Page 1

719PRO

Pressure Calibrator

Users Manual

October 2013

© 2013 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

r

This Fluke product will be free from defects in material and workmanship for three years from the date of purchase. This

warranty does not cover fuses, disposable batteries, or damage from accident, neglect, misuse, alteration, contamination, or

abnormal conditions of operation or handling. Resellers are not authorized to extend any other warranty on Fluke’s behalf.

To obtain service during the warranty period, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that Service Center with a description of the problem.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER WARRANTIES, SUCH AS FITNESS FOR A PARTICULAR

PURPOSE, ARE EXPRESSED OR IMPLIED. FLUKE IS NOT LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES, ARISING FROM ANY CAUSE OR THEORY. Since some states or countries

do not allow the exclusion or limitation of an implied warranty or of incidental or consequential damages, this limitation of

liability may not apply to you.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

11/99

Fluke Eu

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

ope B.V.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

Table of Contents

Title Page

Introduction .................................................................................................................... 1

Contact Fluke ................................................................................................................. 1

Safety Information .......................................................................................................... 2

Symbols ......................................................................................................................... 4

Standard Equipment....................................................................................................... 5

Product Features ............................................................................................................ 5

Display ....................................................................................................................... 8

Language Selection ................................................................................................... 9

Home Menu Functionality .......................................................................................... 10

Backlight Use ............................................................................................................ 10

The MENU Option ..................................................................................................... 10

Main Menu Functionality ............................................................................................ 11

Set the Active Display ........................................................................................... 11

Set Active Display Parameters ............................................................................. 11

Zero Function Use ..................................................................................................... 13

i

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

719PRO

Users Manual

Internal Sensor and Pressure Module (non-absolute) .......................................... 13

Absolute Pressure ................................................................................................ 13

Other Menu Controlled Functions ............................................................................. 14

Set the Contrast ................................................................................................... 14

Lock and Unlock Configurations ........................................................................... 15

Save and Recall Setups ....................................................................................... 15

Set Auto Off Parameters ...................................................................................... 16

Activate and Deactivate a Display ........................................................................ 17

Set the RTD Probe Type ...................................................................................... 17

Damping ............................................................................................................... 18

TM

HART

Pump Limits ......................................................................................................... 18

Initial Setup and Basic Pressure Generation ................................................................. 18

Electric Pump Considerations ........................................................................................ 20

Measure Pressure ......................................................................................................... 20

Media Compatibility ................................................................................................... 21

Measure Pressure with External Modules ................................................................. 21

Measure and Generate Current (4 mA to 20 mA) .......................................................... 22

Measure Voltage............................................................................................................ 24

Measure Temperature with an RTD ............................................................................... 25

Pressure Switch Test ..................................................................................................... 26

Transmitter Calibration .................................................................................................. 29

mA Input Function ..................................................................................................... 29

Pressure-to-Current Transmitter Calibration ............................................................. 30

Percent Error Function .............................................................................................. 30

Minimum and Maximum Storage Capability .................................................................. 35

Factory Setups .............................................................................................................. 36

Custody Transfer / Flow Calibration ............................................................................... 39

Remote Operation ......................................................................................................... 39

Resistor .................................................................................................. 18

ii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

Contents (continued)

Remote Interface ....................................................................................................... 39

Set up the RS-232 Port for Remote Control .............................................................. 41

Change Between Remote and Local Operation ........................................................ 42

Command Use and Types ......................................................................................... 42

Character Processing ................................................................................................ 43

Response Data Types .......................................................................................... 44

Calibrator Status ................................................................................................... 44

Remote Commands and Error Codes ....................................................................... 45

Enter Commands ....................................................................................................... 50

Common Commands ............................................................................................ 50

Calibrator Commands ........................................................................................... 51

Ranges and Resolution .................................................................................................. 59

Maintenance ................................................................................................................... 61

Replace the Batteries ................................................................................................ 61

Clean the Product ...................................................................................................... 63

Clean the Valve Assembly ......................................................................................... 63

User-Replaceable Parts and Accessories ...................................................................... 64

