................................................................................49

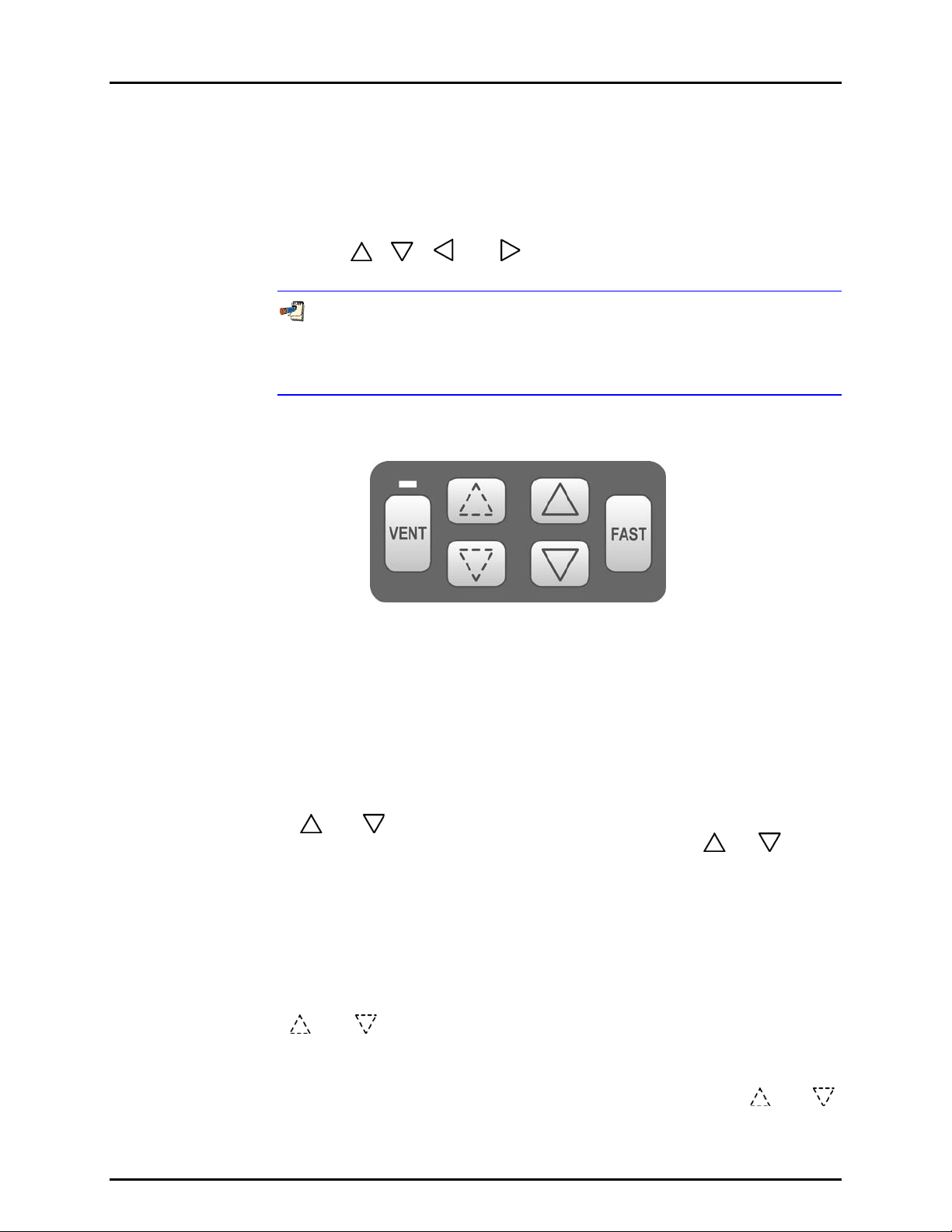

4.2.2.1 KEYPAD LAYOUT AND PROTOCOL......................................................................................................49

4.2.2.2 DIRECT PRESSURE CONTROL KEYS..................................................................................................50

4.2.2.3 MAIN RUN SCREEN................................................................................................................................51

4.2.2.4 SOUNDS..................................................................................................................................................52

4.3 DIRECT FUNCTION KEYS....................................................................................................................53

4.3.1 DIRECT FUNCTION KEYS SUMMARY......................................................................................................53

4.3.2 [P-C], VIEW AND SELECT PISTON-CYLINDER MODULES.....................................................................53

4.3.3 [UNIT], SELECT PRESSURE UNIT OF MEASURE....................................................................................55

4.3.4 [MODE], SELECT PRESSURE MEASUREMENT MODE...........................................................................56

4.3.5 [SYSTEM], VIEW SYSTEM CONDITIONS MEASUREMENT SCREENS..................................................57

4.3.5.1 FIRST SYSTEM RUN SCREEN ..............................................................................................................57

4.3.5.2 SECOND SYSTEM RUN SCREEN .........................................................................................................58

4.3.6 [AMBIENT], VIEW AMBIENT CONDITIONS MEASUREMENTS SCREEN ...............................................59

4.3.7 [HEAD], SET FLUID HEAD CORRECTION HEIGHT..................................................................................60

4.3.8 [ROTATE], MANAGE MOTORIZED PISTON ROTATION..........................................................................62

4.3.8.1 <2PRE-DECEL>.......................................................................................................................................64

4.3.9 [GEN], MANAGE AUTOMATED PRESSURE GENERATION....................................................................64

4.3.9.1 <2TARGET>.............................................................................................................................................66

4.3.9.2 <3RAISE> ................................................................................................................................................66

4.3.9.3 <4UL>.......................................................................................................................................................66

4.3.9.4 <5TOL>....................................................................................................................................................67

4.3.9.5 <6REFLOAT>...........................................................................................................................................67

4.3.9.6 VIEWING AND SETTING PPC3-7M-AF COM1 PORT SETTINGS.........................................................68

4.3.10 [RES], SET MASS LOADING RESOLUTION .............................................................................................68

4.3.11 [SET P], SET OR MEASURE A PRESSURE..............................................................................................69

4.3.11.1 [SET P] IN PRESSURE TO MASS MODE...............................................................................................71

4.3.11.2 [SET P] IN MASS TO PRESSURE MODE...............................................................................................72

4.3.11.3 COMMANDS FOR ZERO PRESSURE, ENDING A TEST......................................................................73

4.3.12 [P OR M], SET PRESSURE TO MASS OR MASS TO PRESSURE OPERATING MODE.........................73

4.3.13 [ ] AND [ ], [←], MANUAL CONTROL OF MOTORIZED ROTATION...............................................74

© 2007 DH Instruments, a Fluke Company Page II

Page 5

TABLE OF CONTENTS

4.4 [SETUP] MENU, MANAGE PRESSURE EQUATION VARIABLE SOURCES......................................75

4.4.1 <1SELECT>.................................................................................................................................................77

4.4.2 <2VIEW>......................................................................................................................................................77

4.4.3 <3EDIT>.......................................................................................................................................................78

4.5 [SPECIAL] MENU..................................................................................................................................81

4.5.1 <1PC/MS>, MANAGE METROLOGICAL ELEMENT DIGITAL IDS............................................................82

4.5.1.1 CREATE PISTON-CYLINDER MODULE.................................................................................................83

4.5.1.2 EDIT PISTON-CYLINDER MODULE.......................................................................................................86

4.5.1.3 VIEW PISTON-CYLINDER MODULE......................................................................................................86

4.5.1.4 DELETE PISTON-CYLINDER MODULE.................................................................................................87

4.5.1.5 SELECT THE ACTIVE PISTON-CYLINDER MODULE...........................................................................87

4.5.1.6 ADD MASS SET.......................................................................................................................................87

4.5.1.7 EDIT MASS SET......................................................................................................................................91

4.5.1.8 VIEW MASS SET.....................................................................................................................................91

4.5.1.9 DELETE MASS SET................................................................................................................................91

4.5.1.10 SELECT MASS SET................................................................................................................................92

4.5.1.11 ADD MASS LOADING BELL....................................................................................................................92

4.5.1.12 EDIT MASS LOADING BELL...................................................................................................................93

4.5.1.13 VIEW MASS LOADING BELL..................................................................................................................94

4.5.1.14 DELETE MASS LOADING BELL.............................................................................................................94

4.5.1.15 SELECT MASS LOADING BELL.............................................................................................................94

4.5.2 <2PRESU>, CUSTOMIZE UNIT FUNCTION SELECTIONS.......................................................................94

4.5.3 <3HEAD>, CUSTOMIZE FLUID HEAD FUNCTIONS .................................................................................96

4.5.3.1 <3HEAD>, <1FLUID>...............................................................................................................................97

4.5.3.2 <3HEAD>, <2UNIT>.................................................................................................................................97

4.5.3.3 <3HEAD>, <3ATM> .................................................................................................................................97

4.5.3.4 <3HEAD>, <4PISTON>............................................................................................................................98

4.5.4 <4PREFS>, SET USER PREFERENCES ...................................................................................................98

4.5.4.1 <4PREFS>, <1SCRSVR>........................................................................................................................98

4.5.4.2 <4PREFS>, <2SOUND>..........................................................................................................................99

