Page 1

ADCS-601™

Air Data Calibration Standard

Operation and Maintenance Manual

© 2005 DH Instruments, Inc.

Page 2

ADCS-601™ OPERATION AND MAINTENANCE MANUAL

Pressurized gases are potentially hazardous. Energy stored in these gases can be released

unexpectedly and with extreme force. Pressurized systems should be assembled and operated only by

personnel who have been instructed in proper safety practices.

© 2005 DH Instruments, Inc. All rights reserved.

Information in this document is subject to change without notice. No part of this document may be reproduced or transmitted in any

form or by any means, electronic or mechanical, for any purpose, without the express written permission of DH Instruments, Inc.

4765 East Beautiful Lane Phoenix Arizona 85044-5318 USA.

DH Instruments makes sincere efforts to ensure the accuracy and quality of its published materials; however, no warranty,

expressed or implied, is provided. DH Instruments disclaims any responsibility or liability for any direct or indirect damages

resulting from the use of the information in this manual or products described in it. Mention of any product or brand does not

constitute an endorsement by DH Instruments of that product or brand. This manual was originally composed in English and was

subsequently translated into other languages. The fidelity of the translation cannot be guaranteed. In case of conflict between the

English version and other language versions, the English version predominates.

DH Instruments, DH, DHI, ADCS-601, ADCS Tools, AMH, COMPASS, FPG8601, PG7601, PPC3 and RPM4 and are trademarks,

registered and otherwise, of DH Instruments, Inc.

Swagelok and Nupro are registered trademarks of the Swagelok Company.

Krytox is a registered trademark of the Dupont de Nemours Company.

Windows, Excel, Word are registered trademarks of the Microsoft Corporation.

Products described in this manual are manufactured under international patents and one or more of the following U.S.

patents: 6,701,791, 5,142,483, 5,257,640, 5,331,838, 5,445,035. Other U.S. and international patents pending.

Document No. 550139b

051222

Printed in the USA

© 2005 DH Instruments, Inc

Page 3

TABLE OF CONTENTS

T

AABBLLEE OOFF

T

C

OONNTTEENNTTS

C

S

TABLE OF CONTENTS ...............................................................I

TABLES..................................................................................V

FIGURES................................................................................VI

ABOUT THIS MANUAL............................................................. IX

1. INTRODUCTION ................................................................. 1

1.1 SPECIFICATIONS....................................................................................................................................1

1.1.1 ADCS SYSTEM GENERAL SPECIFICATIONS............................................................................................1

1.1.2 PG7601 PISTON GAUGE SPECIFICATIONS...............................................................................................2

1.1.2.1 AMBIENT AND PISTON-CYLINDER CONDITION MEASUREMENTS ....................................................2

1.1.2.2 PISTON-CYLINDER MODULE..................................................................................................................2

1.1.2.3 MASS SET.................................................................................................................................................3

1.1.3 FPG8601 GENERAL SPECIFICATIONS.......................................................................................................3

1.1.3.1 AMBIENT AND PISTON-CYLINDER CONDITION MEASUREMENTS ....................................................3

1.1.4 PRESSURE MEASUREMENT AND CONTROL SPECIFICATIONS............................................................3

1.1.4.1 10 TO 380 KPA, PG7601 AND PPC3-700K ..............................................................................................3

1.1.4.2 1 TO 15 KPA, FPG8601 AND PPC3-100K................................................................................................4

2. SYSTEM OVERVIEW ........................................................... 5

2.1 ADCS-601 SYSTEM.................................................................................................................................5

2.1.1 REFERENCE BENCH..................................................................................................................................12

2.1.2 CONTROL CABINET...................................................................................................................................13

2.1.3 GAS SUPPLY PANEL.................................................................................................................................15

2.2 PRESSURE STANDARDS.....................................................................................................................16

2.2.1 PG7601 PISTON GAUGE............................................................................................................................16

2.2.1.1 PG7601 PLATFORM................................................................................................................................17

2.2.1.2 PG7601 TERMINAL.................................................................................................................................17

2.2.1.3 PG7601 10 KPA/KG PISTON-CYLINDER MODULE...............................................................................18

2.2.1.4 AMH-38 AUTOMATED MASS HANDLER...............................................................................................19

2.2.1.5 AMH-38 MASS SET.................................................................................................................................21

2.2.2 FPG8601 FORCE BALANCED PISTON GAUGE .......................................................................................21

2.2.2.1 FPG8601 PLATFORM .............................................................................................................................23

2.2.3 PPC3 PRESSURE CONTROLLERS...........................................................................................................23

2.2.4 RPM4 A116K REFERENCE PRESSURE MONITOR..................................................................................25

2.3 VACUUM PUMPS..................................................................................................................................27

3. INSTALLATION ................................................................ 29

3.1 UNPACKING AND INSPECTION........................................................................................................... 29

3.1.1 ADCS CONTROL CABINET........................................................................................................................30

3.1.2 ADCS REFERENCE BENCH AND ACCESSORIES...................................................................................30

3.1.3 PG7601 PLATFORM AND BELL JAR ........................................................................................................32

3.1.4 PG7601 PISTON-CYLINDER MODULE (PC-7100/7600-10,TC) ................................................................32

3.1.5 PG7601 MASS SET (MS-AMH-38)..............................................................................................................33

3.1.6 PG7601 AUTOMATED MASS HANDLER (AMH-38)..................................................................................34

3.1.7 FPG8601 PLATFORM, PISTON-CYLINDER AND ACCESSORIES...........................................................34

3.1.8 FPG8601 MASS SET (MS-8601-2)..............................................................................................................35

3.1.9 SCROLL VACUUM PUMPS........................................................................................................................35

3.1.10 TURBO MOLECULAR VACUUM PUMP.....................................................................................................35

3.1.11 SYSTEM CONTROLLER.............................................................................................................................36

3.2 SITE REQUIREMENTS..........................................................................................................................36

Page I © 2005 DH Instruments, Inc.

Page 4

ADCS-601™ OPERATION AND MAINTENANCE MANUAL

3.3 SETUP....................................................................................................................................................38

3.3.1 POSITION THE REFERENCE BENCH.......................................................................................................38

3.3.2 INSTALL REFERENCE TURBO VACUUM AND ROUGHING PUMPS......................................................39

3.3.3 POSITION THE PG7601 AND FPG8601 PLATFORMS ON THE REFERENCE BENCH..........................40

3.3.4 PREPARE FPG8601....................................................................................................................................40

3.3.5 MAKE PNEUMATIC INTERCONNECTIONS ON THE REFERENCE BENCH...........................................41

3.3.6 POSITION CONTROL CABINET AND MAKE PNEUMATIC, COMMUNICATIONS AND ELECTRICAL

CONNECTIONS TO REFERENCE BENCH................................................................................................

3.3.7 CONNECT PRESSURE SUPPLIES TO CONTROL CABINET...................................................................43

3.3.8 APPLY SUPPLY PRESSURES AND CHECK GAS SUPPLY PANEL SETTINGS ....................................43

3.3.9 SET UP THE PG7601..................................................................................................................................44

3.3.9.1 PREPARE THE PLATFORM AND INSTALL THE PISTON-CYLINDER MODULE.................................44

3.3.9.2 INSTALL THE AMH-38 MASS SET.........................................................................................................44

3.3.9.3 INSTALL THE AMH-38 MASS HANDLER...............................................................................................45

3.3.9.4 INSTALL THE REFERENCE VACUUM CDG ASSEMBLY .....................................................................46

3.3.10 COMPLETE FPG8601 SETUP....................................................................................................................47

3.3.10.1 INSTALL THE PISTON-CYLINDER.........................................................................................................47

3.3.10.2 CONNECT THE MANIFOLD AND VALVE 9............................................................................................47

3.3.10.3 INSTALL THE REFERENCE VACUUM CDG ASSEMBLY.....................................................................48

3.3.11 COMPLETE REFERENCE VACUUM INTERCONNECTIONS ...................................................................49

3.3.12 INSTALL THE UTILITY VACUUM PUMP....................................................................................................49

3.3.13 SET UP THE SYSTEM CONTROLLER (PC)..............................................................................................49

3.4 POWER UP, INITIALIZATION, VERIFICATION....................................................................................50

3.4.1 MAIN POWER SWITCHES..........................................................................................................................50

3.4.2 SET OR VERIFY DEVICE COMMUNICATION PORT AND OTHER SETTINGS.......................................50

3.4.2.1 COMMUNICATION PORTS.....................................................................................................................50

3.4.2.2 PG7601 EXTERNAL VACUUM GAUGE COMMUNICATION .................................................................50

3.4.2.3 EDIT AND SELECT PG7601 SETUP FILE..............................................................................................51

3.4.3 PG7601 ........................................................................................................................................................51

3.4.3.1 POWER UP..............................................................................................................................................51

3.4.3.2 INITIALIZATION.......................................................................................................................................51

3.4.4 FPG8601......................................................................................................................................................52

3.4.4.1 POWER UP..............................................................................................................................................52

3.4.5 START UP SYSTEM CONTROLLER AND SOFTWARE............................................................................52

3.4.6 VERIFY SYSTEM OPERATION ..................................................................................................................53

3.5 ENTER VALUE OF LOCAL GRAVITY ..................................................................................................54

3.6 SPECIFY TEST GAS SPECIES.............................................................................................................55

3.7 ADDITIONAL PRECAUTIONS TO TAKE BEFORE MAKING PRESSURE MEASUREMENTS...........55

3.8 SHUT DOWN AND RESTART...............................................................................................................55

3.8.1 RESTART.....................................................................................................................................................55

3.8.2 SHUT DOWN ...............................................................................................................................................56

3.8.2.1 SHORT TERM SHUT DOWN ..................................................................................................................56

3.8.2.2 LONG TERM SHUT DOWN.....................................................................................................................56

42

4. OPERATION..................................................................... 57

4.1 GENERAL OPERATING PRINCIPLES..................................................................................................57

4.1.1 SYSTEM CONFIGURATION........................................................................................................................57

4.1.2 READY/NOT READY INDICATIONS...........................................................................................................57

4.1.2.1 OVERVIEW..............................................................................................................................................57

4.1.2.2 READY/NOT READY WHEN USING THE PG7601 PISTON GAUGE....................................................57

4.1.2.3 READY/NOT READY WHEN USING THE FPG8601 FORCE BALANCED PISTON GAUGE................58

4.1.3 TRANSITION BETWEEN STANDARDS, ACTIVE AND INACTIVE STANDARD.......................................58

4.1.4 DIFFERENCE BETWEEN REQUESTED AND ACTUAL SET PRESSURE...............................................60

4.1.5 ASOLUTE AND GAUGE MEASUREMENT MODES ..................................................................................60

4.2 FREQUENTLY USED FUNCTIONS.......................................................................................................61

4.2.1 CONNECTING A DEVICE UNDER TEST (DUT).........................................................................................61

4.2.2 CHANGING PRESSURE UNIT OF MEASURE...........................................................................................61

4.2.3 CHANGING MEASUREMENT MODE (ABSOLUTE, GAUGE)...................................................................62

4.2.4 SETTING PRESSURES...............................................................................................................................62

4.2.4.1 SETTING ZERO PRESSURE..................................................................................................................63

4.2.4.2 SETTING IDLE STATUS..........................................................................................................................63

4.2.5 PRESSURE EXERCISING THE DEVICE UNDER TEST............................................................................63

4.2.6 SETTING A HEAD CORRECTION..............................................................................................................64

4.2.7 STOPPING PRESSURE CONTROL, ABORTING FUNCTION EXECUTION.............................................64

4.2.8 SECURITY, USER RIGHTS.........................................................................................................................65

4.2.8.1 SETTING UP USERS AND MANAGING USER RIGHTS........................................................................65

4.2.8.2 CHANGING ACTIVE USER.....................................................................................................................66

4.2.9 PRESSURE LEAK TEST.............................................................................................................................66

© 2005 DH Instruments, Inc. Page II

Page 5

TABLE OF CONTENTS

4.3 LOCAL OPERATION, ADCS TOOLS....................................................................................................67

4.3.1 OVERVIEW..................................................................................................................................................67

4.3.2 MAIN MENU.................................................................................................................................................69

4.3.3 ADCS MAIN TOOLBARS ............................................................................................................................70

4.3.4 ADCS STATUS BAR....................................................................................................................................74

4.3.5 ADCS RUN SCREEN...................................................................................................................................74

4.3.5.1 ADCS RUN SCREEN CONTROL PANEL...............................................................................................75

4.3.5.2 ADCS SYSTEM DISPLAY .......................................................................................................................76

4.3.5.3 ADCS RUN SCREEN TOOLBAR ............................................................................................................78

4.3.6 OTHER DEVICE RUN SCREENS ...............................................................................................................79

4.3.6.1 PG7601 PRESSURE STANDARD...........................................................................................................79

4.3.6.2 FPG8601 PRESSURE STANDARD ........................................................................................................80

