Page 1

PPC2+ BG0002

Operation and Maintenance Manual

(Use with PPC2+ Operation

and Maintenance Manual)

©2001 DH Instruments, Inc.

Page 2

PPC2+ BG0002 Operation and Maintenance Manual

High pressure liquids and gases are potentially hazardous. Energy stored in these liquids and gases can

be released unexpectedly and with extreme force. High pressure systems should be assembled and

operated only by personnel who have been instructed in proper safety practices.

© 2001 DH Instruments, Inc. All rights reserved.

Information in this document is subject to change without notice. No part of this document may be reproduced or

transmitted in any form or by any means, electronic or mechanical, for any purpose, without the express written

permission of DH Instruments, Inc. 4765 East Beautiful Lane Phoenix AZ 85044-5318 USA.

DH Instruments makes sincere efforts to ensure accuracy and quality of its’ published materials; however, no

warranty, expressed or implied, is provided. DH Instruments disclaims any responsibility or liability for any direct or

indirect damages resulting from the use of the information in this manual or products described in it. Mention of any

product or brand does not constitute an endorsement by DH Instruments of that product or brand. This manual was

originally composed in English and was subsequently translated into other languages. The fidelity of the translation

cannot be guaranteed. In case of conflict between the English version and other language versions, the English

version predominates.

DH Instruments, DH, DHI, PPC2+ and CalTool are trademarks, registered and otherwise, of DH Instruments, Inc.

Swagelok is a registered trademark of the Swagelok Company

Document No. 550124

20010403

Printed in the USA.

©2001 DH Instruments, Inc.

Page 3

PPC2+ BG0002 Operation and Maintenance Manual

T

AABBLLEE O

T

TABLE OF CONTENTS ................................................................................i

TABLES ...................................................................................................iii

FIGURES .................................................................................................iii

ABOUT THIS MANUAL ..............................................................................iv

1. INTRODUCTION .................................................................................... 1

1.1 PRODUCT OVERVIEW............................................................................................................................. 1

1.2 SPECIFICATIONS..................................................................................................................................... 2

2. INSTALLATION .....................................................................................5

2.1 UNPACKING AND INSPECTION.............................................................................................................. 5

2.2 SITE REQUIREMENTS............................................................................................................................. 6

2.3 INITIAL SETUP ......................................................................................................................................... 6

1.2.1 GENERAL SPECIFICATIONS........................................................................................................................2

1.2.2 PRESSURE MEASUREMENT SPECIFICATIONS.........................................................................................2

1.2.3 PRESSURE CONTROL SPECIFICATIONS................................................................................................... 3

2.1.1 REMOVING FROM PACKAGING .................................................................................................................. 5

2.1.2 INSPECTING CONTENTS ............................................................................................................................. 5

2.3.1 PREPARING FOR OPERATION.................................................................................................................... 6

2.3.2 POWER CONNECTION................................................................................................................................. 7

2.3.3 CONNECTING A PRESSURE SUPPLY (SUPPLY PORT) ............................................................................7

2.3.4 CONNECTING A VACUUM PUMP (EXHAUST PORT).................................................................................. 7

2.3.5 CONNECTING TO THE DEVICE UNDER TEST (TEST(+) AND TEST(-) PORTS) ........................................ 8

2.3.6 THE VENT CONNECTION (VENT PORT)......................................................................................................9

2.3.7 THE ATM REF PASS THROUGH (UNLABELED) .........................................................................................9

INSTALLING THE SPLT ................................................................................................................ 9

2.3.5.1

OFF

C

C

O

O

NTTEE

N

NTTSS

N

3. OPERATION........................................................................................ 11

3.1 VENT ....................................................................................................................................................... 11

3.2 CUSTOM CONTROL............................................................................................................................... 11

3.3 UPPER LIMIT .......................................................................................................................................... 11

3.4 SETUP MENU KEY................................................................................................................................. 12

3.5 SPECIAL MENU KEY ............................................................................................................................. 13

4. REMOTE OPERATION.......................................................................... 17

4.1 OVERVIEW ............................................................................................................................................. 17

Page i ©2001 DH Instruments, Inc.

3.3.1 OVERPRESSURE FUNCTION ....................................................................................................................12

3.4.1 CONTROLREF.............................................................................................................................................12

3.5.1 INTERNAL, RESET...................................................................................................................................... 13

3.5.2 VALVE ......................................................................................................................................................... 13

3.5.2.1 BYPASS....................................................................................................................................... 14

3.5.2.2 TEST(-) VENT.............................................................................................................................. 14

3.5.3 INTERNAL, ATM.......................................................................................................................................... 15

Page 4

PPC2+ BG0002 Operation and Maintenance Manual

5. MAINTENANCE, ADJUSTMENTS AND CALIBRATION ............................. 19

5.1 CALIBRATION OF REFERENCE PRESSURE TRANSDUCERS .......................................................... 19

5.2 ADJUSTMENT OF ON-BOARD BAROMETER...................................................................................... 21

5.3 PNEUMATIC CONTROL MODULE CONFIGURATION ......................................................................... 21

5.4 SUBASSEMBLY DESCRIPTION AND LOCATION................................................................................ 23

5.1.1 PRINCIPLE .................................................................................................................................................. 19

5.1.2 EQUIPMENT REQUIRED ............................................................................................................................ 20

5.1.3 SET-UP AND PREPARATION .....................................................................................................................20

6. TROUBLESHOOTING........................................................................... 25

6.1 OVERVIEW ............................................................................................................................................. 25

©2001 DH Instruments, Inc. Page ii

Page 5

PPC2+ BG0002 Operation and Maintenance Manual

T

AABBLLEES

T

Table 1. Default Pressure Control Parameters ........................................................................................ 3

Table 2. PPC2+ Packing List ...................................................................................................................5

Table 3. System Default Control Limits..................................................................................................11

Table 4. Troubleshooting Guide.............................................................................................................25

G

F

IIG

F

Figure 1. Pneumatic Module (Schematic) ...............................................................................................23

URREESS

U

S

Page iii ©2001 DH Instruments, Inc.

Page 6

PPC2+ BG0002 Operation and Maintenance Manual

O

A

BBO

A

This manual is designed to be used in conjunction with the PPC2+ Operation and Maintenance

Manual (Document Number 550091). It contains information specific to the BG0002 model of PPC2+

Pressure Controller/Calibrator.

