Page 1

Via Acquanera, 29 22100 Como

tel. 031.526.566 (r.a.) fax 031.507.984

info@calpower.it www.calpower.it

A40B

Precision AC Current Shunt Set

Instruction Manual

July 2008 Rev. 1, 7/09

© 2008-2009 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and

service. The warranty period is one year and begins on the date of shipment. Parts, product repairs, and

services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of

a Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in

Fluke's opinion, has been misused, altered, neglected, contaminated, or damaged by accident or abnormal

conditions of operation or handling. Fluke warrants that software will operate substantially in accordance

with its functional specifications for 90 days and that it has been properly recorded on non-defective media.

Fluke does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers

only but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is

available only if product is purchased through a Fluke authorized sales outlet or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for importation costs of

repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair,

or replacement of a defective product which is returned to a Fluke authorized service center within the

warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that service center, with a description of the difficulty,

postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following

warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination, alteration, accident, or abnormal

condition of operation or handling, including overvoltage failures caused by use outside the product’s

specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair

costs and obtain authorization before commencing the work. Following repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or

limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not

apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court or other

decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any other

provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

To register your product online, visit http://register.fluke.com

Page 3

Table of Contents

Title Page

Introduction and Specifications ......................................................................... 1

About the Manual.......................................................................................... 1

Safety Information......................................................................................... 1

General Safety Summary .......................................................................... 1

Symbols..................................................................................................... 2

Product Description ....................................................................................... 3

Electrical Specifications .................................................................................... 4

Current Shunt Absolute Accuracy................................................................. 4

Resistance Specifications .............................................................................. 5

Maximum AC-DC Difference....................................................................... 6

Maximum Overload Current ......................................................................... 6

Typical Phase Displacement.......................................................................... 6

General Specifications ....................................................................................... 7

Dimensions (maximum) ................................................................................ 7

Physical/Mechanical Parameters ................................................................... 7

Operating Environment ................................................................................. 7

Storage and Transit Environments

(for models other than the 1 mA Current Shunt)........................................ 7

Additional 1 mA Current Shunt Specifications............................................. 7

Preparing for Operation ..................................................................................... 8

Unpacking and Inspecting the Shunts ........................................................... 8

Accessories.................................................................................................... 8

Table.......................................................................................................... 8

Contacting Fluke ........................................................................................... 9

Shipping Information..................................................................................... 9

Storage Information....................................................................................... 9

Acceptance Test............................................................................................. 9

General Maintenance/Cleaning ..................................................................... 10

Operating Information ....................................................................................... 10

Feature Descriptions...................................................................................... 10

Input/Output Connectors ............................................................................... 12

Maximum Current ......................................................................................... 13

Operating Environment ................................................................................. 13

Correcting for Current Shunt Error Contributions ........................................ 13

Output Voltage Measurement – Loading Effect............................................ 14

Output Voltage Measurement Using a Fluke 5790A .................................... 14

i

Page 4

A40B

Instruction Manual

Output Voltage Measurement Using a Fluke 8508A .................................... 15

Operating Instructions........................................................................................ 16

Introduction ................................................................................................... 16

Measuring Current......................................................................................... 16

Direct Read-out When Measuring Current.................................................... 18

Theory of Operation........................................................................................... 18

Coaxial Shunts............................................................................................... 18

Boxed Shunts................................................................................................. 19

Introduction ................................................................................................... 20

An Overview of Calibration Methods ........................................................... 20

Potential Voltage Measurement Devices .................................................. 21

DC Considerations .................................................................................... 22

AC Considerations .................................................................................... 23

The Fluke Calibration Method ...................................................................... 24

Recommended Tools and Equipment ....................................................... 25

System Calibration for AC-DC Difference............................................... 25

TVC Sensitivity Characterization ............................................................. 26

UUT AC-DC Difference Measurement Sequence and Calculations ........ 27

Current Source DC Noise.......................................................................... 28

UUT DC Resistance Measurement ........................................................... 28

Repair Procedures Including Disassembly and Reassembly ............................. 29

Repair Limits................................................................................................. 29

List of Tools Required for Repair.................................................................. 29

End Plates and Guard Binding Post Replacement (Coaxial Shunts)............. 30

Input N-type Connector Replacement (Coaxial Shunts) ............................... 31

Output N-Type Connector Replacement (Coaxial Shunts) ........................... 32

List of Replaceable Parts ................................................................................... 33

ii

Page 5

List of Tables

Table Title Page

1. Contents of the Current Shunt Set Packaging ........................................................ 8

2. A40B Accessories .................................................................................................. 8

3. Features and Connectors ........................................................................................ 12

4. Typical Loading Effect of a 5790A, 2.2 V Range.................................................. 14

5. Typical Loading Effect of an 8508A 2 V ACV Range.......................................... 15

6. Estimating the Uncertainty of a 5790A Measurement ........................................... 17

7. Sample Calculation of Measured Current .............................................................. 17

8. Single Junction Thermal Voltage Converters ........................................................ 21

9. Fluke 792A AC/DC Transfer Standard.................................................................. 21

10. Fluke 5790A Measurement Standard ..................................................................... 22

11. Other Error Sources and Solutions......................................................................... 23

12. List of Recommended Equipment.......................................................................... 25

13. Final Assembly....................................................................................................... 33

iii

Page 6

A40B

Instruction Manual

iv

Page 7

List of Figures

Figure Title Page

1. Current Shunt Configurations ................................................................................ 3

2. Features and Connectors ........................................................................................ 11

3. Loading Effect of the Measurement Device........................................................... 14

4. Current Shunt - Simplified Electrical Diagram...................................................... 19

5. Circuit Using a Reference Shunt Resistor to Determine Source Current............... 20

6. Sources of Error in AC Measurements .................................................................. 23

7. The Fluke Calibration System................................................................................ 24

8. Calibrating Gain Difference................................................................................... 25

9. Characterizing Sensitivity ...................................................................................... 26

10. AC/DC Difference Sequence ................................................................................. 27

11. Exploded View of a Shunt ..................................................................................... 30

12. N Type Input Current Connector ........................................................................... 31

13. Output Voltage Connector ..................................................................................... 32

14. Final Assembly – Typical Current Shunt from the Set .......................................... 33

v

Page 8

A40B

Instruction Manual

vi

Page 9

Introduction and Specifications

About the Manual

This is the Instruction Manual for the A40B Precision AC Current Shunt Set (hereafter

referred to as the Current Shunt or Current Shunts). It contains all of the information a

Calibration Technician needs to operate and maintain the Current Shunts. The manual is

divided into the following sections:

• Introduction and Specifications

• Preparing for Operation

• Operation Instructions

• Theory of Operation

• Service Instructions

Safety Information

This section addresses safety considerations and describes symbols that may appear

either in this manual or on the Current Shunts.

A

W Caution statement identifies conditions or practices that could result in damage to

the Current Shunts or equipment to which it is connected.

A X

W Warning statement identifies conditions or practices that could result in injury or

death.

To avoid electric shock, personal injury, or death, carefully read

the information under General Safety Summary before

attempting to install, use, or service the Current Shunts.

General Safety Summary

This manual contains information and warnings that must be observed to keep the

Current Shunts in a safe condition and ensure safe operation. Using or servicing the

Current Shunts in conditions other than as specified in the Instruction Manual could

compromise your safety.

To use the Current Shunts correctly and safely, read and follow the precautions on the

next few pages, as well as, the safety instructions or warnings given throughout this

manual. In addition, follow all generally accepted safety practices and procedures when

working with and around electricity.

XW Warning

1

Page 10

A40B

Instruction Manual

To avoid electric shock, personal injury, fire, or death, read the following warnings

before using the Current Shunts:

• Use the Current Shunts only as specified in this manual.

• To avoid damage to eyes, skin, and the respiratory system, do not significantly

• Do not use the Current Shunts in wet environments.

• Inspect each Current Shunt before using it. Do not use the Current Shunt if it appears

• Do not use a Current Shunt if it operates abnormally. If in doubt, have the Current

• Have the Current Shunts serviced only by qualified service personnel.

• Do not use the Current Shunts with voltages above 30 V ac rms, 42 V ac peak, or 42 V

• When servicing the Current Shunts, use only specified replacement parts.

• Do not dispose of batteries in fire. Do not heat, deform, solder, dissemble or modify

• If batteries are removed from the shunt, ensure they are re-inserted with the correct

• Use only the battery charger provided to charge the 1 mA active shunt.

• Always connect the Battery Charger / Power Adapter to the AC outlet before

• When replacing the batteries, replace them all together. Use only Nickel Metal Hydride

• Do not operate the batteries together with other types of batteries, or batteries with

• The batteries in the 1 mA Current Shunt are always connected to the charging socket,

XW Warning

exceed the maximum current rating of a shunt. Doing so may cause tracks on the

printed circuit boards to vaporize. (See Maximum Overload Current in the Electrical

Specifications.)

damaged.

Shunt serviced.

dc. These voltages pose a shock hazard.

the batteries

polarity.

connecting it to the shunt.

(NiMH) batteries.

different charge levels.

even when the Current Shunt is turned off.

2

Symbols

The following safety and electrical symbols may appear on the Current Shunt or in this

manual.

W

F

O

Power on setting

I

Risk of danger.

Important information. See manual.

DC (Direct Current)

Power Off setting

~

:

<

J

Do not dispose of this product as unsorted

municipal waste. Go to Fluke’s website for

recycling information.

Warning. Hot or burn hazard

Recycle

Earth ground

Page 11

Precision AC Current Shunt Set

Introduction and Specifications

Product Description

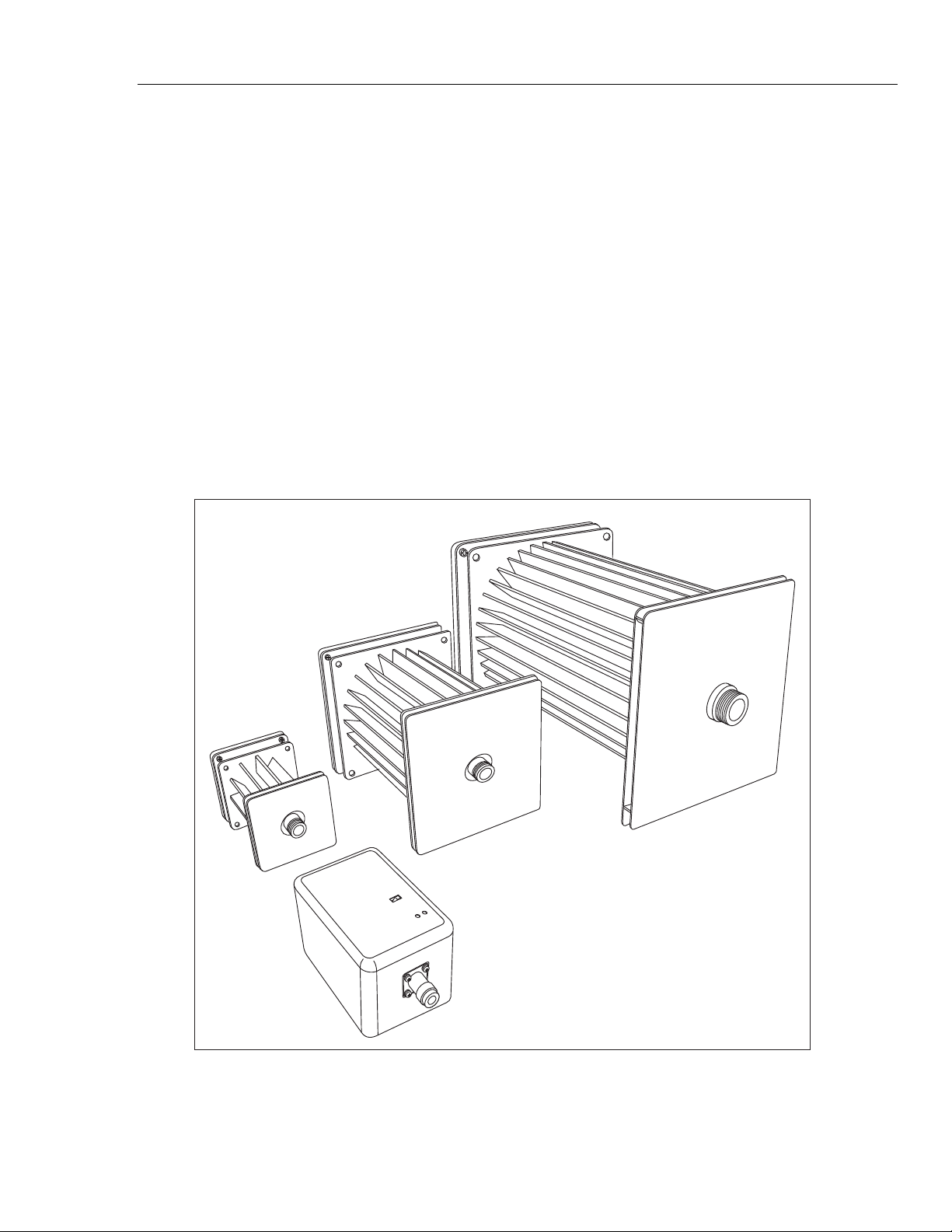

The A40B Precision AC Current Shunt Set consists of 14 Current Shunts, a complement

of adapters, and a rugged transit/storage case. The Current Shunts are designed for

laboratory use in making AC-DC current measurements or absolute AC or DC current

measurements. They exhibit outstanding resistance value stability, excellent self-heating

power coefficient, and a low temperature coefficient. Five configurations of Current

