Page 1

CuffLink

NIBP Analyzer

Operators Manual

PN 2242915

December 2007, Rev. 1, 9/09

© 2007, 2009 Fluke Corporation, All rights reserved. Printed in USA. Specifications subject to change without notice.

All product names are trademarks of their respective companies.

Page 2

Warranty and Product Support

Fluke Biomedical warrants this instrument against defects in materials and workmanship

for one year from the date of original purchase. During the warranty period, we will

repair or at our option replace, at no charge, a product that proves to be defective,

provided you return the product, shipping prepaid, to Fluke Biomedical. This warranty

covers the original purchaser only and is not transferable. The warranty does not apply if

the product has been damaged by accident or misuse or has been serviced or modified by

anyone other than an authorized Fluke Biomedical service facility. NO OTHER

WARRANTIES, SUCH AS FITNESS FOR A PARTICULAR PURPOSE, ARE

EXPRESSED OR IMPLIED. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL,

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

This warranty covers only serialized products and their accessory items that bear a

distinct serial number tag. Recalibration of instruments is not covered under the warranty

This warranty gives you specific legal rights and you may also have other rights that vary

in different jurisdictions. Since some jurisdictions do not allow the exclusion or limitation

of an implied warranty or of incidental or consequential damages, this limitation of

liability may not apply to you. If any provision of this warranty is held invalid or

unenforceable by a court or other decision-maker of competent jurisdiction, such holding

will not affect the validity or enforceability of any other provision.

07/07

Page 3

Notices

All Rights Reserved

© Copyright 2007, Fluke Biomedical. No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval

system, or translated into any language without the written permission of Fluke Biomedical.

Copyright Release

Fluke Biomedical agrees to a limited copyright release that allows you to reproduce manuals and other printed materials for use in

service training programs and other technical publications. If you would like other reproductions or distributions, submit a written

request to Fluke Biomedical.

Unpacking and Inspection

Follow standard receiving practices upon receipt of the instrument. Check the shipping carton for damage. If damage is found, stop

unpacking the instrument. Notify the carrier and ask for an agent to be present while the instrument is unpacked. There are no special

unpacking instructions, but be careful not to damage the instrument when unpacking it. Inspect the instrument for physical damage such

as bent or broken parts, dents, or scratches.

Technical Support

For application support or answers to technical questions, either email techservices@flukebiomedical.com or call 1-800- 648-7952 or

1-425-446-6945.

Claims

Our routine method of shipment is via common carrier, FOB origin. Upon delivery, if physical damage is found, retain all packing

materials in their original condition and contact the carrier immediately to file a claim. If the instrument is delivered in good physical

condition but does not operate within specifications, or if there are any other problems not caused by shipping damage, please contact

Fluke Biomedical or your local sales representative.

Standard Terms and Conditions

Refunds and Credits

Please note that only serialized products and their accessory items (i.e., products and items bearing a distinct serial number

tag) are eligible for partial refund and/or credit. Nonserialized parts and accessory items (e.g., cables, carrying cases,

auxiliary modules, etc.) are not eligible for return or refund. Only products returned within 90 days from the date of original

purchase are eligible for refund/credit. In order to receive a partial refund/credit of a product purchase price on a serialized product, the

product must not have been damaged by the customer or by the carrier chosen by the customer to return the goods, and the product

must be returned complete (meaning with all manuals, cables, accessories, etc.) and in “as new” and resalable condition. Products not

returned within 90 days of purchase, or products which are not in “as new” and resalable condition, are not eligible for credit return and

will be returned to the customer. The Return Procedure (see below) must be followed to assure prompt refund/credit.

Restocking Charges

Products returned within 30 days of original purchase are subject to a minimum restocking fee of 15 %. Products returned in excess of

30 days after purchase, but prior to 90 days, are subject to a minimum restocking fee of 20 %. Additional charges for damage and/or

missing parts and accessories will be applied to all returns.

Return Procedure

All items being returned (including all warranty-claim shipments) must be sent freight-prepaid to our factory location. When you return

an instrument to Fluke Biomedical, we recommend using United Parcel Service, Federal Express, or Air Parcel Post. We also

recommend that you insure your shipment for its actual replacement cost. Fluke Biomedical will not be responsible for lost shipments

or instruments that are received in damaged condition due to improper packaging or handling.

Use the original carton and packaging material for shipment. If they are not available, we recommend the following guide for

repackaging:

Use a double-walled carton of sufficient strength for the weight being shipped.

Use heavy paper or cardboard to protect all instrument surfaces. Use nonabrasive material around all projecting parts.

Use at least four inches of tightly packed, industry-approved, shock-absorbent material around the instrument.

Returns for partial refund/credit:

Every product returned for refund/credit must be accompanied by a Return Material Authorization (RMA) number, obtained from our

Order Entry Group at 1-800-648-7952 or 1-425-446-6945.

Page 4

Repair and calibration:

To find the nearest service center, go to www.flukebiomedical.com/service

In the U.S.A.:

Cleveland Calibration Lab

Tel: 1-800-850-4606

Email: globalcal@flukebiomedical.com

Everett Calibration Lab

Tel: 1-888-993-5853

Email: service.status@fluke.com

In Europe, Middle East, and Africa:

Eindhoven Calibration Lab

Tel: +31-402-675300

Email: ServiceDesk@fluke.com

In Asia:

Everett Calibration Lab

Tel: +425-446-6945

Email: service.international@fluke.com

, or

Certification

This instrument was thoroughly tested and inspected. It was found to meet Fluke Biomedical’s manufacturing specifications when it

was shipped from the factory. Calibration measurements are traceable to the National Institute of Standards and Technology (NIST).

Devices for which there are no NIST calibration standards are measured against in-house performance standards using accepted test

procedures.

WARNING

Unauthorized user modifications or application beyond the published specifications may result in electrical shock hazards or

improper operation. Fluke Biomedical will not be responsible for any injuries sustained due to unauthorized equipment

modifications.

Restrictions and Liabilities

Information in this document is subject to change and does not represent a commitment by Fluke Biomedical. Changes made

to the information in this document will be incorporated in new editions of the publication. No responsibility is assumed by

Fluke Biomedical for the use or reliability of software or equipment that is not supplied by Fluke Biomedical, or by its

affiliated dealers.

Manufacturing Location

The CuffLink NIBP Analyzer is manufactured in Everett, Washington by Fluke Biomedical, 6920 Seaway Blvd., Everett,

WA, U.S.A.

Page 5

Table of Contents

Chapter Title Page

1 Introduction and Specifications......................................................... 1-1

Introduction........................................................................................................ 1-3

Standard Features............................................................................................... 1-4

New Features (Firmware Revision 3.0 and Later)............................................. 1-4

Arrhythmias................................................................................................... 1-4

Pressure Testing............................................................................................. 1-5

Remote Commands ....................................................................................... 1-6

General Safety Considerations........................................................................... 1-6

Symbols ......................................................................................................... 1-6

Warnings and Cautions.................................................................................. 1-7

Instrument Familiarity ....................................................................................... 1-8

Specifications..................................................................................................... 1-12

Accessories ........................................................................................................ 1-16

2 Operation ............................................................................................. 2-1

Powering Up the Analyzer................................................................................. 2-3

Menu Structure and Navigation ......................................................................... 2-3

Preliminary Procedures...................................................................................... 2-6

Assembling Equipment ................................................................................. 2-6

Making Connections...................................................................................... 2-8

Observing Results.......................................................................................... 2-9

Selecting Heart Rate (HtRate) ....................................................................... 2-10

Adjusting the Pressure Envelope (AdjEnv)................................................... 2-11

Simulating Adult Blood Pressure....................................................................... 2-14

Setting Zero Pressure..................................................................................... 2-15

Simulating Other ADAMS Family Target Values ........................................ 2-16

NIBP Monitor Testing Sequence................................................................... 2-16

Simulating Neonatal Blood Pressure ................................................................. 2-17

Simulating Arrhythmias..................................................................................... 2-18

Pressure Testing................................................................................................. 2-19

Leak Testing .................................................................................................. 2-19

Manometer Function ..................................................................................... 2-20

Pop Off Test .................................................................................................. 2-21

Utility Functions ................................................................................................ 2-22

i

Page 6

Cufflink

Operators Manual

Set Clock ....................................................................................................... 2-22

Pop Time ....................................................................................................... 2-24

Logo............................................................................................................... 2-25

System Functions........................................................................................... 2-25

Establishing Communications ........................................................................... 2-31

Configuring RS232........................................................................................ 2-31

Testing the RS232 Port and Connections ...................................................... 2-32

Using Auto Sequences ....................................................................................... 2-33

Executing an Auto Sequence......................................................................... 2-33

Utilities .......................................................................................................... 2-34

Printing Documents ........................................................................................... 2-37

Printing Blood Pressure Test Results ............................................................ 2-37

Printing Manometer, Leak Test, and Overpressure Test Results .................. 2-38

Printing Auto Sequences ............................................................................... 2-38

3 Remote Operation ............................................................................... 3-1

Introduction........................................................................................................ 3-3

Setting Up the medTester .................................................................................. 3-3

Remote Command Syntax ................................................................................. 3-4

Command Syntax for medTester................................................................... 3-4

Command Syntax for Computer.................................................................... 3-4

Command Parameters.................................................................................... 3-4

Terminating Characters ................................................................................. 3-5

Error Messages .............................................................................................. 3-5

Command Descriptions...................................................................................... 3-7

BEEP ............................................................................................................. 3-7

CALPUCKPOS ............................................................................................. 3-8

DEFLATE ..................................................................................................... 3-8

DRAWENV................................................................................................... 3-8

DRAWENVNEO .......................................................................................... 3-11

DRAWPULSE............................................................................................... 3-15

GLOBALINIT............................................................................................... 3-17

GOTOLOCAL............................................................................................... 3-18

IDENT ........................................................................................................... 3-18

INFLATE ...................................................................................................... 3-18

KEYTEST ..................................................................................................... 3-19

LEAKTEST................................................................................................... 3-19

MAKEARM .................................................................................................. 3-20

MAKEARMNEO .......................................................................................... 3-23

MANOMETER ............................................................................................. 3-27

MKARM10.................................................................................................... 3-27

MKARM20.................................................................................................... 3-27

MKARM30.................................................................................................... 3-28

MKARM40.................................................................................................... 3-28

MKARM50.................................................................................................... 3-28

MKARM60.................................................................................................... 3-28

MKARM70.................................................................................................... 3-29

MKARMNEO10 ........................................................................................... 3-29

MKARMNEO20 ........................................................................................... 3-29

MKARMNEO30 ........................................................................................... 3-29

MKARMNEO40 ........................................................................................... 3-30

MKARMNEO50 ........................................................................................... 3-30

MKARR_AF ................................................................................................. 3-30

MKARR_MB ................................................................................................ 3-30

ii

Page 7

Contents (continued)