PPC2+ BG0002 is identical in conception and most features to other PPC2+ models. PPC2+ BG0002

is a specialized PPC2+ model designed to optimize very low gauge pressure performance.

This manual covers the aspects of PPC2+ BG0002 that differ from other PPC2+ models.

To operate a PPC2+ BG0002, use the PPC2+ Operation and Maintenance Manual (Document

Number 550091) and follow the instructions and information. Refer to this manual for details on

BG0002 specifications, installation and set up, pneumatic schematic differences, and [SPECIAL],

<5Valves> operation. PPC2+ BG0002 is normally used in conjunction with accessory package

PK-PPC-BG-DVU (P/N 401699). This package is delivered with its own instruction sheet.

UTT

U

HIISS

T

H

T

M

M

N

AAN

UAALL

U

Manual Conventions

(CAUTION) is used in throughout the manual to identify user warnings and cautions.

(NOTE) is used throughout the manual to identify operating and applications advice and

additional explanations.

[ ] indicates direct function keys (e.g., [RANGE]).

< > indicates PPC2+ BG0002 screen displays (e.g., <1yes>).

©2001 DH Instruments, Inc. Page iv

Page 7

PPC2+ BG0002 Operation and Maintenance Manual

1. INTRODUCTION

1.1 PRODUCT OVERVIEW

PPC2+ BG0002 is a special model of the PPC2+ line of pressure controller/calibrators.

PPC2+ BG0002 is identical to other PPC2+ models except for:

1) Use of a special low pressure “bi-directional gauge” reference pressure transducer (RPT).

2) This model has only one RPT. It does not support dual RPTs.

3) Inclusion and control of two additional internal control valves (a TEST(+)/TEST(-) bypass and a

TEST(-) vent) with local and remote control capabilities for both.

4) Special recalibration recommendations for the very low pressure, bi-directional gauge RPT.

PPC2+ BG0002 is normally used in combination with accessory package PK-PPC-BG-DVU

(P/N 401699) which includes two thermally isolated volumes installed in the test line to improve

control stability. This package is delivered with its own instruction sheet.

Once a PPC2+ BG0002 has been put into service, its operation is identical to other PPC2+ models.

This manual is intended to be used as a supplement to the PPC2+ Operation and Maintenance Manual

(Document Number 550091). To operate a PPC2+ BG0002, use the PPC2+ Operation and

Maintenance Manual and refer to this manual for aspects specific to the BG0002 model. These are

primarily the operating specifications, installation and use recommendations,

recalibration recommendations.

Page 1 ©2001 DH Instruments, Inc.

Page 8

PPC2+ BG0002 Operation and Maintenance Manual

1.2 SPECIFICATIONS

1.2.1 GENERAL SPECIFICATIONS

Specifications below are specific to PPC2+ BG0002. All other specifications are identical to

PPC2+ specifications found in the PPC2+ Operation and Maintenance Manual (Document

Number 550091).

Weight: 12.8 kg (28.2 lb)

Pressure Ranges: PPC2+ BG0002 has three pressure ranges:

H3: -15 to +15 kPa (-2.2 to +2.2 psi)

H2: -10 to +10 kPa (-1.5 to +1.5 psi)

H1: -5 to +5 kPa (-0.8 to +0.8 psi)

Pressure Limits: Line Pressure (min/max low side): 80 to 110 kPaa (11.6 to 16 psia)

Maximum/Minimum Working Test Pressure: +15/-15 kPa (+2.2/-2.2 psi)

Maximum/Minimum Test Pressure without Damage: +16.5/-16.5 kPa

(+2.4/-2.4 psi)

Required Supply Pressure: SUPPLY port: 70 kPa gauge (10 psi)

EXHAUST port: Vacuum of 70 kPaa (10 psia) or less

with displacement of at least 90 lm (3 cfm)

1.2.2 PRESSURE MEASUREMENT SPECIFICATIONS

All values are ± span of the active range unless otherwise indicated.

Warm Up Time: 30 minutes recommended for RPT temperature stabilization

Resolution: To 1 ppm, user settable by individual range

Temperature Effect: Fully compensated with active independent temperature measurement

from 10 to 40 °C

± 0.005 % maximum temperature effect in normal ambient 15 to 35 °C

operating range

Acceleration Affect: ± 0.02 %/g maximum, worst axis

Allows operation at ± 20° from reference plane without significant effect

1

Precision

Stability (w/ Autozero): 90 day

Measurement Uncertainty

1 Measurement Precision: Combined linearity, hysteresis, repeatability of measurements made by

the reference pressure transducer.

2 Measurement Uncertainty: Maximum deviation of the reference pressure transducer indication from

the true value of measured pressure including precision, stability, temperature effect and calibration

standard accuracy of ± 0.003 % of reading.

: ± 0.008 %

1 year

0.003 % 0.009 %

2

: 90 day 1 year

0.010 % 0.015 %

©2001 DH Instruments, Inc. Page 2

Page 9

PPC2+ BG0002 Operation and Maintenance Manual

1.2.3 PRESSURE CONTROL SPECIFICATIONS

All values are ± span of the active range unless otherwise indicated. Control specifications

assume that a PK-PPC-BG-DVU dual volume unit is installed on the TEST lines and that a

vacuum is applied to the PPC2+ BG0002 EXHAUST port.

Modes and Ready

Indication:

Control

Parameters:

Static: Sets pressure within hold limit and stops active control until hold

limit is exceeded

Pressure is Ready when within hold limit and stability test is met

Dynamic: Sets pressure within hold limit and continuously adjusts as close as

possible to target

Pressure is Ready when within hold limit

Hold limit, stability limit (optimum values set by default, can be customized

independently for each measurement range)

