Page 1

AMH-38™/AMH-100™

Automated Mass Handling System

for PG7000 Piston Gauges

Operation and Maintenance Manual

© 2007 DH Instruments, a Fluke Company

Page 2

© 2007, DH Instruments, a Fluke Company All rights reserved.

Information in this document is subject to change without notice. No part of this document may be reproduced or transmitted in any

form or by any means, electronic or mechanical, for any purpose, without the express written permission of DH Instruments, a

Fluke Company 4765 East Beautiful Lane Phoenix AZ 85044-5318 USA.

DH Instruments makes every effort to ensure the accuracy and quality of its published materials; however, no warranty, expressed

or implied, is provided. DH Instruments disclaims any responsibility or liability for any direct or indirect damages resulting from the

use of the information in this manual or products described in it. Mention of any product or brand does not constitute an

endorsement by DH Instruments of that product or brand. This manual was originally composed in English and was subsequently

translated into other languages. The fidelity of subsequent translations cannot be guaranteed. In case of conflict between the

English version and another language version, the English version takes precedence.

DH Instruments, DH, DHI, AMH-38, AMH-100, PG7000, PG7xxx are trademarks of DH Instruments, a Fluke Company, registered

and otherwise.

Krytox is a registered trademark of the Dupont de Nemours Company.

Pyrex is a registered trademark of Dow Corning.

Document No. 550133-02

040726

Printed in the USA.

© 2007 DH Instruments, a Fluke Company

Page 3

TABLE OF CONTENTS

T

AABBLLEE

T

O

O

FF

C

OONNTTEENNTTS

C

S

TABLE OF CONTENTS ...............................................................I

TABLES.................................................................................III

FIGURES................................................................................III

ABOUT THIS MANUAL..............................................................V

1. INTRODUCTION ................................................................. 1

1.1 PRODUCT OVERVIEW ...........................................................................................................................1

1.2 LOCATION AND DESCRIPTION OF THE COMPONENTS....................................................................2

1.2.1 AMH-38..........................................................................................................................................................2

1.2.2 AMH-100........................................................................................................................................................3

1.3 SPECIFICATIONS ...................................................................................................................................4

2. PREPARATION FOR OPERATION ......................................... 5

2.1 UNPACKING AND INSPECTION ............................................................................................................5

2.2 SITE REQUIREMENTS............................................................................................................................7

2.2.1 SITE................................................................................................................................................................7

2.2.2 GAS SUPPLIES.............................................................................................................................................7

2.2.2.1 DRIVE AIR SUPPLY ..................................................................................................................................7

2.2.2.2 VACUUM SUPPLY (AMH-38 ONLY) .........................................................................................................8

2.3 SETTING UP THE AMH FOR OPERATION............................................................................................8

2.3.1 GENERAL CONSIDERATIONS.....................................................................................................................9

2.3.2 SETTING UP THE AMH.................................................................................................................................9

2.3.2.1 CONNECTING THE DRIVE AIR SUPPLY.................................................................................................9

2.3.2.2 CONNECTING THE DRIVE VACUUM SUPPLY (AMH-38 ONLY)..........................................................11

2.3.2.3 CONNECTING ELECTRICAL POWER....................................................................................................11

2.3.2.4 CONNECTING PG7000 PLATFORM COMMUNICATIONS....................................................................12

2.3.2.5 CONNECTING A REFERENCE VACUUM SUPPLY (AMH-38 ONLY)....................................................12

2.3.2.6 CONNECTING AN EXTERNAL REFERENCE VACUUM GAUGE (AMH-38 ONLY)..............................13

2.4 PREPARING THE PG7000 PLATFORM...............................................................................................13

2.4.1 PREPARING PG7102, PG7202, PG7302 PLATFORM HARDWARE FOR AMH-100................................13

2.4.2 PREPARING PG7601 PLATFORM HARDWARE FOR AMH-38................................................................13

2.4.3 VERIFYING PG7000 EMBEDDED SOFTWARE VERSION FOR AMH SUPPORT....................................14

2.5 CHECKING THE PG7000 PISTON-CYLINDER MODULES FOR AMH OPERATION..........................14

2.5.1 CHECKING THE PISTON CAP...................................................................................................................14

2.5.2 CHECKING THE PISTON STOP BUSHING ..............................................................................................15

2.6 INSTALLING THE AMH MASS SET......................................................................................................15

2.7 INITIAL START UP/VERIFICATION......................................................................................................17

3. OPERATION..................................................................... 19

3.1 GENERAL OPERATING PRINCIPLES .................................................................................................19

3.2 OPERATION..........................................................................................................................................22

3.2.1 INSTALLING THE AMH MASS HANDLER ON THE PG7000 PLATFORM ...............................................22

3.2.1.1 INSTALLING AMH-38 ..............................................................................................................................23

3.2.1.2 INSTALLING AMH-100 ............................................................................................................................24

3.2.2 REMOVING THE AMH MASS HANDLER FROM THE PG7000 PLATFORM............................................25

3.2.2.1 REMOVING AMH-38................................................................................................................................25

3.2.2.2 REMOVING AMH-100..............................................................................................................................25

3.2.3 REGULAR MASS TO PRESSURE OR PRESSURE TO MASS OPERATION...........................................26

3.2.4 DIRECT CONTROL OF AMH FUNCTIONS ................................................................................................26

Page I © 2007 DH Instruments, a Fluke Company

Page 4

AMH-38™ AND AMH-100™ OPERATION AND MAINTENANCE MANUAL

3.2.5 MAKING AND BREAKING THE REFERENCE VACUUM (AMH-38 ONLY)...............................................27

3.2.6 ACCESSING THE PG7000 PISTON-CYLINDER MODULE .......................................................................27

3.2.7 INDICATOR LED..........................................................................................................................................27

3.2.8 ERROR MESSAGES...................................................................................................................................28

4. REMOTE OPERATION ....................................................... 31

4.1 OVERVIEW............................................................................................................................................31

5. MAINTENANCE AND ADJUSTMENTS .................................. 33

5.1 MAINTENANCE.....................................................................................................................................33

6. TROUBLESHOOTING ........................................................ 35

7. WARRANTY STATEMENT .................................................. 37

7.1 WARRANTY STATEMENT....................................................................................................................37

© 2007 DH Instruments, a Fluke Company Page II

Page 5

TABLES AND FIGURES

T

AABBLLEES

T

Table 1. AHM-38 Parts List..........................................................................................................................5

Table 2. AHM-100 Parts List........................................................................................................................6

Table 3. Drive Air Pressure Requirement by Mass Set...............................................................................7

Table 4. AMH Errors ..................................................................................................................................28

Table 5. AMH Troubleshooting Checklist ..................................................................................................35

Table 6. DHI Authorized Service Providers...............................................................................................37

F

IIGGUURREES

F

Figure 1. AMH-38 Automated Mass Handler...............................................................................................2

Figure 2. AMH-100 Automated Mass Handler.............................................................................................3

Figure 3. PG7601 Vacuum Plate Detail.....................................................................................................13

Figure 4. Piston Cap Inspection.................................................................................................................15

Figure 5. Piston Cap/Bell Testing ..............................................................................................................15

Figure 6. Piston-Cylinder Module Piston Stop Bushing............................................................................15

Figure 7. AMH Mass Set............................................................................................................................16

Figure 8. AMH Schematic/Operating Principle..........................................................................................21

Figure 9. AMH Installation on PG7000 Platform........................................................................................23

S

S

Page III © 2007 DH Instruments, a Fluke Company

Page 6

AMH-38™ AND AMH-100™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2007 DH Instruments, a Fluke Company Page IV

Page 7

ABOUT THIS MANUAL

A

BBOOUUTT

A

This manual is designed to be used in conjunction with the PG7000 Piston Gauges Manual, to assist in

the set up, operation and maintenance of an AMH-38 or AMH-100 automated mass handling system.

(CAUTION) is used in throughout the manual to identify user warnings and cautions.

(NOTE) is used throughout the manual to identify operating and applications advice and

additional explanations.

T

T

HHIISS

M

AANNUUAAL

M

Manual Conventions

L

Page V © 2007 DH Instruments, a Fluke Company

Page 8

AMH-38™ AND AMH-100™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2007 DH Instruments, a Fluke Company Page VI

Page 9

1. INTRODUCTION

11.

.

I

NNTTRROODDUUCCTTIIOON

I

N

1.1 PRODUCT OVERVIEW

AMH-38 and AMH-100 are automated mass handling systems for PG7000 piston gauges. The AMH

system allows mass values to be loaded and unloaded automatically in response to mass or pressure

entries from the PG7000 terminal or over the PG7000’s COM1 or IEEE-488 interface.

The AMH system lifts the masses off the PG7000 piston, selects the masses to be loaded, and places the

selected masses back onto the piston. This is accomplished using pneumatic and electrical actuation

hardware.

The AMH must be used with a special AMH mass loading bell and mass set. Manipulation of

conventional manual masses cannot be automated.

Both AMH models are accessories to PG7000 Platforms that can be used with an existing manual system

or delivered as part of a new system. Some older PG7000 Platforms require modification before they can

accept the AMH system. Please consult DHI or your DHI representative to determine if an existing

PG7000 Platform is AMH ready.

AMH-38 is compatible with PG7601 and PG7607 Platforms and handles a mass set of nominally 13, 25

or 38 kg. It includes a vacuum chamber for the establishment of a vacuum reference around the masses

when operating in absolute by vacuum mode.

AMH-100 is compatible with PG7201, PG7202, PG7302 and PG7307 Platforms and handles a mass set

of nominally 40, 60, 80 or 100 kg. It does not include a vacuum chamber so the masses are always in

ambient pressure conditions.

