Page 1

BP Pump 2

NIBP Simulator and Tester

Operators Manual

PN 2196592

June 2007

© 2007 Fluke Corporation, All rights reserved. Printed in USA

All product names are trademarks of their respective companies.

Page 2

Warranty and Product Support

Fluke Biomedical warrants this instrument against defects in materials and

workmanship for one year from the date of original purchase. During the warranty period, we will repair or at our option replace, at no charge, a product

that proves to be defective, provided you return the product, shipping prepaid,

to Fluke Biomedical. This warranty covers the original purchaser only and is

not transferable. The warranty does not apply if the product has been damaged

by accident or misuse or has been serviced or modified by anyone other than

an authorized Fluke Biomedical service facility. NO OTHER WARRANTIES,

SUCH AS FITNESS FOR A PARTICULAR PURPOSE, ARE EXPRESSED

OR IMPLIED. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL,

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR

LOSSES, INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE

OR THEORY.

This warranty covers only serialized products and their accessory items that

bear a distinct serial number tag. Recalibration of instruments is not covered

under the warranty

This warranty gives you specific legal rights and you may also have other

rights that vary in different jurisdictions. Since some jurisdictions do not allow

the exclusion or limitation of an implied warranty or of incidental or consequential damages, this limitation of liability may not apply to you. If any provision of this warranty is held invalid or unenforceable by a court or other decision-maker of competent jurisdiction, such holding will not affect the validity

or enforceability of any other provision.

07/07

Page 3

Notices

All Rights Reserved

© Copyright 2007, Fluke Biomedical. No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language without the written

permission of Fluke Biomedical.

Copyright Release

Fluke Biomedical agrees to a limited copyright release that allows you to reproduce manuals and

other printed materials for use in service training programs and other technical publications. If

you would like other reproductions or distributions, submit a written request to Fluke Biomedical.

Unpacking and Inspection

Follow standard receiving practices upon receipt of the instrument. Check the shipping carton for

damage. If damage is found, stop unpacking the instrument. Notify the carrier and ask for an

agent to be present while the instrument is unpacked. There are no special unpacking instructions,

but be careful not to damage the instrument when unpacking it. Inspect the instrument for physical damage such as bent or broken parts, dents, or scratches.

Technical Support

For application support or answers to technical questions, either email

techservices@flukebiomedical.com

1-425-446-6945.

Claims

Our routine method of shipment is via common carrier, FOB origin. Upon delivery, if physical

damage is found, retain all packing materials in their original condition and contact the carrier

immediately to file a claim. If the instrument is delivered in good physical condition but does not

operate within specifications, or if there are any other problems not caused by shipping damage,

please contact Fluke Biomedical or your local sales representative.

or call 1-800- 648-7952 or

Standard Terms and Conditions

Refunds and Credits

Please note that only serialized products and their accessory items (i.e., products and

items bearing a distinct serial number tag) are eligible for partial refund and/or credit.

Nonserialized parts and accessory items (e.g., cables, carrying cases, auxiliary modules,

etc.) are not eligible for return or refund. Only products returned within 90 days from the date

of original purchase are eligible for refund/credit. In order to receive a partial refund/credit of a

product purchase price on a serialized product, the product must not have been damaged by the

customer or by the carrier chosen by the customer to return the goods, and the product must be

returned complete (meaning with all manuals, cables, accessories, etc.) and in “as new” and resalable condition. Products not returned within 90 days of purchase, or products which are not in

“as new” and resalable condition, are not eligible for credit return and will be returned to the customer. The Return Procedure (see below) must be followed to assure prompt refund/credit.

Restocking Charges

Products returned within 30 days of original purchase are subject to a minimum restocking fee of

15 %. Products returned in excess of 30 days after purchase, but prior to 90 days, are subject to a

minimum restocking fee of 20 %. Additional charges for damage and/or missing parts and accessories will be applied to all returns.

Page 4

Return Procedure

All items being returned (including all warranty-claim shipments) must be sent freight-prepaid to

our factory location. When you return an instrument to Fluke Biomedical, we recommend using

United Parcel Service, Federal Express, or Air Parcel Post. We also recommend that you insure

your shipment for its actual replacement cost. Fluke Biomedical will not be responsible for lost

shipments or instruments that are received in damaged condition due to improper packaging or

handling.

Use the original carton and packaging material for shipment. If they are not available, we recommend the following guide for repackaging:

Use a double-walled carton of sufficient strength for the weight being shipped.

Use heavy paper or cardboard to protect all instrument surfaces. Use nonabrasive

material around all projecting parts.

Use at least four inches of tightly packed, industry-approved, shock-absorbent

Returns for partial refund/credit:

Every product returned for refund/credit must be accompanied by a Return Material Authorization (RMA) number, obtained from our Order Entry Group at 1-800-648-7952 or 1-425-446-

6945.

Repair and calibration:

To find the nearest service center, go to www.flukebiomedical.com/service

In the U.S.A.:

Cleveland Calibration Lab

Tel: 1-800-850-4606

Email: globalcal@flukebiomedical.com

Everett Calibration Lab

Tel: 1-888-993-5853

Email: service.status@fluke.com

In Europe, Middle East, and Africa:

Eindhoven Calibration Lab

Tel: +31-402-675300

Email: ServiceDesk@fluke.com

In Asia:

Everett Calibration Lab

Tel: +425-446-6945

mail : se rvice.international@fluke.com

E

material around the instrument.

, or

Certification

This instrument was thoroughly tested and inspected. It was found to meet Fluke Biomedical’s

manufacturing specifications when it was shipped from the factory. Calibration measurements

are traceable to the National Institute of Standards and Technology (NIST). Devices for which

there are no NIST calibration standards are measured against in-house performance standards using accepted test procedures.

WARNING

Unauthorized user modifications or application beyond the published specifications may

result in electrical shock hazards or improper operation. Fluke Biomedical will not be responsible for any injuries sustained due to unauthorized equipment modifications.

Page 5

Restrictions and Liabilities

Information in this document is subject to change and does not represent a commitment

by Fluke Biomedical. Changes made to the information in this document will be incorporated in new editions of the publication. No responsibility is assumed by Fluke Biomedical for the use or reliability of software or equipment that is not supplied by Fluke Biomedical, or by its affiliated dealers.

Manufacturing Location

The BP Pump 2 Non-invasive Blood Pressure Simulator and Tester is manufactured in

Everett, Washington by Fluke Biomedical, 6920 Seaway Blvd., Everett, WA, U.S.A.

Page 6

Page 7

Table of Contents

Chapter Title Page

1 Introduction and Specifications.............................................. 1-1

Introduction .......................................................................................... 1-3

Key Features......................................................................................... 1-3

General Safety Considerations.............................................................. 1-4

Symbols ............................................................................................ 1-4

Warnings and Cautions..................................................................... 1-5

Instrument Familiarity .......................................................................... 1-7

Powering Up the Tester ........................................................................ 1-10

Specifications........................................................................................ 1-10

Accessories ........................................................................................... 1-12

2 Setup, Maintenance, and Support........................................... 2-1

Setting up the Tester ............................................................................. 2-3

Printer Output ................................................................................... 2-4

User-Defined Simulations................................................................. 2-5

Language .......................................................................................... 2-6

Units of Measure............................................................................... 2-6

Self Test............................................................................................ 2-8

Zero Pressure .................................................................................... 2-8

Enable ECG Signal ........................................................................... 2-9

Maintenance and Support ..................................................................... 2-10

Avoiding Damage............................................................................. 2-10

Cleaning............................................................................................ 2-10

Service and Calibration..................................................................... 2-11

Packing Instructions.......................................................................... 2-11

3 Operation .................................................................................. 3-1

Introduction .......................................................................................... 3-3

Configurations for Devices Under Test (DUT)................................. 3-4

Conversion Factors ........................................................................... 3-7

Initializing Tests and Simulations..................................................... 3-7

Error Messages ................................................................................. 3-7

i

Page 8

BP Pump 2

Operators Manual

Pressure Tests....................................................................................... 3-8

Pressure Leak Test............................................................................ 3-8

Pressure Relief Test.......................................................................... 3-10

Pressure Source Test ........................................................................ 3-11

Pressure Gauge Test ......................................................................... 3-12

Simulations........................................................................................... 3-13

Standard BP...................................................................................... 3-14

Patient Conditions ............................................................................ 3-15

Arrhythmias...................................................................................... 3-16

Respiratory Artifacts ........................................................................ 3-18

Neonate ............................................................................................ 3-19

Wrist................................................................................................. 3-20

User-Defined .................................................................................... 3-21

Auto Sequences.................................................................................... 3-21

Editing Auto Sequences ................................................................... 3-22

Printing Auto Sequences .................................................................. 3-23

Running Auto Sequences ................................................................. 3-24

Pressure Gauge............................................................................. 3-25

Leak Test...................................................................................... 3-25

Relief Valve Test.......................................................................... 3-26

Pressure Source ............................................................................ 3-26

Data Sheet Printout....................................................................... 3-27

BP Simulations............................................................................. 3-27

Remote Operation ................................................................................ 3-29

RS-232 Settings................................................................................ 3-29

Ansur Software Control.................................................................... 3-29

Appendices

A ECG Interface............................................................................... A-1

B Questions and Answers ................................................................ B-1

C Abbreviations ............................................................................... C-1

