Page 1

2

TM

MicroScanner

Cable Verifier

Users Manual

January 2007, Rev. 2 8/2016

©2007, 2015, 2016 Fluke Corporation

All product names are trademarks of their respective companies.

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke Networks product is warranted to be free from defects in material and workmanship under normal use and service

unless stated otherwise herein. The warranty period for the mainframe is one year and begins on the date of purchase. Parts,

accessories, product repairs and services are warranted for 90 days, unless otherwise stated. Ni-Cad, Ni-MH and Li-Ion batteries,

cables or other peripherals are all considered parts or accessories. The warranty extends only to the original buyer or end user

customer of a Fluke Networks authorized reseller, and does not apply to any product which, in Fluke Networks’ opinion, has

been misused, abused, altered, neglected, contaminated, or damaged by accident or abnormal conditions of operation or

handling. Fluke Networks warrants that software will operate substantially in accordance with its functional specifications for

90 days and that it has been properly recorded on non-defective media. Fluke Networks does not warrant that software will be

error free or operate without interruption.

Fluke Networks authorized resellers shall extend this warranty on new and unused products to end-user customers only but

have no authority to extend a greater or different warranty on behalf of Fluke Networks. Warranty support is available only if

product is purchased through a Fluke Networks authorized sales outlet or Buyer has paid the applicable international price. To

the extent permitted by law, Fluke Networks reserves the right to invoice Buyer for repair/replacement when a product

purchased in one country is submitted for repair in another country.

For a list of authorized resellers, visit www.flukenetworks.com/wheretobuy.

Fluke Networks warranty obligation is limited, at Fluke Networks option, to refund of the purchase price, free of charge repair,

or replacement of a defective product which is returned to a Fluke Networks authorized service center within the warranty

period.

To obtain warranty service, contact your nearest Fluke Networks authorized service center to obtain return authorization

information, then send the product to that service center, with a description of the difficulty, postage and insurance prepaid

(FOB destination). Fluke Networks assumes no risk for damage in transit. Following warranty repair, the product will be

returned to Buyer, transportation prepaid (FOB destination). If Fluke Networks determines that failure was caused by neglect,

misuse, contamination, alteration, accident or abnormal condition of operation or handling, or normal wear and tear of

mechanical components, Fluke Networks will provide an estimate of repair costs and obtain authorization before commencing

the work. Following repair, the product will be returned to the Buyer transportation prepaid and the Buyer will be billed for

the repair and return transportation charges (FOB Shipping point).

THIS WARRANTY IS BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

FLUKE NETWORKS SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or limitation of

incidental or consequential damages, the limitations and exclusions of this warranty may not apply to every buyer. If any

provision of this Warranty is held invalid or unenforceable by a court or other decision-maker of competent jurisdiction, such

holding will not affect the validity or enforceability of any other provision.

4/15

Fluke Networks

PO Box 777

Everett, WA 98206-0777

USA

Page 3

Table of Contents

Title Page

Introduction .......................................................................................................................................................................... 1

Registration ........................................................................................................................................................................... 1

Contacting Fluke Networks .................................................................................................................................................. 2

Symbols .................................................................................................................................................................................. 2

Safety Information ......................................................................................................................................................... 3

2

MicroScanner

Display Features .................................................................................................................................................................... 8

Auto Shutoff ......................................................................................................................................................................... 9

Changing the Length Units .................................................................................................................................................. 9

Using the Wiremap Adapter and Remote ID Locators ....................................................................................................... 10

Testing Twisted Pair Cabling ................................................................................................................................................ 11

Twisted Pair Test Results ............................................................................................................................................... 12

Features ........................................................................................................................................................ 6

Open on Twisted Pair Cabling ............................................................................................................................... 12

Short on Twisted Pair Cabling ............................................................................................................................... 13

i

Page 4

MicroScanner2 Cable Verifier

Users Manual

Crossed Wires .......................................................................................................................................................... 13

Crossed Pairs ............................................................................................................................................................14

Split Pair .................................................................................................................................................................. 15

Telephone Voltages Detected ................................................................................................................................16

Bridge Tap Detected ............................................................................................................................................... 17

Ethernet Port Detected ........................................................................................................................................... 18

Viewing Individual Results ............................................................................................................................................. 20

Using Multiple Remote ID Locators .............................................................................................................................. 22

Connecting to Telephone Networks Wired in Star Topologies ...................................................................................24

Connecting to Telephone Networks Wired in Bus Topologies ................................................................................... 26

Testing Coaxial Cabling ......................................................................................................................................................... 28

Coaxial Results ................................................................................................................................................................ 29

Open on Coaxial Cabling ........................................................................................................................................ 29

Short on Coaxial Cabling ........................................................................................................................................ 30

Unknown Termination on Coaxial Cabling ........................................................................................................... 30

Detecting Power Over Ethernet ...........................................................................................................................................31

Using the Toner ..................................................................................................................................................................... 32

Toning in IntelliTone Mode (optional IntelliTone probe required) ............................................................................ 32

Analog Toner Mode (optional tone probe required) .................................................................................................. 35

Using the SmartTone Function ...................................................................................................................................... 36

ii

Page 5

Table of Contents

Using the IntelliTone Cable Map Function (optional IP200 probe required) .................................................................... 36

Calibrating Length Measurements ...................................................................................................................................... 38

Setting the NVP to a Specified Value ........................................................................................................................... 38

Determining a Cable’s Actual NVP ............................................................................................................................... 38

Maintenance ......................................................................................................................................................................... 39

Cleaning ......................................................................................................................................................................... 40

Battery Life, Status, and Replacement ......................................................................................................................... 40

Checking the Tester’s Version and Serial Number ....................................................................................................... 41

If Something Seems Wrong .................................................................................................................................................. 41

Options and Accessories ....................................................................................................................................................... 42

Specifications ......................................................................................................................................................................... 43

Environmental Specifications ........................................................................................................................................ 43

General Specifications ................................................................................................................................................... 44

Test Modes ..................................................................................................................................................................... 44

Performance Specifications ........................................................................................................................................... 45

Regulatory Information ................................................................................................................................................. 46

Appendix A: Diagnosing Wiremap Faults ........................................................................................................................... 47

Open ............................................................................................................................................................................... 47

Split Pair ......................................................................................................................................................................... 47

Reversed Pairs ................................................................................................................................................................ 47

iii

Page 6

MicroScanner2 Cable Verifier

Users Manual

Crossed Pairs ................................................................................................................................................................... 47

Short ............................................................................................................................................................................... 48