Shunts comprise the set. They are as follows:

• One boxed active shunt 1 mA

• Three boxed passive shunts 10 mA, 20 mA 50 mA

• Five small size coaxial shunts 100 mA, 200 mA, 500 mA, 1 A, 2 A

• Three medium size coaxial shunts 5A, 10 A, 20 A

• Two large size coaxial shunts 50 A, 100 A

The physical construction and the components used in the Current Shunts ensure that

amplitude displacement (error relative to DC resistance) and phase displacement at

100 kHz are small enough to be neglected in all but the highest accuracy measurements.

Voltage output is nominally 0.8 V for nominal current input. The 1 mA boxed active

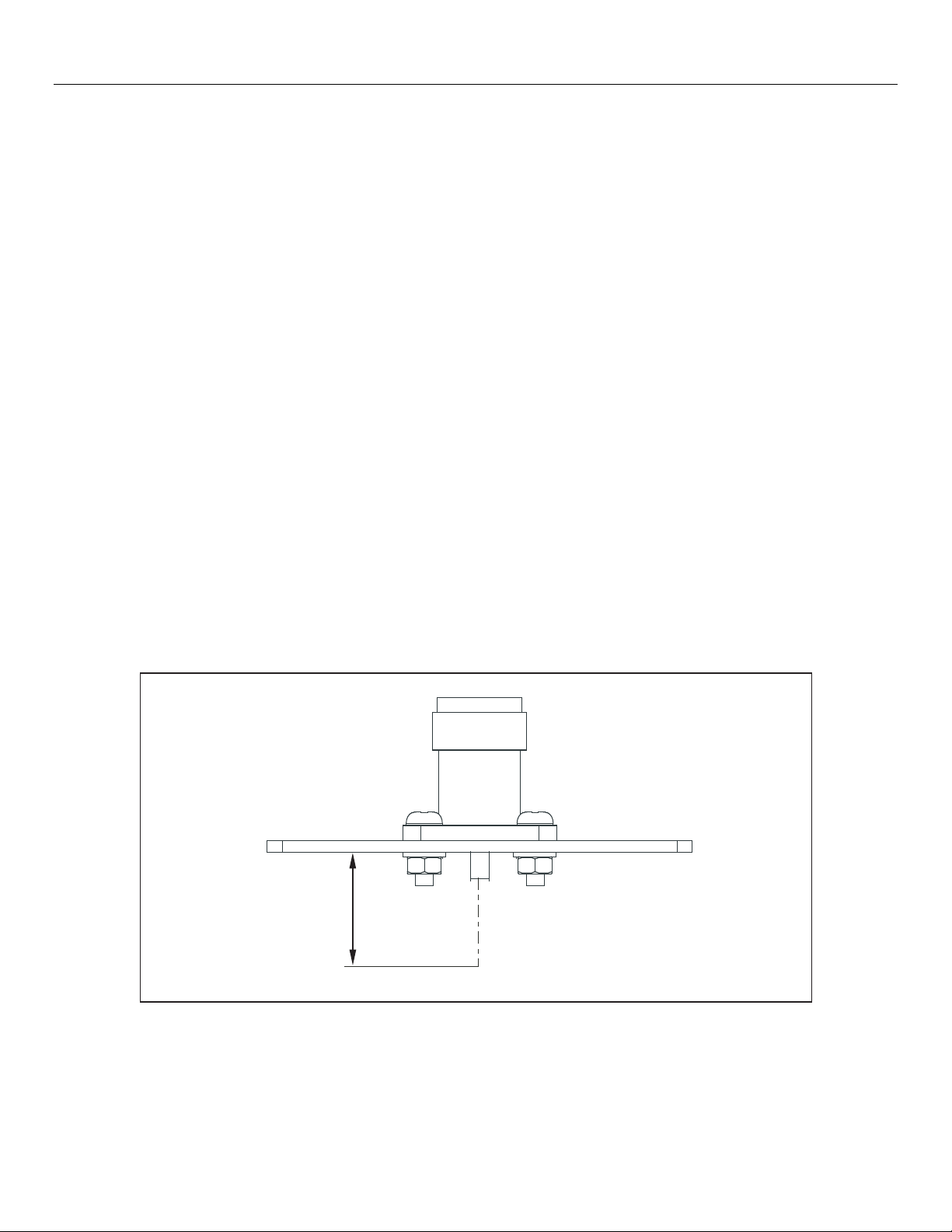

Current Shunt is shown in Figure 1.

Input

Input

Figure 1. Current Shunt Configurations

Input

fim002.eps

3

Page 12

A40B

Instruction Manual

Electrical Specifications

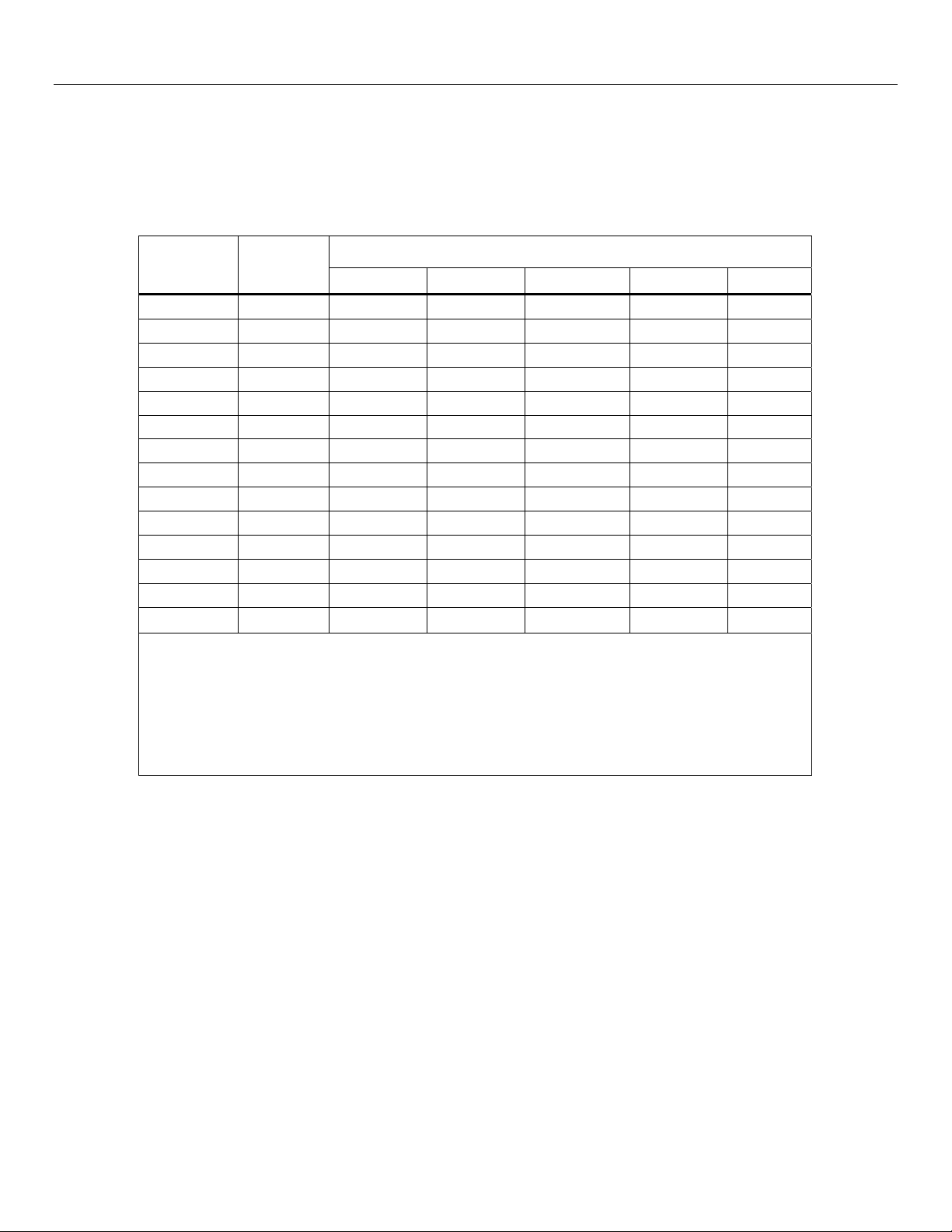

Current Shunt Absolute Accuracy

The following table shows the 1-year absolute accuracy specification stated at k=2, approximately 95% confidence for the

calibrated value. The specifications include 1-year stability, temperature effects over TCal ± 1 °C, and the measurement

uncertainty of the calibrated value.

Shunt Nominal

Nominal

Current

[4]

1 mA

Resistance

(Ohms)

DC 1 kHz 10 kHz 30 kHz 100 kHz

800 20 55 75 75 150

Specification ±μA/A, TCal ±1 °C, ≤50% RH

[1][2][3][5]

10 mA 80 20 26 26 26 26

20 mA 40 20 26 26 26 26

50 mA 16 20 23 23 23 23

100 mA 8 20 24 24 24 24

200 mA 4 20 26 26 26 26

500 mA 1.6 21 27 27 27 28

1 A 0.8 21 27 28 28 31

2 A 0.4 21 27 30 30 48

5 A 0.16 21 31 32 40 71

10 A 0.08 26 37 60 61 92

20 A 0.04 26 43 52 70 113

50 A 0.016 32 55 80 81 144

100 A 0.008 35 65 90 98 174

[1] The measured current is determined from:

I = (V /R

[2] Above 1 kHz interpolate the specification (s

[3] add 20 μA/A if relative humidity is outside specification limits.

[4] 1 mA specifications apply with the battery charger disconnected.