Specifications ................................................................................................................. 67

iii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

719PRO

Users Manual

iv

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

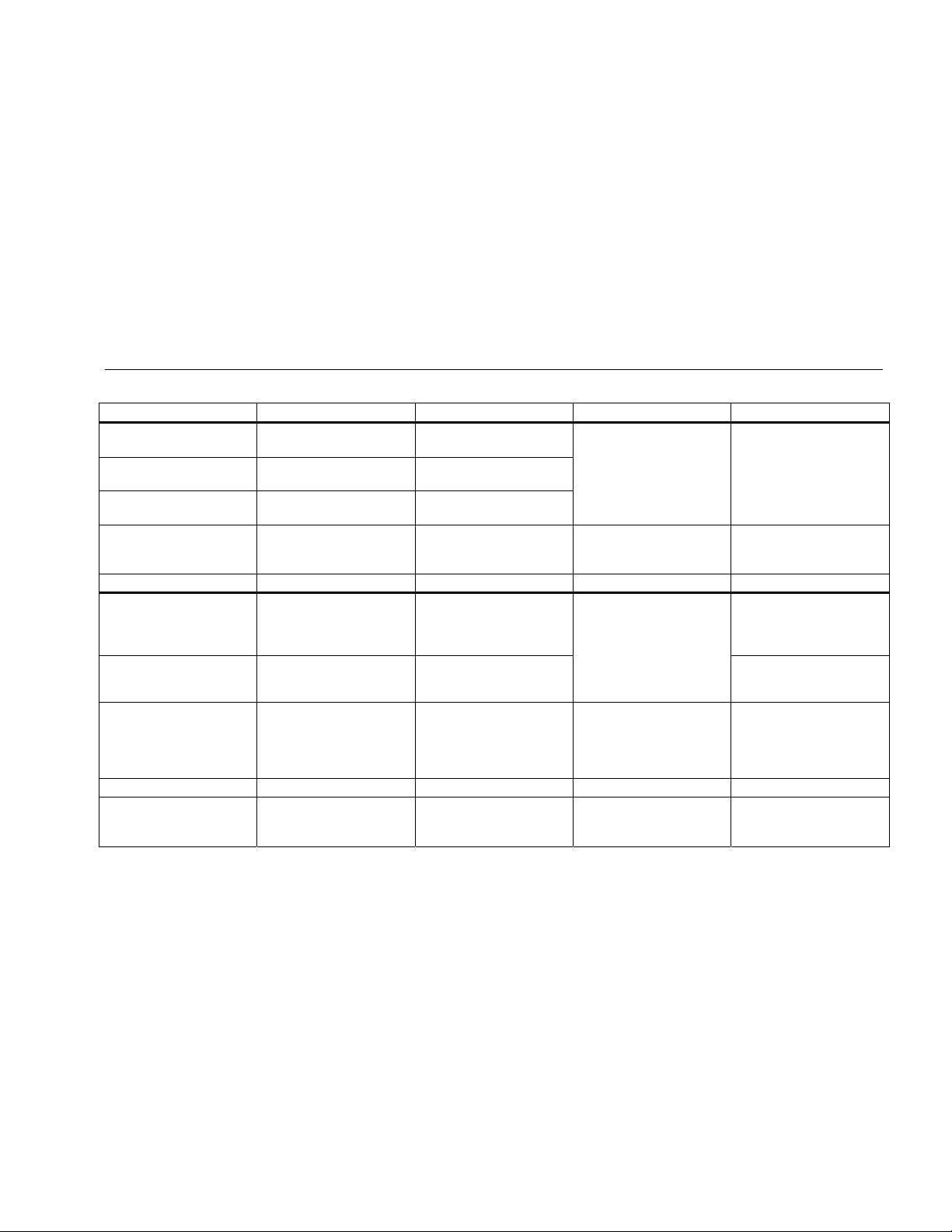

List of Tables

Table Title Page

1. Symbols ................................................................................................................................. 4

2. Product Features ................................................................................................................... 7

3. Display Functions .................................................................................................................. 9

4. Mode Concurrency ................................................................................................................ 12

5. Common Commands ............................................................................................................ 45

6. Calibrator Commands ........................................................................................................... 45

7. Parameter Units .................................................................................................................... 48

8. Error Codes ........................................................................................................................... 49

9. Ranges and Resolutions ....................................................................................................... 59

10. User-Replaceable Parts and Accessories ............................................................................. 64

v

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

719PRO

Users Manual

vi

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

List of Figures

Figure Title Page

1. Product Interface ................................................................................................................... 6

2. Display................................................................................................................................... 8

3. Pump Connection .................................................................................................................. 19

4. Pressure with External Modules ............................................................................................ 21

5. Measure and Generate Current ............................................................................................. 23

