Page 1

BT521

Battery Analyzer

May 2014 Rev.1, 07/15

© 2014, 2015 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

Users Manual

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and

service. The warranty period is three years and begins on the date of shipment. Parts, product repairs, and

services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of

a Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in

Fluke's opinion, has been misused, altered, neglected, contaminated, or damaged by accident or abnormal

conditions of operation or handling. Fluke warrants that software will operate substantially in accordance

with its functional specifications for 90 days and that it has been properly recorded on non-defective media.

Fluke does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers

only but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is

available only if product is purchased through a Fluke authorized sales outlet or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for importation costs of

repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair,

or replacement of a defective product which is returned to a Fluke authorized service center within the

warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that service center, with a description of the difficulty,

postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following

warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination, alteration, accident, or abnormal

condition of operation or handling, including overvoltage failures caused by use outside the product’s

specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair

costs and obtain authorization before commencing the work. Following repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or

limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not

apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court or other

decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any other

provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

11/99

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

Page 3

Table of Contents

Chapter Title Page

1 Product Overview and Specifications ............................................... 1-1

Introduction ............................................................................................ 1-1

Contact Fluke ........................................................................................ 1-1

Product Overview .................................................................................. 1-1

Standard Equipment .............................................................................. 1-3

Safety Information ................................................................................. 1-5

Radio Frequency Data .......................................................................... 1-8

Keys and I/O Terminals ......................................................................... 1-8

LCD Display .......................................................................................... 1-10

Specifications ........................................................................................ 1-11

General Specifications ....................................................................... 1-11

Accuracy Specifications ..................................................................... 1-12

Records Capacity .............................................................................. 1-13

2 Setup .................................................................................................... 2-1

Introduction ............................................................................................ 2-1

Tilt Stand ............................................................................................... 2-1

Belt Strap ............................................................................................... 2-2

Adjust Display Contrast ......................................................................... 2-3

Set Language ........................................................................................ 2-3

Set Date and Time ................................................................................ 2-3

Turn On/Off Beep .................................................................................. 2-4

AutoHold and AutoSave Modes ............................................................ 2-4

Set Auto Power Off Time ....................................................................... 2-5

View Device Information ........................................................................ 2-6

Reset to Factory Mode .......................................................................... 2-6

View Memory Usage Information .......................................................... 2-6

3 Use the Product ................................................................................... 3-1

Introduction ............................................................................................ 3-1

Switch Between Meter Mode and Sequence Mode ............................... 3-1

Use a Profile in Sequence Mode ........................................................... 3-3

Manage Profiles ................................................................................. 3-3

i

Page 4

BT521

Users Manual

Create a Profile .................................................................................. 3-4

Edit a Profile ...................................................................................... 3-5

Edit a Profile During Creation ........................................................ 3-5

Modify a Profile During Measurement ........................................... 3-5

Load a Profile .................................................................................... 3-5

Load a Profile When Switched to Sequence Mode ....................... 3-6

Load a Profile During Measurement in Sequence Mode ............... 3-6

Make Measurements ............................................................................. 3-7

Test Battery Internal Resistance and Voltage ................................... 3-7

Battery Test Probes ....................................................................... 3-8

View Test Readings on the Screen ............................................... 3-9

Measure Strap resistance in sequence mode ............................... 3-10

Save Battery Test Readings .......................................................... 3-10

Erase Test Readings ..................................................................... 3-10

Activate Low-Pass Filter for Resistance Measurement ................. 3-10

Set Measurement Thresholds ....................................................... 3-11

How the Thresholds Work ............................................................. 3-11

Measure Discharge Voltage .............................................................. 3-12

Make Measurements ..................................................................... 3-12

Typical Display .............................................................................. 3-12

Measure DC Voltage ......................................................................... 3-14

Set Measurement Range ............................................................... 3-14

Save DC Voltage Readings ........................................................... 3-14

Measure AC Voltage ......................................................................... 3-15

Measurement Range ..................................................................... 3-15

Save AC Voltage Readings ........................................................... 3-15

Measure Ripple Voltage .................................................................... 3-16

Set Measurement Range ............................................................... 3-16

Save Ripple Voltage Readings ...................................................... 3-16

Measure Current (AUX Function) ...................................................... 3-17

Set Measurement Range ............................................................... 3-17

Save Current Measurement Readings .......................................... 3-17

Use the i410 Current Clamp .......................................................... 3-17

Measure Voltage with TL175 ............................................................. 3-18

4 Use the BTL21 Interactive Test Probe ............................................... 4-1

Introduction ............................................................................................ 4-1

BTL21 Overview .................................................................................... 4-1

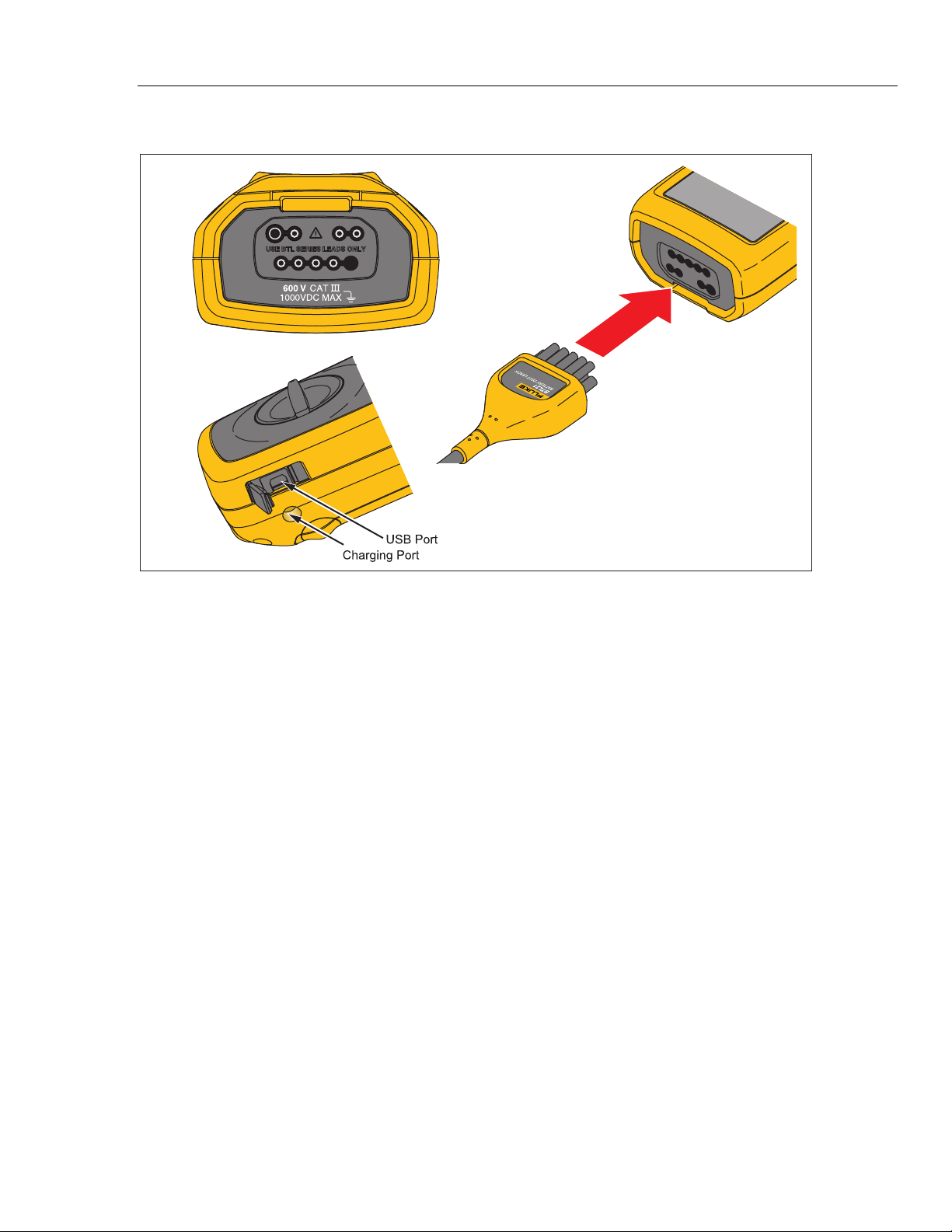

Connect the Probe to the Product ......................................................... 4-2

Configure the Interactive Test Probe on the Product ............................ 4-2

Set the Audio ..................................................................................... 4-2

Set Temperature Unit ........................................................................ 4-2

Set Emissivity Value .......................................................................... 4-3

Turn On/Off Power ................................................................................ 4-5

Understand the Display ......................................................................... 4-5

Long and Short Extenders ..................................................................... 4-6

Replace the Probe Tips ......................................................................... 4-7

Zero Calibration ..................................................................................... 4-8

Measure Temperature ........................................................................... 4-9

5 View Memory ....................................................................................... 5-1

Introduction ............................................................................................ 5-1

View Data Saved in Meter Mode ........................................................... 5-1

Delete Data Saved in Meter Mode ........................................................ 5-2

ii

Page 5

Contents (continued)

View Profiles Saved in Sequence Mode ............................................... 5-3

Delete Profiles Saved in Sequence Mode ............................................. 5-3

6 Connection to PC or Mobile Device ................................................... 6-1

Introduction ............................................................................................ 6-1

Connect the Product to PC .................................................................... 6-1

Connect the Product to a Mobile Device ............................................... 6-2

7 Maintenance ......................................................................................... 7-1

Introduction ............................................................................................ 7-1

Install or Replace the Battery Pack ....................................................... 7-3

Replace the Fuse .................................................................................. 7-4

Clean the Product .................................................................................. 7-5

Charge the Battery ................................................................................ 7-5

Parts and Accessories ........................................................................... 7-7

iii

Page 6

BT521

Users Manual

iv

Page 7

List of Tables

Table Title Page

1-1. Standard Equipment .................................................................................. 1-3

1-2. Symbols ..................................................................................................... 1-7

1-3. Keys .......................................................................................................... 1-8

1-4. Typical Elements on the LCD Display ....................................................... 1-10

4-1. Elements of the Interactive Test Probe ..................................................... 4-2

4-2. Emissivity Table ........................................................................................ 4-3

4-3. Typical Elements on the BTL21 Display .................................................... 4-5

7-1. Parts and Accessories ............................................................................... 7-7

v

Page 8

BT521

Users Manual

vi

Page 9

List of Figures

Figure Title Page

1-1. Standard Equipment .................................................................................. 1-4

1-2. I/O Terminals ............................................................................................. 1-9

2-1. Tilt Stand. .................................................................................................. 2-1

2-2. The Belt Strap ........................................................................................... 2-2

3-1. Test Battery Internal Resistance and Voltage ........................................... 3-7

3-2. Connect Test Probe to Battery .................................................................. 3-8

3-3. Measure DC Voltage ................................................................................. 3-14

3-4. Measure AC Voltage ................................................................................. 3-15

3-5. AUX function ............................................................................................. 3-17

3-6. Measure DC Voltage with TL175 .............................................................. 3-18

4-1. BTL21 Interactive Test Probe .................................................................... 4-1

4-2. Long and Short Probes ............................................................................. 4-6

4-3. Replace the 4-Wire Pins ............................................................................ 4-7

4-4. Zero Calibration Setup .............................................................................. 4-8

4-5. Meaure the Temperature of a Battery Pole ............................................... 4-9

6-1. Connection to PC ...................................................................................... 6-1

7-1. Install or Replace a Battery Pack .............................................................. 7-3

7-2. Replace the Fuse ...................................................................................... 7-4

7-3. Charge the Battery .................................................................................... 7-6

vii

Page 10

BT521

Users Manual

viii 1-1

Page 11

Chapter 1

Product Overview and Specifications

Introduction

This chapter supplies information about the Product, safety information, contact

information, and specifications.

