Page 1

DALE601/601E

Electrical Safety Analyzer

Operators Manual

PN 2243573

May 2008, Rev. 1

© 2008 Fluke Corporation, All rights reserved. Printed in USA. Specifications subject to change without notice.

All product names are trademarks of their respective companies.

Page 2

Warranty and Product Support

Fluke Biomedical warrants this instrument against defects in materials and

workmanship for one year from the date of original purchase. During the warranty period, we will repair or at our option replace, at no charge, a product

that proves to be defective, provided you return the product, shipping prepaid,

to Fluke Biomedical. This warranty covers the original purchaser only and is

not transferable. The warranty does not apply if the product has been damaged

by accident or misuse or has been serviced or modified by anyone other than

an authorized Fluke Biomedical service facility. NO OTHER WARRANTIES,

SUCH AS FITNESS FOR A PARTICULAR PURPOSE, ARE EXPRESSED

OR IMPLIED. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

This warranty covers only serialized products and their accessory items that

bear a distinct serial number tag. Recalibration of instruments is not covered

under the warranty

This warranty gives you specific legal rights and you may also have other

rights that vary in different jurisdictions. Since some jurisdictions do not allow

the exclusion or limitation of an implied warranty or of incidental or consequential damages, this limitation of liability may not apply to you. If any provision of this warranty is held invalid or unenforceable by a court or other decision-maker of competent jurisdiction, such holding will not affect the validity

or enforceability of any other provision.

07/07

Page 3

Notices

All Rights Reserved

© Copyright 2007, Fluke Biomedical. No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language without the written

permission of Fluke Biomedical.

Copyright Release

Fluke Biomedical agrees to a limited copyright release that allows you to reproduce manuals and

other printed materials for use in service training programs and other technical publications. If

you would like other reproductions or distributions, submit a written request to Fluke Biomedical.

Unpacking and Inspection

Follow standard receiving practices upon receipt of the instrument. Check the shipping carton for

damage. If damage is found, stop unpacking the instrument. Notify the carrier and ask for an

agent to be present while the instrument is unpacked. There are no special unpacking instructions,

but be careful not to damage the instrument when unpacking it. Inspect the instrument for physical damage such as bent or broken parts, dents, or scratches.

Technical Support

For application support or answers to technical questions, either email

techservices@flukebiomedical.com

1-425-446-6945.

Claims

Our routine method of shipment is via common carrier, FOB origin. Upon delivery, if physical

damage is found, retain all packing materials in their original condition and contact the carrier

immediately to file a claim. If the instrument is delivered in good physical condition but does not

operate within specifications, or if there are any other problems not caused by shipping damage,

please contact Fluke Biomedical or your local sales representative.

or call 1-800- 648-7952 or

Standard Terms and Conditions

Refunds and Credits

Please note that only serialized products and their accessory items (i.e., products and

items bearing a distinct serial number tag) are eligible for partial refund and/or credit.

Nonserialized parts and accessory items (e.g., cables, carrying cases, auxiliary modules,

etc.) are not eligible for return or refund. Only products returned within 90 days from the date

of original purchase are eligible for refund/credit. In order to receive a partial refund/credit of a

product purchase price on a serialized product, the product must not have been damaged by the

customer or by the carrier chosen by the customer to return the goods, and the product must be

returned complete (meaning with all manuals, cables, accessories, etc.) and in “as new” and resalable condition. Products not returned within 90 days of purchase, or products which are not in

“as new” and resalable condition, are not eligible for credit return and will be returned to the customer. The Return Procedure (see below) must be followed to assure prompt refund/credit.

Restocking Charges

Products returned within 30 days of original purchase are subject to a minimum restocking fee of

15 %. Products returned in excess of 30 days after purchase, but prior to 90 days, are subject to a

minimum restocking fee of 20 %. Additional charges for damage and/or missing parts and accessories will be applied to all returns.

Page 4

Return Procedure

All items being returned (including all warranty-claim shipments) must be sent freight-prepaid to

our factory location. When you return an instrument to Fluke Biomedical, we recommend using

United Parcel Service, Federal Express, or Air Parcel Post. We also recommend that you insure

your shipment for its actual replacement cost. Fluke Biomedical will not be responsible for lost

shipments or instruments that are received in damaged condition due to improper packaging or

handling.

Use the original carton and packaging material for shipment. If they are not available, we recommend the following guide for repackaging:

Use a double-walled carton of sufficient strength for the weight being shipped.

Use heavy paper or cardboard to protect all instrument surfaces. Use nonabrasive

material around all projecting parts.

Use at least four inches of tightly packed, industry-approved, shock-absorbent

Returns for partial refund/credit:

Every product returned for refund/credit must be accompanied by a Return Material Authorization (RMA) number, obtained from our Order Entry Group at 1-800-648-7952 or 1-425-446-

6945.

Repair and calibration:

To find the nearest service center, go to www.flukebiomedical.com/service

In the U.S.A.:

Cleveland Calibration Lab

Tel: 1-800-850-4606

Email: globalcal@flukebiomedical.com

Everett Calibration Lab

Tel: 1-888-993-5853

Email: service.status@fluke.com

In Europe, Middle East, and Africa:

Eindhoven Calibration Lab

Tel: +31-402-675300

Email: ServiceDesk@fluke.com

In Asia:

Everett Calibration Lab

Tel: +425-446-6945

Email: service.international@fluke.com

material around the instrument.

, or

Certification

This instrument was thoroughly tested and inspected. It was found to meet Fluke Biomedical’s

manufacturing specifications when it was shipped from the factory. Calibration measurements

are traceable to the National Institute of Standards and Technology (NIST). Devices for which

there are no NIST calibration standards are measured against in-house performance standards using accepted test procedures.

WARNING

Unauthorized user modifications or application beyond the published specifications may

result in electrical shock hazards or improper operation. Fluke Biomedical will not be responsible for any injuries sustained due to unauthorized equipment modifications.

Page 5

Restrictions and Liabilities

Information in this document is subject to change and does not represent a commitment

by Fluke Biomedical. Changes made to the information in this document will be incorporated in new editions of the publication. No responsibility is assumed by Fluke Biomedical for the use or reliability of software or equipment that is not supplied by Fluke Biomedical, or by its affiliated dealers.

Manufacturing Location

The DALE 601/601E Electrical Safety Analyzer is manufactured in Everett, Washington

by Fluke Biomedical, 6920 Seaway Blvd., Everett, WA, U.S.A.

Page 6

Page 7

Table of Contents

Chapter Title Page

1 Introduction and Specifications.............................................. 1-1

Introduction .......................................................................................... 1-3

Simplicity.......................................................................................... 1-3

Versatility ......................................................................................... 1-4

General Safety Considerations.............................................................. 1-4

Symbols ............................................................................................ 1-4

Warnings and Cautions..................................................................... 1-5

Key Features......................................................................................... 1-6

Instrument Familiarity .......................................................................... 1-7

Specifications........................................................................................ 1-10

Accessories ........................................................................................... 1-12

2 Operation .................................................................................. 2-1

Preliminary Steps.................................................................................. 2-3

Preparing the Analyzer for Use......................................................... 2-4

Verifying the Power Outlet Connections .......................................... 2-5

Measuring Line (Mains) Voltage.......................................................... 2-6

Measuring Device Current.................................................................... 2-7

Measuring Earth Resistance.................................................................. 2-8

Measuring Leakage Current.................................................................. 2-10

Earth Leakage Current...................................................................... 2-10

Enclosure (Chassis) Leakage Current............................................... 2-11

Patient Lead Leakage Current........................................................... 2-12

Measuring Patient Auxiliary Current.................................................... 2-15

Measuring MAP (Patient Lead Isolation) Current................................ 2-16

External Measurements......................................................................... 2-18

Leakage Current................................................................................ 2-19

Electrical Isolation............................................................................ 2-20

Resistance ......................................................................................... 2-21

3 Maintenance and Service ........................................................ 3-1

Maintenance.......................................................................................... 3-3

Avoiding Damage............................................................................. 3-3

Cleaning............................................................................................ 3-3

Verifying Analyzer Performance.......................................................... 3-4

i

Page 8

DALE601/601E

Operators Manual

Service and Calibration ........................................................................ 3-6

ii

Page 9

List of Tables

Table Title Page

1-1. Symbols ................................................................................................ 1-4

1-2. Components and Controls of the Analyzer ........................................... 1-8

1-3. Standard Accessories ............................................................................ 1-12

1-4. Optional Accessories ............................................................................ 1-12

1-5. Optional Probe Adapter Cables............................................................. 1-13

2-1. Ground Resistance of a Ten-foot Power Cable ..................................... 2-8

3-1. Performance Verification Parameters ................................................... 3-4

3-2. Current Verification Parameters ........................................................... 3-5

List of Figures

Figure Title Page

1-1. Analyzer Front Panel Components and Controls .................................. 1-7

1-2. Analyzer Top Panel Components and Controls .................................... 1-8

2-1. Block Diagram of a Line-operated Instrument...................................... 2-3

iii

Page 10

DALE601/601E

Operators Manual

iv

Page 11

Chapter 1

Introduction and Specifications

Contents Page

Introduction ................................................................................. 1-3

Simplicity................................................................................. 1-3

Versatility................................................................................. 1-4

General Safety Considerations..................................................... 1-4

Symbols.................................................................................... 1-4

Warnings and Cautions ............................................................ 1-5

Key Features ................................................................................ 1-6

Instrument Familiarity ................................................................. 1-7

Specifications............................................................................... 1-10

Accessories .................................................................................. 1-12

1-1

Page 12

DALE601/601E

Operators Manual

1-2

Page 13

Introduction and Specifications

Introduction

1

Introduction

The DALE601/601E Electrical Safety Analyzer, hereafter referred to singly as

the Analyzer, is a simple, highly versatile, and portable instrument. The

Analyzer is used to evaluate the basic electrical safety of electrical systems,

medical devices, and physiological instrumentation, and a broad range of

external measurements, as listed under Key Features.