MKARR_PAC............................................................................................... 3-31

MKARR_PVC............................................................................................... 3-31

MKARR_AS ................................................................................................. 3-31

POPOFF ........................................................................................................ 3-32

PRINTTEST .................................................................................................. 3-32

PSCALE ........................................................................................................ 3-33

PULSE........................................................................................................... 3-34

PUMPPCB..................................................................................................... 3-36

RCUSERENV ............................................................................................... 3-36

RDCLOCK.................................................................................................... 3-36

RDENVGAIN ............................................................................................... 3-36

RDENVSHIFT .............................................................................................. 3-37

RDPEAKDIV................................................................................................ 3-37

RDQCDATE ................................................................................................. 3-37

RDUSERENV ............................................................................................... 3-37

READPRESS ................................................................................................ 3-38

RESET........................................................................................................... 3-38

STUSERENV................................................................................................ 3-39

WRCLOCK ................................................................................................... 3-39

WRPEAKDIV ............................................................................................... 3-40

WRUSERENV .............................................................................................. 3-40

ZEROPRESS................................................................................................. 3-41

Programming with Analyzer Commands........................................................... 3-41

Checklist Generated in BASIC...................................................................... 3-41

Adult BP Checklists and Test Results ........................................................... 3-43

Neonate BP Checklists and Test Results....................................................... 3-47

Adult Arrhythmic BP Checklists and Test Results........................................ 3-51

Additional Command Descriptions (Firmware Version 3.20)........................... 3-55

PUMPON ...................................................................................................... 3-55

PUMPOFF..................................................................................................... 3-55

VALVEOPEN ............................................................................................... 3-55

VALVECLOSED .......................................................................................... 3-56

4 Maintenance, Service, and Calibration.............................................. 4-1

Maintenance....................................................................................................... 4-3

Avoiding Damage.......................................................................................... 4-3

Cleaning......................................................................................................... 4-3

Service and Calibration...................................................................................... 4-3

Appendices

A Non-Invasive Blood Pressure (NIBP) Monitoring Tutorial ........................ A-1

B Glossary....................................................................................................... B-1

iii

Page 8

Cufflink

Operators Manual

iv

Page 9

List of Tables

Table Title Page

1-1. New RS232 Remote Commands............................................................................ 1-6

1-2. Symbols.................................................................................................................. 1-6

1-3. Analyzer Top and Front Panel Controls and Indicators ......................................... 1-8

1-4. Rear Panel Controls and Indicators........................................................................ 1-11

1-5. Standard Accessories ............................................................................................. 1-16

2-1. Blood Pressure Parameters Provided by the Select BP Option.............................. 2-6

2-2. Measured Test Parameters ..................................................................................... 2-10

2-3. Arrhythmia Types .................................................................................................. 2-18

2-4. Leak Test Utility Options....................................................................................... 2-20

2-5. Measured Leak Test Parameters ............................................................................ 2-20

2-6. Measured Manometer Parameters.......................................................................... 2-21

2-7. Measured Pop Off Test Parameters........................................................................ 2-22

2-8. Speaker Tests and Adjustments.............................................................................. 2-27

2-9. Display Test Descriptions ...................................................................................... 2-28

2-10. Pop Time and Comm Port Default Values ............................................................. 2-29

2-11. Auto Sequence Defaults ......................................................................................... 2-30

2-12. RS232 Settings ....................................................................................................... 2-32

3-1. medTester Remote Configuration Settings ............................................................ 3-3

3-2. Available Error Messages ...................................................................................... 3-6

3-3. Autosequence Defaults........................................................................................... 3-17

3-4. Pop Time and Comm Port Default Values............................................................. 3-17

v

Page 10

Cufflink

Operators Manual

vi

Page 11

List of Figures

Figure Title Page

1-1. CuffLink Non-Invasive Blood Pressure Analyzer ................................................. 1-3

1-2. Cuff pressure waveform during blood pressure measurement............................... 1-4

1-3. Analyzer Top and Front Panel Controls and Indicators ......................................... 1-8

1-4. Rear Panel Controls and Indicators........................................................................ 1-11

2-1. Analyzer Menu Map .............................................................................................. 2-4

2-2. Adjustments for Adult Cuff Mandrel..................................................................... 2-7

2-3. Neonate Mandrel.................................................................................................... 2-7

2-4. NIBP Test System Diagram ................................................................................... 2-8

2-5. Makearm Display of Test Results .......................................................................... 2-9

2-6. Sample Printout of Auto Sequence Content........................................................... 2-36

2-7. Sample Printout of Adams Adult Family 120/80 Test Results .............................. 2-38

2-8. Sample Printout of Manometer Test Results.......................................................... 2-38

2-9. Sample Printout of Leak Test Results .................................................................... 2-38

2-10. Sample Printout of Overpressure Test Results....................................................... 2-38

2-11. Sample Printout of Adult Auto Sequence Content................................................. 2-40

2-12. Sample Printout of Adult Auto Sequence Test Results.......................................... 2-41

2-13. Sample Printout of Adult BP with Arrhythmia Auto Sequence Content ............... 2-42

2-14. Sample Printout of Adult BP with Arrhythmia Auto Sequence Test Results ........ 2-43

2-15. Sample Printout of Neonate Auto Sequence Content ............................................ 2-44

2-16. Sample Printout of Neonate Auto Sequence Test Results ..................................... 2-46

3-1. Analyzer Adult Blood Pressure Envelope (BP = 120/80)...................................... 3-8

3-2. Analyzer Neonate Blood Pressure Envelope (BP = 120/80).................................. 3-11

3-3. Analyzer Pressure Pulse #3 .................................................................................... 3-15

3-4. POPOFF Command Display .................................................................................. 3-32

3-5. Scale Pulse Amplitude Display.............................................................................. 3-33

3-6. A BASIC Program using Analyzer Remote Commands........................................ 3-42

3-7. medBase Adult BP Checklist ................................................................................. 3-43

3-8. medBase Adult BP Test Results............................................................................. 3-44

3-9. Sentinel Adult BP Checklist................................................................................... 3-45

3-10. Sentinel Adult BP Test Results .............................................................................. 3-46

3-11. medBase Neonate BP Checklist............................................................................. 3-47

3-12. medBase Neonate BP Test Results ........................................................................ 3-48

3-13. Sentinel Neonate BP Checklist .............................................................................. 3-49

3-14. Sentinel Neonate BP Test Results .......................................................................... 3-50

3-15. medBase Adult Arrhythmic BP Checklist.............................................................. 3-51

vii

Page 12

Cufflink

Operators Manual

3-16. medBase Adult Arrhythmic BP Test Results......................................................... 3-52

3-17. Sentinel Adult Arrhythmic BP Checklist ............................................................... 3-53

3-18. Sentinel Adult Arrhythmic BP Test Results........................................................... 3-54

viii

Page 13

Chapter 1

Introduction and Specifications

Title Page

Introduction........................................................................................................ 1-3

Standard Features............................................................................................... 1-4

New Features (Firmware Revision 3.0 and Later)............................................. 1-4

Arrhythmias................................................................................................... 1-4

Pressure Testing............................................................................................. 1-5

Remote Commands ....................................................................................... 1-6

General Safety Considerations........................................................................... 1-6

Symbols ......................................................................................................... 1-6

Warnings and Cautions.................................................................................. 1-7

Instrument Familiarity ....................................................................................... 1-8

Specifications..................................................................................................... 1-12

Accessories ........................................................................................................ 1-16

1-1

Page 14

Cufflink

Operators Manual

1-2

Page 15

Introduction and Specifications

Introduction 1

Introduction

The CuffLink Non-Invasive Blood Pressure Analyzer, hereafter referred to as the

Analyzer, provides accurate and repeatable dynamic blood pressure (BP) waveforms for

evaluation of both semi and fully automated oscillometric non-invasive blood pressure

(NIBP) devices. The Analyzer is shown in Figure 1-1.

CuffLink

NON-INVASIVE BLOOD PRESSURE ANA

LYZER

ESC

F1

F2

F3

F4

F5

BEEPER

V

OLUM

ENT

DISPL

E

AY

VIEW

Max

Da

r

k

fcv001.eps

CUFF

CONNECT

mmHg

CUFF

mmHg

OUTPUTS

PULSE

mHg

DC

Figure 1-1. CuffLink Non-Invasive Blood Pressure Analyzer

To test a device, wrap the BP cuff around the supplied mandrel and insert the cuff adapter

in the pressurized line. All tests are conducted with the BP cuff connected to the system.

The Analyzer can generate BP waveforms for seven adult (oscillometric), five neonate

(oscillometric), and 5 arrhythmias. The different systolic/diastolic pressure gradients

simulate a physiological range of normal, hypotensive, and hypertensive adult or neonate

patients. Actual patient data was used to design the preprogrammed peripheral pulse

waveforms and envelopes.

