Page 1

COMPASS® FOR PPC/RPM™

Pressure Calibration Software

User’s Manual

© 1998-2000 DH Instruments, Inc.

Page 2

High pressure liquids and gases are potentially hazardous. Energy stored in these liquids and gases

can be released unexpectedly and with extreme force. High pressure systems should be assembled and

operated only by personnel who have been instructed in proper safety practices.

© 1998-2000 DH Instruments, Inc. All rights reserved.

Information in this document is subject to change without notice. No part of this document may be

reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose,

without the express written permission of DH Instruments, Inc. 4765 East Bea utiful Lane P hoenix AZ

85044-5318 USA.

DH Instruments makes sincere efforts to ensure accuracy and quality of its’ published materials;

however, no warrant y, express ed or implied, is pr ovided. DH Instruments dis claims an y responsibility or

liability for any direct or indirect damages resulting from the use of the information in this manual or

products described in it. M ention of an y product does not c onstit ute an endors em ent by DH Instruments

of that product. This manual was originally com posed in English and was subs equently translated into

other languages. The f idelity of the translation can not be guaranteed. In case of conflict between the

English version and other language versions, the English version predominates.

DH Instruments, DH, DHI, PPCK, PPC2, PPC2+ and COMPASS are trademarks, registered and

otherwise of DH Instruments, Inc.

Windows is a registered trademark of Microsoft Corporation.

Document No. 550095a-02

020925

Printed in the USA.

Page 3

TABLE OF CONTENTS

T

AABBLLEE OOFF

T

C

OONNTTEENNTTS

C

S

TABLE OF CONTENTS ............................................................. I

TABLES ................................................................................ V

FIGURES .............................................................................. VI

USER REGISTRATION............................................................ IX

ABOUT THIS MANUAL............................................................ XI

1. INTRODUCTION .................................................................1

1.1 PRODUCT OVERVIEW ...........................................................................................................................1

2. GETTING STARTED............................................................ 3

2.1 OVERVIEW..............................................................................................................................................3

2.2 SYSTEM REQUIREMENTS.....................................................................................................................3

2.3 INSTALLING COMPASS FOR PPC/RPM...............................................................................................3

2.4 RUNNING THE PROGRAM.....................................................................................................................3

2.5 LANGUAGE SUPPORT...........................................................................................................................3

2.6 UNINSTALLING.......................................................................................................................................4

3. OPERATING PRINCIPLES ...................................................5

3.1 OVERVIEW..............................................................................................................................................5

3.1.1 BASICS SUMMARY.................................................................................................................................. 6

4. MAIN RUN SCREEN............................................................7

4.1 OVERVIEW..............................................................................................................................................7

4.2 MAIN MENU BAR....................................................................................................................................7

4.3 RUN TEST SCREEN................................................................................................................................8

4.4 RUN TEST TOOLBAR........................................................................................................................... 10

5. THE [RUN] MENU.............................................................11

5.1 OVERVIEW............................................................................................................................................11

5.2 [RUN], [RUN TEST]...............................................................................................................................11

5.2.1 TEST INITIALIZATION............................................................................................................................ 11

5.2.1.1 SELECT DUT FILE.............................................................................................................................. 12

5.2.1.2 PREVIEW DUT.................................................................................................................................... 13

5.2.1.3 SELECT TEST FILE.............................................................................................................................14

5.2.1.4 PREVIEW TES T.................................................................................................................................. 14

5.2.1.5 REFERENCE VERIFICATION............................................................................................................. 15

5.2.1.6 SETUP DUT(S).................................................................................................................................... 16

5.2.1.7 USER ID.............................................................................................................................................. 18

5.2.2 RUN TEST............................................................................................................................................... 18

5.2.2.1 MANUAL ENTRY DATA ACQUISITION............................................................................................... 19

5.2.3 TEST CONCLUSION ............................................................................................................................... 20

5.3 [RUN], [RE-RUN TEST].........................................................................................................................21

5.4 [RUN], [EXIT].........................................................................................................................................21

Page I © 1998-2000 DH Instruments, Inc.

Page 4

COMPASS® FOR PPC/RPM™ USER’S MANUAL

6. THE [DUT] MENU ............................................................. 23

6.1 OVERVIEW............................................................................................................................................23

6.2 [DUT], [CREATE DUT] ..........................................................................................................................23

6.3 [DUT], [EDIT DUT FILE]........................................................................................................................27

6.4 [DUT], [REMOVE DUT FILE].................................................................................................................27

7. THE [TEST] MENU ........................................................... 29

7.1 OVERVIEW............................................................................................................................................29

7.2 [TEST], [CREATE TEST].......................................................................................................................29

7.2.1 [TEST], [CREATE TEST], <TEST POINTS> TABLE............................................................................... 30

7.2.1.1 ZERO ABSOLUTE TEST POINTS.......................................................................................................31

7.2.2 [TEST], [CREATE TEST], [AUTO FILL POINTS] TAB............................................................................ 31

7.2.3 [TEST], [CREATE TEST], [LEAK TEST] TAB......................................................................................... 32

7.2.4 [TEST], [CREATE TEST], [CYCLE] TAB................................................................................................ 34

7.2.5 [TEST], [CREATE TEST], [CONTROL SETTINGS] TAB........................................................................ 35

7.2.6 [TEST], [CREATE TEST], [SEQUENCE] TAB ........................................................................................ 37

7.3 [TEST], [EDIT TEST FILE] .................................................................................................................... 38

7.4 [TEST], [REMOVE TEST FILE].............................................................................................................38

8. THE [TOOLS] MENU .........................................................39

8.1 OVERVIEW............................................................................................................................................39

8.2 [TOOLS], [CONFIG HARDWARE]........................................................................................................ 39

8.2.1 [TOOLS], [CONFIG HARDWARE], [CONFIGURATION] TAB................................................................ 40

8.2.2 [TOOLS], [CONFIG HARDWARE], [REFERENCE] TAB........................................................................ 41

8.2.3 [TOOLS], [CONFIG HARDWARE], [DMM] TAB ..................................................................................... 43

8.2.4 [TOOLS], [CONFIG HARDWARE], [MULTIPLEXER] TAB..................................................................... 46

8.2.5 [TOOLS], [CONFIG HARDWARE], [IEEE 488] ....................................................................................... 48

8.2.6 RS232 SETUP......................................................................................................................................... 48

8.3 [TOOLS], [OPTIONS]............................................................................................................................49

8.3.1 [TOOLS], [OPTIONS], [MAINTAIN LISTS].............................................................................................. 50

8.3.2 [TOOLS], [OPTIONS], [INITIALIZE TEST].............................................................................................. 50

8.3.3 [TOOLS], [OPTIONS], [RUN TEST]........................................................................................................ 51

8.3.4 [TOOLS], [OPTIONS], [DATA FILE]....................................................................................................... 53

8.3.5 [TOOLS], [OPTIONS], [FILE LOCATIONS] ............................................................................................54

8.3.6 [TOOLS], [OPTIONS], [LANGUAGE]...................................................................................................... 54

8.4 [TOOLS], [REMOTE COMMUNICATIONS] ..........................................................................................55

9. THE [DATA] MENU ........................................................... 57

9.1 OVERVIEW............................................................................................................................................57

9.2 [DATA], [VIEW TEST DATA] ................................................................................................................57

9.3 [DATA], [PRINT TEST DATA]...............................................................................................................58

9.4 [DATA], [PLOT TEST DATA]................................................................................................................58

9.4.1 [DATA], [PLOT TEST DATA], [FILE]...................................................................................................... 59

9.4.2 [DATA], [PLOT TEST DATA], [PLOTS].................................................................................................. 59

10. THE [REPORT] MENU ....................................................... 61

10.1 OVERVIEW ............................................................................................................................................61

10.2 REPORT PRINCIPLES.......................................................................................................................... 61

10.3 MAIN MENU BAR..................................................................................................................................62

10.3.1 [FILE] MENU........................................................................................................................................... 62

10.3.1.1 [FI L E ], [ED I T RE P O R T ] ..................................................................................................... 63

10.3.1.2 [FI LE], [GENERATE REPORT] ....................................................................................... 63

10.3.1.3 [FILE], [EDIT TEMPL A TE] ........................................................................................................ 63

© 1998-2000 DH Instruments, Inc. Page II

Page 5

TABLE OF CONTENTS

10.3.1.4 [FILE], [CREATE TEM PLATE] ..................................................................................................64

10.3.1.5 [FILE], [SAVE] .......................................................................................................................... 64

10.3.1.6 [FILE], [SAVE AS ]................................................................................................................................ 65

10.3.1.7 [FILE], [SAVE ALL ]...............................................................................................................................65

10.3.1.8 [FILE], [CLOS E]................................................................................................................................... 65

10.3.1.9 [FILE], [CLOS E AL L ]............................................................................................................................ 65

10.3.1.10 [FILE], [PRINT] ......................................................................................................................... 65

10.3.1.11 [FILE], [PRINT AL L].............................................................................................................................. 65

10.3.1.12 [FILE], [EXIT]....................................................................................................................................... 65

10.3.2 [ED IT] MENU........................................................................................................................................... 66

10.3.2.1 [EDIT], [UNDO] ......................................................................................................................... 66

10.3.2.2 [EDIT], [CUT] ............................................................................................................................ 66

10.3.2.3 [EDIT], [COPY] ......................................................................................................................... 66

10.3.2.4 [EDIT], [PASTE] ....................................................................................................................... 66

10.3.2.5 [EDIT], [FIND] ........................................................................................................................... 66

10.3.2.6 [EDIT], [FIND NEXT]............................................................................................................................ 67

10.3.2.7 [EDIT], [SELECT ALL].......................................................................................................................... 67

10.3.3 [FORMAT] MENU.................................................................................................................................... 67

10.3.3.1 [FORMAT], [INSER T DATE/TIME]....................................................................................................... 67

10.3.3.2 [FORMAT], [INSERT FIELD KEY] ............................................................................................ 67

10.3.3.3 [FORMAT], [SELECT TEMPLATE]....................................................................................................... 68

10.3.3.4 [FORMAT], [PAG E SETUP] ................................................................................................................. 68

10.3.4 [O PTIONS] MENU................................................................................................................................... 69

10.3.4.1 [OPTIONS], [TOOLBAR] ...................................................................................................................... 69

10.3.4.2 [OPTIONS], [FO N T FO R MAT BAR]..................................................................................................... 69

10.3.4.3 [OPTIONS], [RULER]........................................................................................................................... 70

10.3.5 [WINDOW] MENU................................................................................................................................... 71

10.3.6 [H ELP] MEN U......................................................................................................................................... 71

10.4 REPORT EDITOR AUTOMATION .........................................................................................................71

10.4.1 DRAG AND DROP.................................................................................................................................. 72

10.4.2 COMMAND LINE ARGUMENTS............................................................................................................. 72

10.4.3 DDE (DYNAMIC DATA EXCHANGE)...................................................................................................... 72

11. THE [HELP] MENU ........................................................... 73

11.1 OVERVIEW ............................................................................................................................................73

12. DATA FILES .................................................................... 75

12.1 OVERVIEW ............................................................................................................................................75

12.2 DATA FILE CREATION (LOG FILES)...................................................................................................75

12.3 NAMING AND STORING DATA FILES.................................................................................................75

12.4 DATA FILE STRUCTURE......................................................................................................................76

13. APPLICATION EXAMPLES................................................. 79

13.1 OVERVIEW ............................................................................................................................................79

13.1.1 EXAMPLE #1........................................................................................................................................... 79

13.1.1.1 SET UP AN RS232 DUT...................................................................................................................... 79

13.1.1.2 SET UP A PPC2+ AS THE REFERENCE............................................................................................ 80

13.1.1.3 RUN THE TEST................................................................................................................................... 81

13.1.2 EXAMPLE #2........................................................................................................................................... 82

13.1.2.1 SET UP DMM DATA ACQUISITION DUT............................................................................................ 82

13.1.2.2 DMM CONFIGURATION SETUP.........................................................................................................84

13.1.2.3 RUN THE TEST................................................................................................................................... 85

Page III © 1998-2000 DH Instruments, Inc.