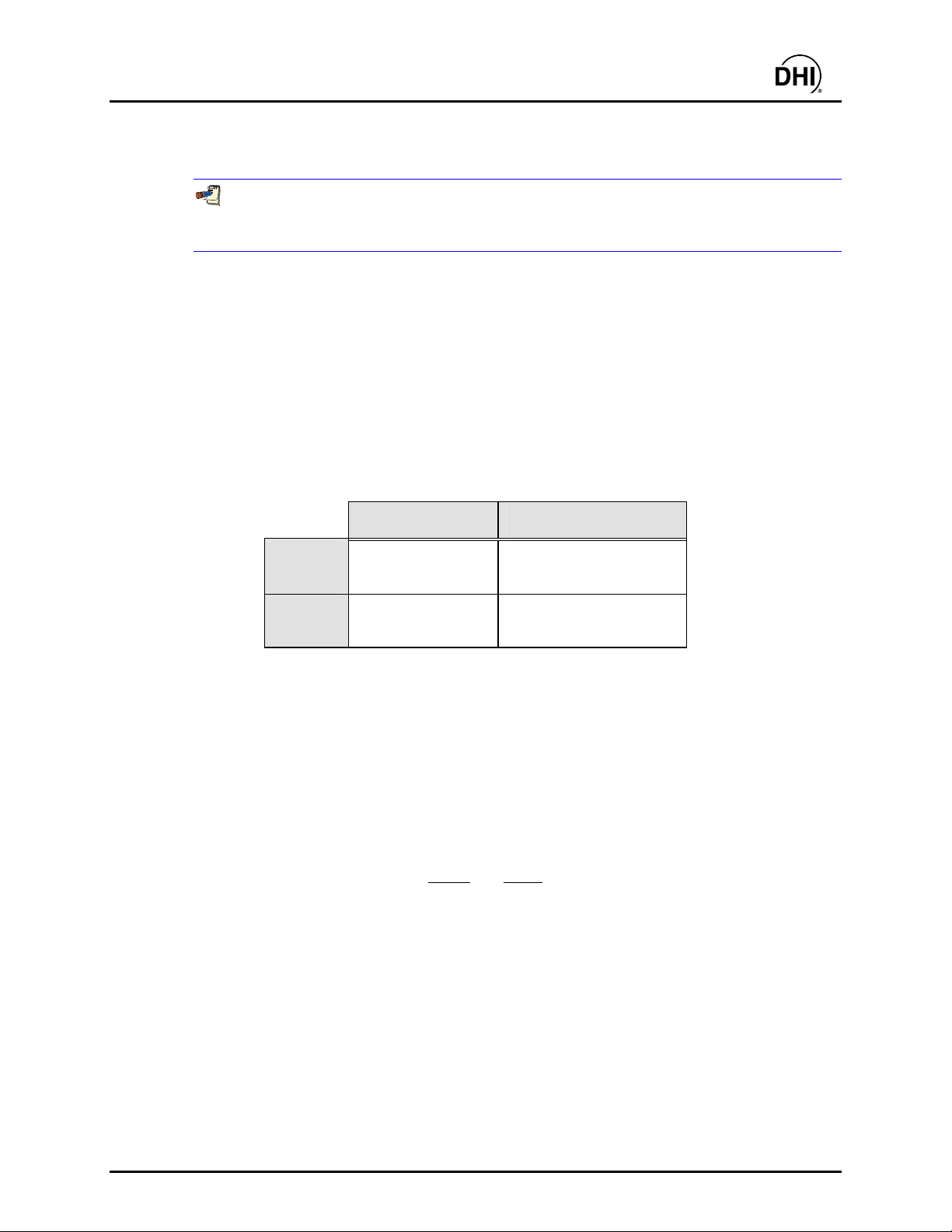

Table 1. Default Pressure Control Parameters

HOLD LIMIT STABILITY LIMIT

STATIC

MODE

DYNAMIC

MODE

± 0.5 % of the active

pressure span

± 0.0025 % FS of the

active pressure span

± 0.0025 % FS/sec of the

active pressure span

± 0.0025 % FS of the

active pressure span

Maximum Control Precision1: ± 0.001 %

Normal Test Volume (in addition to

system volume):

0 to 1 000 cc (250 cc optimal)

System volume includes PPC2+ internal volume and the

PK-PPC-BG-DVU in-line volume of 840 cc

Control Speed: Slew Rate (0 to Controller FS) in

Optimal Volume with No Control: 10 to 15 seconds

Pressure Setting (Typical Time To

Ready Indication in Dynamic Mode): 30 seconds

Minimum Control Pressure: None

Delivered Pressure Uncertainty

2

:

90 day

1 year

0.010 0.015 %

1 Maximum Control Precision: Minimum useable hold limit in dynamic control mode.

2 Delivered Pressure Uncertainty: Maximum deviation from the true value of pressure applied to the

device under test in dynamic control mode with default control limits and assuming measurement

uncertainty as in Section 1.2.2.

Page 3 ©2001 DH Instruments, Inc.

Page 10

PPC2+ BG0002 Operation and Maintenance Manual

N

N

OOTTEES

S

©2001 DH Instruments, Inc. Page 4

Page 11

PPC2+ BG0002 Operation and Maintenance Manual

2. INSTALLATION

2.1 UNPACKING AND INSPECTION

2.1.1 REMOVING FROM PACKAGING

PPC2+ BG0002 is delivered in a custom corrugated container with high density polyethylene

inserts to hold it in place; or in the optional molded polyethylene shipping case with a custom

foam insert for holding the PPC2+ and SPLT (if included).

Remove the PPC2+ and its accessories from the shipping container and remove each

element from its protective plastic bag.

2.1.2 INSPECTING CONTENTS

Check that all items are present and have NO visible damage.

Table 2. PPC2+ Packing List

DESCRIPTION PART NO.

PPC2+ BG0002 Pressure Controller/Calibrator 401696 or 401696-CE

Calibration Certificate 550100

Test Report 550103

Accessories: 401702 or 401702-CE

PPC2+ Operation and Maintenance Manual 550091

PPC2+ BG0002 Operation and Maintenance Manual 550124

Power Cord (7.5 ft.) 100770 or 100770-CE

(6) Rubber Feet Caps 400203

General Accessories Disk (Important: Includes

system support software and documentation.)

102987

Page 5 ©2001 DH Instruments, Inc.

Page 12

PPC2+ BG0002 Operation and Maintenance Manual

2.2 SITE REQUIREMENTS

The PPC2+ BG0002 can be installed on any flat, stable surface at a convenient height. The front

feet can be extended so that the unit can be inclined slightly for easier viewing. The PPC2+ BG0002

can also be mounted in a standard 19-in. rack mount using the optional rack mount kit.

Minimizing the length of tubing connecting the PPC2+ BG0002 to the device or system to be

tested will enhance control performance and reduce pressure setting times.

Consider the location and connections to the PK-PPC-BG-DVU dual volume unit. See the

instruction sheet included with the PK-PPC-BG-DVU kit for additional instructions.

Ready access to the PPC2+ BG0002 rear panel should be considered to facilitate making and

breaking pressure connections.

