Page 1

Datapaq

TP3

Data

Logger

USER MANUAL

for Datapaq

Tracker Systems

with

Insight

™

®

software

MA6020A

Issue 2

Page 2

Page 3

Datapaq TP3

Data Logger

User Manual

for

Datapaq

Issue 2

®

Tracker Systems with Insight

Datapaq is the world’s leading brand of

process temperature-monitoring

instrumentation, and maintains

this leadership by continual development

of its advanced, easy-to-use Tracker systems.

™

software

Europe & Asia

Fluke Process Instruments

Lothbury House, Cambridge Technopark

Newmarket Road

Cambridge CB5 8PB

United Kingdom

Tel. +44-(0)1223-652400

sales@flukeprocessinstruments.co.uk

www.flukeprocessinstruments.com

DATAPAQ PART NO. MA6020 A

North & South America

Fluke Process Instruments

87 Stiles Road, Suite 206

Salem

NH 03079

USA

Tel. +1-425-446-6780

sales@flukeprocessinstruments.com

www.flukeprocessinstruments.com

Page 4

SAFETY

WARNINGS

Indicates potential hazard.

On Datapaq equipment this normally warns of high temperature, but,

where you see the symbol, consult the manual for further explanation.

Warns of high temperatures.

Where this symbol appears on Datapaq equipment, its surface may be

excessively hot (or excessively cold) and may thus cause skin burns.

For safe use of Datapaq equipment, always:

• Take care to follow its supplied instructions.

• Observe any warning signs shown on the equipment.

The following product type

Datapaq TP3 Thermocouple Data Logger

manuf actured by Fluke Process Instruments,

Lothbury House, Cambridge CB5 8PB, UK

complies with the requirements of regional

directives as follows.

International Electrotechnical Commission

IEC 61010-1:2010 (3rd edition) – Safety requirements

for electrical equipment for measurement, control,

and laboratory use.

European Union

Directive 2014/30/EU – ElectroMagnetic

Compatibility (EMC).

EN 61326-1:2013 – Group 1, Class B equipment

(emissions section only), and Industrial Location

Immunity (immunity section only).

Directive 2014/53/EU – Radio Equipment Directive (RED).

EN 300 220-2 V2.4.1 – Electromagnetic

compatibility and Radio spec trum Matters (ERM);

Shor t Range Devices ( SRD); Radio equipment to

be used in the 25 MHz to 100 0 MHz frequency

range with power levels ranging up to 500 mW;

Part 2: Harmonized EN covering essential requirements under ar ticle 3.2 of the R &TTE directive.

EN 300 328 V1.8.1 – Electromagnetic compatibilit y

and Radio spectrum Matters (ERM); Wideband

Fluke Process Instruments makes no representations or warranties of any kind whatsoever with

respect to the contents hereof and specifically disclaims any implied warranties of merchantability or

fitness for any particular purpose. Fluke Process Instruments shall not be liable for errors contained

herein or for incidental or consequential damages in connection with the furnishing, performance or

Fluke Process Instruments reserves the right to revise this publication from time to time and to make

changes to the content hereof without obligation to notify any person of such revisions or changes.

Datapaq and the Fluke Process Instruments logo are registered trademarks of Fluke Process

Instruments. Microsoft and Windows are registered trademarks of Microsoft Corporation.

User manuals are available in other languages ; contact Fluke Process Instruments for details.

use of the Datapaq software, associated hardware or this material.

transmission systems; Data trans mission equipment operating in the 2 .4 GHz ISM band and using

wide band modulation techniques; Harmonized EN

covering the essential require ments of article 3.2

of the R&TTE directive.

EN 301 489-1 V1.9.2 – Electromagnetic compatibility

and Radio spectrum Matters (ERM); ElectroMagnetic

Compatibility (E MC) standard for radio equipment

and ser vices ; Part 1: Common technical requirements.

EN 301 489-3 V1.4.1 – Electromagnetic compatibility

and Radio spectrum Matters (ERM); ElectroMagnetic

Compatibility (E MC) standard for radio equipment

and ser vices ; Part 3: Specific conditions for Short

Range Devices ( SRD) operating on frequencies

between 9 kHz and 40 GHz.

EN 301 489-17 V2.2 .1 – Elect romagnetic

compatibility and Radio spec trum Matters (ERM);

ElectroMagnetic Compatibility (EMC) standard for

radio equipment; Part 17: Specific conditions for

Broadband Dat a Transmission Systems.

Directive 2011/65/EU – Restriction of the use of

cert ain hazardous subst ances in electrical and

electronic equipment (RoHS).

Federal Communications Commission, USA

Electromagnetic Compatibility Directive for digital

devices.

CFR47 Class A – Code of Federal Regulations :

Part 15 Subpar t B, Radio Frequency Devices,

Unintentional radiators.

© Fluke Process Instruments, Cambridge, UK 2018

Manual set in 10 pt Gill Sans.

All rights reserved

Page 5

OPEN-SOURCE

FIRMWARE AND

SOFTWARE

ACKNOWLEDGE MENTS

FreeRTOS

FreeRTOS V8.2.0 – Copyright ©

2015 Real Time Engineers Ltd . All

rights reserved

VIS IT http: //w ww. FreeRTOS.or g TO

ENSURE YOU ARE USIN G THE

LATEST VERSION.

FreeRTOS is free sof tware; you can

redistribute it and/or modify it under

the terms of the GNU General

Public License (version 2) as published by the Free S oftware

Foundation AND MODIFIED BY the

FreeRTOS exception.

NOTE: The modification to the GPL is

included to allow you to distribute a combined work that includes FreeRTOS without being obliged to provide the source

code for proprietary components outside

of the FreeRTOS kernel.

FreeRTOS is distributed in the hope

that it w ill be use ful, but WITHO UT

ANY WARR ANT Y; without even

the implied warrant y of MERCHANTABILIT Y or FITN ESS FOR A

PARTICULAR PURPOSE. Full license

text is av ailable on the following link:

http://www.freertos.org/a00114.html

FreeRTOS provides completely free yet

professionally developed, robust, strictly

quality controlled, supported, and cross

platform software that is more than just

the market leader, it is the industry’s de

facto standard.

Help yourself get star ted quickly while

simultaneously helping to sup port the

FreeRTOS project by purchasing a

FreeRTOS t utorial book , reference manual, or both: http: //www.FreeRTOS.org/

Documentation

http://www.FreeRTOS.org/

FAQHelp.html – Having a problem?

Star t by reading the FAQ page “My

application does not run, what could

be wrong? ”. Have you defined configASS ERT( )?

http://www.FreeRTOS.org/support –

In return for receiving this top quality

embedded sof tware for free we

request you assist our global community by p articipating in the support

forum.

http://www.FreeRTOS.org/training –

Investing in training allows your team

to be as productive as possible as

early as possible. Now you can

receive FreeRTOS training directly

from Ric hard Barry, CEO of Real

Time Engineers Ltd, and the world’s

leading authority on the world ’s leading RTO S.

http :/ /ww w.FreeRTOS.org /plus – A

selection of FreeRTOS ecosystem

products, including FreeRTOS+Trace

– an indispensable productivity tool, a

DOS compatible FAT file system, and

our tiny t hread aware UDP /IP stack .

http://www.FreeRTOS.org/labs –

Where new FreeRTOS products go

to incubate. Come and tr y

FreeRTOS +TCP, our new open

source TCP/IP stack for FreeRTOS.

http :/ /ww w.OpenRTOS.com – Real

Time Engineers ltd. license FreeRTOS

to High Integrity Systems ltd. to sell

under the OpenRTOS brand. Low

cost OpenRTOS licenses of fer ticketed support, indemnification and commercial middleware.

http :/ /ww w.SafeRTOS.com – High

Integrity Systems also provide a safety engineered and independently SI L3

certified version for use in safety and

mission critical applications that

require provable dependability.

Uffs version 1.3.6

UFFS , the Ultra-low-cost Flash File

System.

Copyright © 2005–2009 Ricky Zheng

<ricky_gz_zheng@yahoo.co.nz>

UFFS is free sof tware; you can redistribu te it and /or modify i t under the

GNU Librar y Gener al Public License

as published by the Free Software

Foundation ; either version 2 of the

License, or (at your option) any later

version.

UFFS is distributed in the hope that it

will be useful, but WITHOUT ANY

WARRA NTY; without even the

implied warranty of M ERCHA NTABILITY or F ITNESS FOR A

PARTICULAR PURPOSE. Se e the

GNU Ge neral Public License or

GNU Librar y Gener al Public License,

as applicable, for more details.

You should have received a copy of

the GN U Gener al Public License and

GNU Librar y Gener al Public License

along with UFFS; if not, write to the

Free Software Found ation, Inc.,

51 Franklin Street, Fif th Floor,

Boston, MA 02110-1301, USA.

As a special exce ption, if other files

instantiat e templ ates or use macros

or inline functions from this file, or

you compile this f ile and link it with

other works to produce a work

based on this file, this file does not by

itsel f cause the resulting work to be

covered by t he GNU G eneral Public

License. However the source code

for this file must still be made available in accordance with section ( 3) of

the GN U Gener al Public License v2.

This exception does not invalidate

any othe r reasons why a work b ased

on this f ile might be covered by the

GNU Ge neral Public License.

USB dr ivers – libusb K version

3.0.7.0

Copyright © 2011–2012 Travis Lee

Robinson. All rights reserved.

APPLICABLE FOR ALL LIBUSBK

BINARIES A ND SOU RCE CODE

UNLESS OTHERWISE SPECIFIED.

PLEASE SEE INDIVIDUAL

COMPONENTS LICENSING

TERM S FOR DE TAILS.

NOTE: Portions of dpscat use source

code from libwdi which is licensed for

LGPL use only. (See dpscat .c)

NOTE: libusbK-inf-wizard .exe is

linked to libwdi which is licensed for

LGPL use only.

Redist ribution and use in source and

binar y forms, with or without modif ication, are per mitted provided that

the following conditions are met:

•Redistributions of source code

must retain the above copyright

notice , this list of conditions and the

following disclaimer.

•Redistributions in binary form must

reproduce the above copyright

notice , this list of conditions and the

following disclaimer in the documentation and/or other materials

provided with the distribution.

•Neither the name of Travis Lee

Robinson nor the names of its contribu tors may be used to endorse

or promote products derived from

this software without specific prior

written permission.

THIS SOFTWARE IS PROVIDED BY

THE COPYRIGHT HOLDERS AND

CONTRIBUTORS “AS IS” AND

ANY EXPRES S OR IMPLIED WARRANTIES, INCLU DING , BUT NOT

LIMITED TO, THE I MPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ARE DISCL AIMED.

IN NO EVENT SHALL TR AVIS

ROBINSON BE LIABLE FOR ANY

DIRECT, INDIRECT, INCIDENTAL,

SPECIAL, EXEM PLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING , BUT NOT LIMITED TO,

PROCUREMENT OF SUBSTITUTE

GOODS O R SERVICES; LOSS OF

USE , DATA, OR PROFITS; OR

BUSINESS INTERRUPTION)

HOWEVER CAUSED AN D ON

ANY THEORY OF LIABILITY,

WHETHER IN CONTRACT,

STRICT LIAB ILIT Y, OR TORT

(INCLUDING NEGLIGENCE OR

OTHERWISE) ARISING IN ANY

WAY OUT OF THE USE OF THIS

SOFT WARE, EVEN IF ADVIS ED OF

THE POSSIB ILIT Y OF SUCH

DAMAG E.