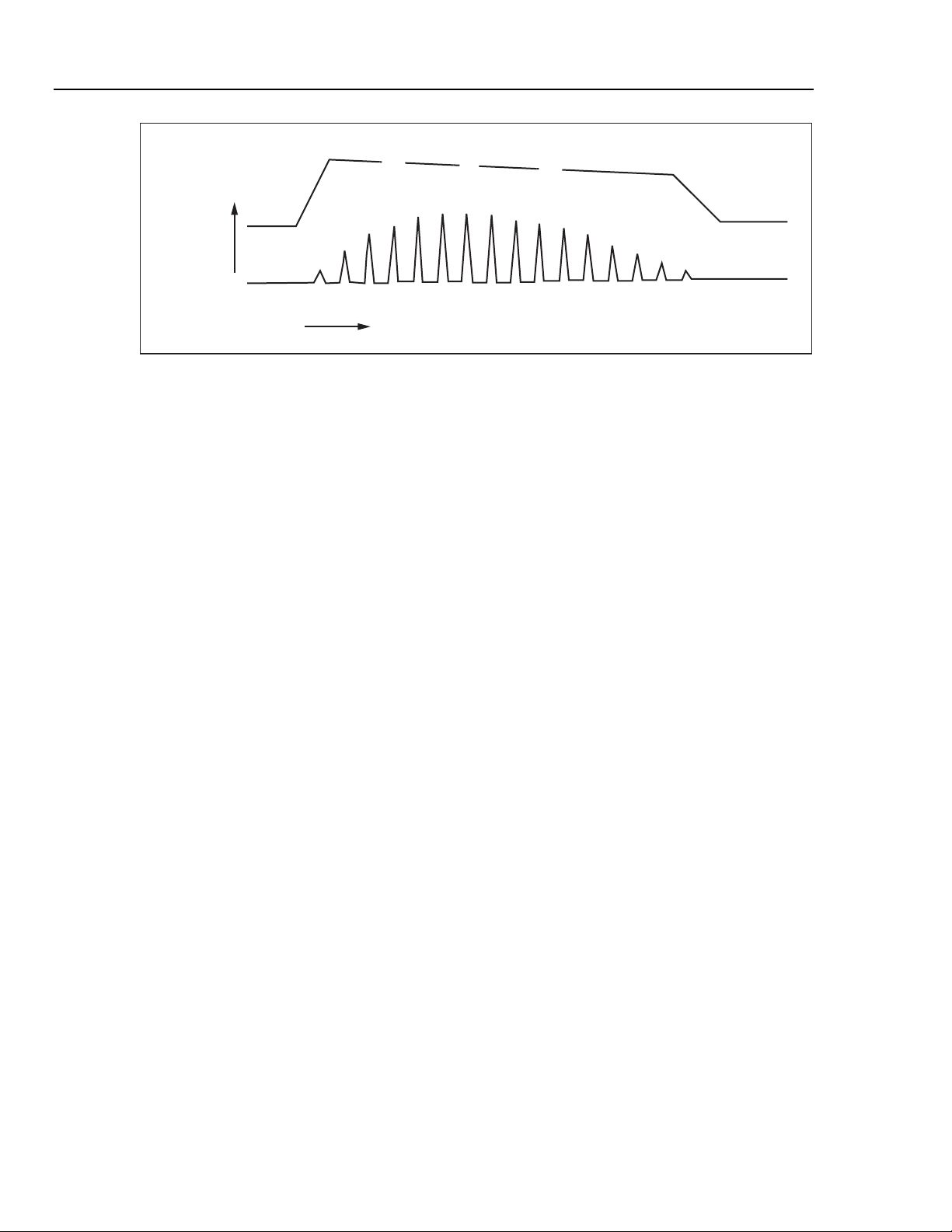

The Analyzer can produce qualitative measurements of BP cuff pressure and inflate /

deflate timing, as shown in Figure 1-2.

1-3

Page 16

Cufflink

Operators Manual

CUFF

PRESSURE

TIME

Figure 1-2. Cuff pressure waveform during blood pressure measurement

The Analyzer also offers automated leak testing of NIBP monitors. An internal pump

pressurizes the NIBP system under test. Press a key to initiate a 60 second leak test once

the desired pressure is reached. Use the Analyzer’s digital manometer instead of a

mercury column for doing pressure measurements. The Analyzer facilitates overpressure

testing of NIBP monitors by automatically detecting and displaying the overpressure

point.

Standard Features

The Analyzer has the following standard features:

• Dynamic oscillometric noninvasive blood pressure simulation

SYS

OSCILLATION AMPLITUDE

MAP

DIA

fcv002.eps

• Automated static pressure measurements, leakage testing, and relief-valve testing

• Five automated NIBP testing autosequences

• Five arrhythmia selections

• Adult and neonatal NIBP selections

• Direct interface with medTester 5000C

• Adjustable heart rate values

• Calendar clock with battery backup

• Internal PCB expansion slot

New Features (Firmware Revision 3.0 and Later)

Firmware revision 3.0 included the following additions and updates, including a set of

adult arrhythmias, an internal pump, and additions to pressure testing.

Arrhythmias

The Analyzer features five new arrhythmias to test NIBP monitors in the presence of

typical patient arrhythmias. These clinically derived simulations are representations of

the peripheral pulse, as seen by an oscillometric NIBP monitor.

Each arrhythmia is generated on a random basis throughout the entire pressure curve

cycle. The variations in pulse timing and amplitude are relatively small.

1-4

Page 17

Introduction and Specifications

New Features (Firmware Revision 3.0 and Later) 1

Premature Atrial Contraction (PAC)

The first pulse of the PAC cycle is premature and lower in amplitude than a normal sinus

pulse. The next pulse would be back in sync with normal sinus and slightly higher in

amplitude. All subsequent pulses are normal.

Premature Ventricular Contraction (PVC)

This is a representation of the peripheral pulse similar to PAC

Atrial Fibrillation (AF)

The AF cycle has an irregular R to R interval. Its occurrence and properties (early vs.

late) are random throughout the pressure curve cycle.

Missed Beat (MB)

A complete beat is randomly skipped during the pressure curve cycle. The following beat

reverts to normal R to R intervals.

Aberrant Sinus Conduction (AS)

The AS cycle inserts one pulse so low that it is virtually non-existent. This causes the

Analyzer to skip one diastolic pulse and then return to normal sinus pulses.

Pressure Testing

The Analyzer now has the following enhancements to its pressure testing capability.

Internal Pump

The Analyzer now has an internal compressor which eliminates the need to manually

inflate the cuff for NIBP monitor testing. This automates static pressure measurements,

leak testing, and relief valve testing.

Pop Off Added to Press Menu

Perform over-pressure tests on NIBP monitors with this addition to the PRESS menu.

Utility Menu Added to Leak Test

Select cuff size, turn printing on or off, and choose a target pressure for leak testing.

Manometer

The Analyzer simulates a digital manometer with pump capabilities.

1-5

Page 18

Cufflink

Operators Manual

Remote Commands

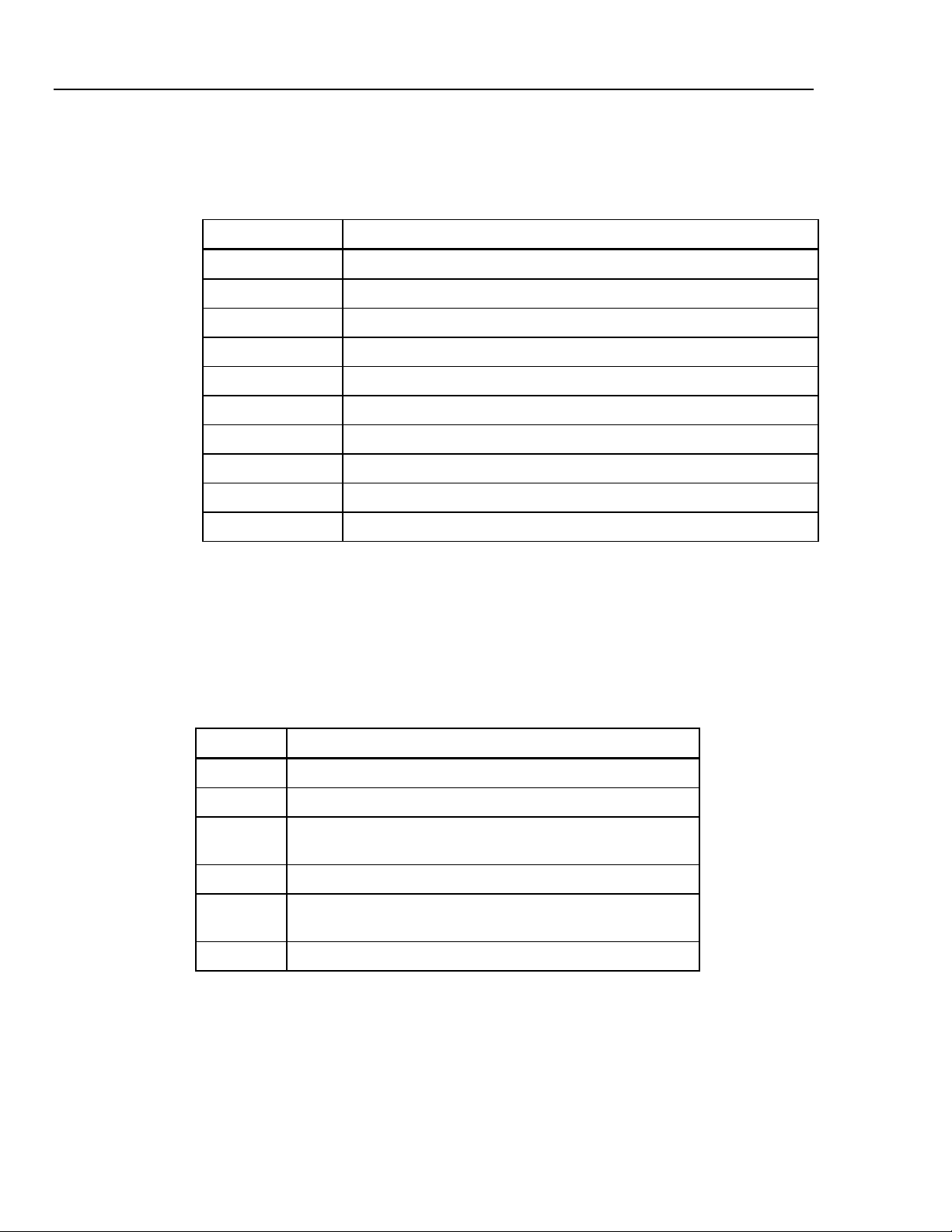

Table 1-1 lists new CuffLink RS232 commands to support new functions.