The Self Purging Liquid Trap (SPLT), if used, should be mounted vertically at the low point of the

pneumatic system. The SPLT should be mounted on the TEST(+) line, between the PK-PPC-BGDVU volume connection and the device(s) under test.

Support facilities required include:

• An electrical power source of 85 to 264 VAC, 50/60 Hz.

• A continuous regulated pressure supply of clean, dry, non-corrosive gas at 70 kPa (10 psig) to

be connected to the SUPPLY port.

• A vacuum source of 70 kPaa (10 psia) or less and with displacement of at least 90 lm (3 cfm) to

be connected to EXHAUST port.

2.3 INITIAL SETUP

2.3.1 PREPARING FOR OPERATION

To prepare PPC2+ BG0002 for check out and operation:

• Remove the plastic caps from the PPC2+ BG0002 rear panel pressure connections.

• Remove the protective plastic sheet from the front panel display.

• Install the rubber feet caps onto the bottom case feet, if desired.

• Familiarize yourself briefly with the front and rear panel (see PPC2+ Operation and

Maintenance Manual, Section 2.3.2).

©2001 DH Instruments, Inc. Page 6

Page 13

PPC2+ BG0002 Operation and Maintenance Manual

2.3.2 POWER CONNECTION

• Check that the PPC2+ BG0002 power switch is OFF.

• Connect the supplied power cable to the rear panel power module.

• Connect the other end of the power cable to an electrical supply of 85 to 264 VAC,

50/60 Hz.

2.3.3 CONNECTING A PRESSURE SUPPLY (SUPPLY PORT)

Using a pressure connecting hose of appropriate pressure rating, connect the pressure supply

to the SUPPLY connection on the rear panel of PPC2+ BG0002. The PPC2+ SUPPLY

connection is 1/8 in. NPT female.

The supply pressure should be 70 kPa gauge (10 psig), ± 10 %.

Never connect a pressure supply greater than 100 kPa gauge (15 psig) to the PPC2+ BG0002

supply port.

2.3.4 CONNECTING A VACUUM PUMP (EXHAUST PORT)

For PPC2+ BG0002 to set pressure properly, a vacuum source must be connected to the

EXHAUST port. The vacuum required is 70 kPa absolute (10 psia) or lower with

displacement of at least 90 lm (3 cfm).

Never connect a pressure supply to or plug the PPC2+ BG0002 EXHAUST port.

To avoid building up pressure on the EXHAUST port and/or the vacuum pump, the vacuum

source should either be continuously ON or should bypass to atmosphere when the vacuum

source is OFF. This is because when a supply pressure is applied to the PPC2+ BG0002

SUPPLY port and the PPC2+ BG0002 is NOT in the vent ON condition, there is a constant gas

exhaust through the PPC2+ BG0002 EXHAUST port to which the vacuum source will

be connected.

Page 7 ©2001 DH Instruments, Inc.

Page 14

PPC2+ BG0002 Operation and Maintenance Manual

2.3.5 CONNECTING TO THE DEVICE UNDER TEST (TEST(+) AND

TEST(-) PORTS)

To achieve in tolerance pressure control, PPC2+ BG0002 should be used with the PK-PPC-BG-

DVU dual volume unit installed in line on both the TEST(+) and TEST(-) ports. In some cases,

the PK-PPC-BG-DVU volumes may be omitted if the volume of each side (high and low) of the

system under test exceeds 800 cc.

Install the PK-PPC-BG-DVU dual volume unit in-line between the PPC2+ BG0002 TEST(+)

and TEST(-) ports and the high and low ports of the system or devices under test. See the

PK-PPC-BG-DVU instruction sheet for details.

If you are using an SPLT, see the PPC2+ Operation and Maintenance Manual,

Section 2.3.5.1 and the SPLT Operation and Maintenance Manual before proceeding to

connect to the device or system under test.

The recommended tubing for PPC2+ BG0002 test port connections is 1/4 in. (6 mm) PFA

tubing or any other large internal diameter tubing that will not restrict the flow between the

PPC2+ and the system under test.

For optimal performance it is important that both the TEST(+) and TEST(-) ports of the

PPC2+ be connected to the high and low or positive and negative ports of the device or

system under test. If no connection is available on the low or negative side of the device or

system under test, operation is possible but pressure control and measurement may be

adversely affected by instability of ambient pressure in the environment in which the PPC2+

BG0002 is being operated.

The PPC2+ BG0002 TEST(+) and TEST(-) connections are both 1/4 in. NPT female.

NEVER connect a pressure supply to the TEST(-) port. The pressure applied to this port

should be maintained between 80 and 110 kPa (11.6 and 16 psia) (roughly atmospheric

pressure ± 15 kPa (2.2 psi) depending on your location. Exceeding these limits may damage

the RPT.

Operating the PPC2+ BG0002 connected to a system with liquid contaminants without taking

proper precautions to purge the system and test line may cause contamination of the PPC2+

BG0002 that will require non-warranty service.

Minimizing the length of the test connection tubing will enhance control performance and

reduce pressure setting time. For normal operation, the total volume of each side (high and

low) of the device or system under test (not including the PK-PPC-BG-DVU accessory volumes)

3

should be between 0 and 1 000 cc (60 in

).

PPC2+ BG0002 pressure control will not operate properly if there are excessive leaks in the

test system. In general, the maximum acceptable leak rate for optimal PPC2+ automated

pressure control operation and to assure in tolerance measurements with default pressure

control parameters is ± 1 % of active span FS/minute. In DYNAMIC CONTROL mode, to handle

higher test system leak rates, increase the hold limit using CUSTOM CONTROL (see the PPC2+

Operation and Maintenance Manual, Section 3.2.6).

©2001 DH Instruments, Inc. Page 8

Page 15

PPC2+ BG0002 Operation and Maintenance Manual

PPC2+ BG0002 pressure control may be adversely affected if the test connection tubing is

too restrictive. For optimum results, the inner diameter of the connecting hose should be at

least 2.5 mm (0.1 in.).

For optimum pressure measurement and control, the PPC2+ BG0002 TEST(-) port should be

connected to the system or device under test low or negative port.

2.3.5.1 INSTALLING THE SPLT

The SPLT (optional) is intended to collect and exhaust liquid that may be present in

the device or system under test so that they do not return to contaminate the PPC2+.