4.3.6.3 PPC3 (FPG’S PRESSURE CONTROLLER)............................................................................................80

4.3.6.4 RPM4 REFERENCE PRESSURE MONITOR .........................................................................................81

4.4 AUTOMATED TESTING ........................................................................................................................82

4.4.1 SETTING UP TO RUN AUTOMATED TESTS.............................................................................................82

4.4.1.1 SETTING UP DEVICE UNDER TEST (DUT)...........................................................................................82

4.4.1.2 SETTING UP TEST DEFINITIONS..........................................................................................................84

4.4.1.3 SETTING UP SUPPORT DEVICES.........................................................................................................85

4.4.1.4 TEST OPTIONS (DATA OPTIONS).........................................................................................................85

4.4.2 RUNNING AUTOMATED TESTS ................................................................................................................86

4.4.2.1 RUNNING A MANUAL TEST...................................................................................................................87

4.4.2.2 RUNNING A TEST DEFINITION..............................................................................................................87

4.4.3 TEST RUN SCREENS.................................................................................................................................88

4.4.3.1 DATA PLOT RUN SCREEN.....................................................................................................................89

4.4.3.2 DATA GRID RUN SCREEN.....................................................................................................................89

4.4.3.3 DUT/REFERENCE COMPARISON RUN SCREEN ................................................................................90

4.4.4 TEST DATA..................................................................................................................................................91

4.4.5 REPORT EDITOR........................................................................................................................................91

4.4.6 RUNNING A MODEL 3682 AIR DATA CALIBRATOR................................................................................92

4.4.6.1 RUNNING A VALIDATION (CALIBRATION) ...........................................................................................92

4.4.6.2 RUNNING A STANDARDIZATION..........................................................................................................97

5. REMOTE OPERATION ......................................................103

6. GENERAL MAINTENANCE AND ADJUSTMENTS ..................105

6.1 SUMMARY...........................................................................................................................................105

6.2 FPG8601, CHECK BUBBLER AND ADD WATER IF NECESSARY...................................................106

6.3 FPG8601, REMOVE CLEAN AND REINSTALL THE PISTON-CYLINDER........................................107

6.3.1 OVERVIEW................................................................................................................................................107

6.3.2 REMOVING THE PISTON-CYLINDER FROM THE MOUNTING POST...................................................109

6.3.3 REMOVING THE PISTON FROM THE CYLINDER ..................................................................................111

6.3.4 CLEANING THE PISTON AND CYLINDER..............................................................................................112

6.3.5 PUTTING THE PISTON INTO THE CYLINDER........................................................................................113

6.3.6 INST AL L I N G T H E P I S T O N -C Y L I N D E R I N T H E M O U N T I N G P O S T ................................................. 114

6.3.7 RESTORING PISTON-CYLINDER LUBRICATION AND MOBILITY........................................................115

6.3.7.1 OVERVIEW............................................................................................................................................115

6.3.7.2 PISTON CENTERING AND LUBRICATING METHODS.......................................................................115

6.4 PG7601, DISASSEMBLE PLATFORM AND REMOVE MOUNTING POST PRT................................117

6.5 PG7601, REMOVE AND REINSTALL THE AUTOMATED MASS HANDLER AND MASS SET ........118

6.5.1 THE MASS HANDLER (AMH)...................................................................................................................118

6.5.2 THE MASS SET.........................................................................................................................................121

6.6 PG7601, REMOVE, CLEAN AND REINSTALL THE PISTON-CYLINDER MODULE.........................122

6.6.1 REMOVING THE PISTON-CYLINDER MODULE .....................................................................................122

6.6.2 INSTALLING THE PISTON-CYLINDER MODULE ...................................................................................123

6.6.3 DISASSEMBLING THE MODULE AND CLEANING THE PISTON-CYLINDER ASSEMBLY..................124

6.6.3.1 OVERVIEW............................................................................................................................................124

6.6.3.2 DISASSEMBLING AND REASSEMBLING THE MODULE ...................................................................124

6.6.3.3 LUBRICATING THE PISTON-CYLINDER MODULE.............................................................................127

6.6.3.4 CLEANING THE PISTON-CYLINDER...................................................................................................128

6.7 PG7601, PISTON POSITION DETECTION ADJUSTMENT................................................................130

6.8 PG7601, REPLACE PISTON ROTATION DRIVE BELTS...................................................................131

6.9 PG7601, ADJUST INTERNAL VACUUM GAUGE...............................................................................131

6.10 PG7601/FPG8601, ADJUST PPC3 PRESSURE CONTROLLERS.....................................................132

Page III © 2005 DH Instruments, Inc.

Page 6

ADCS-601™ OPERATION AND MAINTENANCE MANUAL

6.11 CONTROL CABINET, INTERRUPTING PRESSURE SUPPLY TO THE TEST GAS SUPPLY PORT133

6.12 CONTROL CABINET, DRAIN DRIVE AIR TRAPS..............................................................................133

6.13 CONTROL CABINET, CHECK GAS SUPPLY PANEL SETTINGS.....................................................133

7. MAINTENANCE OF TRACEABILITY AND RECALIBRATION ...135

7.1 PRINCIPLES OF ADCS-601 TRACEABILITY MAINTENANCE..........................................................135

7.2 LOCAL METROLOGY MAINTENANCE BETWEEN RECALIBRATIONS ..........................................135

7.2.1 OVERVIEW................................................................................................................................................135

7.2.2 FPG8601, ZERO AND ADJUST SPAN OF LOAD CELL..........................................................................136

7.2.2.1 AUTOMATICALLY INITIATED LOAD CELL ZERO AND SPAN ADJUSTMENT...................................136

7.2.2.2 OPERATOR INITIATED LOAD CELL ZERO AND SPAN ADJUSTMENT ............................................137

7.2.3 FPG8601, VALIDATE WITH PG7601........................................................................................................137

7.2.3.1 OVERVIEW............................................................................................................................................137

7.2.3.2 RUNNING VALIDATION........................................................................................................................138

7.2.3.3 VIEWING FPG VALIDATION DATA ......................................................................................................141

7.2.4 FPG8601, CHECK ON-BOARD P, T, H MEASUREMENTS.....................................................................141

7.2.5 FPG8601, VALIDATE LOAD CELL LINEARITY.......................................................................................141

7.2.5.1 OVERVIEW............................................................................................................................................141

7.2.5.2 LINEARITY VERIFICATION PROCEDURE...........................................................................................142

7.2.5.3 EVALUATING LINEARITY VERIFICATION DATA................................................................................142

7.2.6 FPG8601 AND PG7601, ZERO REFERENCE VACUUM CDGS..............................................................143

7.2.7 PG7601, ADJUST ON-BOARD P, T, H SENSORS...................................................................................146

7.3 RECALIBRATION................................................................................................................................147

7.3.1 OVERVIEW................................................................................................................................................147

7.3.2 PG7601, CALIBRATION OF PISTON-CYLINDER MODULE...................................................................148

7.3.2.1 PREPARING FOR CALIBRATION.........................................................................................................148

7.3.2.2 UPDATING PISTON-CYLINDER CALIBRATION INFORMATION........................................................148

7.3.3 PG7601, CALIBRATION OF MASS SET...................................................................................................149

7.3.3.1 PREPARING FOR CALIBRATION.........................................................................................................149

7.3.3.2 UPDATING MASS SET CALIBRATION INFORMATION ......................................................................150

7.3.4 PG7601, CALIBRATION OF PISTON-CYLINDER MODULE TEMPERATURE SENSOR.......................151

7.3.4.1 OVERVIEW............................................................................................................................................151

7.3.4.2 PROCEDURE ........................................................................................................................................152

7.3.4.3 CALCULATING AND UPDATING PISTON-CYLINDER TEMPERATURE SENSOR INFORMATION..152

7.3.5 PG7601, CALIBRATION OF REFERENCE VACUUM CDG.....................................................................154

7.3.5.1 OVERVIEW............................................................................................................................................154

7.3.5.2 REMOVING THE CDG ASSEMBLY......................................................................................................154

8. TROUBLESHOOTING .......................................................157

8.1 OVERVIEW..........................................................................................................................................157

9. APPENDIX ......................................................................159

9.1 CONVERSION OF NUMERICAL VALUES..........................................................................................159

9.1.1 PRESSURE................................................................................................................................................159

9.2 GLOSSARY..........................................................................................................................................160

9.3 WARRANTY STATEMENT..................................................................................................................161

© 2005 DH Instruments, Inc. Page IV

Page 7

TABLES & FIGURES

T

AABBLLEES

T

Table 1. ADCS-601 packing list.................................................................................................................29

Table 2. Reference Bench parts list...........................................................................................................30

Table 3. Interconnections kit parts list .......................................................................................................31

Table 4. ADCS accessory kit parts list.......................................................................................................31

Table 5. PG7601 Platform parts list........................................................................................................... 32

Table 6. PC-7100/7600-10, TC piston-cylinder module parts list.............................................................. 33

Table 7. MS-AMH-38 mass set parts list ...................................................................................................33

Table 8. AHM-38 automated mass handler parts list ................................................................................ 34

Table 9. FPG8601 Platform parts list.........................................................................................................34

Table 10. MS-8601-2 mass set parts list...................................................................................................35

Table 11. Valve states................................................................................................................................59

Table 12. User rights user access areas ...................................................................................................65

Table 13. ADCS Tools Main Menu and sub-menus summary ..................................................................69

Table 14. ADCS Main Toolbar buttons.......................................................................................................70

Table 15. ADCS Run Screen Control Panel features................................................................................75

Table 16. ADCS System Display symbols................................................................................................. 77

Table 17. ADCS Run Screen Toolbar........................................................................................................78

Table 18. Mechanical maintenance procedures......................................................................................105

Table 19. PG7601 mounting post wire colors, description and location..................................................117

Table 20. Gas Supply Panel pressure settings........................................................................................133

Table 21. Metrological maintenance procedures.....................................................................................136

Table 22. FPG8601 P, T, H limits............................................................................................................141

Table 23. Recalibration requirements......................................................................................................147

Table 24. Troubleshooting checklist ........................................................................................................157

Table 25. Pressure unit of measure conversions ....................................................................................159

Table 26. DHI Authorized Service Providers ...........................................................................................161

S

Page V © 2005 DH Instruments, Inc.

Page 8

ADCS-601™ OPERATION AND MAINTENANCE MANUAL

F

IIGGUURREES

F

Figure 1. ADCS-601 overall, front view........................................................................................................6

Figure 2. ADCS-601 system pneumatic schematic.................................................................................

Figure 3. ADCS-601 simplified operational schematic ................................................................................8

Figure 4. ADCS-601 system electrical schematic........................................................................................9

Figure 5. ADCS-601 system

Figure 6. ADCS-601 software, communications and control flow chart.................................................... 11

Figure 7. Reference Bench, top view

Figure 8. Pneumatic Interconnections Box, bulkhead ...............................................................................13

Figure 9. Control Cabinet, front and rear views.........................................................................................14

Figure 10. Gas Supply Panel.....................................................................................................................15

Figure 11. Piston gauge operating principle..............................................................................................16

Figure 12. PG7601 Pl

Figure 13. PG7000 Terminal front panel ...................................................................................................17

Figure 14. PG7000 Terminal rear panel ....................................................................................................18

Figure 15. PG7601 10 kPa/kg piston-cylinder module ..............................................................................18

Figure 16. AMH-38 automated mass handler............................................................................................19

Figure 17. AMH-38 operating principle schematic...............................................................................

