Page 1

P3000 Series

Pneumatic Deadweight Testers

Model P3000

Features

• Pressure ranges from

Vacuum through 2 000 psi

(140 b a r)

• Accuracy better than

0.015 % of reading.

(Increased accuracy option

of 0.0 08 %)

• Gas operated with optional

hand pumps

• Dual vacuum/pressure

models available

• Psi, bar, kgf/cm2, kPa and

MPa ranges available

• Piston/cylinder design

provides stability and

repeatability

• Built-in pneumatic hand

pumps for pressure and

vacuum

• High quality needle valves

provide optimum control

• Mounted spirit level and

adjustable feet

• Test station design with

O-rings eliminates the

need for PTFE tape or

wrenches

• Improved case with springloaded latches for hood

• Sturdy weight box with

hinged lid and side

handles for easy transport

The P3000 Series is the culmination

of over 50 years experience in the

production and design of primary pressure standards. With features designed

to improve accuracy and performance,

increase reliability and simplify operation these deadweight testers can be

used to calibrate virtually any pressure

sensing device, including transducers, transmitters, gauges or pressure

switches.

Each instrument is supplied with a

detachable lid that makes it neat, compact and easily portable. The masses

are stored in a high-quality case with

Technical Data

a self-locking mechanism to protect

them during transit.

All units are provided with an

accredited calibration certificate,

M14X1.5, M20X1.5, 1/8, 1/4, 3/8, and

1/2 NPT and BSP female adaptors,

operating fluid (where applicable) and

spare seals.

The piston/cylinder assemblies are

manufactured to the very highest standards and are supplied with accredited

calibration reports with stated instrumental measurement uncertainties.

Page 2

Operating principle

Deadweight testers are the primary standard

for pressure measurements. Utilizing the well

proven piston-gauge system consisting of a

vertically mounted, precision lapped piston and

cylinder assembly, accurately calibrated masses

(Force) are loaded on the piston (Area), which

rises freely within its cylinder. These masses

balance the upward force created by the pressure within the system.

Instrument base

There are four basic variations in the pneumatic

offering; single pressure, single vacuum, dual

vacuum and pressure, and oil-lubricated pneumatically driven high-pressure models. Pressure

or vacuum is generated by an external source or

an optional built-in hand pump (standard on the

lower pressure models). The hand pump option

is not available on instruments above 500 psi

(3.5 MPa).

Piston/cylinder assemblies

The piston/cylinder assembly is the heart of

each deadweight tester. They are manufactured

from materials that provide stability, durability,

and low thermal coefficients and distortion. Our

experience and knowledge of piston/cylinder

production and calibration ensure the precision

and performance required for today’s demanding calibration requirements.

Masses

Standard masses are series 3 non-magnetic

austenitic stainless steel. Each mass is marked

with the serial number of the instrument and

the nominal pressure value relative to the highor low-pressure piston, when applicable. The

masses for the vacuum ranges and the optional

fine increment masses are stainless steel and/or

aluminum.

Force

Area

Pressure

Pressure =

Force

Area

Gravity correction

Gravity varies significantly with geographical

location and this variation has a direct effect

on the force of the weights and the accuracy

of the deadweight tester. Each instrument can

be calibrated to local gravity at no extra cost. If

unspecified, instruments will be calibrated to

Standard Gravity at 980.665 cm/s2.

Gas supply

All instruments are fitted with a 1/4 inch NPT

female external supply port for connection to

the gas supply source. A compressed gas bottle

(nitrogen or dry air) fitted with a pressure regulator is recommended. Ten percent above the

maximum pressure is required. A built-in hand

pump is available on some models to generate

pressures to 300 psi (2 MPa).

For vacuum requirements, an external

vacuum pump can be connected to the 1/4 inch

port. The built-in hand pump will also generate

up to 90 % vacuum.

PressCal Software

Windows-based software program that allows

users to easily apply all necessary corrections

to enhance the deadweight tester performance.

Calibration details are then stored and/or used

to automatically create a calibration certificate.

The use of PressCal allows for an improved

accuracy of 0.008 %.

2 Fluke Calibration P3000 Series Pneumatic Deadweight Testers Model P3000

Page 3

P3000 Series Vacuum and Dual

Vacuum/Pressure Models

The combined vacuum/pressure models are

extremely versatile instruments providing

vacuum through 500 psi (3.5 MPa) capacity in

one unit. An optional built-in hand pump can

be installed to generate vacuum (90 %) through

300 psi (2 MPa).