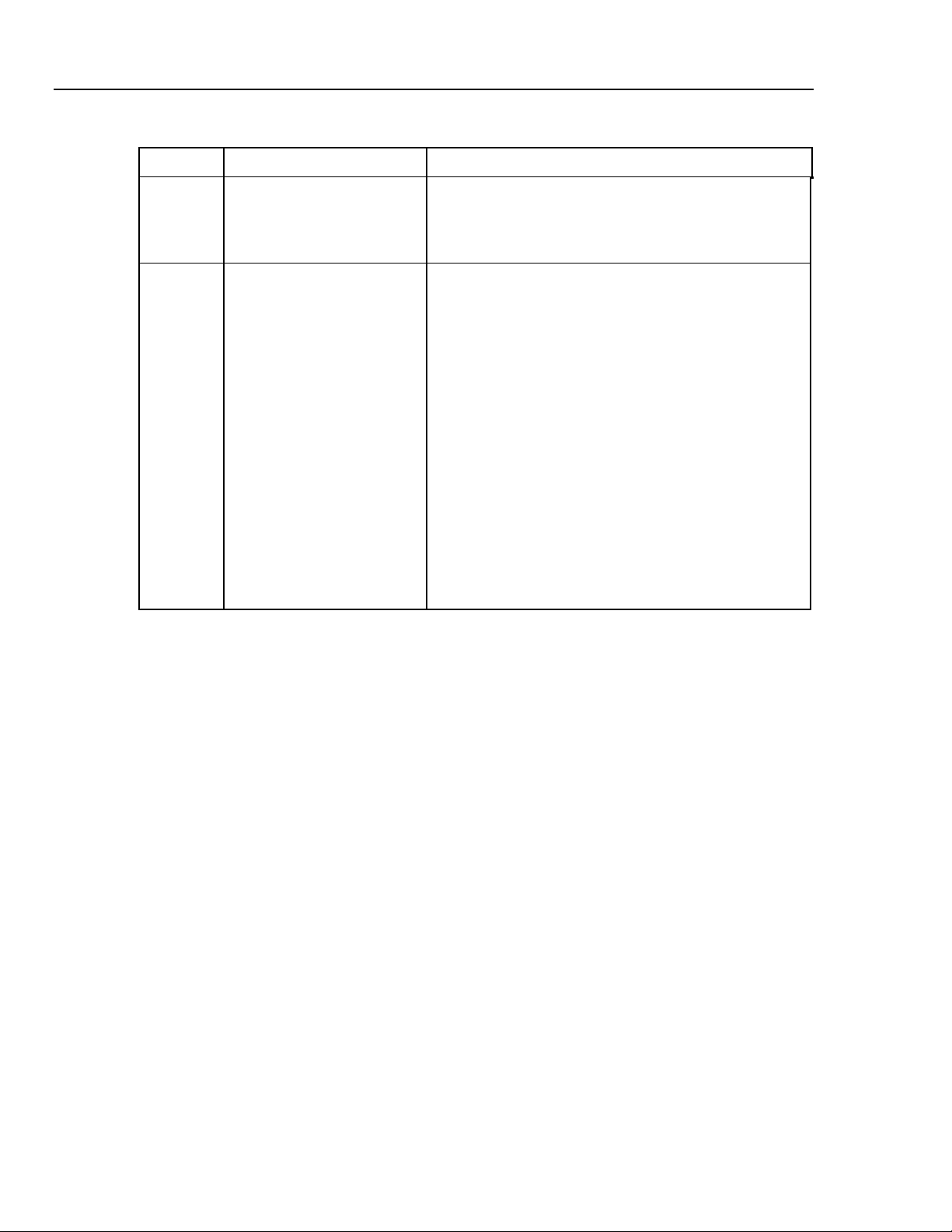

Table 1-1. New RS232 Remote Commands

Command Function

DEFLATE Releases pressure inside CuffLink

INFLATE Pumps CuffLink to 200 mmHg or specified pressure

KEYTEST Tests CuffLink's keyboard

MKARR_AF Simulates atrial fibrillation

MKARR_MB Simulates a missed beat

MKARR_PAC Simulates premature atrial contraction

MKARR_PVC Simulates premature ventricular contraction

MKARR_AS As Simulates aberrant sinus conduction

POPOFF Tests monitor's overpressure valve

PUMPPCB Determines if pump PCB is installed in CuffLink

General Safety Considerations

Read the Users Manual before operating the Analyzer.

Symbols

Table 1-2 describes the symbols associated with the Analyzer.

Table 1-2. Symbols

Symbol Description

X Hazardous voltage

W Important information; refer to manual.

Œ

P Conforms to European Union directives

~

Hg Contains mercury. Dispose properly.

Conforms to UL Std 3101-1; certified to CAN/USA Std C22.2 No.

1010.1

Do not dispose of this product as unsorted municipal waste. Go

to Fluke’s website for recycling information.

1-6

Page 19

Introduction and Specifications

General Safety Considerations 1

Warnings and Cautions

A Warning identifies hazardous conditions and actions that could cause bodily harm or

death.

A Caution identifies conditions and actions that could damage the Analyzer, the

equipment under test, or cause permanent loss of data.

XW Warning

To avoid possible electrical shock or personal injury, follow

these guidelines:

• Use this Analyzer only in the manner specified by the

manufacturer.

• Do not use the product if it operates abnormally.

• Do not connect the Analyzer to a patient or equipment

connected to a patient. The Analyzer is intended for

equipment evaluation only and should never be used in

diagnostics, treatment or in any other capacity where the

Analyzer would come in contact with a patient.

• Do not use the product in wet locations, around explosive

gases or dust.

• Never open the Analyzer's case. Dangerous voltages are

present. There are no user replaceable parts in the

Analyzer.

• Have the Analyzer serviced only by qualified personnel.

• The Analyzer must be properly earthed. Only use a supply

socket that has a protective earth contact. If there is any

doubt as to the effectiveness of the supply socket earth, do

not connect the Analyzer.

• Do not use a two-conductor adapter or extension cord; this

will break the protective ground connection.

W Caution

To avoid damage to the Analyzer or adverse affects on its

performance, follow these guidelines:

• Do not expose the system to temperature extremes. Ambient

temperatures should remain between 0 °C and 50 °C. System

performance may be adversely affected if temperatures fluctuate

above or below this range.

• Clean the Analyzer only by wiping it down with a clean, lint-free

cloth dampened with a mild detergent solution. Do not spray

liquid directly on or immerse the unit.

1-7

Page 20

Cufflink

Operators Manual

Instrument Familiarity

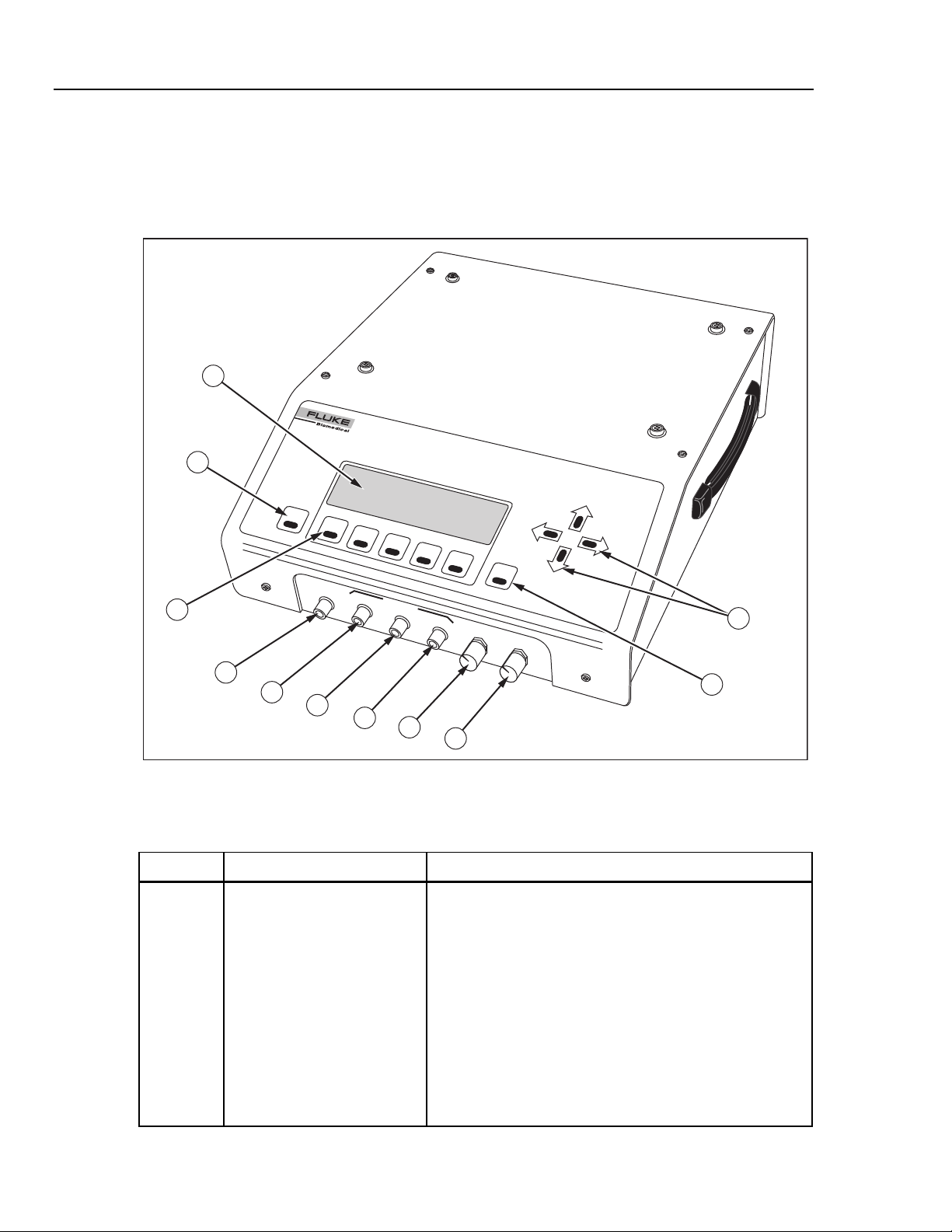

Figure 1-3 shows the top and front panel controls and indicators of the Analyzer.

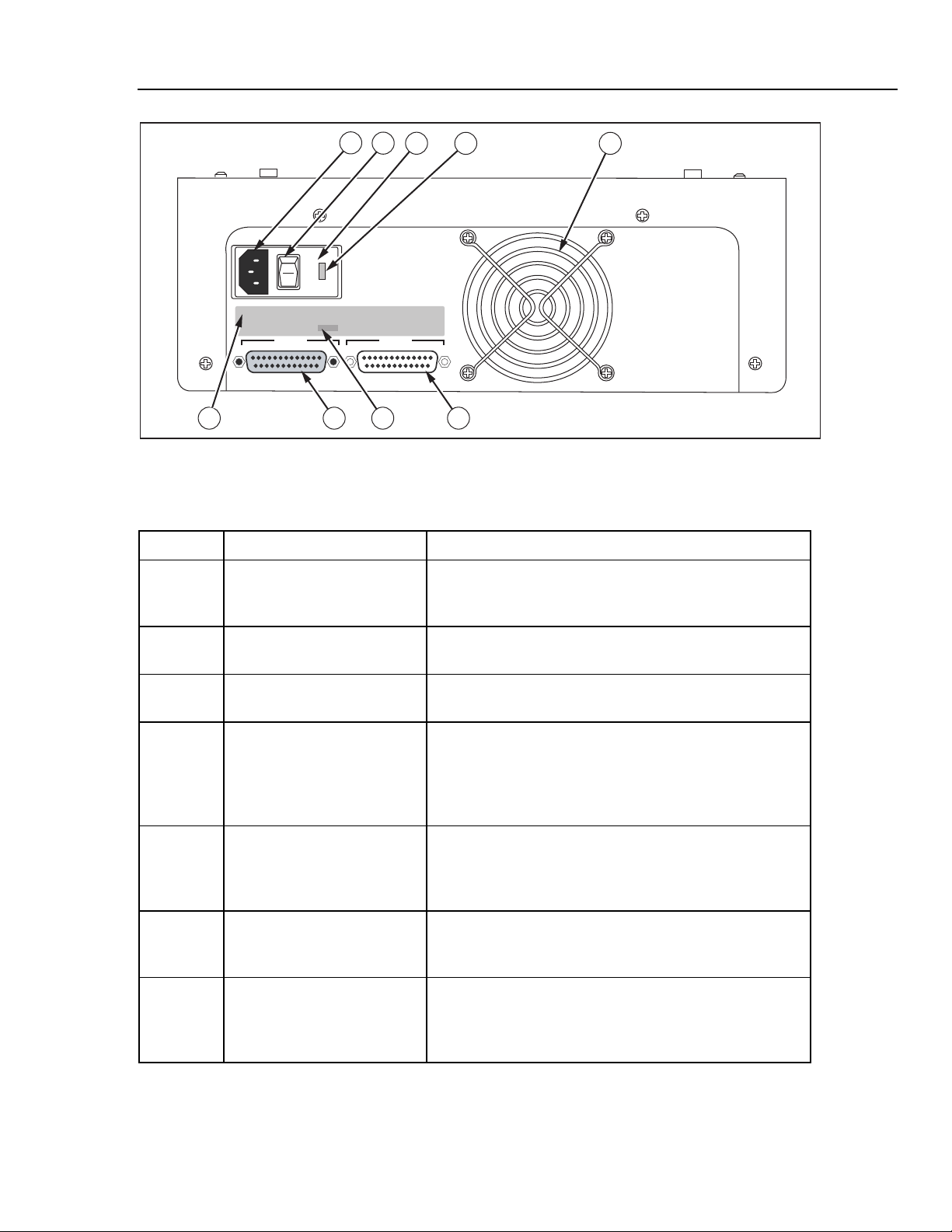

Table 1-3 lists these components with accompanying descriptions. Figure 1-4 shows the

rear panel controls and indicators, and Table 1-4 lists and describes these components.