Figure 18. AMH-38 mass

Figure 19. Force balanced piston gauge operating principle.....................................................................22

Figure 20. FPG8601 front and rear views

Figure 21. PPC3 front panel ......................................................................................................................24

Figure 22. PPC3 rear panel.......................................................................................................................25

Figure 23. RPM4 front

Figure 24. RPM4 rear panel.......................................................................................................................26

Figure 25. Turbo pump local interface panel (local control not used in regular ADCS-601 operation).....28

Figure 26. Typical layout of overall ADCS-601 system at site of use........................................................37

Figure 27. Piston-cylinder module installation...........................................................................................44

Figure 28. Local gravity and pressure medium fields in ADCS Tools .......................................................54

Figure 29. ADCS-601 simplified operational schematic............................................................................59

Figure 30. ADCS Tools

Figure 31. ADCS Tools pressure leak tes

Figure 32. ADCS-601 software, communications and control flow chart.................................................. 68

Figure 33. ADCS-601 program

Figure 34. ADCS Main Toolbar..................................................................................................................70

Figure 35. ADCS Status Bar

Figure 36. ADCS Run Screen....................................................................................................................74

Figure 37. ADCS System Dis

Figure 38. PG7601 Run Screen.................................................................................................................79

Figure 39. FPG8601 Run Screen ..............................................................................................................80

Figure 40. PPC3 Run Screen ....................................................................................................................81

Figure 41. RPM4 Run Screen....................................................................................................................81

Figure 42. Data Plot Run Screen

Figure 43. Data Grid Run Screen

Figure 44. DUT/Reference Comparison Run Sc

Figure 45. FPG8601 bubbler and filter ....................................................................................................106

S

communications schematic

.........................................................................................................12

atform rear panel.....................................................................................................17

set.....................................................................................................................21

..................................................................................................23

panel......................................................................................................................26

pressure exercis

window.....................................................................................................68

......................................................................................................................74

play..............................................................................................................78

...............................................................................................................89

e definition form..........................................................................64

t results form .............................................................................67

..............................................................................................................90

reen................................................................................90

..........................................................................10

....7

......20

© 2005 DH Instruments, Inc. Page VI

Page 9

TABLES & FIGURES

Figure 46. FPG8601 piston-cylinder assembly in mounting post............................................................108

Figure 47. Removing the FPG8601 mounting post .................................................................................110

Figure 48. Removing the FPG8601 piston-cyli

nder.................................................................................110

Figure 49. Alignment of the FPG8601 piston in the cylinder...................................................................113

Figure 50. AMH insta

Figure 51. AMH mass

llation on PG7000 Platform....................................................................................119

set ........................................................................................................................122

Figure 52. PG7601 piston-cylinder module installation ...........................................................................123

Figure 53. 10 kPa/kg gas pist

Figure 54. 10 k

Pa/kg pist

on-cylinder module, expanded view .........................................................125

on insertion tool................................................................................................126

Figure 55. 10 kPa/kg gas piston-cylinder module sleeve nut tool ...........................................................126

Figure 56. 10 kPa/kg piston-cylinder module lubric

Figure 57. PG7601 pist

Figure 58. ADCS Tools FPG Run Sc

on stroke and zones ...........................................................................................131

reen ...............................................................................................137

ation chart.................................................................128

Figure 59. ADCS Tools FPG Validation Setup Form...............................................................................140

Figure 60. ADCS Tools

Figure 61. ADCS Tools CDG Zero Syst

FPG Validation Resu

em Display.................................................................................146

lts Form............................................................................140

Figure 62. PG7601 Ambient Sensors Adjust Form..................................................................................147

Figure 63. ADCS Tools PG7601 Piston-Cylinder Calibration Form ........................................................149

Figure 64. ADCS Tools PG7601 AMH-38 Mass Set Ca

libration Form ...................................................151

Figure 65. ADCS Tools PG7601 Piston-Cylinder Calibration Form ........................................................154

Page VII © 2005 DH Instruments, Inc.

Page 10

ADCS-601™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2005 DH Instruments, Inc. Page VIII

Page 11

ABOUT THIS MANUAL

A

BBOOUUTT

A

This manual provides the information necessary to operate an ADCS-601 Air Data Calibration Standard. The

ADCS-601 is a system made up of several standard instruments. This manual describes the individual

instruments and their operation to the extent necessary for normal operation and maintenance of the

ADCS-601 system. More detailed information on individual instruments and software is contained in each

instrument or program’s specific operation and maintenance manual.

Before using the manual, take a moment to familiarize yourself with the Table of Contents structure. Set

up of an ADCS-601 system should not be attempted without using Section

users should read Section 2. Section 8 is a quick troubleshooting guide. Use the information in Section 8

to troubleshoot unexpected ADCS-601 behavior based on the symptoms of that behavior.

Certain words and expressions have specific meaning as they pertain to ADCS-601 and its instruments.

The Glossary (see

expressions as they are used in this manual.

T

HHIISS

T

Section 9.2) is useful as a quick reference for the definition of specific words

M

AANNUUAAL

M

L

3. All first time ADCS-601

and

Manual Conventions

(CAUTION) is used throughout the manual to identify user warnings and cautions.

(NOTE) is used throughout the manual to identify operating and applications advice and

additional explanations.

[ ] indicates direct function keys or objects (e.g., [RANGE]) on an instrument front panel keypad or in a

software user interface.

< > indicates instrument front panel screen displays or labels in a software user interface (e.g., <1yes>)

Page IX © 2005 DH Instruments, Inc.

Page 12

ADCS-601™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2005 DH Instruments, Inc. Page X

Page 13

1. INTRODUCTION

.

11.

ADCS-601 is a fully automated reference level Air Data Calibration Standard for the verification and

calibration of air data range instruments, in particular Air Data Test Sets (ADTS). ADCS-601’s intended

function is the static pressure calibration of Pt and Ps range pressure transducers with very low measurement

uncertainty. ADCS-601 is not intended to duplicate the functions of an ADTS in calibrating and testing onboard aircraft instruments.

ADCS-601 covers the pressure range of 1 to 380 kPa (0.3 to 120 inHg) in absolute and gauge modes

with fully automated operation and state of the art uncertainty.

ADCS-601 is an integrated system made up of several instruments that work together under the control of

ADCS Tools software running on a personal computer. Operator interaction with ADCS-601 is accomplished

through the keyboard, pointing device and display of the system controller (personal computer).

The heart of the system is a fully automated PG7601 piston gauge or pressure balance that covers the

range of 15 to 380 kPa (4.5 to 120 inHg). The PG7601 range is extended down to 1 kPa (0.3 inHg) by an

FPG8601 force balanced piston gauge with automated pressure control.

I

NNTTRROODDUUCCTTIIOON

I

N

1.1 SPECIFICATIONS

1.1.1 ADCS SYSTEM GENERAL SPECIFICATIONS

Power Requirements

Instruments (AC1)

Reference vacuum pumps (AC2)

Utility pump (AC3)

Pressure Supply Requirements

Operating Temperature Range

Weight

Reference bench

Utility and roughing vacuum pumps

Dimensions

Pressure Ranges Overall

PG7601

FPG8601

Operating Medium

Pressure Connections

CE Conformance

Control cabinet

Reference bench

Control cabinet

TEST(+) port

TEST(-) port

100 to 240 VAC, 50/60 Hz, 240 W max. consumption

Fuse: 250VT 10A

110 V version: 100 – 120V, 50/60 Hz, 1100 W max. consumption

Fuse: 250VT 10A

220 V version: 200 – 240V, 50/60 Hz, 1100 W max. consumption

Fuse: 250VT 10A

110 V version: 100 – 120V, 50/60 Hz, 800 W max. consumption

Fuse: 250VT 10A

220 V version: 200 – 240V, 50/60 Hz, 800 W max. consumption

Fuse: 250VT 10A

Drive air: 0.7 to 1 MPa (100 to 150 psi)

Test gas: Nitrogen or air, 0.45 to 1 MPa (65 to 150 psi), clean and dry

(instrument grade minimum, high purity preferred)

20 to 26 ºC

173 kg (380 lb) approx. (with turbo pump and controller installed)

105 kg (230 lb) approx.

19 kg (42 lb) each

145 cm H x 122 cm W x 76 cm D (57 in. x 48 in. x 30 in.)

124 cm H x 56 cm W x 66 cm D (49 in. x 22 in. x 26 in.)

1 to 380 kPa (0.3 to 120 inHg)

10 to 380 kPa (3 to 120 inHg)

1 to 15 kPa (0.2 to 4.5 inHg)

Nitrogen or air

Quick connector (1/4 in. NUPRO

Quick connector (1/4 in. NUPRO

Available, must be specified.

®

SS-QC4-B1-400)

®

SS-QC4-B1-400)

Page 1 © 2005 DH Instruments, Inc.

Page 14

ADCS-601™ OPERATION AND MAINTENANCE MANUAL

1.1.2 PG7601 PISTON GAUGE SPECIFICATIONS

1.1.2.1 AMBIENT AND PISTON-CYLINDER CONDITION MEASUREMENTS

Temperature

Range

Resolution

Measurement Uncertainty

Barometric Pressure

Range

Resolution

Measurement Uncertainty

Relative Humidity

Range

Resolution

Measurement Uncertainty

Piston Position

Range

Resolution

Measurement Uncertainty

Piston Rotation

(Rate and deceleration)

Range

Resolution

Reference Vacuum

(with on-board gauge)

Range

Resolution

Measurement Uncertainty

(with external capacitance

diaphragm gauge)

Range

Resolution

Measurement Uncertainty

Ambient

0 to 40

0.1 0.01

± 1 ± 0.1

70 to 110 kPa

10 Pa

± 140 Pa

5 to 95 % RH

1 % RH

± 10 % RH

± 4.5 mm

0.1 mm

± 0.2 mm

2 to 99 rpm

1 rpm

0 to 20 Pa

0.01 Pa

± 0.1 Pa or 10 % of reading, whichever is greater

0 to 13.3 Pa (100 mTorr)

0.001 Pa (0.01 mTorr)

± 0.05 Pa (0.38 mTorr)

Piston Cylinder Module

o

C 0 to 40 oC

1.1.2.2 PISTON-CYLINDER MODULE

PC-7100/7600-10

Nominal pressure to mass

Operation

Piston material

Cylinder material

Nominal diameter

Nominal area

Mounting system

Typtical drop rate

Piston assembly nominal mass

© 2005 DH Instruments, Inc. Page 2

10 kPa/kg

Gas operated, gas lubricated

Tungsten carbide

Tungsten carbide

35 mm

1 000 mm

Positive free deformation

0.2 mm/min

0.5 kg

2

Page 15

1. INTRODUCTION

1.1.2.3 MASS SET

Masses > 50g

Material

Finish

Uncertainty in

measured values

304L non-magnetic stainless steel

Electropolished

± 5 ppm or 1 mg, whichever is greater

1.1.3 FPG8601 GENERAL SPECIFICATIONS

1.1.3.1 AMBIENT AND PISTON-CYLINDER CONDITION MEASUREMENTS

Temperature:

Range

Resolution

Accuracy

Relative Humidity:

Range

Resolution

Accuracy

Vacuum:

Range

Resolution

Accuracy

Ambient and Lubrication

Pressure Sensor:

Range

Resolution

Accuracy

Lubrication Gas

[°C] [°C]

0 to 40 0 to 40

0.1 0.01

± 0.2 ± 0.1

5 to 95 %RH

1 %RH

± 10 %RH

13.3 Pa (100 mTorr)

0.001 Pa (0.01 mTorr)

± 0.06 Pa (0.45 mTorr)

200 kPa

1 Pa

± 0.1 kPa

Piston-Cylinder

1.1.4 PRESSURE MEASUREMENT AND CONTROL SPECIFICATIONS

1.1.4.1 10 TO 380 KPA, PG7601 AND PPC3-700K

Sensitivity1

Precision

Measurement uncertainty

Control set point increments

Stability of set pressure

Typical control set point time

1 Sensitivity: The smallest variation in input detectable in output.

2 Precision: Combined linearity, hysteresis, repeatability.

3 Measurement uncertainty:

including all sources of uncertainty combined and expanded (k=2) following the ISO “Guide to the Expression of

Uncertainty in Measurement.”

Maximum deviation of the indicated pressure from the true value of applied pressure

0.02 Pa + 0.5 ppm

2

± (0.01 Pa + 2 ppm)

3

see the piston-cylinder calibration report and

current revision of DHI Technical Note 7920TN01.

1 kPa

± 1 Pa

60 to 180 seconds

Page 3 © 2005 DH Instruments, Inc.

Page 16

ADCS-601™ OPERATION AND MAINTENANCE MANUAL

1.1.4.2 1 TO 15 KPA, FPG8601 AND PPC3-100K

Resolution1

Precision

Measurement uncertainty

0.01 Pa

2

± (2 ppm + 50 mPa)

3

± 0.008% of reading or 0.3 Pa (0.0001 inHg) ,

whichever is larger

Control set point increments

Stability of set pressure

Typical control set point time

1 Resolution: Minimum display increment.

2 Precision: Combined linearity, hysteresis, repeatability.

3 Measurement uncertainty:

including all sources of uncertainty combined and expanded (k=2) following the ISO “Guide to the Expression of

Uncertainty in Measurement.” Note: The uncertainty assigned to the FPG8601 used in an ADCS-601 system is

expanded relative to the standard FPG8601 instrument. to allow validation by the PG7601 and an indefinite

recalibration interval. See Section 7.2.3 and DHI Technical Note 2090TN05.

Maximum deviation of the indicated pressure from the true value of applied pressure

1 Pa

± 1 Pa (0.0003 inHg)

60 to 180 seconds

© 2005 DH Instruments, Inc. Page 4

Page 17

2. SYSTEM OVERVIEW

.

22.

S

YYSSTTEEMM

S

O

VVEERRVVIIEEW

O

W

2.1 ADCS-601 SYSTEM

ADCS-601 is a fully automated reference level Air Data Calibration Standard for the verification and

calibration of air data range instruments, in particular Air Data Test Sets (ADTS). ADCS-601’s intended

function is the static pressure calibration of Pt and Ps range pressure transducers. To this end, the

system automatically sets pressure values with very low measurement uncertainty in the range of 1 to

380 kPa (0.3 to 120 inHg) in absolute and gauge modes. ADCS-601 is not intended to duplicate the

functions of an ADTS.