4.5.4.3 <4PREFS>, <3TIME> ..............................................................................................................................99

4.5.4.4 <4PREFS>, <4ID> ...................................................................................................................................99

4.5.4.5 <4PREFS>, <5LEVEL>..........................................................................................................................100

4.5.5 <5REMOTE>, MANAGE REMOTE COMMUNICATION INTERFACES....................................................103

4.5.5.1 COM1, COM2 AND COM3 (RS232)......................................................................................................104

4.5.5.2 IEEE-488................................................................................................................................................104

4.5.5.3 RS232 SELF TEST................................................................................................................................105

4.5.5.4 EXTERNAL BAROMETER (RPM) COMMUNICATIONS (COM2).........................................................105

4.5.5.5 EXTERNAL VACUUM GAUGE COMMUNICATIONS (COM2) .............................................................107

4.5.6 <6GL>, SET VALUE OF LOCAL GRAVITY..............................................................................................110

4.5.7 <7CAL>, MANAGE INTERNAL MEASUREMENT SENSOR CALIBRATIONS........................................110

4.5.8 <8AMH>, OPERATE AUTOMATED MASS HANDLER (NOT INCLUDED)..............................................110

4.5.9 <9RESET>, USE SYSTEM RESETS.........................................................................................................111

4.5.9.1 <9RESET>, <1SETS> ...........................................................................................................................111

4.5.9.2 <9RESET>, <2UNITS>..........................................................................................................................112

4.5.9.3 <9RESET>, <3COM>.............................................................................................................................112

4.5.9.4 <9RESET>, <4CAL>..............................................................................................................................112

4.5.9.5 <9RESET>, <5SETUPS> ......................................................................................................................113

4.5.9.6 <9RESET>, <6ALL> ..............................................................................................................................113

5. REMOTE OPERATION ......................................................115

5.1 OVERVIEW..........................................................................................................................................115

5.2 INTERFACING.....................................................................................................................................115

5.2.1 RS232 INTERFACE...................................................................................................................................115

5.2.1.1 COM1.....................................................................................................................................................116

5.2.1.2 COM2 AND COM3.................................................................................................................................116

5.2.2 IEEE-488 (GPIB)........................................................................................................................................117

5.3 COMMANDS........................................................................................................................................117

5.3.1 COMMAND SYNTAX.................................................................................................................................117

5.3.2 COMMAND SUMMARY.............................................................................................................................117

5.3.3 ERROR MESSAGES.................................................................................................................................120

5.3.4 COMMAND DESCRIPTIONS.....................................................................................................................121

5.3.4.1 IEEE STD. 488.2 COMMON AND STATUS COMMANDS.....................................................121

5.3.4.2 PG7601-AF COMMANDS......................................................................................................................123

5.4 STATUS SYSTEM................................................................................................................................148

5.4.1 STATUS REPORTING SYSTEM...............................................................................................................149

5.4.1.1 STATUS BYTE REGISTER ...................................................................................................................149

5.4.1.2 STANDARD EVENT REGISTER...........................................................................................................150

Page III © 2007 DH Instruments, a Fluke Company

Page 6

PG7601-SYS-AF™ OPERATION AND MAINTENANCE MANUAL

6. GENERAL MAINTENANCE AND ADJUSTMENTS ..................153

6.1 OVERVIEW..........................................................................................................................................153

6.2 ILLUSTRATED PARTS BREAKDOWN...............................................................................................154

6.3 PISTON-CYLINDER MODULES..........................................................................................................173

6.3.1 DISASSEMBLY AND REASSEMBLY.......................................................................................................173

6.3.1.1 PC-7100/7600-10-L (10 KPA/KG) DISASSEMBLY AND REASSEMBLY..............................................174

6.3.1.2 PC-7100/7600-10-L (10 KPA/KG) PISTON INSERTION TOOL............................................................178

6.3.1.3 PC-7100/7600-50 AND -200 (50 AND 200 KPA/KG) DISASSEMBLY AND REASSEMBLY ................180

6.3.2 CLEANING PISTON-CYLINDERS.............................................................................................................182

6.3.2.1 OVERVIEW............................................................................................................................................182

6.3.2.2 WATER/DETERGENT METHOD...........................................................................................................183

6.3.2.3 QUICK METHOD ...................................................................................................................................184

6.3.3 LUBRICATING PISTON-CYLINDER MODULES......................................................................................185

6.4 PLATFORM..........................................................................................................................................186

6.4.1 PISTON POSITION DETECTION ADJUSTMENT.....................................................................................186

6.4.2 DRIVE BELT REPLACEMENT..................................................................................................................187

6.4.3 DISASSEMBLY AND REASSEMBLY OF PG7601-AF.............................................................................187

6.4.3.1 PLATFORM............................................................................................................................................187

6.4.3.2 TERMINAL.............................................................................................................................................188

6.5 ADJUSTING PRESSURE CONTROLLER INTERNAL PRESSURE SENSOR...................................189

6.6 REFERENCE VACUUM PUMP............................................................................................................191

6.6.1 CHECK/TOP OFF OIL LEVEL...................................................................................................................191

6.6.2 DRAIN AND REFILL OIL...........................................................................................................................191

6.7 RELOADING EMBEDDED SOFTWARE INTO PLATFORM OR PRESSURE CONTROLLER FLASH

MEMORY.............................................................................................................................................192

6.8 STORAGE AND SHIPPING .................................................................................................................192

6.8.1 SHORT AND LONG TERM STORAGE.....................................................................................................192

6.8.2 PREPARATION FOR SHIPPING...............................................................................................................193

6.8.2.1 PISTON-CYLINDER MODULES............................................................................................................193

6.8.2.2 MASS SET.............................................................................................................................................193

6.8.2.3 PLATFORM............................................................................................................................................193

6.8.2.4 PRESSURE CONTROLLER..................................................................................................................194

6.8.2.5 VACUUM PUMP ....................................................................................................................................194

7. MAINTENANCE OF TRACEABILITY AND RECALIBRATION ...195

7.1 PRINCIPLES OF SYSTEM TRACEABILITY MAINTENANCE............................................................195

7.2 LOCAL METROLOGICAL MAINTENANCE BETWEEN RECALIBRATIONS.....................................195

7.2.1 OVERVIEW................................................................................................................................................195

7.2.2 PLATFORM, ADJUST ON-BOARD P, T, H SENSORS............................................................................195

7.2.2.1 BAROMETRIC PRESSURE SENSOR ..................................................................................................196

7.2.2.2 AMBIENT TEMPERATURE SENSOR...................................................................................................197

7.2.2.3 RELATIVE HUMIDITY SENSOR ...........................................................................................................198

7.3 RECALIBRATION................................................................................................................................198

7.3.1 OVERVIEW................................................................................................................................................198

7.3.2 CALIBRATION OF PISTON-CYLINDER MODULES................................................................................199

7.3.2.1 PREPARING FOR CALIBRATION.........................................................................................................199

7.3.2.2 U P D A T I N G P I S T O N- C Y L I N D E R M O D U L E D I G I T A L I D S ...................................................... 199

7.3.3 CALIBRATION OF MASS SET..................................................................................................................200

7.3.3.1 PREPARING FOR CALIBRATION.........................................................................................................200

7.3.3.2 UPDATING MASS SET DIGITAL ID......................................................................................................200

7.3.4 CALIBRATION OF PISTON-CYLINDER MODULE TEMPERATURE SENSOR......................................200

7.3.4.1 OVERVIEW............................................................................................................................................200

7.3.4.2 PROCEDURE ........................................................................................................................................201

7.3.4.3 CALCULATING AND UPDATING PISTON-CYLINDER TEMPERATURE SENSOR INFORMATION..201

7.3.5 CALIBRATION OF RESIDUAL VACUUM GAUGE...................................................................................202

7.3.5.1 OVERVIEW............................................................................................................................................202

7.3.5.2 PROCEDURE ........................................................................................................................................203

7.3.5.3 CALCULATING AND UPDATING VACUUM GAUGE CALIBRATION INFORMATION ........................204

© 2007 DH Instruments, a Fluke Company Page IV

Page 7

TABLE OF CONTENTS

7.4 MANAGING METROLOGICAL ELEMENT DIGITAL IDS WITH CALTOOL™ FOR PG7000

SOFTWARE.........................................................................................................................................205

7.4.1 OVERVIEW................................................................................................................................................205

7.4.2 OPERATION..............................................................................................................................................205

7.4.2.1 GETTING STARTED..............................................................................................................................206

7.4.2.2 PROCESSING A NEW DIGITAL ID FILE (AFTER RECALIBRATION)...................................207

7.4.2.3 STORING DIGITAL IDS FROM THE PG7601-AF IN THE CALTOOL DATABASE OR TO *.DID FILE207

7.4.2.4 ARCHIVING DIGITAL IDS .....................................................................................................................208

8. TROUBLESHOOTING .......................................................209

8.1 OVERVIEW..........................................................................................................................................209

9. APPENDIX ......................................................................213

9.1 CONVERSION OF NUMERICAL VALUES..........................................................................................213

9.1.1 PRESSURE................................................................................................................................................213

9.2 DEFINED PRESSURE CALCULATIONS............................................................................................213