D Computer Control Commands...................................................... D-1

ii

Page 9

List of Tables

Table Title Page

1-1. Symbols ................................................................................................ 1-4

1-2. Top and Side Panel Components .......................................................... 1-8

1-3. Number Key Functions......................................................................... 1-9

1-4. Standard Accessories ............................................................................ 1-12

1-5. Optional Accessories ............................................................................ 1-12

3-1. Conversion Factors ............................................................................... 3-7

3-2. Standard Blood Pressure Simulations ................................................... 3-15

3-3. Patient Condition Simulations .............................................................. 3-16

3-4. Arrhythmia Simulations........................................................................ 3-17

3-5. Respiratory Artifact Simulations .......................................................... 3-18

3-6. Neonate Simulations............................................................................. 3-19

3-7. Wrist Simulations ................................................................................. 3-20

D-1. Computer Control Commands .............................................................. D-1

iii

Page 10

BP Pump 2

Operators Manual

iv

Page 11

List of Figures

Figure Title Page

1-1. Tester Top and Side Panel Components ............................................... 1-7

3-1. Tester Pneumatic Block Diagram ......................................................... 3-3

3-2. Connecting Tester to Single-hose NIBP Monitor (Int Cuff) ................. 3-4

3-3. Connecting Tester to Double-hose NIBP Monitor (Int Cuff)................ 3-5

3-4. Connecting Tester to Single-hose NIBP Monitor (Ext Cuff) ................ 3-5

3-5. Connecting Tester to Double-hose NIBP Monitor (Ext Cuff)............... 3-6

3-6. Connecting Tester to Single-hose NIBP Wrist Monitor (Ext Cuff) ...... 3-6

3-7. Sample Auto Sequence Test Printout.................................................... 3-24

3-8. Sample Data Sheet Printout .................................................................. 3-28

A-1. Optional ECG Interface Adapter........................................................... A-1

v

Page 12

BP Pump 2

Operators Manual

vi

Page 13

Chapter 1

Introduction and Specifications

Contents Page

Introduction .................................................................................. 1-3

Key Features................................................................................. 1-3

General Safety Considerations ..................................................... 1-4

Symbols .................................................................................... 1-4

Warnings and Cautions............................................................. 1-5

Instrument Familiarity.................................................................. 1-7

Powering Up the Tester................................................................ 1-10

Specifications ............................................................................... 1-10

Accessories................................................................................... 1-12

1-1

Page 14

BP Pump 2

Operators Manual

1-2

Page 15

Introduction and Specifications

Introduction

1

Introduction

The Fluke Biomedical BP Pump 2 Non-Invasive Blood Pressure Simulator and

Tester, hereafter known as the “Tester”, is a multi-purpose test instrument for

use with oscillometric Non-Invasive Blood Pressure Monitors (NIBPMs). The

Tester provides dynamic blood pressure simulations, static calibration,

automated leak testing, and pressure relief valve testing. The following

models are available:

• BP Pump 2L (Basic Model)

• BP Pump 2M (High-Accuracy Model)

The Tester allows you to verify the performance claims of different blood

pressure monitors. You can quickly recall the fixed onboard simulations or

define your own. With its internal pump, the Tester can generate pressures up

to 400 mmHg (53.3 kPa) for leak testing, pressure sourcing, and relief valve

testing.

In addition, you can define auto sequences that automate the sequencing of

tests and NIBP simulations and provide an optional printed report.

Key Features

Key features of the Tester include:

• Pressure leak testing on cuff, tubing, and connections

• Relief valve testing on the patient monitor

• Pressure gauge measurements

• Pressure source capability

• NIBP simulations including adult, neonate, arrhythmias, and respiratory

artifacts

• Auto sequences with optional reports

• Internal Adult and Neonatal Cuff simulation

Tester capabilities can be extended with optional accessories that allow:

• ECG synchronization with non-invasive output

• External wrist cuff simulations

1-3

Page 16

BP Pump 2

Operators Manual

Tester pressure accuracy can be improved by upgrading to a high-accuracy

pressure transducer. This is a factory service upgrade and is provided to

customers wanting to meet the DIN EN 1060 requirements for pressure

measurement accuracy. For more information, refer to “Setup, Maintenance,

and Support: Maintenance and Support.”

General Safety Considerations

This Tester complies with safety and technical requirements described in the

following directives:

• UL 3101-1, Electrical Equipment for Laboratory Use; Part 1: General

Requirements.

• CAN/CSA C22.2 No. 1010.1 (1992), Safety Requirements for Electrical

Equipment for Measurement, Control and Laboratory Use, Part 1: General

Requirements.

• EC 73/23/EEC (Amended 93/68/EEC) EN61010-1:2001, Safety

requirement for electrical equipment for measurement, control and

laboratory use, Part 1: General Requirements.

Symbols

Table 1-1 describes symbols used in association with the Tester.

Table 1-1. Symbols

Symbol Description Symbol Description

W

Œ

~

1-4

Risk of danger. Important

information. See manual.

Intertek Electrical Test

Laboratory listed.

Conforms to relevant

Canadian and U.S.

standards.

Do not dispose of this

product as unsorted

municipal waste. Contact

Fluke or a qualified

recycler for disposal.

X

P

Hazardous voltage. Risk

of electrical shock.

Conforms to European

Union directives

Page 17

Introduction and Specifications

General Safety Considerations

Warnings and Cautions

Users are advised to read the manual carefully, observing all warnings and

cautions, before attempting to set up and operate the Tester.

A Warning identifies hazardous conditions and actions that could cause

bodily harm or death.

A Caution identifies conditions and actions that could damage the Tester or

the equipment under test, or cause permanent loss of data.

W X Warning

To avoid possible electric shock or personal injury, follow

these guidelines:

• Read the Users Manual before operating the Tester.

• Use this Tester only in the manner specified by the

manufacturer or the protection provided may be

impaired.

• Do not connect the Tester to a patient or equipment

connected to a patient. The Tester is intended for

equipment evaluation only and should never be used

in diagnostics, treatment or in any other capacity

where the Tester would come in contact with a patient.

1

• Do not use the product in wet locations, around

explosive gases or dust.

• Never open the Tester case, because dangerous

voltages are present. There are no user replaceable

parts in the Tester.

• The Tester must be properly earthed. Only use a

supply socket that has a protective earth contact. If

there is any doubt as to the effectiveness of the supply

socket earth, do not connect the Tester.

• Do not use a two-conductor adapter or extension cord;

this will break the protective ground connection.

• Ensure that the external power source is properly rated

for the system.

1-5

Page 18

BP Pump 2

Operators Manual

• Always connect the system power cord directly to a

three-prong receptacle with a functional ground. Never

use a two-prong plug adapter to connect primary

power to the Tester, thereby disconnecting the utility

ground.

• Disconnect the Tester from the power source before

changing the supply voltage. The Tester operates at a

range of 100 to 240 volts.

W Caution

To avoid damage to the Tester or adverse affects on its

performance, follow these guidelines:

• Allow only qualified technical personnel to service the

Tester.

• Do not expose the system to temperature extremes.

Ambient temperatures should remain between 15° C

and 40° C. System performance may be adversely

affected if temperatures fluctuate above or below this

range.

• Clean the Tester only by gently wiping down with a

clean, lint-free cloth dampened with a mild detergent

solution. Do not immerse the unit.

• Do not apply pressures greater than 400 mmHg (53

kPa) to the pressure port.