The ADCS-601 system is made up of two automated pressure standards with overlapping ranges to

cover the full pressure range. An automated PG7601 piston gauge covers the range of 15 to 380 kPa

(4.5 to 120 inHg) (see Section

FPG8601 force balanced piston gauge with automated pressure control (see Section 2.2.2). The system

also includes vacuum pumps and vacuum measurement instruments to support absolute mode operation.

An RPM4 Reference Pressure Monitor is included to assist

and PG7601 pressure standards.

2.2.1). The PG7601 range is extended down to 1 kPa (0.3 inHg) by an

in performing a comparison of the FPG8601

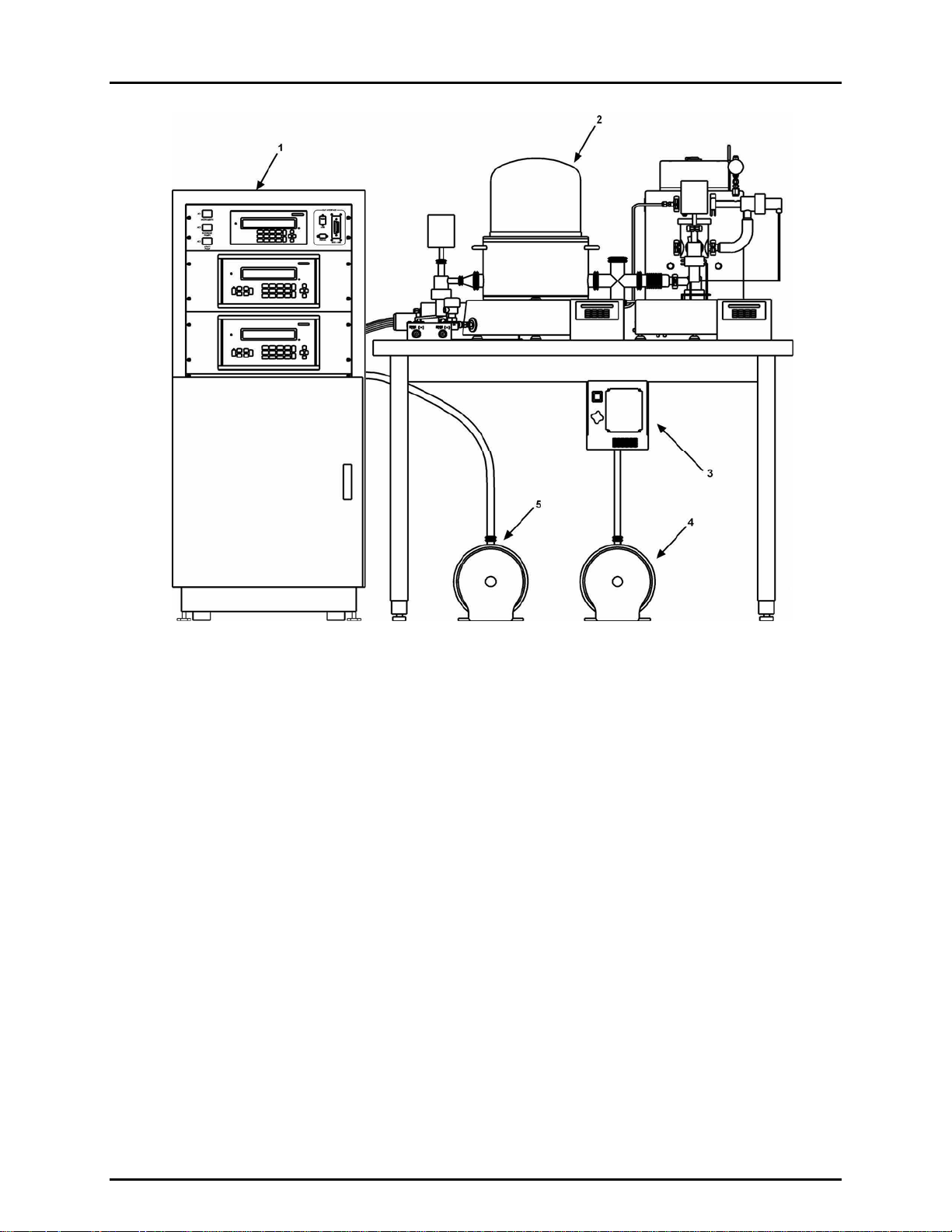

Physically, the ADCS-601 system is divided into two major components (see

Bench (see Section 2.1.1) is a laboratory table onto which are installed the PG7601 and FPG8601

pressure standards, pneumatic control switching hardware and the reference vacuum pumping systems.

The Control Cabinet (see Section

Reference Pressure Monitor and Gas Supply Panel

computer) is connected to the system by a USB interface hub (See Figure 5).

The ADCS-601 system is controlled by ADCS Tools software running on a personal computer (see

Section 4.3.1). ADCS Tools manages the entire system, communicating with other software programs

and system instruments. ADCS Tools

computers display, keyboard and pointing device.

See the following figures in this section describing the overall ADCS-601 system:

Figure 1. ADCS-601 overall, front view

Figure 2. ADCS-601 system pneumatic schematic

Figure 3. ADCS-601 simplified operational schematic

Figure 4. ADCS-601 system electrical schematic

Figure 5. ADCS-601 system communications schematic

Figure 6. ADCS-601 software and communications, flow chart

2.1.2) contains the PPC3 automated pressure controllers, RPM4

(see Section 2.1.3). The system controller (personal

also

provides the overall system interface through the personal

Figure 1). The Reference

Figure 7. Reference Bench, top view

Page 5 © 2005 DH Instruments, Inc.

Page 18

ADCS-601™ OPERATION AND MAINTENANCE MANUAL

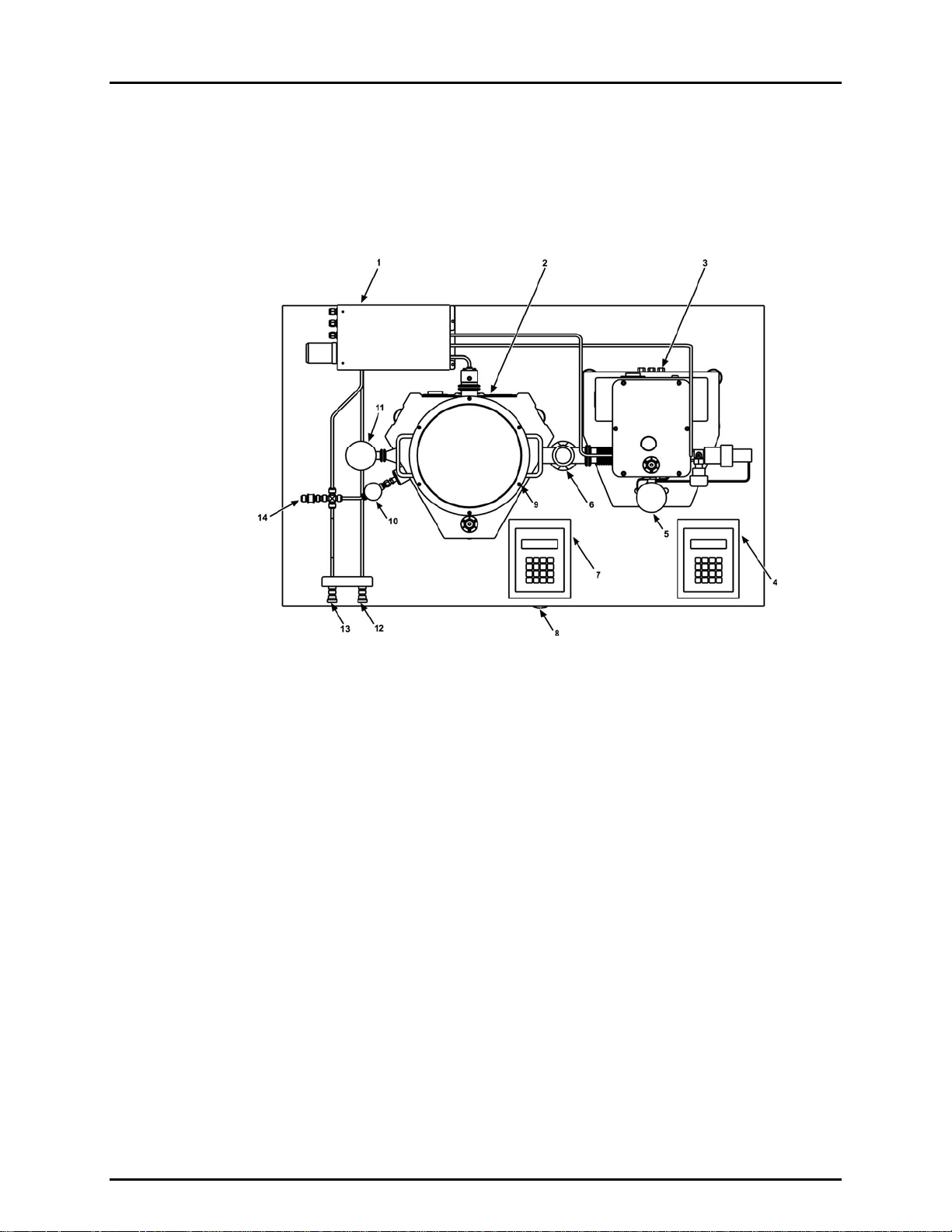

1. Control cabinet

2. Reference bench

3. Turbo pump controller and reference

turbo pump (behind controller)