[5] Specifications assume no loading effects due to the voltage-sensing device. See

Effects

) × (1 + (AC-DC

calibrated

in the operating information.

calibrated

/ 1,000,000)); where AC-DC

) between frequencies f

i

is expressed in ppm

calibrated

and f

upper

lower

)()()(

ffssffss −÷−×−+=

lowerupperlowerupperloweriloweri

using:

Output Voltage Measurement - Loading

4

Page 13

Precision AC Current Shunt Set

Electrical Specifications

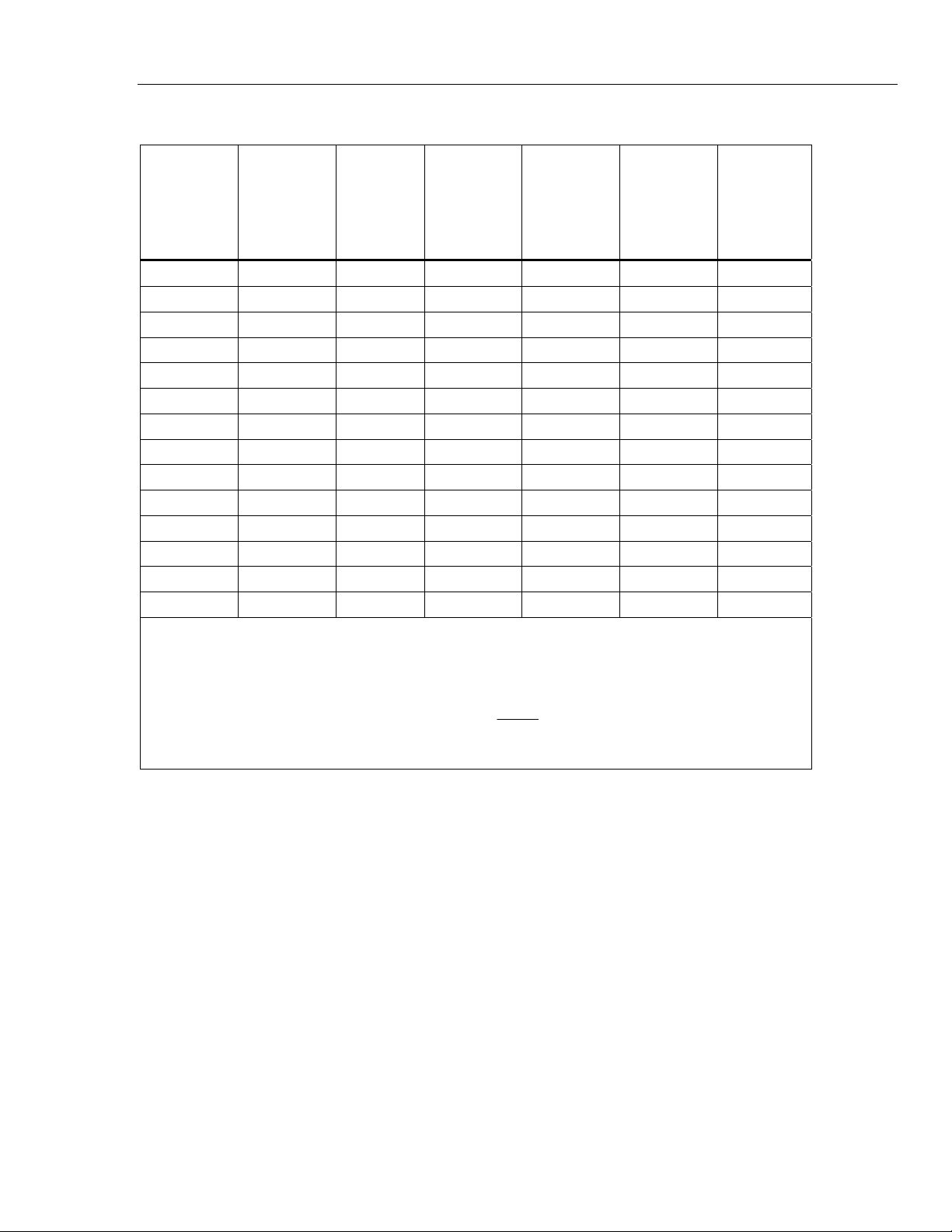

Resistance Specifications

Maximum

Shunt Nominal

Current

1 mA 800 250 8.2 18 5 1

10 mA 80 250 6.8 18 2.5 1

20 mA 40 250 8.2 18 4.5 1

50 mA 16 250 8.3 18 4.5 1

100 mA 8 250 8.3 18 2.5 2

200 mA 4 250 8.6 18 3.5 4

500 mA 1.6 250 9.6 18 4.5 13

1 A 0.8 250 9.3 18 4.5 26

2 A 0.4 250 9.4 18 4.5 26

5 A 0.16 250 9.9 18 4.5 30

10 A 0.08 250 15 18 4.5 65

20 A 0.04 250 14 18 4.5 78

50 A 0.016 250 24 18 4.5 105

100 A 0.008 250 28 18 4.5 105

[1] Stability specification combines long term change due to aging (permanent) and short term fluctuation due to humidity

changes when shunts are used and stored within specified humidity limits. Add 20 ppm if humidity is >50 % RH)

[2] Assume rectangular distribution when combining with other uncertainty contributions.

[3] Calibrated resistance values include the effects of power coefficient at the nominal current. For currents other than nominal,

apply the correction for power coefficient from:

[4] TCal = ambient temperature at calibration

Nominal

Resistance

(Ohms)

Deviation

from Nominal

Resistance

(±μΩ/Ω)

Uncertainty of

Calibrated

Value at 95%

Confidence

(±μΩ/Ω) TCal

[2]

MultipliertCoefficienPowerCorrection

±1ºC

⎡

⎢

1__

⎢

⎣

12 Month

Stability

(±μΩ/Ω)

2

Applied

min

⎤

⎞

⎟

⎥

⎟

⎥

alNo

⎠

⎦

I

⎛

⎜

−×=

⎜

I

⎝

[1][2]

Temperature

Coefficient

(±ppm/ºC)

[2]

Coefficient

Multiplier

(±ppm)

Power

[2][3]

5

Page 14

A40B

Instruction Manual

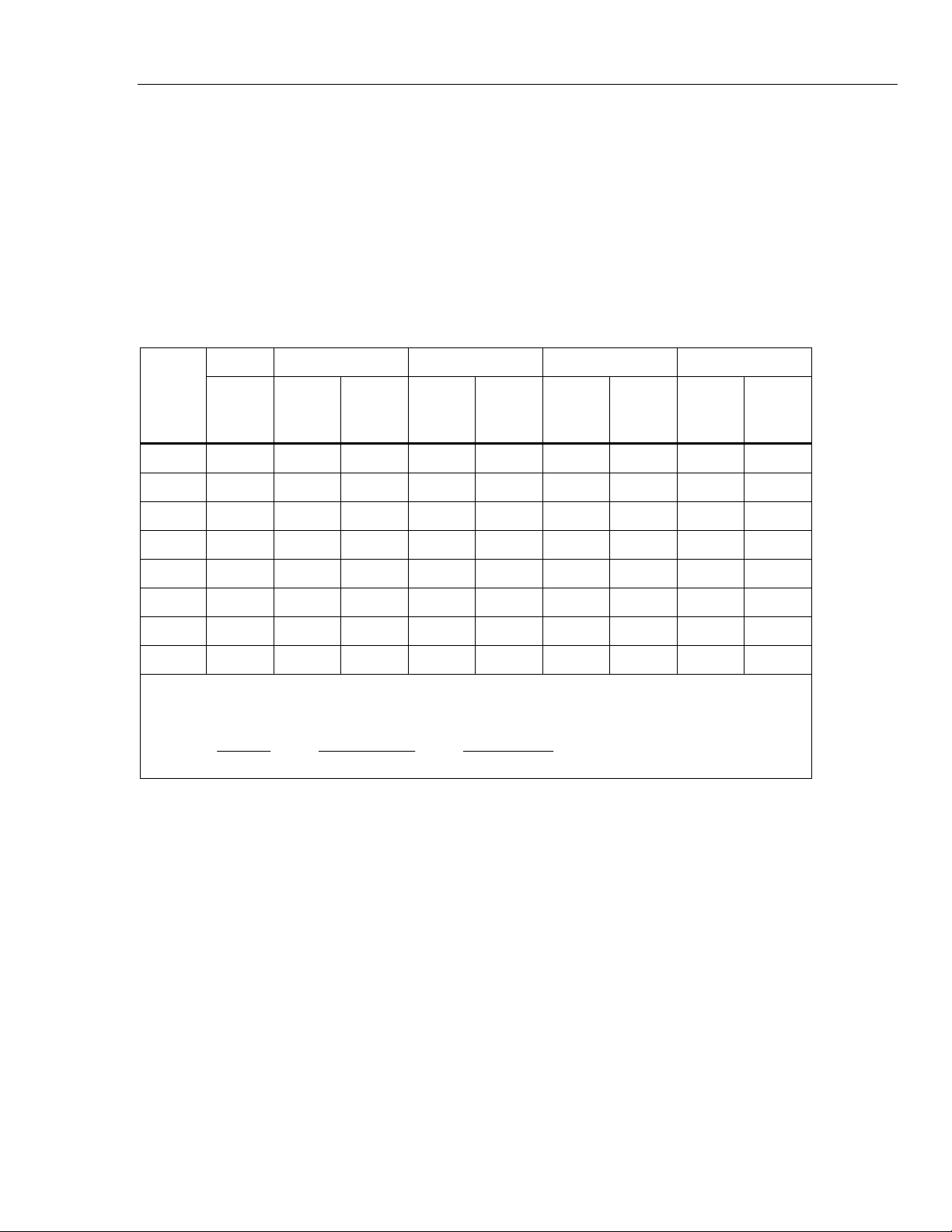

Maximum AC-DC Difference

Shunt Nominal

Current

[3]

1 mA

53 72 72 150

Maximum AC-DC Difference (±ppm)

1 kHz 10 kHz 30 kHz 100 kHz

[1][2]

10 mA 20 20 20 40

20 mA 18 18 19 30

50 mA 13 13 14 16

100 mA 14 15 17 27

200 mA 17 17 18 28

500 mA 17 17 17 21

1 A 17 19 19 23

2 A 17 22 22 44

5 A 23 24 34 69

10 A 28 55 58 98

20 A 37 51 80 150

50 A 47 75 79 180

100 A 60 90 120 300

[1] Specifications indicate the maximum flatness deviation from DC, and include both measured AC-DC difference and the

uncertainty of measurement. They are stated at k=2, approximately 95 % confidence

[2] Includes 1-year stability of the AC-DC difference

[3] Specifications for the 1 mA Current Shunt are for TCal ±1 °C

Maximum Overload Current

Shunt Nominal

Current

Maximum Current

< 5 Seconds

[1]

1 mA 3 mA 2 mA

Maximum

Sustained Current

[2]

[3]

1 A 3.9 A 1.3 A

Shunt Nominal

Current

Maximum

Current < 5

Seconds

[1]

10 mA 150 mA 20 mA 2 A 5.5 A 2.2 A

20 mA 250 mA 40 mA 5 A 17 A 5.5 A

50 mA 450 mA 100 mA 10 A 24 A 11 A

100 mA 1.2 A 200 mA 20 A 42 A 22 A

200 mA 1.7 A 400 mA 50 A 95 A 55 A

500 mA 2.7 A 1 A 100 A 190 A 110 A

[1] Longer than 5 seconds may cause permanent damage to the shunt. The output voltage may be considerably higher than 0.8

V.

[2] Exceeding maximum sustained current may cause a resistance value step change

[3] 1 mA shunt batteries should be fully charged to ensure performance at 2 mA

Maximum

Sustained

Current

Typical Phase Displacement

Typical Phase Displacement

Shunt Nominal Current 1 kHz 10 kHz 100 kHz

1 mA to 200 mA < 0.001 º < 0.006 º < 0.060 º

500 mA to 2 A < 0.003 º < 0.030 º < 0.300 º

2 A to 20 A < 0.008 º < 0.075 º < 0.750 º

20 A to 100 A < 0.013 º < 0.125 º < 1.250 º

[2]

6

Page 15

Precision AC Current Shunt Set

General Specifications

General Specifications

Dimensions (maximum)

[1]

Shunt Value

1 mA to 2 A 70 (2.75) 70 (2.75) 124 (4.9)

5 A to 20 A 130 (5) 130 (5) 210 (8.25)

50 A and 100 A 200 (7.9) 200 (7.9) 343 (13.5)

[1] includes input and output connectors; subject to change by component vendor.

Height

mm (inches)

Width

mm (inches)

Overall Length

mm (inches)

Physical/Mechanical Parameters

Shunt Value

1 mA to 20 A 0.7 ( 1.6) Type-N (female) Type-N (female)

50 A and 100 A 3.4 (7.5) Type-LC (female) Type-N (female)

Weight (maximum)

kg (lb)

Input Connector Output Connector

Operating Environment

Temperature ....................................................... 13 ºC to 33 ºC

Calibration Temperature (TCal) Range............... 18 ºC to 28 ºC

Humidity Range for best specification

Altitude................................................................ 0 m to 3,000 m

[1] Resistance stability is affected by humidity, but changes are reversible.

[2] If the shunts are calibrated outside this RH, stability specifications will be met as long as the shunts are stored and used at the

same relative humidity ±10% RH.