Page 1 © 2007 DH Instruments, a Fluke Company

Page 10

AMH-38™ AND AMH-100™ OPERATION AND MAINTENANCE MANUAL

1.2 LOCATION AND DESCRIPTION OF THE COMPONENTS

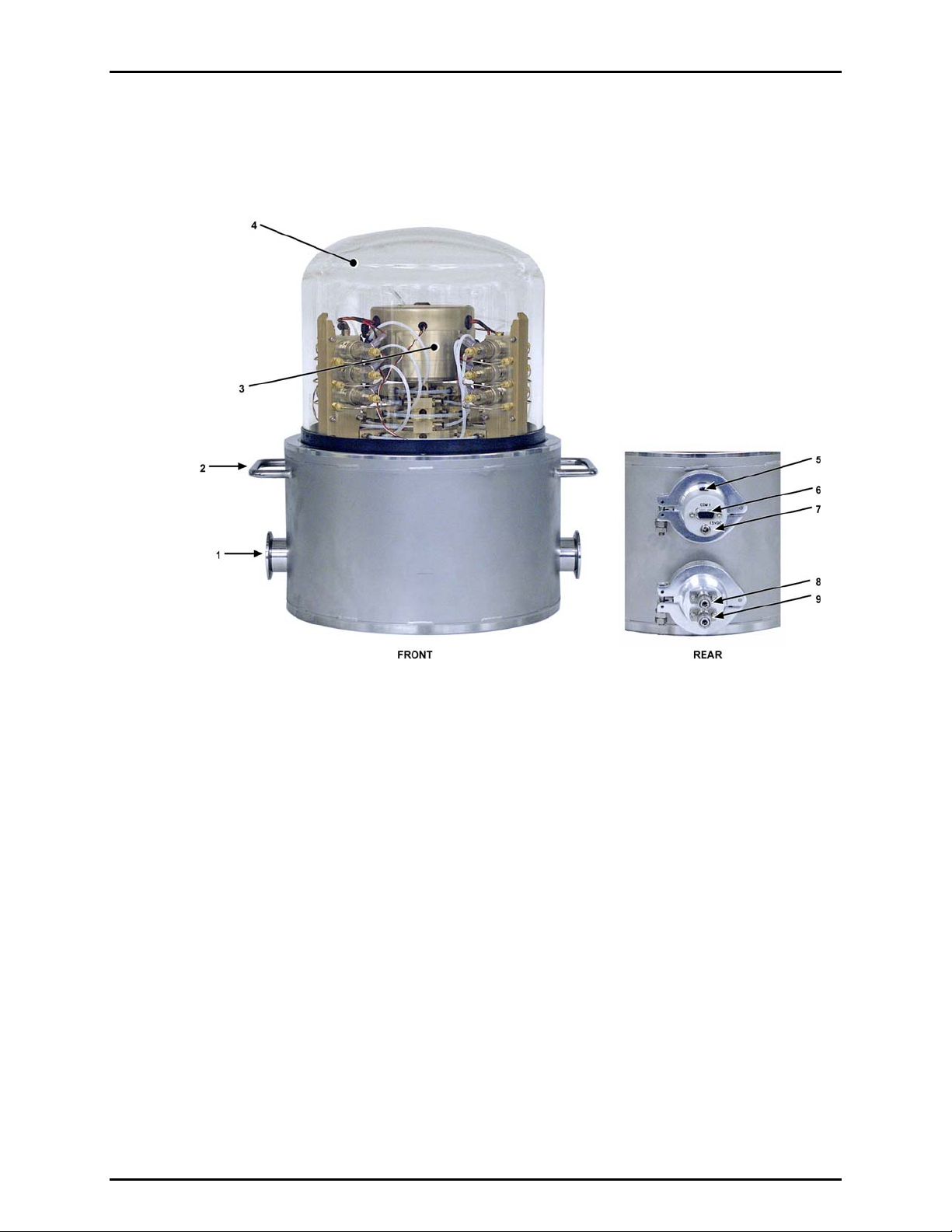

1.2.1 AMH-38

1. KF-40 vacuum connections (2)

2. Lifting handles (2)

3. Mass lifter and pneumatic actuation

solenoid valves

4. Vacuum bell jar (delivered with

PG7601 Platform)

Figure 1. AMH-38 Automated Mass Handler

5. AMH status indication LED

6. RS232 Port, COM1

7. DC power connection

8. Drive air pressure connection

9. Drive vacuum connection

© 2007 DH Instruments, a Fluke Company Page 2

Page 11

1. INTRODUCTION

1.2.2 AMH-100

1. Platform engagement foot

2. Main mass manipulation column

3. Bubble level

4. Mass lifter and pneumatic

actuation cover

Figure 2. AMH-100 Automated Mass Handler

5. Drive air pressure connection

6. RS232 Port, COM1

7. DC power connection

8. AMH status indication LED

Page 3 © 2007 DH Instruments, a Fluke Company

Page 12

AMH-38™ AND AMH-100™ OPERATION AND MAINTENANCE MANUAL

1.3 SPECIFICATIONS

15 VDC @ 2 A, 30 W max. consumption

15 to 35 ºC

41 cm H x 37 cm W x 38 cm D (16.3 in. x 14.6 in. x 15 in.)

41 cm H x 41 cm W x 36 cm D (16.3 in. x 16.1 in. x 14.1 in.)

18 kg (40 lbs)

12 kg (25 lbs)

RS232 (COM1)

275 kPa (40 psi), ± 10%, minimal flow

550 kPa (80 psi), ± 10%, minimal flow

Quick connector equivalent to Swagelok QM Series (QM2-B-200),

Use with DESO (double end shut off) type stem

Quick connector equivalent to Swagelok QM Series (QM2-B-200),

Use with SESO (single end shut off) type stem only.

Power Requirements:

Operating Temperature:

Dimensions:

Weight:

Communications:

Drive Air Supply:

Vacuum Supply:

Pressure Connections:

CE conformance:

AMH-38:

AMH-100:

AMH-38:

AMH-100:

AMH-38:

AMH-100:

AMH-38 only: At least 50 kPa (7.5 pi) under atmosphere, minimal flow

Pressure:

Vacuum:

Available, must be specified

Due to a policy of continuous product improvement, all specifications are subject to change

without notice.

© 2007 DH Instruments, a Fluke Company Page 4

Page 13

22.

2. PREPARATION FOR OPERATION

.

P

RREEPPAARRAATTIIOONN FFOORR

P

O

PPEERRAATTIIOON

O

N

2.1 UNPACKING AND INSPECTION

AMH-38 and AMH-100 are delivered, along with their standard accessories, in a corrugated container

with foam cut outs to hold items in place.

Remove all parts from the shipping box. Be sure not to lose or discard the Accessory Kit.

Inspect all parts for damage. If damage is noted, report it to your Shipping & Receiving Department and

the delivering carrier for appropriate action.

Inspect for any missing components or accessories referring to Table 1 for AMH-38 or Table 2 for AMH-