1

CuffLink

NON-INVASIVE BLOOD PRESSURE ANA

L

YZE

R

2

ESC

F1

F2

F3

F4

F5

BEEPER

V

OLUM

ENT

11

DISPL

E

AY

VIEW

Max

Da

r

k

10

CUFF

CONNECT

CUFF

OUTPUTS

mmHg

PULSE

mHg

DC

3

mmHg

4

5

6

7

8

9

Figure 1-3. Analyzer Top and Front Panel Controls and Indicators

Table 1-3. Analyzer Top and Front Panel Controls and Indicators

Label Component Description

A Display The LCD (Liquid Crystal Display) is a full alphanumeric and

graphic display. The maximum number of characters able

to be on a single line at any given time is 40, and the

number of lines from top to bottom is 8, thereby producing a

possible 320 character display. The graphics mode of the

display is defined by a grid of 64 vertical pixels by 240

horizontal pixels. This mode enables display of the cuff

pressure waveform.

fcv003.eps

1-8

Display viewing angle is adjustable, so if the display appears

blank (view angle set too low), or dark (view angle set too

high) the view angle may need to be adjusted for optimum

visibility (see Display View Control Knob).

Page 21

Introduction and Specifications

Table 1-3. Analyzer Top and Front Panel Controls and Indicators (cont.)

Label Component Description

Instrument Familiarity 1

B Esc Key The Esc (escape) key enables the user to exit any menu,

exit without saving new data, or abort any function of

CuffLink. Continuously holding down the Esc key will return

the user to the CuffLink logo display from any menu.

C Function Keys The function keys are labeled Fl through F5. Pressing any

one of these keys will execute the function, defined by

software, that is displayed above that particular key.

D Cuff Connect A quick disconnect type of port provides the output

connection from the pulse producing motor inside Cufflink,

to the line connecting the cuff and the BP patient monitor.

E Cuff Output This is a voltage output proportional to cuff pressure

(10mv/mmHg). It is always active with a range of -5 V dc to

+5 V dc (-500 mmHg to +500 mmHg). The accuracy is

specified for positive pressures only.

Example:

1.0 V = 100 mmHg

2.5 V = 250 mmHg

This signal is also useful when connected to a storage

oscilloscope or strip recorder to observe the cuff

inflate/deflate cycle.

Output impedance is 100 Ω.

F Pulse output This is a voltage output proportional to pulse pressure. It is

only active when Cufflink is outputting pressure pulses. The

output is at 0 V in the inactive state. The pulse voltage is

taken from the pressure transducer and the large static cuff

pressure is subtracted. For example, if the cuff is inflated to

150 mmHg and the pulse is 1.2 mmHg in amplitude, only the

1.2 mmHg portion of the signal is presented at this output.

The pulse output voltage is 1 V dc/mmHg and has a range

of -5 VDC to +5 VDC (-5 mmHg to +5 mmHg).

Example:

1.0 V = 1.0 mmHg pulse

0.5 V = 0.5 mmHg pulse

When Cufflink is simulating blood pressure it removes the

static cuff pressure from the pulse output (forcing it to 0

VDC) at the beginning of each heartbeat. During the

heartbeat the amplitude of the pulse is output. As the cuff

deflates (or inflates) this process is repeated for each

heartbeat.

Output impedance is 100 Ω.

1-9

Page 22

Cufflink

Operators Manual

Table 1-3. Analyzer Top and Front Panel Controls and Indicators (cont.)

Label Component Description

G Sync Output This is a logic level (0 to 5VDC) that outputs a pulse at the

start of every heartbeat. When CuffLink is not outputting

pressure pulses this output is at OVDC. When CuffLink is

outputting pressure pulses the output is high (5VDC) during

the pulse and low between the end of one pulse and the

start of the next pulse. This output is useful for measuring

heart rate and synchronizing a scope trigger for viewing

individual pressure pulses on the pulse output.

Output impedance is 100 Ω.

H Beeper Volume Control Knob The amplitude of the CuffLink audible feedback may be

adjusted by turning the beeper volume control knob. Turning

the knob clockwise (towards the MAX label next to the knob)

will increase the volume of the beeper, while turning the

knob counterclockwise will decrease the beeper volume.

I Display View Control Knob The angle at which the display is most visible is adjustable

with the display view control knob. Turning the knob

clockwise (towards the DARK label next to the knob) will

increase the contrast of the display, or make the display

darker. Turning the knob counterclockwise will decrease the

contrast, making the display lighter.

J Ent Key Pressing the Ent (enter) key will select a highlighted menu,

initiate a CuffLink function, or store data in EEROM. In

effect, the enter key is the opposite of the Esc key.

K Arrow keys The arrow keys are the cursor control keys. Pressing the up

arrow key moves the cursor on the display in a upward

direction or increases the highlighted value. Pressing the

down arrow key moves the cursor on the display in a

downward direction or decreases the highlighted value. The

down arrow key is also capable of pulling down the

submenus of a highlighted main menu. Pressing the left or

right arrow keys will produce cursor movement in the

corresponding direction. Holding any arrow key down

continuously will cause a repeating of the action of that key.

L Handle The handle for transporting CuffLink is located on the right

side of the instrument case.

1-10

Page 23

Introduction and Specifications

1

2

3

115

I

O

4 5

CuffLink sn 3480

Instrument Familiarity 1

FUSE T3.15a 100-115 VAC 50/60Hz

FUSE T1A 200-230 VAC 50/60Hz

SERIAL NUMBER

PRINTER

3480

INPUT POWER 60 VA

FLUKE BIOMEDICAL CORPORATION

CARSON CITY, NEVADA

MADE IN THE U.S.A

RS232

679 8

Figure 1-4. Rear Panel Controls and Indicators

fcv004.eps

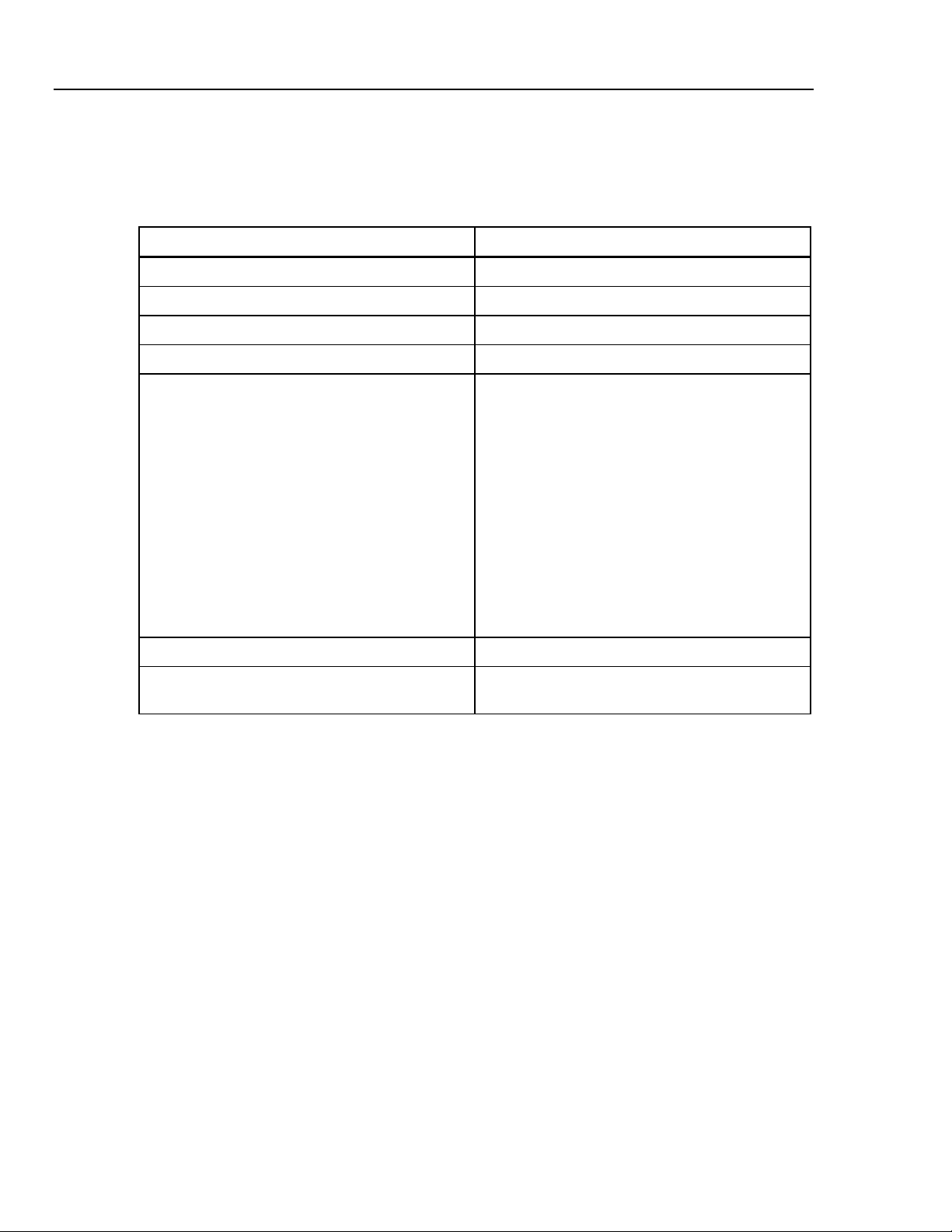

Table 1-4. Rear Panel Controls and Indicators

Label Component Description

A Power Cord Input The input for the Cufflink power cord is located next to the

power switch. This is the connection for the detachable

power cord.