Its compact handheld size makes it an ideal addition to a toolbox, as well as

serving as a bench top instrument for the laboratory. The Analyzer does not

sacrifice functions or accuracy, and its low cost permits putting one on each

bench.

Simplicity

The Analyzer is simple to use, incorporating the following:

• A single, labeled master function switch that leads the user through a

complete specific measurement procedure

• A single range meter for each measurement that minimizes the chance of

erroneous readings

• Heavy-duty switches that change polarity, open and close the neutral, and

select chassis or earth leakage current measurements

• A single slide switch that gives the user a choice of AAMI or IEC test

load

• Five universal EKG lead connectors that allow for any type of lead

connection

• Green and amber lights that indicate five power line conditions

The Analyzer uses sophisticated electronics for true rms measurement of

current and voltage. Input impedance uses the manually selectable AAMI ES11993 or IEC601-1 test load to compensate for high frequency components in

the measurement. Resistance measurements are made with a four-wire Kelvin

bridge to eliminate errors resulting from cable length and connector resistance.

1-3

Page 14

DALE601/601E

Operators Manual

Versatility

The Analyzer has an additional unique capability to make a broad range of

external measurements, including leakage current and/or voltage gradients and

the resistance between two points. Providing the voltage and measuring

function, the Analyzer can independently measure the isolation current of a

device. Thus, the Analyzer can evaluate the electrical system; system

installation; and, separately, the isolation of probes and transducers, in addition

to conventional leakage current measurement.

General Safety Considerations

The Analyzer should be inspected and its related documentation reviewed for

familiarization with safety markings and instructions before operation.

Symbols

Table 1-1 describes the symbols used in association with the Analyzer.

Table 1-1. Symbols

Symbol Description

X Hazardous voltage

W Important information; refer to manual.

P Conforms to European Union directives

~

CAT I

Do not dispose of this product as unsorted municipal waste. Go

to Fluke’s website for recycling information.

IEC Measurement Category I – CAT I equipment designed to

protect against transients in equipment on circuits not directly

connected to MAINS. Under no circumstances should the

terminals of the Analyzer be connected to any MAINS voltage.

1-4

Page 15

Introduction and Specifications

General Safety Considerations

Warnings and Cautions

A Warning identifies hazardous conditions and actions that could cause

bodily harm or death.

A Caution identifies conditions and actions that could damage the Analyzer,

the equipment under test, or cause permanent loss of data.

XW Warning

To avoid possible electrical shock or personal injury,

follow these guidelines:

• Disconnect all patient connections before connecting

the device to be tested to the Analyzer. Continued

connection may jeopardize patient safety by possible

application of measurement currents.

• Maintain care when making connections. Isolation test

uses 120 or 230 V ac applied to patient leads or to

external connections that are accessible to the tester.

Although the voltage is current limited to 1 mA is safe

for healthy intact skin contact, it can be felt and can

result in a startle reaction.

1

• Ensure the mains installation current rating is

adequate for the DUT (device under test). If the DUT

requires 20 A, the Analyzer must be powered by a 20 A

service to avoid overloading the mains installation.

W Caution

To avoid possible damage to the Analyzer, follow these

guidelines:

• Ensure that the DUT power requirements are within the

capabilities of the Analyzer, labeled as 15 A or 20 A at

120 V ac (depending on model purchased) and 10 A at

230 V ac. While the analyzers are equipped with

receptacles limiting access to devices of higher

ratings, the replacement cord set may have been

installed incorrectly.

1-5

Page 16

DALE601/601E

Operators Manual

• This device is sensitive to electromagnetic fields. If

interference is encountered in measurements,

reconfigure the test setup or contact the manufacturer.

• Do not leave the DUT connected and drawing high load

current for extended periods. The Analyzer is not

designed for continuous measurements and may

overheat.

• Always pause in the OFF (middle) position when

switching polarity from normal to reverse. Inductive

loads of the DUT may create high voltage transients

when trying to reverse the direction of current flow

instantaneously.

Key Features

• Small, lightweight, self-contained, portable, hand-held instrument

• 120 V and 230 V operation (DALE601 and DALE601E, respectively)

• Easy to use controls with master range meter for each test

• Five (5) universal EKG lead connectors

• True rms measurement of current and voltage

• Accurate resistance measurements with 4-wire Kelvin bridge

• Manually selectable ANSI/AAMI ES1-1993 or IEC601-1 test loads

• Measures the following:

• Line (Mains) Voltage

• Device Current

• Earth Resistance

• Leakage Current: Earth, Enclosure (Chassis), Patient Lead (Leakage

Currents can be measured in Open/Closed Neutral, Normal/Reversed

Polarity and Open/Closed Ground and are displayed directly in µA.)