[1][2]

........... ≤50 % RH

Storage and Transit Environments (for models other than the 1 mA Current Shunt)

Temperature to avoid damage............................ -20 ºC to 140 ºC

Temperature and Humidity to maintain

performance

Non-operating Altitude ........................................ 0 m to 12,000 m

[1] Storage at extremes of temperature or humidity will cause a temporary change of shunt resistance by up to ±20 ppm. When

subsequently stored or used within the limits of the operating environment, the shunts will recover to their original resistance value

within 30 days.

[1]

................................................ 5 ºC to 45 ºC; 15% to 80 % RH

Additional 1 mA Current Shunt Specifications

Output Resistance .............................................8 mΩ

Maximum Safe Output Current .......................... 11 mA (e.g., 1 V output into 90 Ω )

Maximum Capacitive Load ................................ 800 pF

Output Voltage Regulation ................................. 15 ppm / 100 pF

Maximum Output DCV Offset ............................. ±100 μV (typical ± 25 μV)

Typical Error @ 1 MHz........................................ <2%

Battery Specifications

Battery Size ................................................... AAA (44.5 x 10.5 mm)

Battery Technology......................................... Nickel-Metal Hydride (NiMH)

Number of Batteries Required ........................8 (in 2 groups of 4)

Nominal Battery Voltage ................................. 1.2 V (4.8 V per group of 4)

Typical Battery Capacity ................................. 800 mAh

Charging Time (from fully discharged) ........... 100 minutes

Maximum Operating Time Between Charges:

Maximum Output Load (11 mA) ................ 18 hours

High Impedance Load ............................... 24 hours

Recommended cooling period after

charging the batteries ....................................100 minutes

Storage and Transit Environment to preserve the batteries

Less Than 90 days ..................................... -20 ºC to 40 ºC

Less Than 1 year ........................................ -20 ºC to 30 ºC

To prevent loss of battery capacity recharge at least twice per year.

7

Page 16

A40B

Instruction Manual

Preparing for Operation

Unpacking and Inspecting the Shunts

This section of the manual describes how to unpack and prepare the Current Shunts for

operation.

Note

The coaxial Current Shunts are robust when handled correctly by their

ends. Take care not to damage the horizontal struts of the coaxial shunts.

Upon receiving the Current Shunts from the carrier, carefully unpack and inspect them

for damage. If there is any sign of physical damage, notify the carrier immediately.

As part of the inspection process, check the contents against the list shown in Table 1.

Report any shortages to the nearest Fluke Technical Service Center. See Contacting

Fluke.

Save the container and any packing material for future use in storing or shipping the

Current Shunts

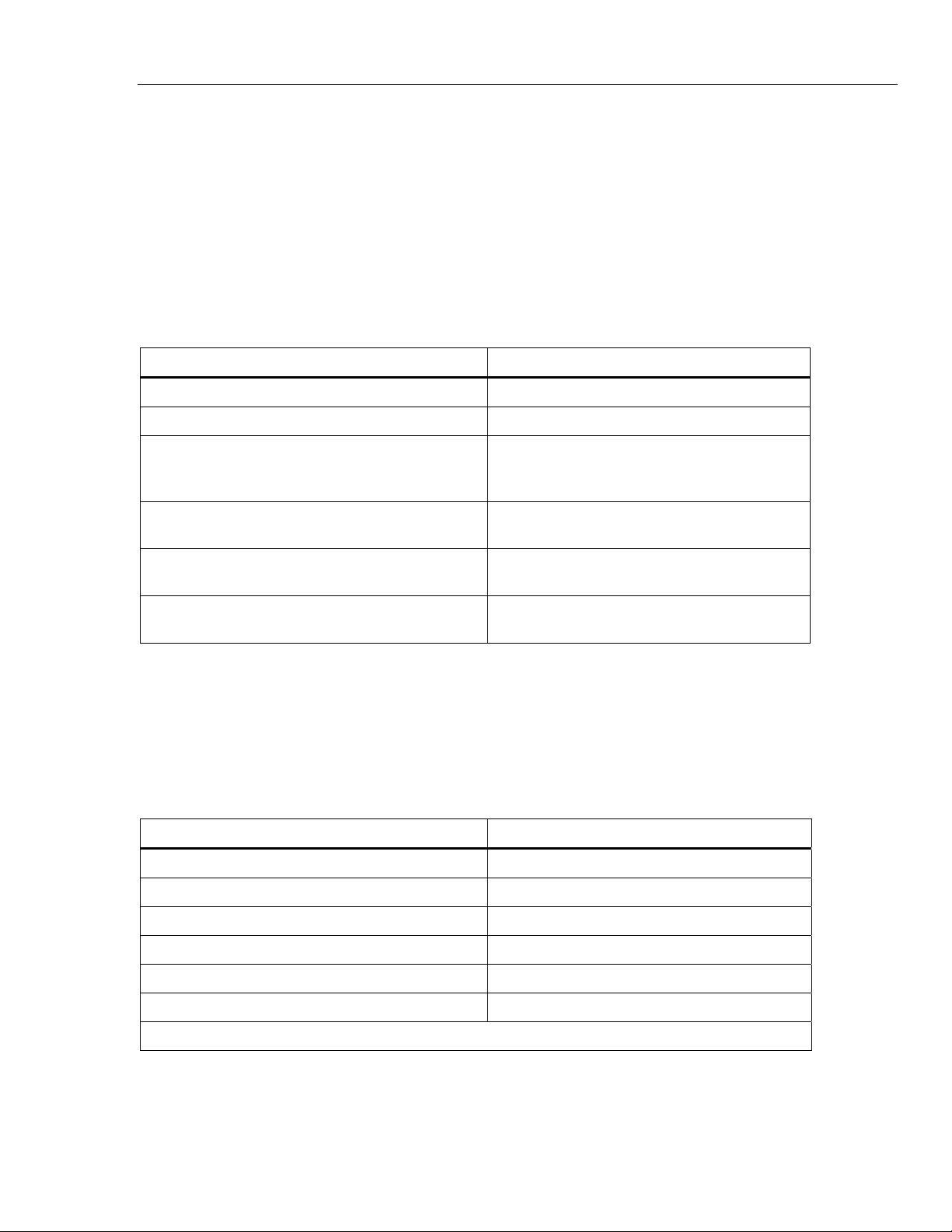

Table 1. Contents of the Current Shunt Set Packaging

Description Quantity

A40B-Case .............................................Transit/storage case for the A40B Current Shunts 1

Packing List of Items............................. Includes the serial number of the Current Shunts 1

Current Shunts

one boxed active shunt with battery charger ...... 1 mA

three boxed passive shunts................................ 10 mA, 20 mA 50 mA

five small size coaxial shunts ............................. 100 mA, 200 mA, 500 mA, 1 A, 2 A

three medium size coaxial shunts ...................... 5A, 10 A, 20 A

two large size coaxial shunts.............................. 50 A, 100 A

Connector Adapters

A40B-ADAPT/LC................................. LC Male to LC Male adapter

A40B-ADAPT/LCN ............................. LC Female to N Male inter-series adapter

A40B-LEAD/N .....................................N Male to N Male lead

A40B-LEAD/4mm ................................ N to 4 mm double banana connector

Battery charger for 1 mA active shunt

CD containing the Instruction Manual (PDF)

Accessories

The LC and N adapters described in Table 2 are available as accessories:

Table 2. A40B Accessories

Accessory Description

A40B-CAL/LC High current adapter to connect two shunts in series for measurement (LC to LC)

A40B-CAL/N Low current adapter to connect two shunts in series for measurement (N to N)

14

1

1

1

2

1

1

8

Page 17

Precision AC Current Shunt Set

Preparing for Operation

Contacting Fluke

• Technical Support USA: 1-800-44-FLUKE (1-800-993-5853)

• Calibration/Repair USA: 1-888-99-FLUKE (1-888-993-5853)

• Canada: 1-800-36-FLUKE (1-800-363-5853)

• Europe: +31 402-675-200

• Japan: +81-3-3434-0181

• Singapore: +65-738-5655

• Anywhere in the world: +1-425-446-5500

Or, visit Fluke's website at www.fluke.com

.

To register your product, visit http://register.fluke.com

.

To view, print, or download the latest manual supplement, visit

http://us.fluke.com/usen/support/manuals

.

Shipping Information

To prepare the Current Shunt Set for shipping, place them in the appropriate pre-cut foam

insert positions in the transit/storage case and secure the lid.

When shipping individual Current Shunts, completely enclose them within at least 5 cm

(2 inches) of polyurethane foam cushioning and pack them in a crush-proof container.

Storage Information

To prepare the Current Shunts for storage, place them in their transit/storage case, and

secure the lid. Then, store the container in a location that complies with the

environmental specifications described earlier in the General Specifications. Storage

outside these conditions may reduce the battery life of the 1 mA shunt or cause a

temporary change in the resistance of the Current Shunts by up to ±20 ppm. When

returned to an acceptable operating environment, the Current Shunts will recover to their

original resistance value within 30 days.

Acceptance Test

Upon initial receipt of the Current Shunts, perform the following acceptance test to

ensure that they are functional:

1. Inspect the physical condition of the Current Shunts for obvious physical damage,

including connector damage as described under General Maintenance/Cleaning.

Repair any damage before proceeding.

Instructions for contacting Fluke are provided earlier in this manual.

2. Functionally test each Current Shunt by applying the nominal current to its input. At

nominal current, the output voltage for each Current Shunt should be approximately

0.8 volts.

Note

Each Current Shunt produces 0.8 volts output for an input at nominal

operating current. The highest current shunts (10 A and above) get warm

when operating at full current. The 50 A and 100 A shunts may become

uncomfortable to touch; their operating temperature can be as high as

70 ºC (158 ºF).

9

Page 18

A40B

Instruction Manual

General Maintenance/Cleaning

For General Cleaning, wipe the Carrying Case and Current Shunts with a damp cloth and

mild detergent. Do not use abrasives, isopropyl alcohol, or solvents.

W Caution

To prevent damage to the instrument:

• Do not use aromatic hydrocarbons or chlorinated solvents

for cleaning the Current Shunts.

• Do not spray liquid on or immerse the Current Shunts.

Other than calibration, the only maintenance the Current Shunts require is inspection of

the input and output connectors for wear or damage. The LC-type input connectors of the

50 A and 100 A shunts are robust, but the N-type connectors on the medium and small

shunts are easily damaged by misuse or mating with out-of-tolerance N-type male

connectors. The center pins of male N-type connectors are prone to moving, particularly

when assembled onto cables. If a center pin on an N-type connector protrudes too much,

the female connector on the shunt will be damaged by splaying the inner connector. If

there is any doubt about connector condition, gauge the connectors (see MIL-C-39012 for

details). Defective connectors can be replaced but it is recommended the work be

performed at a Fluke Service Center.

Operating Information

This section of the manual contains practical information the user needs to know before

and after making a current measurement. The material is intended to help the user make

high quality precision measurements.