Contact Fluke

To contact Fluke, call one of the following telephone numbers:

• Technical Support USA: 1-800-44-FLUKE (1-800-443-5853)

• Calibration/Repair USA: 1-888-99-FLUKE (1-888-993-5853)

• Canada: 1-800-36-FLUKE (1-800-363-5853)

• Europe: +31 402-675-200

• China: +86-400-810-3435

• Japan: +81-3-6714-3114

• Singapore: +65-6799-5566

• Anywhere in the world: +1-425-446-5500

Or, visit Fluke's website at www.fluke.com.

To register your product, visit http://register.fluke.com.

To view, print, or download the latest manual supplement, visit http://en-

us.fluke.com/support/manuals.

Product Overview

The Fluke BT521 Battery Analyzer (the Product) is a multifunctional meter designed for

the test and measurement of a stationary battery system. The Product can measure the

battery internal resistance and voltages. These measurements can be used to determine

the overall condition of the system. It can also measure electrical parameters for battery

system maintenance, including dc voltage up to 1000 V, ac voltage up to 600 V, and

ripple voltage.

Features of the Product include:

• CAT III 600 V Safety Rated – The Product can measure a maximum of 600 V ac in

a Category III environment.

• Battery Internal Resistance – Via the Kelvin connections, the Product measures

the internal resistance. An increase in the internal resistance from a known baseline

indicates the battery is deteriorating. The testing takes less than 3 seconds.

Page 12

BT521

Users Manual

• Battery Voltage – During the internal resistance test, the Product also measures the

voltage of the battery under test.

• Negative Post Temperature – With the BTL21 Interactive Test Probe, the Product

measures the negative post temperature via an IR sensor near the black test tip.

During the test of battery internal resistance, the temperature reading shows on the

LCD display of the interactive test probe and is stored in the Product memory.

• Discharge Volts – The Discharge mode collects the voltage of each battery several

times at a certain interval during a discharge or load test. Users can calculate the

time a battery takes to drop to the cut-off voltage and use this time to determine the

capacity loss of this battery.

• Ripple Voltage Test – Measures the unwanted residual ac component of the

rectified voltage in dc charging and inverter circuits. Allows users to test ac

components in dc charging circuits and find one of the root causes of battery

deterioration.

• Current: Via the clamp accessory and adapter, the AC and DC current can be tested

and then stored in the memory.

• Meter and Sequence Modes – The Meter mode is used for a quick test or trouble-

shooting. In this mode you can save and read the readings in a time sequence. The

Sequence mode is for maintenance tasks with multiple power systems and battery

strings. Before a task starts, users can configure a profile for the task for data

management and report generation.

• Threshold and Warning – Users can configure a maximum of 10 sets of thresholds

and receive a Pass/Fail/Warning indication after each measurement.

• AutoHold – When AutoHold is turned on, the Product freezes the reading when it

remains stable for 1 second. The frozen reading is released when a new

measurement starts.

• AutoSave – When the AutoSave mode is on, measured values are saved to the

internal memory of the Product automatically after AutoHold.

• Fluke Battery Analyzer Software – Easily import data from the Product to a PC.

The measurement data and battery profile information is stored and archived with the

Analyzer Software and can be used for comparison and trend analysis. All

measurement data, battery profile and analysis information can be used to easily

generate reports.

1-2

Page 13

Product Overview and Specifications

Standard Equipment 1

Standard Equipment

Items listed in Table 1-1 are included with the Product. Figure 1-1 shows the items.

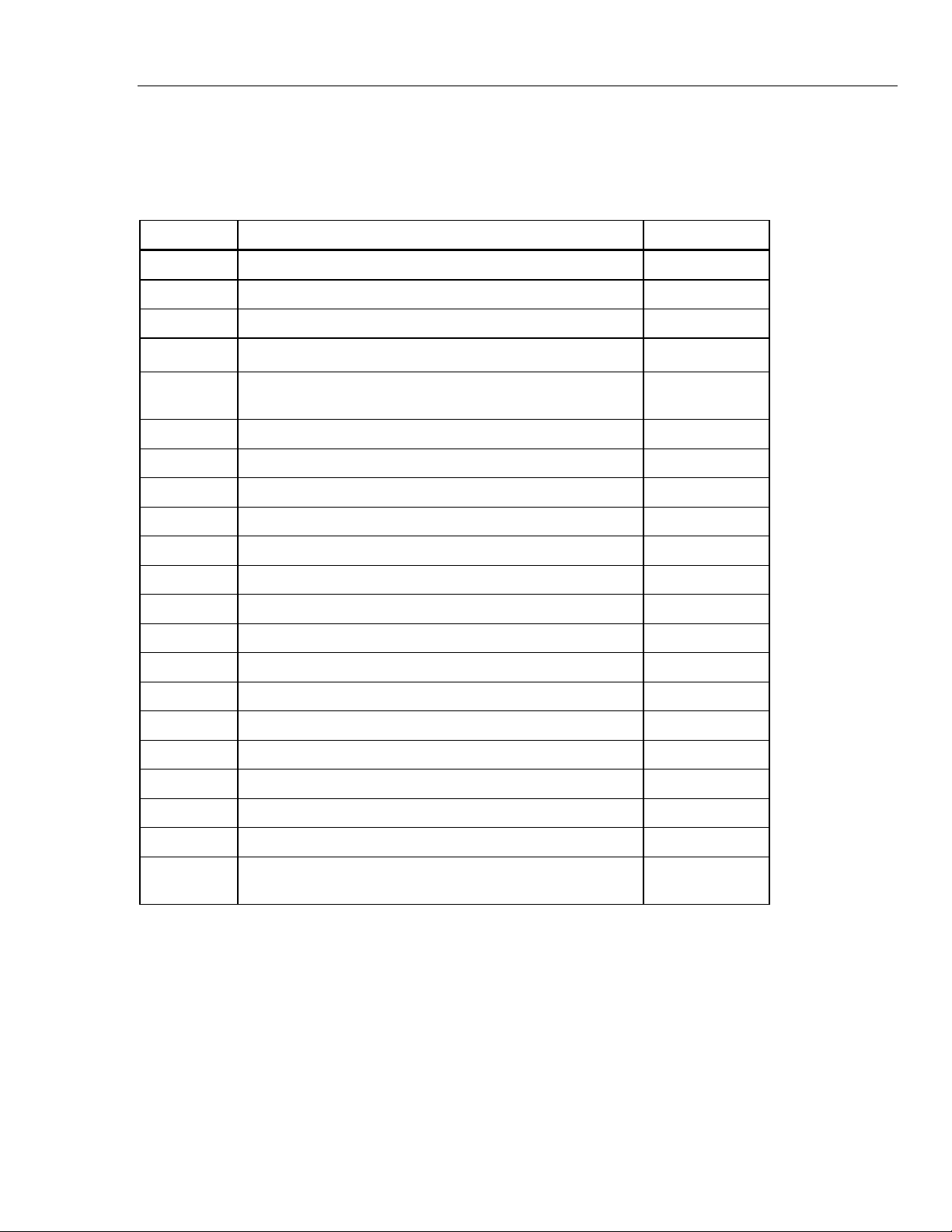

Table 1-1. Standard Equipment

Item No. Description Quantity

Mainframe 1

BTL10, Basic Test Lead 1

TL175, TwistGuard™ Test Leads 1

BTL_A, Voltage/Current Probe Adapter 1

i410, AC/DC Current Clamp 1

BP500, 7.4 V 3000 mAh Lithium-ion battery 1

BC500, 18 V dc charger 1

Power cord 1

Standard mini-b USB cable (cable length: 1 m) 1

BCR, Zero calibration board 1

Shoulder strap 1

Belt strap 1

Magnetic plate 1

C500L Soft carrying case, large 1

Spare fuse 2

Paper battery tags 100

-- Safety Sheet, not shown 1

-- Warranty card, not shown 1

BTL21, Interactive Test Probe set, with extender and

temperature sensor

1

-- Quick Reference Guide, not shown 1

®

Battery (CD) containing USB driver and manuals

--

FlukeView

in all languages, not shown

1

1-3

Page 14

BT521

Users Manual

1 3

2

4

5

6

CAT

600V

600A

ZEROA

CLAMPMETER

i410

600V

7

8

11

12

13

15

9

10

16

14

17

1-4

Figure 1-1. Standard Equipment

hsz056.eps

Page 15

Product Overview and Specifications

Safety Information 1

Safety Information

A Warning identifies conditions and procedures that are dangerous to the user. A

Caution identifies conditions and procedures that can cause damage to the Product or

the equipment under test.

Warning

To prevent possible electrical shock, fire, or personal injury:

• Carefully read all instructions.

• Read all safety information before you use the Product.

• Use the Product only as specified, or the protection supplied

by the Product can be compromised.

• Do not use the Product around explosive gas, vapor, or in

damp or wet environments.

• Do not use the Product if it is damaged.

• Do not use the Product if it operates incorrectly.

• Do not apply more than the rated voltage, between the

terminals or between each terminal and earth ground.

• Do not touch voltages > 30 V ac rms, 42 V ac peak, or 60 V dc.

• Do not exceed the Measurement Category (CAT) rating of the

lowest rated individual component of a Product, probe, or

accessory.

• Do not use the HOLD function to measure unknown potentials.

When HOLD is turned on, the display does not change when a

different potential is measured.

• Use the Current Clamp only as specified in the operating

instructions. Otherwise the clamp’s safety features may not

protect you.

• Do not hold the Current Clamp anywhere beyond the tactile

barrier.

• Before each use, inspect the Current Clamp. Look for cracks

or missing portions of the clamp housing or output cable

insulation. Also look for loose or weakened components. Pay

particular attention to the insulation surrounding the jaws.

• Never use the clamp on a circuit with voltages higher than 600

V (CAT III) or a frequency higher than 400 Hz.

• Use extreme caution when working around bare conductors or

bus bars. Contact with the conductor could result in electric

shock.