Figure 1. ADCS-601 overall, front view

4. Reference roughing vacuum pump

5. Utility vacuum pump

Note: System controller (PC), display and

keypad not shown

© 2005 DH Instruments, Inc. Page 6

Page 19

2. SYSTEM OVERVIEW

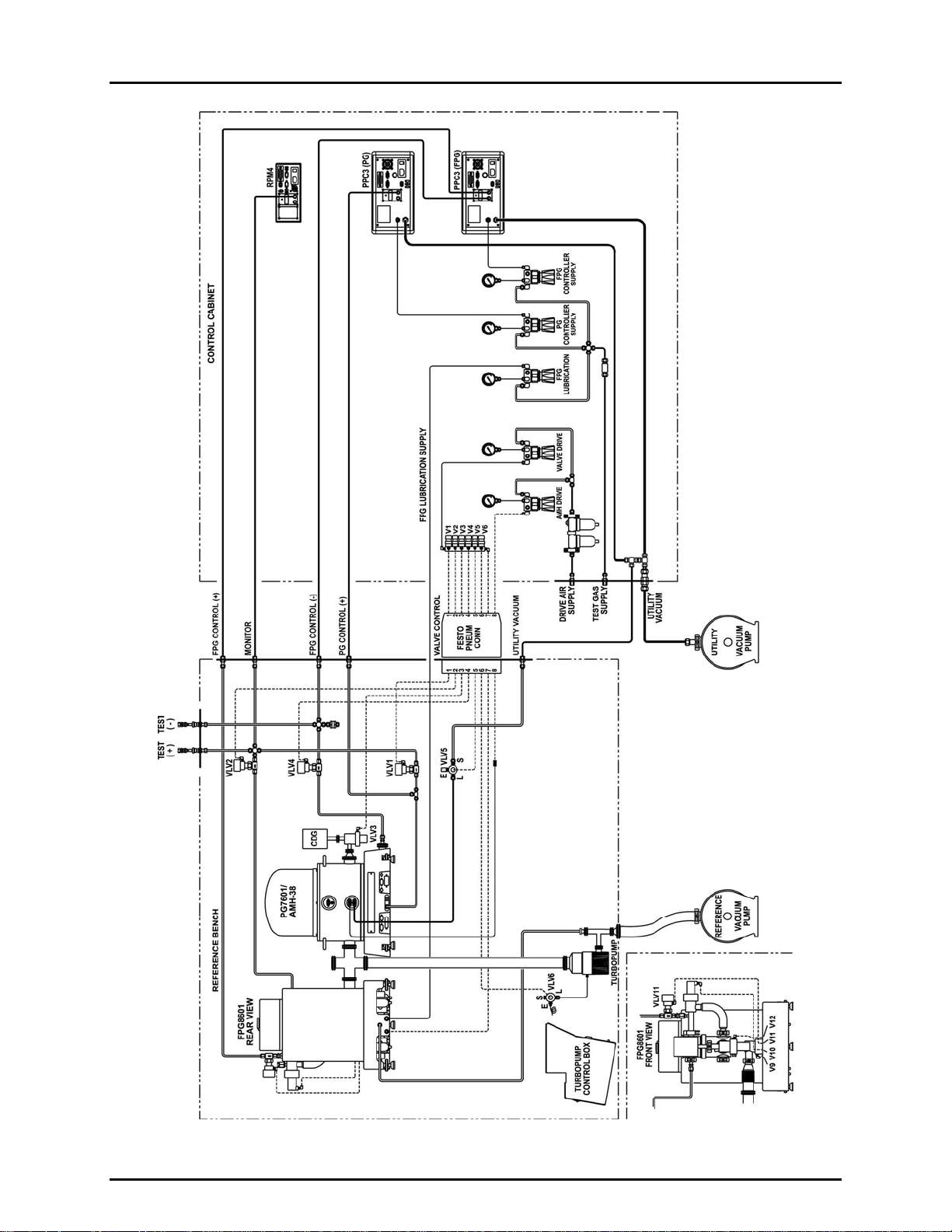

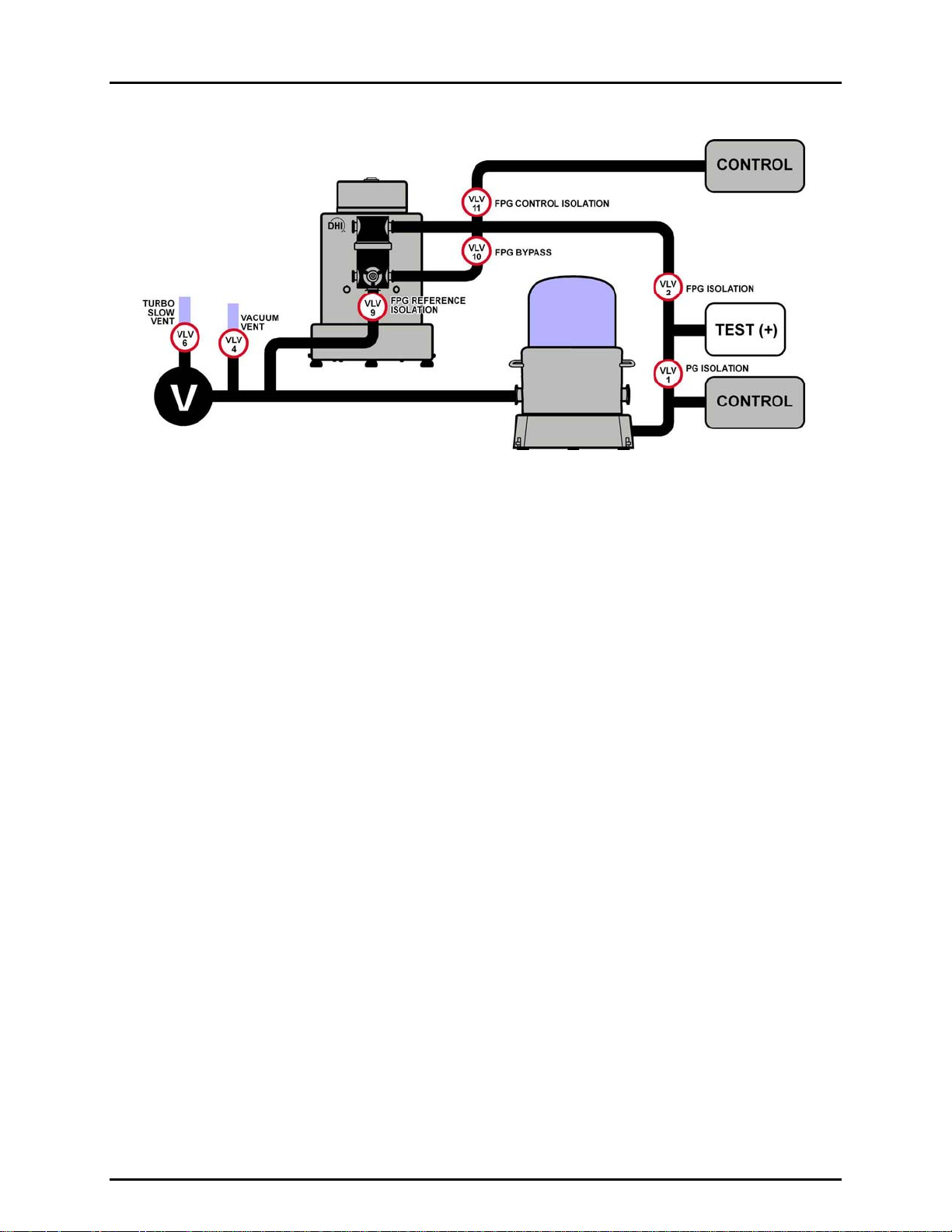

Figure 2. ADCS-601 system pneumatic schematic

Page 7 © 2005 DH Instruments, Inc.

Page 20

ADCS-601™ OPERATION AND MAINTENANCE MANUAL

Figure 3. ADCS-601 simplified operational schematic

© 2005 DH Instruments, Inc. Page 8

Page 21

2. SYSTEM OVERVIEW

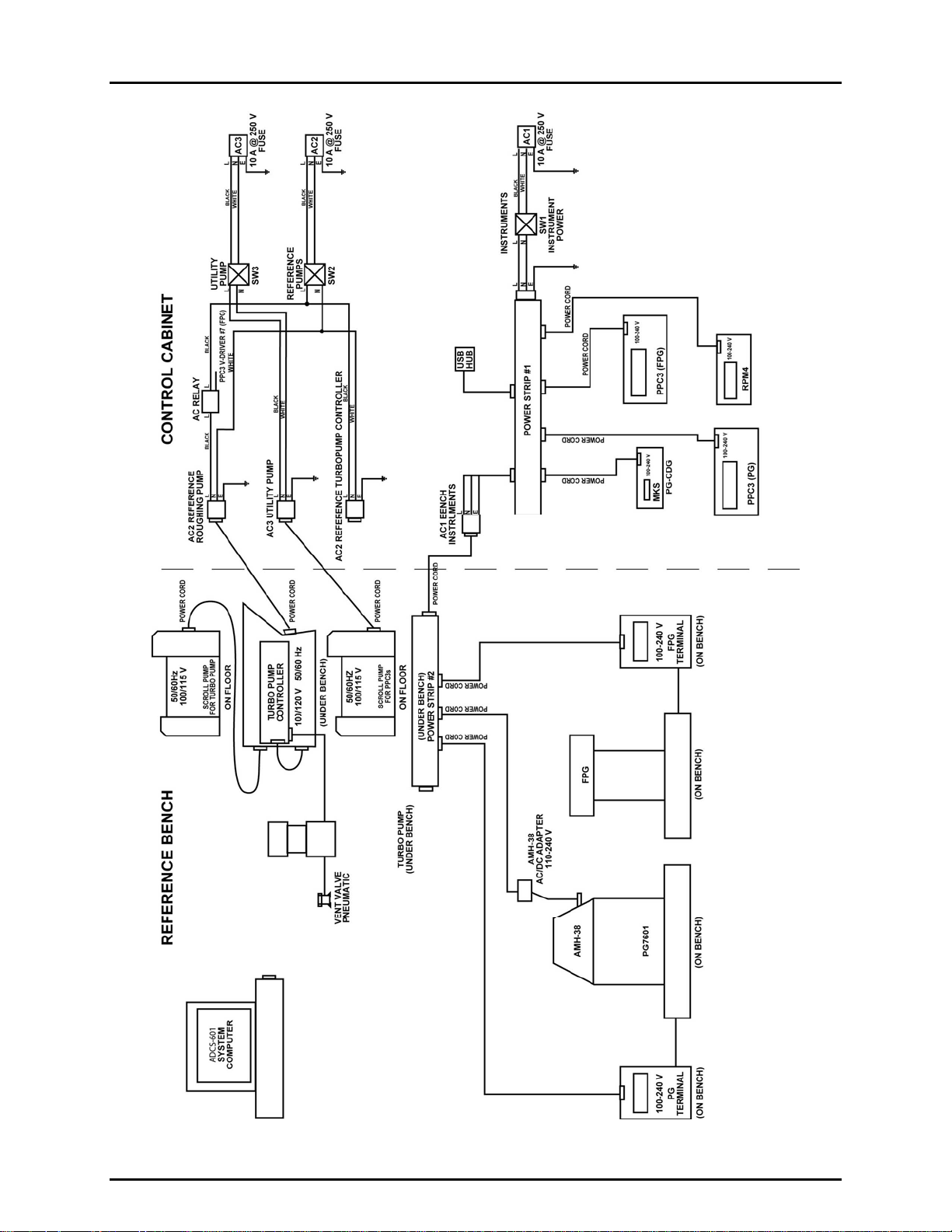

Figure 4. ADCS-601 system electrical schematic

Page 9 © 2005 DH Instruments, Inc.