• Patient Auxiliary Current

• M.A.P. (Patient Lead Isolation) Current

• External Measurements: Leakage Current, Electrical Isolation,

Resistance

1-6

Page 17

Introduction and Specifications

Instrument Familiarity

1

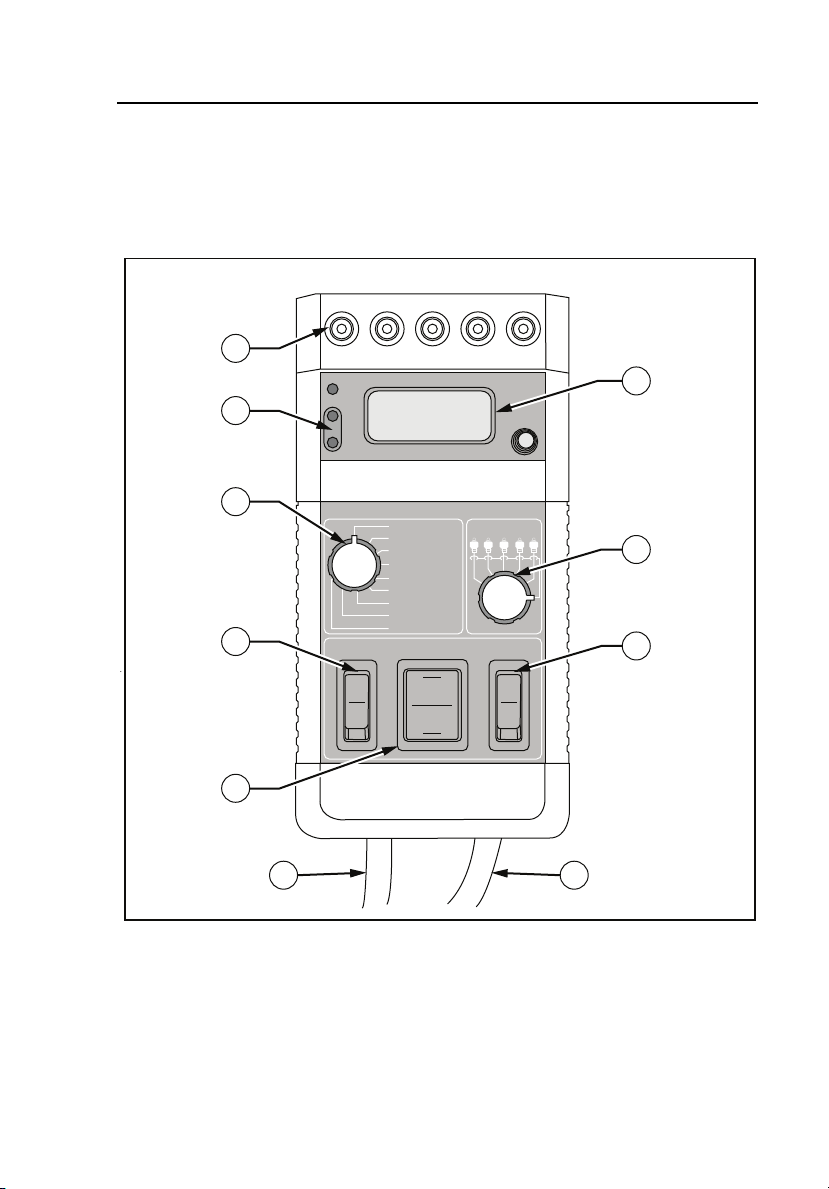

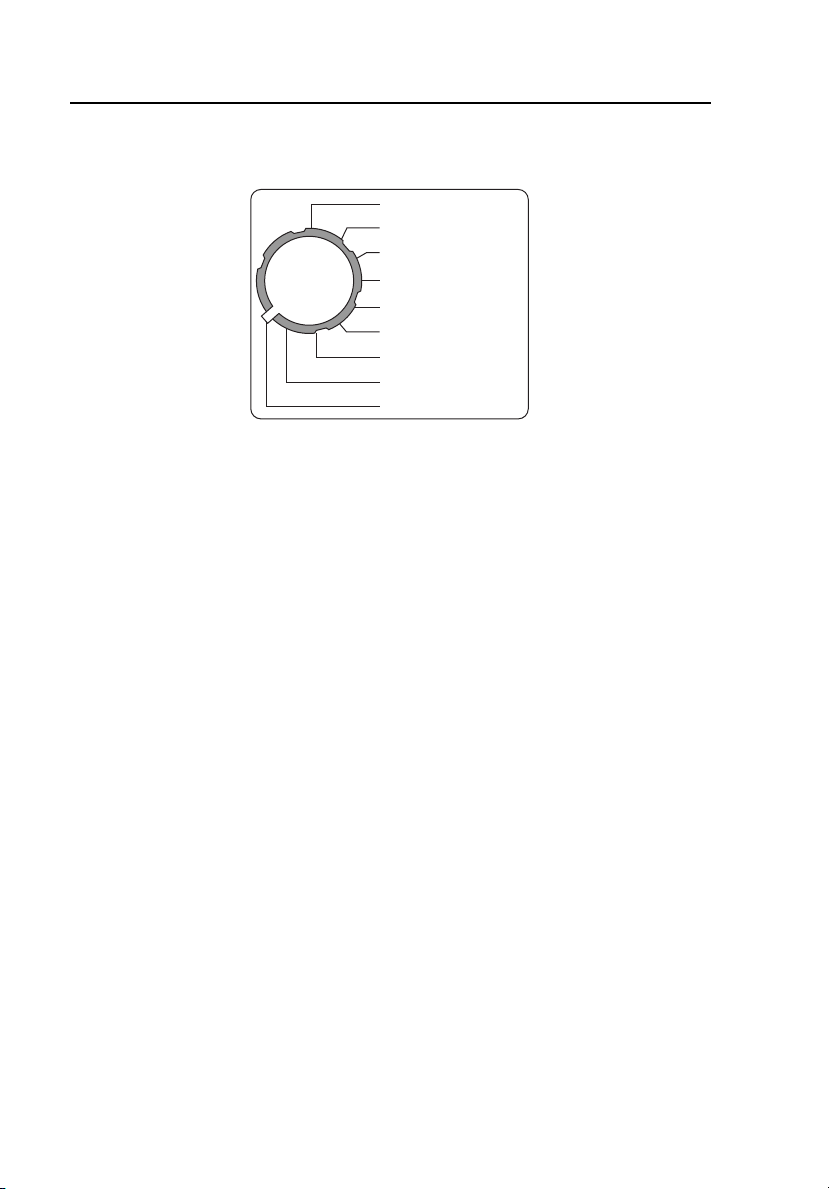

Instrument Familiarity

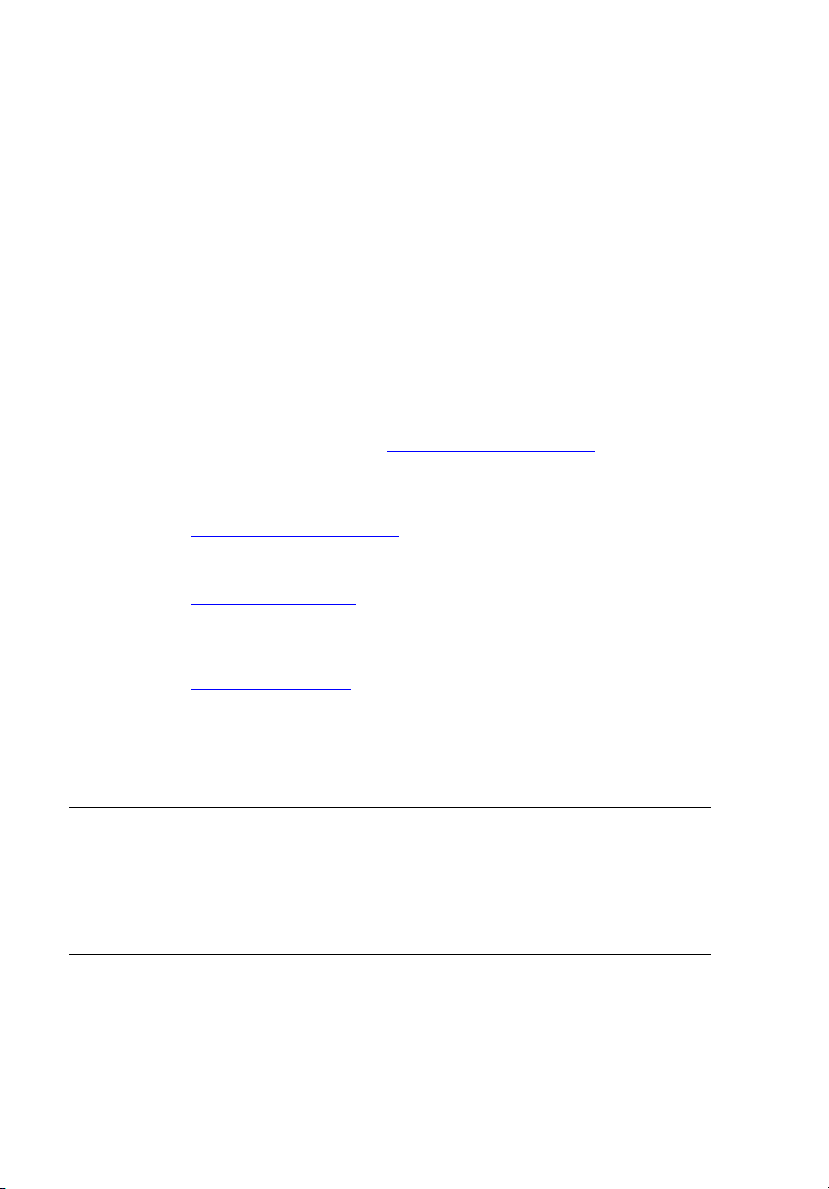

The Analyzer is shown in Figures 1-1 and 1-2, and Table 1-2 describes its

labeled components.

10

9

3

OUTLET

D

7

5

DALE601

CLOSED

OPEN REVERSED

SAFETY ANALYZER

MAINS VOLTAGE

CURRENT AMPS

EARTH RESISTANCE

EARTH LEAKAGE

ENCLOSURE LEAKAGE

PATIENT LEAD LEAKAGE

PATIENT AUX CURRENT

M.A.P.

EXTERNAL

OUTLETL2

NORMAL

OFF OFF

LEADS

M.A.P.