Index ......................................................................................................................................................................................49

iv

Page 7

List of Figures

Figure Title Page

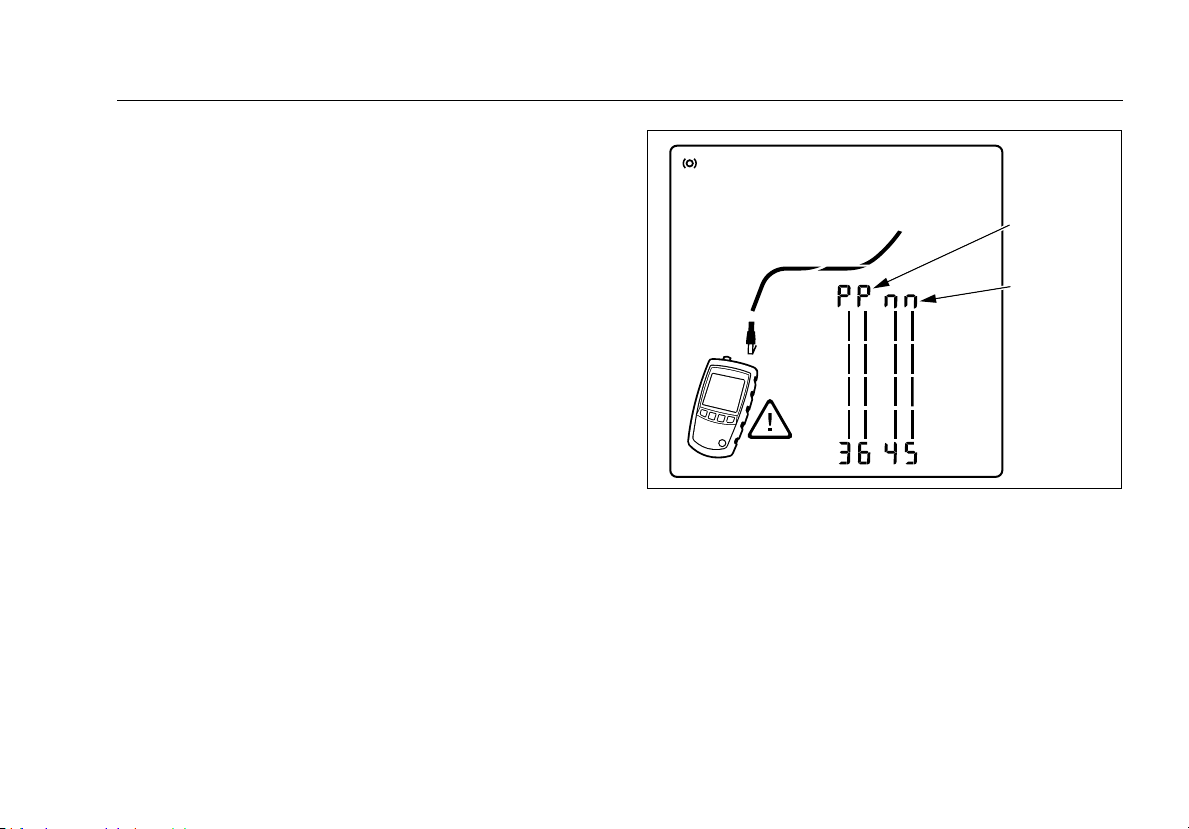

1. High Voltage Display Example ...................................................................................................................... 5

2

2. MicroScanner

3. Display Features ............................................................................................................................................. 8

4. Connecting a Remote ID Locator in a Confined Area or to an RJ11 Jack................................................... 10

5. Connecting to Twisted Pair Network Cabling .............................................................................................. 11

6. Open on Twisted Pair Cabling....................................................................................................................... 12

7. Short on Twisted Pair Cabling....................................................................................................................... 13

8. Crossed Wires ................................................................................................................................................. 13

9. Crossed Pairs ................................................................................................................................................... 14

10. Split Pair.......................................................................................................................................................... 15

11. Telephone Voltages Detected ....................................................................................................................... 16

12. Bridge Tap Detected ...................................................................................................................................... 17

13. Ethernet Port Detected.................................................................................................................................. 19

14. Results Screens for Individual Wire Pairs ...................................................................................................... 21

Features ................................................................................................................................. 6

v

Page 8

MicroScanner2 Cable Verifier

Users Manual

15. Using Multiple Remote ID Locators...............................................................................................................23

16. Connecting to a Telephone Network Wired in a Star Topology................................................................. 25

17. Connecting to a Telephone Network Wired in a Bus Topology.................................................................. 27

18. Connecting to Coaxial Cabling ...................................................................................................................... 28

19. Coaxial Results ................................................................................................................................................ 29

20. Open on Coaxial Cabling ...............................................................................................................................29

21. Short on Coaxial Cabling................................................................................................................................ 30

22. Unknown Termination on Coaxial Cabling................................................................................................... 30

23. PoE Display...................................................................................................................................................... 31

24. IntelliTone Toner Mode Display .................................................................................................................... 33

25. Using the Toner in IntelliTone Mode ............................................................................................................ 34

26. Analog Toner Mode Display .......................................................................................................................... 35

27. Using the Toner with the IP200 IntelliTone Cable Map Function ...............................................................37

28. Replacing the Tester’s Batteries..................................................................................................................... 40

vi

Page 9

MicroScanner2 Cable Verifier

Introduction

2

The MicroScanner

instrument that lets you verify and troubleshoot the wiring

of twisted pair and coaxial cables and detect network

services.

The tester does the following:

Measures length up to 1500 ft (457 m) and detects

opens and shorts on twisted pair and coaxial cabling.

Detects split pairs on twisted pair cabling.

Displays wiremap, cable length, proportional distance

to opens, and the remote ID number all on one screen.

Detects Ethernet ports on twisted pair cabling and

reports the port speed.

Detects PoE (Power over Ethernet) and telephone

voltages on twisted pair cabling.

Cable Verifier is a hand-held test

IntelliTone™ function works with an optional Fluke

Networks IntelliTone probe to help you locate and

isolate cables behind walls, at patch panels, or in

bundles. The analog toner works with standard analog

probes and includes the SmartTone

positive identification of cables in bundles.

™

function for

Registration

Registering your product with Fluke Networks gives you

access to valuable information on product updates,

troubleshooting tips, and other support services. To register,

fill out the online registration form on the Fluke Networks

website at www.flukenetworks.com/registration.

1

Page 10

MicroScanner2 Cable Verifier

Users Manual

Contacting Fluke Networks

www.flukenetworks.com

support@flukenetworks.com

+1-425-446-5500

Australia: 61 (2) 8850-3333 or 61 (3) 9329 0244

Beijing: 86 (10) 6512-3435

Brazil: 11 3759 7600

Canada: 1-800-363-5853

Europe: +31-(0) 40 2675 600

Hong Kong: 852 2721-3228

Japan: 03-6714-3117

Korea: 82 2 539-6311

Singapore: +65-6799-5566

Taiwan: (886) 2-227-83199

USA: 1-800-283-5853

Visit our website for a complete list of phone numbers.

Symbols

Table 1 describes the symbols used on the tester and in this

manual.

Table 1. Symbols

Warning or Caution: risk of damage or

destruction to equipment or software. See

explanations in the manual.

On the tester’s display this symbol indicates a

cable fault or voltage on the cable.

Warning: Risk of electric shock.

This equipment not for connection to public

communications networks, such as active

telephone systems.

Do not put products containing circuit boards

into the garbage. Dispose of circuits boards in

accordance with local regulations.

Conformite Europeene. Conforms to the

requirements of the European Union and the

European Free Trade Association (EFTA).

Certified by CSA Group to North American

safety standards.

Conforms to relevant Australian standards.

2

Page 11

Safety Information

40 year Environment Friendly Use Period

(EFUP) under China Regulation Administrative Measure on the Control of

Pollution Caused by Electronic Information

Products. This is the period of time before

any of the identified hazardous substances

are likely to leak out, causing possible harm

to health and the environment.