With PPC2+ BG0002, the SPLT is installed in the TEST(+) line between the PK-PPCBG-DVU and the system or device under test. No SPLT is needed in the TEST(-) line

as there should be no flow in the TEST(-) circuit. Also see the SPLT Operation and

Maintenance Manual.

2.3.6 THE VENT CONNECTION (VENT PORT)

The PPC2+ BG0002 VENT port is the system vent to atmosphere point. Though a pressure

tube can be connected to the VENT port to direct the vented gas flow, a completely

unobstructed connection to atmosphere must be maintained for PPC2+ reference pressure

measurements to operate normally.

The PPC2+ BG0002 VENT connection is 1/4 in. NPT female.

NEVER plug, obstruct or connect a supply pressure to the PPC2+ vent connection.

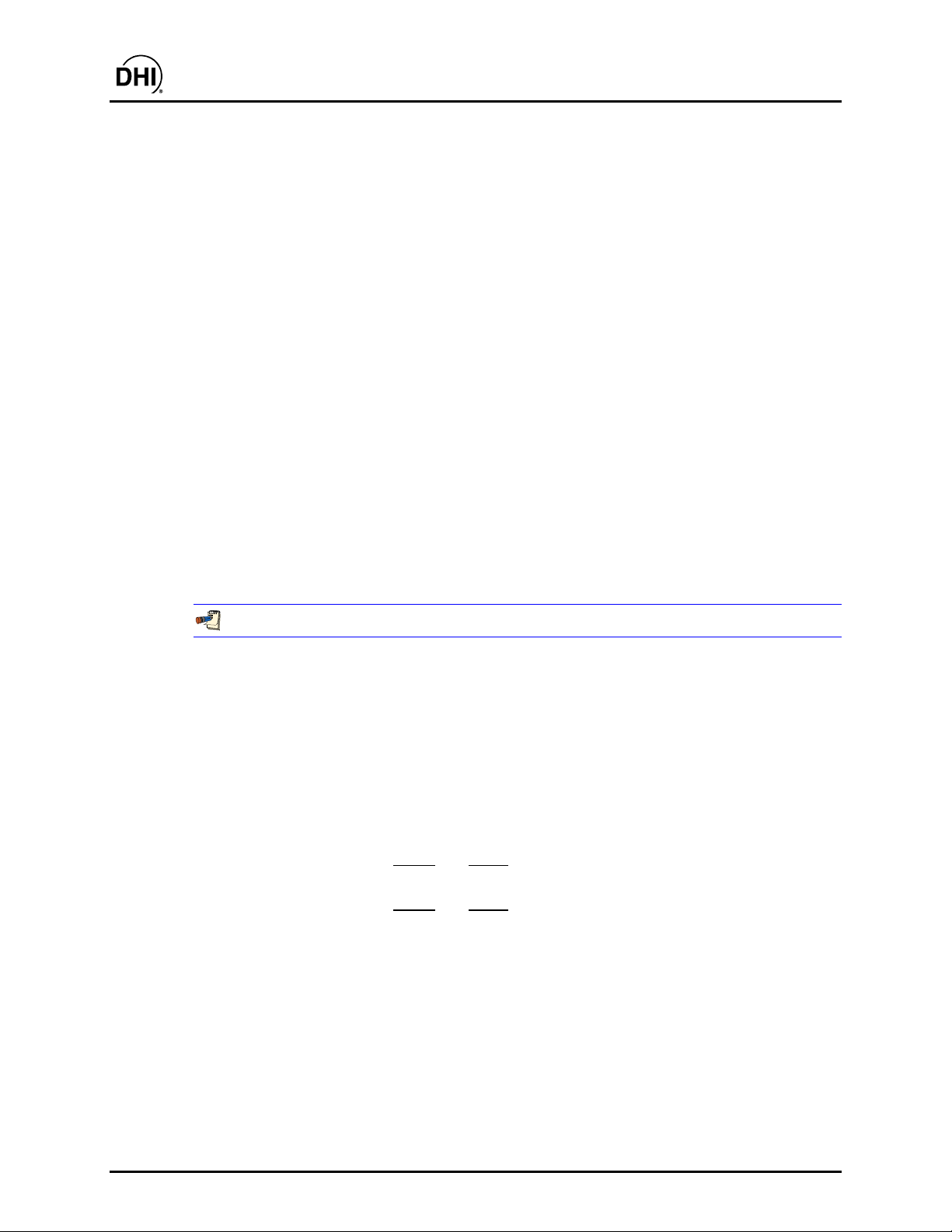

2.3.7 THE ATM REF PASS THROUGH (UNLABELED)

PPC2+ BG0002 does not have an ATM REF pass through. The on-board barometer is

connected to the TEST(-) circuit to measure the pressure on the low side of the RPT (see

Figure 1).

Page 9 ©2001 DH Instruments, Inc.

Page 16

PPC2+ BG0002 Operation and Maintenance Manual

N

N

OOTTEES

S

©2001 DH Instruments, Inc. Page 10

Page 17

PPC2+ BG0002 Operation and Maintenance Manual

3. OPERATION

3.1 VENT

Pressing the [VENT] direct pressure control, sending a remote “VENT” command or requesting zero

as the set pressure causes PPC2+ BG0002 to control pressure to near atmospheric pressure and

then open the system vent, TEST(+)/TEST(-) bypass and TEST(-) vent valves (see Figure 1 and

Section 3.5.2). Vent condition is indicated by lighting a RED LED just above the [VENT] key. All three

valves will remain open until the [VENT] key is pressed again, another direct pressure control key is

pressed or an automated pressure control command is given. Pressing the [VENT] key also causes

the purge function to execute when the PPC2+ LEAK CHECK/PURGE function is active (see the

PPC2+ Operation and Maintenance Manual, Section 3.2.8).

3.2 CUSTOM CONTROL

PPC2+ BG0002 default control limits are different from standard PPC2+ model default control limits.

Table 3. System Default Control Limits

HOLD LIMIT STABILITY LIMIT

STATIC

MODE

DYNAMIC

MODE

± 0.5 % of the active

pressure span

± 0.0025 % FS of the active

pressure span

3.3 UPPER LIMIT

mmmm PRINCIPLE

The PPC2+ BG0002 UPPER LIMIT function differs from other PPC2+ models in that there is both

an UPPER LIMIT and a LOWER limit. This is due to the bi-directional gauge range of the

BG0002 and the possibility of overpressure to the RPT and to devices under test in both the

positive and negative direction.