9.2.1 PG7601-AF ................................................................................................................................................215

9.2.2 FLUID HEADS ...........................................................................................................................................215

9.2.2.1 FLUID HEAD COMPONENTS...............................................................................................................215

9.2.2.2 OVERALL FLUID HEAD CORRECTION...............................................................................................217

9.3 GLOSSARY..........................................................................................................................................217

9.4 WARRANTY STATEMENT..................................................................................................................219

Page V © 2007 DH Instruments, a Fluke Company

Page 8

PG7601-SYS-AF™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2007 DH Instruments, a Fluke Company Page VI

Page 9

TABLES & FIGURES

T

AABBLLEES

T

Table 1. Base system, PG7601-BAS-AF, packing guide .......................................................................... 19

Table 2. Platform, PG7601-AF, packing list...............................................................................................20

Table 3. Pressure interconnections kit, PK-7601-P-AF, packing list.........................................................20

Table 4. Vacuum interconnections kit, PK-7601-V-AF, packing list ..........................................................21

Table 5. Base system accessories kit packing list.....................................................................................21

Table 6. Exchange pack, PG7601-EXC-AF, packing guide......................................................................22

Table 7. Piston-cylinder modules, PC-7100/7600-10-L, PC-7100/7600-50,

Table 8. Mass set, MS-7001-35-AF, packing list.......................................................................................23

Table 9. Exchange pack accessories packing list .....................................................................................23

Table 10. Summary of PG7601-AF PG Terminal direct function key operations...................................... 53

Table 11. SETUP file choices, factory preferred choice and normal value...............................................76

Table 12. Piston-cylinder module digital ID fields......................................................................................84

Table 13. Mass set digital ID fields............................................................................................................88

Table 14. Mass loading bell digital ID fields...............................................................................................92

Table 15. Pressure units of measure available..........................................................................................95

Table 16. Security levels - functions NOT executed per function/level ...................................................102

Table 17. COM1, COM2 and COM3 available settings...........................................................................104

Table 18. COM1 DB-9F pin designation..................................................................................................116

Table 19. COM2 and COM3 DB-9M pin designation ..............................................................................116

Table 20. Command summary.................................................................................................................118

Table 21. Error messages........................................................................................................................120

Table 22. Status byte register..................................................................................................................149

Table 23. Standard event register............................................................................................................150

Table 24. Mechanical maintenance procedures......................................................................................153

Table 25. Top Level Illustrated Parts Breakdown (see Figure 23) .........................................................154

Table 26. PG7601 Illustrated Parts Breakdown for Mass Set, Cases, and Covers (see Figure 24)......156

Table 27. PG7601 Illustrated Parts Breakdown for Piston Cylinders (see Figure 25) ...........................157

Table 28. PG7601 Illustrated Parts Breakdown for Piston Cylinder Cases (see Figure 26)..................157

Table 29. PG7601 Illustrated Parts Breakdown for PG Main Board (see Figure 27).............................159

Table 30. PG7601 Illustrated Parts Breakdown for PG Base Underside (see Figure 28)......................160

Table 31. PG7601 Illustrated Parts Breakdown for PG Base Outside (see Figure 29)..........................162

Table 32. PG7601 Illustrated Parts Breakdown for PG Terminal Outside (see Figure 30)....................163

Table 33. PG7601 Illustrated Parts Breakdown for PG Terminal Inside (see Figure 31).......................164

Table 34. PG7601 Illustrated Parts Breakdown for PPC3 Outside (see Figure 32)...............................165

Table 35. PG7601 Illustrated Parts Breakdown for PPC3 Pneumatic Module (see Figure 33).............167

Table 36. PG7601 Illustrated Parts Breakdown for PPC3 Inside (see Figure 34) .................................169

Table 37. PG7601 Illustrated Parts Breakdown for PPC3 Manifold detail (see Figure 35)....................170

Table 38. PG7601 Illustrated Parts Breakdown for PK-7601-P-AF (see Figure 36).............................. 171

Table 39. PG7601 Illustrated Parts Breakdown for Accessories Kit (see Figure 37).............................172

S

PC-7100/7600-200, packing list..............................................................................................22

Page VII © 2007 DH Instruments, a Fluke Company

Page 10

PG7601-SYS-AF™ OPERATION AND MAINTENANCE MANUAL

Table 40. PG7601-AF mounting post wire colors, description and location............................................188

Table 41. Metrological maintenance procedures.....................................................................................195

Table 42. Recalibration requirements......................................................................................................199

Table 43. Troubleshooting checklist ........................................................................................................209

Table 44. Pressure unit of measure conversions ....................................................................................213

Table 45. Defined pressure calculation variables....................................................................................214

Table 46. DHI Authorized Service Providers ...........................................................................................219

© 2007 DH Instruments, a Fluke Company Page VIII

Page 11

ABOUT THIS MANUAL

F

IIGGUURREES

F

Figure 1. System, PG7601-SYS-AF, standard installation........................................................................10

Figure 2. System, PG7601-SYS-AF, pneumatic schematic ......................................................................11

Figure 3. System, PG7601-SYS-AF, communications schematic.............................................................11

Figure 4. Piston gauge operating principle................................................................................................12

Figure 5. Platform, PG7601-AF, rear view.................................................................................................13

Figure 6. PG Terminal front panel..............................................................................................................14

Figure 7. PG Terminal rear panel ..............................................................................................................14

Figure 8. Piston-cylinder modules, PC-7100/7600-10-L, -50, -200........................................................... 15

Figure 9. Mass set, MS-7100-35-AF.......................................................................................................... 16

Figure 10. Pressure controller, PPC3-7M-AF, front panel.........................................................................17

Figure 11. Pressure controller, PPC3-7M-AF, rear panel..........................................................................17

Figure 12. Reference vacuum pump, D16B, front and side views ............................................................18

Figure 13. Piston-cylinder module installation...........................................................................................28

Figure 14. Piston gauge operating principle..............................................................................................37

Figure 15. Piston stroke and zones ...........................................................................................................42

Figure 16. PG Terminal keypad layout ......................................................................................................45

Figure 17. Platform MAIN run screen display fields...................................................................................47

Figure 18. RUN screen flow chart..............................................................................................................48

Figure 19. Pressure controller keypad layout............................................................................................49

Figure 20. Pressure controller direct pressure control keys......................................................................50

Figure 21. Pressure controller MAIN run screen display fields..................................................................52

Figure 22. Status byte register.................................................................................................................149

Figure 23. Top Level Illustrated Parts Breakdown for PG7601-SYS-AF..................................................155

Figure 24. PG7601 Illustrated Parts Breakdown for Mass Sets, Cases, and Covers..............................156

Figure 25. PG7601 Illustrated Parts Breakdown for Piston Cylinders......................................................158

Figure 26. PG7601 Illustrated Parts Breakdown for Piston Cylinder Cases ............................................158

Figure 27. PG7601 Illustrated Parts Breakdown for PG Main Board .......................................................159

Figure 28. PG7601 Illustrated Parts Breakdown for PG Base Underside................................................161

Figure 29. PG7601 Illustrated Parts Breakdown for PG Base Outside....................................................162

Figure 30. PG7601 Illustrated Parts Breakdown for PG Terminal Outside..............................................163

Figure 31. PG7601 Illustrated Parts Breakdown for PG Terminal Inside.................................................164

Figure 32. PG7601 Illustrated Parts Breakdown for PPC3 Outside......................................................... 166

Figure 33. PG7601 Illustrated Parts Breakdown for PPC3 Pneumatic Module........................................168

Figure 34. PG7601 Illustrated Parts Breakdown for PPC3 Inside............................................................169

Figure 35. PG7601 Illustrated Parts Breakdown for PPC3 Manifold detail..............................................170

Figure 36. PG7601 Illustrated Parts Breakdown for PK-7601-P-AF ........................................................171

Figure 37. PG7601 Illustrated Parts Breakdown for Accessories Kit.......................................................172

Figure 38. 10 kPa/kg piston-cylinder module (expanded view)...............................................................177

Figure 39. Gas piston-cylinder module sleeve nut tool............................................................................177

Figure 40. 10 kPa/kg piston insertion tool................................................................................................178

Figure 41. 50, 200 kPa/kg gas piston-cylinder modules (expanded view)..............................................182

Figure 42. Piston-cylinder module lubrication chart..................................................................................186

Figure 43. Vacuum gauge calibration setup.............................................................................................204

S

Page IX © 2007 DH Instruments, a Fluke Company

Page 12

PG7601-SYS-AF™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2007 DH Instruments, a Fluke Company Page X

Page 13

ABOUT THIS MANUAL

A

BBOOUUTT

A

This manual provides the user with the information necessary to operate and maintain a PG7601-SYS-AF

gas operated piston gauge system.

Before using the manual, take a moment to familiarize yourself with the Table of Contents structure.

All first time PG7601-AF users should read Section 2 and 4. Section 5 covers remote communication

with an external computer. Sections 6 and 7 provide maintenance and calibration information. Section 1

is a quick troubleshooting guide. Use the information in Section 1 to troubleshoot unexpected PG7601AF behavior based on the symptoms of that behavior.

