Page 1

Specifications

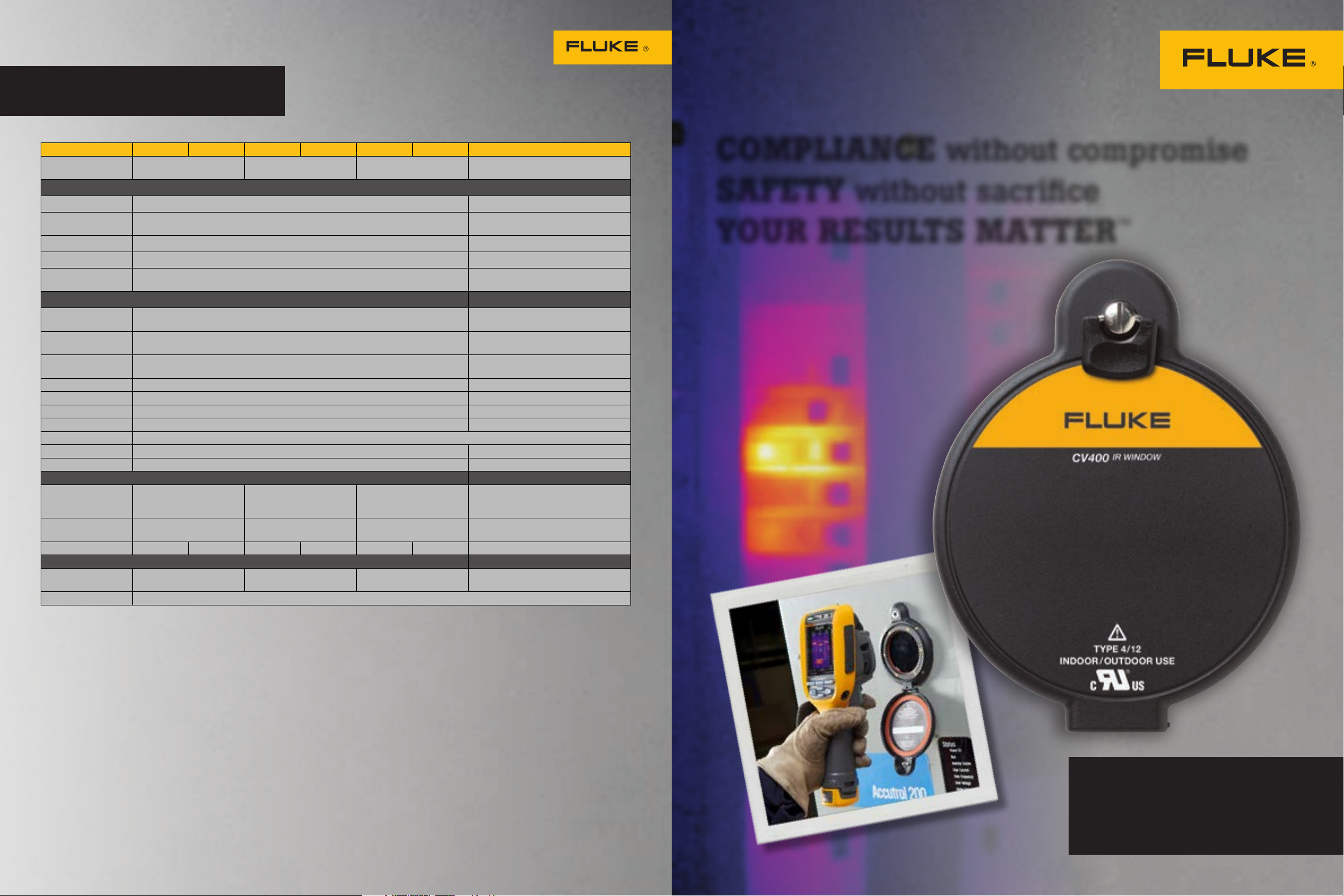

Model CV400 CV401 CV300 CV301 CV200 CV201 CLKT

Size 95 mm (4 in) 75 mm (3 in) 50 mm (2 in)

General

Voltage range Any Any

NEMA Environment

Type Type 4/12 (indoor/outdoor) Type 3/12

AutoGround™

ClirVu® Optic

Operating

temperature -40 °C to +232 °C (-40 ° F to +450 °F) and +260 °C (500 °F) intermittent