100. Should any items be missing, contact DHI or your local DHI representative.

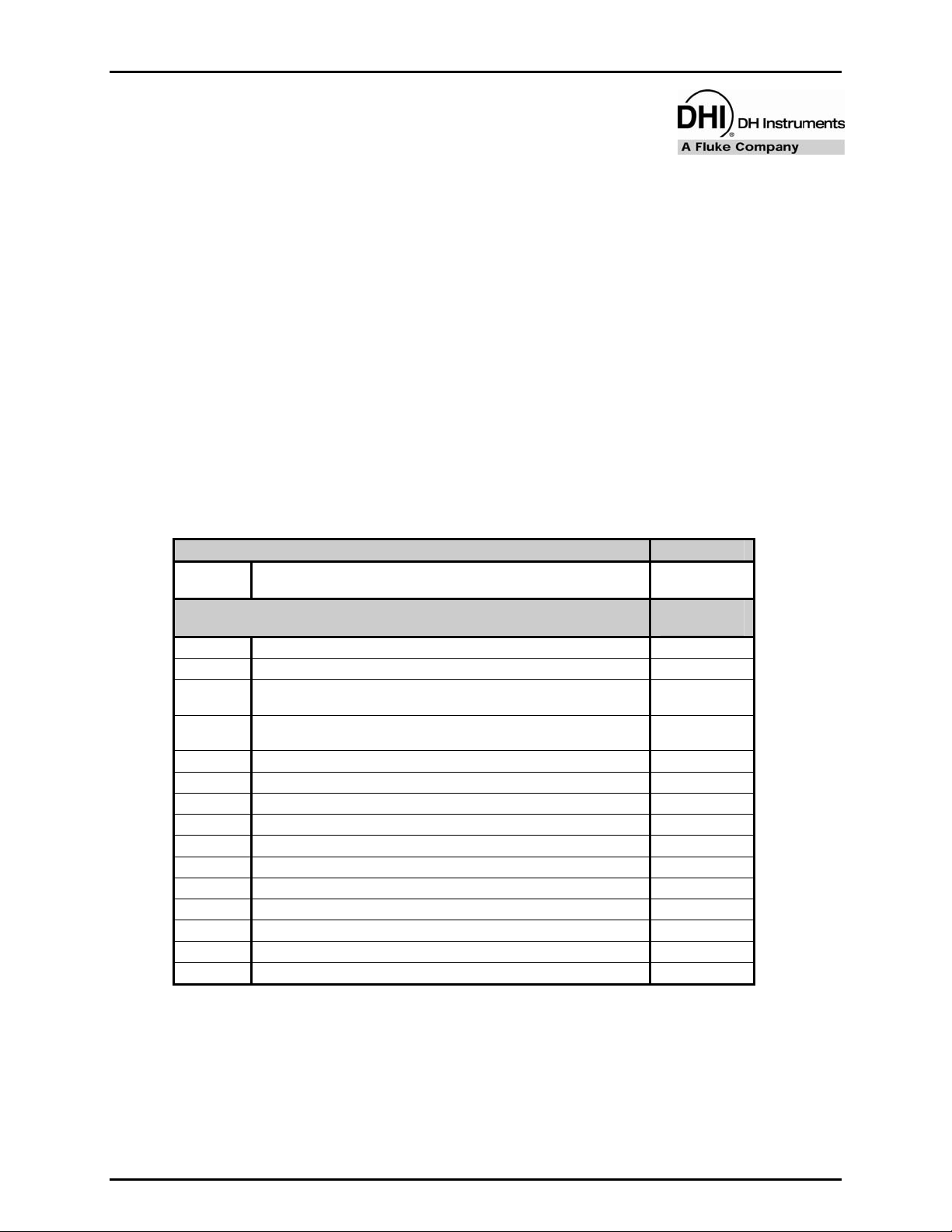

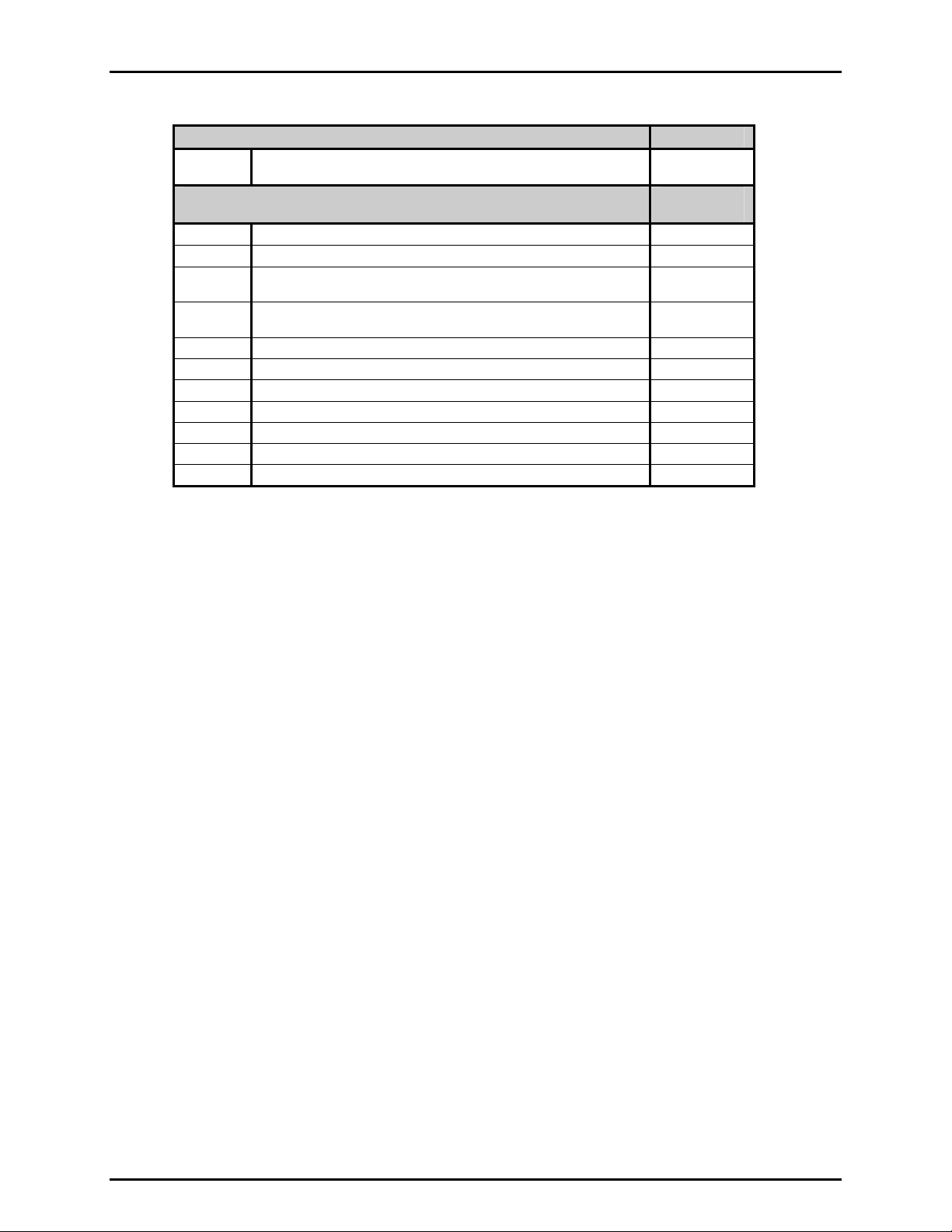

Table 1. AHM-38 Parts List

DESCRIPTION PART #

1 ea. AHM-38 Automated Mass Handler 402061 or

Accessory kit including: 402092 or

1 ea. Operation and Maintenance Manual 550133

1 ea. 15 VDC Power Supply 103986

1 ea. Power Cord 100770 or

1 ea. RS232 cable 100847 or

2 m. 1/8 in. PFA tubing 101392-Z

2 m. 1/4 in. PFA tubing 101450-Z

1 ea. Adaptor, 1/8 in. Swage x 1/4 in. NPT M 102189

1 ea. Tee, 1/4 in. Swage 101487

1 ea. Port Connector, 1/4 in. Swage 101984

1 ea. Quick Connector Stem, 1/8 in. Swage DESO (with red band) 402097

1 ea. Assembly: SESO Quick Connector Stem and Valve 402093

4 ea. Cable Tie, Hook and Loop 103485

1 ea. Tool, 3 mm Hex Wrench (with T handle) 103473

1 ea. O-ring, Viton, 2-273 103493

1 ea. Adaptor, 1/4 in. Swage x 1/4 in. NPT M 101477

402061-CE

402092-CE

100770-CE

100847-CE

Page 5 © 2007 DH Instruments, a Fluke Company

Page 14

AMH-38™ AND AMH-100™ OPERATION AND MAINTENANCE MANUAL

Table 2. AHM-100 Parts List

DESCRIPTION PART #

1 ea. AHM-100 Automated Mass Handler 402062 or

Accessory kit including: 402094 or

1 ea. Operation and Maintenance Manual 550133

1 ea. 15 VDC Power Supply 103986

1 ea. Power Cord 100770 or

1 ea. RS232 cable 100847 or

2 m. 1/8 in. PFA tubing 101392-Z

1 ea. Adaptor, 1/8 in. Swage x 1/4 in. NPTM 102189

1 ea. Quick Connector Stem, 1/8 in. Swage DESO (with red band) 402097

4 ea. Cable Tie, Hook and Loop 103485

1 ea. Tool, 3 mm Hex Wrench (with T handle) 103473

1 ea. Tool, 2.5 mm Hex Wrench (with straight handle) 102257

1 ea. Dust Cover 103503

402062-CE

402094-CE

100770-CE

100847-CE

© 2007 DH Instruments, a Fluke Company Page 6

Page 15

2. PREPARATION FOR OPERATION

2.2 SITE REQUIREMENTS

2.2.1 SITE

General site requirements are the same as for PG7000 piston gauge platforms (see the

PG7000 Operation and Maintenance Manual).

When planning the site for use of AMH, consider that the AMH mass handler will occasionally

be removed from the PG7000 Platform. A convenient place to put it down when it is removed

should be planned. In addition, it is more convenient to leave the pressure, power and other

utilities connected to the AMH when removing it so consider the length and path of these

lines.

2.2.2 GAS SUPPLIES

AMH-38 requires a compressed air source and a vacuum source (see Sections 2.2.2.1,

2.2.2.2).

AMH-100 requires a compressed air source only (see Section 2.2.2.1).

2.2.2.1 DRIVE AIR SUPPLY

The drive air supply provides power to operate the mass lifter and the binary

mass selector pins (see Section 3.1).

Drive air requirements are:

Flow rate: Very low, avoid restrictions or excessive length of connecting

tubing

Cleanliness: If air from a compressor is used it should be filtered and dried,

preferably with a filter regulator with a coalescing filter. The

recommendation is for a 5-micron filter upstream of a 0.01-micron

coalescing filter. The main concern is the elimination of humidity,

which could corrode the AMH pneumatic controls.

Drive air pressures required (± 10%) for different mass sets are listed in Table 3:

Table 3. Drive Air Pressure Requirement by Mass Set

MODEL MASS SET

AMH-38 MS-AMH-13 275 (40)

AMH-38 MS-AMH-25 275 (40)

AMH-38 MS-AMH-38 275 (40)

AMH-100 MS-AMH-40 275 (40)

AMH-100 MS-AMH-60 380 (55)

AMH-100 MS-AMH-80 450 (65)

AMH-100 MS-AMH-100 550 (80)

DRIVE AIR

[kPa (psi)]

Do not operate AMH with drive pressure lower than 275 kPa (40 psi).

Damage to the AMH could result.

Page 7 © 2007 DH Instruments, a Fluke Company

Page 16

AMH-38™ AND AMH-100™ OPERATION AND MAINTENANCE MANUAL

2.2.2.2 VACUUM SUPPLY (AMH-38 ONLY)

The vacuum supply is necessary for AMH-38 operation when there is vacuum in

the AMH-38 vacuum chamber and bell jar (absolute by vacuum mode PG7601

operation). The vacuum supply assures that the binary mass selection pins

remain in the correct position and evacuates internal AMH volumes to minimize

the likelihood of leaks into the reference vacuum.

The vacuum pump or vacuum supply for the pressure controller of the PG7601

system can be used for the AMH-38 vacuum supply.

Vacuum drive requirements are:

Flow rate: Very low, avoid restrictions or excessive length of connecting

tubing

Do not operate AMH-38 when using a PG7601 in “absolute by vacuum” mode

without having a vacuum supply connected to AMH-38. Always check that

AMH-38 is supplied with vacuum before establishing reference vacuum in the

AMH-38 vacuum chamber. Failure to do so may result in damage to the

binary mass pins and/or binary masses.

Vacuum pressure: At least 50 kPa (7.5 pi) under atmosphere

Do not plug the AMH drive vacuum connection. Use only a “SESO” type

quick-connector stem. Plugging the AMH drive vacuum connection will cause

serious damage to AMH internal components.

© 2007 DH Instruments, a Fluke Company Page 8

Page 17

2. PREPARATION FOR OPERATION

2.3 SETTING UP THE AMH FOR OPERATION

2.3.1 GENERAL CONSIDERATIONS

AMH-100 requires only three connections: drive air supply, electrical power, and RS232

cable for communications with PG7000 Platform. Consider these connections when setting

up the AMH-100.