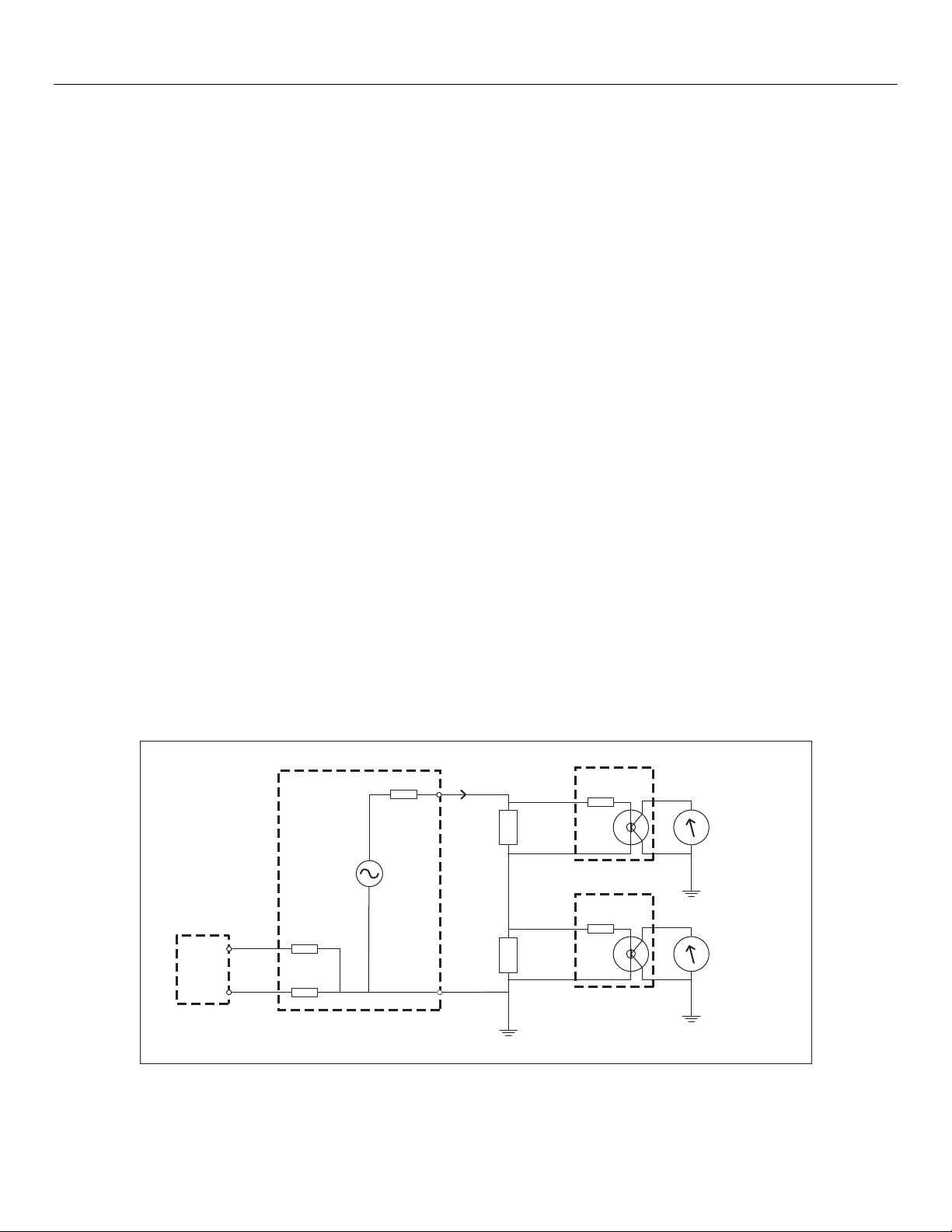

Feature Descriptions

The features and connectors of the Current Shunts are shown in Figure 2 and described in

Table 3.

10

Page 19

Precision AC Current Shunt Set

Operating Information

Bottom

Front

Rear

1

2

3

Passive Shunt (100 mA)

5

6

7

3

1

4

Top

2

Active Shunt (1 mA)

Figure 2. Features and Connectors

fim005.eps

11

Page 20

A40B

Instruction Manual

Input/Output Connectors

Table 3. Features and Connectors

Item Feature Description

A Current Input Connector Connector for applying current to the shunt. All of the

shunts use the N-type female connectors except the 50 A

and 100 A versions which use type LC female Connectors.

B Voltage Output Connector Connector for measuring voltage drop across the shunt.

The output connectors are all N-type female.

C Guard Connection Binding post terminal for making a guard connection to

Shunt Lo.

D PCB Struts Low inductance connections carrying current to and from

the shunt resistors.

E Power on/off switch Switches power for the current Shunt on or off.

F LED indicators Green indicates power on. Red indicates low battery.

G Battery charger connector Input connector for the external battery charger.

XW Warning

To avoid skin burns and possible damage to the 50 A and 100 A

Current Shunts, make sure the current-carrying input

connectors are undamaged and fully tightened before applying

current to them.

The input connectors on the 50 A and 100 A shunts are of the LC-type. Under full current

conditions, the connectors will get hot to the touch. This is normal because of contact

resistance. If the connectors are not fully tightened, they will get hot enough to burn skin

and damage the shunt.

W Caution

To avoid pin damage to N-Type connectors on the Current

Shunts, make sure the male pin of a mating connector is in

tolerance and does not protrude.

All other coaxial connectors on the Current Shunts are 50 Ω, female, N-type. These

connectors are especially vulnerable to damage while being connected to a male N-type

connector. If the male connector is out-of-tolerance or its center pin protrudes too far, it

will splay the center pin of the female connector and lead to a poor connection. If there is

any doubt about the condition of the center pin in a female N-type connector, gauge the

connector (see MIL-C-39012 for details).

In extreme cases of connector damage, the connection resistance may be high enough to

prevent some current sources from driving the additional compliance voltage, particularly

at higher frequencies.

12

Another potential compliance voltage problem occurs when a Current Shunt is in series

with an inductance. The inductance can also burden current sources beyond their

capability. To help counter the effect, make sure the current connections are coaxial and

as short as possible.

A defective connector on a Current Shunt is replaceable. However, Fluke recommends

the work be done at a Fluke Service Center.

Page 21

Precision AC Current Shunt Set

Operating Information

Maximum Current

Each Current Shunt is marked at the input connector with its nominal (rated) current.

Similarly, markings at the voltage output connector indicate the nominal voltage out for

nominal current in. A table in the specifications section provides maximum currents to

maintain performance and to avoid irreversible damage.

XW Warning

To avoid electrical shock hazard, use standard recommended

safety practices when the Current Shunt is connected in a

circuit which will create voltages above 30 V ac rms, 42 V ac

peak, or 42 V dc. Voltages above these levels pose a shock

hazard to the user.

W Warning

To avoid damage to eyes, skin, and the respiratory system, do

not significantly exceed the maximum overload current rating of

a Current Shunt. Doing so may cause tracks on the printed

circuit boards to vaporize. (See Maximum Overload Current in

the Electrical Specifications.)

W Caution

To avoid irreversible damage to the sense shunt resistors, do

not exceed the maximum sustained current for a Current Shunt

as shown earlier in the Electrical Specifications. (See Maximum

Overload Current.)

Operating Environment

The Current Shunts are designed to operate in a controlled environment such as

calibration and measurement laboratories. Temperature and humidity outside specified

storage and transit environment may affect their performance and, in the extreme case,

damage them.

The open coaxial shunts rely on natural convection for cooling. Adverse performance

will result if airflow is restricted.

Correcting for Current Shunt Error Contributions

The Current Shunts are designed for use with a voltage-measuring device to measure

current. When making a measurement, both instruments contribute known measurement

errors and usually require a measurement correction to achieve the best accuracy. The

Current Shunt can be used to directly measure current without the need to make AC-DC

difference comparisons to a DC current reference. The Current Measurement

Specifications table gives the specification for a measurement where the calibrated DC

resistance value and AC-DC difference are corrected for and allowance is made for the

shunt’s 12 month stability.

Use the following formula to determine a measured current, I, from voltage, and

calibrated resistance (R

Where: AC-DC

calibrated

) and AC-DC difference (AC-DC

calibrated

is expressed in ppm.

calibrated

) values:

⎛

⎜

=

I

⎜

R

calibrated

⎝

The formula above is based on the assumption that the voltmeter has infinite input

impedance at the frequency of interest.

⎞

V

⎛

⎟

+×

1

⎜

⎟

⎝

⎠

DC-AC

calibrated

1,000,000

⎞

⎟

⎠

13

Page 22

A40B

Instruction Manual

Output Voltage Measurement – Loading Effect

The published specifications for a Current Shunt represent its performance under ideal

conditions. In practical use, placing the input of the voltage measurement device in

parallel with the Current Shunt introduces an additional impedance (loading effect) which

will result in a measurement error. See Figure 3. The 1 mA boxed Current Shunt has less

than 8 mΩ output resistance, so resistive loading effects are negligible. The capacitive

loading effect is less than 15 ppm per 100 pF at 100 kHz. For the non-active Current

Shunts, the loading effect becomes more significant as the resistance value of the Current

Shunt increases, that is, as the nominal current value decreases. For the most accurate

measurements, the error due to this loading effect must be calculated and used as a

measurement correction.

Z Connect

Current

Input

Shunt Resistor

Z Connect

Figure 3. Loading Effect of the Measurement Device

Voltage

output

Device Input Z

feh004.eps

Output Voltage Measurement Using a Fluke 5790A

The typical input impedance of a 5790A (input 1 or 2) is >10 MΩ (dc) in parallel with

70 pF. The 10 MΩ in parallel with the shunt resistance has a small effect on the lowest

current value Current Shunts at DC. The 5790A impedance typically decreases to

approximately 1.5 MΩ in parallel with 70 pF at 100 kHz, and, at this frequency, the

loading effect is more pronounced. For the lower value shunts, the loading error is

comparable with or exceeds the shunt error when used to measure current directly.

Table 4 shows the loading effect of the 5790A on Current Shunts in the range of 10 mA

to 200 mA.

Table 4. Typical Loading Effect of a 5790A, 2.2 V Range

DC 1 kHz 10 kHz 30 kHz 100 kHz

Current

(mA)

100 -1 -1 0 -1 0 -2 +1 -5 +4

200 0 0 0 0 0 -1 0 -2 +2

Loading

Error

(ppm)

1 0 0 0 -1 +1 -3 +3 -11 +11

10 -6 -6 0 -8 +2 -16 +10 -56 +49

20 -3 -3 0 -4 +1 -8 +5 -26 +23

50 -1 -1 0 -2 0 -3 +2 -10 +9

Loading

Error

(ppm)

AC-DC

Diff.

(ppm)

Loading

Error

(ppm)

AC-DC

Diff.

(ppm)

Loading

Error

(ppm)

AC-DC

Diff.

(ppm)

Loading

Error

(ppm)

AC-DC

Diff.

(ppm)

14

Page 23

Precision AC Current Shunt Set

Output Voltage Measurement Using a Fluke 8508A

The input impedance of an 8508A on its DC function is >10 GΩ and the loading effect

for measuring DC current with any Current Shunt is negligible. The typical AC function

(DC coupled) low frequency input impedance of an 8508A is 1 MΩ in parallel with

135 pF. The impedance reduces with frequency to typically 550 kΩ || 135 pF at 100 kHz.

For the lower-current Current Shunts, the loading error is comparable with or exceeds the

shunt error when used to measure current directly.

Table 5 shows the loading effect of the 8508A on Current Shunts in the range of 1 mA to

1000 mA.

Table 5. Typical Loading Effect of an 8508A 2 V ACV Range

DC 1 kHz 10 kHz 30 kHz 100 kHz

Current

(mA)

Loading

Error

(ppm)

1 0 0 0 -2 +2 -6 +6 -20 +20

10 -80 -80 0 -82 +2 -92 +12 -172 +92

Loading

Error

(ppm)

AC-DC

Diff.

(ppm)

Loading

Error

(ppm)

AC-DC

Diff.

(ppm)

Loading

Error

(ppm)

AC-DC

Diff.

(ppm)

Loading

Error

(ppm)

AC-DC

Diff.

(ppm)

20 -40 -40 0 -41 +1 -45 +5 -80 +40

50 -16 -16 0 -16 0 -18 +2 -31 +15

100 -8 -8 0 -8 0 -9 +1 -15 +7

200 -4 -4 0 -4 0 -4 0 -8 +4

500 -2 -2 0 -2 0 -2 0 -3 +1

1000 -1 -1 0 -1 0 -1 0 -1 0

Use the following formula correct for the loading effect:

Where: AC-DC

⎛

V

⎜

=

I

⎜

R

calibrated

⎝

and Loading error are expressed in ppm.

calibrated

⎞

⎛

⎟

1

⎜

⎟

⎝

⎠

+×

DC-AC

calibrated

1,000,000

⎛

⎞

1

−×

⎜

⎟

⎠

⎝

1,000,000

error Loading

⎞

⎟

⎠

15

Page 24

A40B

Instruction Manual

Operating Instructions

Introduction

Measuring Current

This section of the manual describes how to measure both AC and DC current using any

one of the Current Shunts. The procedures are based on the assumption that the user is

familiar with the Operating Information and Specifications presented earlier in this

manual.

Use the following procedure to measure current using one of the Current Shunts:

1. Analyze the circuit being tested and determine the following:

a. The approximate value of the current that flows in the circuit.

b. The frequency of the current to be measured (DC to 100 kHz).