Page 6

COMPASS® FOR PPC/RPM™ USER’S MANUAL

13.1.3 EXAMPLE #3........................................................................................................................................... 85

13.1.3.1 EXAMPLE MULTIPLEXER SETUP...................................................................................................... 86

13.1.3.2 EXAMPLE DMM SETUP...................................................................................................................... 87

13.1.3.3 UPDATE THE CONFIGURATION ........................................................................................................87

13.1.3.4 CONNECT THE DUTS......................................................................................................................... 87

13.1.3.5 RUN THE TEST................................................................................................................................... 87

14. QUICK TIPS .................................................................... 89

14.1 HOW DO I? ............................................................................................................................................89

15. CALCULATIONS .............................................................. 93

15.1 OVERVIEW ............................................................................................................................................93

15.2 DUT PRESSURE....................................................................................................................................93

15.3 ERROR DETERMINATION.................................................................................................................... 93

15.4 TOLERANCE .........................................................................................................................................94

15.5 BEST FIT................................................................................................................................................94

15.6 LINEARITY.............................................................................................................................................94

15.7 HYSTERESIS.........................................................................................................................................95

15.8 PRESSURE UNIT CONVERSIONS.......................................................................................................95

16. DDE SUPPORT ................................................................97

16.1 OVERVIEW ............................................................................................................................................97

17. TROUBLESHOOTING ........................................................99

17.1 OVERVIEW ............................................................................................................................................99

18. APPENDIX .................................................................... 101

18.1 GLOSSARY .........................................................................................................................................101

19. END USER LICENSE AGREEMENT ................................... 103

19.1 OVERVIEW ..........................................................................................................................................103

INDEX ................................................................................ 105

© 1998-2000 DH Instruments, Inc. Page IV

Page 7

TABLES & FIGURES

T

AABBLLEES

T

Table 1. Run Test Screen............................................................................................................................8

Table 2. Tools Available on the Toolbar ....................................................................................................10

Table 3. <Test Complete> Screen Options................................................................................................20

Table 4. <DUT Definition/Profile> Screen.................................................................................................. 24

Table 5. <Test Points> Table.....................................................................................................................31

Table 6. [Auto Fill Points] Tab.................................................................................................................... 32

Table 7. [Leak Test] Tab............................................................................................................................33

Table 8. [Cycle] Tab...................................................................................................................................35

Table 9. [Control Settings] Tab ..................................................................................................................36

Table 10. [Sequence] Tab..........................................................................................................................37

Table 11. [CONFIGURATION] Tab............................................................................................................ 41

Table 12. [Reference] Tab .........................................................................................................................43

Table 13. [DMM] Tab .................................................................................................................................45

Table 14. [Multiplexer] Tab.........................................................................................................................47

Table 15. COMPASS Lists......................................................................................................................... 50

Table 16. [Initialize Test] Tab..................................................................................................................... 51

Table 17. [Run Test] Tab ...........................................................................................................................52

Table 18. [Data File] Tab............................................................................................................................53

Table 19. <Find> Sc reen............................................................................................................................67

Table 20. Font Format Toolbar ..................................................................................................................70

Table 21. Ruler...........................................................................................................................................71

Table 22. Pressure Unit Conversion Chart ................................................................................................ 96

Table 23. DDE Link Items..........................................................................................................................97

Table 24. Symptom / Probable Cause / Solution Checklist .......................................................................99

S

Page V © 1998-2000 DH Instruments, Inc.

Page 8

COMPASS® FOR PPC/RPM™ USER’S MANUAL

F

IIGGUURREES

F

Figure 1. Language Selection...................................................................................................................... 4

Figure 2. Run Test Screen...........................................................................................................................8

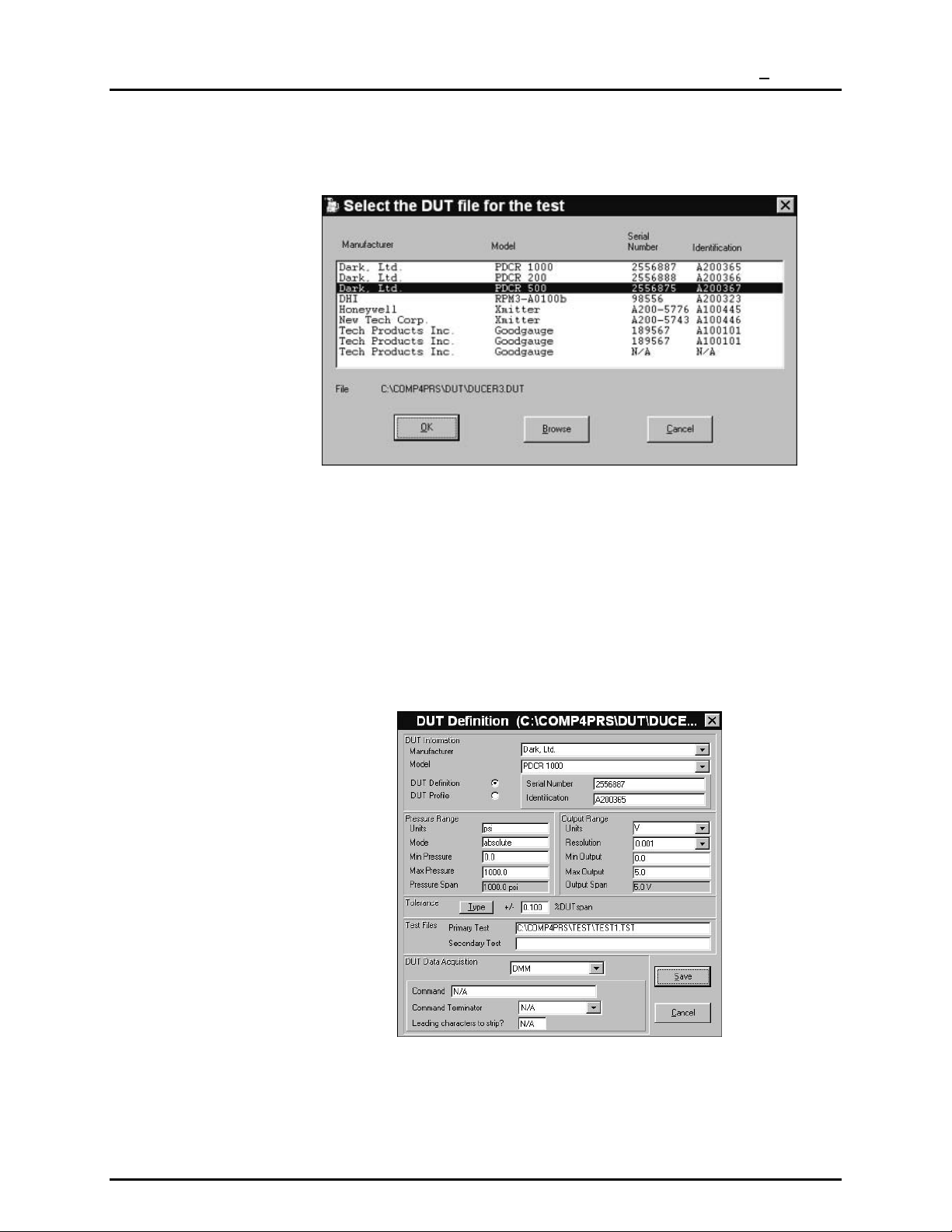

Figure 3. Select the DUT file for the Test Screen ......................................................................................13

Figure 4. DUT Definition (C:\COMP4PRS\DUT\DUCE …) Screen ...........................................................13

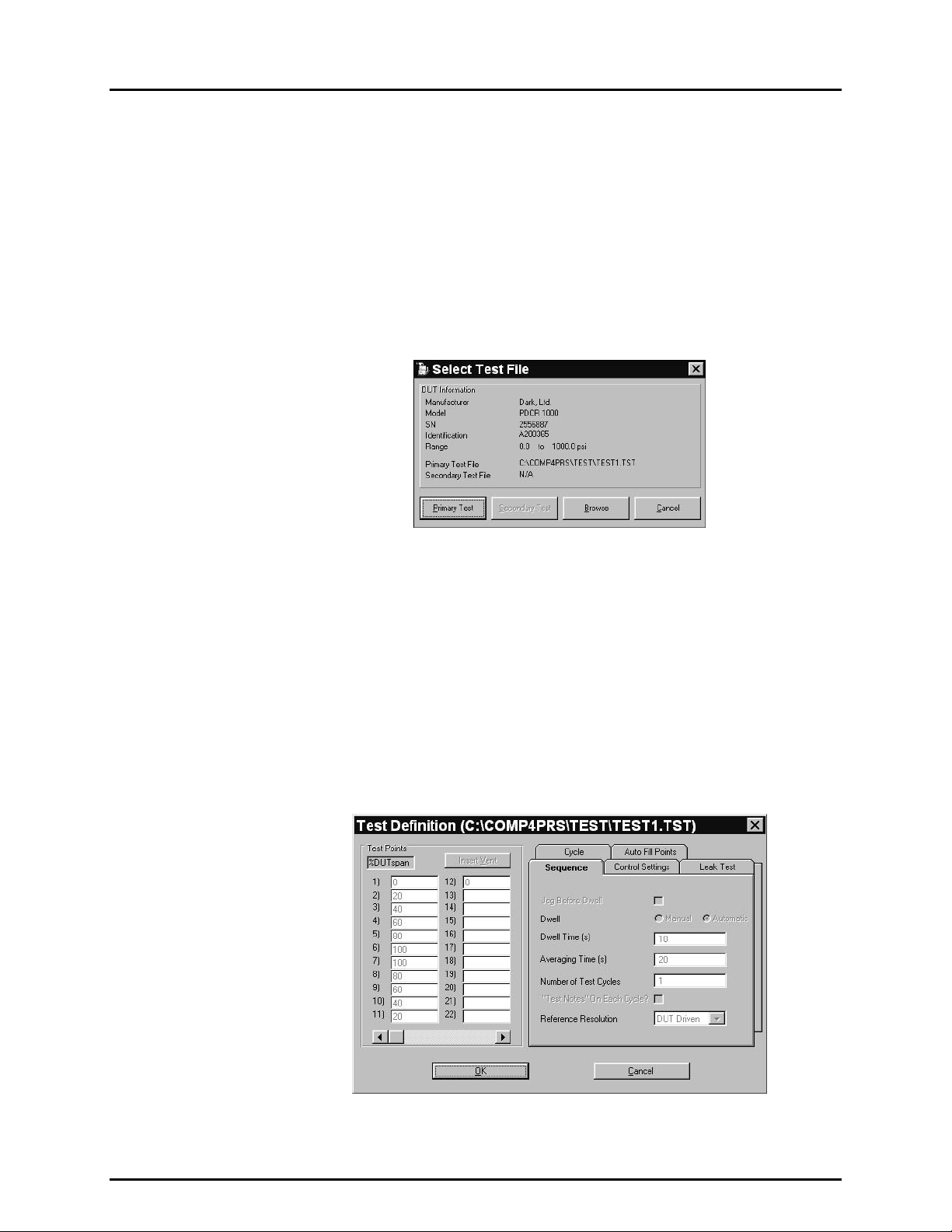

Figure 5. Select Test File Screen...............................................................................................................14

Figure 6. Test Definition (C:\COMP4PRS\TEST\TEST1.TST) Screen...................................................... 14