Ratings and testing

Arc-Tested (IEEE

C37.20.7) 63 kA for 30 cycles @ 60Hz at KEMA 50 kA for 30 cycles @ 60 Hz at KEMA

UL 50V component

recognition Yes Yes

UL 50 /NEMA Environmental Rating

UL1558 Yes No

CSA C22.2 No. Yes Yes

CSA Type Rating Type 4 Type 3/12

IP rating IP67 at TUV IP55

Lloyds Register Up to 11 kV marine switchgear, indoor or outdoor (offshore only)

Vibration rating IEC60068-2-6 at TUV IEC60068-2-6

Humidity rating IEC60068-2-3 at TUV IEC60068-2-3

Install

Actual mounting hole

diameter required 115.42 mm (4.544 in) 89.89 mm (3.539 in) 61.37 mm (2.416 in)

Greenlee Punch Kit =

Punch / Die

Door Latch Hand Turn Security Key Hand Turn Security Key Hand Turn Security Key Hand turn

Optics

Optic insert diameter 95 mm (3.74 in) 75 mm (2.96 in) 50 mm (1.97 in)

Warranty Lifetime replacement against manufacturing defects

742BB = 2984AV /

2983AV

Yes

Yes

NEMA Type 4/12

739BB = 1431AV /

1432AV

76BB = 441AV /

442AV

04247/04246; 100 mm Hole Saw Only

100 mm, 75 mm and

50 mm (4, 3 and 2 in)

Yes

Yes

-40 °C to

+232 °C (-40 ° F to +450 °F)

NEMA Type 3/12

50 mm 43.2 mm (1.7 in);

75 mm 69.9 mm (2.75 in);

100 mm 92 mm (3.62 in)

50 mm 06974/04013; 75 mm

100 mm, 75 mm and

50 mm (4, 3 and 2 in)

COMPLIANCE without compromise

SAFETY without sacrifice

™

YOUR RESULTS MATTER

For more detailed specifications download datasheets at www.fluke.com/irwindows

Fluke Corporation

PO Box 9090, Everett, WA 98206 U.S.A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

Modification of this document is not

permitted without written permission from

Fluke Corporation.

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2006-2013 Fluke Corporation.

Specifications subject to change without notice.

Printed in U.S.A. 8/2013 3839848G_EN

ClirVu® Series

IR Windows

Page 2

Safety shouldn’t

Fluke ClirVu®

IR Windows

Not just a better window

—a clearer view.

Every time you open a panel

cover, you expose yourself to

the potential dangers of arc flash.

99.9 % of all arc flash incidents

occur when the panel door is opened.

Eliminate that risk with ClirVu

®

IR

windows.

be secondary

If Fluke has learned anything in more than 65 years,

it’s not to compromise quality in order to beat a

competitor’s price. Asking, “How well can we make

it?” versus “How cheaply can we make it?” may not

win price wars, but it has established Fluke as the

standard of excellence, and the preferred name in

test and measurement equipment.

Compliance.

The future is clear.

“Better safe than sorry,” is becoming a modern

mantra for companies who want protection from the

physical and economic tragedies that can result from

arc ash incidents.

If there’s ever a problem, it won’t be a question

of whether or not you’ve done the minimums, but

whether you’ve done as much as possible to protect

your people. With Fluke IR Windows comes the

condence that when it comes to the safety of your

people, you have not compromised.

The solution

Don’t open the panel door.

Once a ClirVu® IR Window is installed, there’s no

more need to power down or remove panels—you

may never have to open the panel door again.

Inspections are conducted quickly, easily, and of

course, safely. Decreasing risks of arc ash may also

result in lower insurance costs.

Your greatest investment is not what’s behind

the panel, so when Fluke made the decision to

manufacture infrared windows, our priority was to

offer the ultimate protection for the electricians,

engineers and inspectors who risk their lives doing

their jobs.

At the same time, the quest for safety has led to

numerous technological advancements resulting in

faster installation and inspections. It’s safe to say,

ClirVu is all you need to be both compliant and more

productive at your job.

1

www.fluke.com/irwindows 2

Page 3

When a product far exceeds the minimum

safety and performance standards, that’s confidence.

That’s Fluke

Fast installation

™

with AutoGround

less than 5 minutes.

Yes, ve minutes. That’s about how long it takes

to install a Fluke ClirVu

the only IR Window with AutoGround

its AutoGround design, Fluke has eliminated

the need to separately ground each metal

component of the window. The time saved and

safety benets from installation alone clearly

make Fluke the preferred choice.