AMH-38 requires at least three connections: drive air supply, electrical power, and RS232

cable for communications with PG7000 Platform. If the PG7000 on which the AMH-38 is

installed will be operated with a vacuum in the vacuum chamber, a drive vacuum connection

is also required. AMH-38 includes two KF40 connections that may be used for connection of

a vacuum pump and/or of an external vacuum gauge.

The AMH mass handler is removed from the PG7000 Platform to access the piston-cylinder.

Ease of removal and manipulation of the AMH should be considered in making the various

utility connections. In addition, a safe and convenient location to put it down when it is

removed should be planned.

2.3.2 SETTING UP THE AMH

To setup the AMH for operation, place the AMH bottom down on a sturdy, flat surface. Do

not install it on the PG7000 Platform until the AMH mass set has been installed and the AMH

itself has been it has been started up (see Section 2.7).

The setup of the AMH can be broken down into 6 steps:

• Connecting the drive air supply (see Section 2.3.2.1)

• Connecting the drive vacuum supply (AMH-38 only) (see Section 2.3.2.2)

• Connecting electrical power (see Section 2.3.2.3)

• Connecting PG7000 Platform communications (see Section 2.3.2.4).

• Connecting the reference vacuum supply (AMH-38 only) (see Section 2.3.2.5)

• Connecting an external vacuum gauge (AMH-38 only) (see Section 2.3.2.6).

There are two KF-40 pass throughs on the rear of the AMH-38 vacuum chamber for

electrical and pressure connections to the inside of the chamber. These are not intended

to be loosened or removed by the user. Only qualified service personnel should loosen the

KF- 40 pass through connections on the AMH-38 vacuum chamber.

2.3.2.1 CONNECTING THE DRIVE AIR SUPPLY

The AMH accessories kit includes hardware to facilitate the connection of the drive

air supply (see Tables 1, 2). Locate the drive air connection accessories including:

• Quick-connector stem (DESO type with red band).

• 2 m 1/8 in. O.D. clear PFA tubing.

• 1/8 in. Swage x 1/4 in. NPT M adaptor.

Page 9 © 2007 DH Instruments, a Fluke Company

Page 18

AMH-38™ AND AMH-100™ OPERATION AND MAINTENANCE MANUAL

To use the supplied accessories to make the AMH drive air supply connection

proceed as follows:

Connect the quick-connector to one end of the PFA tube. Loosen the 1/8 in.

Swage nut on the assembly slightly. Slip the PFA tube into the nut until it

stops. Tighten the nut to swage the tube.

Connect the other end of the PFA tube to an appropriate drive air supply (see

Section 2.2.2.1). If desired, use the 1/8 in. Swage x 1/4 in. NPT M adaptor.

Insert the quick-connector stem into the drive air connection quick-connector

(top connector, color coded with red band). Press firmly until the stem clicks

into place.

The quick-connector stem seals when disconnected so the drive air supply

may be applied before the quick-connector stem is inserted into the quickconnector.

Apply drive air pressure to the connection and check for leaks.

Do not operate AMH with drive pressure lower than 275 kPa (40 psi).

Damage to the AMH could result.

© 2007 DH Instruments, a Fluke Company Page 10

Page 19

2. PREPARATION FOR OPERATION

2.3.2.2 CONNECTING THE DRIVE VACUUM SUPPLY (AMH-38 ONLY)

The AMH-38 accessories kit includes hardware to facilitate the connection of the

drive vacuum supply (see Table 1). Locate the drive vacuum connection

accessories including:

• Quick-connector stem (with blue band) and three way sleeve valve assembly.

• 2 m 1/4 in. O.D. PFA tubing.

• 1/4 in. Swage x 1/4 in. NPT M adaptor.

• 1/4 in. Swage tee and 1/4 in. Swage Port Connector.

To use the supplied accessories to make the AMH drive vacuum supply

connection proceed as follows:

Connect the blue banded quick-connector/sleeve valve assembly to one end

of the PFA tube. Loosen the 1/4 in. Swage nut on the assembly slightly. Slip

the PFA tube into the nut until it stops. Tighten the nut to swage the tube.

Connect the other end of the PFA tube to an appropriate vacuum supply (see

Section 2.2.2.2). If desired, use the 1/4 in. Swage x 1/4 in. NPT M adaptor

and/or the 1/4 in. Swage Tee and Port Connector. The Tee and Port

Connector are particularly useful if the vacuum supply is from a DHI

PPC/MPC Vacuum Kit. Install the Tee on the vacuum pump side of the PFA

tube between the vacuum pump and the PPC or MPC, or where the vacuum

tube connects to the PPC or MPC.

Insert the quick-connector stem into the drive vacuum connection quick-

connector (color coded with blue band). Press firmly until the stem clicks

into place. Use only a “SESO” type stem (not self sealing).

Check that the three-way sleeve valve is in the GAUGE position (drive

vacuum not applied to the AMH-38). Apply drive vacuum and check for

leaks.

Do not plug the AMH drive vacuum connection. Use only a “SESO” type

quick-connector stem. Plugging the AMH drive vacuum connection will cause

serious damage to AMH internal components.

A drive vacuum supply must be connected to AMH-38 when using a PG7601

in “absolute by vacuum” mode. Always check that AMH-38 is supplied with

drive vacuum before establishing reference vacuum in the AMH-38 vacuum

chamber. Failure to do so may result in damage to the binary mass pins

and/or binary masses.

2.3.2.3 CONNECTING ELECTRICAL POWER

Connect the electrical power to the power connector on the AMH. Use the

supply pack provided in the AMH accessories. Power supply to the pack is 100 –

240V, 50/60 Hz.

When power is connected, the green LED near the electrical connector should

light and not flash. If the LED flashes, see Section 3.2.7. If the LED doesn’t

light, and you are sure power is connected, contact your DHI Authorized Service

Provider.

Page 11 © 2007 DH Instruments, a Fluke Company

Page 20

AMH-38™ AND AMH-100™ OPERATION AND MAINTENANCE MANUAL

2.3.2.4 CONNECTING PG7000 PLATFORM COMMUNICATIONS

Locate the 9 pin D-sub cable delivered with the AMH accessories.

The communications connection configuration depends upon whether the

PG7000 is being used with a PPC automated pressure controller.

AMH Communications Connection Without a PPC Automated Pressure

Controller

Connect the female end of the 9 pin D-sub cable to the AMH COM1 port.

Connect the male end of the 9 pin D-sub cable to the PG7000 COM3 port.

Set the PG7000 COM3 port to (see the PG7000 Operation and Maintenance

Manual):

− Baud rate: 9600

− Parity: None

− Data bits: 8

− Stop bits: 1

AMH Communications Connection With a PPC Automated Pressure

Controller

The AMH shares PG7000 COM3 with the PPC automated pressure controller.

Connect the female end of the 9 pin D-sub cable to the AMH COM1 port.

Connect the male end of the 9 pin D-sub cable to the PPC COM2 port.

Set the PPC COM2 port to (see the PG7000 Operation and Maintenance

Manual):

− Baud rate: 9600

− Parity: None

− Data bits: 8

− Stop bits: 1

Use another 9 pin D-sub cable to connect the PPC3 COM1 port to the PG7000

COM3 port.

Be sure that the COM3 port of the PG7000 Platform and the COM1 port of the

PPC have the same COM settings (see the PG7000 Operation and Maintenance

Manual).

2.3.2.5 CONNECTING A REFERENCE VACUUM SUPPLY (AMH-38 ONLY)

The AMH-38 vacuum chamber is equipped with two KF-40 vacuum connections.

One of these may be used as an alternate to the KF-25 connection built-in to the

PG7601 platform (see the PG7000 Operation and Maintenance Manual). This

may be desirable when a very low reference vacuum is desired, for example

when using a turbo molecular pump.

To use the KF-40 connection on the AMH-38 for the vacuum reference supply,

use a KF-40 vacuum hose. Plug the platform’s KF-25 connection. Consider the

need to shut-off the vacuum supply when vacuum is not desired in the vacuum

chamber and the need to remove the AMH-38 from the PG7601 Platform to

access the piston-cylinder module or the mass set.

© 2007 DH Instruments, a Fluke Company Page 12

Page 21

2. PREPARATION FOR OPERATION

2.3.2.6 CONNECTING AN EXTERNAL REFERENCE VACUUM GAUGE (AMH-38 ONLY)

The AMH-38 vacuum chamber is equipped with two KF-40 vacuum connections.

One of these may be used to connect an external vacuum gauge as an alternate

to the vacuum gauge built-in to the PG7601 platform. This may be desirable to

measure the reference vacuum with lower measurement uncertainty that the

PG7601’s internal vacuum gauge.

See the PG7000 Operation and Maintenance Manual for information on using an

external vacuum gauge to measure reference vacuum pressure.

2.4 PREPARING THE PG7000 PLATFORM

2.4.1 PREPARING PG7102, PG7202, PG7302 PLATFORM HARDWARE FOR AMH-100

Most PG7102, PG7202 and PG7302 Platforms delivered after 2004, January 1, are AMH

ready. AMH ready platforms have three machined holes in the top surface of the base

casting to seat the AMH-100 legs.

To prepare the AMH ready platform, loosen the three set screws on the sides of the base

casting until the screw is just past flush with the side (2.5 mm allen wrench). Remove the

two black plastic caps and the bubble level assembly, exposing the AMH-100 seating holes.

When AMH-100 is used, the bubble level on the AMH-100 center plate is used to level the

PG7000 system. Retain the casting level in case of future use of the platform without the

AMH accessory.

If your PG7102, PG7202 or PG7302 does not have the three AMH leg holes on the top

surface, the based casting must be replaced before AMH can be used with the platform.

Contact DHI or your local DHI representative.

2.4.2 PREPARING PG7601 PLATFORM HARDWARE FOR AMH-38

Most PG7601 platforms with a serial number higher than 124 are AMH ready. Serial

numbers 124 and lower (units delivered prior to 1994) may require a new vacuum plate. To

determine if a PG7601 vacuum plate is AMH ready, measure the width of the flat horizontal

surface from the outermost diameter of the plate to the inner chamfer. (see Figure 3) If this

width is 12.2 mm, the vacuum plate will accept AMH; if the width is 7.2 mm, the vacuum

place must be replaced. Contact a DHI Authorized Service Provider.

