Page 1

DP120

+

Differential Voltage Probe

Instruction Sheet

®

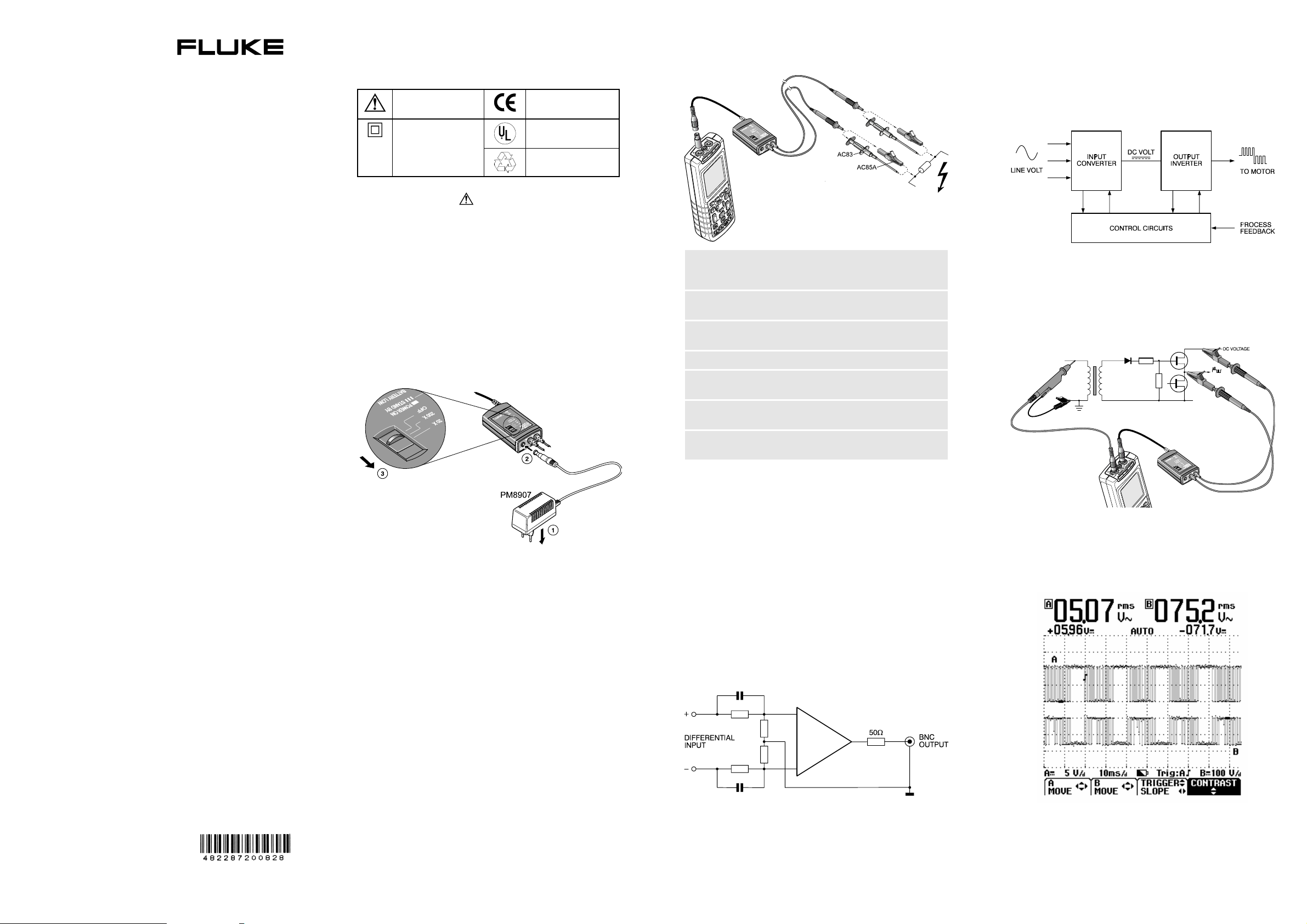

Using the DP120 Safely

In this manual a Warning identifies conditions and actions that pose

hazards to the user. Symbols used on the DP120 and in this

instruction sheet are explained in the next table.

See explanation in

manual

Double Insulation

(Protection class)

Conformité

Européenne

UL3111 listed

Recycle

Using the DP120

To use the differential voltage probe, do the following:

Application of Testing an Adjustable

Speed Drive Timing Circuit

One of the tasks of the control circuitry in an adjustable speed drive

(ASD) is timing of the output inverter switching. The voltage

waveform of the pulse width modulated (PWM) output inverter is a

series of pulses of constant magnitude (height), but varying width.