If no upper limit value is entered by the user, the upper and lower limit for each PPC2+ BG0002

range is set by default to +102 % of each range for the upper limit and –102 % of each range for

the lower limit.

± 0.0025 % FS/sec of the

active pressure span

± 0.0025 % FS of the active

pressure span

Page 11 ©2001 DH Instruments, Inc.

Page 18

PPC2+ BG0002 Operation and Maintenance Manual

mmmm OPERATION

When the [UPPER LIMIT] function key is pressed from the main run screen the display is:

Upper: 2.2000 psi

Lower: -2.2000 psi

1. Entry field to enter desired upper limit value.

2. Entry field to enter desired lower limit value.

Enter the desired upper and lower limit values and PPC2+ returns to the main run screen with

the new limit values active.

When the UPPER or LOWER LIMIT has been exceeded, the display of current pressure flashes

and a buzzer sounds for 3 seconds every 2 seconds. Reduce or increase pressure using direct

pressure control keys or an automated pressure command to return to normal operation.

Upper and lower limit values are specific to each range. Be careful not to assume that the limits

set in one range will apply to another.

3.3.1 OVERPRESSURE FUNCTION

In addition to the UL function, PPC2+ BG0002 has an overpressure function. This function

executes when the measured pressure is greater than +15.75 kPa or less than -17.5 kP

(± 2.3 psi). The overpressure function causes all pressure control to be interrupted and

disabled, opens the TEST(+)/TEST(-) bypass valve (see Section 3.5.2, PRINCIPLE and

Figure 1), changes the range to H3 and causes the display to flash. The overpressure

function also logs the time and date of the overpressure condition to assist in

incident diagnosis. To recover from an overpressure condition, cycle PPC2+ BG0002 power.

3.4 SETUP MENU KEY

3.4.1 CONTROLREF

PPC2+ BG0002 requires that a vacuum source be connected to the EXHAUST port for

pressure control to operate normally. Therefore, the <1ControlRef> setting should always be

<1auto> or <2vac> (see PPC2+ Operation and Maintenance Manual). If you must operate

without a vacuum source connected to the PPC2+ BG0002 EXHAUST port, <1ControlRef>

should be set accordingly but pressure control may not conform to specifications.

©2001 DH Instruments, Inc. Page 12

Page 19

PPC2+ BG0002 Operation and Maintenance Manual

3.5 SPECIAL MENU KEY

3.5.1 INTERNAL, RESET

Reset - Sets

In addition to the standard PPC2+ reset – sets, PPC2+ BG0002 reset – sets:

• TEST(-) vent valve setting to <1Auto> (see Section 3.5.2.2).

3.5.2 VALVE

mmmm PURPOSE

To operate the PPC2+ BG0002 TEST(+)/TEST(-) bypass valve and the TEST(-) vent

valve locally (see Figure 1).

mmmm PRINCIPLE

PPC2+ BG0002 has two additional valves relative to other PPC2+ models. These are the

TEST(+)/TEST(-) bypass valve and the TEST(-) vent valve (see Figure 1).

The TEST(+)/TEST(-) bypass valve connects the TEST(+) and TEST(-) ports directly

together which also connects the BG0002 RPT and the device or system under test high

and low sides directly together. The valve is opened automatically whenever PPC2+ is in

the VENT condition to assure that the RPT and system under test are at zero

differential pressure. The TEST(+)/TEST(-) bypass valve is operated automatically by the

PPC2+ BG0002. It may also be controlled manually using [SPECIAL], <5valve>,

<1bypass> (see Section 3.5.2.1).

The TEST(-) vent valve is used to open the TEST(-) port of the PPC2+ BG0002 to

atmosphere which also connects the BG0002 RPT and the device or system under test

low side to atmosphere. The valve is closed automatically whenever the PPC2+ BG0002

is performing fine pressure control to isolate the low pressure circuit from fluctuations in

ambient pressure. The valve is opened whenever the PPC2+ BG0002 is in the VENT

condition or slewing to assure that the pressure on the low pressure circuit does not move

too far away from atmospheric pressure as it might if it were permanently shut off.

The TEST(-) vent valve is operated automatically by the PPC2+ BG0002. It may also be

controlled manually using [SPECIAL], <5valve>, <2TEST(-) vent> (see Section 3.5.2.2).

mmmm OPERATION

From the main run screen, press [SPECIAL] and

select <5valve>. The display is:

Valves:

1bypass 2test(-)vent

Select <1bypass> to operate the TEST(+)/TEST(-) bypass valve (see Section 3.5.2.1).

Select <2TEST(-)vent> to operate the TEST(-) vent valve (see Section 3.5.2.2).

Page 13 ©2001 DH Instruments, Inc.

Page 20

PPC2+ BG0002 Operation and Maintenance Manual

3.5.2.1 BYPASS

mmmm PURPOSE

To operate the PPC2+ BG0002 TEST(+)/TEST(-) valve locally (see Section 3.5.2

PRINCIPAL and Figure 1).

mmmm OPERATION

To access the bypass function press [SPECIAL] and

select <5Valve>, <1bypass>. The display is:

Bypass valve:

1open 2close

The bypass valve’s operation is normally controlled automatically by PPC2+

BG0002 based on current operation (see Section 3.5.2). W hen the <Bypass

valve:> menu is entered, the cursor is positioned on the number corresponding

to the current valve status.

Press <1open> to open the bypass valve. Operation is momentary so the valve

remains open only as long as the key is pressed.

Press <2close> to close the bypass valve. Operation is momentary so the valve

remains closed only as long as the key is pressed.

3.5.2.2 TEST(-) VENT

mmmm PURPOSE

To operate the PPC2+ BG0002 TEST(-) vent valve locally (see Section 3.5.2

PRINCIPLE and Figure 1).

mmmm OPERATION

The normal setting for the TEST(-) vent valve is <1auto> in which PPC2+ BG0002

automatically controls the valve based on current PPC2+ operation.

Setting other than <1auto> should only be selected by advanced users.

To access the TEST(-) vent valve control press [SPECIAL] and select <5Valve>,

<2TEST(-) vent>.

The display is:

TEST(-)vent: 1auto

2open 3close 4view

Select <1auto> for the TEST(-) vent valve operation to be controlled

automatically by PPC2+ BG0002 based on current operation. This is the normal

and recommended setting.