• Do not use test leads if they are damaged. Examine the test

leads for damaged insulation or exposed metal, or if the wear

indicator shows. Check test lead continuity.

• Connect the common test lead before the live test lead and

remove the live test lead before the common test lead.

1-5

Page 16

BT521

Users Manual

• Avoid simultaneous contact with battery and frame racks or

hardware that may be grounded.

• Comply with local and national safety codes. Use personal

protective equipment (approved rubber gloves, face

protection, and flame-resistant clothes) to prevent shock and

arc blast injury where hazardous live conductors are exposed.

• Examine the case before you use the Product. Look for cracks

or missing plastic. Carefully look at the insulation around the

terminals.

• Use only correct measurement category (CAT), voltage, and

amperage rated probes, test leads, and adapters for the

measurement.

• Measure a known voltage first to make sure that the Product

operates correctly.

• Limit operation to the specified measurement category,

voltage, or amperage ratings.

• Keep fingers behind the finger guards on the probes.

• Remove all probes, test leads, and accessories before the

battery door is opened.

• Use the correct terminals, function, and range for

measurements.

• Use only current probes, test leads, and adapters supplied

with the Product.

• Install the CAT III protective cap of test lead when you use the

product in CAT III environment. The CAT III protective cap

decreases the exposed probe metal to < 4 mm.

• Do not operate the Product with covers removed or the case

open. Hazardous voltage exposure is possible.

1-6

Page 17

Product Overview and Specifications

Safety Information 1

See Table 1-2 for a list of symbols used in this manual and on the Product.

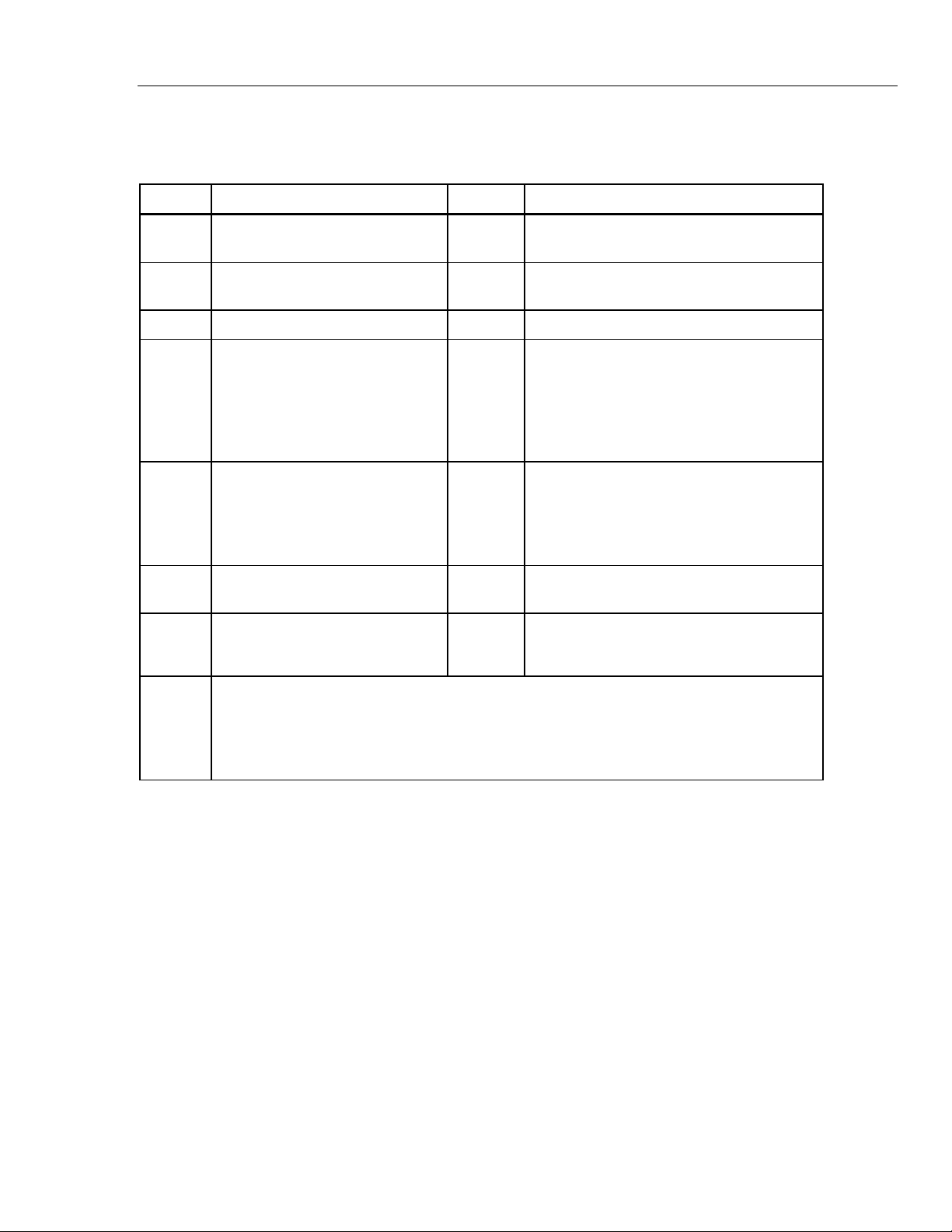

Table 1-2. Symbols

Symbol Description Symbol Description

WARNING. RISK OF DANGER.

See manual.

WARNING. HAZARDOUS

VOLTAGE. Risk of electric shock.

Earth

Measurement Category II is

applicable to test and measuring

circuits connected directly to

utilization points (socket outlets

and similar points) of the lowvoltage MAINS installation.

Measurement Category IV is

applicable to test and measuring

circuits connected at the source

of the building’s low-voltage

MAINS installation.

Certified by TÜV SÜD Product

Service.

Conforms to European Union

directives.

AC (Alternating Current)

DC (Direct Current)

Fuse

Measurement Category III is applicable to

test and measuring circuits connected to the

distribution part of the building’s low-voltage

MAINS installation.

Conforms to relevant South Korean EMC

Standards.

Certified by CSA Group to North American

safety standards.

Conforms to relevant Australian EMC

Standards.

This product complies with the WEEE Directive marking requirements. The affixed label

indicates that you must not discard this electrical/electronic product in domestic household

waste. Product Category: With reference to the equipment types in the WEEE Directive Annex

I, this product is classed as category 9 "Monitoring and Control Instrumentation" product. Do

not dispose of this product as unsorted municipal waste.

1-7

Page 18

BT521

Users Manual

Radio Frequency Data

See the Radio Frequency Data for Class A file on the Fluke website.

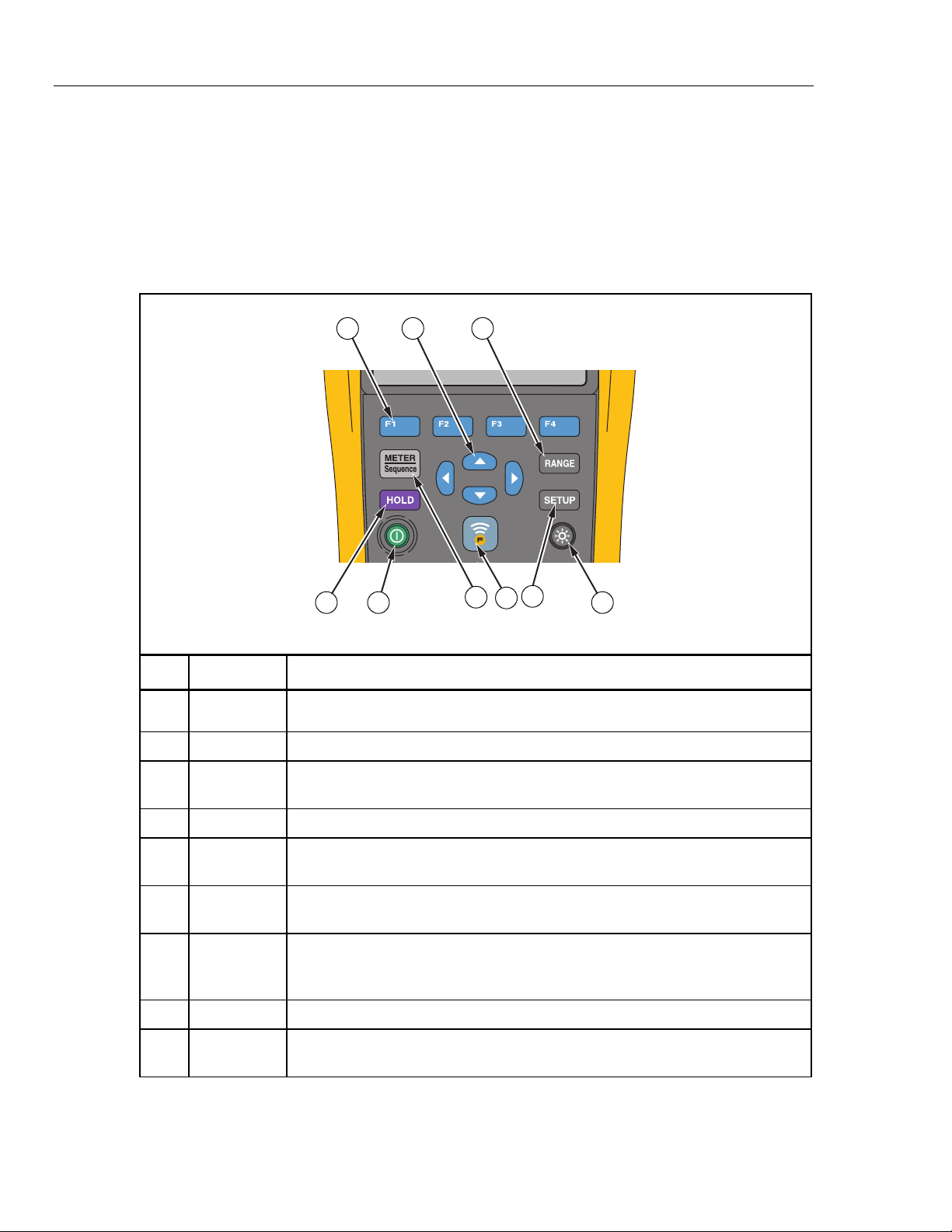

Keys and I/O Terminals

Table 1-3 identifies and describes the keys.

Table 1-3. Keys

1 2 3

89 4

Item Key Function

12

34

L

M

Softkeys that work flexibly for various functions on the display.

Selects an item in a menu and scrolls through information.

Switches between manual ranging and auto ranging. Cycles through all ranges in

manual ranging mode.

Turns on or turns off backlight.

Opens the Setup menu for configurations such as contrast, language, date/time,

and power off time.

Enables connection between the Product and nearby mobile devices for data

transmission.