KCC-REM-FKN-012001001: EMC approval for

Korea

Class A Equipment (Industrial Broadcasting &

Communication Equipment)

This product meets requirements for

industrial (Class A) electromagnetic wave

equipment and the seller or user should take

notice of it. This equipment is intended for

use in business environments and is not to

be used in homes.

Safety Information

Warning

To avoid possible fire, electric shock, or personal

injury:

Read all safety information before you use the

Product.

Carefully read all instructions.

Do not open the case. You cannot repair or

replace parts in the case.

Do not modify the Product.

Use only replacement parts that are approved by

Fluke Networks.

Do not touch voltages > 30 V AC rms, 42 V AC

peak, or 60 V DC.

The tester is not intended to be connected to

active telephone inputs, systems, or equipment,

including ISDN devices. Exposure to the voltages

applied by these interfaces may damage the

tester and create a potential shock hazard. The

tester shows a warning symbol (

) and the

3

Page 12

MicroScanner2 Cable Verifier

Users Manual

voltage polarities ( ) when it detects high

voltage. Disconnect the tester if

appear. Figures 1 and 11 show examples of this

display.

Do not use the Product around explosive gas,

vapor, or in damp or wet environments.

Use this Product indoors only.

Do not connect the Product to voltages that are

higher than the maximum voltage rating for the

Product.

For Products that have multiple connectors for

different types of tests on copper cabling,

disconnect unused test leads from the

connectors before you do a test.

Use the Product only as specified, or the

protection supplied by the Product can be

compromised.

Do not use and disable the Product if it is

damaged.

Do not use the Product if it operates incorrectly.

and

Batteries contain hazardous chemicals that can

cause burns or explode. If exposure to chemicals

occurs, clean with water and get medical aid.

Remove the batteries if the Product is not used

for an extended period of time, or if stored in

temperatures above 50 °C. If the batteries are

not removed, battery leakage can damage the

Product.

The battery door must be closed and locked

before you operate the Product.

Repair the Product before use if the battery

leaks.

Replace the batteries when the low battery

indicator shows to prevent incorrect

measurements. (see "Battery Life, Status, and

Replacement" on page 40)

Turn off the Product and disconnect all test

leads, patch cords, and cables before you replace

the battery.

Be sure that the battery polarity is correct to

prevent battery leakage.

4

Page 13

Positive

Negative

Do not disassemble or crush battery cells and

battery packs.

Do not put battery cells and battery packs near

heat or fire. Do not put in sunlight.

Do not operate the Product with covers removed

or the case open. Hazardous voltage exposure is

possible.

Remove the input signals before you clean the

Product.

Have an approved technician repair the Product.

Do not put metal objects into connectors.

Before using the optional IntelliTone probe, read

the safety information in the probe’s

documentation.

Safety Information

egk29.eps

Figure 1. High Voltage Display Example

5

Page 14

MicroScanner2 Cable Verifier

Users Manual

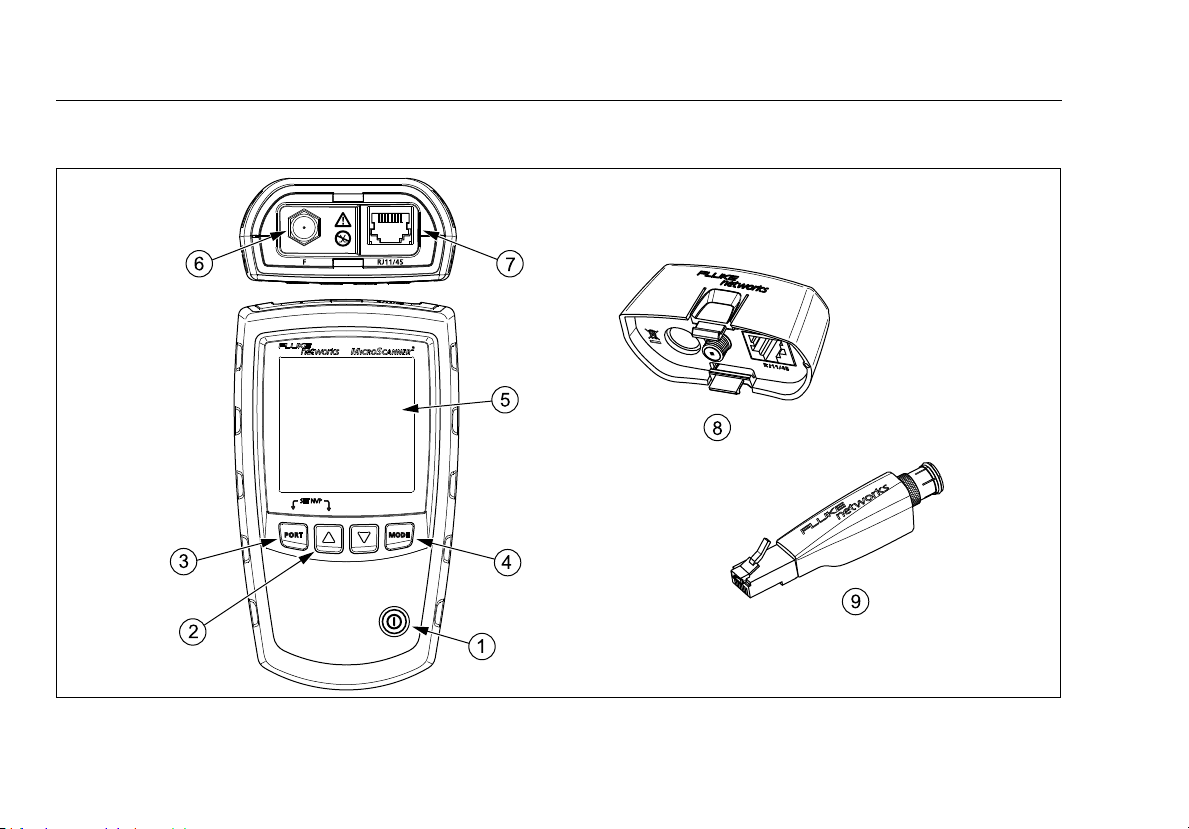

MicroScanner2 Features

egk01.eps

Figure 2. MicroScanner2 Features

6

Page 15

On/off key.

, : Navigates through screens and changes

settings. In toner mode, these keys cycle through the

IntelliTone and analog toner songs.

: Selects the RJ45 or coaxial connector as the active

port.

: Cycles through the cable test, toner, and PoE

detect modes.

For additional modes, hold down keys while turning the

tester on:

+ : Lets you calibrate length measurements and

select meters or feet as the length unit.

+ : Activates a demonstration mode where the

tester shows examples of test result screens.

Note

Auto shutoff is disabled in demonstration mode.

+ : Displays the version and serial number

screens.

MicroScanner2 Features

LCD display with backlight.

F-connector for connecting to 75 coaxial cable.

Modular jack for connecting to telephone and twisted

pair network cable. The jack accepts 8-pin modular

(RJ45) and

6-pin modular (RJ11) connectors.

Wiremap adapter with F-connector and 8-pin modular

jack. See page 10.

Optional remote ID locator with F-connector and 8-pin

modular jack. See page 10.