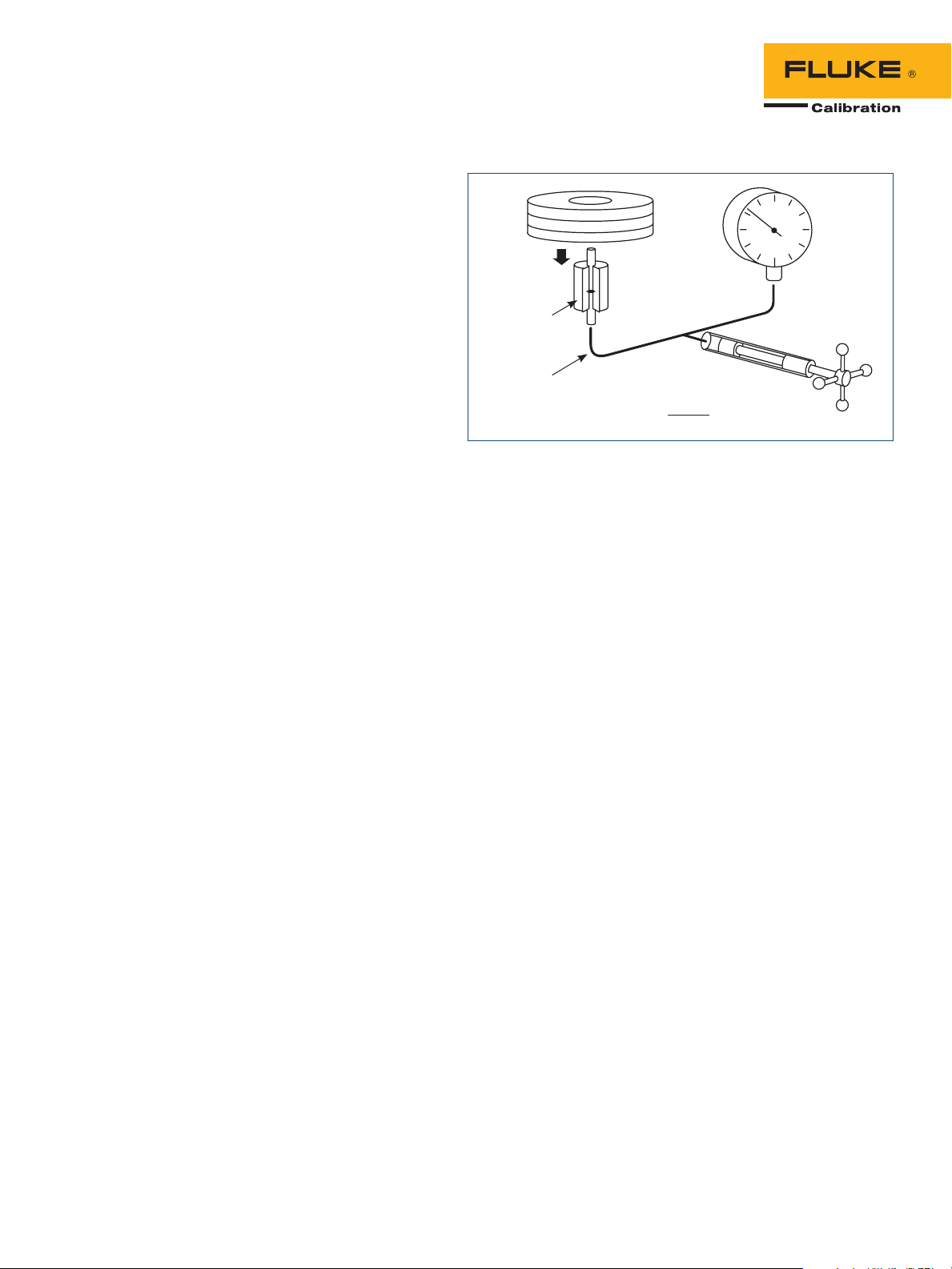

Pressure PCU

System pressure gauge

P3000 Series Liquid Lubricated Gas

Operated Models

The Models P3031 and P3032 feature an oil

lubricated piston/cylinder assembly, which

ensures that the instrument is less susceptible

to performance issues caused by contamination

of the gas supply or the environment in which

the unit is being operated.

The supply gas, via the deadweight tester

controls, is introduced into the piston/cylinder

chamber. As the gas acts directly on the surface

of the oil, there is a rate-less transfer of pressure

within the system.

The instrument is designed to prevent

inadvertent over-filling of the chamber, thus

avoiding contamination of the gas

system. There

is no physical

barrier between

the gas and oil

so there is some

“oil-mist” transfer potential.

Vacuum PCU

3 Fluke Calibration P3000 Series Pneumatic Deadweight Testers Model P3000

Pressure/vacuum

selector valve

Increase/decrease

valves

Cross-sectional illustration of liquid

lubricated piston chamber

Page 4

Specications

Pressure ranges

Instrumental measurement uncertainty ± 0.015 % of reading (± 0.008 % optional)

Mass and PCU materials of construction

Standard weight material Series 3 non-magnetic austenitic stainless steel

Optional fine increment masses Aluminum

P3011, P3012, P3013, P3022, P3023,

P3025 (V)

P3014, P3015, P3025 (P), P3031,

P3032 (P & V)

General

Test port adaptors M14 X 1.5, M20 X 1.5, 1/8 in, 1/4 in, 3/8 in and 1/2 in NPT and BSP

Weight 11 kg (24 lb)

Dimensions (W x D x H) 440 mm x 300 mm x 215 mm (17.5 in x 12 in x 8.5 in)

Mass set weight (typical) 29 kg (65 lb)

Weight increments

Minimum standard weight increments

P3012, P3022 Pressure 1 inH2O, (5 mbar, 0.5 kPa)

P3013, P3023 Pressure 2 inH2O, (10 mbar, 1 kPa)

P3014, P3015, P3025 Pressure 1 psi, (0.1bar, 10 kPa)

P3031, P3032 1 psi, (0.1bar, 10 kPa)

P3011, P3022, P3023, P3025

Vacuum

Optional fractional weights

P3014, P3015, P3025 Pressure 0.1 psi (10 mbar, 1 kPa)

Built-in hand pumps

Pressure mode Max pressure 300 psi (2 MPa)

Vacuum mode To 90 % vacuum

Operating fluid for liquid lubricated models

55-655 mineral oil. For oxygen clean applications, please consult factory.