The vacuum plate of an AMH ready PG7601 must be inspected for damage prior to

attempting to install AMH-38. The AMH-38 vacuum chamber fits over the outside diameter of

the vacuum plate. Displaced material from

dents or dings on the outside corner of the

plate could increase the effective diameter

making it difficult or impossible for the

AMH-38 vacuum chamber to fit over the

plate. Inspect the outside diameter of the

vacuum plate (see Figure 3). Remove any

material on the outside surface and return

to a finish of approximately 0.8

micrometers or better. If you are not

comfortable performing this task with inhouse capabilities, contact an Authorized

DHI Service Provider.

Figure 1. PG7601 V a cuum Plate Detail

Figure 2. PG7601 V a cuum Plate Detail

Figure 3. PG7601 V a cuum Plate Detail

Figure 4. PG7601 V a cuum Plate Detail

Figure 5. PG7601 V a cuum Plate Detail

Figure 6. PG7601 V a cuum Plate Detail

Figure 7.

PG 7601 V acu um P late Det

Figure 3. PG7601 Vacuum Plate Detail

Page 13 © 2007 DH Instruments, a Fluke Company

Page 22

AMH-38™ AND AMH-100™ OPERATION AND MAINTENANCE MANUAL

2.4.3 VERIFYING PG7000 EMBEDDED SOFTWARE VERSION FOR AMH SUPPORT

To use a PG7000 Platform with AMH, the PG7000 Platform embedded software must

support AMH. PG7000 embedded software versions 2.05 or higher support AMH. The

software version can be viewed by pressing and holding the PG7000 [ESCAPE] key from the

main run screen.

If your PG7000 Platform is not running embedded software version 2.05 or higher, the

PG7000 embedded software must be upgraded before AMH can be used. For most

PG7000s, this can be accomplished by downloading a software flashing utility and the

embedded software from the DHI web site,

PG7000 Platforms running an embedded software version lower than 2.02 require hardware

changes to upgrade to version 2.05. Contact a DHI Authorized Service Provider to have this

service performed. Do not attempt to flash new software until the necessary hardware

upgrade has been performed.

www.dhinstruments.com.

2.5 CHECKING THE PG7000 PISTON-CYLINDER MODULES FOR AMH OPERATION

2.5.1 CHECKING THE PISTON CAP

The AMH mass handler lifts the mass loading bell completely off of the piston and lowers it

back down each time the mass load is changed. When adding AMH to an existing PG7000

system, it is important to check the outer circumference of the piston cap for displaced

material from dents or dings that might interfere with the free removal and replacement of the

bell. In this case, in particular, when the bell is lowered back onto the piston with little or no

additional mass, the weight of the bell alone may not cause it to seat properly on the piston

cap, which could cause poor performance.

Before using AMH with existing piston-cylinder modules, examine the outside circumference

of the piston cap (see Figure 4). Remove any material on the outside surface and return to a

finish of approximately 0.8 micrometers or better. Note that the piston mass is a calibrated

value so after removing material, the mass should be redetermined. Also, apply and wipe off

a very thin film of Krytox® lubricant on the inside surface of the top of the mass loading bell

where it contacts the outside perimeter of the piston cap (a tube of Krytox lubricant is

included in the PG7000 Platform accessories). If you are not comfortable performing this

task with in-house capabilities, contact an Authorized DHI Service Provider.

Test the piston-cylinder modules with the AMH mass set bell. To do this, install the pistoncylinder module and binary mass carrier on the PG7000 Platform (see the PG7000 Operation

and Maintenance manual). Then slip the AMH mass bell down over the binary mass carrier.

The bell should seat smoothly and easily. If you push the bottom of the seated bell to one

side, it should naturally and easily fall back to its normal seated position (see Figure 5). If the

bell does not seat easily and/or does not reseat naturally when pushed to one side, there is

likely to be difficulty operating AMH with the piston. If this cannot be corrected locally, the

piston-cylinder module should be returned to a DHI Authorized Service Provider.

© 2007 DH Instruments, a Fluke Company Page 14

Page 23

2. PREPARATION FOR OPERATION

Figure 4. Piston Cap Inspection

Figure 5. Piston Cap/Bell Testing

2.5.2 CHECKING PISTON STOP BUSHING

Piston-cylinder modules used with AMH must be

equipped with the newer style of piston stop bushing

that is threaded and made of white or cream colored,

static dissipative acetal. Before using a PG7000

piston-cylinder module with AMH, inspect the piston

stop bushing (see Figure 6). Verify that the bushing is

made of the required white or cream-colored material.

Black bushings must be replaced before the pistoncylinder module is used with AMH. Contact a your DHI

representative or a DHI Authorized Service Provider

for assistance.

To view the piston stop bushing, the piston cap must

be removed. See the PG7000 Operation and

Maintenance Manual; Piston-Cylinder Modules,

Disassembly, Cleaning and Maintenance.

Figure 6.

Piston-Cylinder Module

Piston Stop Bushing

2.6 INSTALLING THE AMH MASS SET

PG7000 AMH masses are shipped in reusable, molded shipping and storage cases. One of the cases

contains the binary masses, binary mass carrier, mass bell and lifting shaft/trim mass tray. The other

cases contain the main masses of 6.2 (AMH-38) or 10 kg (AMH-100) (see PG7000 Operation and

Maintenance Manual, Inspecting Contents, Mass Set for mass set composition detail). Each mass is

packed in a sealed plastic bag and then placed in a protective shipping insert.

The stability over time of PG7000 pressure measurements is a function of the stability of the

masses loaded on the piston. Precautions should be taken in handling the masses to minimize

influences that may change their mass. This includes always wearing protective gloves when handling

the masses to avoid contaminating them with body oils and perspiration. Protective gloves are

provided in the accessory kits of PG7000 Platforms.

Page 15 © 2007 DH Instruments, a Fluke Company

Page 24

AMH-38™ AND AMH-100™ OPERATION AND MAINTENANCE MANUAL

To install the AMH mass set, follow the order of operation below carefully (refer to Figure 7):

Prepare the masses: Open the shipping cases and remove all the masses and mass set elements

from their plastic bags.

Install a piston-cylinder module in the PG7000 Platform: See the PG7000 Operation and

Maintenance Manual, Installing a Piston-Cylinder Module Into the Platform.

Install the binary mass carrier: Place the pyramidal shaped carrier on top of the piston cap.

Install the mass loading bell: Slip the mass loading bell over the binary mass carrier and slide it

down until the inside top of the bell sits on the binary mass carrier.

Install the main mass discs: Load the main mass discs (6.2 kg each with AMH-38, 10 kg each with

AMH-100) onto the mass bell starting with mass #1 and loading in sequential order. Mass #1

should be at the bottom of the stack and the highest number mass at the top. The mass sequence

numbers are lazer marked on the top surface of each mass. Pass the mass disc over and down the

mass loading bell and center it on the ledge at the bottom of the bell. Load the rest of the main

masses, sequentially, onto the bottom mass.

Install the binary mass tubes: Load the binary mass tubes concentrically from the largest to

smallest, outside to inside. The largest, long tubes slip down between the main mass stack and the

bell and rest on the ledge at the bottom of the mass bell. The smaller masses load onto the

pyramidal steps of the binary mass carrier.

The mass loading process is complete: The mass set is in the all loaded position. The mass lifting

shaft/trim mass tray assembly is not yet installed. It will be attached after the AMH autmomated

mass handler is installed over the masses on the platform.

Create the mass set and mass loading bell in the PG Terminal: See the PG7000 Operation and

Maintenance Manual, Add Mass Set and Add Mass Loading Bell Sections.

SHOWN IS THE MS-AMH-38 MASS SET FOR THE AMH-38 MASS HANDLER. SMALLER MASS SETS MAY INCLUDE LESS

MAIN MASS DISCS. MASS SETS FOR THE AMH-100 MASS SET ARE IDENTICAL TO AMH-38 BUT THE MAIN MASSES

ARE LARGER 10 KG DISCS AND A 7TH BINARY MASS TUBE OF 6.2 KG IS INCLUDED.

Figure 7. AMH Mass Set

© 2007 DH Instruments, a Fluke Company Page 16

Page 25

2. PREPARATION FOR OPERATION

2.7 INITIAL START UP/VERIFICATION

Perform the initial verification of the AMH mass loading system with the AMH sitting on a flat surface next

to the PG7000 Platform. Do not install the AMH onto the platform until steps through below have

been completed.

To verify the AMH mass handler prior to installing it on the PG7000 Platform, proceed as follows:

Make the necessary pressure, power and communications connections: Complete the set up

procedure described in Section 2.3.2. Do not open the valve to apply vacuum to the AMH-38 until a

vacuum is being established in the vacuum chamber.

Do not operate AMH with drive pressure lower than 275 kPa (40 psi). Damage to the AMH could

result.

Insert the mass lifting shaft into the AMH: Insert the shaft into the hole in the center of the AMH

mass lifter and slide it down until the trim mass tray sits on the top of the lifter. This arrangement trips

the AMH’s internal proximity sensor allowing the AMH system to be operated off of the PG7000

Platform without an actual mass load.

Select an AMH mass set and mass bell as the active mass set and bell for the PG7000: This

step can be skipped if the AMH mass set and bell have already been selected, if so go directly to step

. On the PG Terminal, press [SPECIAL], <1PC/MS>, <3mass bell>, <5select> and select the

mass bell of the AMH mass set. Using [SPECIAL], <1PC/MS>, <2mass set>, <5select>, select an

AMH mass set (mass set designated by S/N nnnnA). Selecting the AMH mass set causes the

PG7000 Platform to attempt to establish communication with the AMH system. If the communication

fails, an error message occurs (see Sections 3.2.8, 6).