1-6

Page 19

Introduction and Specifications

Instrument Familiarity

1

Instrument Familiarity

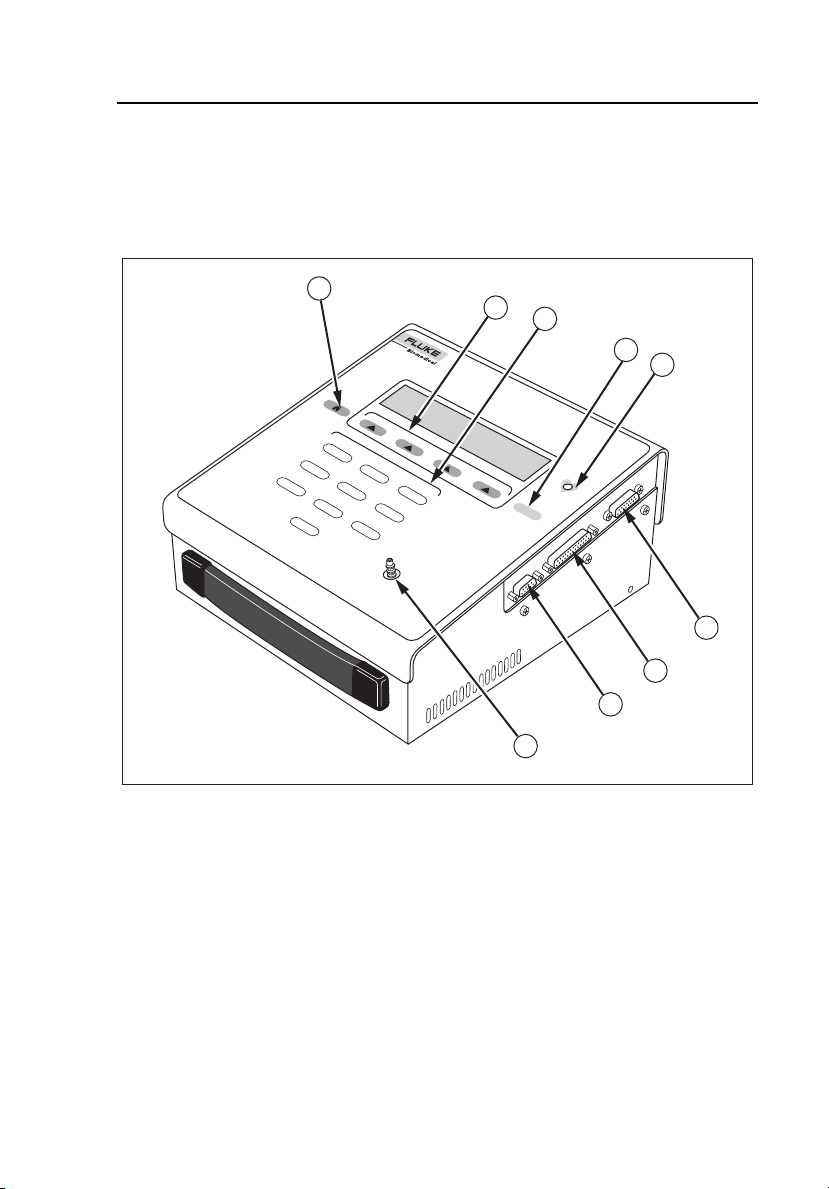

Figure 1-1 shows the Tester. The top and side panel components are described

in Table 1-2 and the number key functions are described in Table 1-3.

1

2

3

4

RESPIRI

ARTI

F

AC

7

USER DEFINED

0

STANDARD BP

TORY

T

4

NEON

8

PRESSURE

LEAK

1

A

T

E

CONDITIONS

TESTS AND SIMULA

PRESSURE

RELIEF

2

PA

TIEN

T

5

ARRHYTHMIAS

6

WRIST

9

PRESSURE PO

TION

S

PRESSURE

TA

3

RT

S

TI

C

BP Pump 2

NON-INV

ASIVE BLOOD PRESSURE MONITOR ANAL

YZE

R

ENT

8

9

Figure 1-1. Tester Top and Side Panel Components

5

6

7

fas10.eps

1-7

Page 20

BP Pump 2

Operators Manual

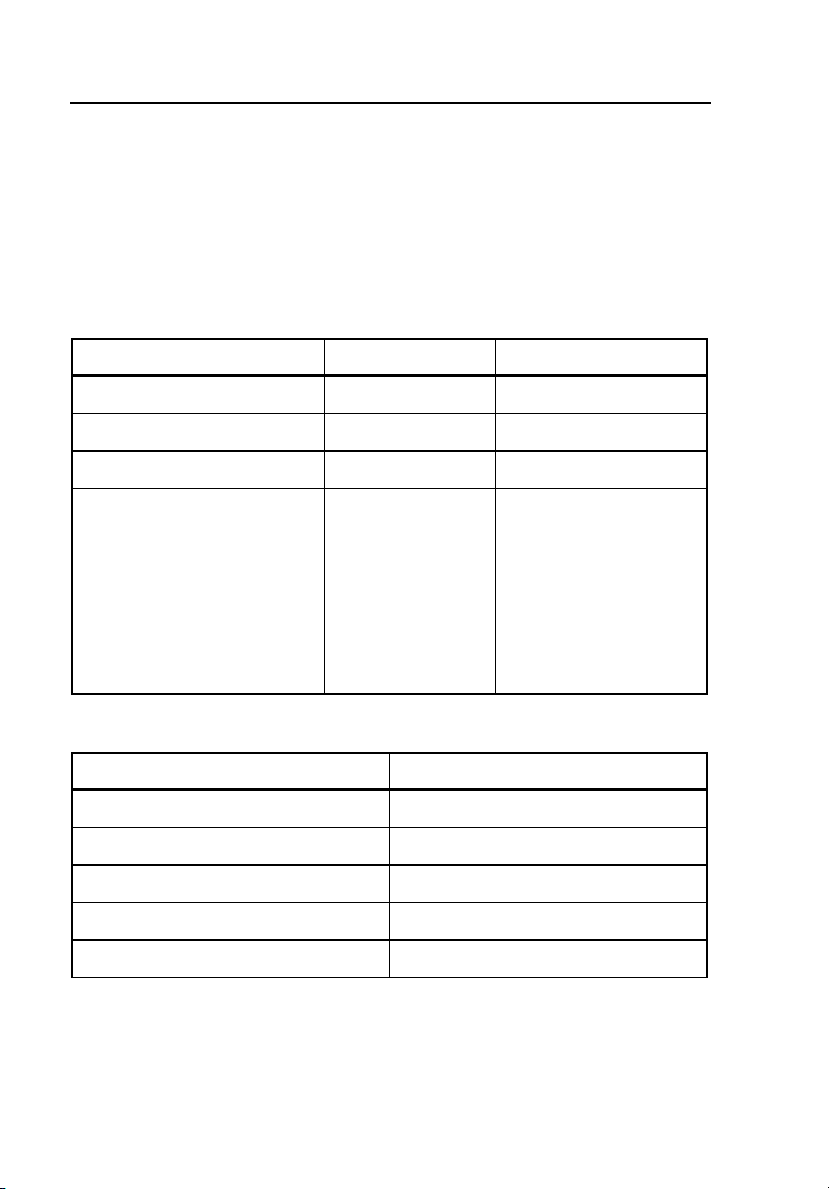

Table 1-2. Top and Side Panel Components

Label Name Function

A Home Key Returns the operator to the Main Menu.

B Soft Keys 1 - 4

C

D Enter Key

E Pulse Indicator

F ECG Interface Port Allows connection of optional ECG

G Printer Port Provides D-25 female connector for

H RS-232 Serial Port Provides serial D-9 female connector for

I Pressure Port

Number (Test and

Simulations) Keys

Makes dynamic assignments based on

the current screen.

Allows the operator to perform auto

sequences and simulations using

numeric keys.

Advances to the next menu or

saves/selects options.

LED blinks in synchronization with

beeper, indicating that the pump is

generating a simulated blood pressure

pulse.

accessory (refer to Appendix, ECG

Option).

external parallel printer.

bi-directional computer control.

Connects to the Non-Invasive Blood

Pressure Monitor for all pressure

simulations and tests.

1-8

Page 21

Introduction and Specifications

Instrument Familiarity

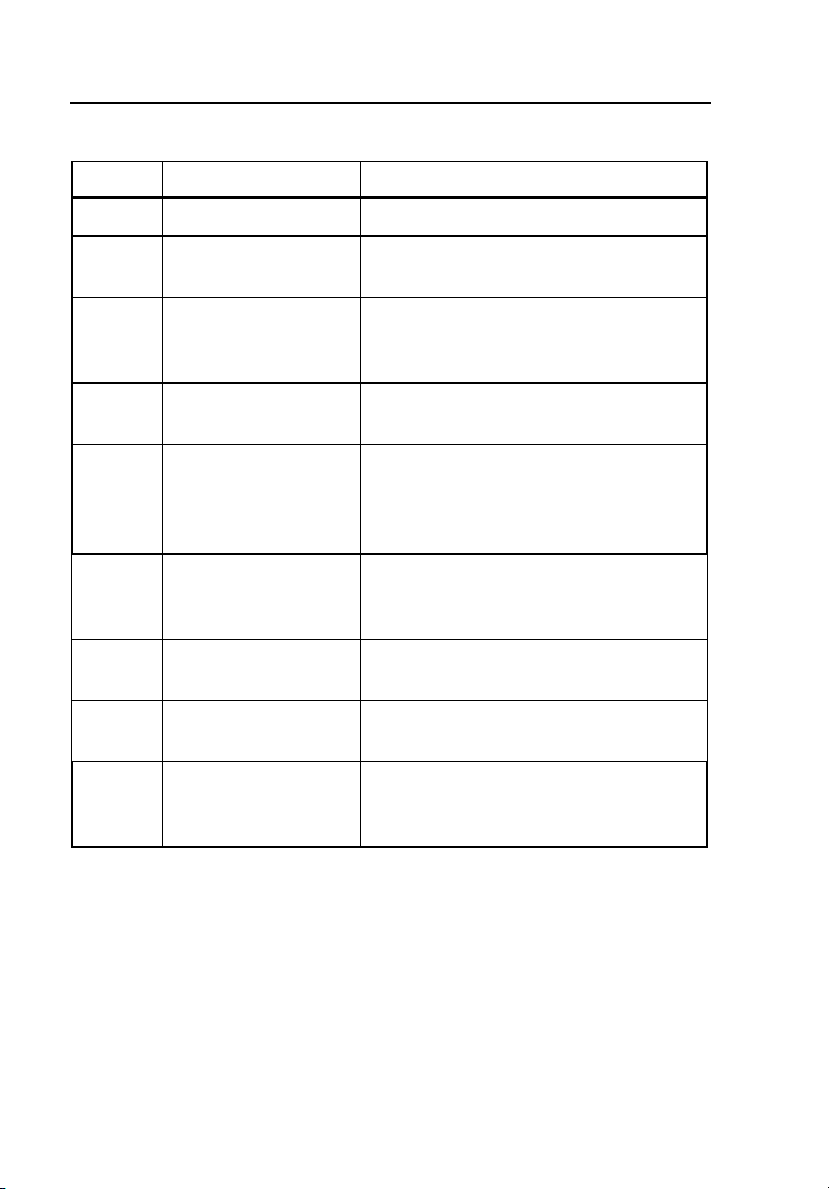

Table 1-3. Number Key Functions

Number Name Function

Pressurizes a pneumatic system to an

1

2

3

4 STANDARD BP

5

6 ARRHYTHMIAS

7

8 NEONATE

9 WRIST Tests wrist cuff NIBP monitors.

0 USER DEFINED

PRESSURE

LEAK

PRESSURE

RELIEF

STATIC

PRESSURE

PATIENT

CONDITIONS

RESPIRATORY

ARTIFACT

operator-defined target pressure up to

400 mmHg (53.3 kPa) and then

measures the loss of pressure over

time.