7

Page 16

MicroScanner2 Cable Verifier

O

P

Users Manual

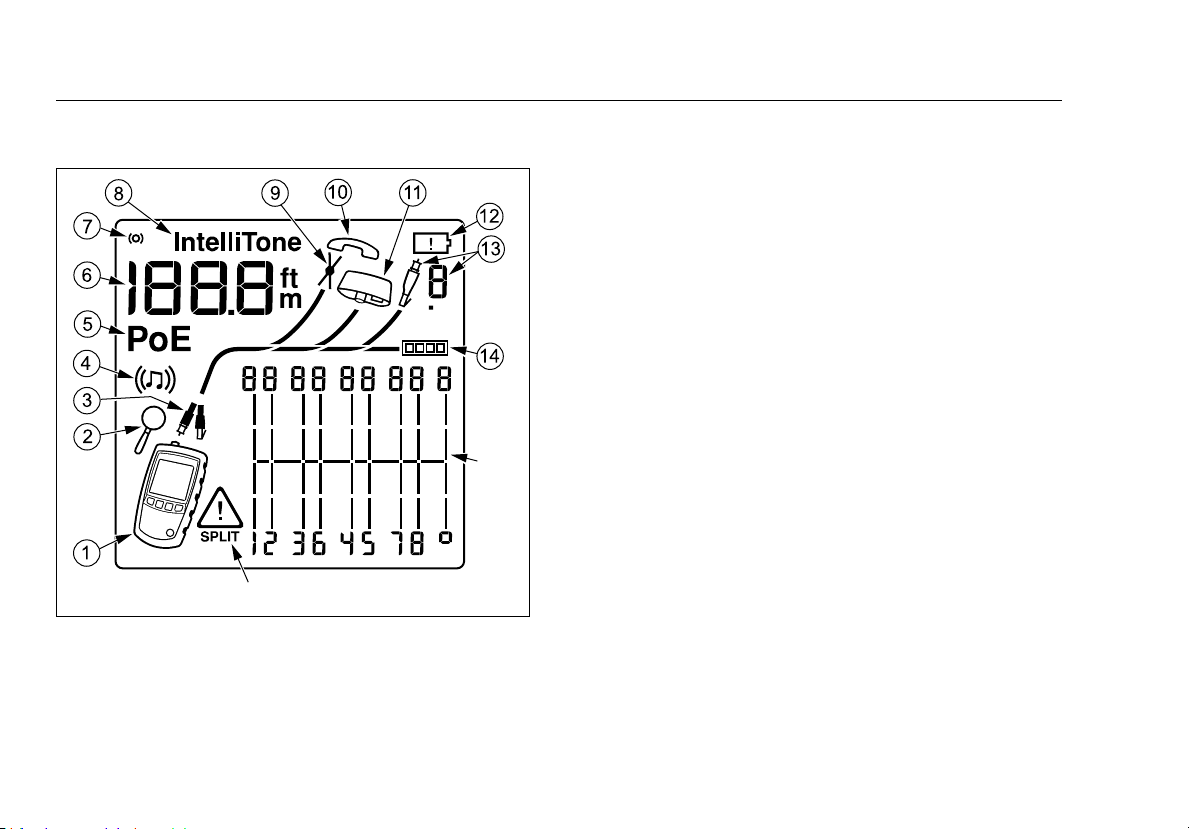

Display Features

Figure 3. Display Features

egk02.eps

Tester icon

Detail screen indicator. See page 20.

Indicates which port is active, the RJ45 port () or the

coaxial port (

Tone mode indicator. See page 32.

Power over Ethernet mode indicator. See page 31.

Numeric display with feet/meters indicator.

Test activity indicator, which is animated when a test is

running.

IntelliTone appears when the toner is in IntelliTone

mode. See pages 32 and 36.

Indicates a short on the cable. See pages 13 and 30.

Telephone voltage indicator. See page 16.

Indicates a wiremap adapter is connected to the far

end of the cable.

Low battery indicator. See page 40.

Indicates an ID locator is connected to the far end of

the cable and shows the locator’s number.

Ethernet port indicator. See page 18.

).

8

Page 17

Wiremap diagram. For opens, the number of segments

lit for the wire pair indicates the approximate distance

to the fault. The rightmost segments indicate the

shield. See pages 12 through 15.

The Indicates a fault or high voltage on the cable.

SPLIT appears when the fault is a split pair. See page 15.

Auto Shutoff

The tester turns off after 10 minutes if no keys are pressed

and nothing changes at the tester’s connectors.

Note

Auto shutoff is disabled in toner and demonstration

modes.

Auto Shutoff

Changing the Length Units

1

Hold down and while turning on the tester.

2

Press to switch between meters and feet.

3

Turn the tester off then on to return to testing mode.

9

Page 18

MicroScanner2 Cable Verifier

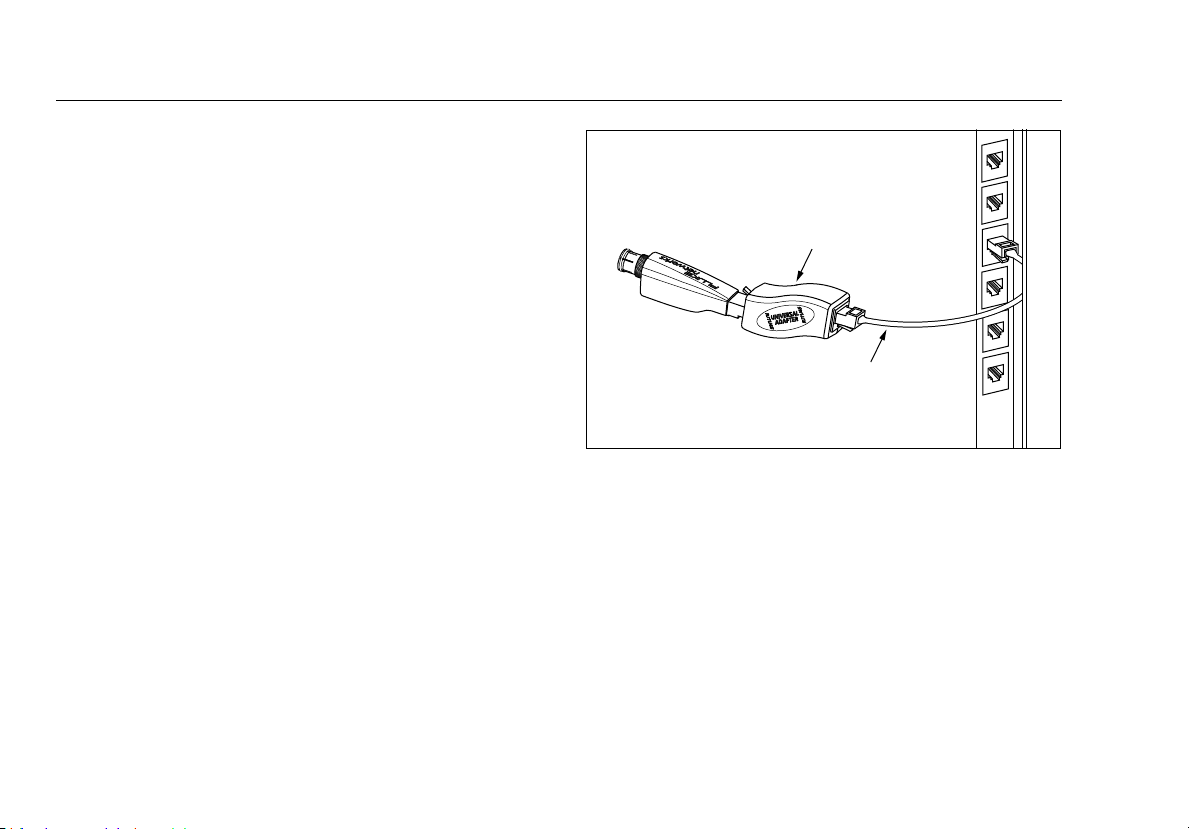

Universal adapter

(8-pin and 4-pin)