Page 6

CONTENTS

9 Introduction

11 Logger Specifications and Operation

12 Specifications

14 Specifications for Specific Thermocouple Types

15 Logger LEDs

15 Battery Status LEDs

16 Logger Status LEDs

16 Four-LED Sequences

17 Start /Stop Button Actions

17 B a t ter y

19 Battery Life

21 NiMH Rechargeable Batteries

23 Alkaline Batteries

25 Lithium Batteries

29 Analog Inputs

29 Bluetooth Communications

30 Pairing

31 More Than One Logger

31 Turning Bluetooth On and Off

32 Bluetooth Telemetry

33 Over-temperature Protection

33 Testing and Calibration

34 Disposal of Batteries and Loggers

35 Restrictions on Use

37 Using the Logger with Insight Software

37 Installing/Removing Insight

38 Installation

38 Upgrading

38 Removal

38 Help System

Page 7

39 Communications Setup

41 Running a Temperature Profile

41 Resetting the Data Logger

47 Starting the Run

48 Downloading Data

52 Preparing the Data for Analysis

52 Specifying Oven/Furnace/Kiln Start

52 Storing Notes and Printing a Report

53 Logger Defaults and Details

54 Pre-trigger Data

54 Marking Events in Real Time

55 Using Hardwired Telemetry

55 Running a Temperature Profile Using

Hardwired Telemetry

56 Resetting and Starting the Logger When Using Hardwired

Telemetry

57 Real-time Display During the Run

58 Ending the Run

58 Multiple Loggers

61 Troubleshooting

61 Logger Download Error Messages

61 Logger Communications Problems

62 Checking the Data

62 Testing the Logger and Thermocouples

63 Printing Problems

63 Datapaq Service Department

64 INDEX

Page 8

Page 9

Introduction

Datapaq ® Tracker systems, incorporating Insight™ software, are complete

systems for monitoring and analyzing the temperature profiles of products

within your heat-treatment process; accurate data acquisition and powerful

analysis techniques are combined with flexibility and ease of use. The Tracker

system’s power and flexibility make it a perfect tool for process-temperature

monitoring, from commissioning and troubleshooting to process optimization,

ensuring consistent quality of product and maximum efficiency.

Current temperature characteristics can quickly be compared with previouslystored reference curves to detect operating abnormalities – and innovative

analysis techniques help in identifying problems, fine-tuning the process and

reducing running costs.

A powerful and flexible printing option allows the user to generate and

customize reports, including any or all of the analysis results or raw

temperature data.

The basic Tracker system hardware comprises:

• Data logger (including communications lead and charger) (p. 11).

• Thermal barrier and thermocouple probes (not covered here; see the

relevant manual supplied with your system).

• Hardwired telemetry (p. 55) as standard, and an optional TM21 radio-

telemetry system (described in its own User Manual).

This manual is for Tracker systems supplied with a Datapaq TP3 data logger,

and focuses on all aspects of using that logger. There is also guidance on setting

up the Insight software; complete information on using the software is contained in the online Help system available after it is installed. For information on

choosing and using the logger’s thermal protection (barriers and heatsinks) and

thermocouple probes, as well as step-by-step instruction on how to collect

temperature-profile data on a product as it runs through your process, see the

relevant manual supplied with your system.

This manual, and other Datapaq user documentation, in various languages, is

available on the Insight installation DVD included with Datapaq systems. During the

software installation (p. 37), you may select documents to be copied to your PC

for rapid on-demand viewing through Insight.

DATAPAQ TP3 Introduction 9

Page 10

10 Introduction DATAPAQ TP3

Page 11

Logger Specifications and

Operation

The TP3 data logger is at home in a wide range of heat-treatment applications.

Its capacity for recording over 3.6 million data-points makes it a supremely

powerful, accurate and in-depth data-collection tool; combined with a built-in

transmitter to see temperature profiles developing in real time, this is an ideal

data logger for all applications.

The logger’s key features are:

• Two model sizes to suit different applications.

• Huge memory capacity for detailed process analysis: a total of over

3.6 million data-points (p. 13).

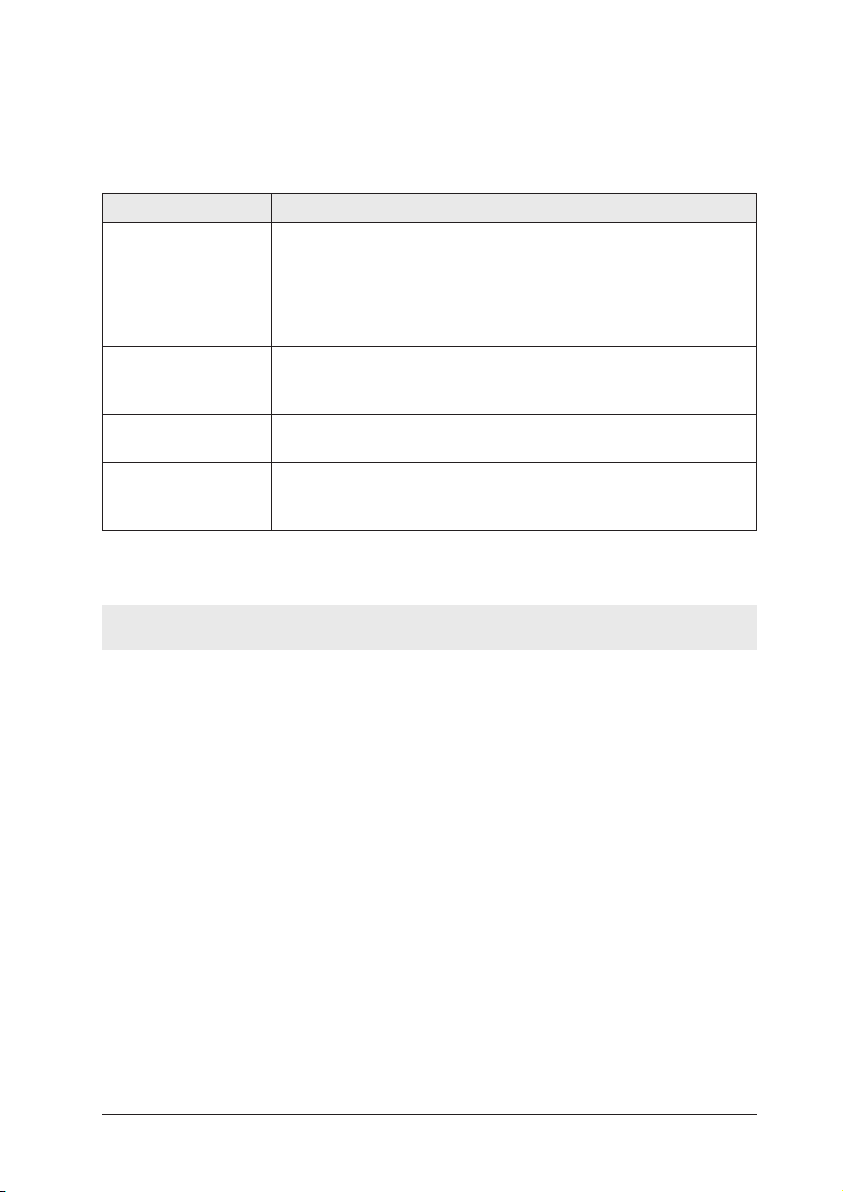

A

B

C

D

E

F

G

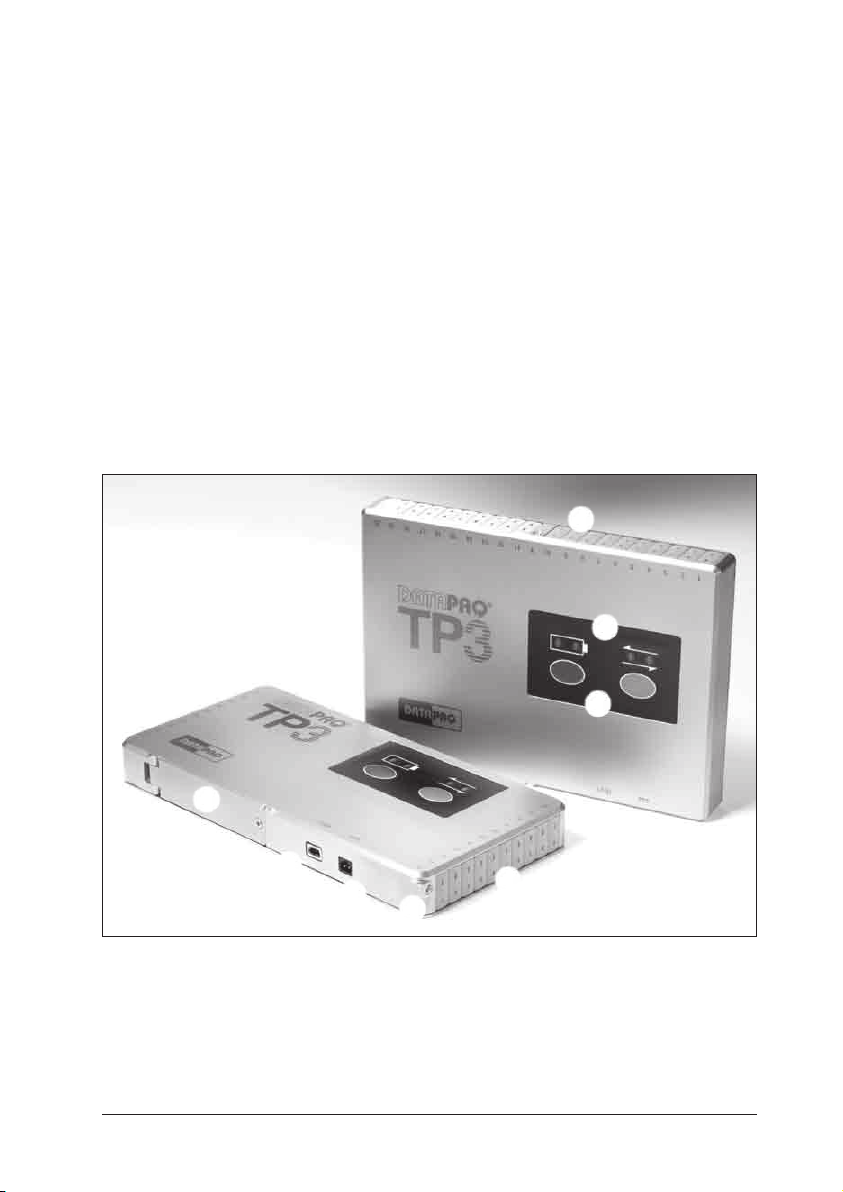

TP3 loggers: 10-channel narrow and 20-channel wide

A Thermocouple sockets.

B Battery and logger status LEDs

(p. 15).

C Stop/start buttons (p. 17).

D Battery compartment door (p. 22).

DATAPAQ TP3 Specifications and Operation 11

A

E USB communications socket

(p. 39).

F Charging socket (p. 21).

G Transmitter-aerial socket (for use

with TM21 telemetry system).

Page 12

• Ten or 20 thermocouple channels (depending on model size; see below)

for maximum data collection on each run.

• Can be specified for use with various thermocouple types (B, J, K, N, R,

S, T; see p. 14) and with analog inputs (current and /or voltage; see

p. 29) – or with a mixture of thermocouple types and/or analog inputs.

• Powered by standard alkaline AA batteries or by user-replaceable

rechargeable NiMH batteries; for high-temperature applications

involving logger operating temperatures (i.e. inside the thermal barrier) of up

to 110°C/230°F, can also be powered by non-rechargeable lithium

batteries. Any logger can use any battery-type interchangeably if

appropriate battery housings are used (available separately). See p. 17.