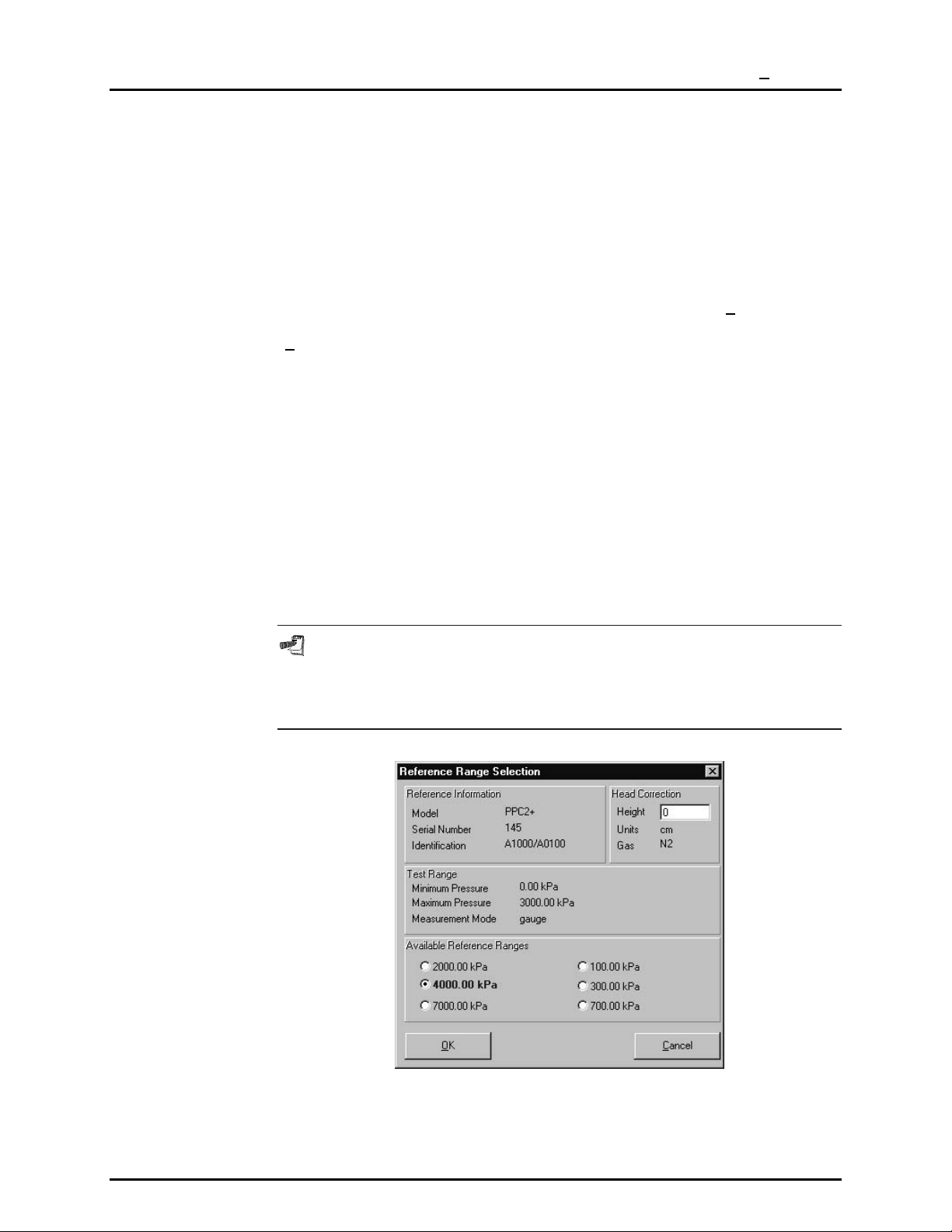

Figure 7. Reference Range Selection Screen ........................................................................................... 15

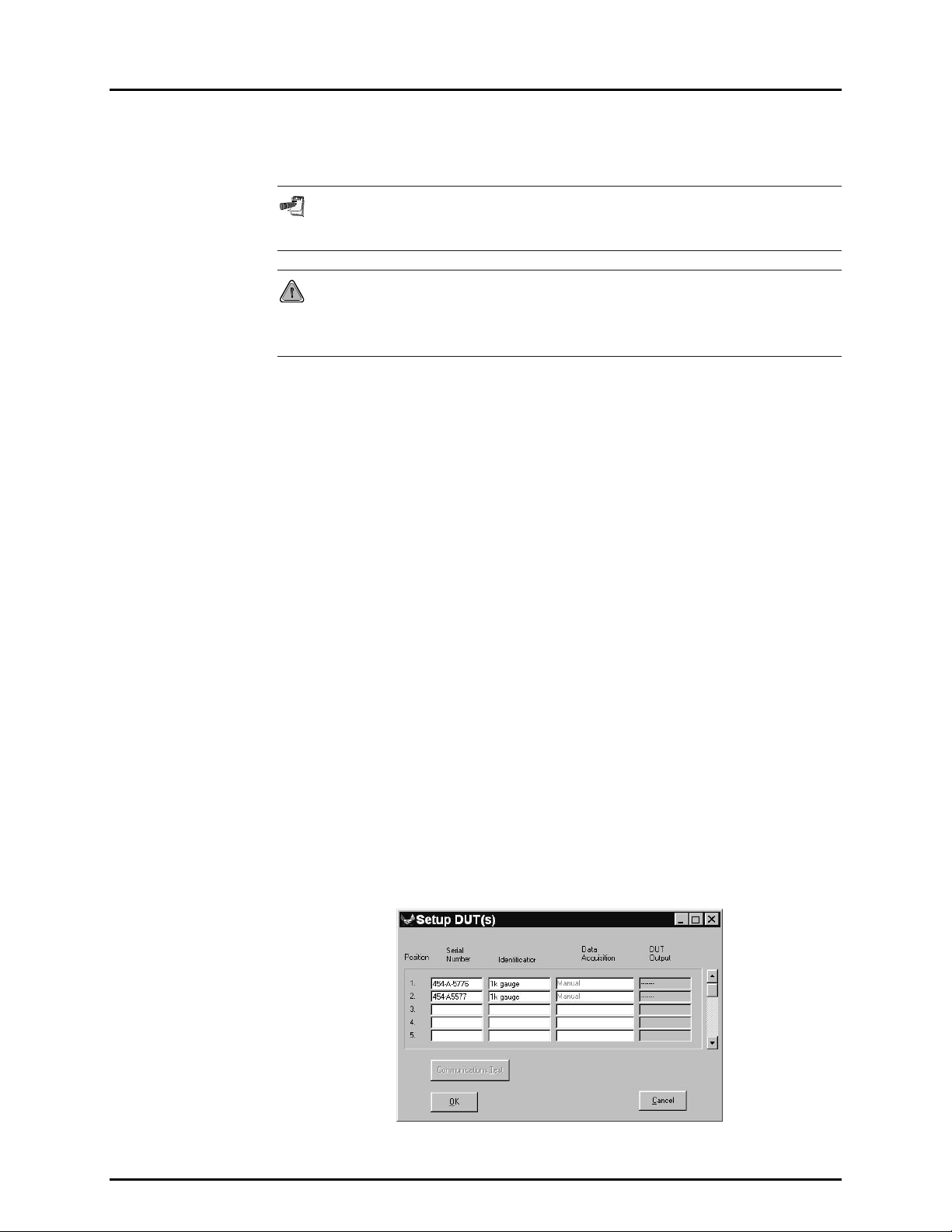

Figure 8. Setup DUT(s) Screen ................................................................................................................. 16

Figure 9. Manual Pressure Entry ...............................................................................................................19

Figure 10. Test Complete Screen..............................................................................................................20

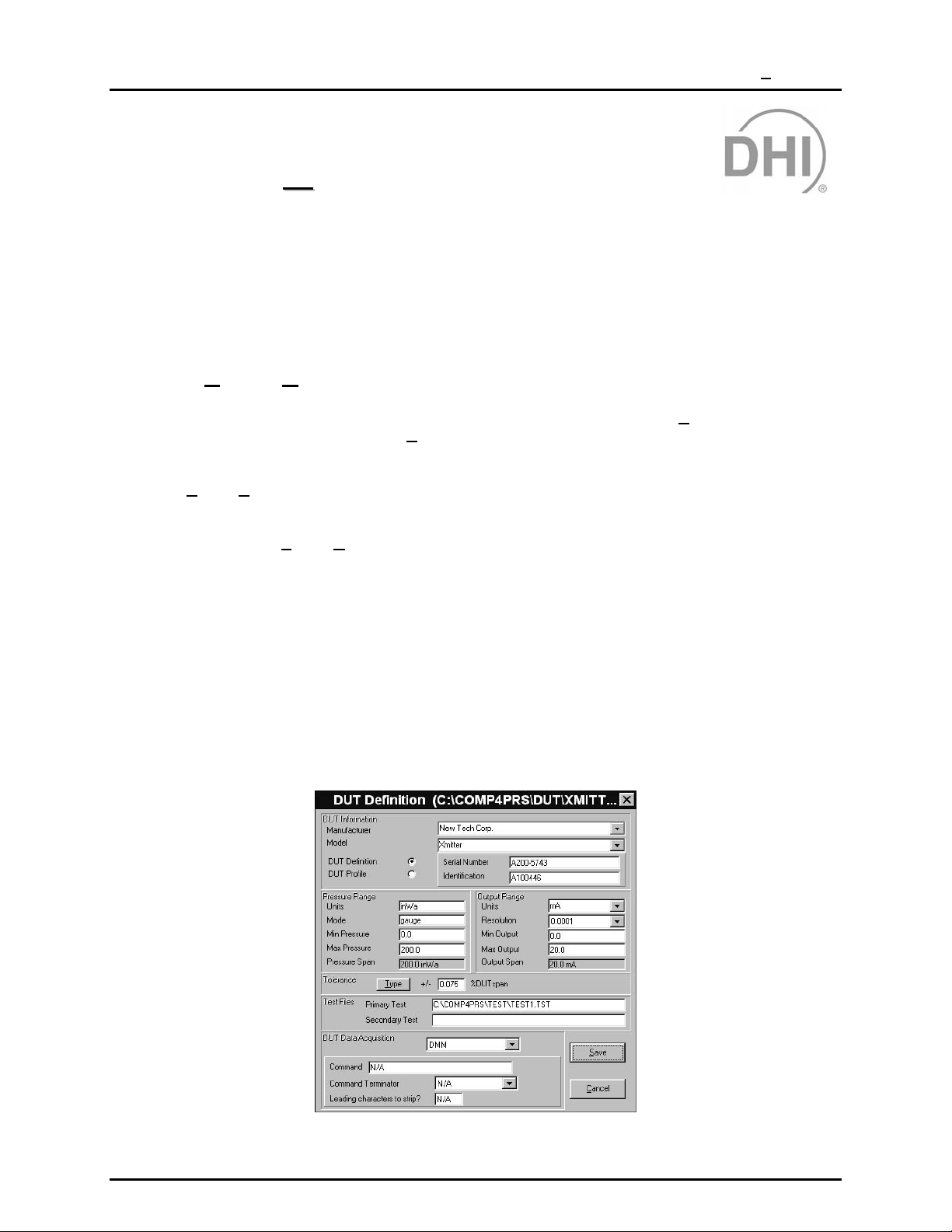

Figure 11. DUT Definition (C:\COMP4PRS\DUT\XMITT …) Screen.........................................................23

Figure 12. Unit/Mode Selection..................................................................................................................24

Figure 13. Test Definition Screen - Sequence...........................................................................................29

Figure 14. Test Definition Screen - Auto Fill Points................................................................................... 32

Figure 15. Test Definition Screen - Leak Test ...........................................................................................33

Figure 16. Test Definition Screen - Cycle..................................................................................................34

Figure 17. Test Definition Screen – Control Settings................................................................................. 36

Figure 18. Test Definition Screen - Sequence...........................................................................................37

Figure 19. COMPASS Configuration Settings Sc reen...............................................................................40

Figure 20. COMPASS Configuration Settings ...........................................................................................42

Figure 21. Edit Reference Device Screen.................................................................................................. 42

Figure 22. COMPASS Configuration Sett ings Sc reen - DMM...................................................................44

Figure 23. Edit DMM Screen ...................................................................................................................... 44

Figure 24. COMPASS Configuration Settings Screen - Multiplexer......................................................... 46

Figure 25. Edit Multiplexer Screen.............................................................................................................46

Figure 26. COMPASS Configuratio n Sett ings Scr een - IEE-488............................................................... 48

Figure 27. RS232 Settings Screen ............................................................................................................ 49

Figure 28. Options Screen - Maintain Lists................................................................................................49

Figure 29. Options Screen - Initialize Test................................................................................................. 50

Figure 30. Options Screen - Run Test ....................................................................................................... 52

Figure 31. Options Screen - File Locations................................................................................................54

Figure 32. Options Screen - Language......................................................................................................55

Figure 33. Remote Communications Screen.............................................................................................56

Figure 34. Data Viewer Screen..................................................................................................................57

Figure 35. Plot Screen ...............................................................................................................................58

Figure 36. COMPASS Report Editor .......................................................................................................... 62

Figure 37. Find Text Screen.......................................................................................................................67

Figure 38. Data Field Insertion Tool Screen ..............................................................................................68

Figure 39. Page Setup Screen ................................................................................................................... 69

Figure 40. COMPASS Report Editor, Main Toolbar ..................................................................................69

Figure 41. COMPASS Report Editor, Font Format Bar ............................................................................. 69

Figure 42. COMPASS Report Editor, Ruler...............................................................................................71

Figure 43. RS232 DUT Example ............................................................................................................... 80

Figure 44. Example #1 PPC2+ Reference Setup ......................................................................................80

S

© 1998-2000 DH Instruments, Inc. Page VI

Page 9

TABLES & FIGURES

Figure 45. Example #1 Configuration ........................................................................................................ 81

Figure 46. Example #1 DUT Interface Setup.............................................................................................81

Figure 47. Example #1 RS232 Setup with Ref Com2................................................................................82

Figure 48. Example #2 User Defined Unit Setup.......................................................................................83

Figure 49. Example #2 DMM DUT Data Acquisition..................................................................................83

Figure 50. Example #2 DMM Setup........................................................................................................... 84

Figure 51. Example #2 DMM Configuration...............................................................................................85

Figure 52. Example #2 DUT DAQ with DMM.............................................................................................85

Figure 53. Example Multiplexer Setup.......................................................................................................87

Figure 54. Multiple DUT Setup with DMM+Multiplexer DAQ.....................................................................88

Page VII © 1998-2000 DH Instruments, Inc.