Remote ID

locator

8-pin or 4-pin

modular patch

cord

Users Manual

Using the Wiremap Adapter and Remote ID Locators

Terminating twisted pair cabling with the standard

wiremap adapter or optional remote ID locators lets the

tester detect all types of wiremap faults. Without this

termination, the tester cannot detect crossed wires or

crossed pairs. For a wire pair with one wire open,

termination is required to detect which wire is open.

Without termination, the tester shows both wires as open.

Using multiple remote ID locators helps you identify

connections at patch panels. The tester shows the number

of the locator connected to the far end of the cabling, as

shown on page 23.

To connect a remote ID locator to a modular (RJ) jack in a

confined area or to a 4-pin modular jack (RJ11), use the

optional universal adapter and a patch cord, as shown in

Figure 4.

egk15.eps

Figure 4. Connecting a Remote ID Locator in a Confined

Area or to an RJ11 Jack

10

Page 19

Testing Twisted Pair Cabling

Wiremap

adapter

Patch panel

RJ45 patch

cords

Wall

outlet

1

Turn on the tester.

Testing Twisted Pair Cabling

If the tester is already on and in coaxial test mode (

to switch to twisted pair test mode ().

press

2

Connect the tester and wiremap adapter or ID locator to

the cabling as shown in Figures 5 through 17.

The test runs continuously until you change modes or turn

the tester off.

Notes

You can measure length without connecting a far

end adapter; however, an adapter is required for a

complete wiremap test.

PoE indicator appears, see page 31.

If the

),

egk03.eps

Figure 5. Connecting to Twisted Pair Network Cabling

11

Page 20

MicroScanner2 Cable Verifier

Users Manual

Twisted Pair Test Results

The following figures show typical test results for twisted

pair cabling.

Open on Twisted Pair Cabling

Figure 6 shows an open on wire 4.

Notes

If only one wire in a pair is open and a wiremap

adapter or remote ID locator is not connected, both

wires are shown as open.

The warning icon (

wires in a pair are open because open pairs are

normal for some cabling applications.

The three segments shown for the wire pair length indicate

the open is approximately 3/4 the distance to the end of the

cabling. The cable length is 75.4 m.

To see the distance to the open, use or to view the

individual result for the wire pair. See page 20.

) does not appear if both

12

egk05.eps

Figure 6. Open on Twisted Pair Cabling

Page 21

Testing Twisted Pair Cabling

“Short”

icon

Shield

indicator

Short on Twisted Pair Cabling

Figure 7 shows a short between wires 5 and 6. The shorted

wires flash to indicate the fault. The cable length is 75.4 m.

Note

When there is a short, the far-end adapter and the

mapping of the unshorted wires are not shown.

Figure 7. Short on Twisted Pair Cabling

ekg06.eps

Crossed Wires

Figure 8 shows that wires 3 and 4 are crossed. The the pin

numbers flash to indicate the fault. Cable length is

53.9 m. The cable is shielded.

Detection of crossed wires requires a far-end adapter.

egk08.eps

Figure 8. Crossed Wires

13

Page 22

MicroScanner2 Cable Verifier

Users Manual

Crossed Pairs

Figure 9 shows that pairs 1,2 and 3,6 are crossed. The pin

numbers flash to indicate the fault. This crossed pair is likely

caused by mixing 568A and 568B cabling.

Detection of crossed pairs requires a far-end adapter.

egk09.eps

Figure 9. Crossed Pairs

14

Page 23

Split Pair

Split pair

icon

The split

pair flashes

Split pair wiring

Figure 10 shows a split pair on 3,6 and 4,5. The split pair

flashes to indicate the fault. The cable length is 75.4 m.

In a split pair, continuity from end to end is correct, but is

made with wires from different pairs. Split pairs cause

excessive crosstalk that interferes with network operation.

Note

Cables with untwisted pairs, such as telephone

cords, typically show split pairs due to excessive

crosstalk.

Testing Twisted Pair Cabling

egk10.eps

Figure 10. Split Pair

15

Page 24

MicroScanner2 Cable Verifier

Telephone

voltage icon

Positive

wire (tip)

Negative

wire (ring)

Users Manual

Telephone Voltages Detected

Figure 11 shows that telephone voltage is detected on pair

4,5.

Length is not shown because the voltage interferes with

length measurements.

Warning

The tester is not intended to be connected to

active telephone inputs, systems, or equipment,

including ISDN devices. Prolonged exposure to

the voltages applied by these interfaces may

damage the tester. Disconnect the tester if

appear.

and

16

egk11.eps

Figure 11. Telephone Voltages Detected

Page 25

Bridge Tap Detected

Figure 12 shows a bridge tap detected at about 53.2 m.

Only the first bridge tap detected is reported. The distance

to a bridge tap is approximate because multiple reflections

from the bridge tap interfere with length measurements.

Note

Bridge taps more than 328 ft (100 m) from the tester

or taps less than 16 ft (5 m) long may not be

detected.

Testing Twisted Pair Cabling

egk12.eps

Figure 12. Bridge Tap Detected

17

Page 26

MicroScanner2 Cable Verifier

Users Manual

Ethernet Port Detected

The tester can detect active and inactive Ethernet ports, as

shown in Figure 13.

Ethernet port icon.

Port speed for an active 1000 megabit port. The speeds

are 10, 100, or 1000 megabits per second. The example

shows 1000 megabits per second. If the port supports

multiple speeds the number cycles through the speeds.

Cable length. Dashes are shown if the tester cannot

measure the length. This can occur if the port does not

produce reflections.

Length may fluctuate or be obviously too high if the

port’s impedance fluctuates or varies from the cable’s

impedance. When in doubt, disconnect the cable from

the port to get an accurate length measurement.

18

Page 27

Figure 13. Ethernet Port Detected

A

B

C

C

A

Active Ethernet port Inactive Ethernet port

Testing Twisted Pair Cabling

egk13.eps

19

Page 28

MicroScanner2 Cable Verifier

Users Manual

Viewing Individual Results

To see individual results for each wire pair, use or ; to

move among the screens.

In this mode, the tester continuously tests only the wire pair

you are viewing.

Figure 14 shows examples of these screens.

Short on pair 1,2 at 29.8 m.

Notes

On the individual results screens, shorts are shown

only when they are between wires in a pair.

When there is a short, the far-end adapter and the

mapping of the unshorted wires are not shown.

Pair 3,6 is 67.7 m long and is terminated with the

wiremap adapter.

Open on pair 4,5 at 48.1 m. The open could be on one

or both wires.