Switches between Meter and Sequence measurement modes. For details, see

Chapter 3. Switches between Meter and Sequence memories. For details, see

Chapter 5.

Turns on or turns off the Product.

Freezes the current reading on the display and allows the display reading to be

saved.

7

5

6

hsz001.eps

1-8

Page 19

Product Overview and Specifications

Keys and I/O Terminals 1

Figure 1-2 shows the terminals of the Product.

Figure 1-2. I/O Terminals

hsz002.eps

1-9

Page 20

BT521

Users Manual

LCD Display

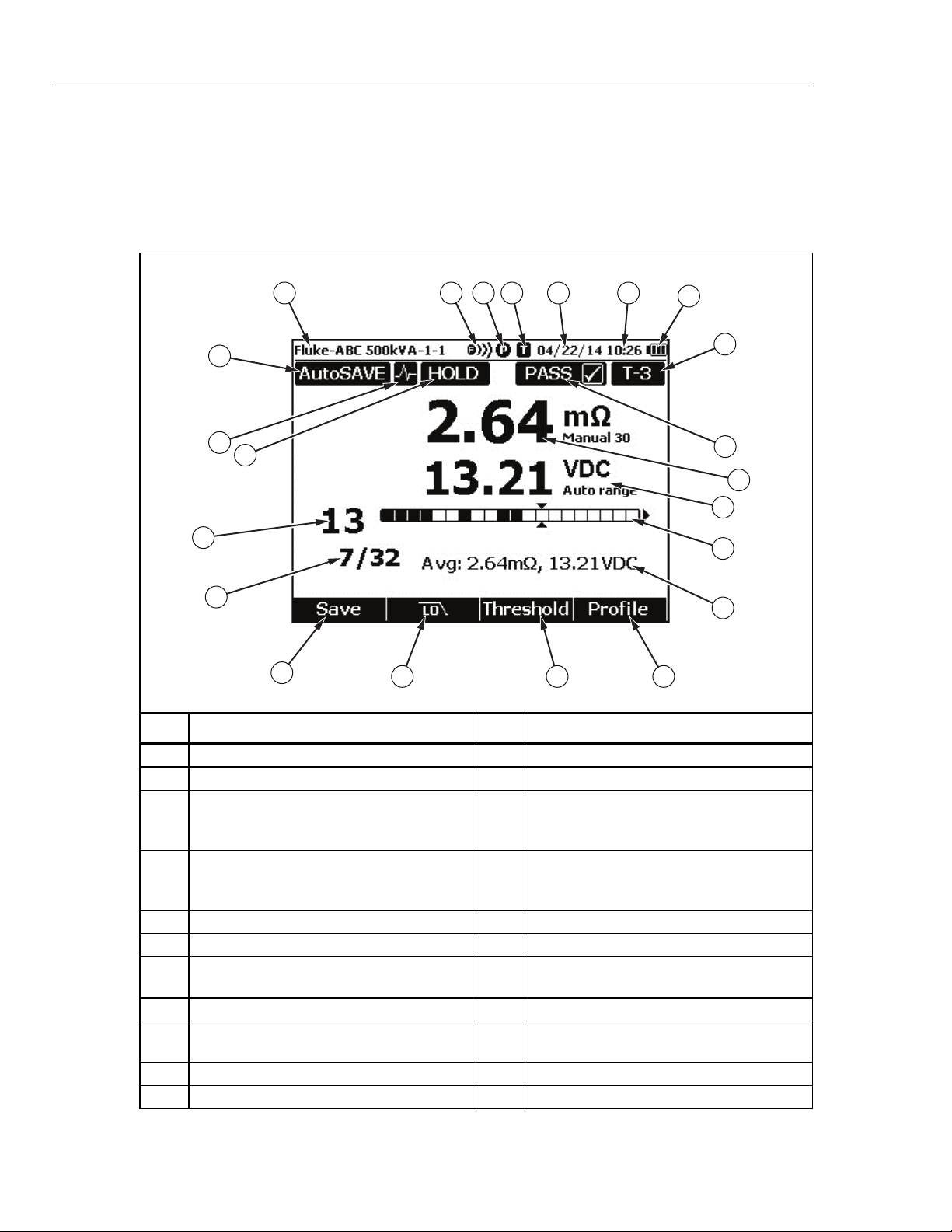

The Product has an LCD display that shows different elements for each measurement

function. Table 1-4 describes the typical elements for battery internal resistance

measurement in Sequence mode.

Table 1-4. Typical Elements on the LCD Display

1 2 3 4 5 6

22

21

20

19

18

17

Item Description Item

7

8

9

10

11

12

13

141516

hsz055.eps

Description

1-10

Profile name Progress bar (Sequence mode only)

Bluetooth connection is on Average readings

Probe connection status. A full circle means

connected; an empty circle means not

Softkey F4 – Profile

connected

Temperature module connection status. A

full circle means connected; an empty circle

Softkey F3 – Threshold

means not connected

Current date Softkey F2 – Low Pass Filter

Current time Softkey F1 – Save (save current reading)

Battery usage

Tested batteries VS Total number of

batteries in a string

Threshold indication Cursor position

Test result (PASS, WARN, or FAIL)

At least one “data hold” succeeded (manual

or auto)

Reading of battery internal resistance AutoHold function enabled

Voltage reading AutoSave function enabled

Page 21

Product Overview and Specifications

Specifications 1

Specifications

General Specifications

Fuse Protection for Resistance ...................... 0.44 A (44/100 A, 440 mA), 1000 V FAST Fuse, Fluke specified part

Power Supply

Battery power ...................................................... BP500 smart battery pack: double cell lithium-ion, 7.4 V, 3000 mAh

Battery life ........................................................... >8 hours in continuous full-load operation

Battery charging time .......................................... ≤4 hours

Power adapter output voltage ............................. Use only BC500 battery charger: 18 V, 840 mA

Line power .......................................................... 100 V ac to 240 V ac adapter with country specific plug

Frequency ........................................................... 50 Hz to 60 Hz

Temperature

Operating ............................................................ 0 °C to 40 °C

Storage ............................................................... -20 °C to 50 °C

Lithium-ion battery charging ............................... 0 °C to 40 °C

Relative Humidity (non-condensing, 10 °C)

Operating ............................................................ ≤80 % at 10 °C to 30 °C

≤75 % at 30 °C to 40 °C

Altitude

Operating ............................................................ 2,000 m

Storage ............................................................... 12,000 m

Temperature Coefficient ....................................... 0.1 x (specified accuracy) /°C (<18 °C or >28 °C)

Size ......................................................................... 58 x 103 x 220 (mm)

Weight .................................................................... 850 g

Memory

Data/Setup flash memory ................................... 4 MB

Real-Time Clock .................................................... Time and date stamp for measurement. The RTC works >50 days

IP Rating ................................................................ IEC 60529: IP 40

Safety ..................................................................... IEC 61010-1, IEC 61010-2-030, IEC 61010-031, Pollution Degree 2

EMI, RFI, EMC, RF ................................................. IEC 61326-1, IEC 61326-2-2, EN 300 328, EN 301 489-1, EN 301 489-

Electromagnetic Compatibility ............................ Applies to use in Korea only. Class A Equipment (Industrial

[1] This product meets requirements for industrial (Class A) electromagnetic wave equipment and seller or user should take notice of it.

This equipment is intended for use in business environments and is not to be used in homes.

only

without battery.

600 V CAT III, 1000 V dc max; Derated to CAT II with CAT II probe cap

installed

17, FCC Part 15 Subpart C Sections 15.207, 15.209, 15.249

CONTAINS FCC IDs: T68-FWCS, XDULE40-S2

IC: 6627A-FWCS, 8456A-LE4S2

Broadcasting & Communication Equipment)

[1]

1-11

Page 22

BT521

Users Manual

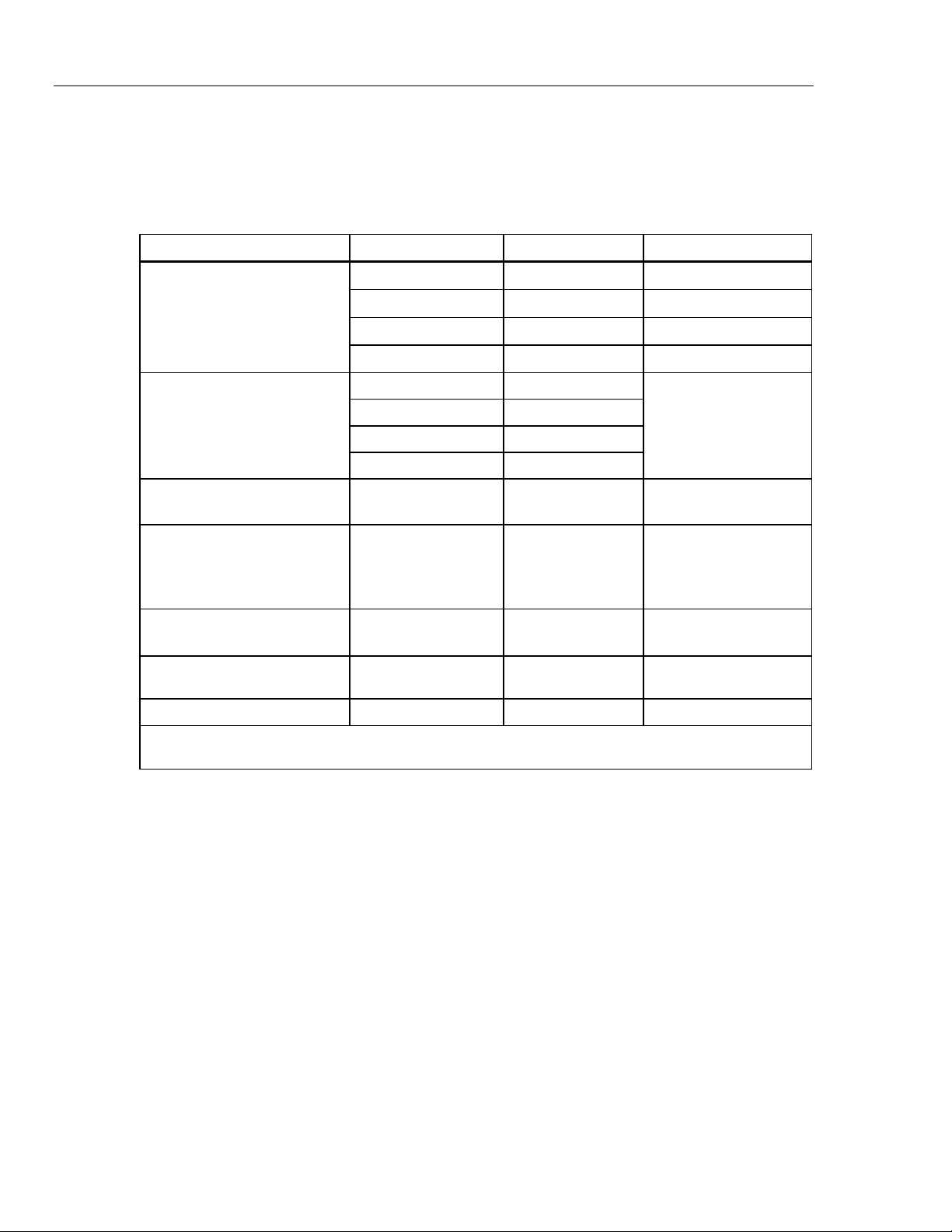

Accuracy Specifications

Accuracy is specified for a period of one year after calibration, at 18 °C to 28 °C (64 °F

to 82 °F), with relative humidity to 80 %. Accuracy specifications are given as: ±([% of

reading] + [number of least significant digits]). Accuracy specification assumes ambient

temperature stable ±1 °C.