6. Voltage Measurement ........................................................................................................... 24

7. Temperature Measurement with RTD Probe ......................................................................... 25

8. Pressure Switch Connection ................................................................................................. 26

9. Pressure-to-Current Transmitter Connections ....................................................................... 31

10. Percent Error Function Connection ....................................................................................... 32

11. Typical Remote Connection .................................................................................................. 40

12. Battery Replacement ............................................................................................................. 62

13. User-Replaceable Parts and Accessories ............................................................................. 66

vii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

719PRO

Users Manual

viii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

Introduction

The 719PRO Pressure Calibrator (the Product) is a

simple to use and versatile pressure calibrator. Its internal

pressure sensor and innovative electrically-powered

pump reach higher pressures (maximum 300 psi) and let

the Product calibrate virtually any pressure device. The

Product features inputs for mA, voltage, switch contacts,

and an RTD probe. An external-pressure module option

gives a wider range of pressure calibration options that

include absolute and differential.

1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

719PRO

Users Manual

Safety Information

A Warning identifies conditions and procedures that are

dangerous to the user. A Caution identifies conditions

and procedures that can cause damage to the Product or

the equipment under test.

Warning

To prevent possible electrical shock, fire, or

personal injury:

• Only assemble and operate high-

pressure systems if you know the

correct safety procedures. High-pressure

liquids and gases are hazardous and the

energy from them can be released

without warning.

• Read all safety information before you

use the Product.

• Carefully read all instructions.

• Do not use the Product around explosive

gas or vapor.

• Use the correct terminals, function, and

range for measurements.

• Do not apply more than the rated

voltage, between the terminals or

between each terminal and earth ground.

• Do not touch voltages > 30 V ac rms,

42 V ac peak, or 60 V dc.

• Remove all probes, test leads, and

accessories before the battery door is

opened.

• Do not exceed the Measurement

Category (CAT) rating of the lowest rated

individual component of a Product,

probe, or accessory.

• Do not use and disable the Product if it

is damaged.

• Remove the input signals before you

clean the Product.

• Use only specified replacement parts.

• Have an approved technician repair the

Product.

• Use the Product only as specified, or the

protection supplied by the Product can

be compromised.

2

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

Pressure Calibrator

Safety Information

• Pressure sensors can be damaged

and/or personnel injury can occur due to

improper application of pressure.

Vacuum should not be applied to any

gauge pressure sensor. The Product

display shows “OL” when an

inappropriate pressure is applied. If “OL”

is shown on any pressure display, the

pressure should be reduced or vented

immediately to prevent Product damage

or possible personnel injury. “OL” is

shown when the pressure exceeds 110 %

of the nominal range of the sensor or

when a vacuum in excess of 2 PSI is

applied on gauge range sensors.

• Push the ZERO button to zero the

pressure sensor when vented to

atmospheric pressure.

• Remove the batteries if the Product is

not used for an extended period of time,

or if stored in temperatures that exceed

the battery manufacturer’s specification.

If the batteries are not removed, battery

leakage can damage the Product.

• Replace the batteries when the low

battery indicator shows to prevent

incorrect measurements.

• Be sure that the battery polarity is

correct to prevent battery leakage.

• Repair the Product before use if the

battery leaks.

• The battery door must be closed and

locked before you operate the Product.

• Use only specified replacement parts.

3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

719PRO

Users Manual

Symbols

Symbols used on the Product or in this manual are shown in Table 1.

Table 1. Symbols

Symbol Description Symbol Description

Risk of Danger. Important information. See

Manual.

Conforms to relevant North American Safety

Standards.

Hazardous voltage. Risk of electric shock. Double Insulated

Conforms to European Union directives. Conforms to relevant Australian EMC standards.

4

Inspected and licensed by TÜV Product

Services.

This product complies with the WEEE

Directive (2002/96/EC) marking requirements.

The affixed label indicates that you must not

discard this electrical/electronic product in

domestic household waste. Product Category:

With reference to the equipment types in the

WEEE Directive Annex I, this product is

classed as category 9 "Monitoring and Control

Instrumentation" product. Do not dispose of

this product as unsorted municipal waste. Go

to Fluke’s website for recycling information.