Increases the pressure in the

pneumatic system until the relief valve

on the NIBP monitor opens or until the

Setpoint is reached, whichever occurs

first.

Accessed via the Pressure Gauge

Test, which enables the Tester to

measure static pressure generated by

an external source in the range of 50

to 400 mmHg 6.7 to 53.3 kPa).

Provides seven variations of NIBP

simulations for both arm and wrist

cuffs.

Includes simulations for healthy,

geriatric, and obese patients, a well as

various levels of exercise.

Measures erratic heart rhythms,

including atrial fibrillation and

premature ventricular contraction.

Exhibits a beat-to-beat variation in the

blood pressure caused by intrathoracic

pressure.

Tests the ability of the NIBP monitors

to detect blood pressure on neonatal

patients.

Allows the operator to define blood

pressure simulations.

1

1-9

Page 22

BP Pump 2

Operators Manual

Powering Up the Tester

The Tester is very simple to power up. Follow these steps:

1. Plug in a three-pronged power cord to the back of the unit.

2. Plug the cord into an appropriate socket, ensuring that the external power

source is properly rated for the system.

3. Move the power switch above the plug to the on position. After two

momentary screens, the Tester displays the Main menu, from which all

Tester functions are selected.

Fluke Biomedical BP Bump 2

PERFORM

SIMULATION

PRESSURE

TESTS

AUTO

SEQUENCE

SETUP

fas31.eps

Specifications

The following are specifications for the Tester. Please contact your Fluke

Biomedical service representative for more information regarding the device

specifications.

Mains Voltage

Range ......................................................................100 - 240 V ac 50/60 Hz, 60 VA

Environmental Conditions

Operating Temperature ...........................................15 °C to 40 °C

Storage Temperature ..............................................-20 °C to +65 °C

Relative Humidity ....................................................90 % max

Pressure Measurement

Units ........................................................................kPa

mmHg

cmH

2

O

inH

2

psi

O

1-10

Page 23

Introduction and Specifications

Specifications

Range ..................................................................... 0 mmHg to +400 mmHg

Resolution............................................................... 0.1 kPa

Resolution (High Accuracy Version) ....................... 0.01 kPa

Accuracy (Standard Version)

0 to 300 mmHg ................................................... ±0.5 % of reading ±1 mmHg

301 to 400 mmHg .............................................. ±2 % of reading

High-Accuracy Version ........................................... <0.8 mmHg (0.1 kPa)

1 mmHg

O

1 cmH

2

O

1 inH

2

0.1 psi

0.1 mmHg

0.1 cmH

0.1 inH

0.01 psi

2

O

2

O

1

Pressure Generation

Pressure Generator, Static Pressure Range .......... 50 mmHg to +400 mmHg

Difference between target pressure

and actual pressure ................................................ ±10 mmHg from 100-400 mmHg with

Internal Leak Rate .................................................. <2 mmHg per minute, with a minimum

a minimum volume of 300 cc

volume of 300 cc

Electrical ECG

Signals .................................................................... RA, LA, RL, LL, V

Waveform ............................................................... Lead II

Amplitude................................................................ 1 mV peak (±10%)

Connections............................................................ Signals available via the optional ECG

adapter

Heart Rate for NIBP Simulations

Heart Rate Accuracy

With ECG disabled ............................................ ±1 BPM

With ECG enabled .............................................. ±1 BPM

Except for the following Patient Conditions:

Weak Pulse, Tachycardia, Obese, Geriatric....... ±1% ±1 BPM

Patient Condition Mild Exercise.......................... ±1.5% ±1 BPM

Patient Condition Strenuous Exercise ................ ±3% ±1 BPM

1-11

Page 24

BP Pump 2

Operators Manual

Accessories

The following are accessories for the Tester. To order, contact your Fluke

Biomedical equipment dealer and use the Fluke Biomedical part numbers

provided. Table 1-4 lists standard accessories shipped with the tester. Table

1-5 lists optional accessories that must be ordered separately.

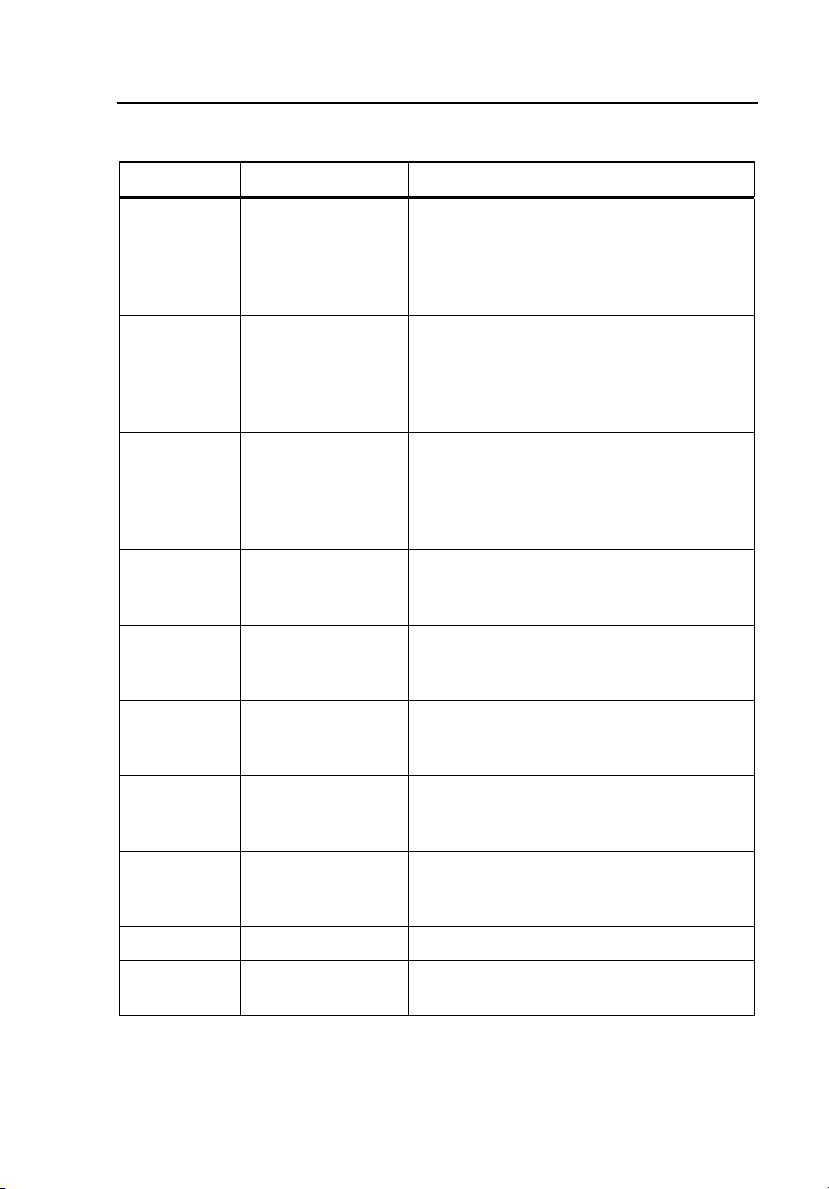

Table 1-4. Standard Accessories

Description Quantity Shipped Part Number

Operator's Manual 1 2196592

Warranty Card 1 2241856

Tubing and Fittings 1 2196394

Country-specific Power Cord

USA

Schuko

UK

AU

1

1

1

1

284174

769422

769455

658641

Table 1-5. Optional Accessories

Description Part Number

Wrist Cuff Mandrel 2391875

ECG adapter 2391894

Carrying Case 2222822

RS-232 Serial Cable (9M-9F) 2238659

BP Pump 2 Ansur Plug-In 2755836

1-12

Page 25

Chapter 2

Setup, Maintenance, and Support

Contents Page

Setting up the Tester..................................................................... 2-3

Printer Output ........................................................................... 2-4

User-Defined Simulations ........................................................ 2-5

Language .................................................................................. 2-6

Units of Measure ...................................................................... 2-6

Self Test.................................................................................... 2-8

Zero Pressure............................................................................ 2-8

Enable ECG Signal................................................................... 2-9

Maintenance and Support............................................................. 2-10

Avoiding Damage..................................................................... 2-10

Cleaning.................................................................................... 2-10

Service and Calibration ............................................................ 2-11

Packing Instructions ................................................................. 2-11

2-1

Page 26

BP Pump 2

Operators Manual

2-2

Page 27

Setup, Maintenance, and Support

Setting up the Tester

2

Setting up the Tester

To set up the tester, carry out the following:

1. Insert the power cord into the Tester and plug the cord into an appropriate

ac power socket.