Function Range Resolution Accuracy

3 mΩ 0.001 mΩ

30 mΩ 0.01 mΩ

Battery Internal Resistance

V dc

V ac (45 Hz to 500 Hz with lowpass filter)

Frequency (Display with V ac,

A ac using i410)

Trigger level: ≥ 10 mV @V ac;

AC Voltage Ripple (20 kHz

max)

Amps dc/Amps ac (With

accessory Fluke i410)

Temperature 0 °C to 60 °C 1 °C 2 °C (typical)

[1] The measurement is based on ac injection method. The injected source signal is <100 mA, 1 kHz.

[2] For A ac frequency measurement, the range is 45 Hz to 400 Hz.

[2]

≥ 10 A @A ac

[1]

300 mΩ 0.1 mΩ

3000 mΩ 1 mΩ

6 V 0.001 V

60 V 0.01 V

600 V 0.1 V

1000 V 1 V

600 V 0.1 V 2 % + 10

45 Hz to 500 Hz 0.1 Hz 0.5 % + 8

600 mV

6000 mV

400 A 1 A 3.5 % + 2

0.1 mV

1 mV

1 % + 8

0.8 % + 6

0.8 % + 6

0.8 % + 6

0.09 % + 5

3 % + 20

3 % + 10

1-12

Page 23

Product Overview and Specifications

Specifications 1

Records Capacity

Function Meter Mode Sequence

Battery Internal Resistance

Battery Voltage

Discharge Voltage Not available

Negative Post Temperature

V dc Up to 999 records Up to 20 records in one profile

V ac Up to 999 records

Hz

AC Voltage Ripple Up to 999 records Up to 20 records in one profile

Saved by test sequence with

time stamp, up to 999 records

Display and save with battery

internal resistance, up to 999

records

Display on BTL 21 only, up to

999 records

Display and save with V ac, up

to 999 records

Up to 450 records in one profile

Display and save with battery

internal resistance, up to 450

records in one profile

Support up to 8 rounds for up to

450 batteries in one profile

Display on BTL 21 only, up to

450 records for one profile

Display and save with V ac, up

to 20 records in one profile

Display and save with V ac, up

to 20 records in one profile

1-13

Page 24

BT521

Users Manual

1-14

Page 25

Chapter 2

Setup

Introduction

This chapter describes how to set up the Product.

Tilt Stand

The Product has a tilt stand that lets you see the screen at an angle when placed on a

flat surface. See Figure 2-1.

Figure 2-1. Tilt Stand

hsz007.eps

2-1

Page 26

BT521

Users Manual

Belt Strap

Figure 2-2 shows how to use the belt strap of the Product.

2-2

Figure 2-2. The Belt Strap

hsz031.eps

Page 27

Setup

Adjust Display Contrast 2

Adjust Display Contrast

To adjust the display contrast:

1. Push to open the Setup menu.

Contrast is already highlighted.

2. Push the – softkey to lighten contrast, or push the + softkey to darken contrast.

Note

If – is pushed too far, the display is blank.

3. Push the Back softkey to return to normal operation.

Set Language

These languages are available on the Product display:

• English

• German

• French

• Italian

• Dutch

• Portuguese

• Russian

• Spanish

• Turkish

• Simplified Chinese

• Korean

The default display language is English.

To select another language:

1. Push to open the Setup menu.

2. Use L to move the menu selector to highlight Language/English.

3. Push the Select softkey to open the Language menu.

4. Use L and to highlight the desired language, and then push the Confirm softkey.

5. Push the Back softkey to return to normal operation.

Set Date and Time

The internal clock of the Product is used on the display and for time-stamping recorded

measurements.

To change the date and time:

1. Push to open the Setup menu.

2. Use L and to highlight General and push the Select softkey.

Date/time is selected by default.

3. Push the Adjust softkey to open the Date/time – Adjust screen.

2-3

Page 28

BT521

Users Manual

4. Use and to highlight the field to be edited. Use and L to increase or decrease

value.

5. When the correct date and time is set, push the OK softkey.

6. Push the Back softkey to return to normal operation.

To change the date format:

1. Push to open the Setup menu.

2. Use L and to highlight General and push the Select softkey.

Date/time is selected by default.

3. Push the Format softkey to open the Date format menu.

4. Use L and to highlight the correct date format.

5. Push the Confirm softkey.

6. Push the Back softkey to return to normal operation.

Turn On/Off Beep

To turn on or turn off beep:

1. Push to open the Setup menu.

2. Use L to highlight Beep, and push the Select softkey.

3. Use and L to highlight Off or On, and push the Confirm softkey.

4. Push the Back softkey to return to normal operation.

AutoHold and AutoSave Modes

Note

AutoHold and AutoSave are available only for the Battery Internal

Resistance and Discharge functions.

When AutoHold is turned on, the "heart beat" icon shows on the display. The Product

will hold the reading when it remains stable for 1 second. After a successful AutoHold,

the HOLD icon shows on the display. The auto-held reading will not be released even

after the user disconnects the test leads from the test object.

In AutoSave mode, the AutoSave icon shows on the display. The auto-held reading is

automatically saved to the internal memory.

2-4

hsz049.jpg

hsz048.jpg

Page 29

Setup

Set Auto Power Off Time 2

Warning

To prevent possible electrical shock, fire, or personal injury, do

not use the HOLD function to measure unknown potentials.

When HOLD is turned on, the display does not change when a

different potential is measured.

To set AutoHold and AutoSave mode:

1. Push to open the Setup menu.

2. Use L and to highlight Auto mode.

3. Push the Select softkey to open the Auto mode menu.

4. Use L and to highlight Disable, HOLD, or HOLD+SAVE.

5. Push the Confirm softkey.

6. Push the Back softkey to return to normal operation.

Set Auto Power Off Time

Use the Auto Power Off Time function to save power. The options are, enable or disable

auto power off and set the time between the last operation and auto power off.

To set the time for auto-power off:

1. Push to open the Setup menu.

2. Use L and to highlight General and push the Select softkey.

3. Use L and to highlight Power off, and push the Select softkey.

4. Use L and to highlight 5 Minutes, 15 Minutes, 30 Minutes, or Never.

5. Push the Confirm softkey.

6. Push the Back softkey to return to the Setup screen.

2-5

Page 30

BT521

Users Manual

View Device Information

The Product provides the following device information: model number, serial number,

version, analog board version, and calibration date.

To view the device information:

1. Push to open the Setup menu.

2. Use L and to highlight General, and push the Select softkey.

3. Use L and to highlight Device info., and push View softkey.

The Device info… screen shows.

4. Push the Back softkey to return to the Setup screen.

Reset to Factory Mode

To reset the Product to factory mode:

1. Push to open the Setup menu.

2. Use L and to highlight General, and push the Select softkey.

3. Use L and to highlight Factory mode, and push the Reset softkey.

4. Push the Confirm softkey to reset the Product to factory mode.

Note

If the Product is reset to factory mode, all current measurement data

will be lost.

View Memory Usage Information

To view memory usage information:

1. Push to open the Setup menu.

2. Use L and to highlight Memory info., and push the Select softkey.

The screen shows the memory usage information in Meter mode and Sequence

mode.

3. Push the Back softkey to return to the Setup screen.

2-6

Page 31

Chapter 3

Use the Product

Introduction

This chapter provides information about how to use the Product. The Product provides

two modes for different measurement purposes: Meter mode and Sequence mode.

Meter mode lets you perform easy and fast measurements and save the measurement

readings and timestamp to the Product memory. In this mode, the Product measures

battery internal resistance and voltage, dc voltage, ac voltage, and ripple voltage.

Sequence mode is designed for battery maintenance personnel who work between

multiple test sites. In this mode, you can create a profile for each battery string to be

tested. The profile specifies information such as user-defined test site, device type, serial

number, battery quantity, and battery model. During the test, all test data, including

battery resistance, voltage, and ripple voltage is stored in the profile. After a battery

string test is completed, you can create a new profile for the next battery string or test

site. You can also recall or delete the test data in a history profile.

With the integrated profile management and the analysis software on the PC, you can

analyze the trend of maintenance data and create reports in an efficient way. For

example, you can create a comprehensive test and maintenance report for a test site or

analyze the resistance changes of one battery string over time.

Switch Between Meter Mode and Sequence Mode

Each time you power on the Product, it is in Meter mode by default. METER MODE

shows on the upper-left corner of the display.

To switch to Sequence mode:

1. Push

2. Push the Continue, New, or Load softkey and make other required selections to

M.

The Enter SEQUENCE mode? screen shows.

enter the measurement screen of Sequence mode.

Note

When you first enter SEQUENCE mode, push the New softkey to

create a new profile.

3-1

Page 32

BT521

Users Manual

hsz001.jpg

To switch back to Meter mode:

1. Push M.

2. When the Back to METER mode? screen shows, push the Continue softkey.

The measurement screen of Meter mode shows.

Note

All measurements taken in Sequence mode are saved to the

memory.

hsz002.jpg

3-2

hsz003.jpg

hsz005.jpg

Page 33

Use the Product

Use a Profile in Sequence Mode 3

Use a Profile in Sequence Mode

In Sequence mode, the Product lets you manage, categorize, and analyze data by

profiles. The figure below shows a typical profile.

hsz006.jpg

Manage Profiles

Each Product stores up to 100 profiles. A profile describes the battery maintenance

environment in a tree view.

For example:

• Site Name: Fluke

• Device name: ABC 500kVA

• Device ID: 1

• Battery string: 1

• Start ID: 1

In this case the upper-left corner shows the profile name Fluke-ABC 500KVA-1-1. The

PC software uses the same structure to categorize the profile.

Fluke recommends that you always use the same profile name for one battery string for

better analysis. The profiles are distinguished by their timestamps.

3-3

Page 34

BT521

Users Manual

Create a Profile

The Product provides these options to create a profile:

• Create by default: Uses system default data to create each profile.

• Copy from template: Copies data from an existing template.

• String+1: Copies data from the previous profile and increases 1 to the value of

Battery string.

Note

The “Copy from template” option is available only after templates are

downloaded the from PC software.