Certain words and expressions have specific meaning as they pertain to PG7601-AFs. The

(see Section 9.3)

they are used in this manual.

The PG7601-SYS-AF system includes a PPC3-7M-AF pressure controller. This manual covers the

pressure controller to the extent necessary for normal operation of the PG7601-AF system. The PPC3-7M-AF

has a complete, independent manual that is included on the PG7601-SYS-AF Support Disc.

FOR THOSE OF YOU WHO “DON’T READ MANUALS”, GO DIRECTLY TO SECTION 3.3 TO SET UP

YOUR PG7601-AF. THEN GO TO SECTION 3.5. THIS WILL GET YOU RUNNING QUICKLY WITH MINIMAL RISK OF

CAUSING DAMAGE TO YOURSELF OR YOUR PG7601-AF. THEN… WHEN YOU HAVE QUESTIONS OR START TO

WONDER ABOUT ALL THE GREAT FEATURES YOU MIGHT BE MISSING, GET INTO THE MANUAL!

T

HHIISS

T

is useful as a quick reference for the definition of specific words and expressions as

M

AANNUUAAL

M

L

Glossary

Manual Conventions

(CAUTION) is used throughout the manual to identify user warnings and cautions.

(NOTE) is used throughout the manual to identify operating and applications advice and

additional explanations.

[ ] indicates direct function keys (e.g., [UNIT]).

< > indicates PG7601-AF screen displays (e.g., <1yes>)

Page XI © 2007 DH Instruments, a Fluke Company

Page 14

PG7601-SYS-AF™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2007 DH Instruments, a Fluke Company Page XII

Page 15

1. INTRODUCTION

11..

PG7601-SYS-AF is a very high performance pressure calibration system for the validation and calibration

of pressure measuring devices using gas as the pressurized medium. It operates on the piston gauge

principle. Pressure is defined by balancing it against the force exerted by a known mass accelerated by

gravity on the effective area of a piston-cylinder.

PG7601-SYS-AF covers the pressure range of 7 to 7000 kPa (1 to 1 000 psi) in absolute and gauge

modes with semi-automated operation and state of the art measurement uncertainty.

A PG7601-SYS-AF is made up of:

PG7601-BAS-AF, p/n 402351, the “base” system, including the piston gauge platform, pressure

controller, vacuum pump and interconnecting hardware (everything except the piston-cylinder modules

and masses).

PG7601-EXC-AF, p/n 402350, the “exchange package”, including the piston gauge’s three different size

piston-cylinder modules and the mass set.

I

NNTTRROODDUUCCTTIIOON

I

N

1.1 SPECIFICATIONS

1.1.1 OVERALL SYSTEM SPECIFICATIONS

Power requirements

Instruments

Reference vacuum pump (D16B)

Operating temperature range

Storage temperature range

Operating humidity range

Storage humidity range

Dimensions

Bench space needed for installation

Weight (shipping)

PG7601-AF platform in case

PG7601-AF vacuum bell jar

PPC3-7M-AF pressure controller

D16B vacuum pump

Base system accessories

35 kg mass set, main masses case

35 kg mass set, fractional masses case

(3) piston-cylinder modules in case

Exchange pack accessories

System external communication ports

Overall pressure ranges

Actual range depends on piston-cylinder

installed

Operating media

85 to 264 VAC, 50/60 Hz, 52 VA max. consumption

100 to 120 VAC, 50/60 Hz, 1430 VA max. consumption, full load 9.4

to 13 A

15 to 35 °C

5 to 90 °C (vacuum pump), -40 to 100 °C (other components)

5 to 95% R.H., non-condensing

5 to 95% R.H., non-condensing

65 cm x 56 cm (65 in. x 22 in.)

36 kg (79 lb)

5 kg (11 lb)

18 kg (40 lb)

40 kg (88 lb)

12 kg (26 lb)

35 kg (77 lb)

20 kg (44 lb)

10 kg (22 lb)

6 kg (13 lb)

RS 232 (COM1), IEEE-488

7 kPa to 7 MPa (1 to 1000 psi), gauge and absolute

air, helium, nitrogen

Page 1 © 2008 DH Instruments, a Fluke Company

Page 16

PG7601-SYS-AF™ OPERATION AND MAINTENANCE MANUAL

Pressure connections

Device under test (DUT)

Test pressure supply (PPC3)

Control vacuum supply

1.1.1.1 PRESSURE MEASUREMENTS

The pressure measurement specifications of the PG7601-AF depend upon the

piston-cylinder module used.

PC-7100/7600-10-L (10 kPa/kg)

PC-7100/7600-50 (50 kPa/kg)

PC-7100/7600-200 (200 kPa/kg)

1. Sensitivity: The smallest variation in input detectable in output.

2. Reproducibility: Combined long term stability of piston-cylinder effective area and masses predicted for 30

months.

3. Measurement uncertainty:

gauge and absolute measurement modes, at the PG7601-AF reference level including precision, predicted 30 month stability,

temperature effect and calibration uncertainty, combined and expanded (k=2) following the ISO “Guide to the Expression of

Uncertainty in Measurement. Assumes the PG7601-AF platform sensors are properly adjusted, use of MS-7001-35-AF mass

set with measurement uncertainty of ± 5 ppm, uncertainty of not more than ± 2 ppm in the value of local acceleration due to

gravity entered into the PG7601-AF Terminal.

Swagelok

stems of 1/4 in. NPT F, 1/8 in. NPT F, AN4 M, 1/4 in. Swage

1/8 in. NPT F

1/8 in. NPT F

Sensitivity

Reproducibility

Measurement uncertainty

Sensitivity

Reproducibility

Measurement uncertainty

Sensitivity

Reproducibility

Measurement uncertainty

Maximum deviation of the PG7601-AF indicatied pressure from the true value of pressure, in

®

SS-QC4-B1-400 quick connector with quick connector

1

0.02 Pa + 0.5 ppm

2

± 4 ppm

3

± (0.2 Pa + 15 ppm)

1

0.1 Pa + 0.5 ppm

2

± 4 ppm

3

± (0.5 Pa + 20 ppm)

1

0.4 Pa + 0.5 ppm

2

± 6 ppm

3

± (2 Pa + 25 ppm)

1.1.2 PISTON GAUGE PLATFORM (PG7601-AF)

Power requirements

Operating temperature range

Weight

Instrument platform

PG Terminal

Dimensions

Instrument platform

PG Terminal

Microprocessors

Instrument platform

PG Terminal

Communication ports

RS232

IEEE-488

85 to 264 VAC, 50/60 Hz, 22 VA max. consumption.

15 to 25 °C

17 kg (37 lb)

1.4 kg (3 lb)

36 cm H (top of bell jar) x 40 cm W x 35 cm D (14.5 in. x 15.8 in. x

13.8 in.)

12 cm H x 15 cm W x 20 cm D (4.7 in. H x 5.9 in. W x 7.9 in. D)

Motorola 68302

Hitachi 64180

COM1: Host computer communications

COM2: Not used (may be used for optional external barometer or

vacuum gauge)

COM3: PPC3 pressure controller communications

Host comptuer

© 2007 DH Instruments, a Fluke Company Page 2

Page 17

1. INTRODUCTION

Overall pressure range

Operating media

Mass load range

Pressure connections

TEST port

Bell jar vent (VACUUM) port

Refe r e n c e v a c u u m pump down port

CE Conformance

7 kPa to 7 MPa (1 to 1000 psi), gauge and absolute (actual range

depends on piston-cylinder selected)

air, helium, nitrogen

0.7 to 36.2 kg

DH200 (for 1/4 in. OD tube, equivalent to AE SF250C, HIP LF4)

DH200

KF25

Available, must be specified.

1.1.2.1 EMBEDDED FEATURES

• Local control with 2 x 20 vacuum fluorescent display and 4 x 4 function

driven keypad.

• Real time (1 second update rate) display and measurement of ambient

(pressure, temperature, humidity) and instrument (piston-cylinder

temperature, piston position, piston drop rate, piston rotation rate, piston

rotation decay rate, reference vacuum) conditions.

• Real time (1 second update rate) mass-to-pressure and pressure-to-mass

calculations taking into consideration all environmental and operational

variables.

• Full gas and liquid fluid head corrections including DUT head correction and

piston position head correction.

• Adjustable mass loading resolution (0.01 g to 0.1 kg).

• Audible prompts of instrument status (piston movement, Ready/Not Ready indication)

with override capability.

• Integrated automated mass handling (optional).

• Interfacing and automatic exploitation of optional external barometer via

RS232 (optional).

• Interfacing and automatic exploitation of external vacuum gauge via RS232

(optional).

• Storage and one step activation of metrological data digital IDs on up to 18 piston-

cylinder modules, (3) mass sets and (3) mass loading bells.

• Continuous pressure Ready/Not Ready indication based on measured

conditions.

• Motorized, intelligent piston drive system based measured rotation rate with

operator alert and manual override.

• Integrated automated pressure control with PPC3-7M-AF pressure controller.

• Full RS232 and IEEE-488 communications with multi-level commands to set

and read all instrument functions.