W X Warning

To avoid possible electric shock, burning of the skin, or

personal injury, ensure that the external power source is

properly rated for the system.

2. Turn the power switch on. When the Tester is powered up, the Main

menu appears.

Fluke Biomedical BP Bump 2

PERFORM

SIMULATION

PRESSURE

TESTS

AUTO

SEQUENCE

SETUP

3. The Tester has several configurable options available from the Setup

menu. You can reach the Setup menu by using the soft keys to follow

the menu path shown below:

MAIN MENU C SETUP

The Setup menu appears, showing the following configurable options:

BP Pump 2 Setup

PRINTER

OUTPUT

USER DEF

SIMULATION LANGUAGE

MORE*

4. Press the MORE soft key in this and each of the following screens to

display additional options:

fas31.eps

fas37.eps

2-3

Page 28

BP Pump 2

Operators Manual

BP Pump 2 Setup

UNITS OF

MEASURE

BP Pump 2 Setup

ZERO

PRESSURE

RS232

SETTINGS

ENABLE

ECG

SELF

TEST

MORE*

MORE*

fas38.eps

fas39.eps

Note

These parameters should be configured and the settings saved the

first time the Tester is used. They need to be configured only once.

Printer Output

Printouts are available for auto sequences. By default, the Printer Output is set

to NONE.

To control the production of when running auto sequences, take the following

actions:

1. Select the desired print format by using the soft keys to follow the menu

path shown below.

SETUP C PRINTER OUTPUT

The Printer Output screen appears, showing the available options:

Printer Output: None

A3CII HP PCL3 NONE

2. Select one option and press ENT to return to the SETUP menu.

3. If desired, press HOME to return to the Main menu.

2-4

fas22.eps

Page 29

Setup, Maintenance, and Support

Setting up the Tester

2

User-Defined Simulations

The Tester supports up to nine user-definable blood pressure simulations

configured through the Setup menu.

To access and modify a user-defined simulation definition, take the following

actions:

1. Use the soft keys to follow this menu path:

SETUP C USER DEF SIMULATION C Number Key (1-9) C

ENT

2. Alternatively, you can access the definition from the number keys:

0 USER DEFINED key C OPTIONS (to scroll through the

numbers) C EDIT

With either method, the User Defined Simulation screen appears:

User Defined Simulation 1

Sys: 120 Dia: 80 Pulse: 0.70cc HR: 75

<- FIELD FIELD ->

fas23.eps

This screen shows the number of the simulation, along with the following

parameters available for configuration. Their valid ranges are as follows:

• Sys: Systolic, 20 – 250 mmHg

• Dia: Diastolic, 10 – 200 mmHg

• Pulse: Pulse Volume, 0.1 cc – 2.4 cc in increments of 0.1 cc

• HR: Heart Rate, 30 – 250 bpm

The systolic and diastolic settings are interdependent. The diastolic must

always be below the systolic. The pulse volume and the heart rate are also

interdependent. The maximum pulse volume cannot be achieved at the

maximum heart rate.

3. Press the soft key <- FIELD or FIELD -> to scroll through options,

making changes to each field by entering numbers from the number keys.

4. Pres ENT to return to the SETUP menu.

5. If desired, press the HOME button to return to the Main menu.

2-5

Page 30

BP Pump 2

Operators Manual

Language

Besides the default of English, the Tester can support up to four additional

languages. Spanish is currently available; additional languages will be

released in the future.

To change the language, take the following actions:

1. Use the soft keys to follow the menu path shown below.

SETUP C LANGUAGE

The Display/Print Language screen appears, showing the available

options:

Display/Print Language: English

ENGLISH SPANISH

2. Select a language by pressing its soft key.

3. When finished, press ENT to return to the SETUP menu.

fas24.eps

4. If desired, press HOME to return to the Main menu.

Units of Measure

The Tester has separate definable measurement units for blood pressure

simulations and pressure tests. For the blood pressure simulations, units of

mmHg (default) and kPa are available. For the pressure tests, units of mmHg

(default), kPa, cmH

To define the pressure units, do the following:

1. Use the soft keys to follow the menu path shown below.

SETUP C *MORE C UNITS OF MEASURE

The Blood Pressure Units: screen appears, showing the available

options:

2-6

O, inH2O, and PSI are available.

2

Page 31

Setup, Maintenance, and Support

Setting up the Tester

Blood Pressure Units: mmHg

MMHG KPA

2. Select one option and press ENT.

The Pressure Measurement Units: screen appears, showing the

available options:

Pressure Measurement Units: mmHg

MMHG KPA CMH2O *MORE

3. Press *MORE to see additional options:

Pressure Measurement Units: mmHg

INH2O PSI *MORE

2

fas25.eps

fas26.eps

fas27.eps

4. Select one of the desired options and press ENT to return to the Setup

menu.

5. If desired, press HOME to return to the Main menu.

Note

Changing the UNITS OF MEASURE also changes the units used in

the auto sequences.

2-7

Page 32

BP Pump 2

Operators Manual

Self Test

The tester runs a self test, displaying the software version and checksum, the

serial number, and the model number. A motor check is also performed.

To run a self test, do the following:

1. Use the soft keys to follow the menu path shown below.

SETUP C *MORE C SELF TEST

The Self Test screen appears:

Fluke BP Pump 2

5180)

Heise Label: 002422 FW Version: 3.36

204634

mm Hg

fas28.eps

2. When finished, press ENT to return to the Setup menu.

3. If desired, press HOME to return to the Main menu.

Zero Pressure

The Zero pressure option allows the user to re-zero the pressure. The function

is similar to the tare of a scale. This re-zeroing lasts until the unit is zeroed

again or until the power is shut off.

To zero the pressure, do the following:

1. Use the soft keys to follow the menu path shown below.

SETUP C MORE C MORE C ZERO PRESSURE

The Zero Pressure (Remove connection …) screen appears:

Remove connection to pressure port and

press ZERO key

HA: 0.3 mmH 0g

ZERO

mm Hg

2. When finished, press ENT to return to the Setup menu.

2-8

fas29.eps

Page 33

Setup, Maintenance, and Support

Setting up the Tester

3. If desired, press HOME to return to the Main menu.

2

Enable ECG Signal

The ECG output is enabled or disabled by the operator. If the patient monitor

under test does not make use of ECG signals, we recommend that the ECG

output be disabled. (The factory default is for ECG to be disabled.) ECG

signals are present for all Standard BP, Patient Condition, and Arrhythmia

NIBP simulations. The ECG signals are present on the ECG Interface Port as

shown in Figure 1-2. An optional ECG Interface adapter, as described in

Appendix A, is available for purchase.

To enable or disable ECG signals, take the following actions:

1. Use the soft keys to follow the menu path shown below.

SETUP C *MORE C MORE C ENABLE ECG

The Enable ECG? screen appears, showing options YES and NO:

Enable ECG?

YES NO

2. Select one option and press ENT to return to the Setup menu.

3. If desired, press HOME to return to the Main menu.

2-9

Ye s

fas30.eps

Page 34

BP Pump 2

Operators Manual

Maintenance and Support

The Tester requires little maintenance or special care; however, it is a

calibrated measuring instrument and should be treated as such. The following

describes how to maintain the Tester and the method of company support.

Avoiding Damage

Do not drop the instrument or subject it to any mechanical abuse that could

cause a shift in the calibrated settings.

W Caution

To avoid damage to the Tester or adverse affects on its

performance, follow these guidelines:

• Do not expose the system to temperature extremes.

Ambient temperatures should remain between 15 and

40 °C. System performance may be adversely affected

if temperatures fluctuate above or below this range.

• Do not apply pressures greater than 400 mmHg (53

kPa) to the pressure port.

Cleaning

Clean the exterior of the Tester occasionally with a cloth dampened with a

mild detergent solution. Take care to keep liquids out of the pressure port.

W Caution

To avoid damage to the Tester or adverse affects on its

performance, clean it only by gently wiping down with a

clean, lint-free cloth dampened with a mild detergent

solution. Do not immerse the unit.

Carefully wipe down the hose adapters and inspect them for damage and

deterioration of the tubing and fittings.

2-10

Page 35

Setup, Maintenance, and Support

Maintenance and Support

2

Service and Calibration

If the Tester fails to operate successfully, please contact the Fluke Biomedical

Service Center immediately, as indicated under “Warranty and Product

Support.”

W Caution

To avoid damage to the Tester or adverse affects on its

performance, allow only qualified technical personnel to

service the Tester.

Annual calibration of the Tester by an authorized Fluke Biomedical Service

Center is recommended. Fluke Biomedical Service Centers have the

appropriate tools and procedures for performing calibrations as well as factoryauthorized updates.

International customers should contact their Fluke Biomedical dealers for

service/product support.

To obtain the name of a local dealer or service center, contact Fluke

Biomedical as indicated under “Return Procedures, Repair and Calibration.”

Packing Instructions

If repairs are required, return the Tester to the factory or the nearest service

center, packed in the original shipping container, using packing materials

supplied by Fluke Biomedical.

1. Before returning the Tester for factory service, contact the Fluke

Biomedical Service Center for a required Return Authorization Number.