To create a profile in Sequence mode:

1. On the measurement screen of Sequence mode, push the Profile softkey.

The Profile info menu shows on the display.

2. Push the New softkey. The Select the Way to Create menu shows on the display.

hsz004.jpg

hsz012.jpg

3. Use and L to select Create by default, Copy from template, or String+1.

4. Push the Create softkey.

The New Profile menu shows on the display.

5. When necessary, push the Edit softkey, and then use the arrow keys and softkeys to

edit the field values.

6. Push the Done softkey to exit the edit status.

7. Push the Start softkey to enter the measurement screen.

Note

• When the same battery string is tested periodically, Fluke recommends

that the same profile name is used. In this way, test data can be archived

and the data trend can be viewed easier.

• After test of one battery string is completed in a system, the String+1

function lets you easily switch to the next battery string without the need of

repeated data input.

3-4

Page 35

Use the Product

Use a Profile in Sequence Mode 3

Edit a Profile

In Sequence mode, profiles can be edited during creation or during measurement.

Edit a Profile During Creation

To edit a profile during creation:

1. On the New Profile menu, use and L to highlight a data field to be edited.

2. Edit the data value.

a. For Device ID and Battery string, use the – and +.softkeys to change the value.

b. For other data fields, push the Edit softkey and use the arrow keys to change the

data value. Use the Select softkey for each selection and the Done softkey to

complete a data field.

3. Push the Start softkey to confirm the change and enter the measurement screen.

Modify a Profile During Measurement

To edit a profile during measurement:

1. Push the Profile softkey.

The Profile info screen shows.

Note

Once a profile is created, the battery number or the Start ID cannot be

changed. Other data values are editable.

2. Push the Modify softkey.

The Edit profile screen shows.

3. Use and L to highlight the data field to be edited.

4. Use the method in the “Edit a profile during creation” section to edit the profile.

Load a Profile

In Sequence mode, the Product can load a previously saved profile when it is switched

to Sequence mode or during measurements in Sequence mode. This method can be

used to continue an unfinished profile.

Note

All data in the current profile will be automatically saved when a

previous profile is loaded.

3-5

Page 36

BT521

Users Manual

Load a Profile When Switched to Sequence Mode

To load a profile when switched to Sequence mode:

1. On the Enter SEQUENCE mode? screen, push the Load softkey.

The Load profile screen shows the list of history profiles in the Product memory.

2. Use and L to highlight the number of the profile to be loaded.

3. Push the Load softkey.

Configurations of the selected profile show on the display.

4. Push the Continue softkey to confirm loading the selected profile.

Name of the loaded profile shows on the upper-left corner of the display.

Load a Profile During Measurement in Sequence Mode

To load a profile during measurements in Sequence mode:

1. On the measurement screen, push the Profile softkey.

The Profile info screen shows.

2. Push the Load softkey.

The Load profile screen shows.

3. Use the Prev and Next softkeys and L to select a profile.

4. Push the Load softkey.

5. Push the Continue softkey to load the selected profile.

3-6

Page 37

Use the Product

Make Measurements 3

Make Measurements

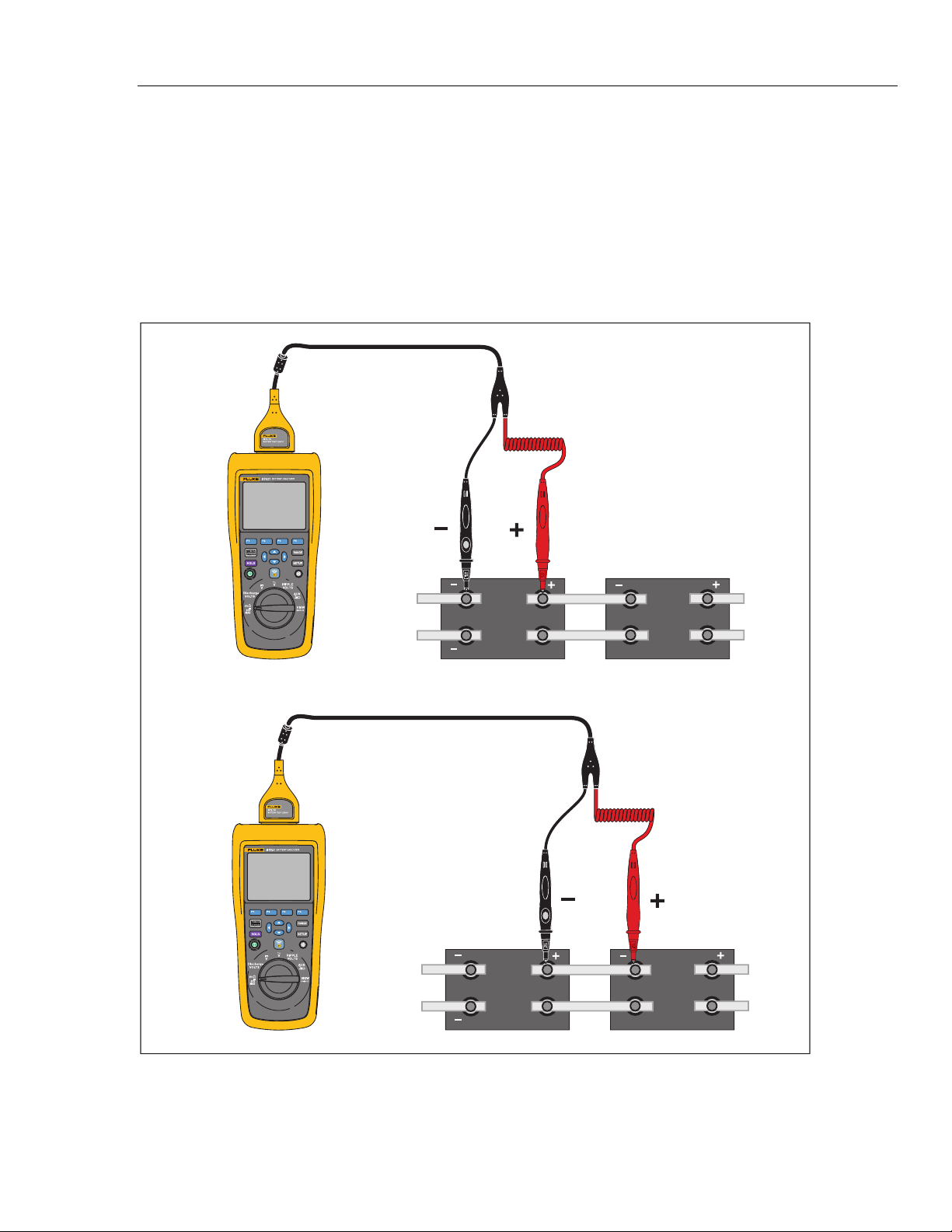

Test Battery Internal Resistance and Voltage

The Product can simultaneously test the internal resistance and voltage of a battery.

This helps you to understand the overall state of the battery health. The Product can

also test strap resistance since upward changes could be caused by corrosion or loose

connections.

To test battery internal resistance and voltage or strap resistance, turn the rotary switch

to mΩ. See Figure 3-1.

Internal Resistance and Voltage

AB CD

Strap Resistance

AB CD

Figure 3-1. Test Battery Internal Resistance and Voltage

hsz068.eps

3-7

Page 38

BT521

Users Manual

Battery Test Probes

To connect test probes to the battery pole:

1. Use the inner tip of the test probe to touch the target surface.

2. Push the test lead to set-back the inner tip, until both the inner tip and the outer tip

are fully connected to the target surface. This will ensure a proper 4-wire connection

to the battery terminal.

Note

Stable and correct readings are shown only when both the inner tip

and the outer tip of the test probe are fully connected to the battery

posts. To get more accurate battery internal resistance reading, do

not connect the test probes to screws. See Figure 3-2.

Examine for open fuse before m

outer tips of both probes. If the m

dashes and then backs to OL, the fuse is good. If m

Ω

measurement by connecting the

Ω

reading changes from OL to

Ω

reading

remains as OL, the fuse is open and needs a replacement.

In this function, the voltage between the positive and negative poles

of a battery must be < 60 V. A voltage >60 V causes the fuse to

open.

Small Hole Cylinder Screw Cube

Circle StripCylinder Clamp

3-8

Figure 3-2. Connect Test Probe to Battery

hsz008.eps

Page 39

Use the Product

Make Measurements 3

View Test Readings on the Screen

This is a typical display of battery test in Meter mode.

hsz028.jpg

This is a typical display of battery test in Sequence mode:

hsz031.jpg

Battery number: Indicates the number of the battery that has been tested.

Progress bar: The progress bar is generated according to the total number of batteries

in the profile. Each cell corresponds to one battery. An empty cell indicates the

corresponding battery is not tested yet. A full cell indicates the corresponding battery has

been tested and the readings have been saved. A cross mark in a full cell indicates that

the threshold function is enabled.

Cursors: Use and to move the cursors. The number of the currently tested battery

changes accordingly. When the cursors are positioned on a full cell, the corresponding

reading of that battery will be shown under the progress bar.

Average readings: After two or more sets of test readings are saved, the Product

shows the average readings, including average resistance and average voltage.

Tip: If the test readings of a battery are significantly different from the average readings,

it could indicate the battery health has been compromised.

3-9

Page 40

BT521

Users Manual

Measure Strap resistance in sequence mode

A strap string is created right behind battery string automatically in the same profile. The

strap number equals to battery number. Push the Strap softkey to switch to strap string

test. The display shows

to indicate strap string. Push Battery softkey to switch back

to battery string test.

Set Measurement Range

Battery resistance or Strap resistance only has manual ranges. The default range for

battery resistance or Strap resistance measurement is 30 mΩ. You can push

to

cycle through different ranges in this sequence: 30 mΩ > 300 mΩ > 3000 mΩ > 3 mΩ.

The battery voltage measurement is in auto ranging mode, and the range cannot be

changed.

Save Battery Test Readings

In Meter mode, push the Save softkey to save the current resistance, voltage and time.

All saved data is stored in chronological order. In Sequence mode, push the Save

softkey to save the current resistance and voltage readings. The current serial number

increases by 1. The test progress bar moves to the right by one cell.

Note

If the test lead does not connect to battery or the test lead is not

installed, the Save function is invalid.

Erase Test Readings

To erase the test readings for a certain battery in Sequence mode:

1. Use and to point the cursors to the cell that corresponds to the correct battery.

2. Push the Erase softkey.

The pointed cell becomes empty. Push the Save softkey to save new test readings

for this battery.

Activate Low-Pass Filter for Resistance Measurement

Excessive high level of ac ripple voltage can have a negative impact on the battery

resistance measurement. Use the built-in low pass filter to stabilize or reduce the impact

of ac ripple on resistance measurements.

To activate the low-pass filter for battery resistance measurement, in Meter mode, push

LO softkey, in Sequence mode, push the More softkey and push LO softkey. The

display shows the LO icon.