©2001 DH Instruments, Inc. Page 14

Page 21

PPC2+ BG0002 Operation and Maintenance Manual

Select <2open> to cause the TEST(-) valve to open and remain open regardless

of PPC2+ BG0002 operation until the <2TEST(-)vent> setting is changed.

If PPC2+ BG0002 detects a condition in which it determines there could be a risk

of overpressure to the RPT by opening the TEST(-) vent valve, the message

<Cannot open lo vent, DP overpressure risk> is displayed. If this message is

displayed, return to normal operation and vent the PPC2+ BG0002 and then

try again.

Select <3close> to cause the TEST(-) valve to close and remain closed

regardless of PPC2+ BG0002 operation until the <2TEST(-)vent> setting

is changed.

Select <4view> to view the current condition of the TEST(-) valve. The display

indicates whether current valve operation is controlled by the PPC2+ BG0002

(<Auto TEST(-)vent>) or has been set manually (<Manual TEST(-)vent>)

followed by the current valve status (<Open> or <Close>).

3.5.3 INTERNAL, ATM

mmmm PURPOSE

To view the value of pressure on the TEST(-) port at measured by the onboard barometer.

mmmm PRINCIPLE

PPC2+ BG0002 has an independent on-board barometer. The on-board barometer is

used to monitor the pressure on the TEST(-) port which is the pressure applied to the low

side of the BG0002 RPT and the system under test. The measurements of TEST(-)

pressure made by the on-board barometer are used to compensate the BG0002 RPT

differential pressure measurements for line pressure.

mmmm OPERATION

To view the current reading of the pressure on the TEST(-) port, press [SPECIAL] and

select <4Internal>, <7Atm>. The display is in the pressure units of the current

PPC2+ range.

Page 15 ©2001 DH Instruments, Inc.

Page 22

PPC2+ BG0002 Operation and Maintenance Manual

N

N

OOTTEES

S

©2001 DH Instruments, Inc. Page 16

Page 23

PPC2+ BG0002 Operation and Maintenance Manual

4. REMOTE OPERATION

4.1 OVERVIEW

PPC2+ BG0002 remote operation and protocol is identical to other PPC2+ models (see PPC2+

Operation and Maintenance Manual, Section 4).

Page 17 ©2001 DH Instruments, Inc.

Page 24

PPC2+ BG0002 Operation and Maintenance Manual

N

N

OOTTEES

S

©2001 DH Instruments, Inc. Page 18

Page 25

PPC2+ BG0002 Operation and Maintenance Manual

5. MAINTENANCE, ADJUSTMENTS AND CALIBRATION

PPC2+ is covered by a limited one (1) year warranty. Unauthorized service or repair during the warranty

period is undertaken at the owner's risk and may cause damage that is not covered under warranty

and/or may void the warranty.

5.1 CALIBRATION OF REFERENCE PRESSURE TRANSDUCERS

5.1.1 PRINCIPLE

The principles of calibrating a BG0002 RPT are the same as other PPC2+ RPTs (see PPC2+

Operation and Maintenance Manual, Section 5).

When calibrating the PPC2+ BG0002, the following should be considered:

• For best results, the TEST(-) port of the BG0002 should be connected to an equivalent

port of the standard being used for calibration. If measures are not taken to assure that

the BG0002 TEST(-) port and the standard are connected together at a common

pressure, noise in ambient pressure during the calibration are likely to affect the results.

• The maximum “line pressure” at which the BG0002 can be calibrated is 110 kPaa

(16 psia). Generally, this rules out calibration at an elevated static pressure using two

piston gauges differentially.

• The BG0002 RPT is a true bidirectional gauge sensor. It should be calibrated by applying

positive and negative pressures to the TEST(+) port, not by applying positive pressures to

the TEST(+) and then the TEST(-) port. The normal calibration sequence is 0 to (+)FS to

(-)FS to 0. However, negative pressures need not be included if the BG0002 will be used

for positive pressure operation only.

Page 19 ©2001 DH Instruments, Inc.

Page 26

PPC2+ BG0002 Operation and Maintenance Manual

5.1.2 EQUIPMENT REQUIRED

1. Gas operated piston gauge (deadweight tester) or other pressure standard, with the

following characteristics:

• Measurement uncertainty of ± 0.003 % reading or 0.15 Pa or better, if best

PPC2+ BG0002 accuracy is to be obtained. A standard with greater measurement

uncertainty may be used but PPC2+ measurement uncertainty will be degraded

proportionally from published specifications.

• Able to apply gauge pressures in the range of -15 kPa to +15 kPa (-2.2 to

+2.2 psi) with a minimum pressure of ±±±± 1 kPa (±±±± 0.15 psi): It is not desirable to

define the negative values by applying positive pressure to the PPC2+

BG0002 TEST(-). Negative pressures need not be included in the calibration data if

the BG0002 will be used for positive pressure operation only.

• The pressure standard should have a high (+) and low (-) test port:

Better results are obtained if the TEST(-) port and the low or (-) side of the reference

can be tied together.

• Able to apply pressures at 20 % increments in the range to be calibrated: It is

not necessary that the calibration pressure standard used apply precisely the nominal

pressure value requested for a calibration point as long as the exact value of the

applied pressure is known. Best results will be obtained if the pressure actually

applied is within ± 2 % of FS of the range being calibrated from the

nominal increment.

The recommended calibration standards for supporting PPC2+ BG0002 are either

the DHI PG7601 Gas Operated Piston Gauge with differential mode or an FPG8601

Force Balanced Piston Gauge system. DHI’s A2LA accredited calibration service is

also available to perform recalibrations. Contact DHI for additional information.

5.1.3 SET-UP AND PREPARATION

Set-up recommendations for the PPC2+ BG0002 are the same as for other PPC2+ models

(see PPC2+ Operation and Maintenance Manual Section 5.2.3) with the following differences:

1. Always connect a vacuum source to the PPC2+ BG0002 rear panel EXHAUST port

(1/4 in. NPT F). There will be a constant bleed of gas through the EXHAUST port so the

vacuum pump should be self-venting or disconnected when OFF.

2. Connect the calibration standard output to the PPC2+ BG0002 rear panel TEST(+) port

(1/4 in. NPT F). Connect the calibration standard low or (-) side to the PPC2+ BG0002

rear panel TEST(-) port (1/4 in. NPT F).