2. Provide the following information:

• The Tester serial number

• The specific steps that reproduce the problem

• A daytime phone number

• Your name/company

• A fax number (if available)

3. Pack the instrument carefully, using the original packing materials. If the

original packing materials are not available, refer to “Return Procedures”

2-11

Page 36

BP Pump 2

Operators Manual

for a list of preferred materials or contact Fluke Biomedical for

replacement packing. Failure to pack the instrument properly could void

your warranty.

4. Place the Return Authorization Number in a prominent place on the

outside of the packing box, and refer to the number in any correspondence

with Fluke Biomedical Service.

5. Enclose your return address and Return Authorization Number.

6. Insure the unit for full retail value and ship to the nearest Fluke

Biomedical service center.

2-12

Page 37

Chapter 3

Operation

Contents Page

Introduction .................................................................................. 3-3

Configurations for Devices Under Test (DUT) ........................ 3-4

Conversion Factors ................................................................... 3-7

Initializing Tests and Simulations............................................. 3-7

Error Messages ......................................................................... 3-7

Pressure Tests............................................................................... 3-7

Pressure Leak Test.................................................................... 3-8

Pressure Relief Test .................................................................. 3-9

Pressure Source Test................................................................. 3-11

Pressure Gauge Test.................................................................. 3-12

Simulations................................................................................... 3-13

Standard BP .............................................................................. 3-14

Patient Conditions..................................................................... 3-15

Arrhythmias .............................................................................. 3-16

Respiratory Artifacts................................................................. 3-18

Neonate..................................................................................... 3-19

Wrist ......................................................................................... 3-20

User-Defined............................................................................. 3-21

Auto Sequences............................................................................ 3-21

Editing Auto Sequences............................................................ 3-22

Printing Auto Sequences........................................................... 3-23

Running Auto Sequences.......................................................... 3-24

Pressure Gauge...................................................................... 3-25

Leak Test............................................................................... 3-25

Relief Valve Test................................................................... 3-26

Pressure Source ..................................................................... 3-26

Data Sheet Printout ............................................................... 3-27

BP Simulations...................................................................... 3-27

Remote Operation......................................................................... 3-29

RS-232 Settings ........................................................................ 3-29

Ansur Software Control............................................................ 3-29

3-1

Page 38

BP Pump 2

Operators Manual

3-2

Page 39

Operation

Introduction

3

Introduction

The Tester contains a microprocessor that reads and controls the front panel

keyboard, the display, serial port, printer port, a diaphragm pump, two solenoid

valves, a step motor, a position sensor, and a pressure transducer (Figure 3-1).

Filter

DC

Diaphragm

Pump

Lead Screw

and Piston

Step

Motor

Home

Position

Sensor

Option

Hi Accuracy

Pressure

Sensor

Check Valve

Ring

12

Rolling

Seal

Standard

Pressure

Transducer

Figure 3-1. Tester Pneumatic Block Diagram

Ring Stud

12

N.C. Solenoid

Valve

Stud

Vent/Zero Port

Front Panel

Pressure Port

N.C. Solenoid

Valve

Internal Adult

Cuff Volume

290cc

fas14.eps

The diaphragm pump is used as a pressure source for the relief valve, leak, and

pressure source tests. The diaphragm pump pulls air through a filter and forces it

through a check valve into the main manifold of the instrument. This main

manifold has an internal volume of approximately 20 cc and is directly connected

to the pressure port on the front panel. Pressure in the manifold is measured by a

pressure transducer and can be released by a solenoid-operated valve. The volume

of the main manifold can be increased by approximately 290 cc, to simulate an

adult pressure cuff, by opening a second solenoid valve.

A stepper motor and lead screw move a piston into the manifold to decrease the

manifold volume, thereby creating pressure pulses to simulate a human subject. A

seal around the piston is maintained by a rolling diaphragm seal. The size and

3-3

Page 40

BP Pump 2

Operators Manual

shape of the pulses are controlled by the microprocessor driving the step motor.

The home position of the piston is detected by an optical interrupter. If the

optional high-accuracy pressure sensor is installed, it also measures the pressure in

the main manifold and is also controlled by the microprocessor.

Configurations for Devices Under Test (DUT)

Connect the Tester to the NIBPM unit with the tubing and fittings (part number

2391882) supplied with the Tester in the desired configurations, as shown in

Figures 3-2 through 3-6.

Basically, configurations involve connecting the NIBPM unit to the Tester directly

or connecting the unit, a cuff, and the Tester, using a “T” connector. When

connected properly, the tubing forms a closed system with the components.

BP Pump 2

NON-INVASIVE BLOOD PRESSURE MONITOR ANALYZER

Single Hose: Internal Cuff

NIBP Monitor

3-4

120

93

80

80

TESTS AND SIMULATIONS

PRESSURE

LEAK

1

STANDARD BP

4

RESPIRITORY

ARTIFACT

7

PRESSURE

RELIEF

2

PATIENT

CONDITIONS

5

NEONATE

8

USER DEFINED

0

S

TA

TIC

PRESSURE

3

ARRHYTHMIAS

6

WRIST

9

Figure 3-2.Connecting Tester to Single-hose NIBP Monitor

(Int Cuff)

PRESSURE PO

ENT

R

T

fas16.eps

Page 41

Operation

Introduction

BP Pump 2

Double Hose: Internal Cuff

NIBP Monitor

120

80

93

80

Figure 3-3. Connecting Tester to Double-hose NIBP Monitor

(Int Cuff)

Single Hose: External Cuff

NON-INVASIVE BLOOD PRESSURE MONITOR ANALYZER

TESTS AND SIMULATIONS

PRESSURE

LEAK

STANDARD BP

4

RESPIRITORY

ARTIFACT

1

7

S

T

A

T

PR

E

S

S

U

R

E

PR

E

S

S

R

E

L

IE

F

3

2

PATIENT

CONDITIONS

ARRHYTHMIAS

6

5

NEONATE

WRIST

8

9

USER DEFINED

0

BP Pump 2

NON-INVASIVE BLOOD PRESSURE MONITOR ANALYZER

IC

U

R

E

PRE

SS

URE

PORT

3

E

N

T

fas17.eps

NIBP Monitor

PRESSURE PO

ENT

R

T

120

93

80

80

Wrap Cuff

around Mandrel

TESTS AND SIMULATIONS

PRESSURE

LEAK

1

STANDARD BP

4

RESPIRITORY

ARTIFACT

7

PRESSURE

RELIEF

2

PATIENT

CONDITIONS

5

NEONATE

8

USER DEFINED

0

S

TA

PRESSURE

3

ARRHYTHMIAS

6

WRIST

9

TIC

Cuff

fas18.eps

Figure 3-4. Connecting Tester to Single-hose NIBP Monitor

(Ext Cuff)

3-5

Page 42

BP Pump 2

Operators Manual

Double Hose: External Cuff

BP Pump 2

NON-INVASIVE BLOOD PRESSURE MONITOR ANALYZER

NIBP Monitor

120

93

80

80

Wrap Cuff

around Mandrel

TESTS AND SIMULATIONS

PRESSURE

LEAK

1

STANDARD BP

4

RESPIRITORY

ARTIFACT

7

PR

E

S

S

R

E

L

IE

2

PATIENT

CONDITIONS

5

NEONATE

8

USER DEFINED

0

S

U

R

E

PR

F

ARRHYTHMIAS

WRIST

Cuff

Figure 3-5. Connecting Tester to Double-hose NIBP Monitor

(Ext Cuff)

BP Pump 2

Single Hose: External Wrist Cuff

NIBP Monitor

120

93

80

Wrist Cuff

80

NON-INVASIVE BLOOD PRESSURE MONITOR ANALYZER

TESTS AND SIMULATIONS

PRESSURE

PR

E

S

S

U

R

E

LEAK

R

E

L

IE

F

1

2

PATIENT

CONDITIONS

STANDARD BP

5

4

RESPIRITORY

NEONATE

ARTIFACT

7

8

USER DEFINED

0

T

A

TIC

E

S

S

U

R

E

3

6

9

S

PR

E

ARRHYTHMIAS

WRIST

E

N

T

PRESSURE

PORT

fas19.eps

E

N

T

T

A

T

IC

S

S

U

R

E

3

6

9

PRESSURE PORT

Bladder Wrist Mandrel

Be sure to attach the cuff so that the bladder is centered over the notch in the

mandrel insert.

Figure 3-6. Connecting Tester to Single-hose NIBP Wrist Monitor

(Ext Cuff)

3-6

fas20.eps

Page 43

Operation

Pressure Tests

3

Conversion Factors

Conversion factors for the Tester are shown in Table 3-1.

Table 3-1. Conversion Factors

Units mmHg

PSI_PER_MMHG 0.019337

CMH2O_PER_MMHG 1.3595

INH2O_PER_MMHG 0.53525

KPA_PER_MMHG 0.13332

Initializing Tests and Simulations

You can access functions of the Tester in two ways:

• Exclusive use of soft keys, the row of up arrow keys just below the display

• Combined use of the number keys and soft keys

For example, you may access a Pressure Source test as follows:

Soft keys only:

PRESSURE TESTS C STATIC PRESSURE C GAUGE C

SOURCE

Combined:

3 STATIC PRESSURE C GAUGE C SOURCE

Either method is acceptable, and it is assumed that you will develop your own,

most effective way of using the keys.

Error Messages

If you encounter any repeatable error messages, contact your Fluke Biomedical

Service Center.