3-10

Set Measurement Thresholds

hsz032.jpg

Page 41

Use the Product

Make Measurements 3

The Product lets you define upper and lower measurement thresholds or tolerance

ranges. These defined threshold values are then compared to the measured values to

automatically identify and prompt the user with a PASS, FAIL or WARN indicator of

battery out of tolerance conditions.

The threshold function is disabled by default. You can set up to 10 set of thresholds and

select one threshold as needed.

To set and select measurement thresholds:

1. On the measurement screen, push the More softkey and Threshold softkey to

open the Select Threshold menu.

2. Use and to select one threshold set out of ten.

hsz033.jpg

3. Use and L to highlight the value to be edited among Voltage lower, Reference,

Warning, Fail, Low limit, and Notes.

4. Edit the selected field.

a. Use the – and + softkeys to change the values for Warning and Fail.

b. For other fields, push the Edit softkey, use the arrow keys to edit the value,

and then push the Confirm softkey to save the value.

5. Once all threshold values are correct, push the Confirm softkey on the save the

threshold set.

The threshold set is applied and the T-X (X stands for value of No.) icon and the

corresponding PASS/WARN/FAIL indication shows on the display.

To disable measurement thresholds:

1. On the measurement screen, push the Threshold softkey to open the Select

Threshold menu.

The value of No. is already highlighted.

2. Use to set No. to ---.

3. Push the Confirm softkey.

The T-X icon no longer shows on the display.

3-11

Page 42

BT521

Users Manual

How the Thresholds Work

When a threshold set is applied, the Product compares each resistance reading with the

resistance reference in the current threshold set.

• If the reading is greater than reference x (1+Fail threshold) or less than the

resistance lower limit, the comparison result is FAIL, indicating that the tested battery

is potentially compromised and should be further investigated.

• If the reading is greater than Reference x (1 + Warning threshold) but less than

Reference x (1 + Fail threshold), the comparison result is WARN, indicating that the

tested battery requires further attention and increase in test frequency.

• If the reading is less than Reference (1+ Warning threshold), the comparison result is

PASS, indicating that the tested battery is within the defined tolerance limits.

For example, you have applied a threshold set where Resistance Reference is set to

3.00 mΩ, Warning set to 20 %, Fail set to 50 %, and low limit set to 2.00 mΩ. The

comparison result is FAIL for resistance readings greater than 3.00 x (1 + 50 %) = 4.50

mΩ. It is PASS for resistance readings less than 3.00 x (1 + 20 %) = 3.60 mΩ. It is

WARN for resistance readings less than 4.50 mΩ but greater than 3.60 mΩ.

At the same time, the Product compares each stable voltage reading with the lower

voltage from the applied threshold set. If the reading is less than the lower voltage

threshold, the comparison result is FAIL. If the reading is greater than the threshold, the

comparison result is PASS.

Note

If the resistance test and the voltage test have different results, the

Product shows the worse result on the display. For example, the

resistance indicates PASS but the voltage indicates FAIL, the

Product still shows FAIL on the display.

Measure Discharge Voltage

In a typical battery load discharge test, you need to test the voltage of each battery in a

battery string multiple rounds. In a typical load discharge test, the voltage of each battery

is monitored from the start of the test when the batteries are at full capacity, until the

voltage of any one battery while under constant load reaches a pre-defined minimum

voltage level.

Make Measurements

To test discharge voltage:

1. Push M as necessary to enter Sequence mode.

2. Turn the rotary switch to Discharge VOLTS.

Note

Discharge voltage can only be measured in Sequence mode.

3-12

Page 43

Use the Product

Make Measurements 3

Typical Display

This is a typical display of discharge voltage measurement.

hsz052.jpg

Progress bar: Indicates the number of the battery that is being tested.

Battery ID and Total Number: The number to the left of / indicates the ID of the battery

that has been tested. The number to the right of / indicates the total number of batteries

in the profile.

Round Number and Test Time: The row above the progress bar shows the round

number and the time when that test round was done.

Cursors: The number to the left of the progress bars indicates the ID of the battery that

corresponds to the cursor-pointed cell. Push and to move the cursors. The number

to the left of the progress bar changes accordingly. If the cursors are moved to a cell that

corresponds to a battery with readings, the readings show under the progress bar.

Average readings: After you have saved two or more sets of test readings, the Product

shows the average voltage reading in this round.

Push the Save softkey to save the current discharge voltage reading and the timestamp.

The current battery number and the progress number automatically increases by 1. The

cell that corresponds to the tested battery becomes full, and the cursors move forward.

Push the F3 softkey to start the next round test. The test time will show beside the round

number when the first reading is saved.

Note

You cannot go back to the previous round when you have started a

new one.

3-13

Page 44

BT521

Users Manual

Measure DC Voltage

The Product can measure dc voltage. It also shows the polarity on the display.

To measure dc voltage, turn the rotary switch to . See Figure 3-3 for connections.

Save

UPS

Figure 3-3. Measure DC Voltage

Vdc

hsz019.eps

Set Measurement Range

In this measurement mode, auto range is used by default. When the input signal reaches

110 % of the upper limit of the current range, the Product automatically increases a

range. When the input signal reaches 90 % of the lower limit of the current range, the

Product automatically decreases a range.

To manually set the range, push to cycle through 6 V, 60 V, 600 V, and 1000 V.

Save DC Voltage Readings

In Meter mode, push the Save softkey to save the current dc voltage reading and the

timestamp. All saved data is stored in chorological order.

In Sequence mode, push the Save softkey to save the current dc voltage reading and

the timestamp. The current battery number automatically increases by 1. The cell that

corresponds to the tested point becomes full, and the cursors move forward.

3-14

Page 45

Use the Product

Make Measurements 3

Measure AC Voltage

The Product supplies two independent readings to show the rms and frequency of ac

voltage.

To measure ac voltage, turn the rotary switch to . See Figure 3-4 for connections.

Vac

Figure 3-4. Measure AC Voltage

UPS

hsz021.eps

Measurement Range

The ac voltage measurement has only one range: 600 V. The frequency measurement

uses auto ranging. This cannot be changed.

Save AC Voltage Readings

In Meter mode, push the Save softkey to save the current ac voltage reading and the

timestamp. All saved data is stored in chorological order.

In Sequence mode, push the Save softkey to save the current ac voltage reading and

the timestamp. The current battery number increases 1 automatically. The cell that

corresponds to the tested point becomes full, and the cursors move forward.

Note

Up to 20 ac voltage readings can be saved in one profile.

3-15

Page 46

BT521

Users Manual

Measure Ripple Voltage

The Product can measure the ac component on a dc voltage, which is also known as ac

ripple. A high ac ripple may result in a battery overheat and negatively impact the battery

life. In addition, it may cause extra energy loss to the system.

To measure ripple voltage, turn the rotary switch to RIPPLE VOLTS.

Set Measurement Range

In ripple voltage function, both ac voltage and dc voltage use auto range by default.

To manually set the range for ac voltage, push to switch between 600 mV and

6000 mV.

The measurement of dc voltage uses auto range. This cannot be changed.

Save Ripple Voltage Readings

In Meter mode, push the Save softkey to save the current ripple voltage reading and the

timestamp. All saved data is stored in chorological order.

In Sequence mode, push the Save softkey to save the current ripple voltage reading and

the timestamp. The current battery number automatically increases by 1. The cell that

corresponds to the tested point becomes full, and the cursors move forward.

Note

Up to 20 ripple voltage readings can be saved in one profile.

3-16

Page 47

Use the Product

Make Measurements 3

Measure Current (AUX Function)

The Product can measure current (dc and ac) contactless with the BTL_A adapter and

the Fluke i410 Current Clamp.

To measure current, turn the rotary switch to AUX. See Figure 3-5.

Figure 3-5. AUX function

hsz054.eps

Set Measurement Range

In AUX function, both ac current and dc current use a fixed 400 A range. This cannot be

changed.

The frequency for ac current uses auto range. This cannot be changed either.

Save Current Measurement Readings

In Meter mode, push the Save softkey to save the current reading (including frequency

in ac current) and the timestamp. All saved data is stored in chorological order.

In Sequence mode, push the Save softkey to save the current reading (including

frequency in ac current) and the timestamp. The current battery number automatically

increases by 1. The cell that corresponds to the tested battery becomes full, and the

cursors move forward.

Note

Up to 20 current readings can be saved in one profile.

Use the i410 Current Clamp

For details about how to use the i410 Current Clamp, refer to the separate i410

Instruction Sheet supplied with the Product.

3-17

Page 48

BT521

Users Manual

Measure Voltage with TL175

With the TL175 test lead, the Product can measure Discharge Volts, VDC, VAC, and

Ripple Volts.

To measure voltage:

1. Connect TL175 to the BTL_A adapter.

2. Connect the BTL_A adapter to the Product.

3. Turn the rotary switch to the necessary position.

For details about the measurements, refer to the “Measure Discharge Volts”, “Measure

DC Voltage”, “Measure AC Voltage” and “Measure Ripple Voltage” sections.

As an example, Figure 3-6 shows how to measure dc voltage with the TL175 test lead.

Guard

drops

3-18

TL175

UPS

Figure 3-6. Measure DC Voltage with TL175

hsz053.eps

Page 49

Chapter 4

Use the BTL21 Interactive Test Probe

Introduction

This Product is shipped with a BTL21 Interactive Test Probe. This chapter describes

how to use the interactive test probe.

BTL21 Overview

Warning

To prevent possible electrical shock, fire, or personal injury,

hold the handle behind the tactile barrier ().

Figure 4-1 shows the BTL21 Interactive Test Probe. Table 4-1 describes the elements.

2

1

5

4

3

6

Figure 4-1. BTL21 Interactive Test Probe

7

8

hsz022.eps

4-1

Page 50

BT521

Users Manual

Table 4-1. Elements of the Interactive Test Probe

Item No. Name Function

Display

LED indicator

Save button Manually saves a measurement reading.

Backlight key Turns on or turns off the backlight for the interactive test probe.

Power key Turns on or turns off the interactive test probe.

Speaker

Probe tip

Tactile barrier

Shows information such as measurement readings and battery

ID.

Indicates the status of a measurement. Green means Pass;

orange means Warning; red means Fail.

Plays audio reminders (PASS, WARNING, FAIL, and battery

number) when enabled.

Connects the interactive test probe to the measured unit. The

probe tips can be replaced.

Hold the handle behind the tactile barrier to prevent personal

injury.

Connect the Probe to the Product

Before the interactive test probe is used, connect the probe to the Product.

Configure the Interactive Test Probe on the Product

Set the Audio

The interactive test probe has a speaker that can play audio reminders.

To set the audio:

1. Push to open the Setup screen.

2. Use L to highlight Handle, and push the Select softkey.

Audio is already highlighted.