Battery

Conforms to relevant South Korean EMC

Standards.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

Pressure Calibrator

Standard Equipment

Standard Equipment

Make sure that the Product shipment is complete. It must

include:

• The Product

• Product Manuals CD

• Getting Started Manual

• Quick Reference Guide

• Test leads

• Calibration Hose kit with fittings

• Carry case

• Calibration certificate

Product Features

Figure 1 and Table 2 shows the location of the buttons,

pressure controls, connection ports, and electrical inputs.

5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

719PRO

Users Manual

2

3

1

4

5

6

12

13

8

7

9

10

11

16

14

15

hix001.eps

Figure 1. Product Interface

6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

Pressure Calibrator

Product Features

Item Description

Table 2. Product Features

Power button. Turns on and off the Product.

Three function buttons. Used to configure the Product. These buttons correspond to messages on the display.

Zero button. Zeros pressure measurements.

Arrow buttons. Controls mA source/sim. and sets pump and % error limits

Pump button. Runs the electric pump.

Home button. Returns to the main menu screen.

Pressure vernier adjust knob

Pressure source or measurement connector

Input terminals to measure current, volts and contact closure for switch test.

External pressure module connector

RTD probe connector

Pressure/Vacuum Selector

Vent

Firmware programming connector (for factory use only)

Pump clean-out valve

Battery door

7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

719PRO

Users Manual

Notes

When is pushed to turn on the Product, a

short startup self-check routine is run. During

that routine, the display shows the current

firmware revision level, auto-shutdown status,

and the range of the internal pressure sensor.

A maximum of 5 minutes warm-up is necessary

for the product to reach rated accuracy. A longer

warm-up period can be necessary for large

changes in ambient temperature. See the “Zero

Function Use” section for more about zeroing

the pressure sensor displays. It is recommended

that pressure ranges be zeroed each time the

Product is started.

Display

The display has two main regions:

• The menu bar (located at the bottom of the screen) is

used to access the Product menu.

• The main display has a maximum of three process

measurement sub-regions.

These sub-regions will be referred to as the UPPER,

MIDDLE and LOWER displays. Figure 2 shows the

location of the different display fields while Table 3

describes them.

3

8

1

4

2

hix007.eps

Figure 2. Display

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

Pressure Calibrator

Product Features

Item

Number

Units

Table 3. Display Functions

Name Description

Primary

Parameters

Span

Indicator

Pressure

Units

Shows what is being

measured.

Shows the percent of the

4 mA to 20 mA span. (For

mA and mA loop functions

only.)

Shows one of 15 pressure

units available for display.

Shows the unit of measure

for the display.

Language Selection

The Product user interface is available in three

languages:

• English

• Norwegian

• German

To select a user interface language:

1. Turn the Product off.

2. Hold down , , and simultaneously.

3. As the Product powers up, the display shows the

language in the top left corner of the display. Repeat

the procedure to show each subsequent language.

Once the necessary language is shown, the Product

user interface stays in that language until another

language is chosen.

9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

719PRO

Users Manual

Home Menu Functionality

There are three options for the Home Menu:

• MENU

• Active Display (LOWER, MIDDLE, or UPPER)

• LIGHT

These options are shown across the bottom of the

display.

From anywhere within the menu structure, push to

get back to the Home Menu.

Backlight Use

From the Home Menu, push to toggle on and off the

backlight. This is one of the few functions that cannot be

controlled by the serial interface. There are no userconfiguration settings for the backlight.

The MENU Option

Push to access the Product Main Menus that start with

CONFIG. Then push and to go to subsequent

menus.

10

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

Pressure Calibrator

Product Features

Main Menu Functionality

There are three options on the Main Menu, shown below:

hix021.eps

Set the Active Display

The active display is indicated by the center option on the

Main Menu. Push from this menu to toggle the active

display (UPPER, MIDDLE, or LOWER).

Set Active Display Parameters

To set the parameters of the active display, push from

the Main Menu to go to the Active Display Configuration

menu, shown below:

hix022.eps

Push to toggle through the selections for each

parameter of the active display. The first parameter is

Mode. Since voltage, current, and switch test modes all

use the same jacks, two of these functions cannot be

used at the same time. The ability to select some

functions is limited based on what is already selected on

a different display.

Push to change to the NEXT active display parameter.

Only RTD and Pressure modes have a second

parameter. RTDs can be read in Celsius or Fahrenheit.

Pressures can be read in 15 engineering units.

With a single display, the modes below are available.

Push to access each mode:

• [P1] = Pressure internal sensor

• [EXT] = Pressure with external pressure module

• [P1] ST = Switch Test with left side sensor

• [EXT] ST = Switch Test with external pressure

module

11

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

719PRO

Users Manual

Note

mA functions are only available on the lower

display.