Pressure Tests

The following tests assess the integrity and accuracy of the Tester, as well as the

instrument under test.

3-7

Page 44

BP Pump 2

Operators Manual

All tests begin from the Main menu:

Fluke Biomedical BP Bump 2

PERFORM

SIMULATION

PRESSURE

TESTS

AUTO

SEQUENCE

SETUP

fas31.eps

After pressing the PRESSURE TESTS soft key to display the Pressure Tests

menu, you can access the pressure tests described below:

PRESSURE

LEAK TEST

PRESSURE

RELIEF

STATIC

PRESSURE

fas35.eps

Pressure Leak Test

The Pressure Leak Test pressurizes a pneumatic system to an operator-defined

target pressure (labeled Setpoint) up to 400 mmHg (53.3 kPa) and then measures

the loss of pressure over time.

To assess leakage, take the following actions:

1. Define the Setpoint by using the soft keys to follow the menu path shown

below.

PRESSURE TESTS C PRESSURE LEAK TEST C SETUP

The Leak Test (Setpoint) screen appears.

Leak Test

Setpoint: 250

fas41.eps

2. Adjust the Setpoint by entering numbers with the number keys. The cursor

moves to the next position after a number is entered

3-8

Page 45

Operation

Pressure Tests

3

Note

Once defined, the Setpoint can be changed in increments of 1 least

significant digit (LSD).

3. Press ENT to display the Leak Test screen.

Leak Test

Cuff: External

CUFF SETUP VENT<START>

Leak Rate: _._ _

Setpoint: 250

Measured: 0

4. Press the VENT soft key to release any unwanted pressure in the system

before performing the test. This feature vents the system for approximately

five seconds and can be repeated as needed to return pressure to zero.

5. Press the <START> soft key to make the Tester deliver air to the system.

Once the system under test reaches the target pressure, the test begins. The

pressure leak rate of the system and the current system pressure are shown

during the test. The leak rate is expressed in mmHg/min by default or can

appear in kPa/min, cmH

O/min, inH2O/min, or psi/min, depending on the

2

pressure measurement unit selection. The leak rate of the Tester is < 2

mmHg/minute.

Note

When testing with an NIBP monitor in the system, it is necessary to put

the monitor in “Service” mode, because most monitors leave the system

open to the atmosphere.

6. Press HOME to return to the Main menu.

fas01.eps

Pressure Relief Test

The Pressure Relief Test increases the pressure in the pneumatic system until the

relief valve on the NIBP monitor opens, or until the Setpoint is reached, whichever

occurs first.

3-9

Page 46

BP Pump 2

Operators Manual

Note

Put the NIBP monitor in “Calibrate” or “Service” mode to close the vent

valve, allowing the Tester to inflate the pneumatic system. Refer to the

NIBP monitor’s service manual to find the method for entering “Service”

mode.

To assess the effectiveness of the relief valve, do the following:

1. Use the soft keys to follow the menu path shown below.

PRESSURE TESTS C PRESSURE RELIEF C SETUP

The Relief Valve Test (Setpoint) screen appears.

Relief Valve Test

Setpoint: 380 mm Hg

fas02.eps

2. If necessary, adjust the Setpoint, which defaults to 380 mmHg, by entering

numbers with the number keys. The cursor moves to the next position after a

number is entered.

3. Press ENT to display the Relief Valve Test screen.

Relief Valve Test

Peak : _._ _

Setpoint : 380

Measured : 0

SETUP VENT<START>

mm Hg

mm Hg

mm Hg

fas03.eps

4. Press the VENT soft key to release any unwanted pressure in the system

before performing the test. This feature vents the system for approximately

five seconds and can be repeated as needed to return pressure to zero.

5. Press the <START> soft key to make the Tester deliver air to the system.

While the Tester is delivering air to the system, the current pressure

(Measured) and peak pressure are being monitored.

If the Setpoint is reached and the monitor does not release the pressure, the

message No Relief Detected appears on the display.

3-10

Page 47

Operation

Pressure Tests

Note

It is recommended that three pressure relief measurements be taken to

check for a sticky relief valve.

Some NIPB monitors do not allow access to a “Service” mode, rendering

it impossible to close a vent valve so that the system can be pressurized

by an outside pump. As a last resort, it is possible to start a blood

pressure determination with the monitor (this closes the valve), then start

the Pressure Relief tests, so that two pumps inflate the system. The results

can vary, but the monitor generally opens a relief valve at some high

pressure.

6. Press HOME to return to the Main menu.

3

Pressure Source Test

The Pressure Source Test enables the Tester to simultaneously generate and

measure pressure.

The Pressure Source Test can be used for static calibration of Non-Invasive blood

pressure monitoring systems, checking sphygmomanometers, and evaluating any

medical device that measures pressure in the ranges of 50 to 400 mmHg (6.7 to

53.3 kPa). Pressures can be generated in 1-mmHg (0.1 kPa) increments.

To perform a Pressure Source test, do the following:

1. Use the soft keys to follow the menu path shown below.

PRESSURE TESTS C STATIC PRESSURE C SOURCE C SETUP

The Pressure Source (Setpoint) screen appears.

Pressure Source

2. If necessary, adjust the Setpoint, which defaults to 200 mmHg, by entering

numbers with the number keys. The cursor moves to the next position after a

number is entered.

3. Press ENT to display the Pressure Source screen.

3-11

Setpoint: 200 mm Hg

fas04.eps

Page 48

BP Pump 2

Operators Manual

Pressure Source

GAUGE SETUP VENT<START>

Measured : 0.4

Setpoint : 200

mm Hg

mm Hg

fas05.eps

4. Press the VENT soft key to release any unwanted pressure in the system

before performing the test. This feature vents the system for approximately

five seconds and can be repeated as needed to return pressure to zero.

5. Press the <START> soft key to make the Tester deliver air to the system. The

Tester pressurizes the system within 10 mmHg of the Setpoint value.

Note

Once the Setpoint has been reached, the Tester will not maintain the

pressure in the system. Therefore, it is recommended that the system be

checked for leaks prior to performing any static pressure tests.

6. Press HOME to return to the Main menu.

Pressure Gauge Test

The Pressure Gauge Test enables the Tester to measure static pressure generated

by an external source in the range of 0 to 400 mmHg (0 to 53.3 kPa).

To measure static pressure, take the following actions:

1. Use the soft keys to follow the menu path shown below.

PRESSURE TESTS C STATIC PRESSURE

The Pressure Gauge screen appears.

Pressure Guage

SOURCE VENT

Measured: 0 0.4 mm Hg

2. Press the VENT soft key to release any unwanted pressure in the system

before performing the test. This feature vents the system for approximately

five seconds and can be repeated as needed to return pressure to zero.

3-12

fas06.eps

Page 49

Operation

Simulations

3

Note

The <START> soft key is not applicable to the pressure gauge test and

does not display.

3. Apply pressure to the pressure port and read the displayed pressure in the

upper right corner of the screen.

Note

You can use a squeeze bulb or syringe to apply adequate pressure.

4. Press HOME to return to the Main menu.

Simulations

The following sections describe various simulations that the Tester accomplishes.

For all of the following tests, it is important to select the correct cuff.

To perform simulations, take the following actions:

1. Power on the NIBP unit.

Note

Either disable the alarm or be prepared to silence it when it sounds.

2. Use the soft keys, beginning from the Main menu:

Fluke Biomedical BP Bump 2

PERFORM

SIMULATION

PRESSURE

TESTS

AUTO

SEQUENCE

SETUP

fas31.eps

3. Press the PERFORM SIMULATION soft key to access the Select

Simulation Type menu. From this menu, you can access the simulations

described below:

3-13

Page 50

BP Pump 2

Operators Manual

Select Simulation Type

STANDARD

BP

PATIENT

CONDITION ARRHYTHMIA

MORE*

4. Press the MORE soft key on this and the following screens for additional

options:

Select Simulation Type

RESPIRATORY

ARTIFACTS

USER

DEFINED NEONAT E

MORE*

Select Simulation Type

WRIST

MORE*

Note

Alternatively, you can access all of the simulations from the number keys,

which is the method described in this section.

fas32.eps

fas33.eps

fas34.eps

Standard BP

The Tester provides many variations of NIBP simulations for both arm and wrist

cuffs.

To perform Standard BP tests, do the following:

1. Access these simulations by pressing the 4 STANDARD BP number key.

The Standard BP screen appears.

3-14

Page 51

Operation

Simulations

3

Standard BP

Preset # 1

Cuff: External

OPTIONS CUFF

ready ....

120/ 80 (93)

80 BPM 0.68 cc

2. Press the OPTIONS soft key to scroll through the simulation choices.

Parameters for Standard BP simulations are shown in Table 3-2.

Table 3-2. Standard Blood Pressure Simulations

Simulation

Number

1 120/80 (93) 80 0.68

2 150/100 (116) 80 0.65

3 200/150 (166) 80 0.60

4 255/195 (215) 80 0.55

5 60/30 (40) 80 0.75

6 80/50 (60) 80 0.71

7 100/65 (76) 80 0.69

Blood Pressure

(mmHg) (MAP)

Heart Rate (bpm)

Pulse volume

(cc)

fas07.eps

3. Press the CUFF soft key to select Internal Adult or External cuff.

4. Press Start on the NIBP unit.

5. Compare values on the NIBP unit with those on the Tester.

6. Press HOME to return to the Main menu.

Patient Conditions

The Patient Condition simulations are intended to provide some basic patient

variations.