LIFT GND

8

6

4

1

2

Figure 1-1. Analyzer Front Panel Components and Controls

fcu01.eps

1-7

Page 18

DALE601/601E

Operators Manual

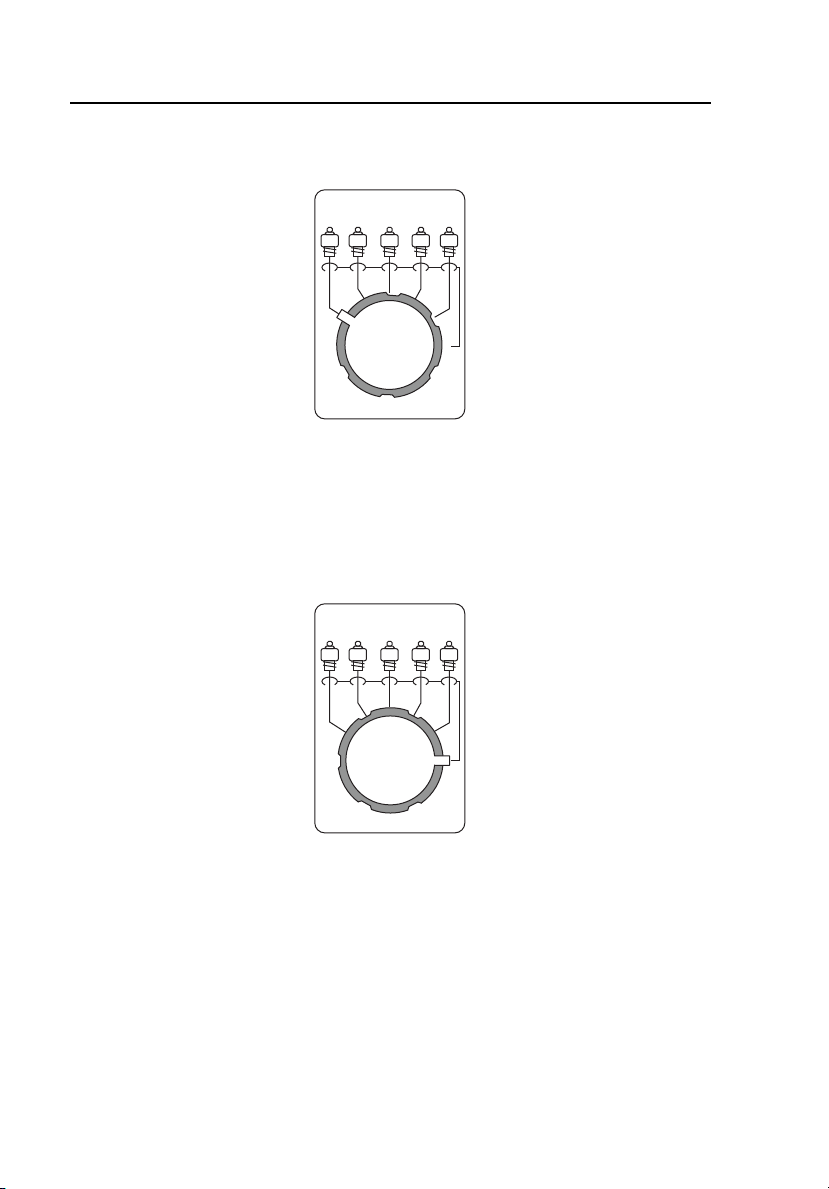

CHASSIS

13

14

EXTERNAL

601

TEST POINTS

AAMI

12

11

Figure 1-2. Analyzer Top Panel Components and Controls

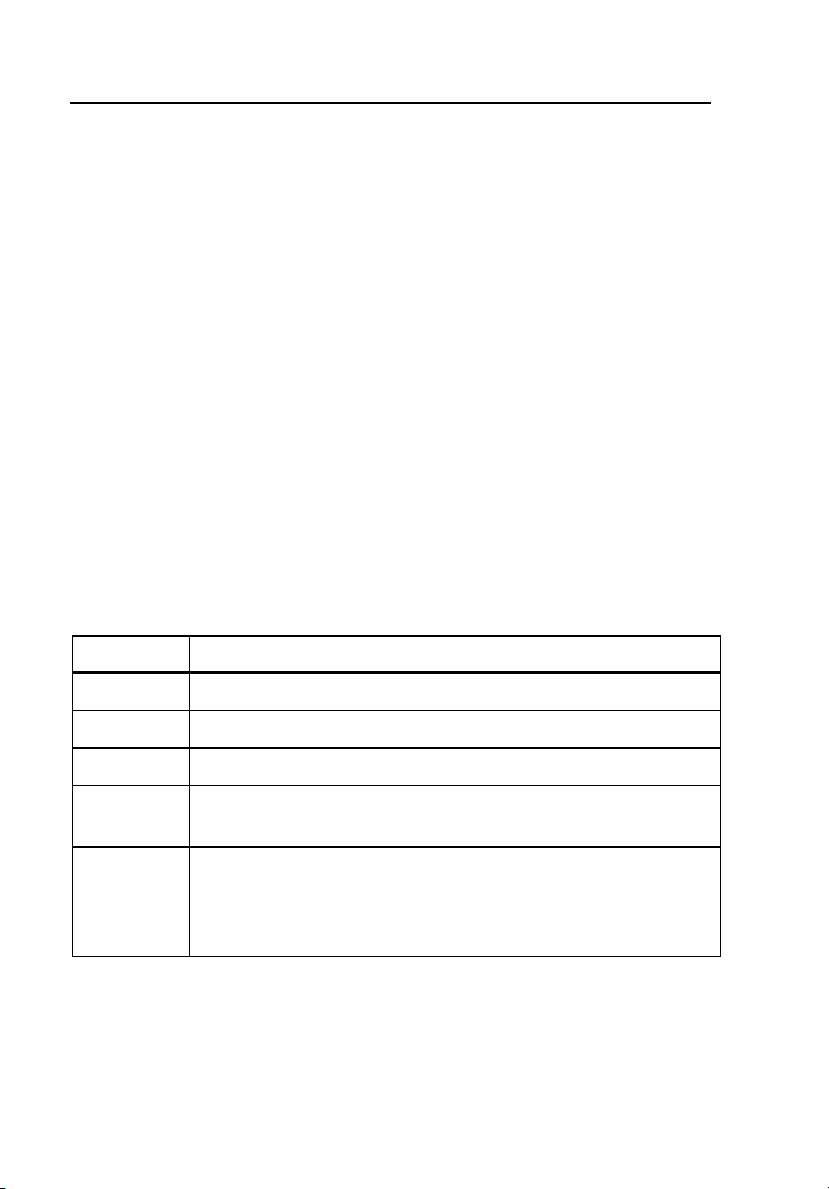

Table 1-2. Components and Controls of the Analyzer

Label Name Function

A Power Cord Supplies power to the Analyzer and to the DUT.

The measurement circuits are energized when

the power cord is plugged into an outlet. There is

no on/off switch.

B Test Receptacle Supplies power to the DUT: DALE601, 15 A at

125 V or DALE601, 20A at 125V; and

DALE601E, 10 A at 230 V.

C Outlet

Indicators

(DALE601 only)

Verifies the polarity and wiring of the outlet to

which the Analyzer is connected. Only correctly

wired outlets should be used. Not applicable to

isolated systems.

fcu02.eps

D Outlet Switch With the center OFF position, permits testing

with both the NORMAL (forward) and

REVERSED polarity of the line. It is

recommended that the switch is paused in the

center OFF position before changing polarity.

1-8

Page 19

Introduction and Specifications

Instrument Familiarity

Table 1-2. Components and Controls of the Analyzer (cont.)

Label Name Function

1

E L2 (Neutral)

Switch

F Lift Ground /

M.A.P. Switch

G Function Switch Provides direct one-step selection of the

Permits making leakage current measurements

under the OPEN neutral (L2) condition as

required by UL and IEC.

A dual function switch. The LIFT GROUND

position will open ground to the device for

leakage current measurements. The MAP test

position will energize the selected patient lead at

mains voltage, current limited, to measure the

isolation current when the function switch is in

the M.A.P. position. With the function switch in

the EXTERNAL position, the isolation test

voltage is supplied to the EXTERNAL connector

for measuring the isolation current of a probe or

transducer.

measurement to be made. The functions are:

Mains voltage, instrument current, grounding

(earth) resistance, earth and leakage currents

and the patient lead currents. These include lead

leakage, auxiliary current and mains on applied

parts (M.A.P.) for isolation (sink) current. An

external position is provided to measure leakage

current between two points, or isolation current

of probes and transducers, independent of their

instruments.

H Lead Switch Directs the selected measurement to the desired

patient lead. When testing a 10 lead device, a

second pass is required for the C leads. The

setting to the far right is the ALL lead position.

I Meter (Display) A large, ½ inch, high contrast 3½-digit display of

the measured parameter. This can display 1999

with decimal points added where required

J Universal

Patient Leads

Provide means for the connection of the patient

leads for leakage current measurement.

1-9

Page 20

DALE601/601E

Operators Manual

Table 1-2. Components and Controls of the Analyzer (cont.)

Label Name Function

K Test Points

L Chassis

Connector

M External

Connector

N Test Load Selector switch between IEC601.1 and AAMI

Chassis Cable

(not shown)

0.15 Ω and 100 µA; provided to check the

Analyzer by clipping onto with the chassis cable

and selecting appropriately, RESISTANCE or

ENCLOSURE LEAKAGE, via the function switch.

Provides means for inputting the chassis cable

with its clip for connection to the DUT chassis or

enclosure. With the FUNCTION switch in the

resistance position, the earth resistance is

measured, and on the enclosure position, the

enclosure leakage current is measured.

Provided for making external measurement of

resistance, voltage gradient, leakage current or

isolation current of probes and transducers,

when used in conjunction with the chassis cable

for the other reference point.

A black coil cord with a clamp with black

insulation for measurement of enclosure leakage

and earth resistance. One is supplied with each

Analyzer.

Specifications

The following are specifications for the Analyzer. Please contact your Fluke

Biomedical service representative for more information regarding the device

specifications.