Page 10

COMPASS® FOR PPC/RPM™ USER’S MANUAL

N

N

OOTTEES

S

© 1998-2000 DH Instruments, Inc. Page VIII

Page 11

USER REGISTRATION

U

SSEERR

U

Please fill out this r egistration s heet and return it to DH Instruments. Registering as a user will allow us

to contact you with important inform ation about COMPASS

and product announcement s .

COMPASS® for PPC/RPM™ User Contact:

Company/Organization:

R

EEGGIISSTTRRAATTIIOON

R

Pressure Calibration Software

Name:

Address 1:

Address 2:

City: State/Province:

Postal Code: Country:

Tel: Fax:

N

®

inc luding prod uct upgrades, p ossible reca lls

email:

1)

I am using COMPASS for PPC/RPM Ver. ____ ___ _ ____ __.

I will run COMPASS on a computer whose operating system is:

2)

Windows95 WindowNT Other__________

I plan to use COMPASS with the following reference pressure devices:

3)

PPC2 PPC2+ PPCK RPM1 RPM3 Other________

I plan to test up to __________ DUTs at a time with COMPASS.

4)

When I run tests with COMPASS, I will acquire data from the DUT(s) using the following:

5)

Manual DMM DMM+multiplexer RS232 direct IEEE 488 direct

Please return this form by mail or fax to: ATTN: COMPASS Registration

DH Instruments, Inc.

4765 East Beautiful Lane

Phoenix AZ 85044-5318

or via

Fax: 602.431.9559

email: dhi@dhinstruments.com

NOTE: COMPASS for PPC/RPM is a licensed software product intended for single computer use.

Page IX © 1998-2000 DH Instruments, Inc.

Page 12

COMPASS® FOR PPC/RPM™ USER’S MANUAL

N

N

OOTTEES

S

© 1998-2000 DH Instruments, Inc. Page X

Page 13

ABOUT THIS MANUAL

A

BBOOUUTT

A

T

T

HHIISS

M

AANNUUAAL

M

L

Manual Conventions

This manual provides the user with the basic information necessary to set up and run COMPASS

for PPC/RPM. It also includes a great deal of additional information provided to help you optimize

COMPASS use and take full advantage of its many features and functions.

Before using the manual, take a moment to familiarize yourself with the Table of Contents structure.

Sections 1 through 12 describe each of the six main menu selections in detail.

Quick Tips (see Section 13) provides responses to commonly asked questions and situations.

Certain words and expressions have specific meaning as they pertain to COMPASS for PPC/RPM.

The Glossary (see Section 15) is useful as a quic k refer ence for us age of s pecific term s and expr essions

as they are used in this manual and the program.

For those of you who don’t read manuals, go directly to Section 2.3 to install COMPASS and then

Section 3 for a summary of operating principles. Later … when you have questions or start to wonder

about all the great features you might be missing, get into the manual.

Cross references are used extensively to direct you towards additional information on a topic.

Cross references are generally in parenth eses and give the reference’s section num ber. For example:

(see Section 11).

[ ] indicates COMPASS menu or tab selections (for example [Data]) . Menu or tab selec tion paths are

always described hierarchically from highest to lowest level. For example: [Tools], [Options],

[Maintain Lists].

< > indicates COMPASS text displays such as screen names, field names, prompts, warnings

and instructions. For example: <Enter user ID>.

File names are designat ed in quotation m arks when they do NOT include a file ex tension. For example:

“log” file or *.log.

(CAUTION) is used in manual to identify user warnings and cautions.

(NOTE) is used in the manual to identify operating and applications advice and

additional explanations.

Page XI © 1998-2000 DH Instruments, Inc.

Page 14

COMPASS® FOR PPC/RPM™ USER’S MANUAL

N

N

OOTTEES

S

© 1998-2000 DH Instruments, Inc. Page XII

Page 15

1. INTRODUCTION

11..

I

NNTTRROODDUUCCTTIIOON

I

N

1.1 PRODUCT OVERVIEW

Welcome to COMPASS® for PPC/RPM™, the complete pressure calibrati on software package f or users

of DHI PPC2, PPC2+, PPCK and RPM3 pressure transfer standards. COMPASS for PPC/RPM is

designed to suppl y the miss ing link nee ded to get f rom individu al autom ated hard ware com ponents to an

automated pressure ca libration s ystem. Using COMPASS for PPC/RPM, you can create any number of

calibration test s cenarios; define characteris tics of various devices u nder test (DUT); run tests ; analyze

test data and generate rep orts without ever leavin g the program or you can exp ort test data for anal ysis

using other applica tions. COMPASS’s flexible approach makes it easil y adaptable to a wide variet y of

hardware and allows you to adjust the level of automation for a variety of tasks and hardware

configurations from analog gauge calibration to fully automated multiple DUT test runs.

Please fill in and return the User Registration form located in this manual immediately following the

Table of Contents.

Page 1 © 1998-2000 DH Instruments, Inc.

Page 16

COMPASS® FOR PPC/RPM™ USER’S MANUAL

N

N

OOTTEES

S

© 1998-2000 DH Instruments, Inc. Page 2

Page 17

2. GETTING STARTED

22..

G

EETTTTIINNGG

G

S

TTAARRTTEED

S

D

2.1 OVERVIEW

This section expla ins how to install COMPASS for PPC/RPM on your computer. Although COMPASS

for PPC/RPM is a multilingual application, the installation always uses English.

2.2 SYSTEM REQUIREMENTS

COMPASS for PPC/RPM is an application designed for Windows 32 bit operating systems.

The following minimum configuration is required to run COMPASS:

• Windows 95, 98, or NT

• 100 MHz, Pentium processor

• 16 MB RAM

• 5 MB free hard disk space

2.3 INSTALLING COMPASS FOR PPC/RPM

Insert the COMPASS for PPC/RPM disk 1 in your floppy drive.

Press the [Start] button and select [Run].

In the Run dialog box, t ype a:\setup or b:\setup, depend ing on the drive in which you plac ed the

COMPASS for PPC/RPM disk.

OR

Insert the COMPASS for PPC/RPM disk 1 in your floppy drive.

Use the Add/Remove Programs feature in the Windows Control Panel. Press [Start] and select

[Settings] followed by [Control Panel].

Double-click the [Add/Remove Programs] icon and c lick the [Install] butto n. Follow the prom pts to

install COMPASS.

2.4 RUNNING THE PROGRAM

When the software installation is complete, a new Windows group is created to hold the

COMPASS program. To run th e program , select it by pressi ng [Start], selecting the [Program s] sub-menu

followed by the [COMPASS] group. Click the [COMPASS for PPC/RPM] icon to start the program.

2.5 LANGUAGE SUPPORT

When COMPASS loads, a prompt displays requiring the selection of the language to use. Make the

selection from the lis t and press [OK]. The progr am displays all m essages and prompts in the selected

Page 3 © 1998-2000 DH Instruments, Inc.

Page 18

COMPASS® FOR PPC/RPM™ USER’S MANUAL

language. Subsequent runs of COMPASS display this dialog in the language selected in the previous run.

The [English] button will always run COMPASS in English and has the same effect as choosing

[English] from the language list. Check the <Do not display..> box at the bottom of the window to

prevent this displa y in the future. The language c an be changed while running COMPASS by selecting

[Tools], [Options], [Language] (see Section 8.3.6).

Figure 1. Language Selection

2.6 UNINSTALLING

To uninstall COMPASS, use the Remove COMPASS for PPC/RPM icon in the COMPASS program

group created during ins tallation. Alternatively, use the Ad d/Remove Programs feature in the W indows

Control Panel and select COMPASS for PPC/RPM. In both cases, a series of prompts must be followed in the

application removal program to uninstall COMPASS. All installation files and registry updates are removed.

Data directories cr eated by running COMPASS are not rem oved by uni nstalling. It is up to the user to

manually remove th ese da ta dir ect ories. T he a pplic ati on rem oval program wil l al ways dis pla y a mes sage

indicating COMPASS was not com pletely removed when executed and th e data directories ar e present.

Any file management tool such as Windows Explorer can be used to remove these data directories.

© 1998-2000 DH Instruments, Inc. Page 4

Page 19

3. OPERATING PRINCIPLES

33..

O

PPEERRAATTIINNGG

O

P

RRIINNCCIIPPLLEES

P

S

3.1 OVERVIEW

COMPASS for PPC/RPM is an application program intended to automate the test and calibration process

to the extent supported by your calibration hardware and appropriate for the DUT being calibrated.

COMPASS supports autom ated operation of DHI PPC and RPM transfer standards but can als o be used

with any type of pres sure standard from any manuf acturer. This feature allows COMPASS to be used

systematically to provide consistent data formats and report generation for all of your pressure calibrations.

COMPASS sets up and maintains files on devices under test (DUT) (see Section 6) and testing

procedures (see Sec tion 7) to assoc iate with DUTs . These files are recalled to run tests. Tests are run

using the hardware th at has been configur ed (see Section 8.2) in COM PASS. While running a tes t, data

is acquired and stored in a standard ASCII comma or tab delimited data file (see Section 12). Within

COMPASS, data files m ay be viewed (see Section 9 .2), used to generate plots (see Sec tion 9.4) and

used to generate reports (see Section 1) which can be customized with user edited templates.

COMPASS operations foll ow conventional Windows protocol for file management, menu and message

formatting, graphics and editing.

Devices under test (DUT) and test pr ocedures are def ined and recorded in *.dut and *.ts t files. To run a

test, first a *.dut f ile m ust b e create d (see Secti on 6.2) to def ine the DUT that wil l be test ed and a *.ts t file

must be created (se e Section 7.2) to pro vide COMPASS with the exac t testing procedure f or that DUT.

The hardware configurat ion, including the pressure referenc e device, the electrical measuring dev ice (if

present) and the computer ’s IEEE 488 card (if present) used to run the t est is specified with a Hardware

Configuration Tool ( see Section 8.2). Once “DUT” and “test” files have been set up, and the hardware

configuration has been defined, tests can be run (see Section 5.2).

Many operationa l preferences relating to how test are i nitialized and ru n, and how data is g athered and

stored are configurabl e with user options (see Sectio n 8.3). The use of these configura ble preferences

results in a test environment that is customizable to meet the testing needs of a diverse group of end users.

As a test runs, the data is c oll ected in a “ l og” f ile ( s ee Sect ion 12 .2) . When the test completes, the r es u lts

of the test are copied f rom the “ log” f ile in to “da ta” f iles . “Data” f iles are des igned to be eas il y exported t o

other applications by the u ser for further analysis or report ge neration. In addition, COMPASS includes

integrated analysis and reporting func tions which allo w full custom ization of repo rts (see Sec tion 1). Any

number of custom report formats can be creat ed and employed. Re ports can then be edit ed, printed or

saved. A plottin g function allows vario us auto-sc aled err or plots fo r test results t o be view ed and printed

(see Section 9.4).

Detailed inform ation and assis tance on COMPASS application a nd functions ar e available i n this manual

and with on-line help (accessed by pressing [F1] or selecting [H

elp]).

Page 5 © 1998-2000 DH Instruments, Inc.

Page 20

COMPASS® FOR PPC/RPM™ USER’S MANUAL

3.1.1 BASICS SUMMARY

In summary, the following steps and sections s hould be refer red to while trying to s et up and

run a test for the first tim e. Subseque nt tests will onl y require a sel ection of the desired DUT

and test file. The Run T est section of this manual has a m ore detailed explanation of the

requirements to run a test in COMPASS (see Section 5.2). Several COMPASS exam ples

and frequently asked ques tions are in t he Qu ick Tips section of this m anual ( see Section 1 3).

These sections are also very useful in gett in g star te d.