• Short sample intervals, to collect maximum data in minimum time

(p. 13) .

• High accuracy for compliance to tight specifications (see p. 14):

for type K thermocouples, ±0.3°C/0.5°F (above −100°C/−148°F);

for type N thermocouples, ±0.4°C/0.7°F (above 0°C/32°F).

• Data gathered by the logger but not yet downloaded (‘hot data’) is

protected by non-volatile memory or by software warning if reset is

attempted before download.

• USB and Bluetooth communication (p. 29).

• Hardwired telemetry (p. 55) or (if specified for use with optional

TM21 system) radio telemetry for monitoring in real time – both with full

analysis functions and alarms to warn the user if the process is out of

specification.

• Four LEDs to show the exact status of the logger’s activity and its batteries

(p. 15) .

• Start and stop buttons for easy user control (p. 17, p. 53).

• Rugged case and electronics allow operation in harsh environments of

dust, pressure and vacuum.

• Reset possible by start button alone, for speed and simplicity (p. 47).

Specifications

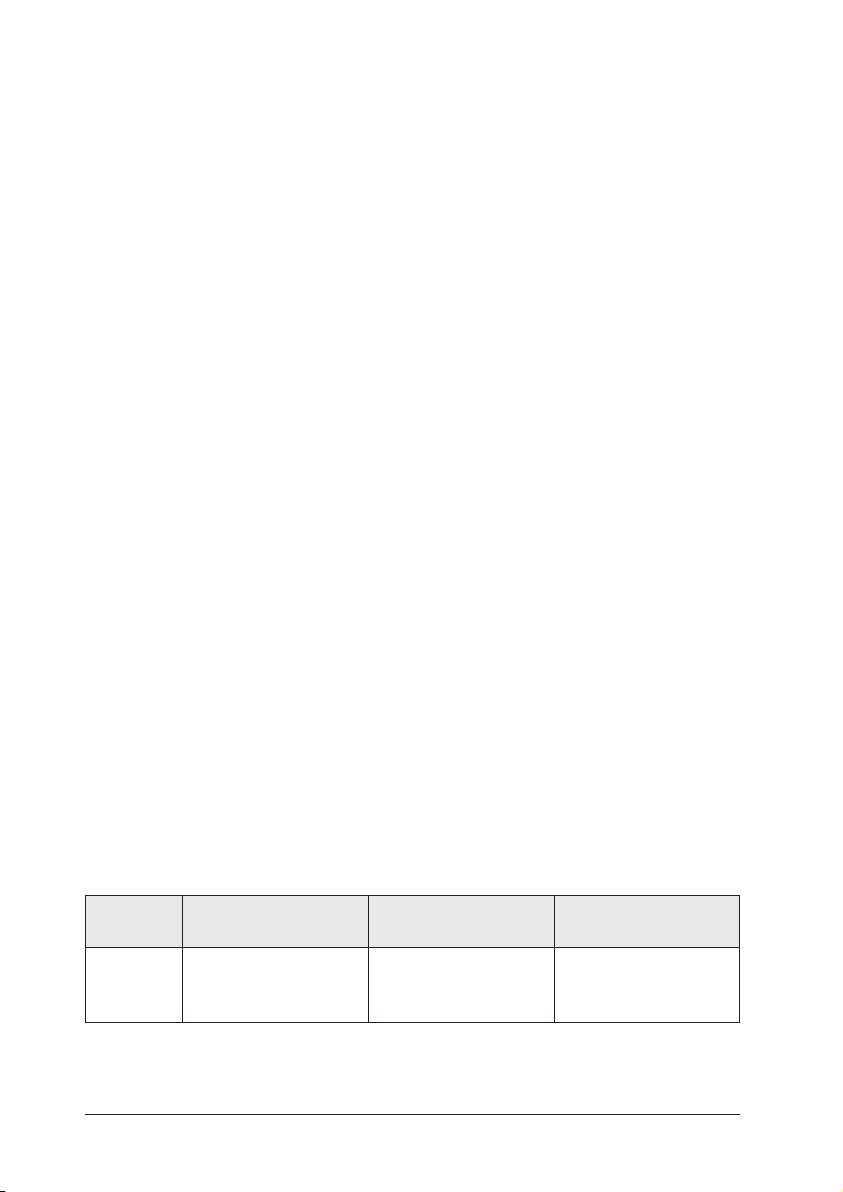

Narrow – 10-channel

TP3000A

Height

Width

Length

20.5 mm/0.8 in.

97 mm/3.8 in.

198 mm/7.8 in.

12 Specifications and Operation DATAPAQ TP3

Narrow – 20-channel

TP3300A

20.5 mm/0.8 in.

97 mm/3.8 in.

198 mm/7.8 in.

Wide – 20 -channel

TP3400A

20.5 mm/0.8 in.

124 mm/4.9 in.

177 mm/7.0 in.

Page 13

Thermocouples Available for a single thermocouple type, or for combinations of

up to three types: B, J, K, N, R, S, T (see specifications for each,

below).

Analog inputs:

Current

See p. 29.

Measurement range 4–20 mA.

Accuracy ±0.1% at 24°C/75°F.

Voltage

Measurement range 0–10 V.

Accuracy ±0.1% at 24°C/75°F.

Operating temperature

(of the logger itself)

Dependent on battery type:

Rechargeable −40°C to 70°C/−40°F to 158°F.

Alkaline −40°C to 55°C/−40°F to 131°F.

Lithium −40°C to 110°C/−40°F to 230°F.

Humidity range 0–100% non-condensing.

Operating pressure

(excluding limitations on

10−7 bar at 20°C to 20 bar at 110°C

1.5 × 10−6 psi at 68°F to 290 psi at 230°F

battery)

Real-time monitoring Hardwired (serial) telemetry via communications lead (p. 55),

or via Bluetooth (p. 32), as standard.

Radio (RF) telemetry via optional built-in transmitter.

Data capacity Over 3.6 million data-points in total, plus associated pre-trigger

data (see p. 54) and calibration data. This is sufficient for, e.g., 10

runs of 10 hrs with 10 probes and sample interval 5 sec. Using

fewer probes (see p. 43) increases the possible run-time.

Hot-data protection By non-volatile memory, and software warning if reset attempted

before download.

Logger reset By Insight (p. 41) or by start button (using previous reset

options) (p. 47).

Sample interval:

No telemetry

1

1–3 channels 0.1 s to 50 min.

4–9 channels 0.2 s to 50 min.

10 channels 0.3 s to 50 min.

11–20 channels 1 s to 50 min.

Hardwired telemetry

1–10 channels 1 s to 50 min.

11–20 channels 2 s to 50 min.

Radio telemetry

2

1–20 channels 2 s to 50 min. In Japan, 4 s to 50 min.

Data-collection start No trigger, Start button, Date and time, Rising temperature,

Falling temperature.

Pre-trigger data stored Yes (configurable; see p. 53).

Multiple runs Collect data from up to 10 runs before downloading (see p. 45).

Multiple events Up to 10 events (different probe selections, sample intervals and

trigger modes for different stages of a profile run; see p. 45).

Communications USB 2.0, Mini-B socket.

Bluetooth (p. 29) (not available in all countries).

PC/software compatibility See p. 37.

cont. >>

DATAPAQ TP3 Specifications and Operation 13

Page 14

Battery Interchangeable types, each in different battery housing (see

p. 17 ):

•NiMH rechargeable, 4 × 1.2 V (only Datapaq battery-packs

are suitable). For battery life, s

ee p. 21.

•Alkaline, 4 × AA 1.5 V (Duracell or other quality batteries

recommended). For battery life, s

ee p. 24.

•Lithium thionyl chloride non-rechargeable, 4 × AA 3.6 V,

for high-temperature use (only Datapaq battery-packs are

suitable). For battery life, s

ee p. 25.

Battery charger CH0 070 power-supply unit: input 90 –264 V AC, 50 –60 Hz,

400 mA. Must not be used if the ambient temperature is below

10°C/50°F or over 40°C/104°F.

USB power Logger is powered by USB when connected; no batteries are then

required (except when being reset for a non-telemetry run ; see

p. 41).

1

Intervals of 1 s and above can be set only in whole seconds.

2

Data applies to radio telemetry using a single transmission, i.e. no interleaving (see TM21 Radio-telemetry

System User Manual; or, in Insight’s Help system, select Menu Functions > Logger > Reset).