Controls

Function Switch.............................................9 position rotary

Lead Switch.........................................................6 position rotary

Neutral Switch .....................................................2 position rocker (Open/Closed)

Polarity Switch.....................................................3 position rocker

Leakage Switch ...................................................2 position rocker (Chassis/Earth)

(Normal/Off/Reversed)

1-10

Page 21

Introduction and Specifications

Specifications

1

MAP / Ground Switch ......................................... 2 position rocker (Open Ground /

DUT Power............................................................. 15 A @ 120 V, 20 A @ 120 V,

Physical Size ......................................................... 4.0 x 7.8 x 1.6 in

Mains Voltage

Range ................................................................. Line Voltage

Accuracy ............................................................. ±2 % of reading, ±1 digit

Current Consumption

Range ................................................................. 0 – 14.99 A (Dale601-1515)

Accuracy ............................................................. ±5 % of reading, ±1 digit

Earth Resistance

Range ................................................................. 0 – 19.99 Ω

Accuracy ............................................................. ±1 % of reading, ±1 digit

Current Source...................................................... 10 mA DC (four-wire bridge)

Leakage Current

Range ................................................................. 0 – 1999 µA

Accuracy

DC and 25 HZ to 1 KHz ................................. ±1 % of reading, ±3 LSD

1.0 KHz to 100 KHz ........................................ ±2.5 % of reading, ±3 LSD

100 KHz to 1 MHz .......................................... ±5 % of reading, ±3 LSD

Type Measurement......................................... True rms

Test Load........................................................ AAMI or IEC601 – 1 (selectable)

Isolation Test (Mains on Applied Parts)

Voltage................................................................ Mains voltage

Current................................................................ Limited @ 1 mA

Current Capacity

DALE601-1515 ................................................... 15 A

DALE601E .......................................................... 10 A

DALE601-1520/2020 .......................................... 20 A, 20 % duty cycle

Environmental

Operating Temperature ...................................... 15 – 40 ºC

Storage Temperature.......................................... - 20 – 65 ºC

Relative Humidity................................................ 90 % max

Apply Mains on Applied Part test

voltage)

10 A @ 230 V

(102 x 196 x 41 mm)

0 – 19.99 A (Dale601-1520/2020)

0 – 9.99 A (Dale601E)

(0 – 1.99 Ω)

±2 % of reading, ±1 digit

(2 – 19.99 Ω)

(2 minutes on, 8 minutes off)

1-11

Page 22

DALE601/601E

Operators Manual

Accessories

Standard accessories and part numbers are listed in Table 1-3. Optional

accessories and part numbers are listed in Tables 1-4 and 1-5.

Table 1-3. Standard Accessories

Name Description Part Number

Chassis Cable: black

coil cord, 8 ft extended

length with clamp with

black insulation

Soft Carrying Case

Operators Manual This book 2243573

For measurement of

earth resistance and

enclosure leakage

current. Also used as

reference lead for

external measurement.

Case to carry

accessories and to

protect the Analyzer

when placed in a

toolbox.

Table 1-4. Optional Accessories

2392409

2392584

Name Description Part Number

Chassis cable: 8-foot

black cable- with large

clamp with black

insulation

Chassis Cable: black

coil cord, 16 ft extended

with clamp with black

insulation

Chassis Ground Probe:

black coil cord with

copper needle probe for

testing receptacles and

for tight spaces, 8 ft long

extended

1-12

Used for dual lead

leakage

For measurement of

earth resistance and

enclosure leakage

current. Also used as

reference lead for

external measurement.

For measurement of

earth resistance and

enclosure leakage

current. Also used for

grounding saline baths

for isolation testing of

probes and transducers.

2392409

2231563

2392427

Page 23

Introduction and Specifications

Accessories

Table 1-4. Optional Accessories (cont.)

Name Description Part Number

External Leakage Cable:

coiled cord is 8 ft,

extended with a clamp

with red insulation

External Leakage Cable:

coiled cord is 16 ft

extended with a clamp

with red insulation

Hard Carrying Case Case for carrying the

Standard auxiliary cable

for external

measurements of

leakage current and

voltage gradient

between two conductive

surfaces.

Standard auxiliary cable

for external

measurements of

leakage current and

voltage gradient

between two conductive

surfaces.

Analyzer and

accessories.

2392448

2331563

2231830

1

Table 1-5 lists optional probe adaptor cables needed for isolation testing.

These make electrical contact with all terminals of an ultrasound probe

connector.

Table 1-5. Optional Probe Adapter Cables

Description Part Number

GEYMS probe (for GE product) 2392453

LOGIQ series probe (for GE product) 2392466

For Model 21369A probe (for HP/Agilent product) 2392482

For Model 21364A probe (for HP/Agilent product) 2392494

UNIVERSAL Ultrasound Transducer Probe 2231616

1-13

Page 24

DALE601/601E

Operators Manual

1-14 2-1

Page 25

Chapter 2

Operation

Contents Page

Preliminary Steps......................................................................... 2-3

Preparing the Analyzer for Use................................................ 2-4

Verifying the Power Outlet Connections ................................. 2-5

Measuring Line (Mains) Voltage................................................. 2-6

Measuring Device Current........................................................... 2-7

Measuring Earth Resistance......................................................... 2-8

Measuring Leakage Current......................................................... 2-10

Earth Leakage Current ............................................................. 2-10

Enclosure (Chassis) Leakage Current ...................................... 2-11

Patient Lead Leakage Current.................................................. 2-12

Measuring Patient Auxiliary Current........................................... 2-15

Measuring MAP (Patient Lead Isolation) Current....................... 2-16

External Measurements................................................................ 2-18

Leakage Current....................................................................... 2-19

Electrical Isolation ................................................................... 2-20

Resistance................................................................................. 2-21

Page 26

DALE601/601E

Operators Manual

2-2

Page 27

Operation

Preliminary Steps

2

Preliminary Steps

The Analyzer measures electrical parameters, as described below. These

voltages and currents are a natural phenomenon, and their presence within

reasonable limits does not constitute a hazard. However, it is necessary to

measure their values to determine if there is a significant change from previous

measurements or from the device specifications.

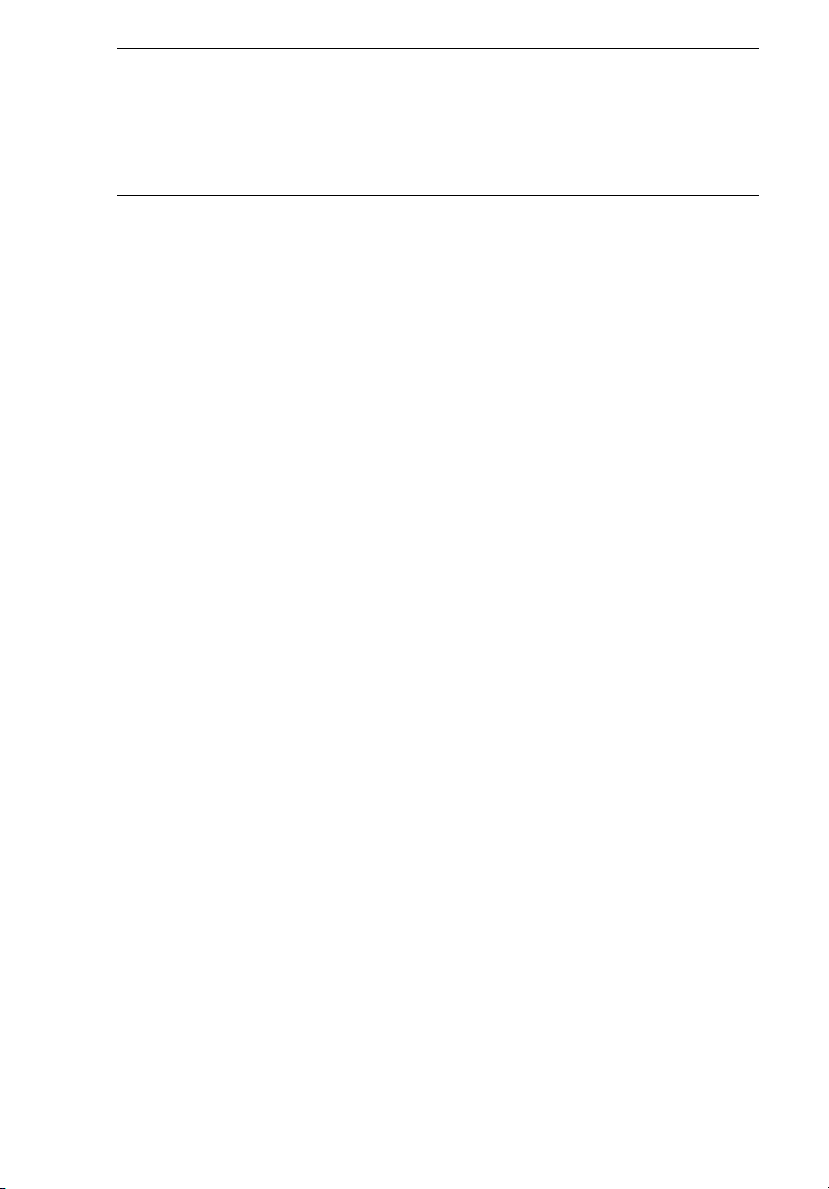

Figure 2-1 is a block diagram of a typical line-operated instrument with patient

connections. Measured parameters are labeled, and the discussions that follow

are keyed to the labels in the diagram.