• Select [DUT], [Create] to create a DUT (see Section 6.2). A DUT that outputs an

electrical signal suc h as V, m V or m A will most lik ely use a dig ital m ultimeter . This DMM

should be set up in the program configuration (see Section 8.2).

• Select [Tools], [Configure Hardware] to update the program configuration

(see Section 8.2). This includes setting up the press ure reference as well as any other

peripheral devices required by a DUT. This option should be used t o set up a DMM,

multiplexer and s elect the system IEEE 488 i nterface card. Once these selec tions are

made there is no need to access the configuration unless a change in one of these

devices occurs. M ake sure the des ired selec tions are m ade on the [CONFIGURATION]

tab of the hardware configuration.

• Select [Test] , [Create Test] to create a test that will define the pr essure sequence and

other aspects of the testing procedure (see Section 7.2).

• Select [Run], [Run Test] or the corresponding toolbar shortcut to run the test.

© 1998-2000 DH Instruments, Inc. Page 6

Page 21

4. MAIN RUN SCREEN

44..

M

M

AAIINN

R

R

UUNN

S

CCRREEEEN

S

N

4.1 OVERVIEW

The main screen contains the:

• Main menu bar to access all COMPASS menus and functions (see Section 4.2).

• Run test toolbar with seven test running short cut keys (see Section 4.4).

• Run test screen providing complete real tim e information on test progress and results as a test is

running (see Section 4.3).

4.2 MAIN MENU BAR

The main menu is divi ded into seven separate selections. Each menu item is summarized below and

covered in detail in Sections 1 through 1:

[Run] Initialize and run tests. This menu also contains the choice used to exit the program

(see Section 1).

[DUT] All device under test (DUT ) inf orm ation is hand led her e b y creating, editin g and d eletin g *.dut

files (see Section 6).

[Test] All test procedure information is handled here by creating, editing and deleting *.tst files

(see Section 7).

[Tools] Access tools to c onfigure the test hard ware used by COMPASS, sel ect user preferences to

customize test ini tializati on and exec ution, select user pref erences f or file locati ons, m aintain

lists and send discreet commands to interfaced devices (see Section 8).

[Data] View, plot or print the raw data contained in the *.dat files that result from test execution

(see Section 9).

[Report] Edit report templates. Generate reports from *.dat files, save and print reports (see Section 1).

[Help] Access on-line help (see Section 1.

Page 7 © 1998-2000 DH Instruments, Inc.

Page 22

COMPASS® FOR PPC/RPM™ USER’S MANUAL

4.3 RUN TEST SCREEN

The Run Test screen provides real time information on test execution while a test is running.

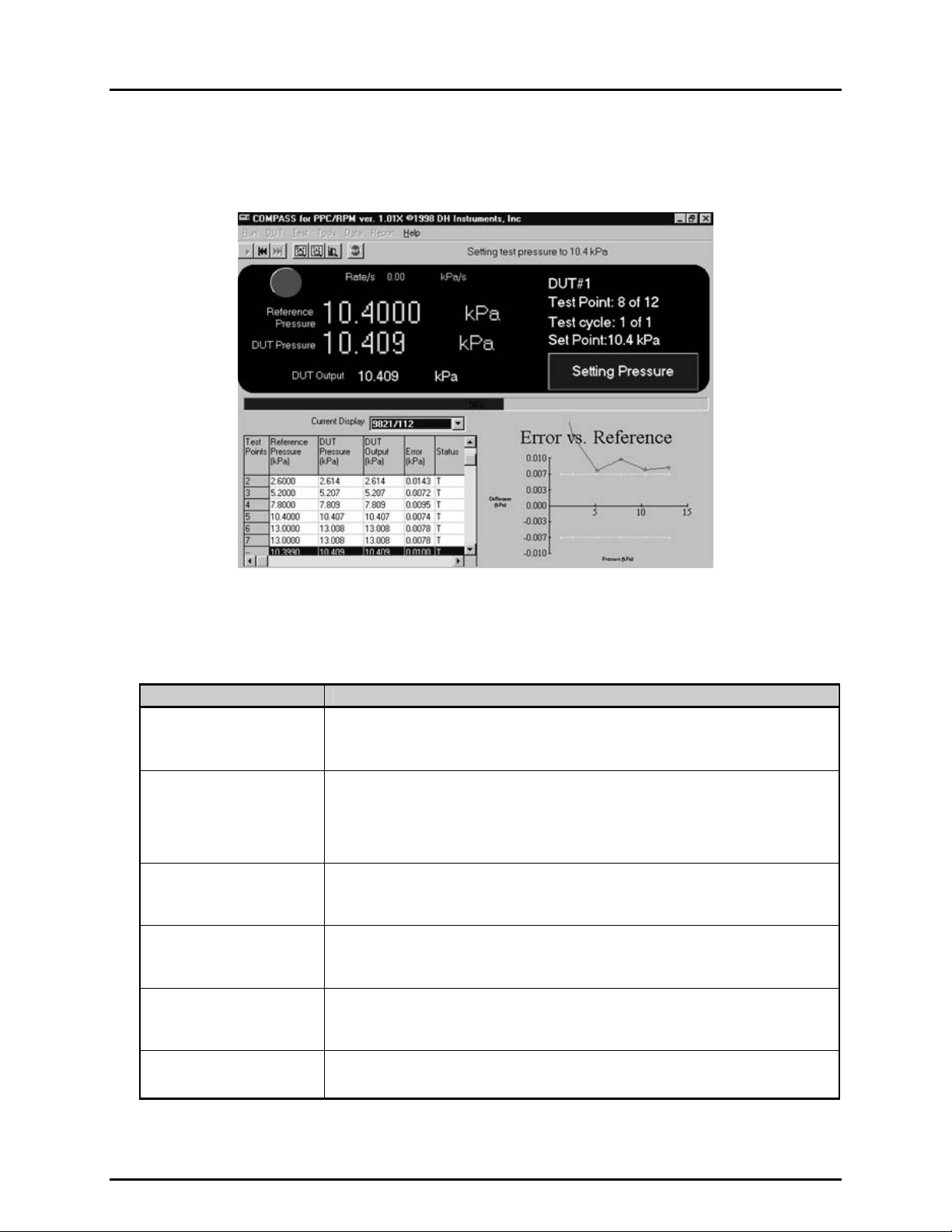

Figure 2. Run Test Screen

The run test screen is segmented into eight functional areas described on Table 1.

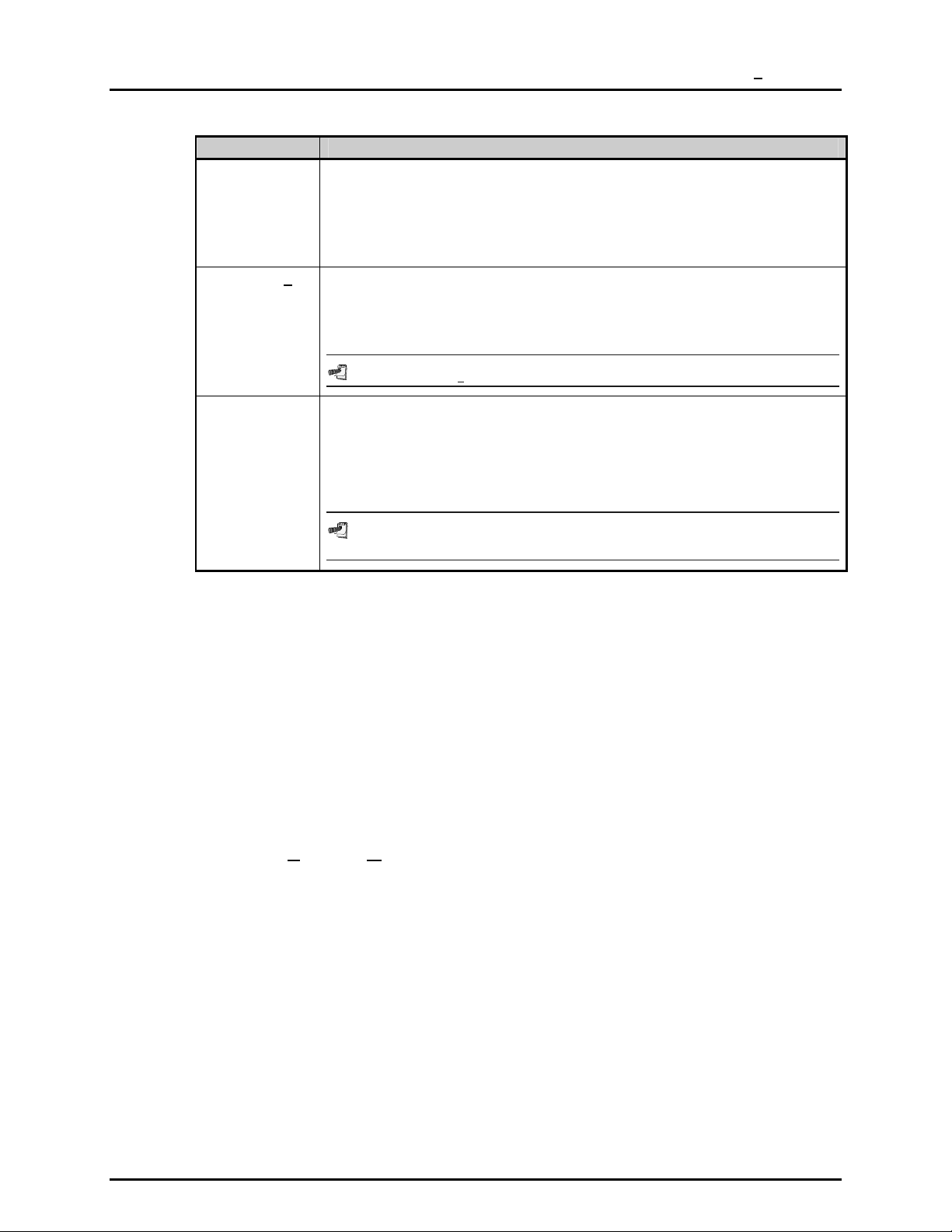

Table 1. Run Test Screen

FEATURE DESCRIPTION

Status Message Bar

(Top line next to the

run test toolbar)

Read-out Panel

(Top left hand

quarter of screen)

Ready Indication LED

(Circle in the top left hand

corner of the screen)

Test Progress Summary

(WHITE characters in upper

right hand quarter of screen)

Current Function Box

(BLUE box in top right hand

quarter of screen)

Test Progress Bar

(Across middle of screen)

Displays real time messages describing t he sp ecific acti on COMPASS is executing. Uses

color coding and font changes to indicate that the program is running and to draw attention

when needed.

Provides real time readings of reference press ure, DUT output, DUT pressure (c alculated

from DUT output if DUT output is other than pressure), rate of change (stability) of

reference pressure and a green/red circular indicator of pressure ready/not ready (see

PPC or RPM Operation and Maintenance Manual for ready/not ready definition).

Readings are only displayed for values that can be read remotely by COMPASS from

interfaced devices. If no values are available, the fields show < -------- >.

Changes color from GREEN to RED to indicate whether the pressure reference meets or

fails the stability criterion specified in the test file.

Displays current DUT # (always one for single DUT tests), test point currently being

executed and total number of points in test, cycle # (always one for single c ycles tests),

and nominal pressure of current test point.

Indicates the current macro test function being executed by COMPASS (<IDLE>,

<Initialize Test>, <Leak Check>, <Pressure Cycle>, <Setting Pressure>, <Dwelling>,

<Taking Data>).

Visualizes test progress with a p rogressive horizontal bar and percent executed value.

Progress is in terms of current test point over total number of test points.

© 1998-2000 DH Instruments, Inc. Page 8

Page 23

4. MAIN RUN SCREEN

FEATURE DESCRIPTION

<Current Display> Selector

(Top of bottom left hand

quarter of screen)

Test Point Log

(Bottom left hand quarter of

screen)

Run Time Plot

(Bottom right hand

quarter of screen)

Identifies the DUT that is currently being displayed in the test point log and in the run time

plot. DUTs are identified by serial number/ID. If multiple DUTs are being tested, a dropdown menu to select an individual DUT or <All> is available.

Selecting <Pre Test> causes information on the leak test and/or cycling (exercising)

conducted at the beginning of the test to be displayed i f these were included in the test

definition.

The data for each test point is recorded and displayed in the test point log. If the DUT

error for the current test point exceeds the DUT tolerance, the computer beeps (if audible

feedback is enabled) and the row containing the t est point is highlighted (only the most

recent out of tolerance test point is highlighted). The status column for this point will

include a <T> for out of tolerance.