2. Select a Current Shunt capable of safely handling the estimated current.

3. If using the 1 mA Current Shunt, switch it to On and verify that the battery low (red)

indicator is off. If the 1 mA Current Shunt has been charging, disconnect the charger.

The charging process creates heat in the battery so for the best accuracy allow the

shunt temperature to stabilize for 100 minutes after charging completes.

4. Remove power from the circuit under test and connect the input of the Current Shunt

in series with the circuit.

5. Connect an appropriate voltage measuring device to the output of the Current Shunt,

and select the correct range. The output voltage of the Current Shunt is proportional

to the input current; 0.8 V for nominal rated current.

It is generally appropriate to set the measuring device to remote guard and connect its

guard terminal to the guard on the Current Shunt. Refer to the measuring device

documentation.

6. Apply power to the circuit and measure the resulting output voltage. This output

voltage is directly proportional to the current flowing in the circuit.

7. Use the voltage measurement and the Operating Information in the previous section

of this manual to accurately determine the current level.

Determine the current using the following formula:

Where: AC-DC calibrated and Loading error are expressed in ppm.

⎛

⎜

=

I

⎜

R

calibrated

⎝

⎞

V

⎛

⎟

1

+×

⎜

⎟

⎝

⎠

DC-AC

calibrated

1,000,000

error Loading

⎛

⎞

1

−×

⎜

⎟

⎝

⎠

1,000,000

⎞

⎟

⎠

16

Page 25

Precision AC Current Shunt Set

Operating Instructions

Example: Estimating the Uncertainty of a 5790A Measurement

The following example shows how to estimate the measurement uncertainty of a

calibration measurement (ambient temperature 23 °C). It illustrates one of the

performance verification tests for the Fluke 5720A calibrator. Specifically it tests

200 mA at 1 kHz, as documented in the 5720A's full verification procedure.

Source: Fluke 5720A – 200 mA output at 1 kHz

Measurement Equipment: Fluke Current Shunt, 200 mA (calibrated at 23 °C) and a

Fluke 5790A

Make the measurement and estimate the uncertainty using the information given in Table

6. A sample calculation of Measured Current using arbitrary values is shown in Table 7.

As described in the 5720A full verification procedure, evaluating the measured current

uses limits based on the specification at 200 mA, 1 kHz of +/-145 ppm; calculated by the

5720A's 1 year, 99 % confidence specification of +/-(130 ppm of output + 3 μA). As

shown, the expanded measurement uncertainty is very adequate to reliably confirm this

level of performance.

Table 6. Estimating the Uncertainty of a 5790A Measurement

Error Component

Standard deviation of measurement

[1]

noise

Shunt current measurement

specification (95 %)

Shunt temperature coefficient

Shunt power coefficient

5790A loading effect uncertainty

5790A specification (2.2 V range)

Notes:

[1] Value arbitrarily chosen for this example

[2] Power Coefficient = 0 as shunt is used at nominal current value

[3] Typical uncertainty at 1 kHz

5790A reading 0.799977 V

Calibrated resistance value 3.999770

Uncorrected calculated 5720A current output (V/R) 0.2000058 A

Add A40B AC-DC difference error (ppm) +1 ppm

Subtract 5790A loading error (ppm) 0 ppm

Total measurement correction +1 ppm

Corrected measurement result 0.2000060

Measurement uncertainty in Amperes

[2]

[3]

Table 7. Sample Calculation of Measured Current (Arbitrary Values)

Givens/Calculations Values Units

Value

(ppm)

5 normal 1 5 25

26 normal 2 13 169

0 rectangular 1.73 0 0

0 rectangular 1.73 0 0

1 normal 2 0.5

22 normal 2.58 8.53 72.71

Expanded, rounded uncertainty in ppm (k = 2)

Distribution Divisor

Sum of squared value

Std uncertainty = square root of the sum

Expanded Uncertainty

±0.0000066

Value at

k=1

Squared

Value

266.96

16.34

33

±0.0000066 A

Ω

A

A

17

Page 26

A40B

Instruction Manual

Direct Read-out When Measuring Current

When using a Current Shunt with a meter that allows the displayed value to be

manipulated using math functions, the meter can be configured to give a direct reading of

current. For Example:

In the following scenario, a current source is measured with a 100 mA Current Shunt and

a Fluke 8508A.

Assumptions:

• Calibrated DC resistance of the Current Shunt (z) = 7.999600

• Calibrated AC-DC difference of the Current Shunt at this frequency = +7 ppm

• Loading effect at this frequency = -9 ppm

1. Combine the AC-DC difference and loading effect numbers:

Combined ppm errors = -(+7) -9 = -16 ppm

Note

AC-DC difference error is the amount the AC value would have to be

changed to make it the same as the DC value. To change this into a

frequency flatness error, reverse the sign.

2. Convert the combined ppm errors into a multiplier (m)

16

−

⎛

1 =

−=m

⎜

⎝

3. Enter the z value (7.99960) into the z store of the 8508A

4. Enter the m value (1.000016) into the m store of the 8508

5. Activate divide by z and multiply by m on the 8508A

The 8508A now gives a direct reading of the current being measured.

To measure the same current level at a different frequency; calculate a new value for m

and enter the new value into the 8508A m store. The z value remains the same.

000,000,1

Theory of Operation

The Current Shunts are essentially a resistance through which a current is passed to

develop a voltage. They are intended for precision AC-DC current measurements in the

range 1 mA to 100 A at frequencies DC to 100 kHz. Inductance tends to make accurate

measurement difficult as current and frequency increases.

Coaxial Shunts

The coaxial shunts are especially designed for low-inductance. The design is similar to

that developed by Mendeleyev Institute, St Petersburg. The key components of the

coaxial shunts are the printed circuit board (PCB) construction and the precision resistive

elements. The design provides several parallel current paths (struts) each with its own

resistive element. Each current path is symmetrical to minimize mutual inductance.

Resistive elements comprise 1 to 8 discrete high precision bulk foil resistors per strut

depending on the current rating of the Current Shunt.

⎞

000016.1

⎟

⎠

18

Individual PCB struts, collected in a cylindrical construction to reduce external magnetic

fields, form the path through the shunt. Figure 4 shows the current path through one of

the strut/resistor elements.

Page 27

Precision AC Current Shunt Set

Theory of Operation

B

Voltage Output

Connector - Inner

Bulk Foil Resistor

feh006.png

Current Input

Connector - Inner

Current Input

Connector - Outer

Figure 4. Current Shunt - Simplified Electrical Diagram

AC

Segment Top

Side Copper

Segment Bottom

Side Copper

The PCB designated A in Figure 4 is copper clad on both sides. PCBs B and C are single

sided. Current flows into the shunt through the input connector, through one side of the

PCB A, along one side of the struts to the resistor. The current return is through the

resistor and along the other side of the struts and end PCB to the input connector. The

voltage across the resistor is carried by the strut to the dual PCB end (B and C in Figure

4) and to the output connector.

The parallel current paths provided by the PCB struts and ends minimize mutual

inductance. Using numerous bulk foil resistors reduces skin effect in the resistive element

and provides excellent stability.

Boxed Shunts

With the exception of the 1 mA Current Shunt the boxed Current Shunts are electrically

simpler than the coaxial versions. Inductance and self heating become less of a problem

so the resistive elements can be enclosed to reduce external influences. The 1 mA Current

Shunt includes a battery powered amplifier to buffer the shunt resistance from loading

effects.

19

Page 28

A40B

Instruction Manual

Calibration

Introduction

An Overview of Calibration Methods

This section of the manual describes the calibration of the Current Shunts. The

description is presented in two parts:

1. An overview/discussion of the considerations for calibration of Current Shunts.

2. A description of the Fluke Calibration Method.

Neither of the descriptions contains detailed step by step procedures for calibrating the

Current Shunts. Rather, the descriptions are meant to provide a foundation for the

seasoned calibration technician to work with and use the Fluke method of calibrating

Current Shunts.

Current Shunts can be used in AC-DC difference or absolute AC or DC measurements.

This requires that both AC flatness and DC resistance performance are calibrated. Both

AC and DC calibration involves passing a known current through the device being

calibrated (UUT) and measuring the voltage output.

The Fluke calibration method for the Current Shunts is to transfer calibration against

reference shunts. This eliminates the need for a calibrated current source. However, the

source current must be stable and able to provide the necessary voltage compliance

levels. Figure 5 shows the basic configuration.

I

Rs

Ref

Std

shunt

UUT

shunt

V source

Figure 5. Circuit Using a Reference Shunt Resistor to Determine Source Current

V measurement

Z

L

V measurement

Z

L

feh014.eps

20

Page 29

Precision AC Current Shunt Set

Theory of Operation

Potential Voltage Measurement Devices

TVC

The system could use thermal voltage converters (TVC) in conjunction with a DC

voltmeter to measure the voltage output from a Current Shunt. The TVC produces a dc

output voltage proportional to the ac or dc voltage applied and is intrinsically flat across

the entire frequency range required for this application. The TVC can only be used to

compare two signals and does not provide an absolute measurement; hence its main use is

AC-DC difference measurements. There are various forms of TVC; Table 8 lists

advantages and disadvantages of the simplest: the single junction TVC (SJTVC).

Table 8. Single Junction Thermal Voltage Converters

Advantage Disadvantage

Frequency flatness errors are generally very small. Slow to reach thermal stability

Input impedance is mainly resistive Low input resistance (90 Ω)

Very good output / input isolation. Negligible errors

due to common-mode current

Maximum input voltage is 0.45V. Appropriate

series resistor is required to increase input

voltage capability

Square law response offers poor amplitude

linearity

Nanovoltmeter or potentiometer /null detector

required to resolve mV output levels

Susceptible to small changes in local

environment (draughts, heat source)

Fluke 792A AC-DC Transfer Standard

The Fluke 792A can be used to make AC-DC difference measurements and has many

advantages over the SJTVC. See Table 9. It does, however, have one disadvantage that

reduces its usefulness for this application. Unlike the single junction TVC, the 792A is

subject to common-mode interference, particularly when used as the measurement device

for the Reference Standard shunt.

Table 9. Fluke 792A AC-DC Transfer Standard

Advantage Disadvantage

Frequency flatness errors are generally very small. Common-mode errors

Solid state TVC with 2 V output. Requires DC voltmeter to resolve output

[1]

Faster to settle than SJTVC Input impedance varies with frequency

Smaller DC reversal error

Linear response

High input impedance

[1] Common-mode errors are the biggest source of error for mains powered devices.

21

Page 30

A40B

Instruction Manual

Fast settling Common-mode errors

Absolute (not comparative) measurements Overall accuracy lower than TVC / DC meter

Fast readings Input impedance varies with frequency

Good accuracy over a wide bandwidth Frequency flatness errors must be corrected

No additional equipment required

DMM / Measurement Standard

The output voltage of the Current Shunts is nominally 0.8 V making them ideal for use

with instruments such as the Fluke 5790A and Fluke 8508A. The obvious advantages of

this type of instrument are fast settling time and absolute measurement capability. See

Table 10. The 5790A provides AC-DC difference measurement capability although the

Current Shunts allow direct AC measurements with accuracy adequate for many

applications. Instruments like the Fluke 8508A have math functions that allow the

resistance value of the Current Shunt to be entered into memory so that the reading

displayed is the measured current.

Table 10. Fluke 5790A Measurement Standard

Advantage Disadvantage

[1]

Two inputs; ratio measurements

Very good linearity

Not as sensitive to local environment as TVC

Can do AC-DC difference transfer

[1] Common-mode errors are the biggest source of error for mains powered devices.

DC Considerations

Note that the impedance of the measuring device is in parallel with the shunt, causing a

loading effect. Generally, the loading becomes more significant as the resistance value of

the Current Shunt increases, that is, as the nominal current value decreases.

Example

Assume the UUT is the 10 mA Current Shunt with a resistance of 80 Ω. The measuring

device across the UUT is a 0.8 V, 5 mA SJTVC. Its input impedance is typically 160 Ω.