If communication succeeds, the PG7000 initializes the AMH mass handler. The trim mass tray should

rise approximately 2.5 cm (1 in.) above the top of the lifter; followed by the sound of the main mass

selection columns rotating. Then the trim mass tray should be lowered back down. The steps of this

procedure are commented on the PG Terminal display as they execute. If the sequence does not

complete and/or any error messages are observed, see Section 6 and Table 4 for troubleshooting

assistance. If the sequence completes, the AMH system has been cleared and put into a known

state in which all mass holding ledges and pins are retracted so that it can safely be slipped down

over the AMH mass set and installed on the PG7000 Platform.

The PG7000 Platform must be able to initialize the AMH system before start up can proceed.

Clear the AMH and test its operation: Press [SPECIAL], <8AMH>, <2control>, <3loadall>. The

trim mass tray should rise approximately 2.5 cm (1 in.) above the top of the lifter, followed by the

sound of the main mass selection columns rotating. Then the trim mass tray should be lowered back

down. The steps of this procedure are commented on the PG Terminal display as they occur. If the

sequence does not complete and/or any error messages are observed, see Section 6 and Table 4 for

troubleshooting assistance. If the sequence completes, the AMH mass handler has been cleared

and put into a known state in which all mass holding ledges and pins are retracted so that it can

safely be slipped down over the mass set and installed on the PG7000 Platform.

If desired, visually inspect the condition of the AMH mass handler by carefully tipping the AMH to look

inside. The main mass selection columns should have their all flat surfaces (no ledges) oriented

towards the center and all binary mass selection pins should be retracted (see Section 3.1).

When this step is complete, the AMH mass handler is ready to be installed on the PG7000 Platform

(see Section 3.2.1).

Page 17 © 2007 DH Instruments, a Fluke Company

Page 26

AMH-38™ AND AMH-100™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2007 DH Instruments, a Fluke Company Page 18

Page 27

3. OPERATION

33.

.

O

PPEERRAATTIIOON

O

N

3.1 GENERAL OPERATING PRINCIPLES

Numerical reference in this section refers to Figure 8.

The purpose of the AMH-38 or AMH-100 system is to automatically load specified values of mass onto

the PG7000 piston. This is accomplished by lifting the complete mass set up off and above the pistoncylinder to the mass selection position, selecting the individual masses to be loaded and retained, and

then placing the masses to be loaded back onto the piston.

To accomplish the mass lifting, selection and lowering function, the AMH mass handler uses four main

sub-systems. These systems are present in both the AMH-38 and AMH-100 models.

1. Electronic and electrical controls(7): The AMH electronic and electrical controls are located

just above the mass lifter, under a protective cap. These support the AMH operating logic, a

proximity sensor to detect mass load position, reading of the main mass selection column

switches, operation of the column rotating motor and actuation of the pneumatic control solenoid

valves.

2. Mass lifter(8): The mass lifter is used to lift the entire mass load to the mass selection position

and then to lower the selected masses onto the piston. The mass lifter is pneumatically actuated.

A flexible diaphragm(4) is connected to a lifting assembly(5). A three-way solenoid valve (e.g. 9)

can be actuated to admit or exhaust drive air pressure to and from the volume under the

diaphragm. Admitting drive pressure forces the lifting assembly up. Exhausting the pressure

lowers it. With AMH-38, the pressure is exhausted outside the vacuum chamber, to the AMH

drive vacuum supply when there is vacuum in the chamber.

As the mass lifting assembly (5) rises, it engages a ledge on the mass lifting shaft(6), pushing it

up. The mass lifting shaft is connected to the binary mass carrier(10) and the mass bell(1) sits

on the binary mass carrier. As the mass lifting shaft goes up, it lifts the binary carrier and the bell,

which in turn lifts the main masses(14) and the binary mass tubes(2). When the lifting assembly

reaches the top of its stroke, the entire mass load is lifted completely off the piston cap(12) and

the masses are in the mass selection position. In this position, the ledges on the main mass

selection columns(13) align with the gaps between the main masses and the binary mass

selector pins(e.g. 3) align with the holding grooves in the binary mass tubes. When gas is

exhausted from the volume under the lifting assembly, it descends, lowering the selected masses

onto the piston.

3. Main mass disc selection columns(13): The three main mass selection columns are used to

retain the main mass discs(14) that are not to be loaded onto the piston. The columns are

rotated synchronously by a DC motor and a drive belt(11). Contact switches are used to monitor

the column position. Each column has a number of sides equal to the maximum number of main

masses plus one (six sides for AMH-38, ten sides for AMH-100). One side, which retains all the

masses so that none are loaded, has a ledge for each mass. Each subsequent side has one less

ledge, moving from the bottom up. The last side has no ledges and is used to select all the main

masses for loading. When the mass load is lifted to the mass selection position, the motor is

operated to rotate the columns to retain the desired number of masses. The rest of the main

masses are free and are lowered onto the piston when the lifting assembly descends.

Page 19 © 2007 DH Instruments, a Fluke Company

Page 28

AMH-38™ AND AMH-100™ OPERATION AND MAINTENANCE MANUAL

4. Binary mass tube selection pins(3): The binary mass selection pins are used to retain the

binary mass tubes that are not to be loaded onto the piston. Three pins for each mass are

located in a circular pattern around the top of each mass. The pins are pneumatically actuated

and double acting. Two three-way solenoid valves(e.g. 9) control drive pressure to each set of

three pins. One valve admits pressure to one side of the pin to extend it and the other admits

pressure to the other side of the pin to retract it. Once the pins have been moved, the pressure is

exhausted; the exhaust is to vacuum when there is vacuum in the vacuum chamber of AMH-38.

When the mass load is lifted to the mass selection position, the pins are operated to retain the

binary masses that are not to be loaded. The rest of the binary masses are free and are placed

onto the piston when the lifting assembly descends.

Do not put your fingers or anything else beneath the AMH trim mass tray. AMH may lower up

to 100 kg (220 lbs) onto anything that is under the trim mass tray. This could cause

damage and/or injury.

© 2007 DH Instruments, a Fluke Company Page 20

Page 29

3. OPERATION

1. Mass loading bell

2. Binary mass tubes

3. Binary mass selection pins

4. Flexible diaphragm

5. Mass lifting assembly

6. Lifting ledge on mass lifting shaft

7. Electronics and electrical controls

Figure 8. AMH Schematic/Operating Principle

Page 21 © 2007 DH Instruments, a Fluke Company

8. Mass lifter

9. Solenoid valve

10. Binary mass carrier

11. Main mass column rotation belt

12. Piston cap

13. Main mass column

14. Main masses

Page 30

AMH-38™ AND AMH-100™ OPERATION AND MAINTENANCE MANUAL

3.2 OPERATION

Once the AMH mass set has been installed (see Section 2.6) and the AMH mass handling system has

been initialized (see Section 2.7) and installed, regular operation of the AMH is controlled by the P7000

Platform in response to local commands entered on the PG Terminal or remote commands received over

the PG7000 Platform’s COM1 or IEEE-488 interface.

Generally, AMH operation is transparent to the operator. The AMH system changes the mass load on

the piston automatically as needed when a pressure or mass load setting command is given to the

PG7000. The AMH mass handler and mass set are removed only when it is necessary to access the

piston-cylinder assembly, for example to change ranges.

Subsections of this section describe various aspects of AMH operation.

See Sections 3.2.1 and 3.2.2 for instructions on installing and removing the AMH mass handler.

See Section 3.2.3 for information on regular pressure to mass or mass to pressure operation.

See Section 3.2.4 for information on controlling the AMH mass handling system directly, outside of

pressure to mass or mass to pressure operation.

See Section 3.2.5 for information on making and breaking the reference vacuum in AMH-38.

See Section 3.2.6 for information on accessing the piston-cylinder module when an AMH is installed.

See Section 2.3.7 and 3.2.8 for a description of the indications of the AMH LED and a listing of AMH

related error messages.

See Section 4 for information on controlling PG7000 equipped with AMH by remote commands from a

computer.

3.2.1 INSTALLING THE AMH MASS HANDLER ON THE PG7000 PLATFORM

To avoid possible damage to the AMH automated mass handler, always perform the

initial start/verification procedure described in Section 2.7 BEFORE attempting to install

AMH on the PG7000 Platform. Failing to do so, may result in attempting to install AMH

with mass selection columns or pins in the incorrect position, which can damage the

AMH mass handler.

© 2007 DH Instruments, a Fluke Company Page 22

Page 31

3. OPERATION

Figure 9. AMH Installation on PG7000 Platform

3.2.1.1 INSTALLING AMH-38

To install the AMH-38 mass handler on the PG7601 platform, proceed as follows

(see Figure 9).

Prepare the AMH-38: Perform the AMH start up/verification procedure

describe in Section 2.7. This assures that the AMH mass selection columns

and pins are all correctly positioned.

Make sure that the mass lifting shaft is NOT installed on the mass bell.

If the KF-40 port on the side of the AMH is being used for the vacuum

reference connection, consider waiting to connect it after the AMH is on the

PG7601 platform.

Check that the large O-ring at the bottom inside circumference of the AMH-

38 vacuum chamber is well seated.

Lift the AMH-38 onto the PG7601 platform: Using the handles on the side of

the AMH-38 vacuum chamber, lift the AMH-38 above the PG7601 platform and

masses. Center it over the mass load and gently lower it down until the bottom

circumference of the AMH-38 vacuum chamber reaches the PG7601 vacuum

Page 23 © 2007 DH Instruments, a Fluke Company

Page 32

AMH-38™ AND AMH-100™ OPERATION AND MAINTENANCE MANUAL

plate. Check that the vacuum chamber is well aligned on the vacuum plate.

The AMH may be rotated on the platform to the most convenient position.

Install the mass lifting shaft: Slip the threaded end of the shaft down through

hole in the center of the mass lifter. Thread the shaft into the binary mass

carrier by holding and rotating the trim mass tray. NOTE THAT SHAFT HAS A

LEFT HAND THREAD SO IT MUST BE ROTATED COUNTER-CLOCKWISE

TO TIGHTEN IT. Use the 3 mm allen wrench supplied in the AMH-38

accessories to tighten the assembly until you feel the mass start to rotate.