I

L

L1 (Hot)

V

L

C

L

Z

I

L2 (Neutral)

Ground

I

E

I

C

Earth

Z

L

C

R

L

R

G

L

ENCLOSURE

Grounded

Data and

Control

Circuits

CHASSIS

Isolated

Patient

Circuit

Figure 2-1. Block Diagram of a Line-operated Instrument

I

A

I

I

120/220 Vac

I

P

fcu20.eps

2-3

Page 28

DALE601/601E

Operators Manual

Preparing the Analyzer for Use

XW Warning

To avoid possible electrical shock or personal injury to the

patient, disconnect all patient connections to the device to

be tested before starting.

To prepare the Analyzer for use:

1. Place the Analyzer’s switches in the following initial positions:

FUNCTION switch Mains Voltage

NEUTRAL switch CLOSED

OUTLET switch OFF (center)

2. Plug the Analyzer into a properly-rated outlet.

XW Warning

To avoid possible electrical shock or personal injury to the

patient, plug the Analyzer only into a grounded, “Hospital

Grade” power receptacle. Do not circumvent this

precaution for any reason.

The Analyzer is equipped with a hospital-grade power plug. Grounding

reliability can be achieved only when the Analyzer is connected to an

equivalent power receptacle marked "Hospital Grade." Grounding is

important for personnel safety and to make some of the tests offered by

the Analyzer.

Note

This device is sensitive to electromagnetic fields. If interference is

encountered in measurements, reconfigure the test setup or contact

the manufacturer.

2-4

Page 29

Operation

Preliminary Steps

2

Verifying the Power Outlet Connections

Note

This section is not applicable to isolated power systems or to the

601E (230 V version).

Three neon lamps provide indication of the polarity and condition of the outlet

used, as determined by the following chart.

REV

● ● ● ○ ○

OK ● ○ ○ ○ ●

○ ● ○ ○ ●

Correct

wiring

Reverse

polarity

Open

ground

Open hot

Hot /

ground

reversed

Note

Lamps do not check open neutral or neutral/ground reversal.

If the line is found faulty, correct the problem before proceeding. If the line

checks OK, plug the device to be tested into the Analyzer's line receptacle.

XW Warning

To avoid possible electrical shock or personal injury due

to faulty device under test, follow these guidelines:

• Do not touch the metal chassis, any accessible

conductive part, or terminal of the DUT with mains

power applied until all applicable tests have been

completed and the product is verified as compliant.

• Keep fingers behind guards on supplied test

accessories and/or if necessary remove power from

the DUT before making necessary connections.

2-5

Page 30

DALE601/601E

Operators Manual

Measuring Line (Mains) Voltage

Line Voltage (VL) is the mains power supplied by the electrical distribution

system of the hospital. It is shown as a three-wire system of HOT, NEUTRAL

(L2) and GROUND with NEUTRAL, like GROUND, returned to true earth at

entry into the building.

Measurement is made between the HOT and NEUTRAL wires via transformer

coupling to isolate the measuring circuits from the line.

To measure line voltage:

1. Set the FUNCTION switch to MAINS VOLTAGE (the recommended

starting position).

MAINS VOLTAGE

CURRENT AMPS

EARTH RESISTANCE

EARTH LEAKAGE

ENCLOSURE LEAKAGE

PATI E NT LEAD LEAKAGE

PATI E NT AUX CURRENT

M.A.P.

EXTERNAL

fcu03.eps

The Analyzer displays the mains voltage with a resolution of 1 V.

2. Set the OUTLET switch to the NORMAL position and POWER ON the

DUT.

3. The Analyzer displays mains voltage, but under the load of the device

being tested. Depending on the DUT operating current and the electrical

supply wiring, the voltage differential may be significant.

Note

The difference between the line voltages with the DUT powered off

and powered on indicates whether the line is adequate for the device.

A large drop may suggest that a dedicated, higher ampacity line

should be run in for the device.

2-6

Page 31

Operation

Measuring Device Current

2

4. Check the value under load against the DUT ratings to be sure that the

actual value remains within prescribed limits.

Measuring Device Current

Device Current (IL) (instrument current) is that used by the DUT. When

powered on, the DUT should be operated in its various modes to determine the

worst condition to track. Verify that the DUT current is within the current

rating of the Analyzer being used.

Measurement is made in the HOT wire via transformer coupling to ensure that

the total current is measured, because it is possible that the NEUTRAL and

GROUND wires share the return path

To measure device current.

1. Set the FUNCTION switch to CURRENT AMPS.

MAINS VOLTAGE

CURRENT AMPS

EARTH RESISTANCE

EARTH LEAKAGE

ENCLOSURE LEAKAGE

PATI E NT LEAD LEAKAGE

PATI E NT AUX CURRENT

M.A.P.

EXTERNAL

fcu04.eps

The Analyzer displays the DUT current to 19.99 A.

2. Set the OUTLET switch to NORMAL and L2 to CLOSED.

3. POWER ON the DUT and place it in its maximum load condition to

obtain the proper reading.

4. Log this data and note changes in values to help detect problems early.

2-7

Page 32

DALE601/601E

Operators Manual

Measuring Earth Resistance

Earth Resistance (RG) (grounding resistance) is the resistance from the DUT

conductive "grounded" chassis to the grounding terminal on the receptacle into

which it is plugged. Maintaining a low resistance is important to protect the

chassis from becoming "hot" with current as a result of an internal fault. The

resulting voltage drop across the ground wire raises the potential of the chassis

with respect to the local ground, creating a potential hazard.

The ground wire in the power cable is responsible for most of the resistance,

which is proportional to the cable length. See Table 2-1 for typical values for a

10-foot cable. The resistance measurement also includes the junction

resistance in connecting the wire at both ends and the bulk resistance of the

chassis from the grounding point to the point of measurement.

Low resistance values are being measured between the clip on the black

chassis cable and the grounding pin receptacle of the Analyzer. Therefore, the

Analyzer uses a four wire Kelvin bridge to make the measurement, avoiding

errors caused by the contact resistance of the cable connectors and the length

of the test cable.

Table 2-1. Ground Resistance of a Ten-foot Power Cable

Wire Size (AWG) Resistance (milliohms)

18 64

16 41

14 25

Note

Underwriters Laboratory (UL) limits the ground resistance for new

products to 100 m

Association (NFPA) limits ground resistance to 150 m

products and 500 m

Ω

(0.1 Ω), and the National Fire Protection

Ω

for new

Ω

for devices in the field.

To measure earth resistance:

Note

This test is applicable only to devices using three-wire (grounded)

power cords.

2-8

Page 33

Operation

Measuring Earth Resistance

2

1. Set the OUTLET switch to the OFF position.

2. Connect the standard cable (supplied with unit) that has a black coil cord

cable with the clamp with black insulation to the CHASSIS connector on

the top panel of the Analyzer.

3. Clamp the cable clip to the exposed chassis of the DUT or to the

enclosure, if conductive.

Note

Ensure that bare metal is reached and that both jaws of the clip are in

contact with the chassis. Do not use metal labels or incidental

conductive hardware for this test.

4. Once connection is made, set the FUNCTION switch to EARTH

RESISTANCE.

MAINS VOLTAGE

CURRENT AMPS

EARTH RESISTANCE

EARTH LEAKAGE

ENCLOSURE LEAKAGE

PATIENT LEAD LEAKAGE

PATIENT AUX CURRENT

M.A.P.

EXTERNAL

fcu05.eps

The earth resistance value is displayed to 19.99 Ω.

2-9

Page 34

DALE601/601E

Operators Manual

Measuring Leakage Current

Leakage current is the flow of current through or over the surface of an

insulating material or insulator. Leakage current is caused by the proximity of

the hot wire or line potential components to the chassis. In Figure 2-1, this

relationship is represented by Z

resistance (R

) components. For example, if a person comes in contact with an

L

operational device, leakage current flows from the contact point, through the

person’s body, and back to ground. Measurement of leakage current is required

on all mains power products.

Earth Leakage Current

Earth Leakage Current (IE) (internal chassis current) flows in the ground wire

of the power cable to return the chassis leakage current to true earth ground.

This current is not a hazard if the ground wire remains intact and the current

does not become excessive. This leakage can occur if a major fault results in

the ground wire sharing the load current with the neutral wire or in supplying

the total return. The measurement is made using the 1000 Ω AAMI load

placed directly in series with the ground wire. Open neutral usually represents

the worst case.

, a combination of capacitance (CL) and

L

To measure earth leakage current:

Note

Earth leakage current flows normally in the ground wire of the

device. This test is applicable only to devices using three-wire

(grounded) power cords.