To perform Patient Conditions simulations, do the following:

1. Access these simulations by pressing the 5 PATIENT CONDITIONS key.

The Patient Condition screen appears.

3-15

Page 52

BP Pump 2

Operators Manual

Patient Condition

Healthy

Cuff: External

OPTIONS CUFF

ready ....

120/ 80 (93)

75 BPM 0.68cc

fas08.eps

2. Press the OPTIONS soft key to scroll through the simulation choices.

Parameters for Patient Condition simulations are shown in Table 3-3.

Table 3-3. Patient Condition Simulations

Patient Condition

Healthy Heart 120/80 (93) 75 0.68

Weak Pulse 110/80 (90) 95 0.50

Mild Exercise #1 140/90 (106) 120 1.00

Strenuous Exercise #2 140/90 (106) 162 1.40

Obese Subject 120/80 (93) 90 0.50

Geriatric Subject 150/110 (123) 95 0.40

Tachycardia 120/105 (110) 130 0.40

Blood Pressure

(mmHg) (MAP)

Heart Rate

(bpm)

Pulse volume

(cc)

Bradycardia 120/60 (80) 45 1.10

3. Press the CUFF soft key to select Internal Adult or External cuff.

4. Press Start on the NIBP unit.

5. Compare values on the NIBP unit with those on the Tester.

6. Press HOME to return to the Main menu.

Arrhythmias

These waveforms cause erratic readings on some NIBPMs. The blood pressure

determination strongly depends on exactly what is happening with the subject's

blood pressure when the cuff pressure is at a particular level. Some NIBPMs

pause until they detect two or more equivalent beats. The pattern of step deflations

and the measured blood pressure depend on which beats occur during each step of

the cuff pressure.

3-16

Page 53

Operation

Simulations

3

To perform Arrhythmia Simulations, do the following:

1. Access these simulations by pressing the 6 ARRHYTHMIA key. The

Arrhythmia screen appears.

Arrhythmia Simulation

Pre Atrial Cont. 1

Cuff: External

OPTIONS CUFF

ready ....

138/ 53 (81)

80 BPM

2. Press the OPTIONS soft key to scroll through the simulation choices.

Parameters for Arrhythmia simulations are shown in Table 3-4.

Table 3-4. Arrhythmia Simulations

Arrhythmia Type

Premature Atrial Cont. #1 138/53 (81) 80

Premature Atrial Cont. #2 144/64 (90) 83

Premature Ventricular Cont. 118/61 (80) 83

Atrial Fib and PVCs 139/72 (94) 91

Blood Pressure (mmHg)

(MAP)

Heart Rate

(bpm)

3. Press the CUFF soft key to select Internal Adult or External cuff.

4. Press Start on the NIBP unit.

5. Compare values on the NIBP unit with those on the Tester.

fas09.eps

6. Press HOME to return to the Main menu.

3-17

Page 54

BP Pump 2

Operators Manual

Respiratory Artifacts

The Respiratory Artifact exhibits a beat-to-beat variation in the blood pressure

caused by intra-thoracic pressure. Changes in the intra-thoracic pressure affect

filling of the ventricles during diastole. This in turn affects the stroke volume of

the heart. A large stroke develops a higher systolic pressure than a small stroke.

To perform Respiratory Artifact simulations, do the following:

1. Access these simulations by pressing the 7 RESPIRATORY ARTIFACT

key. The Respiratory Artifact screen appears.

Respiratory Artifact

Spont Breath # 1

Cuff: External

OPTIONS CUFF

ready ....

138/ 65 (89)

104 BPM

2. Press the OPTIONS soft key to scroll through the simulation choices.

Parameters for Respiratory Artifact simulations are shown in Table 3-5.

Table 3-5. Respiratory Artifact Simulations

Blood

Artifact Type

Spontaneous Breathing #1 138/65 (89) 104 Varies

Spontaneous Breathing #2 149/65 (93) 105 Varies

Spontaneous Breathing #3 112/47 (68) 86 Varies

Controlled Ventilation 132/44 (73) 98 Varies

Pressure

(mmHg) (MAP)

Heart Rate

(bpm)

Pulse

volume (cc)

3. Press the CUFF soft key to select Internal Adult or External cuff.

4. Press Start on the NIBP unit.

5. Compare values on the NIBP unit with those on the Tester.

fas11.eps

6. Press HOME to return to the Main menu.

3-18

Page 55

Operation

Simulations

3

Neonate

The Neonate simulations are provided to test the ability of the NIBP monitors to

detect blood pressure on neonatal patients.

To perform Neonate simulations, do the following:

1. Access these simulations by pressing the 8 NEONATE key. The Neonate

Simulation screen appears.

Neonate Simulation

Neonate # 1

Cuff: Internal Neonate

OPTIONS CUFF

ready ....

35/ 15(22)

120 BPM 0.11 cc

2. Press the OPTIONS soft key to scroll through the simulation choices.

Parameters for Neonate simulations are shown in Table 3-6.

Table 3-6. Neonate Simulations

Simulation

Number

1 35/15 (22) 120 0.11

2 60/30 (40) 120 0.10

3 80/50 (60) 120 0.10

4 100/70 (80) 120 0.10

Blood Pressure

(mmHg) (MAP)

Heart Rate (bpm)

Pulse volume

(cc)

3. Press the CUFF soft key to select External or Internal Neonate.

4. Press Start on the NIBP unit.

5. Compare values on the NIBP unit with those on the Tester.

fas12.eps

6. Press HOME to return to the Main menu.

3-19

Page 56

BP Pump 2

Operators Manual

Wrist

The Wrist simulations are provided to test wrist cuff NIBP monitors.

To perform Wrist simulations, do the following:

1. Access these simulations by pressing the 9 WRIST key. The Wrist

Simulation screen appears.

Wrist Simulation

WristCuff # 1

Cuff: External

OPTIONS

ready ....

120/ 80 (93)

80 BPM 0.50 cc

fas13.eps

2. Press the OPTIONS soft key to scroll through the simulation choices. The

simulation is automatically set up to use the external cuff and cannot be

changed. Parameters for Wrist simulations are shown in Table 3-7.

Table 3-7. Wrist Simulations

Simulation

Number

Blood Pressure

(mmHg) (MAP)

Heart Rate (bpm)

Pulse volume

(cc)

1 120/80 (93) 80 0.50

2 160/100 (120) 80 0.50

3 80/55 (63) 80 0.50

7. Press Start on the NIBP unit.

8. Compare values on the NIBP unit with those on the Tester.

9. Press HOME to return to the Main menu.

3-20

Page 57

Operation

Auto Sequences

3

User-Defined

User-Defined simulations and how to create them are described in “Setting Up the

Tester.”

The following describes how to run such a simulation.

1. Select from any of the previously-defined simulations by pressing the 0

USER DEFINED key. The User Defined screen appears.

User Defined

Simulation 1:

Cuff: External

OPTIONS CUFF EDIT

ready ....

120/ 80

75 BPM 0.70 cc

fas15.eps

2. Press the OPTIONS soft key to scroll through the simulation choices.

3. Press the CUFF soft key to select External, Internal Adult, or Internal

Neonate cuff.

Note

It is important to select the correct cuff.

4. Press Start on the NIBP unit.

5. Compare values on the NIBP unit with those on the Tester.

6. Press HOME to return to the Main menu.

Auto Sequences

It is possible to create up to nine customized auto sequences. An auto sequence

contains all four pressure tests and five simulations. The operator can disable any

of these tests or simulations. A printout of the auto sequence result can also be

enabled. The operator must make a cuff selection; this determines what NIBP

simulations are displayed for that selection.

3-21

Page 58

BP Pump 2

Operators Manual

Editing Auto Sequences

Use the following steps to edit an auto sequence:

1. Press the AUTO SEQUENCE soft key to access the Auto Sequence

menu.

Auto Sequence

EDIT PRINTRUN

fas36.eps

2. Press the EDIT soft key.

3. At the Select Auto Sequence prompt, press a numeric key (1-9), followed

by the ENT key. You are prompted to select, enable, or disable each of the

components listed below. Press the ENT key at each of the prompts to

advance to the next selection.

• Print Auto Sequence Result

• Pressure Gauge Test

• Pressure Source Test

• Pressure Leak Test

• Pressure Relief Valve Test

• Cuff Selection

• NIBP Simulations (1-5)

Note

By default, each auto sequence is configured to perform the Leak Test,

Relief Test, and BP Simulation #1 (120/80) Changing the cuff selection

changes the available BP Simulation options.

4. When finished, either press the RUN soft key to run the sequence or press

HOME to return to the Main menu.

3-22

Page 59

Operation

Auto Sequences

3

Printing Auto Sequences

Use the following steps to print an auto sequence definition.

Note

Refer to ‘Setting up the Tester” for printer output setup instructions.

1. To determine which tests and simulations are defined in an auto sequence,

press the AUTO SEQUENCE soft key to access the Auto Sequence menu.

Auto Sequence

EDIT PRINTRUN

2. Press the PRINT soft key. The Select Auto Sequence (1-9) screen

appears.

Select Auto Sequence: 1

3. Press a numeric key (1-9), followed by the ENT key.