Page 22

ADCS-601™ OPERATION AND MAINTENANCE MANUAL

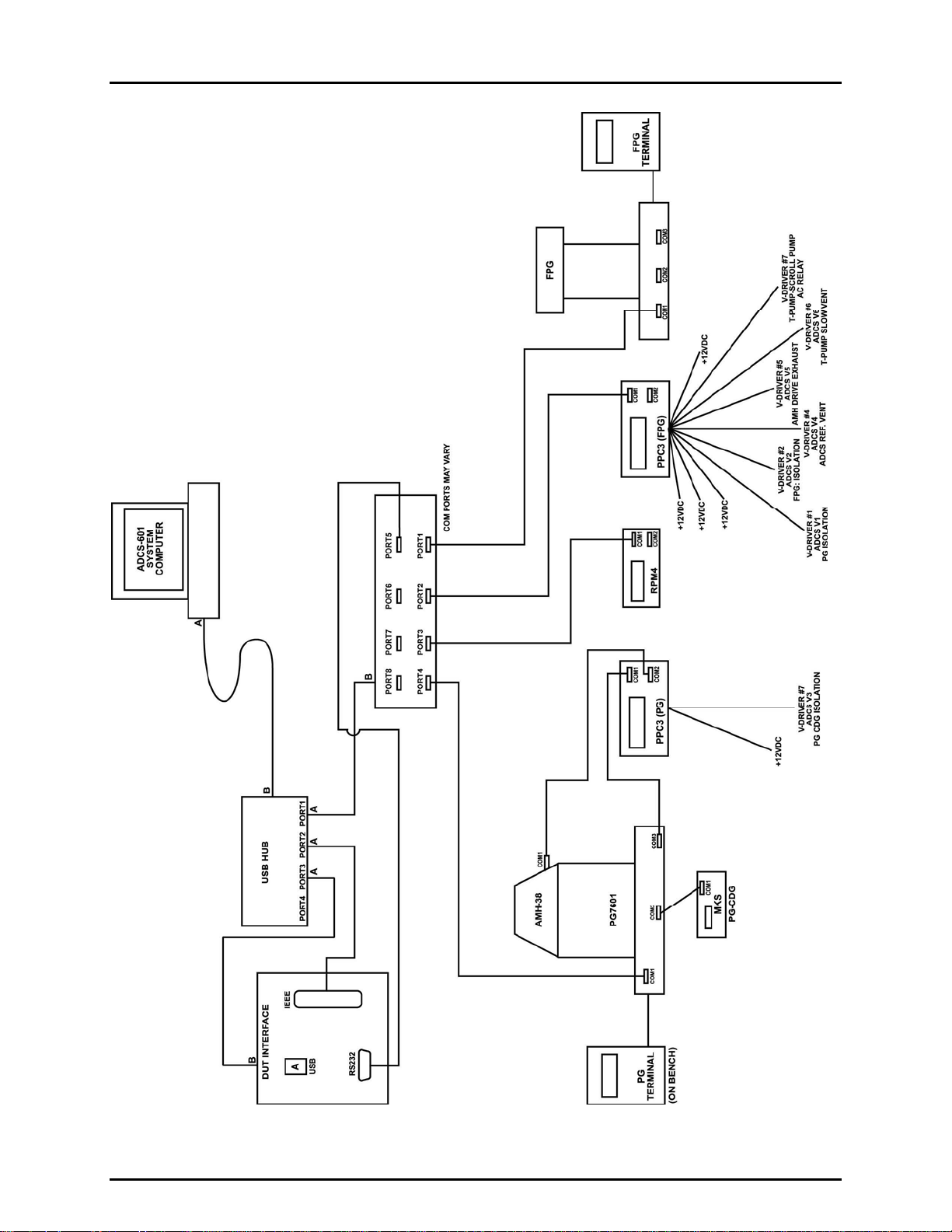

Figure 5. ADCS-601 system communications schematic

© 2005 DH Instruments, Inc. Page 10

Page 23

2. SYSTEM OVERVIEW

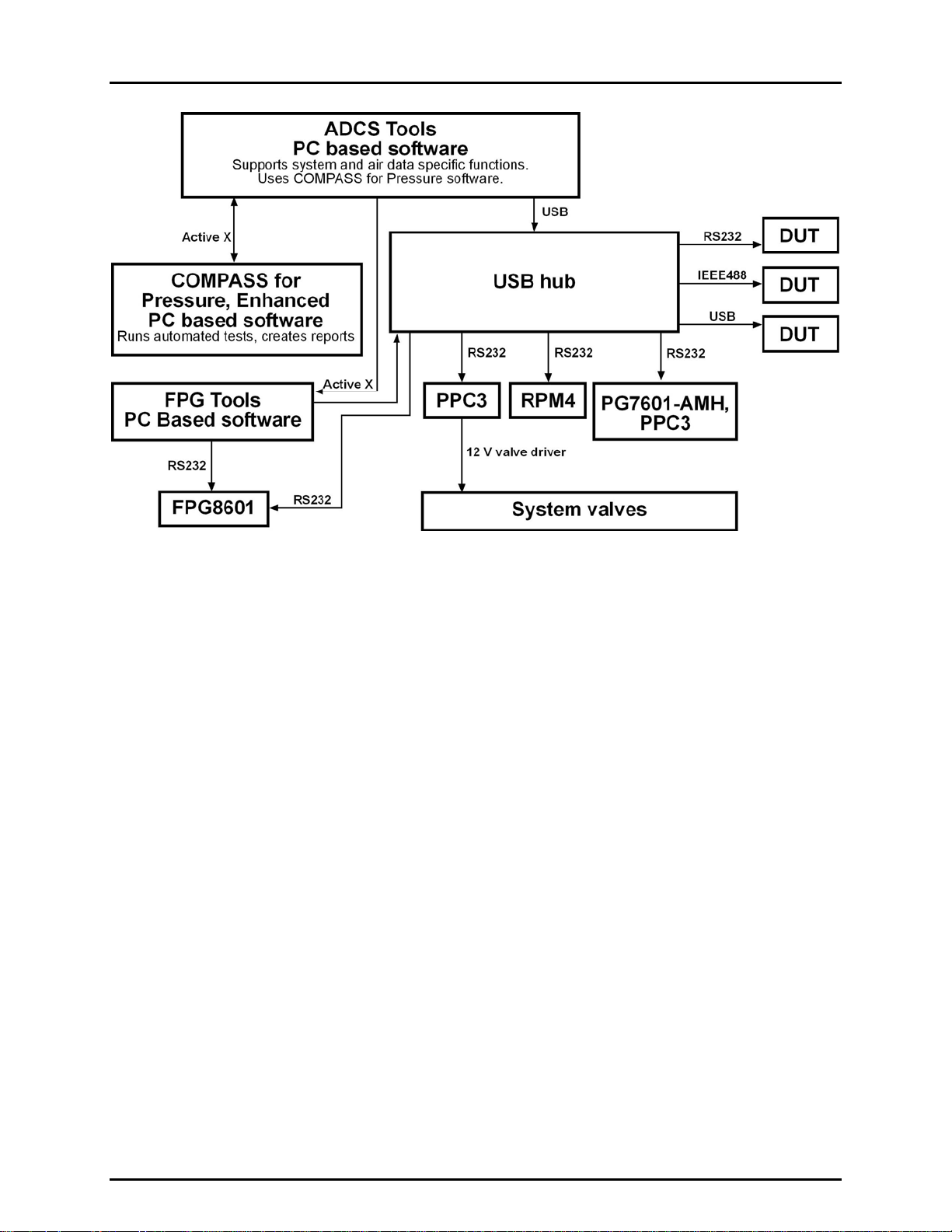

Figure 6. ADCS-601 software, communications and control flow chart

Page 11 © 2005 DH Instruments, Inc.

Page 24

ADCS-601™ OPERATION AND MAINTENANCE MANUAL

2.1.1 REFERENCE BENCH

The ADCS-601 Reference Bench is a wooden topped laboratory work bench onto which are

installed the PG7601 and FPG8601 pressure standards. Also included on the bench is a

pneumatic interconnections box (see

test (DUT) and the pumping system for the reference vacuum against which absolute

pressure is defined. The vacuum pumps may be purchased separately.

Figure 8), the system connections to the device under

1. Pneumatic interconnections box

2. PG7601 piston gauge

3. FPG8601 force balanced piston gauge

4. FPG Terminal

5. FPG reference vacuum CDG

6. Reference vacuum manifold

7. PG Terminal

8. Reference turbo pump and controller,

reference roughing vacuum pump, utility

vacuum pump (may be purchased

separately)

Figure 7. Reference Bench, top view

9. AMH-38 automated mass handler

10. Reference vacuum vent valve

11. PG reference vacuum CDG

12. Pressure Connection, TEST (+) (connect

absolute pressure tests and “high” side of

differential pressure tests)

13. Pressure Connection, TEST (-) (connect

low side of differential pressure tests)

14. Reference connection to atmosphere for

gauge mode operation

© 2005 DH Instruments, Inc. Page 12

Page 25

2. SYSTEM OVERVIEW

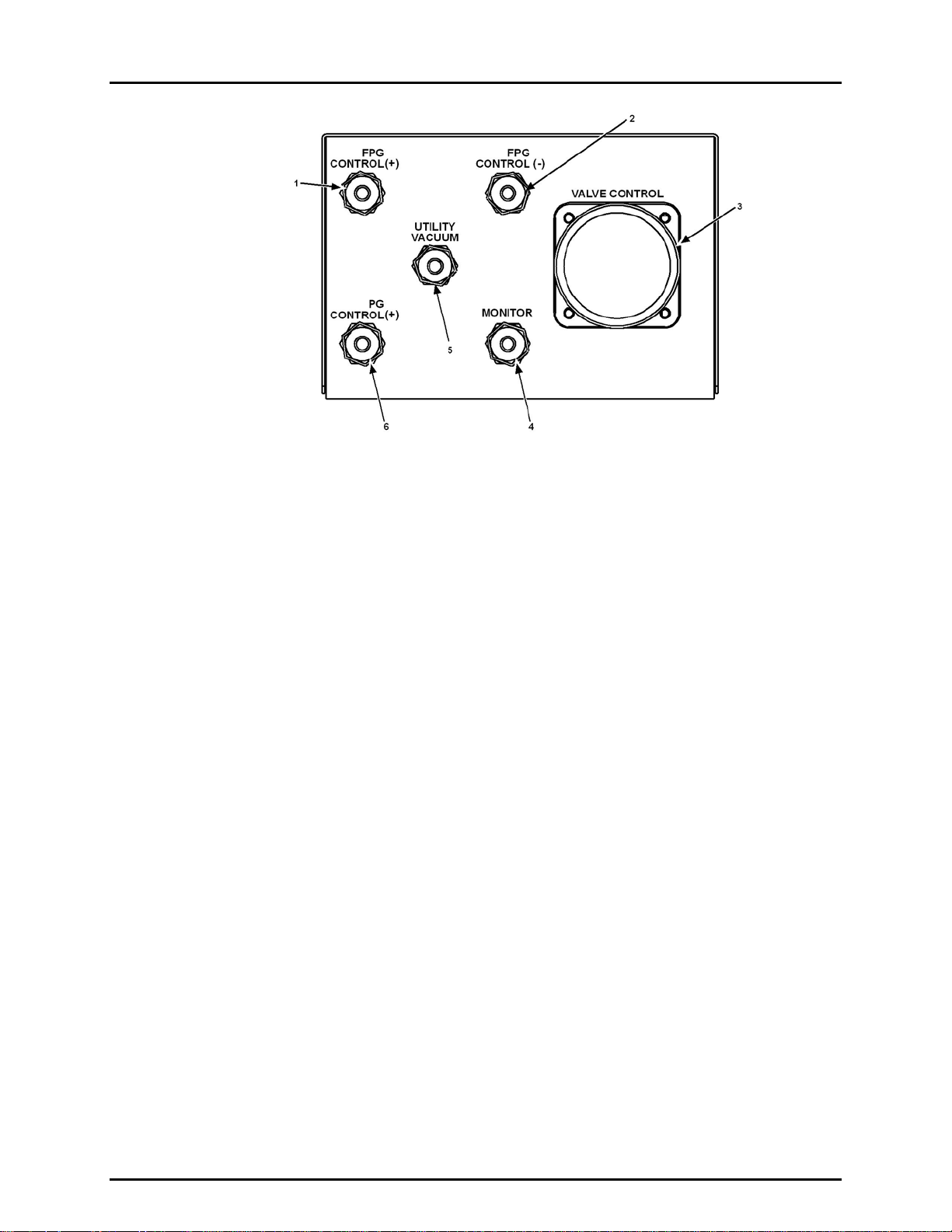

1. Connection to FPG8601’s PPC3

pressure controller TEST(+) port in

control cabinet, 1/4 in. SWG

2. Connection to FPG8601’s PPC3

pressure controller TEST(-) port in

control cabinet, 1/4 in. SWG

3. Connection to valve driver manifold in

control cabinet, (8) channel pneumatic

4. Connection to RPM4 TEST(+) port in

control cabinet, 1/4 in. SWG

5. Connection to utility vacuum source,

1/4 in. SWG

6. Connection to PG7601’s PPC3 pressure

controller TEST(+) port in control

cabinet, 1/4 in. SWG

Figure 8. Pneumatic Interconnections Box, bulkhead

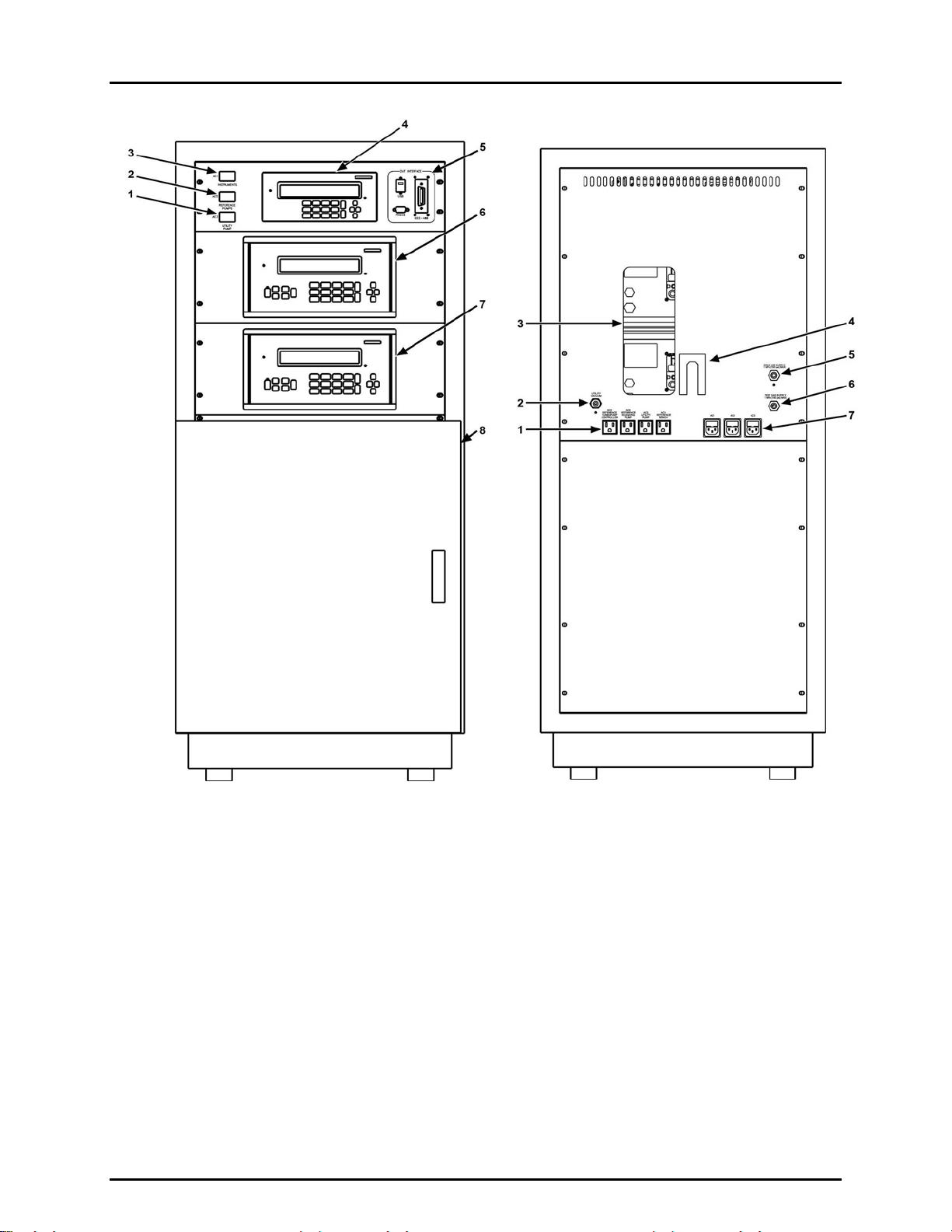

2.1.2 CONTROL CABINET

The ADCS-601 Control Cabinet is a 19 inch rack mount enclosure into which are mounted

the PPC3 pressure controllers that provide automated pressure control for the PG7601 and

FPG8601 pressure standards and an RPM4 Reference Pressure Monitor used to perform the

validation comparison of the PG7601 and FPG8601 (see

control cabinet are electrical power connections and a Gas Supply Panel (see Section 2.1.3)

which sets and indicates gas pressure supplies to various parts of the system.