1. Set the FUNCTION switch to EARTH LEAKAGE.

2-10

Page 35

Operation

Measuring Leakage Current

MAINS VOLTAGE

CURRENT AMPS

EARTH RESISTANCE

EARTH LEAKAGE

ENCLOSURE LEAKAGE

PATIENT LEAD LEAKAGE

PATIENT AUX CURRENT

M.A.P.

EXTERNAL

2

fcu06.eps

The leakage current displays to 1999 µA.

2. Take measurements under all combinations of the OUTLET switch in

NORMAL and REVERSE, the L2 NEUTRAL switch in CLOSED and

OPEN, and the device power turned ON and OFF.

Note

Be sure to pause in the OFF (middle) position when switching from

NORMAL to REVERSE.

Enclosure (Chassis) Leakage Current

Enclosure Leakage Current (IC) flows between the accessible conductive

chassis or enclosure and earth ground, as measured through a 1000 Ω

impedance. Under the condition of an open ground, this current is the same as

the earth current. With ground intact, the current should be very low, reflecting

the mΩ impedance of the ground wire paralleling the 1000 Ω AAMI load.

Note

Differentiation is made between earth and chassis currents because

the wide use of insulated enclosures makes a conductive chassis

inaccessible. Under this condition, earth current represents total

leakage.

To measure enclosure leakage current:

1. Connect the standard cable (supplied with unit) that has a black coil cord

cable with the clamp with black insulation to the CHASSIS connector on

the top panel of the Analyzer.

2-11

Page 36

DALE601/601E

Operators Manual

2. Clamp the cable clip to accessible conductive sections of the chassis and

the enclosure.

Note

Ensure that bare metal is reached and that both jaws of the clip are in

contact with the chassis. Do not use metal labels or incidental

conductive hardware for this test.

3. Set the FUNCTION switch to ENCLOSURE LEAKAGE.

MAINS VOLTAGE

CURRENT AMPS

EARTH RESISTANCE

EARTH LEAKAGE

ENCLOSURE LEAKAGE

PATI E NT LEAD LEAKAGE

PATI E NT AUX CURRENT

M.A.P.

EXTERNAL

fcu07.eps

The enclosure leakage displays in µA.

4. Take measurements under all combinations of the OUTLET switch in

NORMAL and REVERSE, the GROUND switch CLOSED and

OPEN, the L2 NEUTRAL switch in CLOSED and OPEN, and the

device power turned ON and OFF.

Note

Be sure to pause in the OFF (middle) position when switching from

NORMAL to REVERSE.

Patient Lead Leakage Current

Patient Lead Leakage Current (IP) (source current) would flow through

individual patient leads and all of the patient leads connected together, if the

patient were to come into contact with earth ground. This test was originally

required only for devices incorporating intra-cardiac electrodes or conductive

2-12

Page 37

Operation

Measuring Leakage Current

2

pathways directly to the heart, but it has become standard for all devices

having any patient-applied parts.

This test simulates the condition of a patient with leads attached touching

ground such as an electric bed. If the patient connections are not isolated, this

current reflects the earth current when tested under the open ground condition,

as this is its only path back to true earth. For devices incorporating isolated

patient connections, this current is reduced by the patient isolating impedance

Z

, a combination of resistive and capacitive leakage.

I

Measurement is made to the lead selected by the lead selector switch, with the

other side of the AAMI load connected to system ground.

To measure patient lead leakage:

1. Connect the patient leads to the corresponding universal connectors on the

front of the Analyzer.

2. Set the FUNCTION switch to PATIENT LEAD LEAKAGE.

MAINS VOLTAGE

CURRENT AMPS

EARTH RESISTANCE

EARTH LEAKAGE

ENCLOSURE LEAKAGE

PATI E NT LEAD LEAKAGE

PATI E NT AUX CURRENT

M.A.P.

EXTERNAL

fcu08.eps

The leakage current displays in µA.

2-13

Page 38

DALE601/601E

Operators Manual

3. Select the lead to be tested by the LEADS switch.

LEADS

4. Take measurements for any combination of the OUTLET switch, the

ground intact or lifted, and the DUT power ON or OFF.

5. Rotate the LEADS switch to test each lead individually, including the

ALL position for testing all leads connected together.

LEADS

Current measured should be the same for all leads, including the ALL

position, as the current represents the isolation impedance to the patient

circuit.

fcu12.eps

fcu17.eps

2-14

Page 39

Operation

Measuring Patient Auxiliary Current

2

Measuring Patient Auxiliary Current

Patient Auxiliary Current (IA) (lead-to-lead current) flows from any patient

lead to any other patient lead and to all other leads connected together,

including:

• Bias current of the input amplifier

• Reverse leakage current of input protection diodes

• Lead-off sensing current

• Impedance measurement current such as for respiration

The currents can be dc or ac or a combination of both. They are measured

using a true rms to provide the common base necessary for accurate readout

with a variety of common waveforms.

Measurement is made with a completely floating circuit to avoid extraneous

leakage currents to ground introducing errors. Measurement is made from the

selected lead to all other leads connected together, thus reducing the

permutations required to cover all possibilities.

To measure patient auxiliary current:

1. Connect the patient leads to the universal connectors on the front of the

analyzer.

2. Set the FUNCTION switch to PATIENT AUX CURRENT.

MAINS VOLTAGE

CURRENT AMPS

EARTH RESISTANCE

EARTH LEAKAGE

ENCLOSURE LEAKAGE

PATI E NT LEAD LEAKAGE

PATI E NT AUX CURRENT

M.A.P.

EXTERNAL

fcu09.eps

2-15

Page 40

DALE601/601E

Operators Manual

3. Select by the LEADS switch to test individual leads.

LEADS

fcu12.eps

4. Make measurements under all combinations of the OUTLET switch,

NORMAL and REVERSE; the NEUTRAL switch CLOSED and

OPEN; GROUND CLOSED and the LIFT GROUND switch OPEN;

and the device power turned ON and OFF.

Under normal conditions, the current is primarily input bias current,

measuring current or leadoff sensing current. The worst case condition is

measured from the individual lead to all other leads connected together.

The single lead carrying the most current is generally considered the

reference lead (RL) because it acts as the return for the other leads.

Therefore, the leads can be taken in groups of four with the common

reference lead (RL) and then summed.

Measuring MAP (Patient Lead Isolation) Current

MAP (Mains on Applied Parts) Current (II) (patient lead isolation current) is

that which would flow into the DUT if the patient were to come into contact

with full line voltage. An example is an electric patient bed that has become

ungrounded and has a short to the frame.

Measurement is made in each individual leads, but a common value is found

for all leads, as well as for the ALL position, as this is the measurement for the

isolation of the patient circuit. To assure proper reading, the test should be run

with ground intact. For additional safety, the current is applied to the patient

leads only when the ISO TEST switch is pressed.

2-16

Page 41

Operation

Measuring MAP (Patient Lead Isolation) Current

2

For this test, the Analyzer provides a specially shielded line voltage secondary

on its power transformer that minimizes internal leakage currents from the

measuring circuit. This avoids the necessity of measuring the current and

subtracting it from all readings. The current is limited with a 120 KΩ resistor

for user protection.

XW Warning

To avoid possible electrical shock or personal injury to the

patient, take care when handling the patient leads. High

voltage, 120/230 volts with respect to earth ground, is

accessible at the patient connections during part of this

test.

To measure lead isolation sink current:

1. Connect the patient leads to the universal lead connectors on the front of

the analyzer.

2. Set the FUNCTION switch to M.A.P.

MAINS VOLTAGE

CURRENT AMPS

EARTH RESISTANCE

EARTH LEAKAGE

ENCLOSURE LEAKAGE

PATI E NT LEAD LEAKAGE

PATI E NT AUX CURRENT

M.A.P.

EXTERNAL

fcu10.eps

3. Select the individual lead to be tested by the LEADS switch.

2-17

Page 42

DALE601/601E

Operators Manual

LEADS

fcu12.eps

4. Press the ISO TEST switch to safely apply the high voltage to the leads.

5. While the ISO TEST is energized, read the isolation current in µA.

6. Take measurements for all combinations of the OUTLET in both

NORMAL and REVERSE and L2 switch CLOSED and with the DUT

ON and OFF.

External Measurements

The Analyzer provides the extended capability of making leakage current and

isolation current measurements between selected points, performing as

follows:

• An ohmmeter capable of measuring resistance in the mΩ range for chassis

bonding measurements.

• A low impedance (1000 Ω) voltmeter as specified by the NFPA, with a

range to 1999 mV.

• A 1000 µA ammeter to measure the leakage current between two devices

or between the DUT and a local ground reference. Range is to 1999 µA.

• An isolation tester for testing ultrasound probes and other transducers

independently from the device in which it is used.

Note

Additional optional accessory cables must be purchased to perform

these tests.

2-18

Page 43

Operation

External Measurements

2

Leakage Current

Leakage Current and Voltage Gradients between two points are also measured

for permanently installed equipment as additional verification of the integrity

of the installation. These measurements are equivalent, because the

relationship between volts and current across 1000 Ω is one mV per µA.