Page 3 © 2007 DH Instruments, a Fluke Company

Page 18

PG7601-SYS-AF™ OPERATION AND MAINTENANCE MANUAL

1.1.2.2 MEASUREMENT OF AMBIENT AND INSTRUMENT

CONDITIONS

Temperature

Range

Resolution

Measurement uncertainty

Barometric Pressure

with Internal Sensor

Range

Resolution

Measurement uncertainty

Relative Humidity

Range

Resolution

Measurement uncertainty

Piston Position

Range

Resolution

Measurement uncertainty

Piston Rotation

(Rate and deceleration)

Range

Resolution

Ambient

15 to 25

0.1 0.01

± 1 ± 0.1

70 to 110 kPa

10 Pa

± 140 Pa

Barometric pressure can also be read automatically with any

RS232 device such as a DHI RPM (not included in

PG7601-SYS-AF).

5 to 95 % RH

1 % RH

± 10 % RH

± 4.5 mm

0.1 mm

± 0.2 mm

2 to 99 rpm

1 rpm

Piston Cylinder Module

o

C 15 to 25 oC

Vacuum

Range

Resolution

Measurement uncertainty

0 to 20 Pa

0.1 Pa

± 0.1 Pa or 10 % of reading, whichever is greater

© 2007 DH Instruments, a Fluke Company Page 4

Page 19

1. INTRODUCTION

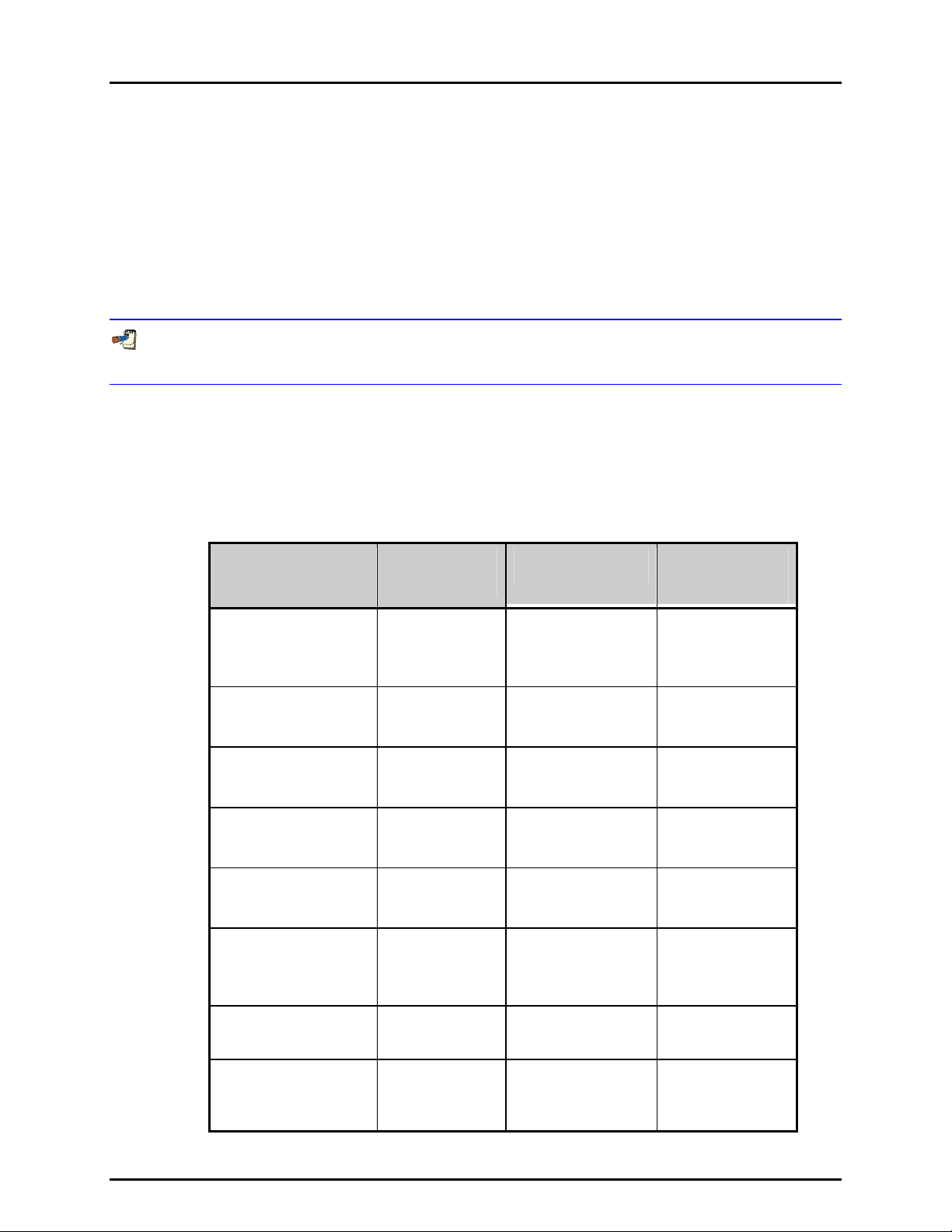

1.1.3 PISTON-CYLINDER MODULES (PC-7100/7600-10-L, -50, -200)

The PG7601-SYS-AF piston-cylinders are integrated modules including mounting hardware

delivered in individual shipping and storage bullet cases.

PC-7100/7600-10-L

Range

Operation

Piston material

Nominal mass of piston assembly

Cylinder material

Nominal diameter

Nominal area

Mounting system

Typical drop rate (35 kg load)

Nominal mass to pressure 10 kPa/kg (1.5 psi/kg)

7 to 350 kPa (1 to 50 psi)

Gas operated, gas lubricated

Tungsten carbide

0.4 kg

Tungsten carbide

35 mm

1 000 mm

Simple free deformation

0.1 mm/min

2

PC-7100/7600-50

Range

Operation

Piston Material

Nominal mass of piston assembly

Cylinder Material

Nominal Diameter

Nominal Area

Mounting system

Typical drop rate (35 kg load)

PC-7100/7600-200

Range

Operation

Piston Material

Nominal mass of piston assembly

Cylinder Material

Nominal Diameter

Nominal Area

Mounting System

Typical drop rate (35 kg load)

Nominal mass to pressure 50 kPa/kg (7.5 psi/kg)

25 to 1750 kPa (3.6 to 254 psi)

Gas operated, gas lubricated

Tungsten carbide

0.2 kg

Tungsten carbide

16 mm

2

200 mm

Negative free deformation

0.5 mm/min

Nominal mass to pressure 200 kPa/kg (14.5 psi/kg)

100 to 7000 kPa (14.5 to 1015 psi)

Gas operated, gas lubricated

Tungsten carbide

0.2 kg

Tungsten carbide

8 mm

50 mm

Negative free deformation

1.0 mm/min

2

Page 5 © 2007 DH Instruments, a Fluke Company

Page 20

PG7601-SYS-AF™ OPERATION AND MAINTENANCE MANUAL

1.1.4 MASS SET (MS-7001-35-AF)

Set composition

Mass discs and pucks

Material

Finish

Adjustment tolerance

Uncertainty in measured values

Mass loading bell

Material

Finish

Adjustment tolerance

Uncertainty in measured value

Trim masses < 50g

Adjustment tolerance

Uncertainty in measured value

1 x 4.5 kg disc(makeup mass)

5 x 5 kg disc

2 x 2 kg disc

1 x 1 kg disc

1 x 0.5 kg puck

2 x 0.2 kg puck

1 x 0.1 kg puck

1 x 0.3 kg mass loading bell

Trim mass set of 50 g to 0.01 g (total 100 g)

304L non-magnetic stainless steel

Electropolished

± 20 ppm of nominal value

± 5 ppm

6AL-4V titanium (bell and hanger), 304L stainless steel

(adjustment ring), nickel plated 1018 steel (speed ring)

Mechanically polished

± 20 ppm of nominal value

± 8 mg

Adjusted to nominal value

± 1 mg

© 2007 DH Instruments, a Fluke Company Page 6

Page 21

1. INTRODUCTION

1.1.5 PRESSURE CONTROLLER (PPC3-7M-AF)

Power requirements

Operating temperature range

Weight

Microprocessors

Communication ports

Fuses

Pressure range

Operating medium

Pressure connections

Test pressure supply

Control vacuum supply

Pressure limits

Maximum working pressure

Maximum supply pressure

On-board utility sensor

Resolution 0.001 % of span

Precision 0.1 % of span

85 to 264 VAC, 50/60 Hz, 30 VA max consumption

15 to 35 °C

12.7 kg (28.2 lb) approx

Motorola 68302, 16 MHz

RS232 (COM1), RS232 (COM2), IEEE-488.2

1 A, 250 VAC fuse, 5 x 20 mm, time lag type fuse

Internal power supply fuse not replaceable by operator: 2A, 250 V (UV 440-2

power supply), 3.15A, 250 V (NFS40-7612 power supply)

7 kPa to 7 MPa (1 to 1000 psi), gauge and absolute

Any clean, dry, non-corrosive gas

SUPPLY: 1/8 in. NPT F

TEST(+): 1/8 in. NPT F

TEST(-): 1/8 in. NPT F

ATM (Vent):10-32 UNF

EXHAUST:1/4 in. NPT F

7.7 MPa (1100 psi)

Ultimate pressure lower than 2 kPa (0.3 psia); capacity 85 slm (3 cfm) min

7.03 MPa (1020 psi)

9.6 MPa (1 400 psi)

The pressure measurements made by the PPC3-7M-AF utility sensor are used only for

pressure control and indication. They have no metrological function therefore they do not require

traceable calibration. Adjustment of the PPC3 utility sensor is performed only for operational

reasons (see Section 6.5).