Figure 9). Also included in the

Page 13 © 2005 DH Instruments, Inc.

Page 26

ADCS-601™ OPERATION AND MAINTENANCE MANUAL

1. Main power switch for utility vacuum pump (AC3)

2. Main power switch for reference vacuum roughing pump,

turbo pump and turbo pump controller (AC2)

3. Main power switch for all instruments (AC1)

4. RPM4 used in comparison to validate FPG8601 with PG7601

5. Connections for remote communication with device under test

(RS232, USB, IEEE-488)

6. PPC3 pressure controller for PG7601 system

7. PPC3 pressure controller for FPG8601 system

8. Access door to Gas Supply Panel

Figure 9. Control Cabinet, front and rear views

© 2005 DH Instruments, Inc. Page 14

1. Power sockets for system components

2. Utility vacuum supply connection (1/4 in. NPT F)

3. Control Cabinet connections pass through and storage

4. Power cable holder for stress relief

5. Drive air supply connection (1/4 in. NPT F)

6. Test gas supply connection (1/4 in. NPT F)

7. Power supply connections (IEC-320-C13)

Page 27

2. SYSTEM OVERVIEW

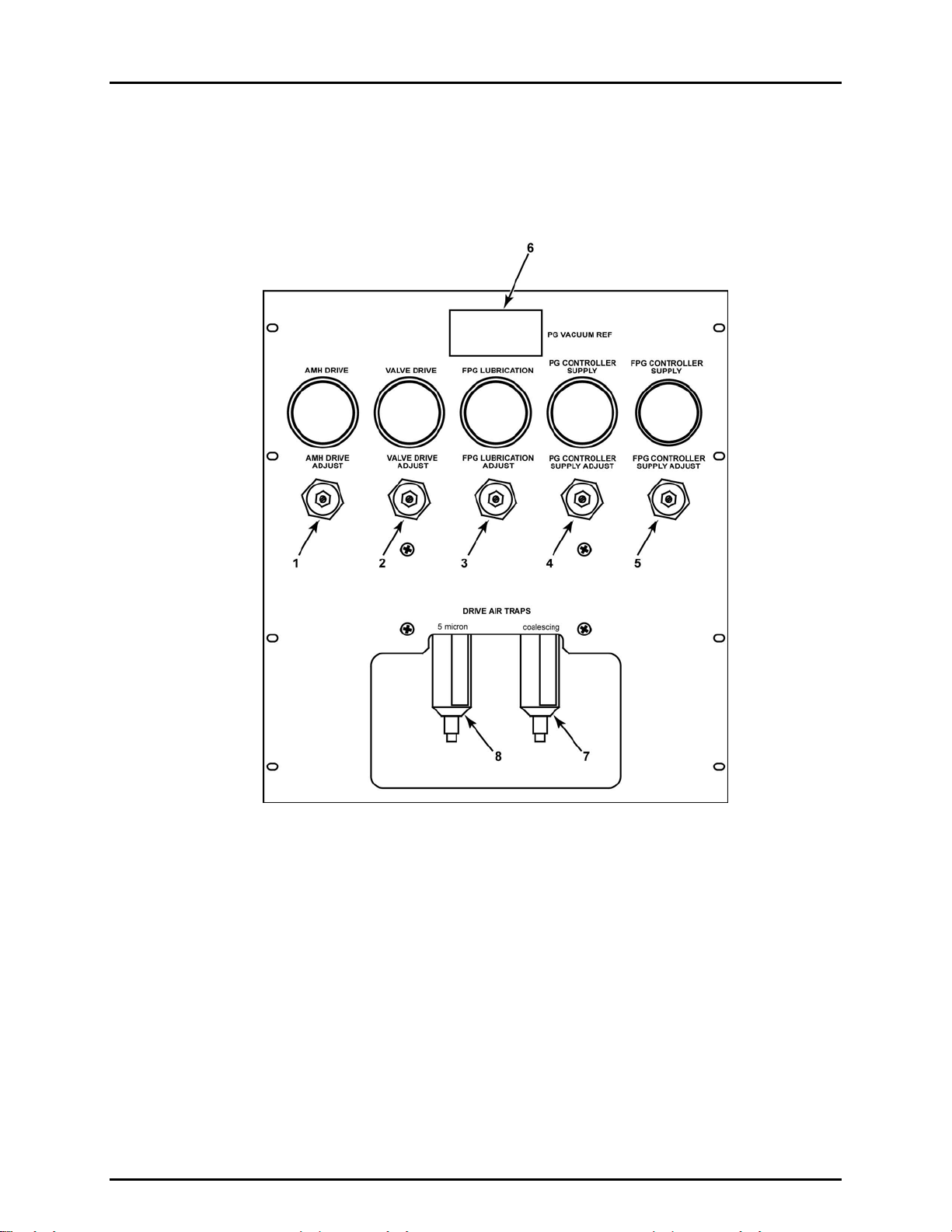

2.1.3 GAS SUPPLY PANEL

The Gas Supply Panel is in the ADCS-601 Control. It is accessed by a door in the lower part

of the front of the Control Cabinet (see Figure 9).

The Gas Supply Panel is used to set and indicate gas pressure supplies

ADCS-601 systems and components (see

Figure 10).

to various

1. Regulator and gauge to set PG7601’s

AMH (automated mass handler) drive

air pressure.

2. Regulator and gauge to set drive

pressure for system pneumatically

actuated vavles.

3. Regulator and gauge to set FPG8601

piston-cylinder purge pressure supply

4. Regulator and gauge to set pressure

supply to the PG7601 system’s PPC3

pressure controller

5. Regulator and gauge to set pressure

supply to the FPG8601 system’s PPC3

pressure controller

6. Gas supply panel gauges and regulators

7. Drive air supply 5 micron filter trap

8. Drive air supply coalescing filter trap

*See Section 6.13 for regulator set values

Figure 10. Gas Supply Panel

Page 15 © 2005 DH Instruments, Inc.

Page 28

ADCS-601™ OPERATION AND MAINTENANCE MANUAL

2.2 PRESSURE STANDARDS

2.2.1 PG7601 PISTON GAUGE

The heart of the ADCS-601 Air Data Calibration Standard is a PG7601 gas operated piston

gauge. The PG7601 piston gauge system includes:

- PG7601 piston gauge platform with terminal (on reference bench)

- PC-7600/7100-10, TC 10 kPa/kg piston-cylinder module (mounted in platform)

- MS-AMH-38, 38 kg mass set (installed on platform)

- AMH-38-VAC, automated mass handler (installed on platform)

- CDG-VAC-REF, capacitance diaphragm gauge with display and isolation valve for

measurement of PG7601 reference vacuum in absolute mode (installed on platform)

- PPC3-700K pressure controller to automate PG7601 system pressure control (in

The PG7601 piston gauge, AMH-38 automated mass handler and PPC3-pressure

control cabinet).

controller are stand alone products for which separate Operation and Maintenance

manuals are available with much more complete information than is included in this

manual. Copies of these manuals are provided on the ADCS-601 Support CD and are

available at www.dhinstruments.com.

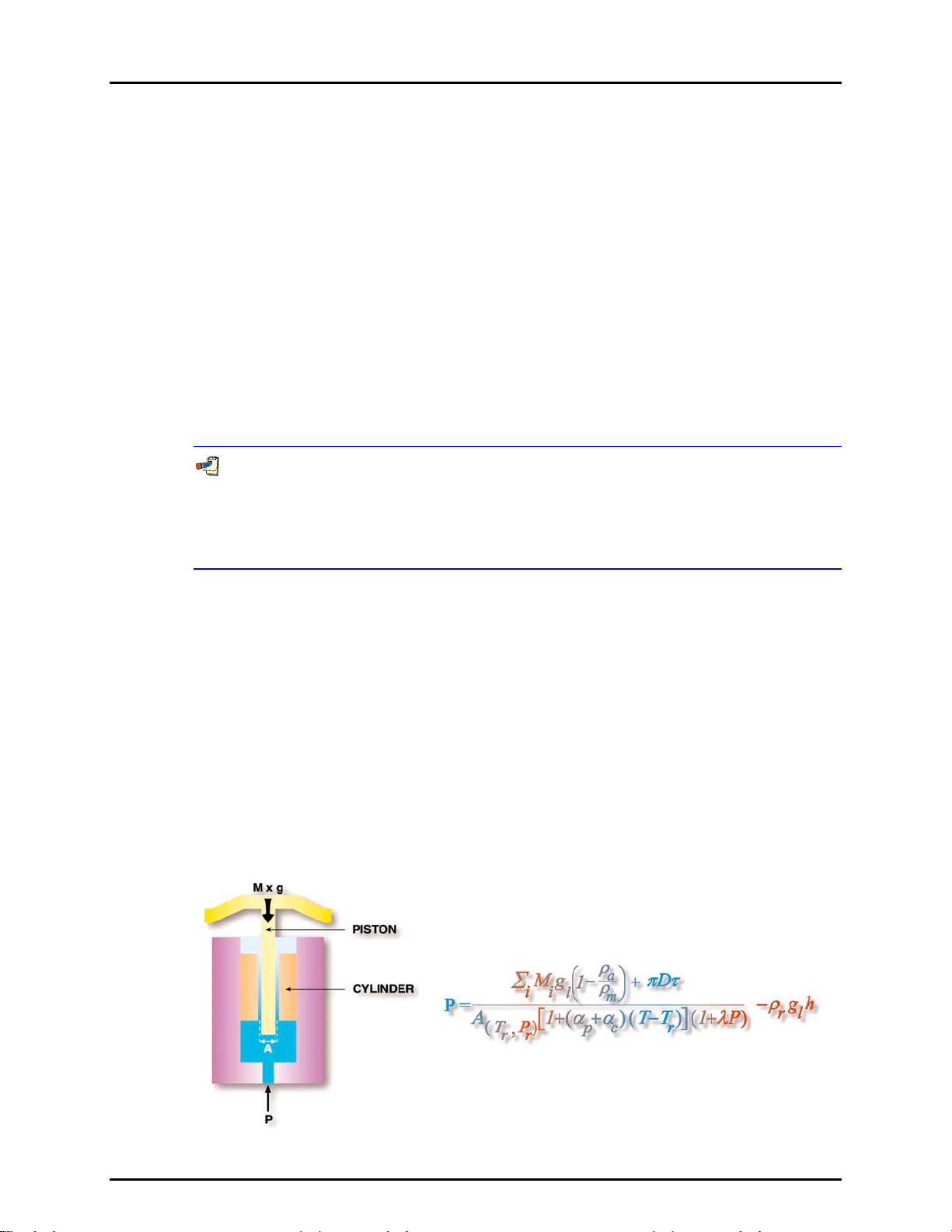

The PG7601 operates on the principle of the piston gauge in which pressure is defined by

balancing it against a known force on a known area (see Figure 11). The known area is

defined by a vertically mounted piston rotating in a cylinder and the known force is applied to

the piston by loading it with known mass subjected to acceleration due to gravity. When

the

force applied by the pressure and the force applied by the mass accelerated by gravity are in

equilibrium, the piston floats and the pressure under the piston remains constant. The pressur e

can be calculated following the equation in

also

lubricates

the gap between the piston and the cylinder. When floating, the piston must be

Figure 11. The pressurized fluid under the piston

rotating to keep it well centered in the cylinder.

The PG7601 is equipped with a 10 kPa/kg piston-cylinder module and 38 kg mass set, giving

it a range of 10 to 380 kPa (3 to 120 inHg). The PG7601 Platform includes a bell jar that can

be evacuated with a vacuum pump so that pressure can be defined against vacuum

(absolute mode) or atmosphere (gauge mode). The AMH-38 mass handler allows the mass

load to be changed automatically. The PPC3 pressure controller adjusts pressure

automatically to float the piston (see Section

2.2.3).

Figure 11. Piston gauge operating principle

© 2005 DH Instruments, Inc. Page 16

Page 29

2. SYSTEM OVERVIEW

2.2.1.1 PG7601 PLATFORM

The PG7601 Platform is the instrument base into which the piston-cylinder onto

which the masses are loaded is mounted. The platform also includes the

PG7601’s electronic measurement system.

The PG7601 Platform rear panel provides the connection to the PG Terminal,

remote communication connections and pressure connection ports.