The control circuitry manages the timing of these pulses.

Introducing the DP120

The DP120 is a safety designed differential voltage probe for

floating high voltage measurements. The probe can be used on

electronic high-power converters, motor speed controls, switch

mode power supplies, and other high voltage circuits.

Unpacking

Check that the following items are included with the DP120:

• DP120 - Differential Voltage Probe

• AC85A - Large Jaw Alligator Clips (red and black)

• AC83 - Pin-Grabber Test Clips (red and black)

• 9V Alkaline Battery

LIMITED WARRANTY & LIMITATION OF LIABILITY

This Fluke product will be free from defects in material and

workmanship for one year from the date of purchase. This warranty

does not cover fuses, disposable batteries or damage from

accident, neglect, misuse or abnormal conditions of operation or

handling. Resellers are not authorized to extend any other warranty

on Fluke’s behalf. To obtain service during the warranty period,

send your defective product to the nearest Fluke Authorized Service

Center with a description of the problem.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER

WARRANTIES, SUCH AS FITNESS FOR A PARTICULAR

PURPOSE, ARE EXPRESSED OR IMPLIED. FLUKE IS NOT

LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES, ARISING FROM ANY

CAUSE OR THEORY.

Since some states or countries do not allow the exclusion or

limitation of an implied warranty or of incidental or consequential

damages, this limitation of liability may not apply to you.

Fluke Corporation Fluke Industrial B.V.

P.O. Box 9090 P.O. Box 90

Everett WA 7600 AB Almelo

98206-9090, USA The Netherlands

April 1997, Rev. 6, 4/10

© 1997, 1999, 2010 Fluke Corporation

All rights reserved.

Printed in the Netherlands

All product names are trademarks of their

respective companies.

Warning

Do the following to avoid electrical shock or fire if the

probe is connected to more than 42V peak (30V rms):

• Use only Fluke power adapter, model PM8907

(option).

• Connect the power adapter to the AC outlet

before connecting it to the DP120.

• Do not insert metal objects in the power adapter

connector.

• Use 600V rated test lead adapters. The maximum

allowable input voltage is 600V, Category III.

Powering the DP120

Follow the procedure (steps 1 to 3) to power the probe from a

standard ac outlet.

The power adapter is optional. For available Power Adapter models,

see the section ‘Servicing the DP120’.

Storing the DP120

If you are storing the differential voltage probe for an extended

period of time, the battery should be removed and stored

separately.

c Connect the probe’s output cable to the desired input on

the test tool. For Fluke 123, use the black banana-toBNC adapter (BB120).

d On the probe, select the 200x range. Ensure that the

green POWER ON-indicator is lit.

e On the test tool, ensure that the probe correction is set to

200:1. If not available, set to 100:1.

When one of the stages of the output inverter does not function

properly, check the following:

• the output stage

• the control circuitry

The figure below shows how to connect a ScopeMeter

and a DP120 to the circuitry.

®

test tool

f Connect both probe inputs to the measuring points.

g When the test tool is not in auto range, adjust the vertical

range for optimal display.

TOMOTOR

_

DCVOLTAGE

h When using the 100:1 probe correction, multiply the

voltage reading on the screen by 2x.

i At completion, be sure to set the range selection switch

to OFF again.

Measurement tips:

• Use the 20x range on the differential voltage probe for smaller

signals, such as ripple on a high voltage reference lead.

• At 20x range, set the test tool range to 20:1 (or 10:1).

• When the probe is battery operated, the red LED indicates that

the battery level is low and the battery needs to be replaced.

• When battery operated, the probe automatically goes to

standby mode after 30 minutes to conserve battery power. A

blinking green LED indicates that the probe is in standby

mode. To continue operation, turn the range selection switch

from OFF to 20x or 200x.

• Connect the red probe cable to a higher voltage level than the

black probe cable.

• For a dual measurement on test tool inputs A and B, connect

the common to earth ground. This ensures optimal

measurement accuracy on all inputs. For operating and

grounding principles of the differential voltage probe, see the

next figure.

Note that the timing circuit for the FET (Field Effect Transistor) drive

is referenced to earth ground. The gate drive signal is isolated with

a transformer coupling to the FET, which is connected to the DCvoltage.

An example of comparing the timing signal to the signal at the drive

output can be seen in the screen below.