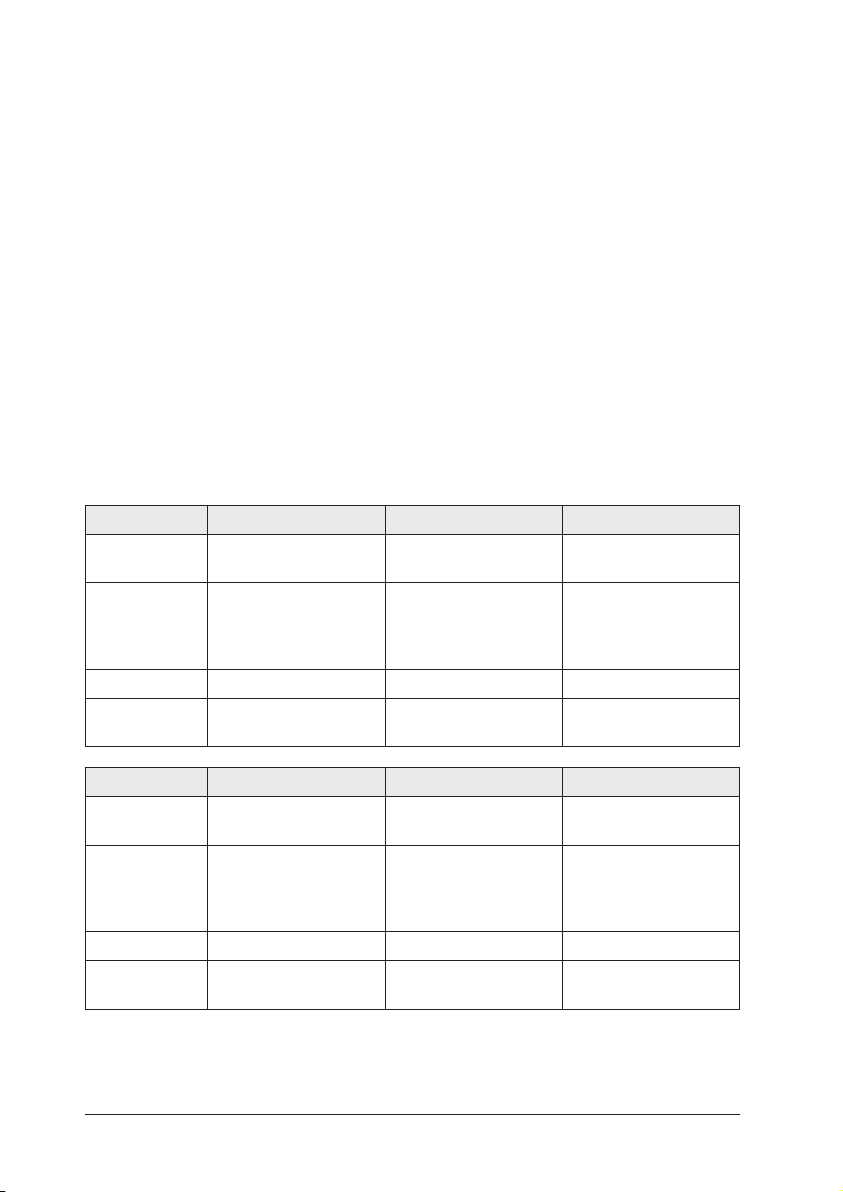

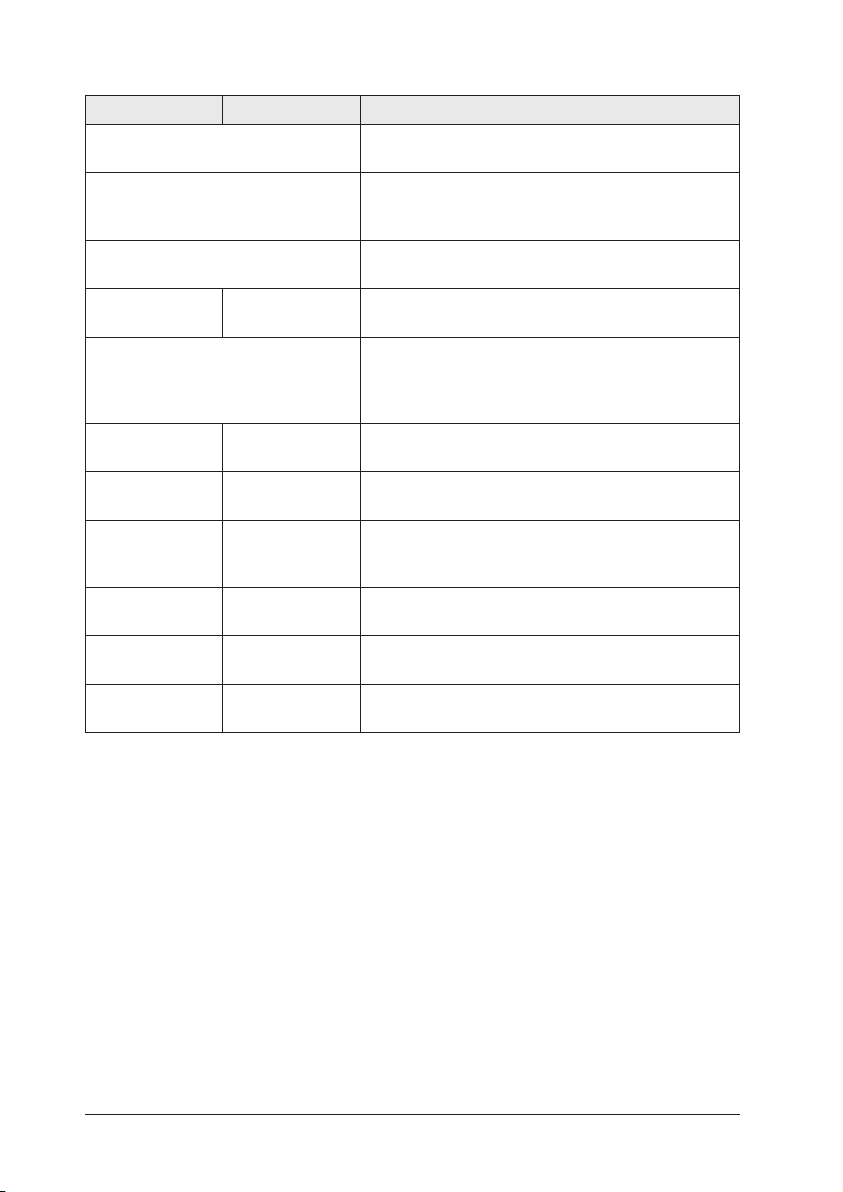

Specifications for Specific Thermocouple Types

Type B Type J Type K

Measurement

range

Accuracy *

(using sample

interval > 0.8 s)

Resolution 0.1°C/0.2°F 0.1°C/0.2°F 0.1°C/0.2°F

Socket color

(IEC 60584-3)

55°C to 1,815°C

131°F to 3,299°F

±3.0°C at 400°C

±1.0°C at 1,500°C

±5.4°F at 752°F

±1.8°F at 2,732°F

0°C to 800°C

32°F to 1,472°F

±0.3°C

±0.5°F

−190°C to 1,370°C

−310°F to 2,498°F

±0.5°C below −100°C

±0.3°C above −100°C

±0.9°F below −148°F

±0.5°F above −148°F

Gray Black Green

Type N Typ e R Type S

Measurement

range

Accuracy *

(using sample

interval > 0.8 s)

−190°C to 1,300°C

−310°F to 2,372°F

±0.5°C below 0°C

±0.4°C above 0°C

±0.9°F below 32°F

±0.7°F above 32°F

0°C to 1,760°C

32°F to 3,200°F

±1.0°C at 200°C

±0.8°C at 1,00 0°C

±1.8°F at 392°F

±1.4°F at 1,832°F

0°C to 1,760°C

32°F to 3,200°F

±1.0°C at 200°C

±0.8°C at 1,00 0°C

±1.8°F at 392°F

±1.4°F at 1,832°F

Resolution 0.1°C/0.2°F 0.1°C/0.2°F 0.1°C/0.2°F

Socket color

Pink Orange Orange

(IEC 60584-3)

14 Specifications and Operation DATAPAQ TP3

Page 15

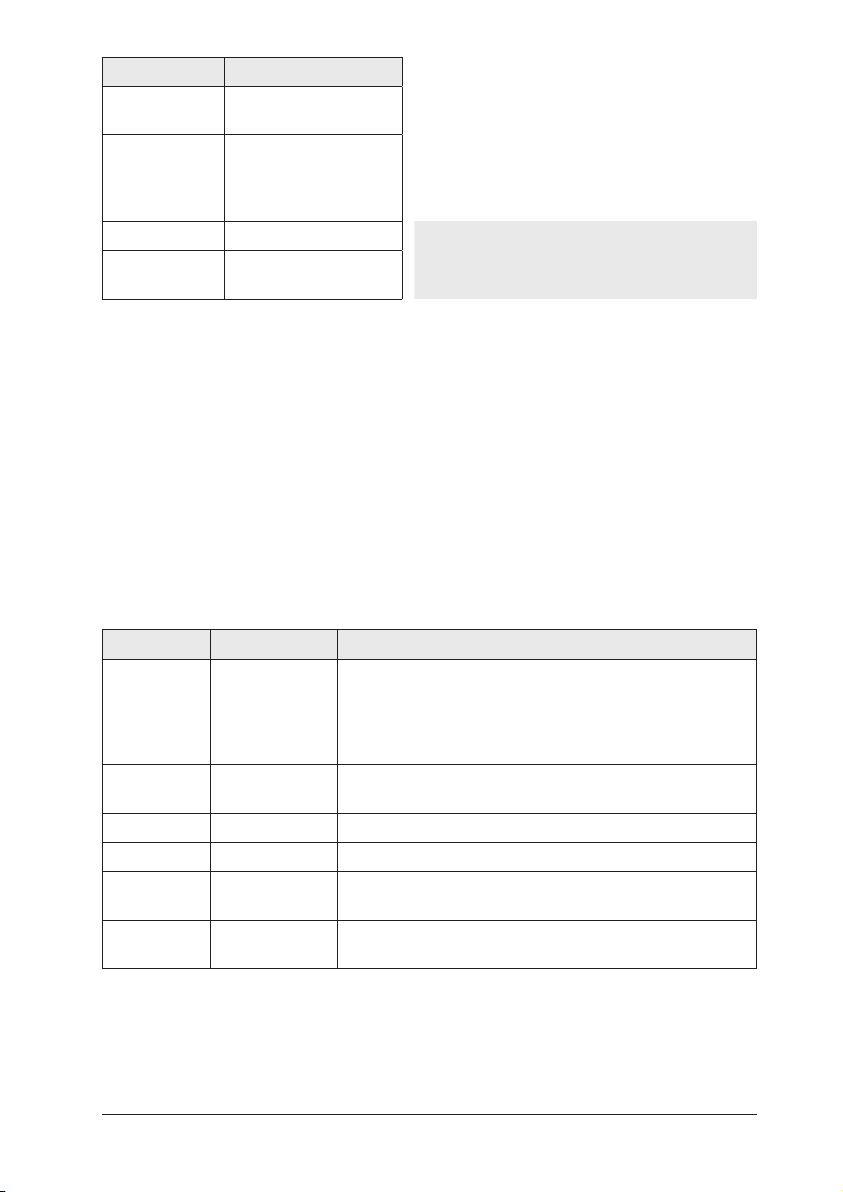

Type T

Measurement

range

Accuracy *

(using sample

interval > 0.8 s)

Resolution 0.1°C/0.2°F

Socket color

(IEC 60584-3)

−196°C to 400°C

−321°F to 752°F

±0.5°C below −100°C

±0.3°C above −100°C

±0.9°F below −148°F

±0.5°F above −148°F

Brown

*

There will be an additional error of 0.01°C for every

1°C difference between the temperature at which

the logger is operated (i.e. the logger’s internal

temperature) and the temperature at which it was

calibrated. For more-detailed accuracy data, contact

Fluke Process Instruments.

Due to continuing product development,

specif ications are subject to change

without notice.

Logger LEDs

The logger is equipped with two sets of two LEDs:

• Ye l l ow and green/red show the status of the battery.

• Red and green show the status of the logger and its memory.

To see an animated demonstration of all the LED sequences: in Insight,

select Help > LED Sequences; or, in Insight’s Help system, select Introduction >

Logger LEDs.

Battery Status LEDs

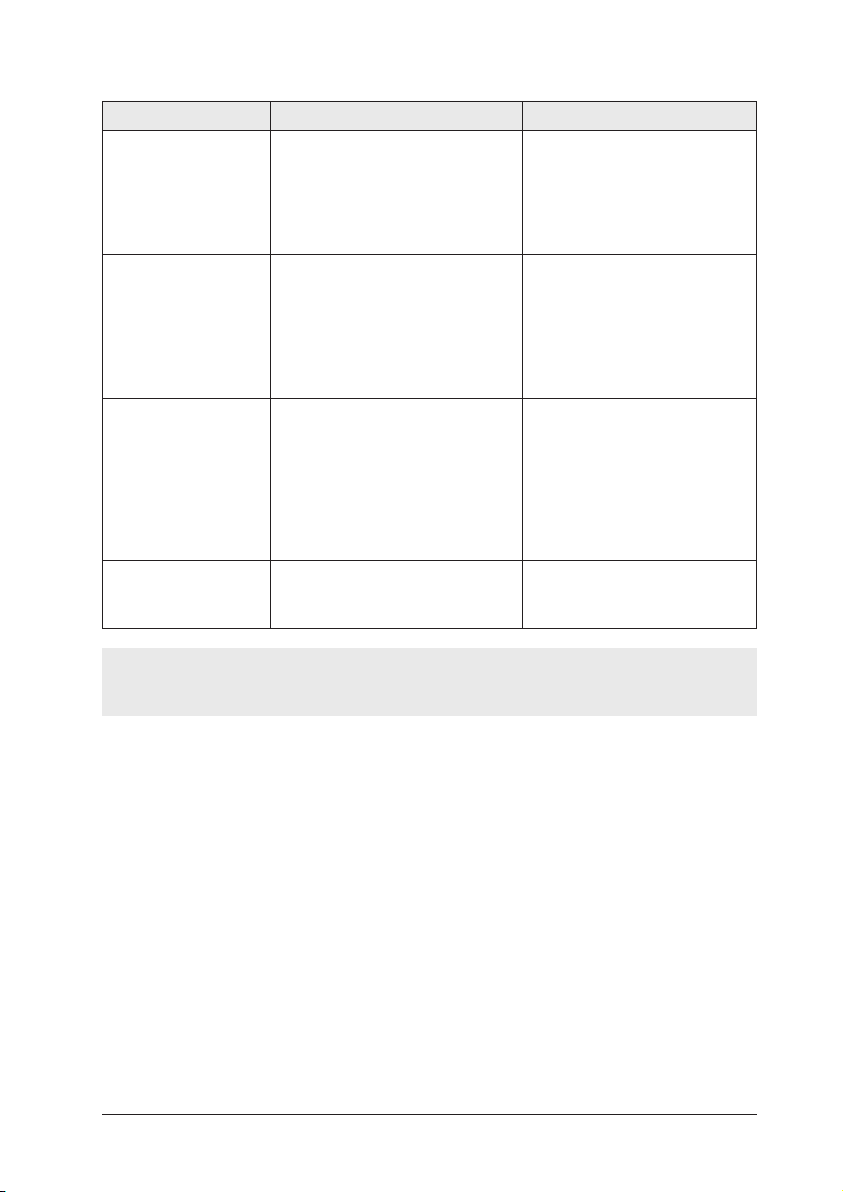

Yell o w Green/Red Meaning

Off Off Battery has at least 20% of full charge (charger not

Flashing every

second

Off RED Battery charging.