The Reference Shunt is also a 10 mA Current Shunt, but its voltage is measured with a

Fluke 792A, 700 mV range – input impedance more than 10 MΩ. The entire 10 mA

current generated by the source passes through the Reference Shunt. Because of the

shunting effect of the SJTVC, 6.7 mA flows in the UUT and 3.3 mA flows in the SJTVC;

the UUT Current Shunt is operating at 66 % of nominal value. This would be

unacceptable for an absolute level measurement of DC (or AC). However, for an AC-DC

difference measurement, half current has long been the norm as this is how shunts are

traditionally used. Table 11 lists other potential sources of error and recommended

solutions.

22

Page 31

Precision AC Current Shunt Set

Theory of Operation

Table 11. Other Error Sources and Solutions

Potential Error Source Solution

Is the current stable, i.e., the same for both measurements?

Is the loading effect of the measuring device the same for each

measurement? It will not be if the Reference Shunt and the UUT

have significantly different resistance values resulting in a change of

the current in the circuit between measurements. The value of the

source resistance (Rs in Figure 5) influences the magnitude of the

error.

How significant is the difference between different measurement

devices? Switching would allow the same device to measure both the

UUT and the Reference Shunt, but switch impedance repeatability

may introduce more problems than it solves.

Careful selection of equipment.

All Current Shunts experience I2R self-heating to some extent. The

temperature coefficient of the Current Shunt causes a change in its

resistance value.

How will DC zero errors be compensated?

How will the measurement overcome thermal emf?

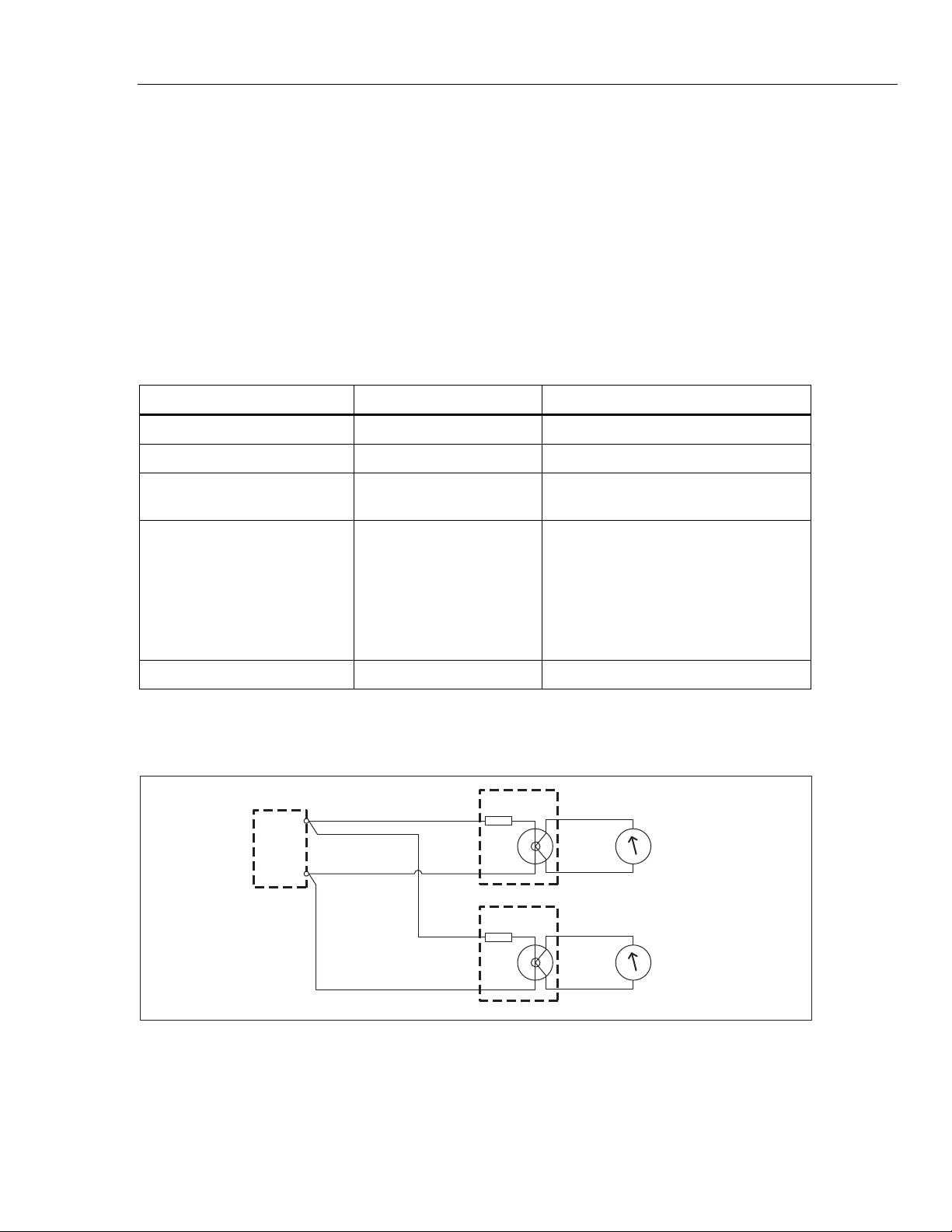

AC Considerations

Most of the DC considerations also apply to AC measurements. Figure 6 shows the

measurement device input impedance as a resistance and capacitance to indicate that

impedance changes with frequency. The low input resistance value of SJTVC (160 Ω) is

beneficial in this respect; it swamps the capacitance. Devices with active input circuits

generally have high input resistance and capacitance becomes more influential on

frequency flatness. Tables 4, 5, and 6 provide typical values and errors for Fluke 5790A

and 792A.

I

Rs

Ref Std

Shunt

Careful selection of equipment.

Allow all elements in the system

to stabilize at normal operating

temperature before

measurements are started.

Take the average of positive and

negative DC measurements (DC

reversal).

Gu

Lo

Hi

V Sour ce

Zc

UUT

Shunt

Hi

Lo

C

Gu

Figure 6. Sources of Error in AC Measurements

Gu

C

Gu

feh016.eps

23

Page 32

A40B

Instruction Manual

Common-mode current can be very significant in Current Shunt measurements especially

when one or more of the voltage measuring devices is mains (line) powered. The main

cause of common-mode current is capacitance between the measurement circuits and

ground. Careful guarding can reduce, but not eliminate, the effect. In Figure 6. Gu

represents instrument guards and C

the capacitance to ground. Notice that CGu in the

Gu

lower measurement circuit is almost shorted out by the Gu / ground connections. The

voltage drop caused by connection impedances means that Gu in the lower circuit is not

exactly at ground and the difference changes with frequency. As a result, common-mode

current will cause small UUT measurement errors. Common-mode current errors usually

increase with frequency.

The errors caused by common-mode current in the Reference Standard measurement

circuit are potentially much greater. Zc in Figure 6 is the impedance of the connection

between the shunts. It can immediately be seen that the Gu / ground potential difference

in the upper circuit is higher so more common-mode current flows in C

of the

Gu

Reference Standard measurement circuit than in the UUT circuit. Note the connection of

the detector in the upper circuit. In this configuration C

is driven by the source current

Gu

reducing the effect of common-mode errors associated with the Reference Standard

shunt. The voltage across the UUT, Zc and the Reference Standard will increase with

frequency because of inductance. This compounds the frequency dependence of

common-mode current errors. Careful design of this connection to minimize inductance

is essential.

Common-mode chokes are often used in the input of measuring devices to reduce

common-mode effects. However, care must be taken to avoid resonances with C

within

Gu

the frequency range of interest.

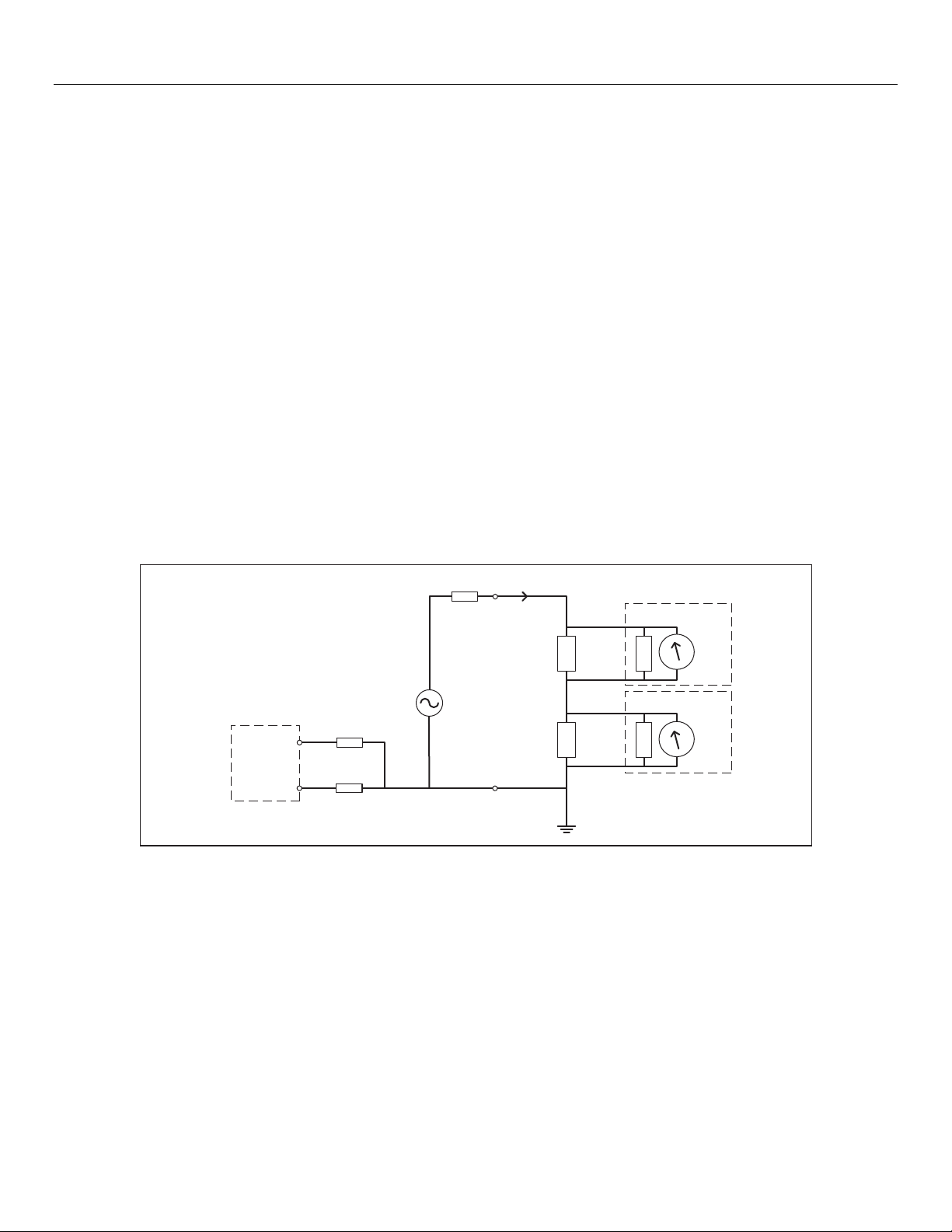

The Fluke Calibration Method

The Fluke calibration method makes automated AC-DC difference and DC Resistance

measurements. See Figure 7. The voltage outputs from the reference and UUT shunts are

each detected with a 0.8 V, 5 mA SJTVC and a Keithley 2182A nanovoltmeter. A single

manual intervention during the calibration disconnects the TVC assemblies and connects

the shunt outputs to the nanovoltmeter secondary inputs. A comparative measurement is

made to calibrate resistance at nominal current.

Clarke-Hess model 8100

Fluke

5720A

Rs

I

Ref Std

Shunt

UUT

Shunt

TVC assy

R

SJTVC

TVC assy

R

SJTVC

Keithley 2182A

Digital

Nanovoltmeter

Keithley 2182A

Digital

Nanovoltmeter

24

Figure 7. The Fluke Calibration System

feh018.eps

Page 33

Precision AC Current Shunt Set

Theory of Operation

The TVC assembly comprises a 5 mA SJTVC and a 70 Ω precision series resistor to drop

the 0.8 V output of the Reference Standard shunt to the 0.45 V maximum of the SJTVC.