Torture Tested™ to the highest

arc blast test ratings

• IEEE C37.20.7: 63 kA Arc tested at KEMA

• UL 50/50E/50V, UL1558, IEC60529-1: IP67,

IEC 60068, NEMA 4/12, CSA C22.2 NO.

14-13:2012, and CE

• Grounds instantly to metal enclosure with

patent-pending AutoGround

• Maintains panel arc test ratings up to 63 kA

when properly installed

®

CV Series IR Window,

design—

™

process

™

. With

It’s time

Save time with quick

and easy installation

—5 minutes or less!

• One technician

• One hole with standard Greenlee

punch

• Panel door does not need to be

removed

• Grounds instantly to metal enclosure

with patent-pending AutoGround

process

• Maintains panel arc test ratings up to

63 kA when properly installed

®

™

1

Lock out–tag out

Can you afford not to install

ClirVu® IR Windows?

Arc ash accidents can cost an employer in excess

of a million dollars. Lost production, equipment and

facility repair and replacement may just scratch the

surface of costs. There’s always the potential for

lawsuits, skyrocketing insurance premiums, and

staggering nes from OSHA (or other occupational

safety bodies around the world). Of course, the

monetary costs are overshadowed by serious

injuries, or the loss of a valued employee’s life. Fluke

ClirVu IR Windows gives you and your company an

extra layer of protection to avoid the tragedy of an

arc-ash incident.

Convenience at

the turn of a key

ClirVu® IR Windows are designed with hinged

covers that can be easily opened with the

quarter turn latch or key to perform an infrared

inspections. The covers also protect the

windows from accidental exterior impact.

3

2

Punch hole

3

Attach and secure cover

Watch the video at fluke.com/install

www.fluke.com/irwindows 4

Page 4

The line

Fluke ClirVu® IR Windows are

Hierarchy of controls

100 mm (4 in),

75 mm (3 in)

and 50 mm

(2 in)

50 mm

(2 in)

™

Torture Tested

From a northern Canadian winter to a California

desert to the corrosive conditions of offshore oil rigs

and anywhere in between, you can count on ClirVu

IR Windows to stand up to the challenge.

• No more removing the panel door for installation.

• A signicant reduction of work permit requirements

and NFPA 70E processes are now in your future

• Full PPE is often not required so inspections are

done faster and more comfortable

Built to the highest arc blast protection

(63kA arc tested):

• High temperature silicon gaskets

• Mounting and door latches provide high pressure

gasket compression

• Die cast components are manufactured with the

highest strength alloys

• Jam nut screws are made from 4037 steel, heat

treated to 160,000 psi tensile

Torture Tested to the highest test ratings

• IEEE C37.20.7 63 kA Arc tested at KEMA, UL

50/50E/50V, UL1558, IEC60529-1: IP67, IEC 60068,

NEMA 4/12, CSA C22.2 NO. 14-13:2012, and CE

• Corrosion and UV resistance for challenging

outdoor environments

®

Occupational Health and Safety Organization (OSHA) and the National Fire Protection

Association (NFPA) recommend the system of Hierarchy of Controls to minimize

or eliminate exposure to occupational hazards. OSHA and NFPA are United States

organizations but the Hierarchy of Controls concept is relevant worldwide.

Elimination/substitution—removes a hazard all together or controls a hazard

by substituting something in its place that would be non-hazardous or less

hazardous.

Engineering controls—physical changes or modications designed

to eliminate or reduce hazardous exposure to equipment or a work

environment. This is the preferred method for eliminating and reducing

workplace hazards.

Safe work practice controls—safe work practices are designed

to change the way a job is performed to remove the employee

from exposure to the workplace hazard.

Administrative Controls—changes to include additional

backup workers, breaks and the rotation of workers to

reduce exposure to work hazards.

Personal Protective Equipment—protective

equipment or clothing worn by employees to reduce

injuries or exposure to hazardous or toxic substances.

Most effective

IR Window

installations fall

into this category

75 mm

(3 in)

Least

effective

Arc flash facts

The arc flash itself can achieve

temperatures in excess of 35,000 °F.

Source: National Fire Protection Association

95 mm

(4 in)

5 www.fluke.com/irwindows 6

Approximately 2,000 workers will

be admitted to hospital burn units this

year due to thermal burns from arc

flash or arc blast accidents.

Source: National Fire Protection Association

5 to 10 arc flash explosions occur

every day in the US.

Source: CapShell, Inc.

Loading...

Loading...