1. COM2 (RS232) - External

vacuum gauge (Reference

vacuum CDG)

2. COM3 (RS232) – PPC3 pressure

controller, AMH automated mass

handler

3. COM1 (RS232) – System

controller (PC) communications

4. Ambient temperature sensor

5. IEEE-488 - host communications

(not used)

6. Ambient relative humidity sensor

7. Pressure ports: TEST port

(DH200), VACUUM vent port

(DH200, not used)

8. PG7000 Terminal port

Figure 12. PG7601 Platform rear panel

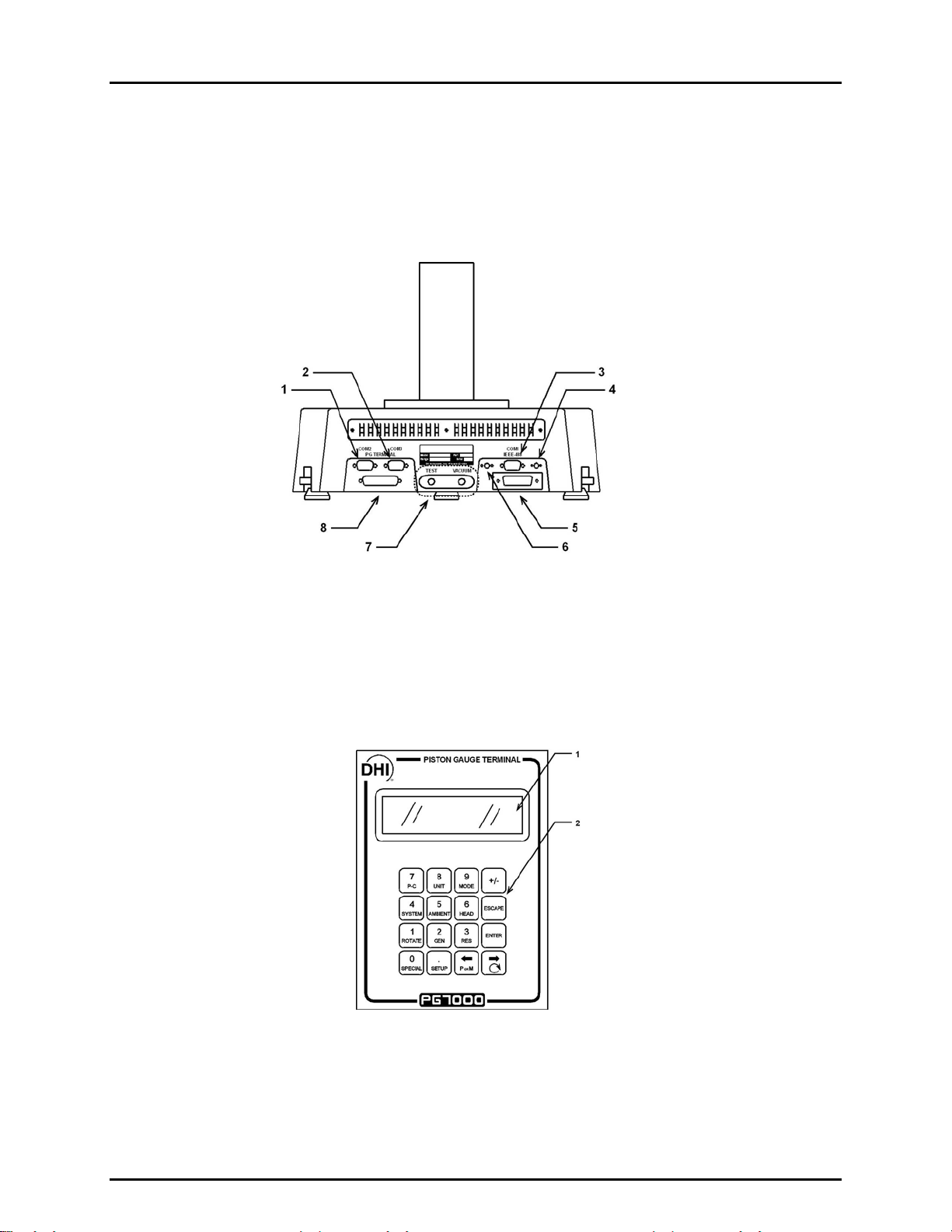

2.2.1.2 PG7601 TERMINAL

The PG7000 Terminal contains the PG7601 power supplies. It also provides a

local user interface through a 2 x 20 vacuum fluorescent display and 4 x 4

membrane keypad. Local commands to PG7601 are not used in normal

ADCS-601 operation. See the PG7000 Operation and Maintenance manual for

details on local operation of PG7000.

1. Fluorescent display

2. Keypad

Figure 13. PG7000 Terminal front panel

Page 17 © 2005 DH Instruments, Inc.

Page 30

ADCS-601™ OPERATION AND MAINTENANCE MANUAL

The PG7000 Terminal rear panel assembly provides the communications

connection to the PG7000 Platform and the power connection module.

Figure 14. PG7000 Terminal rear panel

2.2.1.3 PG7601 10 KPA/KG PISTON-CYLINDER MODULE

The piston-cylinder module is mounted in the PG7601 Platform (see Section

2.2.1.1) and performs the pressure to force conversion.

1. Power switch

2. Fuse

3. Power receptacle

4. Connector for

cable to PG7000

(25-pin)

5. Cooling fan

Figure 15. PG7601 10 kPa/kg piston-cylinder module

© 2005 DH Instruments, Inc. Page 18

Page 31

2. SYSTEM OVERVIEW

2.2.1.4 AMH-38 AUTOMATED MASS HANDLER

The AMH-38 automated mass handler is mounted on the PG7601 Platform (see

Section 2.2.1.1) and serves to automatically change the mass load on the pistoncylinder to set different values of pressure.

The AMH-38 automated mass handler is a stand alone product for which a

separate Operation and Maintenance manual is available with much more

complete information than is included in this manual. A copy of the AMH

manual is provided on the ADCS-601 Support CD and is available at

www.dhinstruments.com

.

1. KF-40 vacuum connections (2)

2. Lifting handles (2)

3. Mass lifter and pneumatic actuation

solenoid valves

4. Vacuum bell jar (delivered with

PG7601 Platform)

5. AMH status indication LED

6. RS232 Port, COM1

7. DC power connection

8. Drive air pressure connection

9. Drive vacuum connection

Figure 16. AMH-38 automated mass handler

Page 19 © 2005 DH Instruments, Inc.

Page 32

ADCS-601™ OPERATION AND MAINTENANCE MANUAL

1. Mass loading bell

2. Binary mass tubes

3. Binary mass selection pins

4. Flexible diaphragm

5. Mass lifting assembly

6. Lifting ledge on mass lifting shaft

7. Electronics and electrical controls

Figure 17. AMH-38 operating principle schematic

© 2005 DH Instruments, Inc. Page 20

8. Mass lifter

9. Solenoid valve

10. Binary mass carrier

11. Main mass column rotation belt

12. Piston cap

13. Main mass column

14. Main masses

Page 33

2. SYSTEM OVERVIEW

2.2.1.5 AMH-38 MASS SET

The masses of the 38 kg mass set are loaded onto in the piston-cylinder as required

to apply a force corresponding the the set pressure desired. The AMH-38 mass

handler (see Section

2.2.1.4) loads and unloads the masses automatically.

Figure 18. AMH-38 mass set

2.2.2 FPG8601 FORCE BALANCED PISTON GAUGE

The ADCS-601 Air Data Calibration Standard includes an FPG8601 force balanced piston

gauge to cover the air data pressure range below the range of the PG7601 gas operated

piston gauge. The FPG8601 system includes:

- FPG8601 piston gauge platform with terminal and 10 kPa/kg piston-cylinder (installed

on Reference Bench).

- Capacitance diaphragm gauge with display and isolation valve for measurement of

FPG8601 reference vacuum in absolute mode (mounted on platform).

- PPC3-100K A116Ks/BG15Ks, pressure controller to automate FPG8601 system

pressure control (see Section

- MS-8601-2, 2 kg mass set with

(accessory used separately in metrological maintenance (see Section

The FPG8601 force balanced piston gauge and PPC3 pressure controller are stand alone

products for which separate Operation and Maintenance manuals are available with much

more complete information than is included in this manual. A copy of the FPG8601

manual is provided on the ADCS-601 Support CD and is available at

www.dhinstruments.com.

The FPG8601 operates on the principle of the piston gauge (see Section 2.2.1); however, the

force resulting from a difference in pressure across the piston is measured by a force

balanced, load cell rather than balanced directly against masses subjected to the

acceleration due to gravity (see

Figure 11). The piston-cylinder is suspended from the load

cell. Rather than rotating the piston in the cylinder, the piston-cylinder gap is conical and gas

flow through the gap is used to center the piston. The force across the piston is transmitted

to the load cell through a coupling system. There are two independent chambers at either

end

of the piston-cylinder. The lower chamber is held at atmosphere or vacuum while the

pressure to be measured is applied to the upper chamber. The load cell is zeroed with a

pressure difference of zero across the piston (bypass open), taring out the weight of the

piston and coupling and other parasitic forces. Then, with the pressure bypass between the

2.2.3) (in control cabinet).

hanger for validation of FPG8601 load cell linearity.

7.2.5)).

Page 21 © 2005 DH Instruments, Inc.

Page 34

ADCS-601™ OPERATION AND MAINTENANCE MANUAL

two chambers closed, the net force resulting from the difference in pressure between the two

chambers is transmitted to the load cell through the coupling. The value of the pressure is

calculated from the effective area of the piston-cylinder and the net force value measured by

the load cell. The 10 kPa/kg piston-cylinder combined with 1.5 kg net measurement span of

the load cell give the FPG8601 a pressure range of 0 to 15 kPa (4.5 inHg).

The FPG8601 Platform is interfaced with the system controller (PC) running FPG Tools

software that calculates pressure and controls the FPG8601 functions.

The PPC3 pressure controller is used to automate pressure control to set the pressure

measured by the FPG8601.

SUPPLY

LUBRICATING

FLOW

REG

MASS

COMPARATOR

P

hi

P

lub

Figure 19. Force balanced piston gauge operating principle

© 2005 DH Instruments, Inc. Page 22

P

ref

Page 35

2. SYSTEM OVERVIEW

2.2.2.1 FPG8601 PLATFORM

1. Upper mounting post

2. TEST(+) port, KF-16

3. Mounting post

temperature sensor

(PRT) connector

4. TEST(-) port, KF-16

5. Lower mounting post

2.2.3 PPC3 PRESSURE CONTROLLERS

The ADCS-601 system includes two PPC3 pressure controllers that are installed in the

Control Cabinet (see Section 2.1.2). One of the pressure controllers is used to automate

pressure control for the PG7601 piston gauge system (see

to automate pressure control of the FPG8601 force balanced piston gauge system.

The two pressure controllers are:

6. Vacuum reference port,

KF-25

7. Mounting post reference

8. Reference vacuum CDG

connector

9. CDG port, KF-16

10. Instrument reference level

1. COM2 (RS232) - Not used

2. COM1 (RS232) – remote

host communications

3. IEEE-488 – remote host

communications

– Not used

4. Utility vacuum port,

1/8 in. NPTF

5. Bubbler

6. Lubrication pressure

supply port, 1/8 in. NPTF

7. Drive air supply, 1/8 in.

NPTF

8. Coalescing filter

9. Drivers option connector

– Not Used

10. COM3 (RS232)

– Not used

11. FPG Terminal port

Figure 20. FPG8601 front and rear views

Section 2.2.1). The other is used

- PPC3-700K – for the PG7601 piston gauge system.

PPC3-100K A116Ks/BG15Ks with special very low pressure control option for

the FPG8601 force balanced piston gauge system.

Page 23 © 2005 DH Instruments, Inc.

Page 36

ADCS-601™ OPERATION AND MAINTENANCE MANUAL

The PPC3 pressure controllers are stand alone products for which a separate Operation

and Maintenance manual is available with much more complete information than is

included in this manual. A copy of the PPC3 manual is provided on the ADCS-601

Support CD and is available at www.dhinstruments.com.

The PPC3 pressure controller uses on/off solenoid valves and internal high precision pressure

transducers to adjust and stabilize pressure precisely in response to remote commands.

The PPC3 front panel provides a local user interface and display for the PPC3 Pressure

Contro ller . Local commands to PPC3s are not used in normal ADCS-601 operation. See the

PPC3 Operation and Maintenance manual for details on local operation of PPC3.

1. Ready/Not ready indicator

2. Display

3. Remote activity indicator

Figure 21. PPC3 front panel

4. Cursor control keys

5. Multi-function keypad

6. Direct pressure control keys

© 2005 DH Instruments, Inc. Page 24

Page 37

2. SYSTEM OVERVIEW

1. Label, product

2. VENT port

3. COM2 connector

4. IEEE-488 connector

5. COM1 connector

6. Drivers (12 V) connector

7. Power switch

8. Fuse

9. Electrical power connector (IEC-320-C13)

10. Remote [ENT] connector

11. Pressure connection, TEST(+)

12. Pressure connection, TEST(-)

13. Pressure connection, EXHAUST

14. Pressure connection, SUPPLY

Figure 22. PPC3 rear panel

2.2.4 RPM4 A116K REFERENCE PRESSURE MONITOR

The ADCS-601 system includes an RPM4 Reference Pressure Monitor that is installed in the

Control Cabinet (see Section 2.1.2). The RPM4 is used as a precise pressure comparator in

the process of comparing the PG7601 and FPG8601 measurements when validating the

FPG8601 (see Section

The RPM4 is an RPM4 A116Ks.