The components of the TVC assembly are packed in expanded polystyrene in a metal box

to provide thermal stability. Construction is coaxial. The TVC assembly input connector

is an N-type plug (male) which mates directly with the Reference Standard output

connector.

Recommended Tools and Equipment

Table 12 provides a list of recommended equipment for using the Fluke Calibration

Method to calibrate the Current Shunts. When using substitutes for the recommended

models, make sure they meet or exceed the minimum use specifications shown in the

table.

Table 12. List of Recommended Equipment

Nomenclature Recommended Model Minimum Use Specifications

Multifunction Calibrator Fluke 5720A 0 to 10 volts, DC to 100 kHz

Transconductance Amplifier Clarke-Hess 8100 100 A, 100 kHz

Precision AC Current Shunt Set A40B Calibrated at a National Measurement

Institute or a Fluke Service Center

TVC Assembly (two required) A UHF, 5 mA Single Junction

0.8V, 5 mA DC to 100 kHz

thermocouple device or

thermal voltage convertor

such as the Fluke Model

A55, Ballantine 1394A, or

Measuretech EL1200; A

70 Ω resistor.

Nanovoltmeter (two required) Keithley 2182A 10 mV DC, 1 nV resolution

System Calibration for AC-DC Difference

Periodic system calibration is required to compensate for the gain difference between the

two TVC assemblies. Figure 8 shows how this is achieved.

TVC assy

Fluke

5720A

R

SJTVC

TVC assy

R

SJTVC

Keithley 2182A

Digital

Nanovoltmeter 1

Keithley 2182A

Digital

Nanovoltmeter 2

Figure 8. Calibrating Gain Difference

The Fluke 5720A produces an output of 0.8 V. The relative AC-DC difference of the

SJTC assemblies is measured and applied as a correction.

feh020.eps

25

Page 34

A40B

Instruction Manual

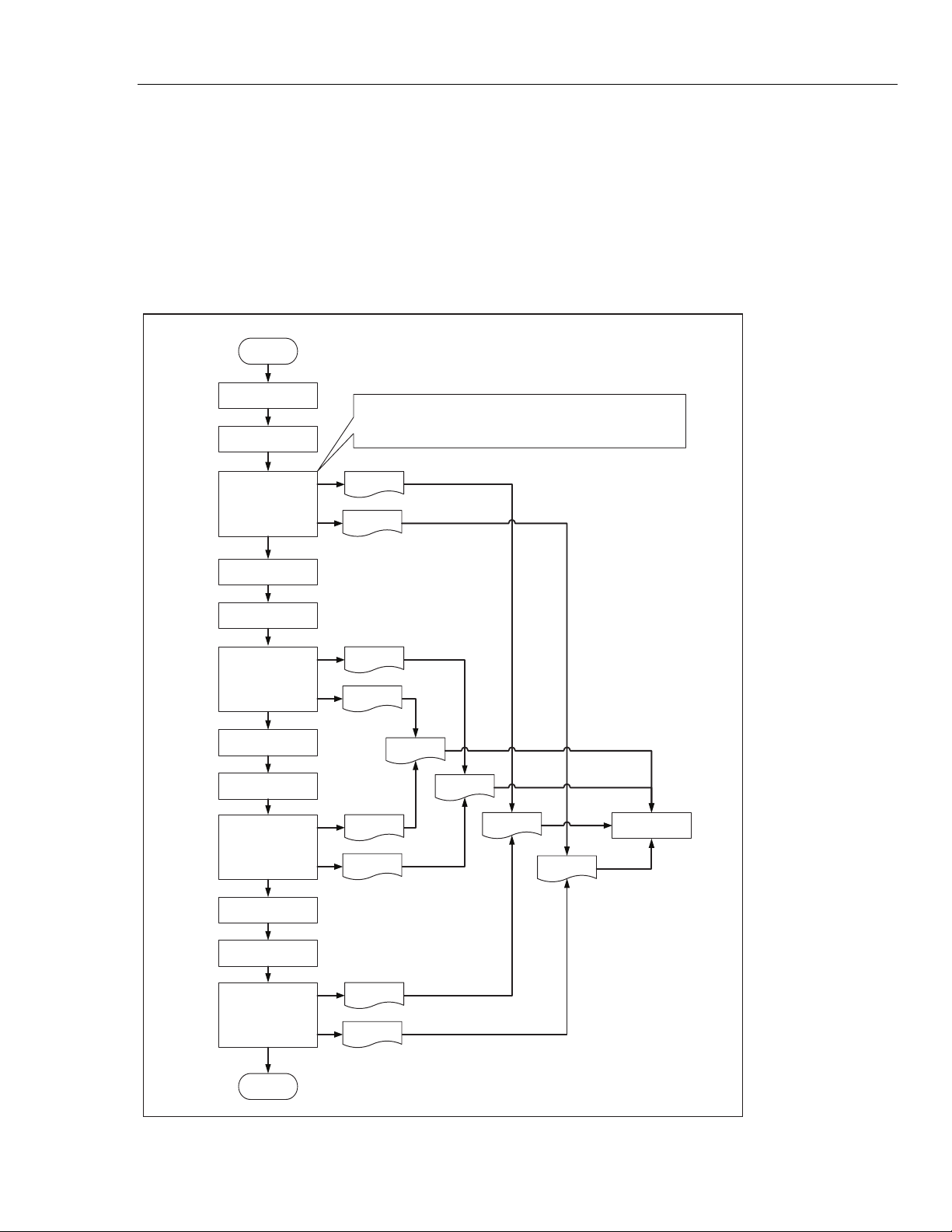

TVC Sensitivity Characterization

The voltage output of a SJTVC output is proportional to the square of the applied

voltage. Thus the device is inherently non-linear and transresistance gain or sensitivity

changes with input current. Sensitivity characterization minimizes the resulting errors by

determining mean sensitivity in a narrow band ±500 ppm from the nominal current.

Sensitivity characterization is performed before UUT calibration with the system

configured as for UUT measurement (Figure 7). Figure 9 shows the characterization

sequence w

Vin is the setting on the 5720A

Vout_1 , 2 and 3 are the voltages reported by the measuring devices.

here:

Vin_1 = nominal + 500 ppm

Vin_2 = nominal - 500 ppm

Vin_3 = nominal + 500 ppm

The gain factor n is a measure of the sensitivity of the device used to measure the output

voltage

Start

Apply Nominal

value + 500 ppm

Delay

Measure Vout

Apply Nominal

value - 500 ppm

Delay

Measure Vout

Apply Nominal

value + 500 ppm

Delay

Measure Vout

End

Figure 9. Characterizing Sensitivity

V

V

V

V

V

V

in_1

out_1

in_2

out_2

in_3

out_3

feh022.eps

26

+

VV

3_1_

OUTOUT

2

×

Δ

factor Gain

Vout

=

η

Δ

Vin

)ppmin(

=

)ppmin(

V

OUT

+

VV

ININ

2

×

V

2_

IN

1

−

2_

3_1_

1

−

The +500 ppm measurement is performed twice to counter drift in the measurement.

Page 35

Precision AC Current Shunt Set

Theory of Operation

UUT AC-DC Difference Measurement Sequence and Calculations

In order to minimise the effects of drift, the measurement sequence is symmetrical in the

form AC1, +DC, -DC, AC2. The ±DC measurements cancel thermal emf and zero offset.

The two AC measurements compensate for drift during the measurement. Figure 10

shows the sequence where:

V

= average of magnitude of VDC

DCUUT

V

= average of magnitude of VDC

DCSTD

V

= average of V

ACUUT

V

ACSTD

= average of V

Start

ACUUT -1

ASTDT -1

and V

and V

ACUUT -2

ACSTD -2

+UUT

+STD

and V

and V

DC-UUT

DC-STD

Apply AC signal

Initial Delay

Simultaneous

measurement of

UUT and Std

Apply DC+ signal

Delay

Simultaneous

measurement of

UUT and Std

Apply DC- signal

Delay

Simultaneous

measurement of

UUT and Std

To overcome short term DC noise in the Clarke Hess 8100 the

output of the reference and UUT shunts are measured

simultaneously.

V

ACUUT_1

V

ACSTD_1

V

DC+ STD

V

DC+UUT

V

DCUUT

V

DCSTD

V

V

DC-UUT

V

DC-STD

ACUUT

V

ACSTD

Calculations

Apply AC signal

Delay

Simultaneous

measurement of

UUT and Std

End

V

ACUUT_2

V

ACSTD_2

Figure 10. AC-DC Difference Sequence

feh024.eps

27

Page 36

A40B

Instruction Manual

Current Source DC Noise

The AC-DC difference of the UUT shunt in ppm is determined from:

VV

−

δδ

+=

STDUUT

DCSTDACSTD

V

×

DCSTDSTD

−

VV

−

DCUUTACUUT

ηη

V

×

DCUUTUUT

66

10*)(10*)(

δδ

−+

TVCUUTTVCUSTD

::

Where:

δ

= AC-DC Difference of UUT in ppm

UUT

δ

δ

δ

V

V

V

V

η

η

= AC-DC Difference of UUT SJTVC at the test frequency in ppm

UUT:TVC

= AC-DC Difference of reference Shunt in ppm

STD

= AC-DC Difference of STD SJTVC at the test frequency in ppm

STD:TVC

= Reference shunt voltage with AC current

ACSTD

= Reference shunt voltage, average of forward and reverse DC current

DCSTD

= UUT shunt voltage with AC current

ACUUT

= UUT shunt voltage, average of forward and reverse DC current

DCUUT

UUT

STD

= Gain sensitivity of the UUT measurement system

= Gain sensitivity of the Reference Standard measurement system

From some transconductance amplifiers, noise on DC can be problematic. The Fluke

system addresses this problem by triggering the two nanovoltmeters at the same time so

they integrate simultaneously to maximize noise immunity.

UUT DC Resistance Measurement

The DC resistance of the UUT is determined by Ratio measurement against the Reference

Standard shunt. See Figure 7. The TVC assemblies are disconnected and the outputs of

the Reference Standard and UUT shunts are each connected to the second input of their

nanovoltmeter. DC reversal is employed to minimize thermal emf and DC zero offset

errors.

28

Page 37

Precision AC Current Shunt Set

Repair Procedures Including Disassembly and Reassembly

Repair Procedures Including Disassembly and Reassembly

Repair Limits

This section of the manual provides procedures for making minor repairs to the Current

Shunts. These procedures are limited to the following replaceable parts as shown in Table

11 and Figure 14:

• Coaxial shunt guard Binding Post

• Coaxial shunt end plates

• N-Type Connectors

The N-type connectors of the 10 mA, 20 mA and 50 mA boxed Current Shunts can be

replaced after removing the cover plate on the underside, but it is recommended the

Current Shunts be returned to a Fluke Service Center for repair. Other than battery

replacement, do not attempt to service the 1 mA Current Shunt.

Replacement batteries for the 1 mA Current Shunt must be NiHM. See the Battery

Specifications earlier in the General Specification section of this manual. A NiMH

battery replacement kit is available from Fluke; see Table 13. Read the Safety

Information earlier in this manual before replacing the batteries.

All other repair and/or parts replacement should be performed at a Fluke Service Center.

See Contacting Fluke earlier in this manual to find the location nearest you.

A replacement procedure for the N-type connectors is included in this

manual. However, Fluke highly recommends having the work performed at

a Fluke Service Center.

The LC-type connectors (50 A and 100 A shunts) cannot be repaired or

replaced in the field. These connectors are very robust and do not need to

be replaced unless they are damaged or worn. (Excessive heat build up

under load may indicate damage or wear.) If replacement of an LC

connector is necessary, have the work performed at a Fluke Service Center.

List of Tools Required for Repair

A list of the tools required for disassembly, repair, and reassembly follows:

• 2.5 mm Allen wrench for Current Shunts rated at 20 A or less

• T25 Torx driver for Current Shunts rated at 50 A and 100 A

• 7 mm wrench (output end plate only)

• No. 10 Torx driver

• Magnetized slim line 5.5 mm wrench

• 50 W Soldering iron thin enough to work between the PCB struts

• Solder removal copper braid

• Solder suction tool

• T20 Torx driver for replacing the batteries in the 1 mA Current Shunt

Note

29