1.1.6 REFERENCE VACUUM PUMP (D16B)

Power requirements

Operating temperature range

Weight

Oil capacity

Nominal pumping speed

Pumping speed

Ultimate total pressure

Pressure connections (intake

and exhauts)

100 to 120 VAC, 50/60 Hz, 1430 W max consumption, full load 9.4 to 13 A

12 to 40 °C

26 kg (57 lb) approx

0.5 l (1 qt)

3

/h (11.1 cfm)

18.9 m

16.5 m3/h (9.7 cfm)

0.2 Pa (1.5 mTorr)

KF25

Page 7 © 2007 DH Instruments, a Fluke Company

Page 22

PG7601-SYS-AF™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2007 DH Instruments, a Fluke Company Page 8

Page 23

2. SYSTEM AND COMPONENT OVERVIEW AND DESCRIPTION

.

22.

S

YYSSTTEEMM AANNDD

S

C

OOMMPPOONNEENNTT

C

O

VVEERRVVIIEEWW AANNDD

O

2.1 SYSTEM OVERVIEW (PG7601-SYS-AF)

PG7601-SYS-AF is a very high performance pressure calibration system for the validation and calibration of

pressure measuring devices using gas as the pressurized medium in the range of 7 to 7000 kPa (1 to 1 000 psi).

A PG7601-SYS-AF is made up of:

PG7601-BAS-AF, the “base system”. The base system is the operational piston gauge

system, not including the piston-cylinder modules and mass set. The base system includes:

- PG7601-AF piston gauge platform with PG Terminal and vacuum bell jar

- PPC3-7M-AF pressure controller

- D16B reference vacuum pump

- Pressure and vacuum interconnecting hardware packages

PG7601-EXC-AF, the “exchange package”. The exchange package is the system’s

metrological elements: the piston-cylinder modules and mass set. The exchange package

includes:

D

EESSCCRRIIPPTTIIOON

D

N

- (3) piston-cylinder modules, PC-7100/7600-10-L, -50 and -200.

- MS-7001-35-AF 35 kg mass set

The following figures in this section describe the PG7601-SYS-AF system:

Figure 1. System, PG7601-SYS-AF, standard installation

Figure 2. System, PG7601-SYS-AF, system pneumatic schematic

Figure 3. System, PG7601-SYS-AF, electrical and communications schematic

Page 9 © 2007 DH Instruments, a Fluke Company

Page 24

PG7601-SYS-AF™ OPERATION AND MAINTENANCE MANUAL

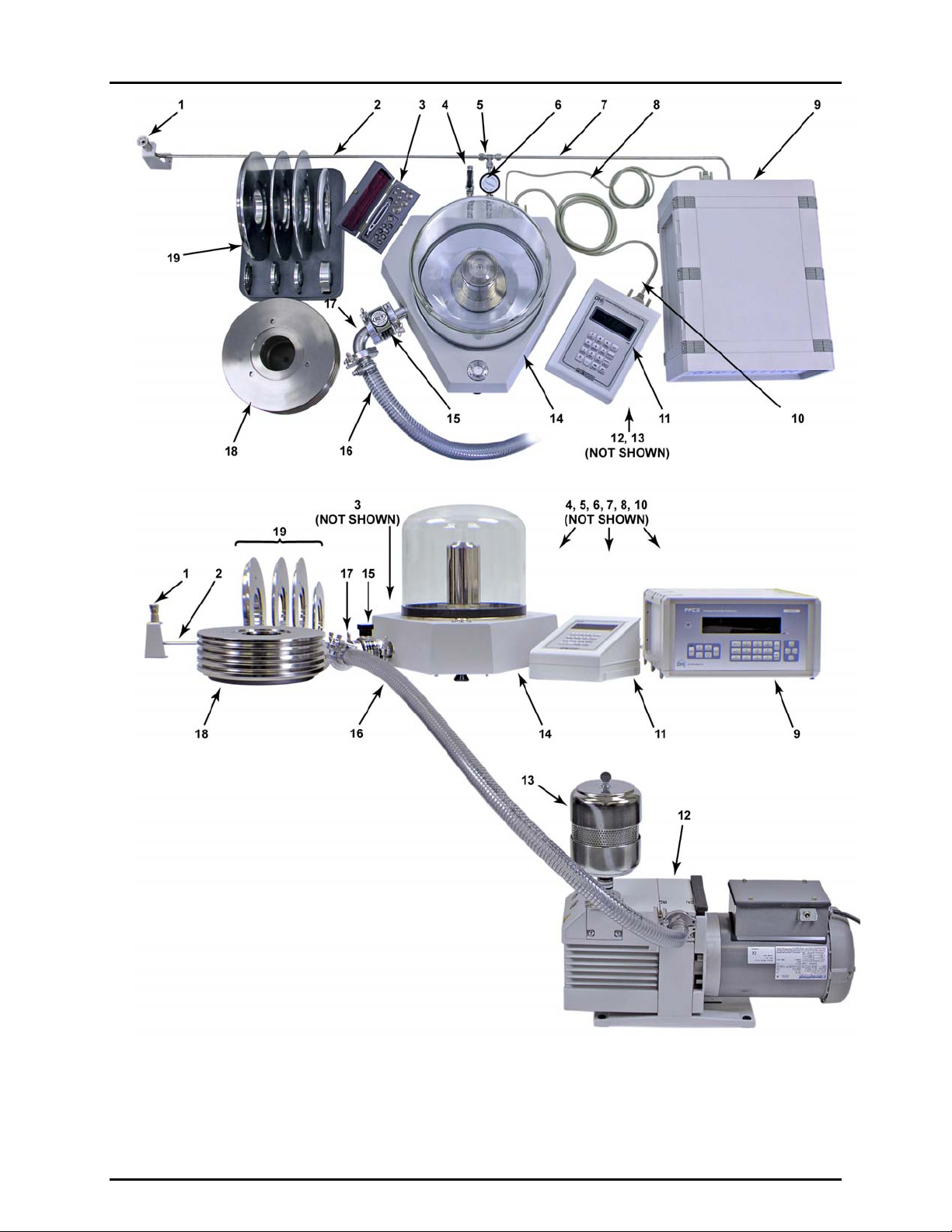

1. DUT quick connector on stand

2. Tube, DUT connector to tee

3. Trim mass set

4. Vacuum vent valve

5. Tee

6. Platform shutoff valve

assembly

7. Tube, pressure controller to tee

8. RS232 cable, pressure

controller to platform

9. PPC3-7M-AF pressure

controller

10. PG Terminal to platform cable

11. PG Terminal

12. D16B reference vacuum

pump

13. Vacuum pump smoke

eliminator

14. PG7601-AF platform

15. Vacuum shutoff valve

16. KF25 hose

17. KF25 elbow

18. Main mass stack

19. Fractional mass tray

Figure 1. System, PG7601-SYS-AF, standard installation

© 2007 DH Instruments, a Fluke Company Page 10

Page 25

2. SYSTEM AND COMPONENT OVERVIEW AND DESCRIPTION

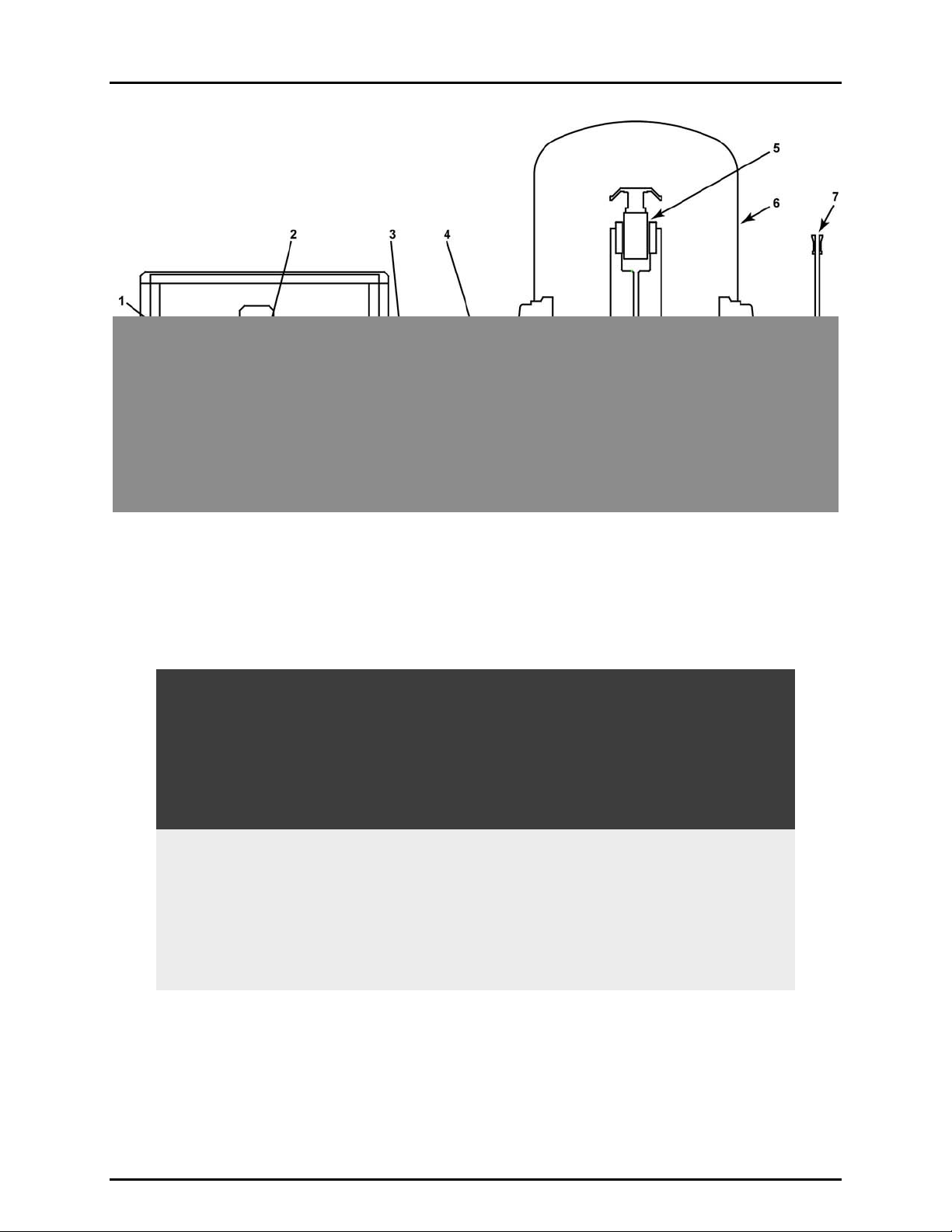

1. Test pressure supply

2. Pressure controller connection

3. Reference vacuum pump

4. Vacuum shutoff valve

5. Piston-cylinder module

6. Reference vacuum bell jar (removed in

gauge measurement mode)

7. DUT connection

8. Vacuum vent valve

9. Platform shutoff valve

10. Control vacuum supply

Figure 2. System, PG7601-SYS-AF, pneumatic schematic

1. Electrical power cords

2. PG Terminal to PG7601-AF platform data and

power connection

3. PG7601-AF platform to PPC3-7M-AF pressure

controller connection (RS232)

4. PG7601-SYS-AF system remote communications

(RS232)

5. PG7601-SYS-AF system remote communications

(IEEE-488)

Figure 3. System, PG7601-SYS-AF, communications schematic

Page 11 © 2007 DH Instruments, a Fluke Company

Page 26

PG7601-SYS-AF™ OPERATION AND MAINTENANCE MANUAL

2.2 PISTON GAUGE PLATFORM AND TERMINAL (PG7601-AF)

The heart of the PG7601-SYS-AF is the PG7601-AF gas operated piston gauge and its piston-cylinder

modules and mass set.

The PG7601-AF operates on the principle of the piston gauge in which pressure is defined by balancing it

against a known force on a known area (see Figure 4). The known area is defined by a vertically

mounted piston rotating in a cylinder and the known force is applied

mass subjected to acceleration due to gravity. When the force applied by the pressure and the force

appl ied by t he ma ss accelerated by gravity are in equilibrium, the piston floats and the pressure under the

piston remains constant. The pressure can be calculated following the equation in Figure 4. The

pressurized gas under the piston also lubricates the gap between the piston and the cylinder.

floating, the piston must be rotating to keep it well centered in the cylinder and perfectly mobile.

The system includes three piston cylinder modules and a 35 kg mass set. The combination provides

three ranges of 7 to 350 kPa (1 to 50 psi), 25 to 1750 kPa (3.6 to 260 psi) and 100 to 7 000 kPa (14.5 to

1000 psi). The PG7601-AF platform includes a bell jar that can be evacuated using the supplied

reference vacuum pump so that pressure can be defined against vacuum (absolute mode) or atmosphere

(gauge mode). The PPC3-7M-AF pressure controller adjusts pressure automatically or manually to float

the piston (see Section 4.1.2).

to the piston by loading it with known

When

Figure 4. Piston gauge operating principle

© 2007 DH Instruments, a Fluke Company Page 12

Page 27

2. SYSTEM AND COMPONENT OVERVIEW AND DESCRIPTION

2.2.1 PLATFORM

The PG7601-AF platform is the instrument base into which the piston-cylinder modules are

mounted and onto which the masses are loaded. The platform also includes the electronic

measurement system.

The PG7601-AF platform rear panel provides the connection to the PG Terminal, remote

communication connections and pressure connection ports.

1. COM2 (RS232) for external barometer (optional), external

vacuum gauge (optional), pass through communications

2. COM3 (RS232) – for PPC3-7M-AF pressure controller,

AMH-38 automated mass handler (optional)