©2001 DH Instruments, Inc. Page 20

Page 27

PPC2+ BG0002 Operation and Maintenance Manual

5.2 ADJUSTMENT OF ON-BOARD BAROMETER

mmmm PURPOSE

To adjust the output of the on-board barometer (see the PPC2+ Operation and

Maintenance Manual).

mmmm PRINCIPLE

The on-board barometer output can be adjusted using PA and PM values in the same manner as

for the reference pressure transducers (see the PPC2+ Operation and Maintenance Manual).

The on-board barometer is a low accuracy sensor. In PPC2+ BG0002 it is used to measure the

pressure on the TEST(-) side of the BG0002 RPT. This measurement is used to compensate the

BG0002 RPT differential pressure readings for static or line pressure.

mmmm OPERATION

To edit the values of PA and PM for the barometer, press [SPECIAL] and select <4Internal>,

<2cal>, <2barometer>. Pressing [ENTER] steps through displays of the calibration date

[YYMMDD] and PA/PM. In edit mode, the values can be edited. Pressing [ENTER] after the last

screen activates the edited values.

To view the current atmospheric pressure measurement made by the barometer board, press

[SPECIAL] and select <4Internal>, <7Atm>.

5.3 PNEUMATIC CONTROL MODULE CONFIGURATION

mmmm PURPOSE

In addition to the configuration function described in the PPC2+ Operation and

Maintenance Manual:

PPC2+ BG0002 is designed to control pressure into an 840 cc accessory volume in addition to the

volume under test. If the PPC2+BG0002 is used to control pressure without the accessory

volume, the configuration function should be used to adapt pressure control to the

different volume.

mmmm OPERATION

Poor control is usually caused by invalid control parameters excessive leaks, restrictions in the

test line and/or other set up problems. These issues should be identified and eliminated before

resorting to use of the configuration function (see Section 6).

Page 21 ©2001 DH Instruments, Inc.

Page 28

PPC2+ BG0002 Operation and Maintenance Manual

To access the Config function press [SPECIAL] and select <4Internal>, <1Config>.

The display is:

Selecting <2Defaults> will cause PPC2+ to reload the factory default control coefficients.

This feature can be useful to return to a normal condition if a faulty Config routine has

been activated.

Selecting <1Run> will cause the pneumatic module configuration routine to execute.

Before running a user Config, be sure the KP-PPC-BG-DVU dual volume unit, and no other

volume, is connected to the TEST(+) port. Connect the normal supply pressure to the rear panel

SUPPLY port and a vacuum source to the EXHAUST port.

The display is:

1vac 2atm

Select <1vac>, do not use <2atm> with the BG0002 model. If the ControlRef setting (see the

PPC2+ Operation and Maintenance Manual, Section 3.3.1) does not correspond to your choice,

you will receive an error.

The next display is:

CAUTION: About to

set -0.4939 kPa g

This display notifies the user that pressure will increase to roughly 50 % of range H3.

Press [ENTER] to continue.

PPC2+ will then pulse and set pressures around mid scale pressure (near zero for PPC2+

BG0002), and "CFG" will flash in the lower right corner of the display. After about ten minutes, the

user will be asked whether or not to save the new configurations. If the Config function ran

completely and without incident, select <1Yes>. Selecting <2No> returns to the main run screen

with no change to the internal pressure control coefficients.

1Yes 2No

The configuration routine must be run with the BG0002 PK-PPC-BG-DVU accessory volume

connected to the TEST(+) port. Running the configuration routine without the accessory volume

with which the BG0002 is normally used, will result in poor pressure control.

The effect of the Cfg function can be eliminated and control coefficients returned to factory

defaults by pressing [SPECIAL] and selecting <4Internal>, <1Config>,<1Defaults>.

©2001 DH Instruments, Inc. Page 22

Page 29

PPC2+ BG0002 Operation and Maintenance Manual

5.4 SUBASSEMBLY DESCRIPTION AND LOCATION

See PPC2+ Operation and Maintenance Manual for complete information. See Figure 1 for PPC2+

BG0002 pneumatic schematic.

BAROMETER

TEST ( )

-

VENT

TEST (+)

RPT

SLOW

UP

-

+

SLOW

DOWN

RPT

BYPASS

-

TEST ( ) VENT

VENT

SUPPLY

LEGEND : (ISO 1219-1976)

DIFFERENTIAL

FLOW CONTROLLER

UPSTREAM

DIFFERENTIAL

FLOW CONTROLLER

UPSTREAM

FAS T

FAST

DOWN

UP

BYPASS

FLOW CONTROLLER

BYPASS

DIFFERE NTIAL

FLOW CONTROLLER

DOWNSTREAM

PRESSURE

TRANSDUCER

RESTRICTION

TUBING

OR

Figure 1. Pneumatic Module (Schematic)

VACUUM SENSOR

DIFFERENTIAL

FLOW CONTROLLER

DOWNSTREAM

NORMALLY CLOSED

SOLENOID VALVE

NORMALLY OPEN

SOLENOID VALVE

EXHAUST

Page 23 ©2001 DH Instruments, Inc.

Page 30

PPC2+ BG0002 Operation and Maintenance Manual

N

N

OOTTEES

S

©2001 DH Instruments, Inc. Page 24

Page 31

6. TROUBLESHOOTING

6.1 OVERVIEW

See the PPC2+ Operation and Maintenance Manual, Section 6 for general PPC2+

troubleshooting advice. The table below covers troubleshooting specific to the PPC2+

BG0002 model.

SYMPTOM POSSIBLE CAUSE SOLUTION

PPC2+ BG0002 Operation and Maintenance Manual

Table 4. Troubleshooting Guide

Poor pressure control and/or

cannot set negative pressure.

Pressure appears unstable in

vented condition.

Poor pressure measurement,

incorrect pressure

measurement.

There is no vacuum applied to

the EXHAUST port.

The TEST(-) vent valve is set

to closed.

The BG0002 line pressure limit

is being exceeded.

Connect a vacuum source to

the EXHAUST port.

Use [SPECIAL], <5valve>,

<2TEST(-)vent> to set the

TEST(-) vent valve to AUTO

(see Section 3.5.2.2).

Assure that pressure on

TEST(-) side is between 80

and 110 kPa (11.6 and

16 psia).

Page 25 ©2001 DH Instruments, Inc.

Page 32

PPC2+ BG0002 Operation and Maintenance Manual

N

N

OOTTEES

S

©2001 DH Instruments, Inc. Page 26

Loading...

Loading...