To measure leakage current and voltage gradient between two points:

1. Connect the black coil cord cable with the clamp with black insulation to

the CHASSIS connector and the black cable with the clamp with red

insulation to the EXTERNAL connector on the top panel of the Analyzer.

Note

Do not plug a device into the Analyzer. The measurement circuit must

remain isolated from ground.

2-19

Page 44

DALE601/601E

Operators Manual

2. Set the FUNCTION switch to EXTERNAL.

MAINS VOLTAGE

CURRENT AMPS

EARTH RESISTANCE

EARTH LEAKAGE

ENCLOSURE LEAKAGE

PATI E NT LEAD LEAKAGE

PATI E NT AUX CURRENT

M.A.P.

EXTERNAL

3. Clip the cables to the two points for which leakage current is to be

measured.

The Analyzer displays the leakage current between the two points to 1999

µA. The number displayed is also the voltage gradient in mV between the

two points, based on a voltmeter with an input impedance of 1000 Ω.

fcu11.eps

Electrical Isolation

Isolation testing of probes and transducers that make internal contact to a

patient is provided to assure the reliability of the isolation barrier. Such devices

incorporate electrical circuits that can introduce or sink hazardous currents to a

patient who comes into contact with line potential or who becomes grounded.

Note

For devices that require sterilization before use, testing before

sterilization is recommended.

To measure electrical isolation of a probe or transducer:

1. Connect the black coil cord cable with the clamp with black insulation to

the CHASSIS connector and the black cable with the clamp with red

insulation to the EXTERNAL connector on the top panel of the Analyzer.

2-20

Page 45

Operation

External Measurements

2

2. Set the FUNCTION switch to EXTERNAL.

MAINS VOLTAGE

CURRENT AMPS

EARTH RESISTANCE

EARTH LEAKAGE

ENCLOSURE LEAKAGE

PATI E NT LEAD LEAKAGE

PATI E NT AUX CURRENT

M.A.P.

EXTERNAL

fcu11.eps

3. Press the ISO TEST switch.

This action applies isolated line voltage between the two sides. The

Analyzer displays the isolation current that flows.

Note

The method for making connection to either side of the isolation

barrier varies with the device to be tested.

XW Warning

To avoid possible electrical shock or personal injury take

care when handling the cables. High voltage, 110 percent

of line volts, will be accessible between the two cables

when the LIFT GROUND/ISO TEST switch is in the ISO

TEST position.

Resistance

Resistance measurements between two points are made to verify the integrity

of permanently installed equipment whose ground cannot be broken to

measure the chassis leakage current. These are usually high power devices,

which can have high leakage currents and depend on the bonding of all chassis

to a common point for safety. It is recommended that these devices be powered

off for testing.

2-21

Page 46

DALE601/601E

Operators Manual

Measurement is made with a 10 mA dc current and is highly resistant to ac

currents flowing between the measurement points as a result of chassis leakage

current from either or both devices. However, such leakage current may have a

dc component from rectification within the instrument. This dc current adds

and subtracts from the measurement current, resulting in some error that can be

corrected for by reversing the connections, remeasuring, and averaging the two

readings.

To measure resistance between two points:

1. Connect the two black chassis cables with clamps with black insulation to

the CHASSIS and EXTERNAL connectors on the top panel of the

Analyzer.

2. Clip the cables onto the two points to be measured.

Note

Do not plug a device into the Analyzer. Ensure that ground

connections do not provide parallel measurement circuits causing

erroneous results.

3. Set the FUNCTION switch to EARTH RESISTANCE.

MAINS VOLTAGE

CURRENT AMPS

EARTH RESISTANCE

EARTH LEAKAGE

ENCLOSURE LEAKAGE

PATIENT LEAD LEAKAGE

PATIENT AUX CURRENT

M.A.P.

EXTERNAL

The display shows the resistance between the two points.

2-22

fcu05.eps

Page 47

Chapter 3

Maintenance and Service

Contents Page

Maintenance................................................................................. 3-3

Avoiding Damage .................................................................... 3-3

Cleaning ................................................................................... 3-3

Verifying Analyzer Performance................................................. 3-4

Service and Calibration................................................................ 3-6

3-1

Page 48

DALE601/601E

Operators Manual

3-2

Page 49

Maintenance and Service

Maintenance

3

Maintenance

The Analyzer requires little maintenance or special care; however, it is a

calibrated measuring instrument and should be treated as such. Store the

Analyzer in its optional carry case, and ensure that the storage environment is

free from vibration.

Avoiding Damage

Do not drop the instrument or subject it to any mechanical abuse that could

cause a shift in the calibrated settings.

W Caution

To avoid damage to the Analyzer or adverse affects on its

performance, do not expose the system to temperature

extremes. Ambient temperatures should remain between

15 °C and 40 °C, with a relative humidity less than 90 %.

Cleaning

Clean the exterior of the Analyzer occasionally with a cloth dampened with a

mild detergent solution.

W Caution

To avoid damage to the Analyzer or adverse affects on its

performance, do not spray liquid directly on or immerse

the unit.

Carefully wipe down the cables and inspect them for damage and deterioration

of the insulation. Check the cable connections for integrity of the cable clamp

and strain relief.

3-3

Page 50

DALE601/601E

Operators Manual

Verifying Analyzer Performance

The general performance of the Analyzer can be verified, using the procedures

summarized in Table 3-1 and the parameters in Table 3-2. If the Analyzer does

not perform correctly, contact the Fluke Biomedical Service Center

immediately.

Table 3-1. Performance Verification Parameters

Parameter Procedure Desired Reading

Mains Voltage Use a multimeter. Volts

Current

Resistance

Enclosure

Leakage

Patient Lead

Leakage

Patient Aux.

Leakage

Connect a lamp with a

standard incandescent

bulb to the DUT receptacle

and set the OUTLET

switch to NORMAL.

Connect the black chassis

cable with black insulation

to the CHASSIS connector

and clip it to the 0.15 Ω

test point.

Connect the black chassis

cable with a clamp with

black insulation to the

CHASSIS connector and

clip it to the 100 µA test

point.

Attach a clip lead to the

100 µA test point and the

other end to the LEAD

snap selected.

Attach a clip lead to the

100 µA test point and the

other end to the LEAD

snap selected.

Amps, approximately as

shown in Table 3-2

0.15 ±0.02 Ω

100 ±2 µA

100 ±2 µA

100 ±2 µA

3-4

Page 51

Maintenance and Service

Verifying Analyzer Performance

Table 3-1 Performance Verification Parameters (cont.)

Parameter Procedure Desired Reading

3

M.A.P. (lead

isolation current)

External; for

leakage current

measurement

Isolation Clip the black external

Calibration Do not attempt. Not Applicable

Connect the black chassis

cable with a clamp with

black insulation to the

EXTERNAL connector and

the clip to the lead

selected. Press ISO

TEST.

Connect the black external

cable with a clamp with

red insulation to the

EXTERNAL connector and

the clip to the 100 µA test

point.

cable with a clamp with

red insulation to the black

chassis cable and press

the ISO TEST switch.

1000 ±15 %, depending on

line voltage

100 ±2 µA

1000 ±15 %, depending on

the line voltage

Table 3-2. Current Verification Parameters

Bulb (Watts)

120 V Line 230 V line

60 0.50 0.30

75 0.63 0.35

100 0.83 0.45

150 1.25 0.70

Current (Amps)

3-5

Page 52

DALE601/601E

Operators Manual

Service and Calibration

If the new Analyzer fails to operate properly or if it needs a recommended

yearly calibration, please contact the Fluke Biomedical Service Center

immediately, as indicated under Warranty and Product Support.

W Caution

To avoid damage to the Analyzer or adverse affects on its

performance, allow only qualified technical personnel to

service the Analyzer.

Packing

If repairs or calibration are required, return the Analyzer to the factory or the

nearest service center.

1. Before returning the Analyzer for factory service, contact Fluke

Biomedical Service Center for a required Return Authorization Number.

2. Provide the following information:

• The Analyzer serial number

• The specific steps that reproduce your problem

• A daytime phone number

• Your name / company

• A fax number (if available)

3. Pack the instrument carefully, using the original shipping container and

packing materials supplied by Fluke Biomedical. If the original packing

materials are not available, refer to Return Procedures for a list of

preferred materials or contact Fluke Biomedical for replacement packing.

Note

Failure to pack the instrument properly could void your warranty.

3-6

Page 53

Maintenance and Service

Service and Calibration

3

Shipping

1. Place the Return Authorization Number in a prominent place on the

outside of the packing box, and refer to the number in any correspondence

with Fluke Biomedical Service.

2. Enclose your return address and Return Authorization Number.

3. Insure the unit for full retail value and ship to the nearest Fluke

Biomedical service center.

3-7

Page 54

DALE601/601E

Operators Manual

3-8

Loading...

Loading...