When testing multiple DUTs, selecting a single DUT in the <Current Display> selector

causes the complete test log for the DUT to be shown; selecting <All> causes the current

point for all the DUTs to be shown. The change f rom a single t o all DUTs c an be made at

any time.

<Test Point> is the number of the pressure point in the pressure point sequence.

<Reference Pressure> is the reading from the reference pressure device.

<DUT output> is the output recorded from the DUT. <DUT Pressure> is the pressure

calculated from the output using the output and pressure spans from the “DUT” file. If the

DUT output is pressure, DUT output and DUT pressure are identical.

<Error> is the difference between the DUT pressure and the ref erence pressure (DUT

pressure – reference pressure).

The <Status> column reports the status of the test point.

<OK> indicates that the test point executed normally and the DUT error was in tolerance.

<T> indicates that the DUT error was out of tolerance.

<S> indicates that data was taken from the reference when the reference was not ready

(applies only to automated reference devices).

The run time plot shows a plot of the DUT error (DUT pressure - reference pressure) in the

DUT pressure units.

The plot can scale automatically to the error data or include DUT tolerance bars and scal e

automatically to the DUT tolerance. Which scaling is used is determined by user

preference: [T

When testing multiple DUTs, selecting a single DUT in the <Current Display> selector

causes the error plot of the selected DUT only to be shown; selecting <All> causes error

plots for all the DUTs to be shown simultaneously. The change from a single to all DUTs

can be made at any time. Clicking on the plot causes a plot legend to appear.

The <Maximiz e Graph> key of the run test tool bar (see Section 4.4) may be used to

maximize the graph to the full screen. Click the key again to minimize the graph.

ools], [Options], [Run Test], <Plot data to tolerance> (see Section 8.3.3).

Page 9 © 1998-2000 DH Instruments, Inc.

Page 24

COMPASS® FOR PPC/RPM™ USER’S MANUAL

4.4 RUN TEST TOOLBAR

The run test toolbar pro vides a shortcut method for starting a t est, accessing DUT and test procedure

information while a test is running and other test func tions. The toolbar is located in the up per left-hand

corner of the main run screen. To use a tool, click on the tool icon.

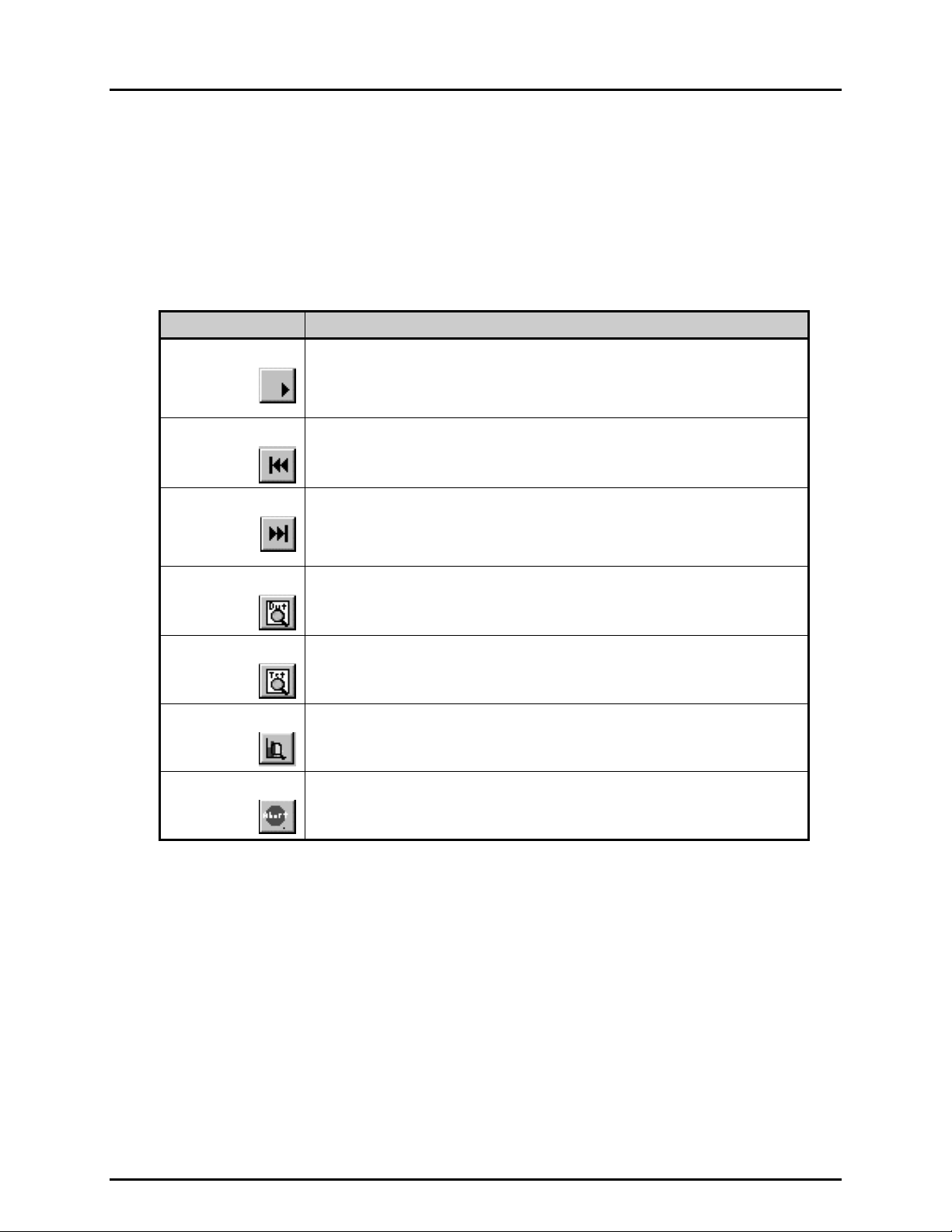

Table 2 lists the tools available on the toolbar.

Table 2. Tools Available on the Toolbar

ICON DESCRIPTION

Starts a test, beginning with DUT selection or displays an option to re-run a test. Tests

Run

can be re-run only if the previous test was succ essfully initialized, and no configuration

changes have occurred since the com pletion of the previous run. The current DUT and

test file can be edited only. If this criterion is not met, the re-run option will not display

and test initialization immediately begins with DUT selecti on.

Step Back

Step Forward

View DUT

View Test Procedure

Maximize Graph

Causes the current test point to be interrupted and t he test point sequence to st ep back

to the most recent set pressure step. Subsequent clicks caus e the tes t to step back one

point for each click. This key is used to repeat points when needed.

Causes the current test point to be interrupted and the test point sequence to step

forward to the set pressure s tep of the next pressure point. This key enables only after

the step back key has been used; it cannot be us ed to s tep f orward over tes t point s t hat

have not been executed. Most often it is used to avoid repeating all previously execut ed

points when the step back key has been used to go back several pressure points.

Causes the DUT Profile screen to be displayed over the run test screen. This allows

complete information on the DUT being run to be reviewed without i nterrupting the t est.

Click <OK> to close the screen.

Causes the Test Definition screen to be dis played over the run tes t screen. This al lows

complete information on the current test proc edure to be reviewed without interrupting

the test. Click <OK> to close the screen.

Causes the current run time plot t o be maximized. Toggles between maximized and

standard size plots.

Abort

Causes the <Abort Test> confirmation pop-up to appear to abort the test that is running.

© 1998-2000 DH Instruments, Inc. Page 10

Page 25

5. THE [RUN] MENU

55..

T

T

HHEE

[[R

R

N

UUN

M

]] M

U

EENNU

5.1 OVERVIEW

The [Run] menu is used to execute a test and to exit COMPASS. It has the following choices:

un Test], [Re-Run Test] and [Exit].

[R

5.2 [RUN], [RUN TEST]

This menu selectio n is used to start execution of a test. Pressing the [Run] key on the r un test toolbar

has the same effect as selecting this menu option. Test execution is divided into three sequential parts:

Test Initialization Selects the DUT and test procedure to run, sets up the reference, sets up DUT

identification and communications, enters user ID. The sequential steps of test

initialization can be turned ON or OFF using [Tools], [Options], [Initialize Test]

(see Section 8.3.2).

Run Test uns leak check (if included), runs pressure cycling to exercise DUTs (if included),

runs test pressure points and takes data at each point. The test run details are

defined by the *.dat file. Certain aspects of operation can be customized using

[Tools], [Options], [Run Test] (see Section 8.3.3).

Test Conclusion Presents <Test Notes> screen to rec ord test specific notes and <T est Complete>

screen with various test conclusion options.

5.2.1 TEST INITIALIZATION

Test initialization is the first part of test execution. The seven sequential steps of test

initialization can be turned ON or OFF using [To

(see Section 8.3.2). The test initialization sequential steps are listed immediately following

below (see Sections 5.2.1.1 through 5.2.1.7 for details on each initialize test step):

Select DUT File (see Section 5.2.1.1): The DUT selection tool is presented allowin g

browsing of DUTs avai lable and selection of the DUT file to run. If this s tep is turned

OFF, the screen is not shown and the last DUT file used is automatically selected.

Preview DUT (see Section 5.2.1.2): The DUT profile screen is presented to allow

verification of the DUT file to run. If this step is turned OFF, the step is omitted entirely.

Select Test File (see Section 5.2.1.3): The select test file screen is presented

identifying the primary and secondary test files associated with the current DUT and

allowing browsing of the test f iles available. If this ste p is turned OFF , the scree n is not

shown and the primary test file associated with the DUT is automatically selected.

Preview Test (see Sect ion 5.2.1.4): The pre view test file sc reen is presented to allow

verification of the test file to run. If this step is turned OFF, the step is omitted entirely.

ols], [Options], [Initialize Test]

Page 11 © 1998-2000 DH Instrument s, Inc.

Page 26

COMPASS® FOR PPC/RPM™ USER’S MANUAL

Reference Verification/Range Selection (see Section 5.2.1.5): The reference

verification scree n is presented ident ifying the source of reference pressur es to be used

in running the test. If the reference has m ultiple ranges and ca n be communic ated with

remotely, the range selection function is included. The range recommended by

COMPASS or a d ifferent r ange can be selec ted. If this step is turned OF F, the screen is

not shown and the recommended range is automatically accepted.

Setup DUT(s) (see Section 5.2.1.6): The setup DUT(s) screen is presented.

This screen is intended to allow input of DUT identification and communication details

if necessary. If the DUT being run is a m anual data acquisition t ype DUT and the DUT

file is a DUT defini tion, t he scr een serves as verificat ion of DUT identif ication onl y. If the

DUT file is a DUT prof ile, identification of the DUT( s) must be provided. If the DUT(s)

being run is/are DMM, RS232 or IEEE 488 data acquisition type, the DUT

communications deta ils can be verified, changed and tested. If this step is turn ed OFF

and the DUT file is a DUT definition, the step is om itted entirely when all requ ired DUT

communications inf ormation is curren tly configured. T his means that a DMM is set up for

a DMM output DUT and the default R S232 or IEEE 488 comm ands have been set up to

meet the requirem ents of the current DUT (see Sectio n 8.3.3). If this step is turned OF F

and the DUT file is a DUT profile or the previous inform ation is not set up, the screen is

still presented and DUT identification(s) must be entered.

User ID Entry (see Section 5.2.1.7): The user ID entry screen is presented. T he last

user ID can be accepted, a new user ID m ay be enter ed, or a previo usly ent ered user ID

may be selected from the user ID drop-do wn list. If thi s s tep is turned OF F, the s creen is

not shown and the last user ID selected is automatically used.

Test initialization is complete, run test begins (see Section 5.2.2).

5.2.1.1 SELECT DUT FILE

The DUT selection tool is presented allowing browsing of DUTs available and

selection of the DUT file to run. If this step is turned OFF, the screen is not

shown and the last DUT file used or accessed is automatically selected.

DUTs available are listed by manufacturer, model, serial number and

identification as extracted from *.dut files. The list is alphabetical by

manufacturer. Us e your k eybo ard’s ar ro w k e ys or po in ting de vic e to hi ghl ig ht th e

desired DUT. The highlighted DUT file name and path are listed following:

Figure 3. Select the DUT file for the Test Screen

© 1998-2000 DH Instruments, Inc. Page 12

Page 27

5. THE [RUN] MENU

To select the DUT based o n its f ile nam e, or if the f ile you want was not store d in

the directory specified for DUTs in your file location preferences (see Section

8.3.5), click <Browse> to activate a standard Windows file selection pop-up.