Page 2

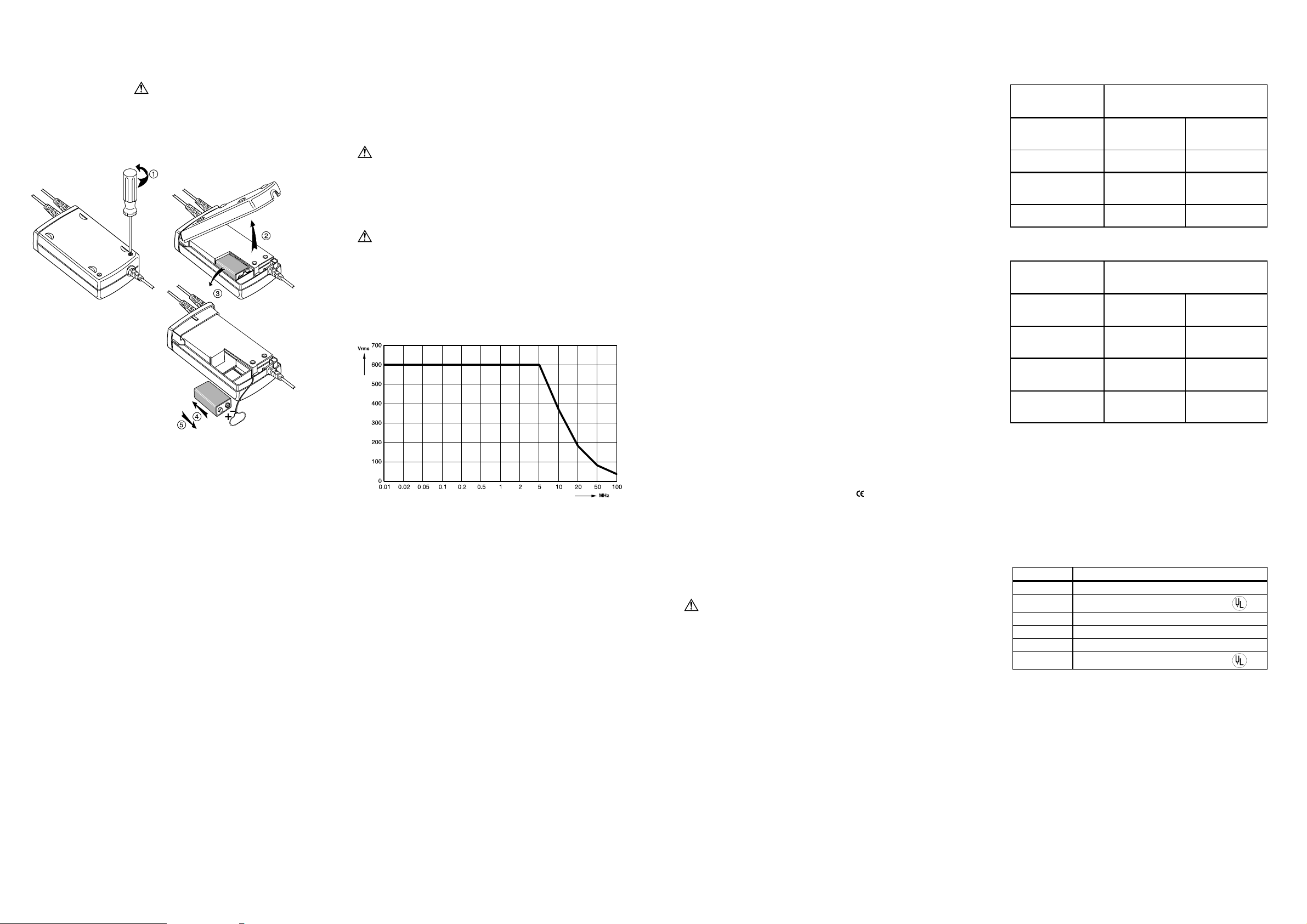

Installing or Replacing the Battery

Replace the battery when the red LED lights, or when both red and

green LEDs are off when the probe is turned on.

Warning

To avoid electrical shock, disconnect the differential

voltage probe from any conductor, and disconnect

the ScopeMeter

replacing the battery.

Follow the procedure (steps 1 to 5) to install or replace the battery.

®

test tool or oscilloscope before

Characteristics

FLUKE guarantees the properties expressed in numerical values

with the stated tolerance. Specified non-tolerance numerical values

indicate those that could be nominally expected from the mean of a

range of identical differential voltage probes.

Input Characteristics

Input Probe Tip Style: Shrouded banana probe tip

Probe Cable Length: 1.5 meter (60 inch)

Maximum Input Voltage to Ground:

600V CAT III

1000V CAT II

Installation Category III refers to distribution level and fixed

installation circuits inside a building. Installation Category II refers to

local level, which is applicable for appliances, and portable

equipment.

Maximum Differential Input Voltage:

1000 VDC, or

1000 Vrms, or

1200V (DC+AC peak), whichever is smaller.