B Power Switch The on position of the power switch is represented by 1 and

the off position is labeled 0.

C Fuse Cover The fuse(s) are located behind the fuse cover. The fuse

cover may be carefully pried open at 3a.

D Voltage Selector CuffLink is able to operate on two different line voltages.

The voltage selector indicates the voltage (either 120V or

240V) at which CuffLink will operate. There are an

additional two voltages (100V and 220V) listed on the back

panel. These do not apply to CuffLink.

E Fan Intake A hole cut in the rear panel of the case provides ventilation

for Cufflink from the fan. Care should be exercised not to

block the fan intake or to insert anything into the metal

protector.

F RS232 Port This is the connector for the RS-232 serial interface. It

is a 25 pin (DB25), male, D shell connector (same

pinout as PC compatible computer).

G Printer Port The connector for the parallel printer is a 25 pin

(DB25), female, D shell connector. The printer port is

Centronics compatible (same pinout as a PC

compatible computer).

1-11

Page 24

Cufflink

Operators Manual

Table 1-4. Rear Panel Controls and Indicators

Label Component Description

H Serial Port The four digit Cufflink serial number is located above

the printer port. The serial number should be

documented along with the model number whenever

Cufflink is shipped to Dynatech Nevada.

I Fuse Label The fuse label documents the type of fuses needed.

Use one 1ASB 250 V ac fuse (DNI part no. 1005-

0184) if Cufflink is set for 120 V operation, and two

1/2 A 250 V ac fuses (DNI part no. 1005-0185) if

Cufflink is set for 240 V operation.

Replacing Fuses

1. Turn Cufflink's power off and unplug the power cord.

2. Remove the fuse cover with a small blade screwdriver.

The plastic fuse holder should pop out of the Cufflink

case.

3. Use the screwdriver to pry the old fuse out of the plastic

holder.

4. Install the new fuse.

5. Replace the fuse holder by simply pushing the fuse

holder back into place.

Specifications

The following are general and electrical specifications for the Analyzer.

Physical Dimensions

Size ......................................................................... Width 12.5 inches

Weight..................................................................... 15 pounds

Power Requirements

Power ..................................................................... 120/250 V ac

Input voltage range...................................................... 60 VA

Fuses ...................................................................... T3.15a 110-115 V ac 50/60 Hz

Environmental Conditions

Operating Temperature........................................... 15 °C to 40 °C

Storage Temperature.............................................. -20 °C to +65 °C

Relative Humidity.................................................... 90 % max

Height 5.0 inches

Length 15.0 inches

50 Watts average

100 Watts peak

50/60 Hz

T1A 200-300 V ac 50/60 Hz

1-12

Page 25

Introduction and Specifications

Specifications 1

Display

Alphanumeric and Graphic LCD Display

Alphanumeric Mode............................................ 8 lines by 40 characters

Graphics Mode ................................................... 64 vertical by 240 horizontal dot matrix

Illumination.............................................................. Backlight with Viewing Angle Adjustment

Displayed Graphics................................................. Dynamic real-time NIBP cuff-pressure waveform, programmed

peripheral pulse and envelope waveforms

Control Keys

Function Keys ........................................................ F1 to F5

Cursor .................................................................... Up

Enter

Escape

Down

Left

Right

Parameter Selections

Menus ..................................................................... Pull down with on-screen help

Function keys.......................................................... Software defined, F1 to F5

Storage

Environment............................................................ Store in a dry area, temperature range of 32°F to 122°F.

Inspection or maintenance during storage.............. None required

Digital Interfaces

RS232/Serial........................................................... Baud Rates: 300, 600, 1200, 2400, 4800, 9600

Parallel Port (Printer) .............................................. Centronics compatible

Pulse Sync .............................................................. 0 to 5 V dc (TTL)

Stop Bits: 1, 2

Parity: Odd, Even, Off

Handshake: Xon/Xoff, RTS/CTS, None

Target Blood Pressure Selections

Select BP

Target Value (MAP)

(mmHg)

Adult 60/30 (40)

80/50 (62)

100/65 (75)

120/80 (90)

150/100 (115)

200/150 (165)

255/195 (215)

Neonate 60/30 (40)

80/50 (62)

100/65 (75)

120/80 (90)

150/100 (115)

Arrhythmias 120/80 (90) 80 Premature Atrial Contraction

HR

(BPM)

30

40

60

120

160

200

240

30

40

60

120

160

200

240

Waveform Type

Normal Sinus

Normal Sinus

Premature Ventricular Contraction

Atrial Fibrillation

Missed Beat

Aberrant Sinus Conduction

1-13

Page 26

Cufflink

Operators Manual

Preprogrammed Pulse Envelope

Horizontal Axis (cuff pressure) ............................... 0 to 300 mmHg in 1.0 mmHg steps

Vertical Axis ............................................................ 2.0 mmHg (nominal)

Pulse Amplitude (adult) .......................................... 2.0 mmHg @ MAP 100% gain

Repeatability ........................................................... ±1 % of selected target value

Pulse Waveforms

100% gain with normal adult cuff

0 to 2% selectable

Pulse ID # Pulse Width (ms) Rise Time (ms)

0 800 270

1 500 165

2 250 85

3 720 90

4 230 80

5 280 96

6 350 100

7 480 108

8 980 180

9 1980 460

10 1480 330

Digital Manometer

Pressure Range ...................................................... Maximum = 499.75 mmHg

Measurement Parameters ...................................... Instantaneous and peak

Pump....................................................................... 2.0 liter/minute minimum (free flow)

Automated Leak Testing

Start Pressure ......................................................... Maximum = 499.75 mmHg

Elapsed Time .......................................................... Fixed at 60 seconds

Leak Rate Range .................................................... 0.25 to 499.75 mmHg/minute

Pump....................................................................... 2.0 liter/minute minimum (free flow)

Monitor Pop-off Relief Valve Testing

Measurement Parameters ...................................... Instantaneous and peak pressure

Maximum Pressure ................................................. 499.75 mmHg

Accuracy

Dynamic NIBP Response Repeatability

(Systolic/Diastalic/Mean)......................................... ±1 % of Target Value

Cuff Pressure .......................................................... ±1.0 % of reading (±1 mmHg)

Input Overpressure Limit......................................... ±1500 mmHg

1-14

Page 27

Introduction and Specifications

Specifications 1

Ranges for MAKEARM Test Values

On Line Cuff Pressure ............................................ 0.0 to 500 mmHg on display

Peak Cuff Pressure................................................. 500 mmHg peak

Inflate Time ............................................................. 0.1 to 999.9 seconds

Inflate Rate.............................................................. 0.1 to 999.9 mmHg/second

Deflate Time............................................................ 0.1 to 999.9 seconds

Deflate Rate ............................................................ 0.1 to 999.9 mmHg/second

Total Measurement Time ........................................ 999.9 seconds maximum

Heart Rate............................................................... 30

0.0 to 300 mmHg on graph

40

60

80

120

160

200

240

Analog Outputs

Cuff Pressure .......................................................... 0 to 499.75 mmHg FS, ±1.0 % of reading,

Pulse Pressure........................................................ 0 to 5.0 mmHg FS, ±1.0 % of reading

±±.0 mmHg (cuff)

10 mV/mmHg

1.0 V/mmHg

Mandrels

Adult........................................................................ Five interlocking plastic blocks that produce four circumferences;

Large Adult................................................................ 39.5 cm; use all blocks

Adult.................................................................... 33 cm; use 2 curved end blocks and 2 rectangle blocks

Small Adult.......................................................... 26.6 cm; use 2 curved end blocks and 1 rectangle block

Child.................................................................... 20 cm; use 2 curved end blocks

Neonate .................................................................. One plastic truncated cylinder that accommodates three different

circumferences: 14 cm, 10 cm, and 7.6 cm; maximum cuff width of

7.6 cm.

a maximum cuff width of 15.25 cm:

1-15

Page 28

Cufflink

Operators Manual

Accessories

Soft vinyl accessory pouch 2248408

Operators Manual 2242915

Hospital grade power cord set 2198846

Adult cuff mandrel spacer blocks 2392381

Table 1-5 lists standard accessories provided with the Analyzer.

Table 1-5. Standard Accessories

Accessory Part Number

Cuff/hose adapters (8)

Male/Female LUER Locking

Female/Mole LUER Non-Locking Taper

5/32" Male/Male Hose Barb

¼” Male/Male Hose Barb

1/8" Male/Male Hose Barb

Male/Female Clippard (Critikon, Siemens)

Colder/CPC (Marquette, Protocol)

OBAC Quick Release (Hewlett Packard)

Adult cuff mandrel end blocks (two required) 2230305

External cuff mandrel neonatal (truncated plastic

cylinder diameters: 7, 6, 10, and 14 cm)

2242233

2242225

2242257

2242284

2242240

2242190

2242202

2242216

2392328

1-16

Page 29

Chapter 2

Operation

Title Page

Powering Up the Analyzer................................................................................. 2-3

Menu Structure and Navigation ......................................................................... 2-3

Preliminary Procedures...................................................................................... 2-6

Assembling Equipment ................................................................................. 2-6

Making Connections...................................................................................... 2-8

Observing Results.......................................................................................... 2-9

Selecting Heart Rate (HtRate) ....................................................................... 2-10

Adjusting the Pressure Envelope (AdjEnv)................................................... 2-11

Simulating Adult Blood Pressure....................................................................... 2-14

Setting Zero Pressure..................................................................................... 2-15

Simulating Other ADAMS Family Target Values ........................................ 2-16

NIBP Monitor Testing Sequence................................................................... 2-16

Simulating Neonatal Blood Pressure ................................................................. 2-17

Simulating Arrhythmias..................................................................................... 2-18

Pressure Testing................................................................................................. 2-19

Leak Testing .................................................................................................. 2-19

Manometer Function ..................................................................................... 2-20

Pop Off Test .................................................................................................. 2-21

Utility Functions ................................................................................................ 2-22

Set Clock ....................................................................................................... 2-22

Pop Time ....................................................................................................... 2-24

Logo............................................................................................................... 2-25

System Functions........................................................................................... 2-25

Establishing Communications ........................................................................... 2-31

Configuring RS232........................................................................................ 2-31

Testing the RS232 Port and Connections ...................................................... 2-32

Using Auto Sequences ....................................................................................... 2-33

Executing an Auto Sequence......................................................................... 2-33

Utilities .......................................................................................................... 2-34

Printing Documents ........................................................................................... 2-37

Printing Blood Pressure Test Results ............................................................ 2-37

Printing Manometer, Leak Test, and Overpressure Test Results .................. 2-38

Printing Auto Sequences ............................................................................... 2-38

2-1

Page 30

Cufflink

Operators Manual

2-2

Page 31

Operation

Select BP

ADAMS Adult

Powering Up the Analyzer 2

Powering Up the Analyzer

To power up the Analyzer, follow these directions:

1. Attach the supplied power cord to the power cord input on the back panel.

2. Plug the unit into a properly rated outlet.

3. Turn the Analyzer on by pushing the power switch on the back panel to the ON

position (marked I). The Analyzer performs a self test and system initialization,

during which the logo display is visible for about five seconds:

16:15:36

09/19/07

CuffLink

3.21, Pump

Non-Invasive Blood Pressure Analyzer

F1 F2 F3 F4 F5

The current time and date is in the upper right hand corner, and the software revision,

along with installed options, appears directly below the Analyzer name. After the

five-second logo display, the Main Menu displays:

Press Util Comm Auto

ADAMS Adult

ADAMS Neonate

Arrythmias

Select adult ADAMS family blood pressure

F1 F2 F3 F4 F5

Menu Structure and Navigation

The Main Menu options listed across the top of the display are:

• Select BP (Select Blood Pressure)

• Press (Pressure Tests)

• Util (Utilities)

fcv101.eps

fcv096.eps

• Comm (Communications Ports)

• Auto (Auto Sequences)

Each of these options has its own submenu. See Figure 2-1 for a complete menu map.