20

Page 29

Figure 14. Results Screens for Individual Wire Pairs

Testing Twisted Pair Cabling

egk14.eps

21

Page 30

MicroScanner2 Cable Verifier

Users Manual

Using Multiple Remote ID Locators

Using multiple remote ID locators helps you identify

multiple network connections at a patch panel, as shown in

Figure 15.

The display in Figure 15 shows that the tester is connected

to the cable terminated with remote ID locator number 3.

Caution

Do not use multiple far end adapters in star or

bus topologies. Doing so causes incorrect

wiremap results.

22

Page 31

Patch panel

Locator # 2

Locator # 3

Locator # 4

Locator # 5

Remote ID locators

connected to wall

outlets

Testing Twisted Pair Cabling

Figure 15. Using Multiple Remote ID Locators

egk04.eps

23

Page 32

MicroScanner2 Cable Verifier

Users Manual

Connecting to Telephone Networks Wired in Star Topologies

Telephone cables wired in a star topology (Figure 16) are

connected together at a bridge tap at the distribution

center. The bridge tap connects each wire to all other wires

of the same number.

The tester detects bridge taps and measures the distance to

the bridge tap. To measure the length of each cable

connected to the bridge tap, connect the wiremap adapter

or remote ID locator to the bridge tap and the tester to the

wall outlet.

The tester cannot measure length past the bridge tap

because reflections from the bridge tap connections

interfere with measurements.

If you connect the tester to the bridge tap, the tester

measures the length only to the bridge tap, which is only

the patch cord length.

Caution

Do not use multiple far end adapters in star or

bus topologies. Doing so causes incorrect

wiremap results.

24

Page 33

Distribution

center

Common connection

to bridge tap

Wiremap

adapter

RJ11 patch

cord

Wall

outlets

Note: For a correct length reading, connect the

tester and wiremap adapter as shown. See

“Connecting to Star Topologies” for details.

RJ11 patch

cord

Testing Twisted Pair Cabling

Figure 16. Connecting to a Telephone Network Wired in a Star Topology

egk16.eps

25

Page 34

MicroScanner2 Cable Verifier

Users Manual

Connecting to Telephone Networks Wired in Bus Topologies

Telephone cables wired in a bus topology (Figure 17)

connect the wall outlets in series. In this topology, you

measure the length from the last outlet to the wiremap

adapter.

If you connect to an outlet in the middle of the series, the

tester reports a bridge tap. The length reported is the

length to the outlet, which is the patch cord length. The

tester cannot measure length past the outlet because

reflections from the cables on either side interfere with

measurements.

If you are unsure which outlet is the last in the bus, do the

following:

1

Connect the wiremap adapter or ID locator to the

beginning of the bus at the distribution center.

2

Connect the tester to an outlet and run the twisted pair

cable test.

If the tester reports a bridge tap, move to another

outlet. The last outlet will not show a bridge tap, and

will show the length to the distribution center.

Caution

Do not use multiple far end adapters in star or

bus topologies. Doing so causes incorrect

wiremap results.

26

Page 35

Distribution

center

Connection to bus

Wiremap

adapter

RJ11 patch

cord

Wall

outlets

Note: Locations of the tester and wiremap

adapter may be swapped.

RJ11 patch

cord

Testing Twisted Pair Cabling

egk17.eps

Figure 17. Connecting to a Telephone Network Wired in a Bus Topology

27

Page 36

MicroScanner2 Cable Verifier

Connection to

service

Coaxial patch cords

Wiremap

adapter

Wall

outlet

Users Manual

Testing Coaxial Cabling

1

Turn on the tester; then press to switch to coaxial

test mode (

2

Connect the tester and wiremap adapter or ID locator to

the cabling as shown in Figure 18.

For cabling not terminated with an F-connector, use an

adapter or hybrid patch cord to connect to the cabling.

The test runs continuously until you change modes or turn

the tester off.

).

egk19.eps

Figure 18. Connecting to Coaxial Cabling

28

Page 37

Testing Coaxial Cabling

Coaxial Results

Figure 19 shows a good coaxial cable 38.4 m long and

terminated with remote ID number 3.

Figure 19. Coaxial Results

egk20.eps

Open on Coaxial Cabling

Figure 20 shows an open 12.1 m from the tester.

egk21.eps

Figure 20. Open on Coaxial Cabling

29

Page 38

MicroScanner2 Cable Verifier

Users Manual

Short on Coaxial Cabling

Figure 21 shows a short 12.1 m from the tester.

Figure 21. Short on Coaxial Cabling

Unknown Termination on Coaxial Cabling

Figure 22 shows a cable connected to a device at the far

end, such as a television, CATV service, VCR, DVD player,

satellite dish, splitter, or antenna. Dashes shown for length

mean the tester cannot measure length because the device

does not produce reflections.

egk22.eps

egk23.eps

Figure 22. Unknown Termination on Coaxial Cabling

30

Page 39

Detecting Power Over Ethernet

The tester can detect PoE voltage from 802.3af sources.

Detecting Power Over Ethernet

To select PoE mode, press

display, as shown in Figure 23 (

In PoE mode, the tester solicits PoE power on pairs 1,2-3,6

and 4,5-7,8. The tester may activate a PoE source and will

not be damaged by PoE power.

If PoE power is detected,

pairs (

). The may blink as the PoE source turns the

power on and off.

In twisted pair test mode, a flashing

means that PoE power may be available. To verify the

presence of a PoE source, switch the tester to PoE mode.

The tester will not detect PoE schemes that are not

compliant with the IEEE 802.3af standard, such as

®

Inline Power.

Cisco

until PoE appears on the

).

appears above the powered

PoE mode indicator

Note

egk30.eps

Figure 23. PoE Display

31

Page 40

MicroScanner2 Cable Verifier

Users Manual

Using the Toner

You can use the tester with an optional tone probe to

locate cables in bundles, at patch panels, or behind walls.

Use the tester’s IntelliTone

Networks IP100 or IP200 tone probe. The digital IntelliTone

signal is easier to detect at a distance than analog tones,

and its frequency and encoding eliminate cable

misidentification due to signal bleed and radiated or

ambient noise.

The tester’s analog tone mode is compatible with most tone

probes.

The analog tone mode features the SmartTone

for positive identification of cables in bundles.

™

mode with an optional Fluke

™

function

Toning in IntelliTone Mode (optional IntelliTone probe required)

Refer to Figures 24 and 25.

1

Connect the tester to the cable.

2

Press to select twisted pair () or coaxial () cable.

3

Press until , IntelliTone, and and a scrolling

pattern of 1s and 0s appear on the display (, , and

in Figure 24).

4

To toggle between the two IntelliTone songs press

then

. The display shows the song number ().

If you press

through the IntelliTone and analog songs.

5

Turn the probe’s rotary switch to (locate).

6

Use the probe to find the general location of the tone at

a cable rack, patch panel, or behind a wall, as shown in

Figure 25. The SYNC LED lights up green when the

probe is receiving the IntelliTone signal.

The probe’s LEDs light up from 1 to 8 as the signal

strength increases. The higher the number, the stronger

the signal.

or repeatedly, the tester cycles

32

Page 41

Notes

If you cannot locate the IntelliTone signal on

2-conductor cables, the cable may be shorted. Use

the tester to check for shorts. See pages 11 and 13.