Note

(DC+AC peak) limit is determined by the point at which

the differential voltage probe starts clipping.

For derating of each input probe (red or black), see figure below.

Input Impedance:

Between each input to shielding BNC: 5 MΩ , 6 pF

Between the inputs: 10 MΩ , 5 pF

Output Impedance: 50Ω

Noise:

200x: <2 mVrms

20x: <3 mVrms

Offset: ≤10 mV into 1 MΩ

Switch positions: OFF, 200x, 20x

Power

External:

Via power adapter PM8907 (optional)

Internal:

Battery Power: Alkaline 9V, IEC6LR61

Battery Life: 8 hour operation

400 hour in auto standby

Battery life measured @ 25

battery. (Delivered with probe.)

Power indicators:

Green LED: ON at normal operation.

blinks at standby.

To change from standby to normal operation turn switch

from OFF to 20x or 200x.

Red LED: ON when battery needs to be replacing.

Auto Stand By:

After 30 minutes, only when battery operated.

°

C with Duracell® alkaline

Environmental

Meets requirements of:

MIL-T-28800E, Type III, Class 3.

Output Characteristics

Output Cable: Safety designed BNC cable

Cable Length: 0.5 meter (20 inch)

Max. Output Voltage Range: ±6.5V into 1 MΩ

Electrical Characteristics

Attenuation: 200x and 20x

Bandwidth: (into 1 MΩ , 50 pF)

200x: DC to 20 MHz (-3 dB)

20x: DC to 20 MHz (-3 dB)

Accuracy: ±2.5% into 1 MΩ

Rise time:

200x: 17.5 ns

20x: 17.5 ns

CMRR:

200x: @60Hz= >80 dB, @1 MHz= >50 dB

20x: @60Hz= >70 dB, @1 MHz= >40 dB

EN 50081-1, Electromagnetic Compatibility Generic Emission

Standard: EN55022 and EN60555-2.

EN 50082-2, Electromagnetic Compatibility Generic Immunity

Standard: IEC1000-4 -2, -3, -4, -5. (see also Tables 1 and 2)

This product is in conformity with Electromagnetic Compatibility

Directive 2004/108/EC and Low Voltage Directive 2006/95/EC.

This conformity is indicated by the symbol

Européenne”.

Temperature:

Operating: 0°C to +50°C (+32°F to +122°F)

Storage: -10°C to +60°C (+14°F to +140°F)

Altitude:

Operating: 3 km (9850 feet)

Storage: 12 km (40 000 feet)

, i.e. “Conformité

Safety Specifications

Meets requirements of:

EN61010-2-31 (IEC1010-2-31).

Compliant with:

UL3111-1 (including listing)

CSA C22.2 No.1010.1-92 (including approval)

Max. Floating Output Voltage:

600V Category III, up to 400 Hz. (From shielding to ground.)

The DP120 conforms with the EEC directive 2004/108/EC for EMC

immunity, as defined by IEC1000-4 -3, with the addition of the

following tables.

Table 1

Frequency range:

10 kHz to 25 MHz

20x, 200x <1% <1%

Frequency range:

25 MHz to 1 GHz

20x, 200x

Frequency range:

1.4 GHz to 2 GHz

20x, 200x No visible

Frequency range:

2 GHz to 2.7 GHz

20x, 200x --- No visible

E = 3 V/m E = 10 V/m

E = 3 V/m E = 10 V/m

≤1% ≤2%

E = 3 V/m E = 1 V/m

disturbance

E = 3 V/m E = 1 V/m

Susceptibility

(in % of full dynamic range)

Table 2

Susceptibility

(in % of full dynamic range)

---

disturbance

Servicing the DP120

For service information, contact your Fluke service center. To locate

an authorized service center, visit us on the World Wide Web:

http://www.fluke.com

or call Fluke using any of the phone numbers listed below:

+1-888-993-5853 in U.S.A. and Canada

+31-40-2675200 in Europe

+1-425-446-5500 from other countries

Available power adapters:

Model Description

PM8907/801 Universal Europe 230V, 50 Hz

PM8907/803 North America 120V, 60 Hz

PM8907/804 United Kingdom 240V, 50 Hz

PM8907/806 Japan 100V, 60 Hz

PM8907/807 Australia 240V, 50 Hz

PM8907/808 Universal 115V/230V

Note

The 230V rating of the PM8907/808 is not for use in North

America. A line plug adapter complying with the

applicable National Requirements may be provided to

alter the blade configurations for a specific country.

Service sheet:

Ordering Number: 4822 872 05374

Loading...

Loading...