Figure 3. Select the DUT file for the Test Screen

5.2.1.2 PREVIEW DUT

The DUT profile screen is presented to allow verification of the DUT file to run. If this

step is turned OFF , the ste p is sk ipped entir ely. Edits cannot be m ade to a DUT

file during test initialization.

If the previe wed D UT is cor r ect, clic k <OK> and test ini ti ali zat io n wi ll c ont in ue. If the

DUT is not correc t, click <Cancel> to return to the DUT selection tool an d make

a new DUT selection. To abor t the tes t completely, click <Cancel> from the DUT

selection tool.

Figure 4. DUT Definition (C:\COMP4PRS\DUT\DUCE …) Screen

Page 13 © 1998-2000 DH Instrument s, Inc.

Page 28

COMPASS® FOR PPC/RPM™ USER’S MANUAL

5.2.1.3 SELECT TEST FILE

The select test file s c reen i s pres ente d i dent ifying the primary and secondary test

files associated with the current DUT and allowing browsing of the test files

available. If this step is tur ned O FF , the s cr een is not s ho wn and the pr imary test

file associated with the DUT is automatically selected.

The test selection screen c ontains the core information about the s elected DUT

which may be helpful in selecting the test file to run. The DUT’s primary and

secondary test files display and one of these can be selected by clicking the

corresponding selection button. To select a test file other than the primary or

secondary test file associated with the DUT, click <Browse> to activate a

standard Windows file selectio n pop-up. Click <Cancel> to abort the test completely.

Figure 5. Select Test File Screen

5.2.1.4 PREVIEW TEST

The preview test screen is presented to allow verification of the test file to run. If this

step is turned OFF, the step is skipped entirely.

The test cannot be m odified using this po p-up, but all the charac teristics can be

viewed by clicking on the appropriate tabs.

If the previewed test is correct, click <OK> and test initialization will continue. If the

test is not correct, click <Cancel> to return to the tes t selection tool and make a

new test selection. To abort the test completely, click <Cancel> from the test

selection tool.

Figure 6. Test Definition (C:\COMP4PRS\TEST\TEST1.TST) Screen

© 1998-2000 DH Instruments, Inc. Page 14

Page 29

5. THE [RUN] MENU

5.2.1.5 REFERENCE VERIFICATION

The reference verif ication sc reen is pr esented identif ying the sour ce of r eference

pressures to be used in ru nning the test. If COMPASS can communicate with

the reference remotely and the reference has multiple ranges, the reference

range selection tool and h ead adjustment is also included . If this step is turned

OFF, the screen is not shown, the recommended range is automatically accepted

and the current head (if the reference supports head corrections) is accepted.

See the Reference Pressure Device Operations and Maintenance Manual for

details on head corrections.

The reference shown is the reference currently selected in [T

ools], [Config

Hardware], [CONFIGURATION]. To change references, abort the test and go to

ools], [Config Hardware], [CONFIGURATION] to set up and/or select a

[T

different reference (see Section 8.2.1).

If COMPASS is able to communicate remotely with the reference, the range

selection tool is disp la yed. T his too l rec omm ends the range tha t COM P ASS has

determined to be the optimum range based on the span and pressure

measurement mode of the DUT . A different range may be selec ted by clicking

on the corresponding button.

If COMPASS is able to communicate remotely with the reference and the

reference supports automated pressure head corrections the current head

correction height is displayed and m ay be edited to reflect the correc t height for

the current setup. The head correction un its and/or medium cannot be change d

using this pop-up. To change these, abort the test and m ake the changes using

the reference device’s front panel function keys then restart the test. See

Reference’s Operatio n and Mainte nance Manua l for com plete information o n the

head correction function).

Erroneous data may be logged if the reference device’s characteristics are

modified manually without restarting the test. Always restart the test if

pressure reference device changes are made using the reference device’s

front panel.

Figure 7. Reference Range Selection Screen

Page 15 © 1998-2000 DH Instrument s, Inc.

Page 30

COMPASS® FOR PPC/RPM™ USER’S MANUAL

5.2.1.6 SETUP DUT(S)

The setup DUT( s) screen is pr esented. T his screen is intended to a llow input of

DUT identification and communication details if necessary.

See Section 6.2 for information on DUT profiles vs. definition files and DUT

data acquisition type.

Do not use the following characters in the serial number or identification

fields: \,/, :, *, ?, “, <,>, |, a comma or tab character. These characters will cause

problems when importing the “data” file or creating the “data” file directory.

The setup DUT(s) screen’s appearance and operation vary depending on

whether the DUT file being run is a DUT definition or a DUT profile and on th e

DUT’s data acquisition type (see Section 6.2):

• If the DUT file is a DUT definition file and the DUT data acquisition type is

manual, the screen sets up for a single DUT. The screen serves only for DUT

verification as the DUT ide ntification comes from the *.dut file and there are

no communications to verify. If the setup DUT step is turned OFF, setup

DUT is omitted entirely.

• If the DUT file is a DUT definition file and the DUT data acquisition type

is DMM, RS232 or IEEE 488, the screen sets up for a single DUT.

DUT communication details c an be verif ie d, c han ged a nd tested. If the setup

DUT step is turned OFF, s etup DUT is omitted ent irely. This f eature can be

removed only when a DUT definition is used with DMM data acquisition or the

default interface parameters (see Section 8.3.3) will work with the current DUT.

• If the DUT fi le is a DUT p rofil e file , the scr een se ts f or entr y of up to 5 0 DUTs .

The screen requires entry of a DUT serial number for each DUT to be t es ted.

Serial number entr y in the DUT position is the means b y which COMPASS

determines how many DUTs to include in the test run and the position of

the DUTs. Identification is not a requ ired field. If the DUT data acquisiti on

type is DMM, RS232 or IEEE 48 8, DUT comm unication det ails for each DUT

individually can be verified, changed and tested. If the setup DUT step is

turned OFF, the setup DUT sc reen will still ap pear and r equire serial num ber

entry to identify the DUTs to be tested.

To check communications with the DUT(s), click the <Communications

Test> button. COMPASS attempts to comm unicate with all DUTs that have

had a serial number entered using the command specified in the DUT file

and the current comm unications settings. If communication is successful, the

DUT output is update d in the <D UT O utp ut> column. If communication fails,

an error message is displayed.

Figure 8. Setup DUT(s) Screen

© 1998-2000 DH Instruments, Inc. Page 16

Page 31

5. THE [RUN] MENU

Setup DUT(s) - Data Acquisition

When using the <Setup DUTs> screen, keep in mind that DUT Data

Acquisition type refers to the manner in which data will be gathered from the

DUT. DUTs with electrical outputs are read with a DMM and the data

acquisition type is DMM (it is not the interface on the DMM such as RS232

or IEEE 488). Only DUTs read directly by RS232 or IEEE 488 interfaces are

considered to use RS232 or IEEE data acquisition.

The data acquisition colum n of the DUT Setup table (third column from the lef t)

varies depending on the DUT data acquisition type.

The data acquisition t ype can be m anual, DMM, DMM + MUX, RS232, I EEE 488

(see Section 6.2):

• If the DUT data acquisition type is manual, the data acquis ition colum n is

labeled <Data Acquisit ion> an d <Manual> is listed for the DUTs . When the

test is run, DUT readings will be entered manually.

• If the DUT data acquisition type is RS232 or IEEE 488, the data

acquisition column is labeled <RS232 Settings> or <IEEE 488 Address>.

When a test is run, COMPASS will r ead the DUT(s) directly using R S232 or

IEEE 488 and the command strings defined in the *.dut file. The default

RS232 DUT set tings or IE EE 48 8 addr ess are ente red f or e ach DUT . T he DUT

RS232 settings or I EEE 488 address can be changed by d ouble clicking on

the corresponding c olumn entry to access the sett ings pop-up. The def ault

RS232 parameters and IEEE 488 address for DUT communications can be

changed using [T

ools], [Options], [Run Test]. <Default DUT

Communications> (see Section 8.3.3). If RS232 is the DUT data

acquisition type, a <Chained DUTs> check box appears above the data

acquisition column. Checking the box forces RS232 settings for multiple

DUTs to be the same for all the DUTs.

• If the DUT data acquisition type is DMM, the data acquisition column is

labeled <Data Acquisition > and <DMM> is listed f or all the DUT s. When a

test is run, DUT readings will be read automatically from the DMM. The actual

DMM communications are defined and changed, if desired, in the DMM

configuration (see Section 8.2.3).

• If the DUT data acquisition type is DMM and a multiplexer is included in

the hardware configuration, the data acquisition co lumn is labeled <Data

Acquisition> and <DMM + M ultiplexer> is listed f or all the DUTs. When a

test is run, the multiplexer will automaticall y switch DUT outputs to the DMM

and DUT readings will be read automatically from the DMM. The actual

DMM and multiplexer com munications are defined and changed, if desired,

in the DMM and multiplexer configuration (see Sections 8.2.3 and 8.2.4).

For DUT profiles with RS232 or IEEE 488 data acquisition type, the position

in the communication setup corresponds to the DUT number in the DUT

command list of the DUT profile (see Section 6.2) (i.e., COMPASS will use the

command assigned to DUT 3 in the DUT profile to communicate with

Position 3 of the communications setup, even if there is no entry in

Positions 1 and 2). When setting up DUT communications, for DUT profiles

with DMM data acquisition type using a multiplexer to switch DUTs, the position

in the communication setup corresponds to the multiplexer command

number from the multiplexer definition (see Section 8.2.4) (i.e., COMPASS will

use multiplexer switching Command 3, followed by the DMM command, to read

Page 17 © 1998-2000 DH Instrument s, Inc.

Page 32

COMPASS® FOR PPC/RPM™ USER’S MANUAL

Position 3 of the communications setup, even if there is no entry in

Positions 1 and 2).

5.2.1.7 USER ID

The user ID entry screen is presented. T he last user ID can be ac cepted, a ne w

user ID may be entered, o r a previously entered user ID m ay be selected from

the user ID drop down l ist. If this step is turned OFF , the screen is not shown

and the last user ID selected is automatically used.

Any time a new user ID is entered, it is automaticall y added to the user ID list.