Along the bottom of the Main Menu display is a brief description of the contents or

purpose of the highlighted menu option. If a pull down menu, or submenu, is visible

below the highlighted Main Menu option, the menu description refers to what is

available in the highlighted submenu.

2-3

Page 32

Cufflink

Operators Manual

After initialization, ADAMS Adult (in the Select BP submenu) is highlighted as the

default. Pressing the Esc key twice returns to the logo display and initialization

procedure.

Select BP Press Util Comm Auto

ADAMS Adult Leak Test Set Clock Configure Execute

60/30 (40) Manometer Pop Time Comm Test Utility

80/50 (62) Pop Off Logo Edit

100/65 (75) System View

120/80 (90) Print Test Name

150/100 (115) Key Test Print

200/150 (165) Speaker Test Init

255/195 (215) 440 Print All

HiRate Adjust Play Init All

AdjEnv Adjust Freq

Print Adjust Period

Zero Pressure Sweep

ADAMS Neonate Display Test

60/30 (40) Short

80/50 (62) Long

100/65 (75) Disply QC Date

120/80 (90) ROM Checksums

150/100 (115) U2

HiRate U3

AdjEnv U4

Print Config Init

Zero Pressure User Envelope

Arrhythmias Store User

NSR Recall User

PAC Draw User

PVC Print User

AF Make Arm

MB Pulse

ASC Select

Scale

Draw

Rate

2-4

Figure 2-1. Analyzer Menu Map

Page 33

Operation

Menu Structure and Navigation 2

To navigate the system of menus:

Note

Holding any of the keys down results in a repeating action of that key

1. Highlight a Main Menu option by pressing a left or right arrow key.

Note

When the desired menu is highlighted and no submenu is shown, press the

Down arrow to pull down the submenu.

2. Press either the Up or Down arrow key to move the dark blue rectangle (hereafter

referred to as the cursor) up or down in the submenu.

3. When the cursor is at the desired location on any menu, press the Ent (enter) key to

select or activate the highlighted option.

4. When finished, take one of the following actions:

a. Press the Esc key to return to the previous menu. For example, pressing Esc

when the Set Clock display is visible returns one step back to the Util submenu.

b. Hold the Esc key down to return from any menu or submenu back to the logo

display and initialization procedure.

2-5

Page 34

Cufflink

Operators Manual

Preliminary Procedures

The analyzer simulates a human arm and produces target value blood pressures for the

purpose of testing the accuracy of blood pressure readings on an NIBP monitor. The test

is initiated from the Select BP Main Menu option that provides the parameters listed in

Table 2-1.

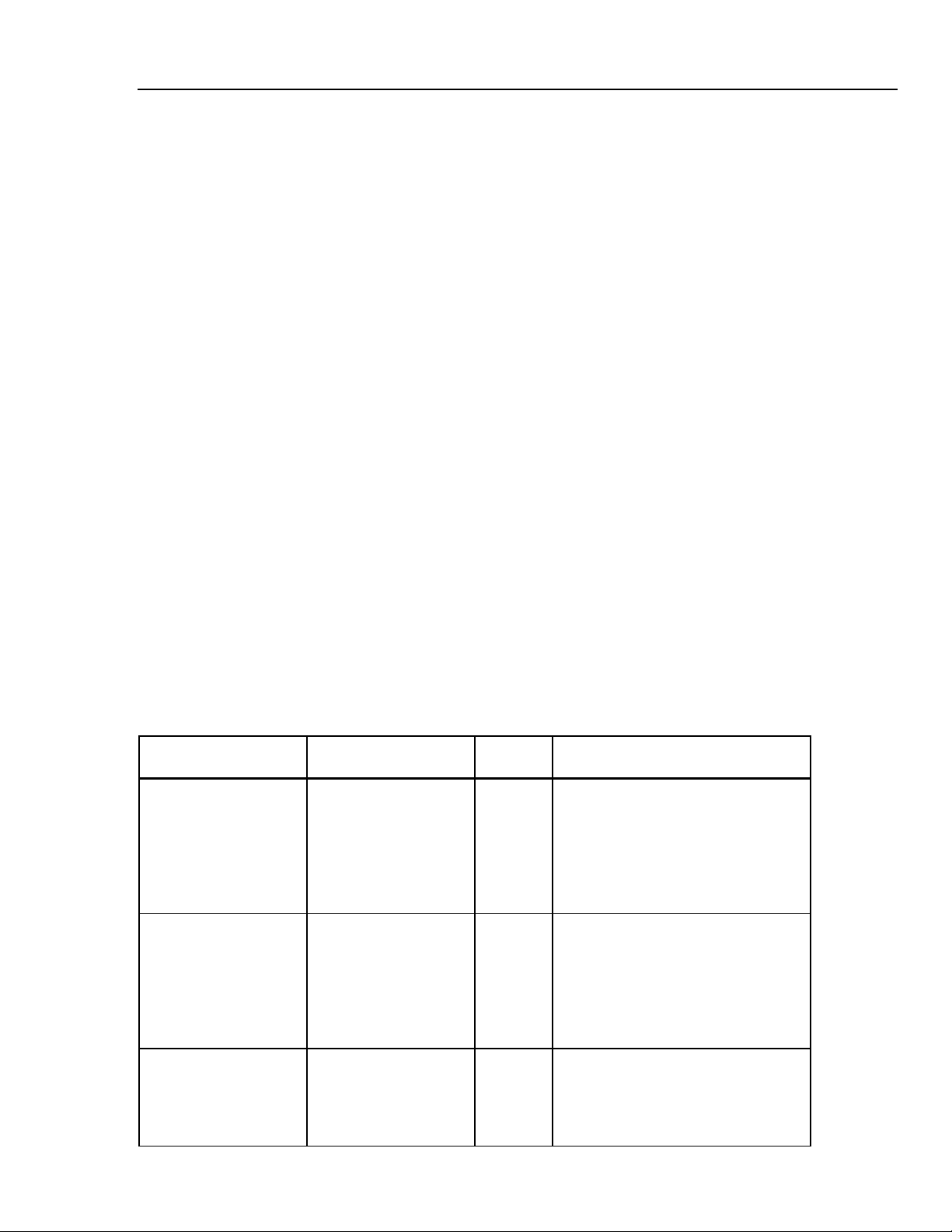

Table 2-1. Blood Pressure Parameters Provided by the Select BP Option

Blood

Pressure

(mmHg)

60/30

80/50

400/65

120/80

150/100

200/150

255/195

Adult Neonate

Mean Arterial

Pressure (mmHg)

40

62

75

90

115

165

215

Heart Rate Selections

Blood Pressure

(mmHg)

60/30

80/50

400/65

120/80

150/100

30

40

60

80

120

160

200

240

Mean Arterial

Pressure (mmHg)

40

62

75

90

115

Adult

Arrhythmias

Premature Atrial

Contractions

Premature

Ventricular

Contraction

Atrial fibrillation

Missed Beat

Aberrant Sinus

Conductions

Blood Pressure

and Heart Rate

Blood Pressure

fixed at 120/80 (90)

Heart Rate fixed at

80 BPM

2-6

Assembling Equipment

The following equipment is needed to test NIBP monitor blood pressure readings. Figure

2-2 shows the proper way to combine Adult cuff mandrels to simulate various sizes of

arms.

• NIBP monitor

• NIBP Analyzer

• Mandrel (supplied with the Analyzer)

• BP cuff

• Hoses to attach the cuff to the monitor

• Cuff adapter for the monitor DUT (device under test) (supplied with the Analyzer)

Page 35

Operation

Adult Cuff Mandrel Sizes:

Preliminary Procedures 2

Large Adult

Adult

Small Adult

Child

Figure 2-2. Adjustments for Adult Cuff Mandrel

Figure 2-3 shows the neonate mandrel.

Large

Medium

Use 2 end blocks and

3 spacer blocks

Use 2 end blocks and

2 spacer blocks

Use 2 end blocks and

1 spacer blocks

Use 2 end blocks and

no spacer blocks

fcv011.eps

Figure 2-3. Neonate Mandrel

Small

fcv012.eps

2-7

Page 36

Cufflink

Operators Manual

Making Connections

Figure 2-4 is an annotated diagram of the properly-connected test system.

NIBP Monitor

Cuff Connector

Pneumatic Hose(s)

Cuff Connect Port

Dual hose systems: connect

Cuff Adapter to hose

marked “Sense”. If both

hoses are unmarked,

connect Cuff Adapter to

either hose.

(front panel)

To connect: Push Cuff Adapter

in until a click is heard.

To disconnect: push sleeve

back to release Cuff Adapter.

“T” Connector

Must be connected closer

to cuff than monitor

Wraps around mandrel

Cuff Adapter

BP Cuff

Figure 2-4. NIBP Test System Diagram

Cuff Mandrel

Cufflink

fcv015.eps

To correctly connect the components of the test system:

1. Attach the BP cuff to the NIBP monitor as shown in Figure 2-4. Refer to the monitor

operators manual, as necessary.

2. Wrap the cuff tightly around the appropriate mandrel. See Figures 2-2, and 2-3.

3. Connect the cuff adapter T connector into the line nearest the cuff.

If the NIBP monitor has two pneumatic hoses connected to the cuff, insert the cuff

adapter into the hose labeled Sense. If neither hose is labeled, insert the cuff adapter

into either hose.

2-8

Note

Do not connect the cuff adapter to the Analyzer until the Analyzer has

warmed up for at least 15 minutes.

4. Power up both the Analyzer and the NIBP monitor.

Page 37

Operation

Preliminary Procedures 2

The Analyzer is now ready to simulate the human arm and reliably evaluate the accuracy

of the NIBP monitor.