Be sure that the mass lifting shaft is fully threaded into the binary

mass carrier. Thread it by hand, then tighten it using the allen wrench

supplied with the AMH-38 until you feel the masses rotate. If the

mass lifting shaft is not fully threaded, the mass will not align properly

with the AMH mass handling columns and pins and damage may result.

Install the bell jar: Install the PG7601 Pyrex® bell jar over the upper

portion of the AMH mass handler. Make the reference vacuum connection

if the KF40 connection on the side of the AMH is being used.

If preparing to operate w ith vacuum in the AMH-38 bell jar, open the

AMH vacuum supply valve to admit drive vacuum to the AMH-38 (see

Section 2.3.2.5). If operating without vacuum in the AMH-38 bell jar,

vent the AMH-38 vacuum supply port atmosphere.

Do not operate AMH-38 when using a PG7601 in “absolute by vacuum” mode

without having a vacuum supply connected to AMH-38. Always check that

AMH-38 is supplied with vacuum before establishing reference vacuum in the

AMH-38 vacuum chamber. NEVER plug the AMH drive vacuum port. Failure

to do so may result in damage to the binary mass pins and/or binary

masses (see Section 2.3.2.5).

The PG7601 with AMH-38 is now ready to operate (see Section 3).

3.2.1.2 INSTALLING AMH-100

To install the AMH-100 mass handler on the PG7000 Platform, proceed as

follows (see Figure 9).

Prepare the AMH-100 and PG7000 Platform: Perform the AMH start

up/verification procedure describe in Section 2.7. This assures that the

AMH mass selection columns and pins are all correctly positioned.

Loosen the set screws that are across from the AMH mounting holes on the

PG7000 vertical sides. Use a 2.5 mm allen wrench to loosen the set

screws until they extend just beyond side of the PG7000 Platform.

Make sure that the mass lifting shaft is NOT installed on the mass bell.

Lift the AMH-100 onto the PG7000 Platform: Grasping the AMH-100 by

the horizontal platform in its middle, lift the AMH-100 above the PG7601

platform and masses. Align it so that the bubble level on the AMH is at the

front of the PG7000 Platform. Center it over the mass load and gently lower

it down until the AMH feet enter the holes in the PG7000 Platform. Assure

that all three feet fully enter and seat in the platform holes. Tighten the

platform set screws using a 2.5 mm allen wrench provided in the AMH-100

accessories, one for each of the feet.

© 2007 DH Instruments, a Fluke Company Page 24

Page 33

3. OPERATION

Install the mass lifting shaft: Slip the threaded end of the shaft down through

hole in the center of the mass lifter. Thread the shaft into the binary mass

carrier by holding and rotating the trim mass tray. NOTE THAT SHAFT HAS A

LEFT HAND THREAD SO IT MUST BE ROTATED COUNTER-CLOCKWISE

TO TIGHTEN IT. Use the 3 mm allen wrench supplied in the AMH-100

accessories to tighten the assembly until you feel the masses begin to rotate.

Be sure that the mass lifting shaft is fully threaded into the binary

mass carrier. Thread it by hand, then tighten it using the allen wrench

supplied with the AMH-100 until you feel the masses rotate. If the

mass lifting shaft is not fully threaded, the mass will not align properly

with the AMH mass handling columns and pins and damage may result.

The PG7000 with AMH-100 is now ready to operate (see Section 3).

3.2.2 REMOVING THE AMH MASS HANDLER FROM THE PG7000 PLATFORM

3.2.2.1 REMOVING AMH-38

To remove the AMH-38 mass handler from the PG7601 platform, proceed as

follows (see Figure 9).

Load all the mass: Use [SPECIAL], <8AMH>, <2control>, <3loadall> to

load all the masses of the AMH mass set. This assures that no masses are

retained in the AMH so it will be able to be lifted off the platform freely.

Open the vacuum chamber and bell jar to atmospheric pressure:

Check that the vacuum chamber and bell jar are open to atmosphere. It is

not possible to remove the AMH with internal pressure less than

atmospheric pressure.

Remove the bell jar: Remove the PG7601 Pyrex® bell jar and set aside. If

the KF-40 connection on the side of the AMH vacuum chamber is being

used for the vacuum reference, consider disconnecting it before lifting the

AMH off the platform.

Remove the mass lifting shaft: Use the 3 mm allen wrench supplied in the

AMH-38 accessories to loosen and unscrew the shaft. NOTE THAT

SHAFT HAS A LEFT HAND THREAD SO IT MUST BE ROTATED

CLOCKWISE TO LOOSEN IT. Slip the shaft up and out of the mass

handler.

Lift the AMH-38 off of the PG7601 platform: Using the handles on the

side of the AMH-38 vacuum chamber, lift the AMH-38 straight up until it

clears the masses and set it on a flat surface. The AMH-38 mass handler

weighs about 18 kg (40 lb.).

3.2.2.2 REMOVING AMH-100

To remove the AMH-100 mass handler from the PG7000 Platform, proceed as

follows (see Figure 9).

Load all the mass: Use [SPECIAL], <8AMH>, <2control>, <3loadall> to

load all the masses of the AMH mass set. This assures that no masses are

retained in the AMH so it will be able to be lifted off the platform freely.

Loosen the mass handler column set screws: Loosen the set screws that

are across from the AMH mass selection columns on the PG7000 Platform

Page 25 © 2007 DH Instruments, a Fluke Company

Page 34

AMH-38™ AND AMH-100™ OPERATION AND MAINTENANCE MANUAL

vertical sides. Use the 2.5 mm allen wrench supplied in the AMH accessories

to loosen the set screws until they extend just beyond side of the PG7000

Platform.

Remove the mass lifting shaft: Use the 3 mm allen wrench supplied in the

AMH-38 accessories to loosen and unscrew the assembly. NOTE THAT

SHAFT HAS A LEFT HAND THREAD SO IT MUST BE ROTATED

CLOCKWISE TO LOOSEN IT. Slip the shaft up and out of the mass

handler.

Lift the AMH-100 off of the PG7000 Platform: Grasping the AMH-100 by

the horizontal platform in its middle, lift the AMH-100 straight up until it

clears the masses and set it on a flat surface. The AMH-100 mass handler

weighs about 12 kg (25 lb.).

3.2.3 REGULAR MASS TO PRESSURE OR PRESSURE TO MASS OPERATION

See the PG7000 Operation and Maintenance Manual, General Operation, for details on

PG7000 operation. If the PG7000 is equipped with AMH, AMH automatically loads the

requested mass values transparently to the operator.

Generally, the PG7000 is used to set pressures by loading mass onto the piston and

adjusting the pressure under the piston to float the piston. The PG7000 supports this

operation locally from its main run screen in pressure entry or mass entry mode (see the

PG7000 Operation and Maintenance Manual, [M or S]). In pressure entry mode, when AMH

is installed and initialized, when the operator enters the pressure to set, the corresponding

mass load is loaded automatically with the AMH’s 0.1 kg mass loading resolution. If the

PG7000 is set for finer than 0.1 kg resolution (see the PG7000 Operation and Maintenance

Manual, [RES], the operator is prompted to load a trim mass value manually. In mass entry

mode, if a mass value with resolution higher than 0.1 kg is entered, after AMH loads the

value within 0.1 kg, the operator is prompted to load the remaining trim mass value manually.

Do not put your fingers or anything else beneath the AMH trim mass tray. AMH may

lower up to 100 kg (220 lbs) onto anything that is under the trim mass tray. This could

cause injury and/or damage.

3.2.4 DIRECT CONTROL OF AMH FUNCTIONS

In normal PG7000 operation, the AMH mass handler is operated transparently to the

operator when a mass change is necessary.

For AMH to be operated it must first be initialized by selecting an AMH mass set (see

PG7000 Operation and Maintenance Manual, Select Mass Set.

The status of the AMH (current masses loaded) can be viewed and its operation controlled

directly using [SPECIAL], <8AMH>.

Select <1status> to view which AMH masses are loaded.

Select <2control>, <1up/down> to raise and lower the mass load without changing the

selected masses.

Select <2control>, <2discreet> to select specific masses to load and unload.

Select <2control>, <3loadall> to clear the AMH and load all the masses on the piston. This

is the condition used to remove and install the AMH. In this state, the AMH retains no

masses.

Select <2control>, <1unloadall> to clear the AMH and unload all the masses from the

piston. In this state, the AMH retains all the masses.

© 2007 DH Instruments, a Fluke Company Page 26

Page 35

3. OPERATION

3.2.5 MAKING AND BREAKING THE REFERENCE VACUUM (AMH-38 ONLY)

When making and breaking the reference vacuum in the AMH 38 vacuum chamber to switch

the PG7000 between absolute and gauge mode operation, it is important that the AMH mass

manipulation actuators also be exposed to the correct pressure. The correct pressure is

vacuum in absolute mode and atmosphere in gauge mode.

If AMH-38 is to be operated with a vacuum in its vacuum chamber, a vacuum supply must be

connected to the drive vacuum connection quick connector so that the AMH actuators (mass

lifter, mass selector pins) are evacuated when they are not pressurized. See Section 2.3.2.2

for information on correctly connecting the drive vacuum supply to AMH-38.

When using AMH-38 in absolute mode, the drive vacuum supply sleeve valve must be set to

the VACUUM position just before establishing the reference vacuum.

When operating with atmosphere in the vacuum chamber, set the drive vacuum supply

sleeve valve to GAUGE so that the AMH actuators vent to atmosphere.

Failure to supply vacuum to the AMH-38 before establishing a vacuum in its vacuum

chamber may cause unexpected operation of the binary mass selector pins which could

result in damage to the AMH mass handler and or masses (see Section 2.3.2.5). NEVER

plug the AMH drive vacuum port.

3.2.6 ACCESSING THE PG7000 PISTON-CYLINDER MODULE

To access the piston-cylinder module in a PG7000 Platform with AMH installed, the AMH

mass handler and mass set must be removed.