7

Turn the probe’s rotary switch to (isolate).

8

Use the probe to isolate the tone source in the cable

bundle or at the patch panel. The SYNC LED lights up

green when the probe is receiving the IntelliTone signal.

The probe’s LEDs light up from 1 to 8 as the signal

strength increases. The higher the number, the stronger

the signal.

Using the Toner

egk07.eps

Figure 24. IntelliTone Toner Mode Display

33

Page 42

MicroScanner2 Cable Verifier

Locating Cables

Volume

control

Wall

outlet

Isolating Cables

Users Manual

34

Figure 25. Using the Toner in IntelliTone Mode

egk24.eps

Page 43

Analog Toner Mode (optional tone probe

A

required)

Refer to Figure 26.

1

Connect the tester to the cable.

Using the Toner

C

2

Press to select twisted pair or coaxial cable.

3

Press until appears on the display (); then

press

to enter analog toner mode. The display shows

a scrolling sinewave in analog toner mode (

4

To change songs, press . The display shows the song

number (

If you press

through the analog and IntelliTone songs.

5

Use the probe to search for the cable.

). The analog toner has four songs.

or repeatedly, the tester cycles

B

).

egk25.eps

Figure 26. Analog Toner Mode Display

35

Page 44

MicroScanner2 Cable Verifier

Users Manual

Using the SmartTone Function

Use the SmartTone™ function when you have trouble

locating a cable. This function changes the toner’s song

when you short a wire pair in the cable connected to the

tester. SmartTone works with the IntelliTone probe and

with analog probes.

Note

Use the SmartTone function only on dry pairs of

wires that are unterminated at both ends. Do not

use this function on powered wires.

1

Press to select twisted pair or coaxial cabling.

2

Press until appears on the display.

3

Press to select the analog toner mode (IntelliTone

disappears from the display).

4

At the far end of the cabling, place the probe near the

ends of the cables.

5

Momentarily short a wire pair in a cable (twisted pair) or

short the conductor and shield in a cable (coaxial). If the

song changes when you release the short, you have

found the cable connected to the tester.

Using the IntelliTone Cable Map Function (optional IP200 probe required)

The tester’s IntelliTone function works with an optional

IP200 probe’s cable map function to verify wiring at the far

end of the cabling. The probe’s cable map function

identifies the most common wiring faults on twisted pair

cabling: shorts, opens, and crossed pairs.

1

Press to select twisted pair cabling ().

2

Turn the probe’s rotary switch to CABLE MAP.

3

Connect the tester and probe to the cabling as shown in

Figure 27.

4

Press until appears on the display. IntelliTone

mode is indicated by IntelliTone and a scrolling pattern

of 1s and 0s on the display. See Figure 27.

5

The probe’s LEDs light in sequence to indicate the

cable’s wiring. See the probe’s documentation for

details.

36

Page 45

Using the IntelliTone Cable Map Function (optional IP200 probe required)

LEDs show the

wiremap. See

the IntelliTone

manual for

details.

Note

Normally, the probe’s SYNC LED lights to indicate

reception of the IntelliTone signal. You may change

the LED’s function to indicate shield continuity. See

the probe’s documentation for details.

egk26.eps

Figure 27. Using the Toner with the IP200 IntelliTone

Cable Map Function

37

Page 46

MicroScanner2 Cable Verifier

Users Manual

Calibrating Length Measurements

The tester uses an NVP value (nominal velocity of

propagation) and the signal delay through the cable to

calculate length. The tester’s default NVP values are usually

accurate enough to verify length; however, you can

increase the accuracy of length measurements by adjusting

the NVP to a specified or actual value.

The default NVP values are 70 % for twisted pair cable and

82 % for coaxial cable.

Note

NVP values can vary among cable types, lots, and

manufacturers. In most cases, these differences are

minor and may be disregarded.

Setting the NVP to a Specified Value

To enter the NVP value specified by the manufacturer:

1

Turn on the tester while holding down the and

keys.

2

To set the NVP for the coaxial port (), press .

3

Use and to set the NVP value.

4

To save the setting and exit NVP mode, turn the tester

off then on again.

Determining a Cable’s Actual NVP

You can determine a cable’s actual NVP by adjusting the

measured length to match a known length of cable.

To determine a cable’s NVP:

1

Turn on the tester while holding down the and

keys.

2

To set the NVP for the coaxial port (), press .

3

Connect a known length of the cable to be tested to the

tester’s twisted pair or coaxial connector.

38

Page 47

Maintenance

Notes

The cable must be at least 49 ft (15 m) long. If the

cable is too short, “---” appears for the length.

For the best accuracy, use a cable between 49 ft

(15 m) and 98 ft (30 m) long.

The cable must not be connected to anything.

4

To switch between meters and feet, press .

5

Use and to change the NVP until the measured

length matches the actual length of the cable.

6

To save the setting and exit NVP mode, turn the tester

off then on again.

Maintenance

Warning

To avoid possible fire, electric shock, personal

injury, or damage to the tester:

Do not open the case. No user-serviceable parts

are inside.

Replacing electrical parts yourself will void the

tester’s warranty and might compromise its

safety features.

Use only specified replacement parts for userreplaceable items.

Use only Fluke Networks authorized service

centers.

39

Page 48

MicroScanner2 Cable Verifier

Users Manual

Cleaning

Clean the display with glass cleaner and a soft, lint-free

cloth. Clean the case with a soft cloth dampened with

water or water and a mild soap.

Caution

To avoid damaging the display or the case, do

not use solvents or abrasive cleansers.

Battery Life, Status, and Replacement

Warning

To avoid possible electric shock or personal

injury:

Turn off the tester and disconnect all test leads

before replacing the battery.

Use only the correct type of batteries, properly

installed in the case, to power the tester.

The batteries last for about 20 hours of typical use.

Replace the tester’s batteries when the low battery

indicator (

) appears. See Figure 28.

You can use the following types of AA (IEC LR6) batteries in

the tester:

Alkaline

Lithium

Rechargeable nickel-metal hydride (NiMH)

Rechargeable nickel-cadmium batteries (NiCD)

egk28.eps

Figure 28. Replacing the Tester’s Batteries

40

Page 49

If Something Seems Wrong

Checking the Tester’s Version and Serial Number

Turn the tester on while holding down the and keys.

Use

and to scroll through the screens:

: Software version

: Serial number

: Factory test date

To exit this mode, turn the tester off.

Table 2. Troubleshooting the Tester

Symptom Action

The keypad does not respond. Press and hold until the tester turns off; then turn the tester on again.

The tester will not turn on.

Length measurements are incorrect. Check the NVP value. See “Calibrating Length Measurements” on page 38.

Replace the batteries, verifying that they are installed correctly. See Figure 28

on page 40.

If Something Seems Wrong

If something seems wrong with the tester, refer to Table 2.

If Table 2 does not help you solve a problem with the tester,

contact Fluke Networks for additional help. If possible, have

the tester’s version and serial number.

For warranty information, refer to the warranty at the

beginning of this manual. If the warranty has lapsed,

contact Fluke Networks for repair prices.

41

Page 50

MicroScanner2 Cable Verifier

Users Manual

Options and Accessories

See Table 3.