3. Push the Select softkey.

4. Use and L to highlight Disable, Threshold result, Battery number, or Both.

5. Push the Confirm softkey.

6. Push the Back softkey to return to the Setup screen.

Set Temperature Unit

To set the temperature unit for the interactive test probe:

1. Push to open the Setup screen.

2. Use L to highlight Handle, and push the Select softkey.

3. Use L to highlight Temperature unit, and push the Select softkey.

4. Use and L to highlight Celsius or Fahrenheit, and push the Confirm softkey.

5. Push the Back softkey to return to the Setup screen.

4-2

Page 51

Use the BTL21 Interactive Test Probe

Configure the Interactive Test Probe on the Product 4

Set Emissivity Value

Emissivity describes the energy-emitting characteristics of materials. Most organic

materials and painted or oxidized surfaces have an emissivity of approximately 0.95,

which is the default setting for the Product. Battery posts or terminals may require a

different emissivity setting. See Table 4-2 if a different emissivity is needed.

Table 4-2. Emissivity Table

Material Emissivity

Aluminum foil 0.03

Aluminum, anodized 0.90

Copper, polished 0.04

Copper, oxidized 0.87

Stainless steel, polished 0.16

Stainless steel, oxidized 0.80

Lead, oxidized 0.63

Lead, oxidized, Gray 0.28

Plastics, opaque any color 0.95

The interactive test probe also lets you set the emissivity rate on the Product.

To set the emissivity value:

1. Push .

2. Push L until Handle is highlighted.

3. Push the Select softkey.

The Handle menu shows.

4. Push L until Emissivity is highlighted.

5. Push the Edit softkey, and use the four arrow keys to set the emissivity value.

6. Push the Confirm softkey.

4-3

Page 52

BT521

Users Manual

hsz059.jpg

hsz061.jpg

hsz060.jpg

hsz062.jpg

Note

The default emissivity value is 0.95. Available emissivity value is

between 0.10 and 1.00.

4-4

Page 53

Use the BTL21 Interactive Test Probe

Turn On/Off Power 4

Turn On/Off Power

The interactive test probe is powered by the Product.

When the interactive test probe is connected to the Product, it automatically turns on.

Push the power key below the probe display to turn on or turn off the power of the

interactive test probe.

To conserve product battery power, push the power key below the handle display.

Note

When the interactive test probe is powered off, its display, LED

indicator, Save button, speaker, and temperature measurement

function are disabled. You can still use the probe to take other

measurements and see the readings on the Product display.

Understand the Display

Table 4-3 describes the typical elements on the display of the BTL21 Interactive Test

Probe.

Table 4-3. Typical Elements on the BTL21 Display

2

1

11

10

Item No. Description Item No. Description

Battery ID(Sequence mode) Unit of resistance

Hazardous voltage V ac or V dc

AutoHold function is enabled. Unit of frequency

Temperature reading Voltage or frequency reading

V ac, mV ac, or V dc

Unit of temperature (Celsius or

Fahrenheit)

3

4

5

6

7

8

9

Voltage or resistance reading

hsz027.eps

4-5

Page 54

BT521

Users Manual

Long and Short Extenders

Figure 4-2 shows how to interchange the long and short extenders.

1

3

2

Figure 4-2. Long and Short Extenders

hsz024.eps

Note

To get accurate readings, the connectors between handles and

extenders should be fully fastened.

4-6

Page 55

Use the BTL21 Interactive Test Probe

Replace the Probe Tips 4

Replace the Probe Tips

Figure 4-3 shows how to replace the probe tips.

Warning

To prevent possible electrical shock, fire, or personal injury,

use correct tip covers (CAT II or CAT III) in different CAT

environments.

Figure 4-3. Replace the Probe Tips

hsz026.eps

Note

Probe tips are not covered under Warranty.

4-7

Page 56

BT521

Users Manual

Zero Calibration

A zero calibration is required each time after a test probe is replaced.

To do zero calibration:

1. Locate the zero calibration board on a flat surface horizontally. See Figure 4-4.

2. Set zero calibration in the Setup menu.

a. Push .

b. Push L until General is highlighted.

c. Push the Select softkey.

d. Push L until Zero calibration is highlighted.

e. Push the Zero softkey.

3. Insert the red and black probe tips to the calibration holes.

4. Push the Calibrate softkey.

ZERO CALIBRATION BOARD

Figure 4-4. Zero Calibration Setup

The Product starts zero calibration for all function ranges. After the zero calibration is

completed, the Product beeps to indicate a success and automatically exits zero

calibration mode.

Note

During zero calibration, make sure the inner and outer pins of the

probe tips are fully connected to the calibration board.

hsz028.eps

4-8

Page 57

Use the BTL21 Interactive Test Probe

Measure Temperature 4

Measure Temperature

The black extenders (long and short) of the BTL21 Interactive Test Probe each has an

IR temperature sensor. The IR temperature sensors can measure the temperature of

battery poles (negative pole).

To measure the temperature of a battery pole:

1. Aim the IR sensor on the battery pole.

2. Adjust the test lead to let the entire flare fall on the battery pole. See Figure 4-5.

The temperature reading shows on the LCD of the interactive test probe.

3. Push the Save key on the interactive test probe.

The temperature reading is saved in the Product memory. The reading can only be

accessed through a PC.

Figure 4-5 shows the measurement field of a battery pole.

BTL21

Test Lead

Figure 4-5. Measure the Temperature of a Battery Pole

To set objective surface emissivity in accordance with battery post

material, push Setup > Handle > Emissivity. See the Emissivity

section.

Note

D = 11.5 mm

hsz023.eps

4-9

Page 58

BT521

Users Manual

4-10

Page 59

Chapter 5

View Memory

Introduction

This chapter provides information about how to view measurement data that is manually

or automatically saved to the Product memory.

The Product has an internal memory that stores measurement data that can be viewed.

Measurement data in Meter mode and Sequence mode shows separately. The total

memory usage can be viewed in the Setup menu.

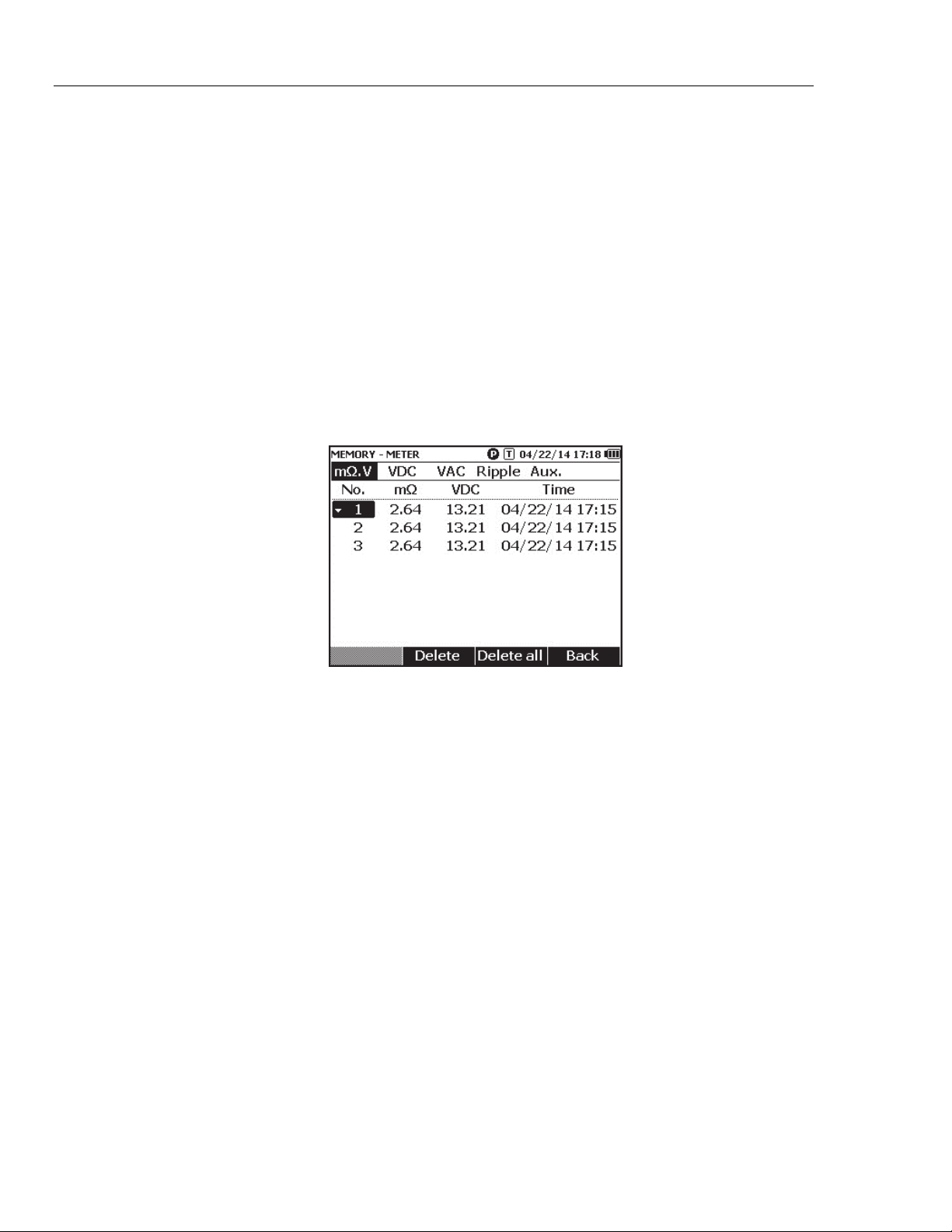

View Data Saved in Meter Mode

To view measurement data that is saved in Meter mode:

1. Turn the rotary switch to VIEW memory.

2. Push M until MEMORY – METER shows on the upper left corner of the display.

3. View the memory items, and push the Next softkey to view next page as required.

4. Use 1 to cycle through these four data sets: mΩ.V, VDC, VAC, Ripple, and AUX.

hsz063.jpg

5-1

Page 60

BT521

Users Manual

Delete Data Saved in Meter Mode

To delete data saved in meter mode:

1. Turn the rotary switch to VIEW memory.

2. Push M until MEMORY – METER shows on the upper left corner of the display.

3. When the data to be deleted shows on the display, push the More softkey.

a. To delete data entries one by one, use and L to highlight a data entry, and

then push the Delete softkey.

When the display shows Confirm to delete the reading?, push the

Delete softkey.

b. To delete all data in the measurement set, push the Delete all softkey.

When the display shows Confirm to delete all readings?, push the Delete

softkey.

hsz064.jpg

5-2

Page 61

View Memory

View Profiles Saved in Sequence Mode 5

View Profiles Saved in Sequence Mode

To view measurement data that is saved in Sequence mode:

1. Turn the rotary switch to VIEW memory.

2. Push M until MEMORY – SEQUENCE shows on the upper left corner of the display.