Off GREEN Charging complete (charger connected).

Off Flashing RED

Double-flash

every second

Off Battery has 20% or less of full charge (charger not

once per second

Off Lithium batteries are being depassivated (see p. 27).

connected), or...

Charger is connected but logger is acquiring data (in which

case logger-status green LED will be flashing), or...

Fault with battery or logger.

connected).

Battery being preconditioned due to being too hot, too cold

or too deeply discharged (see p. 22).

DATAPAQ TP3 Specifications and Operation 15

Page 16

Logger Status LEDs

Red Green Meaning

Red and green LEDs each give 5

flashes, alternating with each other

Red and green LEDs flash

continuously, alternating with each

other, at sample interval *

Red and green LEDs continuously give

double-flash together, every 5 seconds

On Flashing at sample

Red and green LEDs flash together, at

sample interval *

Off Flashing at sample

Flashes 5 times Off Connection between communications lead and logger

Flashing every

5 seconds

2 quick flashes

every second

Flashing every

second

One flash Off Start button pressed during a profile run to mark an

*

Flashing interval will actually fall in range 0.5 –5 s.

interval *

interval *

Off Logger has data in memory which has not been

Off Logger too hot to start logging (after pressing start

Off Internal error. (Logger will power-off after 5 mins – or

Logger successfully reset.

Logger awaiting trigger (see p. 43) (in most

situations, except as below).

Logger awaiting start-button trigger for 2nd or

subsequent runs in multiple-run mode (see p. 45).

Logger awaiting trigger, but one or more of the

enabled input channels is open circuit.

All probes are above trigger temperature, and thus

data-recording cannot be triggered by rising temperature (or, if falling trigger is set, all probes are below

trigger point). Reset temperature trigger (see p. 43).

Logger acquiring data.

has been made.

downloaded. (Logger will power-off after 5 mins – or

after 30 mins if Bluetooth is on.)

button).

after 30 mins if Bluetooth is on.)

event (see p. 53).

Four-LED Sequences

When the logger is able to receive Bluetooth communication (p. 29),

each of the four LEDs will flash once in horizontal sequence, repeating every

20 seconds.

When green and red buttons are pressed, together, to turn off logger (see

below), all four LEDs flash together, once.

16 Specifications and Operation DATAPAQ TP3

Page 17

Start/Stop Button Actions

Action Results Notes

Press GREEN button

after data from previous

run has been

downloaded and/or

logger has been reset.

Press GREEN button

when logger contains

‘hot data’, i.e. data

which has not been

downloaded.

Press RED button. Stops logging. Data retained in memory. Logger

Press GREEN and

RED buttons together

and hold for 5 seconds.

Starts logging. If logger was not reset after

If in single-run mode or if in multiple-

run mode and 10 runs have been

performed (p. 45), logger powers

up (but will not start a new run or

delete data). If in multiple-run mode

and fewer than 10 runs have been

performed, logger starts logging.

Turn s logger off. All four LEDs

flash together, once.

previous run, the last reset

options (sample interval, probe

selection, etc.) are used as

default. In telemetry mode,

logger also starts sending data.

Each run of a multiple run will

be performed using the same

data-collection options, until the

logger is reset.

cannot be re started until data is

downloaded (unless in multiplerun mode, p. 45). Red LED

flashes every 5 seconds to warn

of data in memory. If in telemetry

mode, will also send ‘end of run’

signal to end real-time run.

Data retained in memory. The

previous reset options are

retained as current default.

It is possible to set the logger up so that use of the stop button is disabled during

a profile run. See p. 53.

Battery

Every TP3 logger can use three battery types interchangeably.

• NiMH rechargeable (see p. 21).

• Alkaline AA (see p. 23).

• Lithium non-rechargeable for high-temperature use (see p. 25).

Each type uses a different battery housing, identified by a different-colored label

(see below) which also shows the logger’s permitted operational temperature.

All types can be replaced by the user.

DATAPAQ TP3 Specifications and Operation 17

Page 18

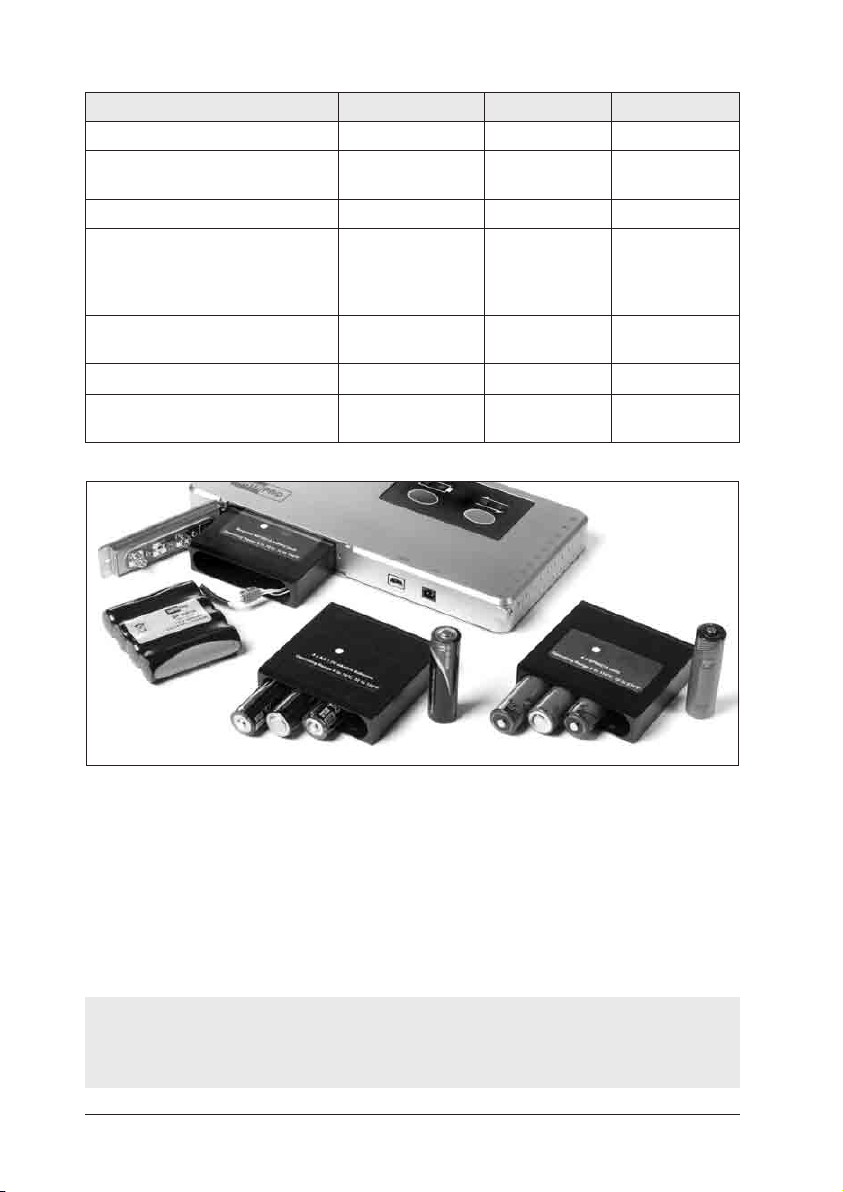

The key differences between the three battery types, in use, are as follows.

NiMH Alkaline Lithium

Label on battery housing Green Blue Red

Logger’s operating

temperature (internal)

Rechargeable Yes No No

Battery life

(10 channels, sample interval 1 min.,

logger temperature 70–100°C/

158–212°F, no telemetry)

Charge level shown by Insight

(p . 19)

Special safety measures No No Yes (see p. 27)

Disposal (p. 34) Return to Fluke

−40°C to 70°C

−40°F to 158°F

200 hrs (between

charges)

(see p. 21)

Yes Yes No

Process Instruments

−40°C to 55°C

−40°F to 131°F

450 hrs

(see p. 24)

Recycling center Recycling center

−40°C to 110°C

−40°F to 230°F

500 hrs

(see p. 25)

(see also p. 28)

Interchangeable battery-packs and housings:

NiMH rechargeable (left, p. 21), alkaline (center, p. 23) and lithium (right, p. 25).

The logger automatically detects the type of battery in use, which prevents

damage to non-rechargeable batteries if the charger is connected by mistake.

To remove the battery housing from the logger (in order to replace with a

new one or to change the battery type in use), see p. 23.

For disposal of batteries, see p. 34.

When the communications lead is attached, the logger is powered via USB.

Batteries can be left in the logger, but they are not then required (except when the

logger is being reset for a non-telemetry run; see p. 41).

18 Specifications and Operation DATAPAQ TP3

Page 19

Battery Life

For a given battery type, battery life is affected by the following factors.

• Operating Temperature – Essentially, the higher the ambient

temperature the battery operates in, the shorter will be the life. Batteries

that operate for a large part of the process cycle at relatively low

temperatures will have a longer life than those that operate for the majority

of the process cycle at the maximum operating temperature.

• Sample Interval – The shorter the sample interval, the shorter will be the

battery life. This is because power is being consumed each time the logger

takes a reading. A short sample interval will achieve the maximum amount of

information, but this must be balanced against the greater battery charge

required.

• Bluetooth – Bluetooth communication causes extra battery drain, and

should be turned off (see p. 31) if not used.

• Operating with Radio Telemetry – Sending data to a receiver outside

the oven, furnace or kiln requires more power than that needed simply to

read and store the data.

Given the factors that can affect the life of a battery it is obviously difficult to

predict accurately. The LEDs on the logger will give the best indication of when

the battery is low. In the user’s own conditions, experience will quickly indicate

typical battery life, and a log should be kept for the first few runs, noting sample

interval and whether radio telemetry was used.

See the sections below on specific battery types for guideline battery-life data.

The Logger Reset dialog (p. 42) shows actual battery use: the time since

the battery was last charged or last changed.

Charge Level of Batteries

When the battery’s charge drops to 20% of the full level, this will be shown by

the logger LEDs (p. 15) .

For NiMH and alkaline batteries only... When connected to the PC, the

Insight software shows the logger’s battery-charge level as a percentage of full

charge, as follows:

• In the main Logger Reset dialog (p. 41).