For the latest list of options and accessories visit the Fluke

Networks website at www.flukenetworks.com.

Table 3. Options and Accessories

Option or Accessory Fluke Networks Model Number

Remote ID Locator Kit, numbers 2-7 MS2-IDK27

Wiremap adapter MS2-WM

Test lead, 8-pin modular plug (RJ45) to 8 alligator clips CLIP-SET

Coaxial Adapter Kit (F-connector barrel adapter, female-to-female BNC adapter,

CIQ-COAX

female-to-female RCA adapter)

Universal adapter, 8-pin/4-pin modular jack to 8-pin/4-pin modular jack CIQ-RJA

Carrying case for MicroScanner

Carrying pouch for MicroScanner

2

Professional kit MS2-CPK

2

tester MS2-POUCH

42

Page 51

Specifications

Specifications apply at 23 oC (73 oF), unless otherwise noted.

Environmental Specifications

Operating temperature 32 °F to 113 °F (0 oC to 45 oC)

o

Storage temperature -4 °F to +140 °F (-20

Operating relative humidity

(% RH without condensation)

90 % (50 °F to 95 °F; 10

75 % (95 °F to 113 °F; 35

C to +60 oC)

o

C to 35 oC)

o

C to 45 oC)

Specifications

Shock and Vibration

Random, 2 g, 5 Hz-500 Hz (Class 2)

1 m drop test with and without wiremap adapter attached

rd

Safety IEC 61010-1 3

Edition

Altitude 4,000 m; Storage: 12,000 m

EMC IEC 61326-1

43

Page 52

MicroScanner2 Cable Verifier

Users Manual

General Specifications

Test connectors

Power

Dimensions and weight

(with batteries installed and

wiremap adapter attached

Display Monochrome LCD with backlight

Shielded 8-pin modular jack accepts 8-pin modular (RJ45) and 4-pin modular (RJ11) plugs.

F-connector for coaxial cable.

Battery type: 2 AA (NEDA 15A, IEC LR6) alkaline batteries

Battery life: 20 hours of typical use

Other compatible battery types: 2 AA photo lithium, NIMH, NICAD

3 in x 6.4” x 1.4 in (7.6 cm x 16.3 cm x 3.6 cm)

0.8 lb (0.36 kg)

Test Modes

Cable test

Tone Generates Intellitone™ and normal analog toning signals

PoE Solicits and detects the presence of 802.3af compatible PoE (Power over Ethernet) devices

Measures length, verifies wiremap, identifies remote ID locators, and detects Ethernet ports.

Displays results on one screen.

44

Page 53

Performance Specifications

Specifications

Cable types tested

Twisted pair: U TP, FT P, S ST P

Coaxial: 75 , 50 , 93

Length test

Range: 460 m (1500 ft)

Resolution: 0.3 m (1 ft)

Typical accuracy: 4% or 0.6 m (2 ft) whichever is greater. NVP uncertainty is an additional

error.

Calibration: User-settable NVP for twisted pair and coax. Can determine actual NVP with

known length of cable.

Wiremap test

Detects single-wire faults, shorts, miswires, split pairs, and up to seven far-end adapter IDs.

The wiremap is drawn with proportional length to visually indicate the approximate location

of faults.

Port detection Detects the advertised speed of 802.3 Ethernet ports.

Tone generator

Supports toning and cable mapping with a Fluke Networks digital IntelliTone

Generates four tones compatible with typical analog probes.

SmartTone

™

feature gives positive identification of cables in bundles when using an

IntelliTone or an analog probe.

™

probe.

45

Page 54

MicroScanner2 Cable Verifier

Users Manual

Regulatory Information

This equipment generates, uses, and can radiate radio

frequency energy, and, if not installed and used in

accordance with the manual, may cause interference to

radio communications. It has been tested and found to

comply with the limits for a Class A digital device pursuant

to Part 15, Subpart J of the FCC rules, which are designed to

provide reasonable protection against such interference

when operated in a commercial environment. Operation of

the equipment in a residential area is likely to cause

interference, in which case the user, at his own expense, will

be required to take whatever measures may be required to

correct the interference.

46

Page 55

Appendix A: Diagnosing Wiremap Faults

Appendix A lists the typical causes of wiremap failures.

Open

Wires connected to wrong pins at connector or

punchdown blocks

Faulty connections

Damaged connector

Damaged cable

Wrong pairs selected in setup

Wrong application for cable

Split Pair

Wires connected to wrong pins at connector or punchdown

block.

Reversed Pairs

Wires connected to wrong pins at connector or punchdown

block.

Crossed Pairs

Wires connected to wrong pins at connector or

punchdown block.

Mix of 568A and 568B wiring standards (12 and 36

crossed).

Crossover cables used where not needed (12 and 36

crossed).

47

Page 56

MicroScanner2 Cable Verifier

Users Manual

Short

Damaged connector

Damaged cable

Conductive material stuck between pins at connector.

Improper connector termination

Wrong application for cable

48

Page 57

Index

Symbols

"?" on coaxial screen, 30

–A–

accessories, 42

analog toner, 35

auto shutoff, 9

–B–

batteries, 40

bridge tap, 17

bus topology, 26

–C–

cable map function, 36

cable tests

coaxial cabling, 28

twisted pair, 11

cleaning, 40

coaxial

connections, 28

open, 29, 30

short, 30

unknown termination, 30

connections

coaxial, 28

twisted pair, 11

connectors, 7

crossed pairs, 14

crossed wires, 13

49

Page 58

MicroScanner2 Cable Verifier

Users Manual

customer support

contacting Fluke Networks, 2

problem with the tester, 41

–E–

Ethernet port detected, 18

–F–

Fluke Networks, 2

–H–

help

contacting Fluke Networks, 2

problem with the tester, 41

high voltage, 5, 16

–I–

IntelliTone mode

cable map function, 36

toner, 32

ISDN, 5, 16

–K–

keys, 7

–L–

length calibration, 38

–M–

maintenance, 39

–N–

NVP, 38

–O–

open

coaxial, 29, 30

twisted pair, 12

options, 42

–P–

PoE (Power over Ethernet), 31

problems (with the tester), 41

50

Page 59

Index

–R–

registration, 1

remote ID locator, 10, 22

replacement parts, 42

RJ11 jack, 10

–S–

safety information, 3, 39

serial number, 41

service, 41

short

coaxial, 30

twisted pair, 13

SmartTone function, 35, 36

specifications, 43

split pair, 15

star topology, 24, 27

symbols, 2

–T–

telephone cord (split pair), 15

telephone voltages, 5, 16

testing

coaxial cabling, 28

twisted pair cabling, 11

toner, 32

analog mode, 35

IntelliTone mode, 32

SmartTone function, 35, 36

troubleshooting

cabling faults, 47

the tester, 41

twisted pair

bridge tap, 17

connections

bus topology, 26

network cabling, 11

star topology, 24, 27

crossed pairs, 14

crossed wires, 13

individual results, 20

open, 12

PoE detection, 18

short, 13

51

Page 60

MicroScanner2 Cable Verifier

Users Manual

split pair, 15

telephone voltages, 16

–U–

universal adapter, 10

–V–

version information, 41

voltage detection, 5, 16

–W–

wiremap adapter, 10

52

Loading...

Loading...