• mA measure = Milliamps measure without loop

power

• mA w/24V = Milliamps measure with loop power

• mA source = Milliamps source

• mA sim = Milliamps simulate an external supply from

the UUT

Table 4. Mode Concurrency

[P1]

[EXT]

[P1] ST X X X X X

[EXT] ST X X X X X

mA X X X X

OTHER DISPLAYS

mA Loop X X X X

Volts X X X X

RTD

X = Not a valid mode

[P1] [EXT] [P1] ST [EXT] ST mA

• VOLTS = Voltage Measure

• RTD = RTD Temperature Measurement (if a probe is

connected)

Table 4 shows functions available at the same time. An X

in a column shows that the mode in the active display is

not available if the mode in that row is in operation on a

different display.

Current Display

mA

Loop

VOLTS RTD

12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

Pressure Calibrator

Product Features

Zero Function Use

If a pressure mode is selected and pressure is within the

zero limit, the Product zeros the active display when Z is

pushed. The zero limits are within 10 % of the full-scale

range of the selected sensor. If the display shows “OL,”

the zero function will not operate.

Note

Z is only used for pressure.

Internal Sensor and Pressure Module (nonabsolute)

When a sensor or module is selected on the active

display, and Z is pushed, the Product subtracts the

current reading from the output. The zero limits are within

10 % of the full-scale range of the selected sensor. If the

display shows “OL,” the zero function will not operate.

Absolute Pressure

When an absolute pressure range is selected on the

active display, and Z is pushed, the Product prompts for

the barometric reference pressure as in the screen below.

hix023.eps

Push and to use the on-screen arrows to record the

correct barometric reference pressure. The sensor port

should be open (vented) to atmosphere while this

procedure is done.

13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

719PRO

Users Manual

Other Menu Controlled Functions

There are 12 “sub-main” menus that can be accessed

with from the Main Menu. A “sub-main” menu contains

three options. The first option is unique to the function.

The second and third options of a “sub-main” menu are

always the same. goes to the next “sub-main” menu.

For the last “sub-main” menu, goes back to home.

Note

If a “sub-main” menu has subordinate menus, it

will be referred to as {function} Main Menu. For

example, the display contrast sub-main menu

will be called the Contrast Main Menu. If not, it

will be called the {function} menu.

The 12 sub-main menus are:

• CONFIG (Main Menu start point)

• %ERROR

• MINMAX

• CONTRAST

• LOCK CFG

• SETUPS

• AUTO OFF

• DISPLAY

• PROBE TYPE

• DAMP

• HART

• PUMP

Set the Contrast

From the Contrast main menu, push to access the

Contrast Adjustment Menu. See the Contrast Main Menu

below.

hix024.eps

Push and to adjust the display contrast to the

necessary level. Push to finish the adjustment and go

home as shown below.

hix025.eps

14

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

Pressure Calibrator

Product Features

Lock and Unlock Configurations

Use the LOCK CFG or UNLOCK CFG options of the

Configuration Lock Menu (CONFIG), shown below, to

lock or unlock the display configuration.

hix026.eps

When the LOCK CFG option is pushed, the menu display

goes home and the menu configuration option on the

Main Menu is locked. All menus are locked with the

exception of:

• Min Max menu

• Contrast Adjustment menu

• Configuration Lock menu

When the UNLOCK CFG option is selected, the

configuration is unlocked and the menu display goes to

the subsequent sub-main menu.

Save and Recall Setups

The Product automatically saves the current setup for

recall at power up. Five setups can be accessed through

the SETUPS menu. Select the SETUPS option from the

Setups Main Menu shown below.

hix027.eps

Push to store a setup, to show the setup, or to

do nothing and go to the Main Menu.

hix028.eps

15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

719PRO

Users Manual

If or is pushed, use the on-screen arrows, as shown

below, to select the setup location. Then use to save

the current setup into the selected location or to recall

the setup stored in the selected location. The display

menu automatically goes to the Main Menu.

hix029.eps

hix030.eps

Set Auto Off Parameters

The Product can be set to automatically power off after a

chosen number of minutes. This function can also be

disabled. To set the auto off parameters, push on the

Auto Off Main Menu shown below.

hix031.eps

Push or to select the number of minutes before the

Product turns off or scroll down to 0 to disable Auto Off as

shown below.

hix032.eps

Push to set the parameters and go to the main menu.