• When using wizards which reset the logger.

• During communications setup (p. 40).

• When using the Real Time Tool dialog during Bluetooth telemetry (p. 32)

or during use of the optional TM21 radio-telemetry system.

DATAPAQ TP3 Specifications and Operation 19

Page 20

For alkaline batteries, the battery-charge level displayed by Insight will be valid

only if Duracell or other quality batteries are fitted. Using inferior batteries may

cause misleading percentages to be shown.

Battery Voltage

The logger records the battery voltage during a profile run. This is then

downloaded to be stored in the paqfile and can be displayed on screen alongside

the temperature profile. See p. 53.

Auto Power-off

To save battery life, the logger will power-off automatically in the following

situations.

• The communications lead is unplugged when the logger does not contain

data which has not been downloaded (e.g. after a data-download) and the

logger has not been reset.

• The PC is powered down while the logger is connected to it.

• The logger contains data from a previous run which has not been

downloaded (the logger-status red LED will be flashing every 5 seconds), and

has been in this state for 5 minutes (or for 30 mins if Bluetooth is turned on;

see p. 29). Note that:

○ The power-off will not cause this data to be lost.

○ The data will continue to be marked as ‘not yet downloaded’, reducing

the chance of it being accidentally deleted later.

• The logger-status LEDs have been indicating an error (red LED will be

flashing every second) for 5 minutes.

• The logger has Bluetooth turned on but there has been no Bluetooth

communication for 30 minutes.

When the communications lead is attached, the logger is powered via USB (see

p. 18) and will not automatically power-off.

The logger will automatically power-up in the following situations.

• The communications lead (connected to a powered PC) is plugged in. The

logger is then ready to communicate with the PC.

• The start button is pressed. The logger will then resume the mode that it

was in when it powered-off, e.g. not-yet-downloaded data will continue to

be protected from accidental deletion.

20 Specifications and Operation DATAPAQ TP3

Page 21

NiMH Rechargeable Batteries

The logger can use a pack of four rechargeable 1.2 V nickel-metal-hydride

(NiMH) cells. These are suitable for applications where the logger’s operating

temperature (i.e. the temperature of the logger itself) does not exceed

70°C/158° F. Only Datapaq battery-packs are suitable.

For the service life and replacement of the battery, see p. 22.

Life of NiMH Batteries

The data below can serve as a guide – though the values given are no more than

an indication of the battery life that can be expected. See p. 19 for general

considerations that affect actual battery life.

No. of

Channels

10 3 25°C/77°F – –

10 3 70°C /158°F – 150

10 60 25°C/77°F 280 –

10 60 70°C /158°F 200 –

10 180 25°C/77°F – –

10 180 70°C /158°F – 240

20 3 25°C/77°F – –

20 3 70°C/158° F – 110

20 60 25°C/77°F 200 –

20 60 70°C/158° F 150 –

20 18 0 25°C/77°F – –

20 18 0 70°C/158° F – 160

Sample

Interval

(sec.)

Logger

Temperature

Battery Life (hrs)

No Radio

Telemetry

Radio

Telemetry Used

Charging NiMH Batteries

Recharge the battery as follows.

1. Plug the charger into the electricity supply.

2. Plug the charger lead into the charging socket on the logger.

A full charge is typically delivered in less than 2 hours, maximum about 3 hours.

Indication of battery/charging status is provided by colored LEDs on the logger

(see p. 15).

The charger must not be used if the ambient temperature is below 10°C/50°F

or over 40°C/104°F.

DATAPAQ TP3 Specifications and Operation 21

Page 22

The logger intelligently monitors the battery, ensuring it is never overcharged.

Thus, by leaving the charger connected to the logger, the logger will always be on

charge and ready for use. This will not damage the battery or reduce its service life.

Note that the logger will not charge while collecting data. The charger can be

connected to the logger while logging, but charging will stop as soon as data-

collection starts.

New batteries – or ones which have been unused for several months – should

be charged for 24 hours before use.

NiMH batteries discharge slowly even when not in use and will need

charging if left for more than three weeks.

WARNING

If the logger is not in regular use, the battery should be charged at least

every 3 months. If this is not done, the battery may drain to a level where it

cannot successfully be recharged.

Where batteries are too cold (below 0°C/32°F), too hot (over 45°C/113°F) or

too deeply discharged, they must be preconditioned before fast charging can

begin. Pre-conditioning (slow charging) occurs automatically if it is required, and

is shown by the battery status LEDs (steady yellow + flashing red). If the battery

is still being pre-conditioned after 5 hours, there may be a fault; contact Fluke

Process Instruments.

Replacing NiMH Batteries

WARNING

Use only the correct Datapaq battery-pack. Using unapproved batteries can lead to

battery-leakage producing toxic fumes and causing respiratory irritation and

chemical skin burns. Never use a damaged battery-pack (e.g. with split in

heatshrink covering, wires detached, etc.).

Keep battery-packs clean and dry. Clean dirty connectors with a dry, clean cloth.

Do not disassemble or crush battery-packs.

Do not put battery-packs near heat or fire, nor in sunlight.

The logger employs non-volatile memory, so – even when the battery is

removed and replaced – stored data will not be lost.

Service life of the rechargeable NiMH battery is up to about 500 charge/

discharge cycles.

22 Specifications and Operation DATAPAQ TP3

Page 23

The battery-pack is easily replaced by the user, as follows.

1. Ensure the logger is powered off: press green and red buttons together,

and hold for 5 seconds.

2. On the side of the logger, remove the single screw securing the battery-

compartment door. See photo, p. 11.

3. Carefully squeeze the metal clips

on the side of the battery-pack

connector and pull the two

halves of the connector apart

(A, see photo).

4. Turn the logger to let the old

battery-pack slide out of its

housing, and dispose of the pack

appropriately (see p. 34).

WARNING

Do not pull or hold battery-packs (whether old or new) by their connector wires.

Only Datapaq NiMH battery-packs are suitable.

5. Connect the new battery-pack and slide it into the battery housing. Take

care not to damage the connector wires nor to leave any debris in the

battery compartment as this could cause malfunction.

6. Position the wires so that the connector lies flat on the end of the

battery-pack (A).

7. Secure the battery-compartment door with its screw.

8. Charge for 24 hours before first use (see p. 21).

A

To remove the battery housing (in order to replace with a new one or to

change the battery type in use), proceed as follows.

1. Open the battery-compartment door and remove the battery-pack, as above.

2. Pull out the battery housing.

3. Insert the new battery housing with its label towards the front face of

the logger, ensuring the internal connector has engaged.

4. Fit the battery-pack and secure the battery-compartment door as described

above.

Alkaline Batteries

If the correct battery housing is fitted (see p. 17), the logger can use four

alkaline AA 1.5 V. cells. Fluke Process Instruments recommends the use of

Duracell or other quality batteries. These are suitable for applications where

DATAPAQ TP3 Specifications and Operation 23

Page 24

the logger’s operating temperature (i.e. the temperature of the logger itself)

does not exceed 55°C/131°F.

For alkaline batteries, the battery-charge level displayed by Insight (p. 19) will

be valid only if Duracell or other quality batteries are fitted. Using inferior batteries

may cause misleading percentages to be shown.

Life of Alkaline Batteries

The data below can serve as a guide – though the values given are no more than

an indication of the battery life that can be expected. See p. 19 for general

considerations that affect actual battery life.

No. of

Channels

10 3 25°C/77°F – –

10 3 70°C /158°F – 150

10 60 25°C/77°F – –

10 60 70°C /158°F 450 –

20 3 25°C/77°F – –

20 3 70°C /158°F – 210

20 60 25°C/77°F – –

20 60 70°C /158°F 370 –

20 180 25°C/77°F – –

20 180 70 °C /158 °F – 420

Sample

Interval

(sec.)

Logger

Temperature

Battery Life (hrs)

No Radio

Telemetry

Radio

Telemetry Used

Replacing Alkaline Batteries

Carry out as follows.

1. Ensure the logger is powered off: press green and red buttons together,

and hold for 5 seconds.

2. On the side of the logger, remove the single screw securing the battery-

compartment door. See photo, p. 11.

3. Turn the logger to let the old batteries slide out of the housing, one at a

time, and dispose of them appropriately (see p. 34).

4. Slide new batteries into the housing, one at a time, observing polarity.

Check that you are using the correct battery type for the battery housing

fitted. If in doubt, remove the housing (see p. 23) and check the label on it.

24 Specifications and Operation DATAPAQ TP3

Page 25

5. Secure the battery-compartment door with its screw.

To remove the battery housing from the logger (in order to replace with a

new one or to change the battery type in use), see p. 23.

Lithium Batteries

For high-temperature applications, if the correct battery housing is fitted (see

p. 17), the logger can use four lithium thionyl chloride non-rechargeable AA

3.6 V cells. These are suitable for applications where the logger’s operating

temperature (i.e. the temperature of the logger itself) does not exceed

110°C/230°F.

WARNING

Only lithium batteries supplied by Datapaq, BP0021, are suitable for use with the

TP3 logger.

Life of Lithium Batteries

The data below can serve as a guide – though the values given are no more than

an indication of the battery life that can be expected. See p. 19 for general

considerations that affect actual battery life.

No. of

Channels

10 3 25°C/77°F – –

10 3 10 0 °C/212°F – 370

10 60 25°C/77°F – –

10 60 10 0 °C/212°F 500 –

10 18 0 25°C/77°F – –

10 18 0 100 °C/212° F – 480

20 3 25°C/77°F – –

20 3 100 °C/212° F – 200

20 60 25°C/77°F – –

20 60 100 °C/212° F 500 –

20 180 25°C/77°F – –

20 180 100°C/212° F – 500

DATAPAQ TP3 Specifications and Operation 25

Sample

Interval

(sec.)

Logger

Temperature

Battery Life (hrs)

No Radio

Telemetry

Radio

Telemetry Used

Page 26

Replacing Lithium Batteries

When the logger ceases to operate due to exhausted batteries, they should be

immediately removed and disposed of.

WARNING

Lithium batteries – Fire, explosion and severe burn hazard

Lithium batteries are potentially dangerous and require great care in handling

and storage. You must read the section ‘Handling Lithium Batteries’ (below) and

the Safety Data Sheet supplied with the batteries.

Remove and replace the batteries as follows.

1. Select a clean, dry, non-conductive work surface; do not use a metallic

surface or anti-static matting. Take off any conductive jewellery and put it

out of the way. Wear eye protection.

2. Ensure the logger is powered off: press green and red buttons together,

and hold for 5 seconds.

3. On the side of the logger, remove the single screw securing the battery-

compartment door. See photo, p. 11.

4. Turn the logger to let the old batteries slide out of the housing, one at a time.

Ensure that the battery terminals cannot be short-circuited in any way – to each

other, to the logger or to any tools. There is risk of explosion.

5. Place each battery separately on the work surface, maintaining good

separation between them. Mark the work surface area into which they are

placed, in order to identify them as the old batteries. Ensure the battery

compartment is clean and dry, and carefully wipe the battery contacts with a

dry lint-free cloth or tissue with attention to the contact area. Do not bend

or distort the contacts.

6. Remove the new batteries from their protective UN-compliant packaging,

and retain this for later use.

7. Carefully install each new battery, one at a time, into the battery housing.

Check that you are using the correct battery type for the battery housing

fitted. If in doubt, remove the housing (see p. 23) and check the label on it.

Observe the polarity of the batteries and of the contacts within the

battery compartment.