3. COM1 (RS232) - remote host communications

4. Ambient temperature sensor

Figure 5. Platform, PG7601-AF, rear view

5. IEEE-488 (GPIB) - remote host

communications

6. Ambient relative humidity sensor

7. VACUUM port, for vacuum vent valve

8. TEST port, for connection to test system

9. PG Terminal port

Page 13 © 2007 DH Instruments, a Fluke Company

Page 28

PG7601-SYS-AF™ OPERATION AND MAINTENANCE MANUAL

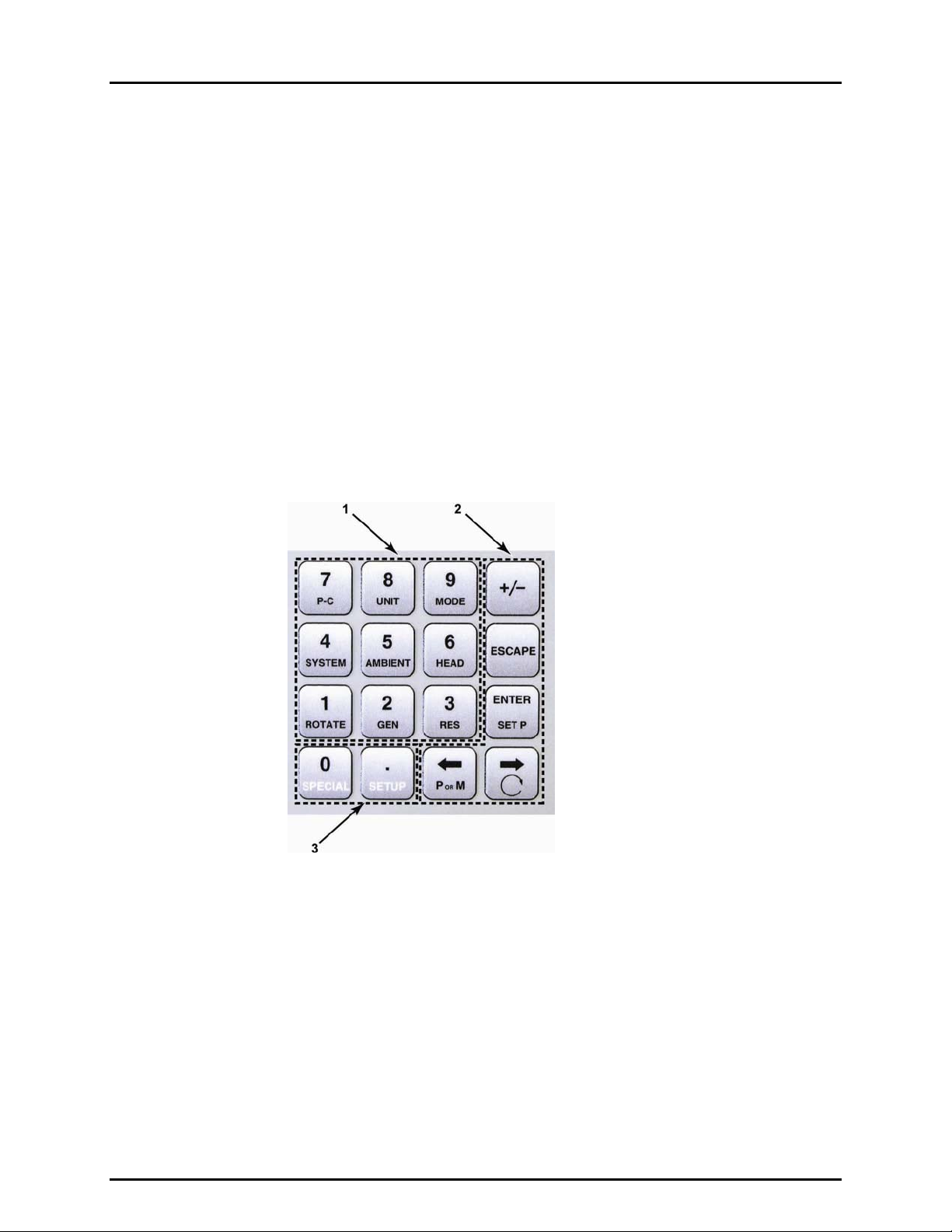

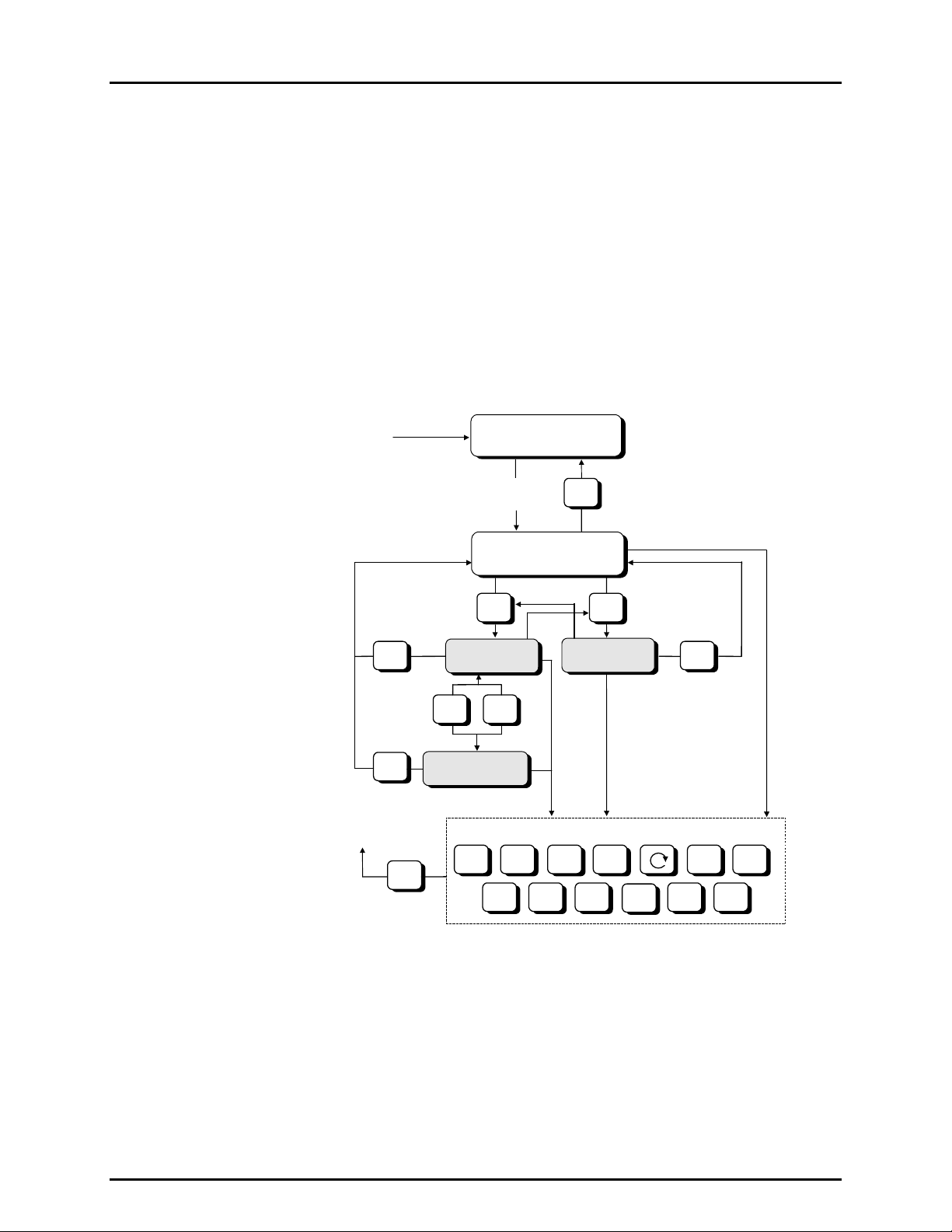

2.2.2 PG TERMINAL

The PG Terminal houses the PG platform power supplies and provides the local user

interface for interaction with the PG7601-SYS-AF system.

The front panel assembly provides a 2 x 20 vacuum fluorescent display and a 4 x 4

membrane keypad for local user interface.

1. Vacuum fluorescent display

2. Keypad

Figure 6. PG Terminal front panel

The PG Terminal rear panel assembly provides the communications connection to the

PG7601-AF platform and the power connection module.

1. Power switch

2. Fuse (25-pin)

3. Power receptacle

Figure 7. PG Terminal rear panel

4. Connector for cable to PG7000 platform

5. Cooling fan

© 2007 DH Instruments, a Fluke Company Page 14

Page 29

2. SYSTEM AND COMPONENT OVERVIEW AND DESCRIPTION

2.3 PISTON-CYLINDER MODULES (PC-7100/7600-10-L, -50, -200)

The piston-cylinder module is mounted in the PG7601-AF platform. The piston-cylinder precisely

converts pressure to a proportional force (see Section 4.1.1). There are three piston-cylinder modules for

three different pressure ranges.

Figure 8. Piston-cylinder modules, PC-7100/7600-10-L, -50, -200

Page 15 © 2007 DH Instruments, a Fluke Company

Page 30

PG7601-SYS-AF™ OPERATION AND MAINTENANCE MANUAL

2.4 MASS SET (MS-7001-35-AF)

Combinations of masses from the 35 kg mass set are loaded onto in the piston-cylinder, as needed, to result

in the set pressure desired.

The mass set is made up of (1) mass loading bell of 0.3 kg, (1) 4.5 kg makeup mass disc, (5) 5 kg mass

discs, (2) 2 kg discs, (1) 1 kg disc, (1) 0.5 kg puck, (2) 0.2 kg puck, (1) 0.1 kg puck, 50 g to 0.01 g trim mass

set in 1-2-2-1 progression.

Figure 9. Mass set, MS-7100-35-AF

2.5 PRESSURE CONTROLLER (PPC3-7M-AF)

The PPC3-7M-AF pressure controller is used to set and adjust pressure in the PG7601-SYS-AF system.

Its operation can be fully automated to float the PG7601-AF’s piston under control of the PG7601-AF

platform’s AutoGen function (see Section 4.1.2). It can also be used manually under direct operator

control using its front panel direct pressure control keys.

The PPC3-7M-AF pressure controller is a component of the PG7601-SYS-AF system. It can also act as

a stand alone component. For information on use of PPC3-7M-AF outside of the PG7601-SYS-AF system, see

the PPC3 Operation and Maintenance Manual.

The pressure measurements made by the PPC3-7M-AF utility sensor are used only for pressure control

and indication. They have no metrological function therefore they do not require traceable calibration.

Adjustment of the PPC3 utility sensor is performed only for operational reasons (see Section 6.5).

© 2007 DH Instruments, a Fluke Company Page 16

Page 31

2. SYSTEM AND COMPONENT OVERVIEW AND DESCRIPTION

1. Ready/Not Ready indicator

2. Display

3. Remote activity indicator

4. Cursor control keys

5. Multi-function keypad

6. Direct pressure control keys

Figure 10. Pressure controller, PPC3-7M-AF, front panel

1. Label, product

2. VENT port

3. COM2 connector

4. IEEE-488 connector

5. COM1 connector (PG7601-AF

communications)

6. Drivers (12 V) connector

7. Power switch

8. Fuse

9. Electrical power connector (IEC-320-C13)

10. Remote [ENTER] connector

11. Pressure connection, TEST(+)

12. Pressure connection, TEST(-)

13. Pressure connection, EXHAUST

14. Pressure connection, SUPPLY

Figure 11. Pressure controller, PPC3-7M-AF, rear panel

Page 17 © 2007 DH Instruments, a Fluke Company

Page 32

PG7601-SYS-AF™ OPERATION AND MAINTENANCE MANUAL

2.6 REFERENCE VACUUM PUMP (D16B)

The reference vacuum pump is connected to the PG7601-AF platform reference vacuum port using the

PK-7601-V-AF vacuum interconnections kit. It is used to establish a vacuum under the platform’s

vacuum bell jar when operating in absolute measurement mode against a vacuum.

1. Smoke eliminator

2. Exhaust flange

3. Intake flange

4. Handle

5 Power switch

6. Oil fill plug

Figure 12. Reference vacuum pump, D16B, front and side views

7. Maximum oil fill line

8. Minimum oil fill line

9. Oil drain plug

10. Oil level sight glass

11. Gas ballast valve

© 2007 DH Instruments, a Fluke Company Page 18

Page 33

3. INSTALLATION

.

33.

I

NNSSTTAALLLLAATTIIOON

I

N

3.1 UNPACKING AND INSPECTION

3.1.1 UNPACKING AND INSPECTION OF PG7601-BAS-AF BASE SYSTEM

The PG7601-BAS-AF is the PG7601-SYS-AF gas piston gauge base system. It includes the

system operational components but not the piston-cylinder modules and mass sets which are

in the PG7601-EXC-AF exchange pack.

Check that all items included in the PG7601-BAS-AF base system are present and have NO

visible signs of damage.

Table 1 provides a parts list of the base system major components and how they are

Unpack and inspect the items following the instructions in Sections 3.1.1.1 to 3.1.1.6 and

detailed packing lists in Table 2 to Table 5.