Names can be removed from the list using [To

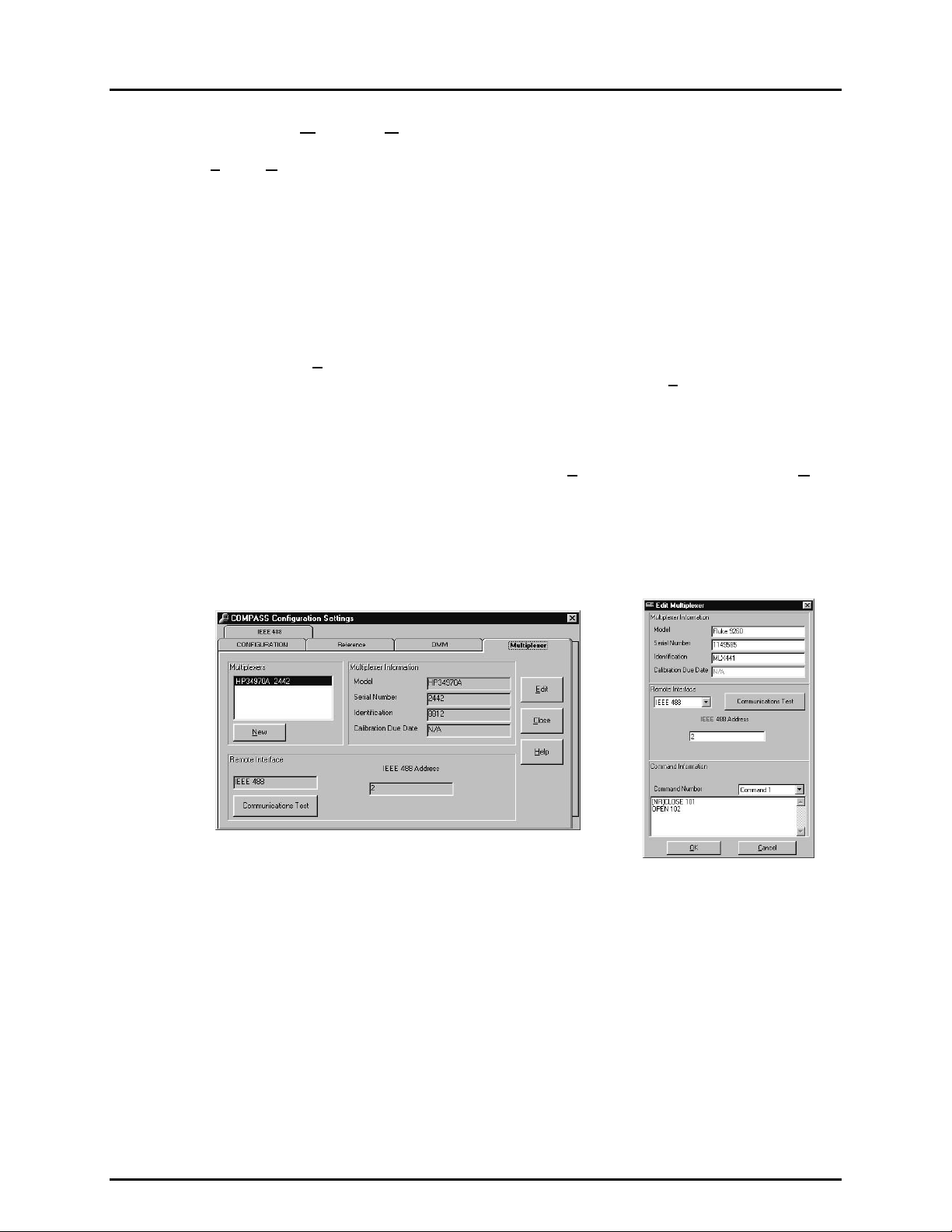

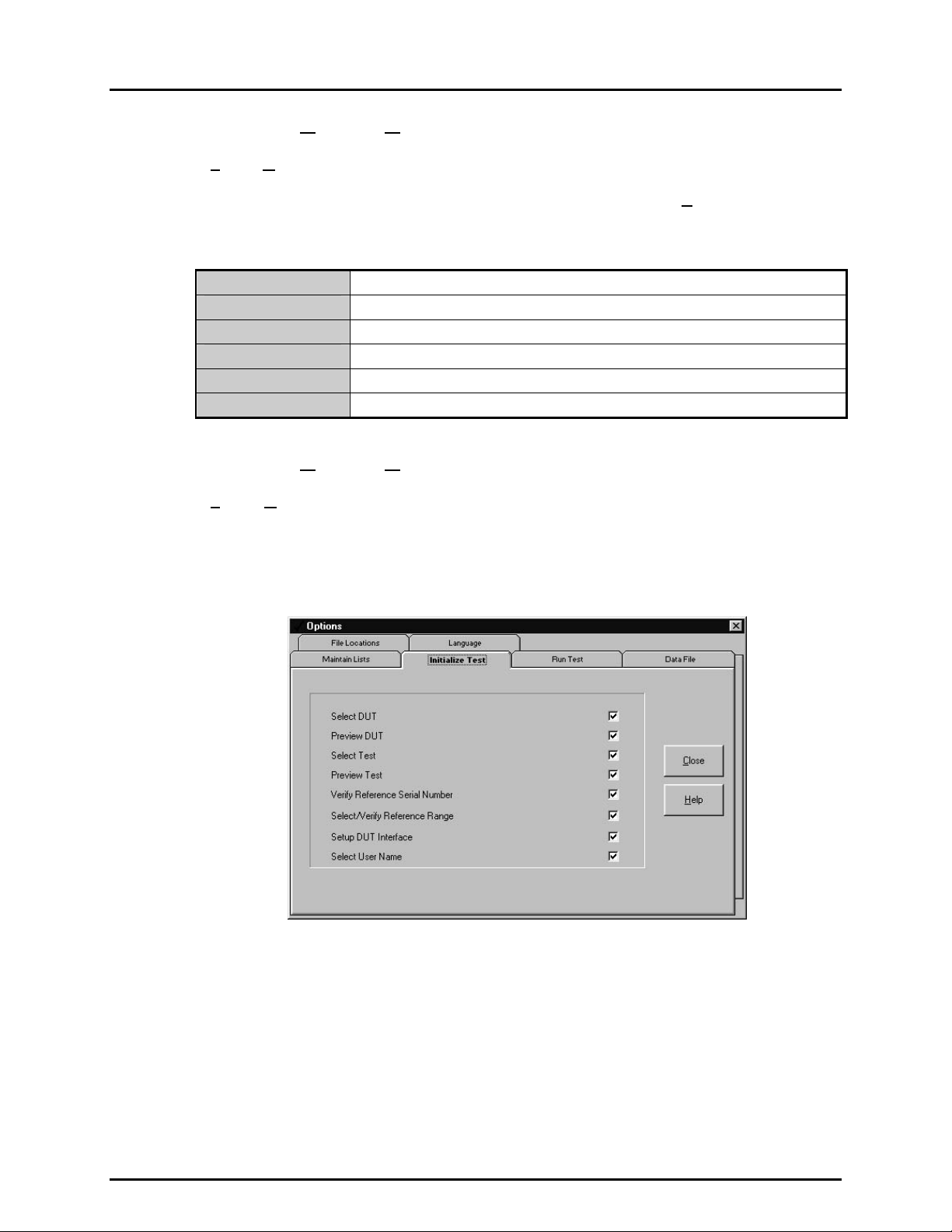

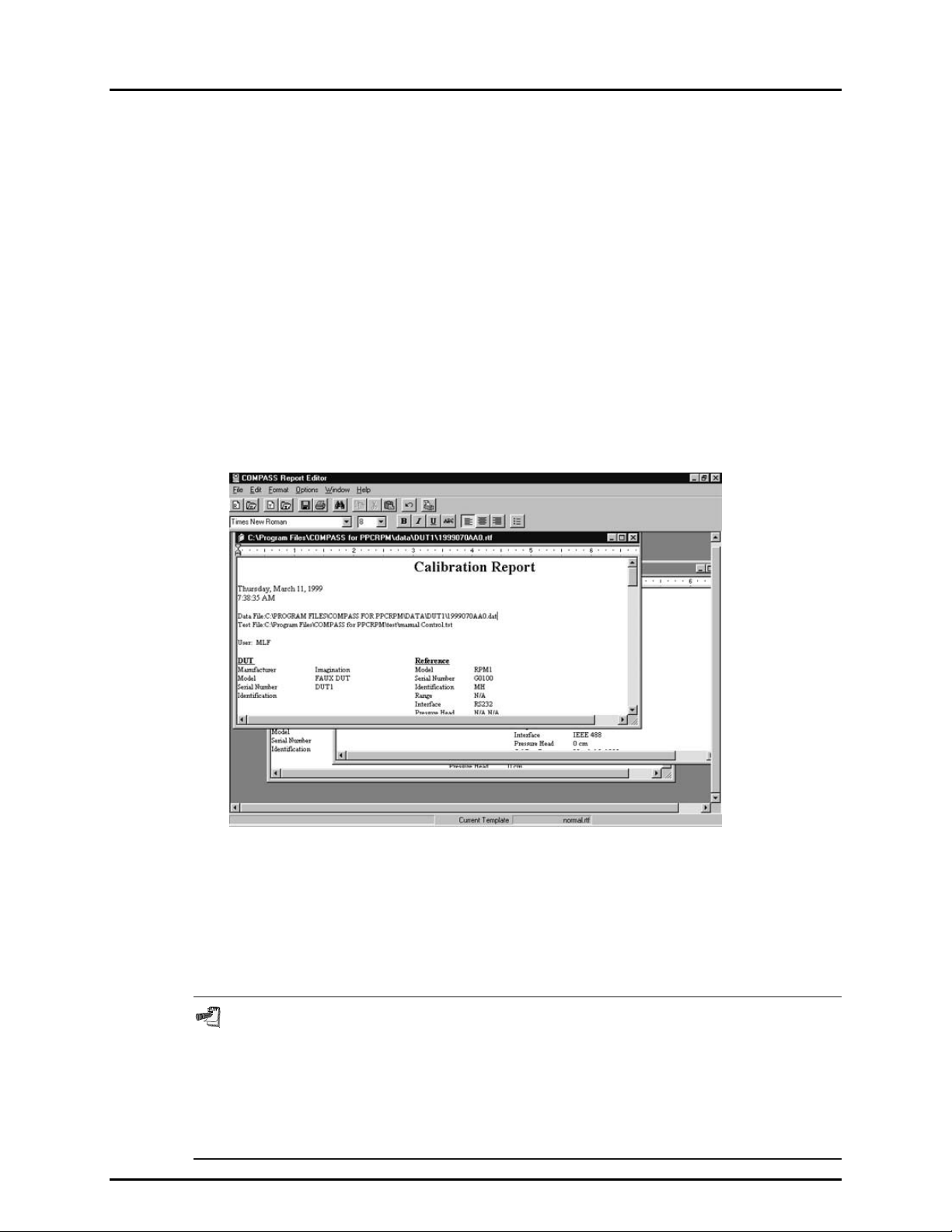

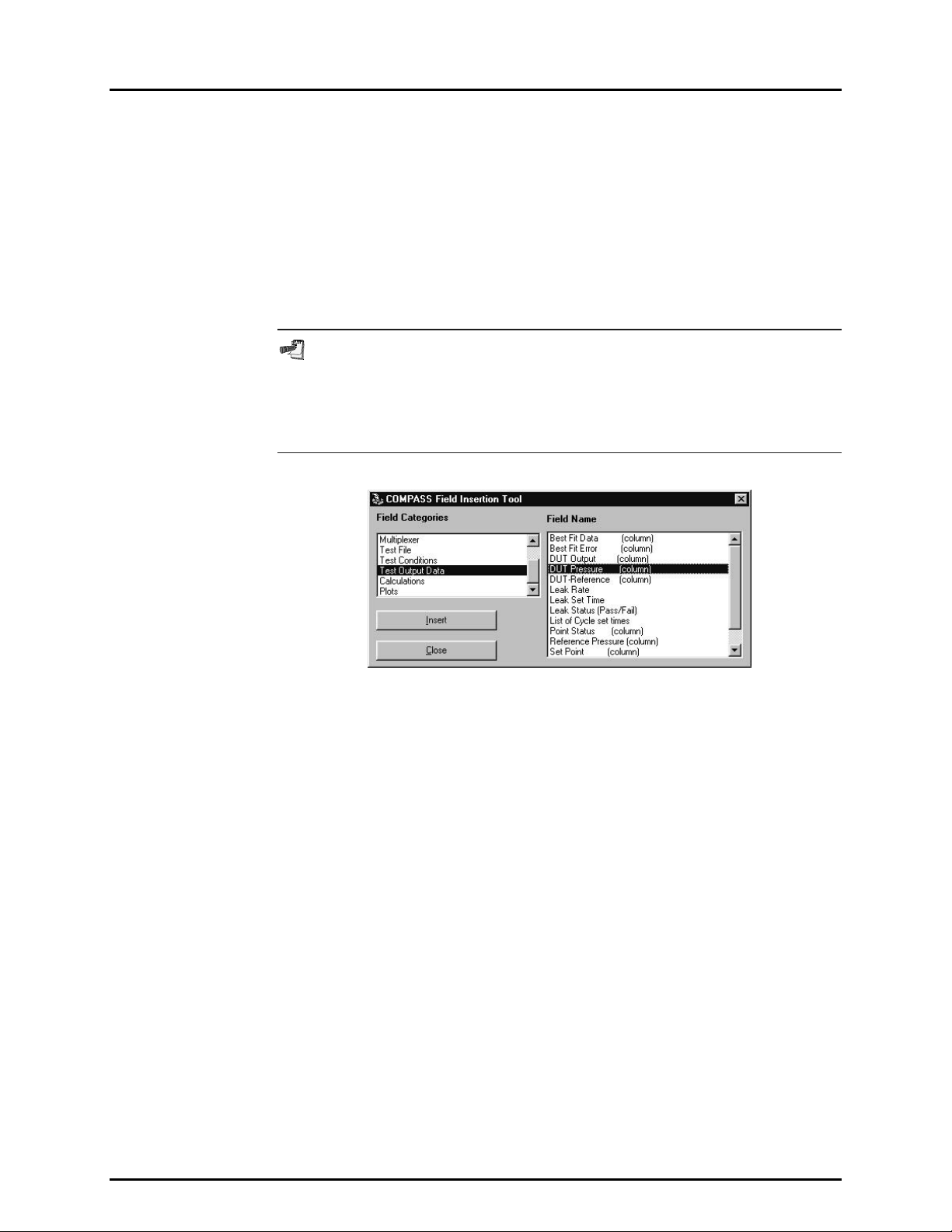

(see Section 8.3.1).