Ensure that the battery terminals cannot be short-circuited in any way – to each

other, to the logger or to any tools. There is risk of explosion.

26 Specifications and Operation DATAPAQ TP3

Page 27

Always replace all of the batteries at the same time.

Never use batteries other than those supplied by Datapaq.

Do not mix different types of Datapaq battery, nor batteries of any other type;

this could lead to an explosion.

8. Carefully place the old batteries one at a time into the empty packaging. Do not

allow them to be short-circuited. See below for disposal of lithium batteries.

9. Re-check that batteries are installed with correct polarity, then secure the

battery-compartment door with its screw.

10. Datapaq batteries must be depassivated before they are used for the first

time. This takes place automatically after placing them in the logger, as

follows.

a. Yellow LED produces two rapid flashes every second.

b. After 20 minutes, yellow LED stops flashing.

c. Logger is ready for use.

To remove the battery housing from the logger (in order to replace with a

new one or to change the battery type in use), see p. 23.

Handling Lithium Batteries

WARNING

Lithium batteries – Fire, explosion and severe burn hazard

Lithium batteries are potentially dangerous and require great care in handling

and storage.

Do not short-circuit • Do not attempt to recharge •

•

Do not reverse-connect • Do not open batteries •

•

Do not expose battery contents to water •

•

Do not solder anything to the battery • Do not incinerate •

•

Do not mix cells • Do not leave discharged cells in the logger •

•

These instructions must be carefully read in full, and understood, by any person

likely to handle, replace or dispose of lithium thionyl chloride batteries.

Do not open, crush or deform the battery cells. If the lithium metal within the

cell is exposed to the air and moisture, an explosion or fire may result. The

contents are flammable, corrosive and extremely irritating to the lungs and

respiratory system. Lithium metal and thionyl chloride cause chemical burns on

contact with skin.

The Datapaq inorganic lithium thionyl chloride batteries will, when used

correctly, provide a safe and dependable source of power. They represent the

only current battery technology that can meet the demands of high-temperature

operation. Unlike more conventional batteries, lithium cells contain flammable

materials, and consequently safety precautions must be taken during transport,

DATAPAQ TP3 Specifications and Operation 27

Page 28

storage, handling and disposal. If lithium batteries are mistreated there is a risk

of leakage of the flammable contents or an explosion resulting in a fire.

Each battery is marked as follows:

Warning : Fire, explosion, and severe burn hazard.

Do not recharge, disassemble, heat above 150°C , incinerate or expose contents

to water.

To meet the requirements of the Control of Substances Hazardous to Health

Regulations 2002 (COSHH), each battery consignment includes a Safety Data

Sheet. Any person likely to handle, replace or dispose of lithium thionyl chloride

batteries must be made aware of this data sheet. The sheet should be passed to

your Health and Safety officer for future reference; extra copies are available

from Fluke Process Instruments. The sheet contains details of first-aid and

firefighting procedures.

Transport, and Storage Before Use

Due to the flammable content, lithium thionyl chloride batteries are classified as

Dangerous Goods under UN transport regulations. The packaging used to

supply the cells is UN-compliant and is labeled accordingly. The batteries must

be transported only within this packaging.

Packages containing lithium batteries should be handled with care. Rough

handling may result in batteries becoming damaged which may cause leakage,

explosion or fire.

On receipt do not remove the lithium batteries from their UN-compliant

packaging. Store the batteries within their original packaging until required.

The lithium batteries should be stored apart from all other flammable materials.

The storage area should be cool, dry, ventilated and weatherproof. Temperatures generally should be below 35°C/95°F. Do not store next to radiators or

boilers or in direct sunlight. Avoid storage temperatures above 75°C/167°F.

Disposal of Used Lithium Batteries

The used batteries should be disposed of as soon as possible. Even though no

longer capable of powering the logger, the batteries remain flammable and have

sufficient energy to cause a fire or to explode if short-circuited. The

UN-compliant packaging should thus be used to store the used batteries after

removal from the logger and at disposal. Under the European Union Batteries

and Accumulators Directive, the used batteries which are removed from the

logger by the user should be disposed of at an appropriate recycling center. Do

not dispose of in fire and do not incinerate. Datapaq BP0021 lithium

batteries do not contain mercury, cadmium or any other heavy metal or other

hazardous material according to EU Directives 91/157/EEC and 93/86/EEC.

28 Specifications and Operation DATAPAQ TP3

Page 29

Analog Inputs

In addition to storing data from thermocouple input, the TP3 can be specified to

support the recording of current and/or voltage data to allow other types of

sensor to be used. For measurement ranges and accuracy, see p. 13.

Such analog input is made via one or more of the logger’s numbered sockets

(when fitted, colored white), relevant channel numbers being shown on a label

on the rear of the logger. For each analog input on the logger, a white plug is

provided for connection to the chosen sensor device.

WARNING

Incorrect connection to the current and/or voltage sockets may cause serious

damage to the logger. Always check the label carefully to ensure that input cables

are connected to the correct channels.

Data from the analog-input channels is displayed by Insight as a custom unit on

the right-hand axis of the graph window. To set up custom units in Insight,

select Tools > Options > Units, and click Help for a full explanation.

Analogue inputs support the same sample intervals as thermocouples (see p. 13).

Analog inputs can be calibrated by Fluke Process Instruments, and this generates a

separate calibration certificate from that produced by calibrating thermocouple

inputs (see p. 33). Unlike thermocouple inputs, however, the logger does not

store the results of analog-input calibration, and thus: a calibration certif icate

cannot be printed by the user; a logger correction factor f ile for analog inputs

cannot be produced.

Bluetooth Communications

Bluetooth communication is not available in all countries.

Where unavailable, Bluetooth options in Insight will be greyed out.

As an alternative to using its communications lead, the logger can use Bluetooth

to communicate with the PC. This can be used for:

• Resetting the logger (p. 41).

• Downloading data from the logger to the PC (p. 48).

• Short-range wireless telemetry (see below).

• Downloading diagnostic information for troubleshooting (see p. 64).

DATAPAQ TP3 Specifications and Operation 29

Page 30

The reliable transmission range will vary but will typically not exceed 5 m, and

reception will not normally be possible from a logger inside a thermal barrier.

Bluetooth communication will not operate if the logger’s temperature is

above 85°C/185°F.

The logger will power-off automatically if Bluetooth is turned on (see below) but

there has been no Bluetooth communication for 30 minutes.

Bluetooth communication causes extra battery drain, and should be turned off (see

p. 31) if not used.

The TP3 logger is configured by default to be ready to use Bluetooth

communication. All that is necessary (as with any Bluetooth device) is to pair it

with the PC with which it will communicate. Thereafter, the operations listed

above can be performed without connecting the communications lead between

logger and PC. If Bluetooth is turned on but the communications lead is

connected, the lead (not Bluetooth) will be used preferentially.

Pairing

The logger and PC must be paired as two Bluetooth devices before

communication can take place between them. For PCs without built-in

Bluetooth support, it will be necessary to fit a Bluetooth adapter (dongle) to a

spare USB port; if using the adapter for the first time, follow its driverinstallation procedure.

Most available Bluetooth adapters are suitable – but NB that the adapter must be

Bluetooth ‘Classic’; adapters which are ‘low energy’, ‘LE’ or ‘Smart’ only (and are

not Classic) are not suitable.

Ensure that the logger is not connected to the PC with the communications lead, then

proceed as follows (details may vary, depending on the Windows version in use).

1. Ensure that Bluetooth is enabled on your PC by checking for the icon in

your Windows system tray (notification area), usually at the bottom right of

your Windows desktop: right-click it, and select ‘Open Settings’ to open the

Bluetooth Settings dialog. Ensure the following settings:

○ Uncheck ‘Allow Bluetooth devices to find this computer’ (if you wish to

prevent unauthorized connection to your PC).

○ Check ‘Allow Bluetooth devices to connect to this computer’.

Click ‘OK’ to close the dialog.

2. In Insight, select Logger > Setup to display the Communications Setup dialog

(see p. 40). Click ’Detect’, and wait until Insight recognizes and lists

suitable nearby loggers. (Loggers shown in red are those previously used

30 Specifications and Operation DATAPAQ TP3

Page 31

and/or too far away. To remove such a logger from the list, right-click on its

name and click Remove on the popup.)

3. Select the name of the logger in the ‘Bluetooth’ section of the dialog, click

the ‘Test’ button in the ‘Logger’ section, and the logger name will be

displayed there to confirm that communication is possible with that logger.

Clicking the ‘Diagnostic’ button should expand the dialog to show current

probe information and other data (p. 40).

4. Click ‘OK’ to close the dialog.

The logger and PC are now paired and ready to communicate.

Troubleshooting

In case of problems with establishing Bluetooth communication, try the following.

• Move the logger closer to, or further away from, the PC. If the logger’s

name is shown in red in the Communications Setup dialog, the logger is too

far away.

• If using a Bluetooth adapter, unplug and re-insert it.

• Unplug any devices attached to USB 3 ports (active USB 3 ports can

interfere with Bluetooth).

• Restart the logger (see p. 61).

More Than One Logger

When Bluetooth communication is initiated (e.g. by starting a logger reset), and

more than one Datapaq Bluetooth logger is present, Insight will display the

Select Logger dialog with a list of available loggers and their serial numbers.

Select the chosen logger and then click ‘OK’; clicking ‘Cancel’ will cancel

communication.

Turning Bluetooth On and Off

By default, as soon as pairing has been achieved (see above), Bluetooth is turned

on in the logger, but, under the following conditions, it will automatically be

turned off:

• When the logger and PC are connected by communications lead. Thus will

be turned off when hardwired telemetry (p. 55) is in use.

• When the logger is collecting data and storing it in memory.

• When radio-telemetry is in use.

When the logger is able to receive Bluetooth communication, each of the four

LEDs will flash once in horizontal sequence, repeating every 20 seconds.

DATAPAQ TP3 Specifications and Operation 31

Page 32

Bluetooth communication causes extra battery drain, and should be turned off,

as follows, if not used.

1. Ensure the logger is connected to the PC using the communications lead.

Logger and PC must be connected by the communications lead in order

to turn Bluetooth either on or off.

2. In Insight, select Logger > Setup to display the Communications Setup dialog.

3. Click ‘Test’, The logger name will be displayed and the ‘Bluetooth’ button

will be enabled.

4. Click ‘Bluetooth’ to display the Bluetooth Setup dialog.

5. A message below the ‘Check Status’ button will show whether Bluetooth is

currently enabled or disabled (turned on or off) – or whether the logger and

PC are not connected by cable. Click the button if necessary.

6. Click ‘Enable Bluetooth’ (to turn on) or ‘Disable Bluetooth’ (to turn off) as

required, and a message will confirm the change.

Bluetooth Telemetry

Temperature-profile data gathered by the logger can be passed directly to the

PC, in real time, by using Bluetooth communications. Because good Bluetooth

reception cannot usually be achieved with a logger inside a thermal barrier (see

p. 30), the logger will normally be outside the thermal process, with

thermocouples trailing from the oven/furnace/kiln to the logger. The process of

running a profile is thus as for hardwired telemetry (p. 55) – and the major

benefit of Bluetooth telemetry is to isolate the logger from the PC and thereby

avoid earth-loop problems.

The procedure follows that used for hardwired telemetry (see p. 55) except that:

• Logger reset (p. 41) must be carried out using Bluetooth (i.e. do not

connect the logger to the PC using the communications lead). The

‘Bluetooth Telemetry’ option is then available to be selected in the Logger

Reset dialog.