Observing Results

Results of the analysis are provided by the Analyzer Makearm display, shown in Figure

2-5.

Cuff Pressure

in mmHg

200

160

120

80

40

010

Elapsed time in seconds

Cuff Pressure Waveform

(drawn during testing)

20 30

Heart Rate Indicator

(appears during testing)

Measured

parameters

CuffPres

CuffPeak

DeflRate

DeflTime

InflRate

InflTime

TotlTime

120/80

Current BP

Target Value

0

162

5.1

17.5

46.7

3.3

22.0

(90) A

MAP

fcv016.eps

Figure 2-5. Makearm Display of Test Results

The Makearm display includes a graph, the vertical axis of which indicates the cuff

pressure in millimeters of mercury (mmHg). The horizontal axis indicates elapsed time in

seconds. The graph is auto-ranging; if the cuff pressure curve values extend beyond the

displayed ranges, the entire graph is redrawn on the display to make the curve appear

more compact.

On the right side of the display are listed the measured test parameters, as defined in

Table 2-2.

2-9

Page 38

Cufflink

100/80 (75)

Operators Manual

Selecting Heart Rate (HtRate)

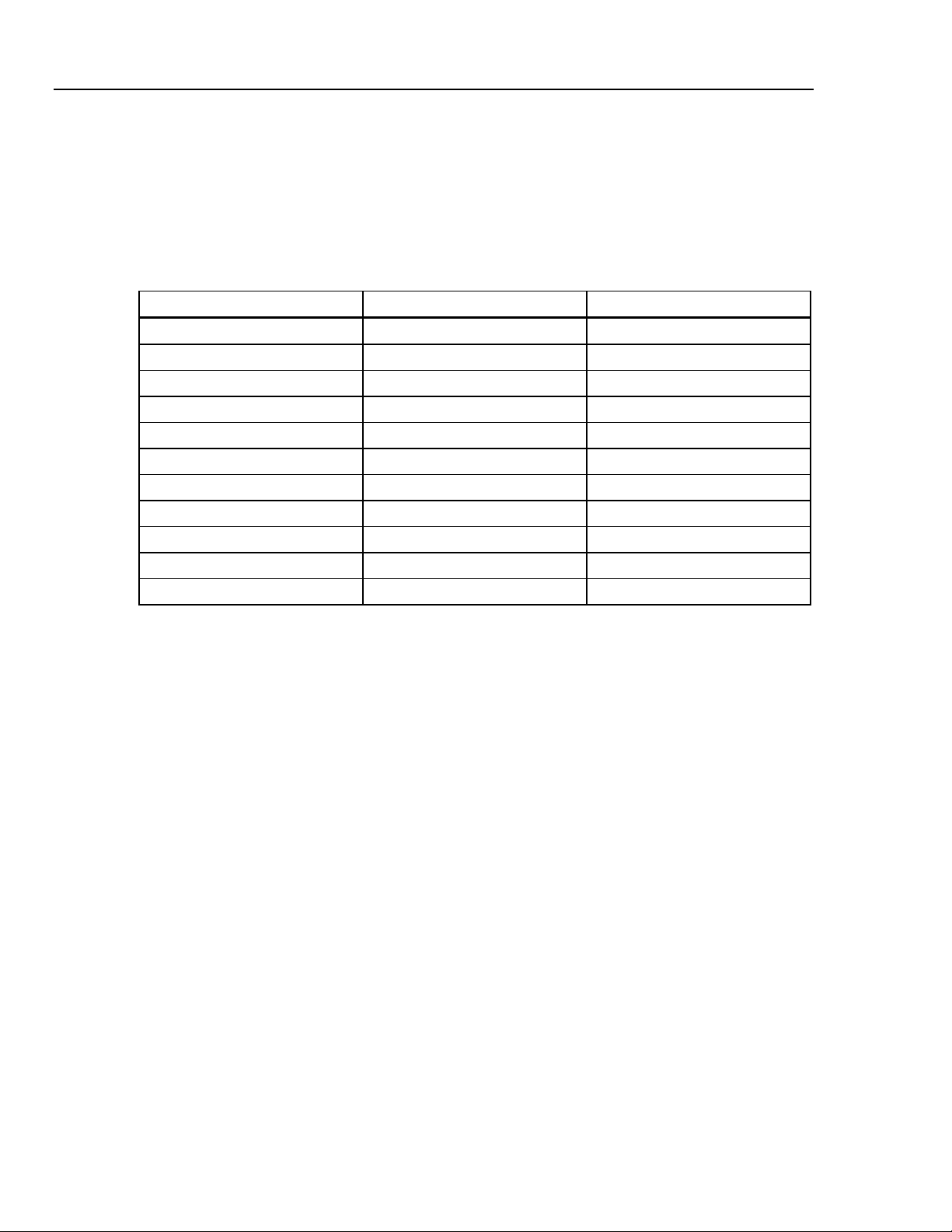

Table 2-2. Measured Test Parameters

Abbreviation Parameter Unit of Measurement

CuffPres On-line Cuff Pressure mmHg

CuffPeak Peak Cuff Pressure mmHg

DeflRate Deflate Rate mmHg/second

DeflTime Deflate Time seconds

InflRate Inflate Rate mmHg/second

InflTime Inflate Time seconds

TotlTime Total Measurement Time seconds

The current blood pressure target value is shown just below the list of test parameters on

the Makearm display and indicates which BP target value is currently being simulated

by the Analyzer.

To select the heart rate to be tested:

1. From the Select BP submenu, highlight ADAMS Adult (or ADAMS Neonate)

and press the Ent key. The ADAMS Adult Family Target Values screen

displays:

*** ADAMS Adult Family ***

Target Values

60/30 (40) 150/100 (115)

80/50 (62) 200/150 (165)

100/80 (75)

HtRate AdjEnv Print ZeroPres

F1 F2 F3 F4 F5

fcv100.eps

2. Highlight the blood pressure target value to be simulated.

3. Press F1 HtRate.

Note

The term ADAMS Family refers collectively to Adult and Neonate options.

2-10

Page 39

Operation

Preliminary Procedures 2

The Analyzer displays the available heart rates:

*** Select Heart Rate (BPM) ***

30 40 60 80 120 160 200 240

Use arrow keys to select new heart rate.

F1 F2 F3 F4 F5

fcv017.eps

4. Use the arrow keys to choose a heart rate and then press the Ent key. A popup

window briefly displays, confirming the heart rate chosen.

80 BPM

5. When the target value display reappears, press the Ent key to display the Makearm

graph. The current heart rate setting is shown in the upper part of the Makearm graph

next to CuffPres:

Current Heart Rate Setting

200

160

120

80

40

0102030

80 BPM

CuffPres

CuffPeak

DeflRate

DeflTime

InflRate

InflTime

TotlTime

120/80

0

162

5.1

17.5

46.7

3.3

22.0

(90) A

fcv018.eps

Adjusting the Pressure Envelope (AdjEnv)

To modify the gain (amplitude) or shift (BP value) of the blood pressure envelope and to

draw the envelope specified:

1. From the Select BP submenu, highlight ADAMS Adult or ADAMS Neonate and

press the Ent key.

2. Highlight the blood pressure target value to be simulated.

3. Press F2 AdjEnv to display the Pressure Curve Adjust screen:

2-11

Page 40

Cufflink

Operators Manual

*** Pressure Curve Adjust ***

120/ 80 (90)

Shift Gain%

F1 F2 F3 F4 F5

Draw

fcv111.eps

1. Press F1 Gain% to move the selection box to Gain% and use the Up and Down

arrow keys to change the percent of gain. This factor affects the pressure pulse

amplitude. The default value is 100 %, and the range is from 1 % to 200 %. A change

in the Gain% appears below the heart rate on the Makearm graph:

Envelope Gain%

200

160

120

80

40

0102030

80 BPM

G 50

S 12

CuffPres

CuffPeak

DeflRate

DeflTime

InflRate

InflTime

TotlTime

120/80

0

162

5.1

17.5

46.7

3.3

22.0

(90) A

fcv020.eps

2. Press F2 Shift to move the selection box to Shift and use the Up and Down arrow

keys to shift the entire blood pressure envelope to the left (- shift, Down arrow) or

right (+ shift, Up arrow). If a target value of 120/80 is selected with a shift of +10

mmHg, the actual blood pressure target value simulated changes to 130/90. The

default value for a shift is 0 mmHg, and the range is from -100 mmHg to +100

mmHg.

2-12

The graphs below illustrate a blood pressure envelope with no shift, a negative shift,

and a positive shift, respectively:

Page 41

Operation

Pressure Envelope

1.0

0.8

0.6

0.4

0.2

04080 120 160 200

Preliminary Procedures 2

Max

1000

Min

1

mm

fcv021.eps

1.0

0.8

0.6

0.4

0.2

04080 120

Negative 10 mmHg Shift

120/80/Envelope

1.0

0.8

0.6

0.4

0.2

04080 120

Positive 10 mmHg Shift

Max

1000

Min

1

mm

160 200

Max

1000

Min

1

mm

160 200

fcv022.eps

A change in the Shift appears below the Gain% on the Makearm graph:

2-13

Page 42

Cufflink

Operators Manual

Envelope Shift

200

160

120

80

40

0102030

80 BPM

G 50

S 12

CuffPres

CuffPeak

DeflRate

DeflTime

InflRate

InflTime

TotlTime

120/80

0

162

5.1

17.5

46.7

3.3

22.0

(90) A

3. Press the Esc key to undo any changes.

4. When finished, press the Ent key to save the pressure envelope and return to the

Pressure Curve Adjust screen.

5. When finished, press F3 Draw to view the pressure envelope.

6. Press the Ent key.

The user is now ready to start the NIBP monitor, simulate the blood pressure, and take

measurements.

fcv023.eps

Simulating Adult Blood Pressure

To simulate the ADAMS Adult 120/80 Blood Pressure target value:

1. From the Select BP submenu, highlight ADAMS Adult and press the Ent key.

Target values and available blood pressures are displayed for the ADAMS Adult

Family Target Values screen. The cursor is initially at 120/80. The heart rate is

fixed at 80 BPM.

2. Press the Ent key to enter the Makearm function for a blood pressure of 120/80. The

Analyzer briefly displays a confirmation, verifying which parameter was chosen:

120/80 (90)

Note

The analyzer pop-up windows are not visible if Pop Time is set to 0.00

2-14

Page 43

Operation

100/80 (75)

Simulating Adult Blood Pressure 2

The Makearm display appears:

Cuff Pressure

in mmHg

200

160

120

80

40

010

Elapsed time in seconds

Setting Zero Pressure

The value for cuff pressure (CuffPres) in the upper right corner of the Makearm

display should be zero (0 mmHg) before a test is started.