First, remove the AMH mass handler as described in Section 3.2.2.

Then, remove the AMH mass set following the instructions in Section 2.6 in reverse order.

Once the AMH mass handler and mass set are removed, the piston-cylinder module can be

accessed and removed by simply unscrewing it from the mounting post following the

standard procedure (see the PG7000 Operation and Maintenance Manual).

3.2.7 INDICATOR LED

There is a green indicator LED located on AMH-38 and AMH-100 near the power supply

connection. It is on the rear electrical, vacuum chamber pass through of AMH-38 and on the

top cover of AMH-100 (see Figures 1, 2).

The indicator has four possible conditions:

• Off: AMH is not powered.

• Solid green: AMH is powered and operation is normal.

• Slow flashing green: AMH is powered and is in an unknown state. To recover use

[SPECIAL], <8AMH>, <2control>, <3loadall> or <4unloadall> or initialize AMH by

selecting an AMH mass set (see Section 2.7., Step ).

• Fast flashing green: AMH is powered and has encountered a known error condition.

The error is displayed on the PG Terminal (see Section 3.2.8) and available remotely

using the “AMHERR” command. To recover use [SPECIAL], <8AMH>, <2control>,

<3loadall> or <4unloadall> or initialize AMH by selecting an AMH mass set (see Section

2.7, Step ).

Page 27 © 2007 DH Instruments, a Fluke Company

Page 36

AMH-38™ AND AMH-100™ OPERATION AND MAINTENANCE MANUAL

3.2.8 ERROR MESSAGES

The AMH mass handler can inform the PG7000 of certain error conditions.

An AMH error condition is indicated on the PG Terminal by an error message and listing of

the error number on the bottom right hand of the display.

An AMH error is indicated remotely by the PG7000 return string including the character “E” in

the third “Ready indicator position”. The “Ready” indication is included in the “PR” and

“STATUS” commands. When an “E” has been returned, the error identification can then be

retrieved using the “AMHERR” command. See the PG7000 Operation and Maintenance

Manual, Remote Operation for additional information.

The possible errors are listed in table 4.

Table 4. AMH Errors

AMH

ERROR

NUMBER

None

(Remote

error #29)

None

(Remote

error #28)

2 None Text argument is too long.

6 None Argument out of range.

7 None Missing or improper argument.

9 None Unknown Command.

10 None Invalid command suffix.

13 None Receive buffer overflow. Buffer has been flushed.

18 None Command not available.

60 None Watchdog reset has occurred.

100 None Present mass setting unknown.

102 None 6.2 kg binary mass not available on AMH-38.

103

104

105

106 None Mass load must first be lifted.

107

108

110

111

112

113

114

115

116

117

118

119

PG TERMINAL MESSAGE COMMENT

<AMH response fault>

<AMH not responding>

<AMH memory failure>

<AMH memory failure>

<AMH logic failure>

<AMH logic failure>

<AMH logic failure>

<AMH unable to rotate column

motor>

<AMH unable to rotate column

motor>

<AMH unable to rotate column

motor>

<AMH unable to rotate column

motor>

<AMH logic failure>

<AMH logic failure>

<AMH logic failure>

<AMH logic failure>

<AMH logic failure>

<AMH logic failure>

The AMH has returned a string that the PG7000 cannot

identify. This is a PG7000 generated error.

The PG7000 has not received a response from the AMH.

This is a PG7000 generated error as a consequence of a time

out while attempting to communicate with AMH.

Mass memory.

Non-volatile memory is corrupt.

Fatal electronics error.

Incorrect CPLD version.

CPLD logic error.

Column motor switch error on column 0 (C0).

Column motor switch error on column 1 (C1).

Column motor switch error on column 2 (C2).

Wrong column switch detected.

JTAG buffer overflow.

JTAG max retries.

JTAG TDO mismatch.

JTAG illegal state.

JTAG ENDxR state unknown.

JTAG unknown error.

© 2007 DH Instruments, a Fluke Company Page 28

Page 37

3. OPERATION

Table 4. AMH Errors (continued)

AMH

ERROR

NUMBER

120

121

122

123

124

125

126

130

131

132

133

134

135

136

137

138

139

140

141

142

143

PG TERMINAL MESSAGE COMMENT

<AMH unable to lift mass load>

<AMH unable to lower mass load>

<AMH unable to lift mass load>

<AMH unable to lower mass load>

<AMH unable to lift mass load>

<AMH unable to rotate column

motor>

<AMH unable to rotate column

motor>

<AMH valve failure>

<AMH valve failure>

<AMH valve failure>

<AMH valve failure>

<AMH valve failure>

<AMH valve failure>

<AMH valve failure>

<AMH valve failure>

<AMH valve failure>

<AMH valve failure>

<AMH valve failure>

<AMH valve failure>

<AMH valve failure>

<AMH valve failure>

Mass lift valve not sensed.

Mass is dropping unexpectedly.

Mass never lifted.

Mass is not dropping when it should.

IR beam malfunction. AMH will not attempt lift

Column motor switch on column 1 is misaligned.

Column motor switch on column 2 is misaligned.

6.2 kg binary mass pin engage valve (VLV#14) not sensed.

3.2 kg binary mass pin engage valve (VLV#6) not sensed.

1.6 kg binary mass pin engage valve (VLV#12) not sensed.

0.8 kg binary mass pin engage valve (VLV#4) not sensed.

0.4 kg binary mass pin engage valve (VLV#10) not sensed.

0.2 kg binary mass pin engage valve (VLV#2) not sensed.

0.1 kg binary mass pin engage valve (VLV#8) not sensed.

6.4 kg binary mass pin disengage valve (VLV#15) not

sensed.

3.2 kg binary mass pin disengage valve (VLV#7) not sensed.

1.6 kg binary mass pin disengage valve (VLV#13) not

sensed.

0.8 kg binary mass pin disengage valve (VLV#5) not sensed.

0.4 kg binary mass pin disengage valve (VLV#11) not

sensed.

0.2 kg binary mass pin disengage valve (VLV#3) not sensed.

0.1 kg binary mass pin disengage valve (VLV#9) not sensed.

Page 29 © 2007 DH Instruments, a Fluke Company

Page 38

AMH-38™ AND AMH-100™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2007 DH Instruments, a Fluke Company Page 30

Page 39

4. REMOTE OPERATION

.

44.

4.1 OVERVIEW

The AMH mass handling system is equipped with an RS232 interface (COM1). The interface is used for

communications between the AMH mass handler and the PG7000 Platform’s COM3 (directly, or through

a DHI pressure controller). The AMH mass handler is not intended to be addressed directly with remote

commands from a computer. Its functionality is achieved by commands addressed to the PG7000

Platform. For example, sending a “PS=” command to the PG7000 Platform when an AMH is already

initialized, causes the AMH to load mass automatically. Certain AMH specific commands can be sent to

the PG7000 Platform, for example a command to clear the AMH and load all the mass on the piston.

These commands are listed in the PG7000 Operation and Maintenance Manual, Remote Operation along

with the other PG7000 remote commands.

MOOTTEE

RREEM

OOPPEERRAATTIIOONN

Page 31 © 2007 DH Instruments, a Fluke Company

Page 40

AMH-38™ AND AMH-100™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2007 DH Instruments, a Fluke Company Page 32

Page 41

55.

5. MAINTENANCE AND ADJUSTMENTS

.

M

AAIINNTTEENNAANNCCEE AANNDD

M

A

DDJJUUSSTTMMEENNTTS

A

S

5.1 MAINTENANCE

The AMH mass handler is designed for long term, maintenance free operation.

Certain day-to-day procedures are required for proper operation.

• Lubricate the threads of the mass lifting shaft: Occasionally, and especially after cleaning,

lubricate the threads on the bottom of the mass lifting shaft. Wipe on a very thin film of Krytox®

grease (supplied with the PG7000 Platform accessories). Wipe off all excess grease.

• Lubricate the inside of the mass bell: Occasionally perform the bell positioning test described

in Section 2.5.1. If the test fails, or if any sign of the bell not disengaging and engaging from the

piston when the mass load is lifted is observed in operation, apply and wipe off a very thin film of

Krytox® grease (supplied with the PG7000 Platform accessories) to the inside surface of the top

of the mass loading bell where it contacts the outside perimeter of the piston cap.

If AMH returns no errors and no operational issues are observed, no regular maintenance is required. To

avoid any planned downtime, an AMH overhaul is recommended every 10000 hours of operation or three

years. Contact a DHI Authorized Service Provider to have this service performed.

Page 33 © 2007 DH Instruments, a Fluke Company

Page 42

AMH-38™ AND AMH-100™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2007 DH Instruments, a Fluke Company Page 34

Page 43

6. TROUBLESHOOTING

66.

.

T

RROOUUBBLLEESSHHOOOOTTIINNG

T

G

Identify the symptom or unexpected behavior you are observing from the SYMPTOM list below.

A PROBABLE CAUSE is provided and a SOLUTION is proposed including references to manual

sections that provide information that may be of assistance.

This troubleshooting guide is for the AMH mass handler. For general PG7000 troubleshooting, see the

PG7000 Operation and Maintenance Manual.

Table 5. AMH Troubleshooting Checklist

SYMPTOM PROBABLE CAUSE SOLUTION

PG Terminal displays <AMH not

responding>.

PG Terminal displays <AMH unable

to lift mass load ERR#122>.

Mass handling system will not go down

over the masses to be installed on the

platform.

AMH masses rock back and forth

when lifted to the mass selection

position.

Main masses move when mass is in

mass selection position and main

mass selection columns are rotating.

PG Terminal displays <AMH unable

to rotate column motor> and

ERR#110, ERR#111 or ERR#112.

Poor behavior of PG7000 with

symptoms such as inconsistent

indication of piston position, unstable

pressure when piston is floating.

Mass handling error occurs with AMH38 in absolute mode due to binary

mass selection pins being extended

when they should be retracted.

Cannot remove bell jar from AMH-38

though there is no vacuum in the bell

jar.

When setting pressures, PG Terminal