• While a run is in progress, you may use the Real Time Tool dialog to

check the integrity of data-packets as they are received, as well as the status

of the logger (click on the toolbar, or select View > Real Time Tool).

Data can be collected from only one logger at a time. If more than one logger is

present and gathering data, choose which logger’s data to gather and display in

real time by selecting Logger > Logger Listen Mode; this displays the Select

Logger dialog (see p. 31).

Wireless telemetry over greater ranges, and/or involving use of a thermal

barrier, will require the TM21 radio-telemetry system (available separately).

32 Specifications and Operation DATAPAQ TP3

Page 33

Over-temperature Protection

The logger and the Insight software work together to reduce the likelihood of

damage occurring due to the logger’s internal temperature being too high. (For the

logger’s operating-temperature range, see p. 13.)

• Insight can be instructed to show a warning message if a reset is

attempted (p. 41), or to prevent a reset, while the logger is above a

specified temperature (default 45ºC/113ºF); see p. 53.

• If logging is started without resetting the logger using Insight (i.e. by simply

pressing the start button and thus using the previous reset options; see

p. 47), the logger will not start logging if its internal temperature is above

45ºC/113ºF. The logger-status red LED will show 2 quick flashes every second.

• If the logger’s internal temperature exceeds 75ºC/167ºF (when fitted with

NiMH or alkaline battery) or 115ºC/239ºF (when fitted with lithium battery),

it shuts down, preserving data already collected. When the data is

downloaded, Insight will give a warning that this has happened.

The logger records its internal temperature during a profile run. For access to this

data, see p. 53.

To check the logger’s current internal temperature when connected to a PC running

Insight, select Logger > Setup and click ‘Diagnostic’ (p. 39). The temperature is

also displayed in the Reset dialog (p. 41).

Testing and Calibration

It is recommended that the logger is tested and calibrated by Fluke Process

Instruments at least once a year. The calibration procedure comprises:

• Inspection of the logger, externally and internally.

• Battery- and charge-testing.

• Heat-cycle test of up to 14 hours in the ovens of Fluke Process Instruments.

• Stability testing, using a stable temperature source and varying ambient

temperatures.

• Calibration and updating of the logger’s firmware.

• Issue of certificate, which can be traced back to UKAS or NIST calibration

standards.

To calibrate your logger, please return it to the Service Department at Fluke

Process Instruments (see p. 63).

For full certification and traceability, calibration data is stored in each logger for

instant access by Fluke Process Instruments engineers. To print a calibration

certi ficate for a logger, in Insight select File > Print Calibration Certificate (NB not

available with all Insight products), and then choose whether to print a certificate for:

DATAPAQ TP3 Specifications and Operation 33

Page 34

• The logger which was used to create the currently displayed paqfile

(temperature profile). or

• The logger (if any) which is currently connected to the PC.

For maximum accuracy, Insight can use the logger’s calibration data to create a

logger correction factor file which can be applied to downloaded

temperature-profile data (NB not available with all Insight products). The file may

be created from calibration data which is:

• Entered manually, or

• Contained in the logger, or

• Contained in a paqfile.

To create a logger correction factor file, run the Logger Correction Factor

Wizard (select File > New > Logger Correction Factors). To be prompted to

apply a correction factor file whenever data is downloaded, select Tools >

Options > Logger, and check ‘Prompt for correction factors when downloading’.

Even without creating a logger correction factor file, the logger can be set to

apply logger correction to collected data automatically every time data is

downloaded. Connect the logger to the PC, and in Insight select Tools >

Options > Logger, and check ‘Automatically apply logger correction when

downloading’. (NB not available with all Insight products.)

For a full description of logger correction factors, see ‘Correction Factors’ in Insight’s

Help system.

To carry out your own basic testing of the operation of the logger and its

thermocouples, see p. 62.

Disposal of Batteries and Loggers

Always adhere to the applicable statutory regulations for recycling and waste

disposal. For details of recycling Fluke Process Instruments products within the

European Union, see www.fluke.com.

Under the European Union Batteries and Accumulators Directive,

used alkaline and lithium batteries which are removed from the

logger by the user should be disposed of at an appropriate recycling

center. For additional information on handling and disposing of lithium

batteries, see p. 27.

Under the European Union WEEE Directive, users should return all

NiMH batteries and all loggers (whether or not containing

batteries) to Fluke Process Instruments for disposal at the end of their

useful life.

34 Specifications and Operation DATAPAQ TP3

Page 35

Restrictions on Use

The following general considerations apply to use of the logger

and its associated equipment. For reasons of health and safety,

and to avoid harm or damage to the logger, to other equipment

and to the environment, always observe the following

restrictions and cautions.

For the logger’s specifications, see p. 11.

• The logger is not approved for use in potentially-explosive

atmospheres as defined by the EU ATEX directives. Do not use the

logger in such atmospheres: there is risk of major injury or death.

• It is essential to use the logger with the correct Datapaq thermal

barrier for your individual process, as supplied and approved by Fluke

Process Instruments. Failure to use the appropriate approved barrier, or

use in an unapproved manner (e.g. using above the specified temperature,

or for longer than the specified time, or with insufficient opportunity for

adequate cooling between profile runs), can cause catastrophic damage to

the data logger or to other equipment, and can endanger health, or may

lead to major injury or death. In particular, exceeding the logger’s

specified temperature range for any length of time may cause battery-

leakage producing toxic fumes and leading to respiratory irritation and

chemical skin burns. For the same reasons, never use a damaged thermal

barrier.

• Ensure that all dimensions of your logger/barrier/accessory assembly are

such that it will fit comfortably within the oven through all stages of

the process. Pay particular attention to handles, catches, etc., and to

trailing thermocouples. Failure to do this can cause the assembly to jam in

the oven with consequent overheating and potentially-severe damage to

the equipment. Resultant battery-leakage, and the process of recovering

the equipment, may cause skin burns and respiratory irritation.

• Batteries:

○ If using rechargeable batteries (see p. 17), use only the Datapaq

mains battery charger supplied with your logger. Using a charger

which is not approved by Fluke Process Instruments for use with

your logger could cause major injury or death.

○ Do not charge the battery in a wet environment, e.g. outside. This

could cause major injury or death.

○ Always use the correct Datapaq batteries (see p. 17). Using with

unapproved batteries may cause battery-leakage producing toxic

fumes and leading to respiratory irritation and chemical skin burns.

Never use a damaged battery-pack (e.g. with split in heatshrink

covering, wires detached, etc.).

cont. >>

DATAPAQ TP3 Specifications and Operation 35

Page 36

○ First plug the battery charger into the mains, i.e. before

connecting the logger.

○ Charge batteries only within temperature range 5 – 45 ° C / 41–113 ° F

(mains charger) or 0–85°C/32–185°F (PC’s USB port).

○ Keep battery-packs clean and dry. Clean dirty connectors with a dry,

clean cloth.

○ Do not disassemble or crush battery-packs.

○ Do not put battery-packs near heat or fire, nor in sunlight.

○ If not used for an extended period, remove battery-pack from logger

to prevent battery-leakage and resultant damage.

• Do not use the logger, or other Datapaq equipment, in humid/wet

process environments or corrosive atmospheres unless specifically

approved for such use by Fluke Process Instruments. Damage to the

equipment may result.

• Never connect thermocouples to mains electricity, nor allow

thermocouples to touch an oven’s heating elements. This could cause

major injury or death.

• Take care when handling thermocouple cables to avoid accidental damage

to the eyes by sharp thermocouple-tips.

• Use PTFE thermocouples only within their approved temperature

range. Use at higher temperatures produces irritant toxic fumes. See the

dedicated User Manual for your Datapaq Tracker system.

• Never carry the logger by holding the attached communications

lead or thermocouples. This can lead to injury by dropping the logger

onto your body, and may damage the lead, thermocouples or sockets.

• On removal from the oven, the thermal barrier and logger will be

hot enough to burn skin – even though their temperature will not be

apparent. Use protective gloves.

• Do not remove the logger from the thermal barrier by tipping it out of

the barrier. This can lead to injury by dropping the logger onto your

body, and may damage the logger.

• The user must on no account attempt any disassembly or repair

of the logger (other than to replace batteries, p. 17). Any such attempt

risks battery-leakage and may cause skin burns and respiratory irritation,

and will invalidate any existing warranty or service agreement with Fluke

Process Instruments. For information on the Datapaq Service

Department, see p. 63.

36 Specifications and Operation DATAPAQ TP3

Page 37

Using the Logger with

Insight Software

See your dedicated Datapaq Tracker system manual for full details on:

• Choosing appropriate thermal barriers and thermocouple probes.

• Installing the logger into the barrier.

• Conducting a temperature-profile run of your process.

Before the logger is used for the first time, you must:

1. Install Insight software (see below).

2. Establish communication between the logger and the computer/software

(p. 39).

Before each profile run, you will:

3. Reset the logger to prepare it to receive fresh data (p. 41).

After the logger/barrier assembly is recovered from the oven /furnace/kiln, you

will then:

4. Download the data from the logger (p. 48).

These stages are described below.

Installing/Removing Insight

Datapaq Insight used with the TP3 logger requires the following minimum

computer specification.

• 1 GHz processor.

• 2 Gb RAM.

• Monitor resolution 1024 × 768, 256 colors.

• 100 Mb free hard disk space.

• DVD drive.

• 1 free USB port.

• Microsoft Windows™ Vista (32-bit only), 7, 8, 10 or above.

• Microsoft Internet Explorer 4 or above.

The TP3 logger operates only with Datapaq Insight v.8.0 and above.

DATAPAQ TP3 Using Insight Software 37

Page 38

Installation

Ensure you are logged into Windows in Administrator mode.

For most systems, installation will start automatically on placing the Insight DVD

in the drive. (If installation does not start, click the Windows Start button and

select Run; browse to your DVD drive, and run Setup.exe.) As part of the

installation, you can choose PDFs of Datapaq user documentation to be copied

to your PC for rapid on-demand viewing through Insight.

Follow the on-screen instructions. You will need your license number to hand,

which is to be found on:

• Your license agreement.

• The outside of the DVD case.

• The outside of the system packaging.

Insight’s link with the logger must also be made while Windows is in Administrator mode, and it is thus best to do this now, as part of the Insight installation:

connect the logger to the PC and follow the procedure under ‘Communications

Setup’ (below). Once this has been done, an operator will be able to use Insight

with the logger connected to the PC without being in Administrator mode.

Upgrading

It is not necessary to remove an existing version of the software before

installing a new one. Settings and data files used with the current installation will

be maintained.

Removal

Use the standard procedure for your Windows version, e.g.

• In Windows 7 – Start button > Control Panel > Programs and Features, and

double-click Datapaq Insight.

• In Windows 10 – Start button > Settings > System > Apps & features, and

click Datapaq Insight.

Help System

Full details on using the Insight software are contained entirely within its online

Help system: access this by clicking Help, and then Contents, on Insight’s main

menu. Then, within Help, click on Contents headings and topics to expand and

read them.

38 Using Insight Software DATAPAQ TP3

Page 39

You may also click the Help button in any dialog – or press the F1 key – to bring

up help information relevant to the task being performed.

Communications Setup

After Insight has been installed, it is necessary to establish communication

between the data logger and the PC, as follows.

By default, only one logger at a time can be connected to the PC and it is not

possible to connect simultaneously more than one logger to different USB ports on

the PC and then to choose which logger to use (but see p. 58 for use of

multiple loggers). (Bluetooth communication does permit switching between multiple

loggers; see p. 31.)