Note: For more information on the uncertainty, including the

% reading threshold, please see technical note, "Guide for the

Uncertainty Analysis in Pressure When Using P3000 Series Deadweight Testers"

Density: 7.8 g/cm

Density: 2.7 g/cm

Piston material Cylinder material Coefficient of

Ceramic Martensitic steel 11 ppm/°C

Tungsten carbide Martensitic steel 16.5 ppm/°C

0.2 inHg (10 mbar, 1 kPa)

3

3

expansion

4 Fluke Calibration P3000 Series Pneumatic Deadweight Testers Model P3000

Page 5

Ordering information

Air operated—single PCU

Model

P3012-KPA-P 1.5 to 100 kPa

P3 012-M B A R-P 15 to 1 000 mbar

P3012-INH2O-P 5 to 400 inH2O

P3013-KPA-P 3 to 200 kPa

P3013- MBAR-P 30 to 2 000 mbar

P3013-INH2O-P 12 to 800 inH2O

P3014-BA R-P 0.2 to 10 bar

P3014-KG C M 2 - P 0.2 to 10 kgf/cm

P3014-PSI-P 3 to 150 psi

P3014-KPA-P 20 to 1 000 kPa

P3014-5MPA-P 0.02 to 1 MPa

P3 015 -BAR- P* 0.2 to 35 bar

P3 015 -KG C M2- P* 0.2 to 35 kgf/cm

P3015-PSI-P* 3 to 500 psi

P3015-KPA-P* 20 to 3 500 kPa

P3015-MPA-P* 0.02 to 3.5 MPa

* -P ind icates built-in pump option al.

2

2

Liquid lubricated

Model

P30 31- B A R 1 to 70 bar

P30 31- KGCM2 1 to 70 kgf/cm

P3031-PSI 10 to 1 000 psi

P30 31- K PA 100 to 7 000 kPa

P30 31- M PA 0.1 to 7 MPa

P3032-BAR 1 to 140 bar

P3032-2KGCM2 1 to 140 kgf/cm

P3032-PSI 10 to 2 000 psi

P3032- KPA100 to 14 000 kPa

P3032-MPA 0.1 to 14 MPa

Vacuum operated—

single PCU

Model

P 3 0 11- K PA - P * 3 to 100 kPa

P 3 0 11- M B A R - P * 30 to 1 000 mbar

P3011-INHG-P* 1 to 30 inHg

P3011-MMHG-P* 20 to 760 mmHg

* -P ind icates built-in pump option al.

Air operated—dual PCU

Model Pressure range Vacuum range

P3022-KPA-P* 1.5 to 100 kPa 3 to 100 kPa

P3022-MBAR-P* 15 to 1,000 mbar 30 to 1 000 mbar

P3022-INH20-P* 5 to 400 inH2O 1 to 30 inHg

P3023-K PA- P* 3 to 200 kP 3 to 100 kPa

P3023-MBAR-P* 30 to 2 000 mbar 30 to 1 000 mbar

P3023-INH20-P* 12 to 800 inH2O 1 to 30 inHg

P3025-BAR-P* 0.2 to 35 bar 30 to 1 000 mbar

P3025-KGCM2-P* 0.2 to 35 kgf/cm

P3025-PSI-P* 3 to 500 psi 1 to 30 inHg

P3025 -K PA- P* 0.02 to 3.5 MPa 3 to 100 kPa

P3025 -M PA- P* 0.02 to 3.5 MPa 3 to 100 kPa

* -P ind icates built-in pump option al.

2

20 to 760 mmHg

2

2

Fluke Calibration.

Precision, performance, confidence.

™

Options

Built-in pump (where applicable)

Fine Increment Weights (where applicable)

Conversion Weight Set to allow pressure increments in other pressure units

0.008 % Improved Accuracy (PressCal Software)

COMPASS for Pressure Calibration Software

5 Fluke Calibration P3000 Series Pneumatic Deadweight Testers Model P3000

Fluke Calibration

PO Box 9090, Everett, WA 98206 U.S. A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more in formation call:

In the U.S.A. (877) 355-3225 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.flukecal.com

©2011, 2015, 2017 Fluke Cal ibration.

Specifications s ubject to change w ithout notic e.

Printed in U. S.A . 3/2017 3833551f-en

Pub-ID: 11744-eng

Modi ficat ion of th is doc umen t is not pe rmit ted

without wr itten p ermi ssion f rom Fluke Cal ibration.

Loading...

Loading...