The auto off time is reset when a key is pushed.

16

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

Pressure Calibrator

Product Features

Activate and Deactivate a Display

From the Display Main Menu, push to access the

Display Activation Menu.

hix033.eps

The {display} option can be used to select which display

is active. The selected display and current on/off state are

shown in the lower display as seen below.

hix034.eps

Push to save the changes and go back to the Main

Menu. When a display is deactivated, its configuration is

saved. When the display is activated, its configuration is

compared against the configurations of the other

currently-active displays. If the configurations are in

conflict, the recalled display configuration is changed to

prevent conflict. If all three displays are deactivated, the

LOWER display comes on automatically.

Set the RTD Probe Type

Push from the Probe Type Main Menu to access the

RTD Probe selections.

hix035.eps

There are four probe types to select from:

• P100-385 (select this type for use with Fluke-

720RTD probe accessory)

• P100-392

• P100-JIS

• CUSTOM

Push to select the necessary probe type (see the

figure below). Push to store the change and go to the

Main Menu.

Note

The default probe type is PT100-385.

hix036.eps

17

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 28

719PRO

Users Manual

Damping

Turn Damping on or off with the Damping menu selection.

When damping is on, the Product shows a running

average from ten measurements. The Product makes

approximately three indications per second.

TM

HART

An internal 250 Ω HART resistor can be enabled when

the Product operates in the mA Measure-24 V mode. This

lets a HART Communicator be connected across the mA

terminals. It is not necessary to add an external resistor.

Resistor

Note

When the HART resistor is on, the maximum

Ω

load-driving capacity is 750

.

Pump Limits

To prevent overpressure of sensitive devices, the

maximum pressure (pump limit) can be set. When in this

mode, use the arrow softkeys to set the maximum

pressure.

Initial Setup and Basic Pressure Generation

The Product is supplied with a special low-volume

calibration hose kit for faster pumping to pressure and

quick pressure stabilization. The necessary “quick-fit”

hose connectors and BSP adapter for non-NPT

applications are also included. Fluke recommends that

this type of hose be used to get the best performance

from the Product. When the fittings are installed and the

Product is connected to the unit under test (UUT), the

Product is ready. Figure 3 shows a typical setup.

1. Before pressure is generated, make sure the Product

is configured for the application. If necessary, review

the “Calibrator Interface” section to select the correct

configuration.

2. Make sure that the pressure vacuum knob is set for

the correct function (+ for pressure and – for

vacuum).

18

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 29

Pressure Calibrator

Initial Setup and Basic Pressure Generation

3. Close the vent knob.

4. Push the pump key and see the pressure (or

vacuum) increase until the necessary pressure is

reached.

Note

The pump motor speed will start slowly when

pressure is low (<15 psi) for better control at low

pressures.

Valve

Figure 3. Pump Connection

hix009.eps

5. Use the fine adjustment vernier to fine tune the

pressure/vacuum indication as necessary.

6. To fully decrease or bleed off the pressure, slowly

turn the vent knob to the open position. When this is

done carefully, the pressure-bleed rate can be

carefully controlled and this helps when taking downscale pressure readings.

19

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 30

719PRO

Users Manual

Electric Pump Considerations

The Product uses a small, battery-powered pneumatic

pump that can quickly build rated high pressure. Because

the pump has an upper pressure generation limit, there

may be atmospheric conditions where it cannot go to fullscale pressure. High-altitude use (about 3000 ft or

1000 meters), or use at cold temperatures, can limit the

pump to about 90 % of its rated pressure. In these cases,

the vernier adjustment can be used to supply additional

pressure necessary if full-scale pressure must be

supplied.

In these situations, start the calibration with the vernier in

the full counter-clockwise position and then, when the

electric pump reaches its limit, turn the vernier clockwise.

This will raise the pressure to set the necessary reading.

See Figure 3.

Measure Pressure

To measure pressure, connect the Product with the

correct fitting. Select a pressure setting for the display

that is used. The Product has one internal sensor and

many optional external sensors (EPMs) are available.

Make sure to choose the sensor based on working

pressures and accuracy.

Warning

To prevent personal injury:

• Pressure sensors can be damaged

and/or personnel injury can occur due to

improper application of pressure. Refer

to Table 9 for information on

overpressure and burst pressure ratings.

Vacuum should not be applied to any

gauge pressure sensor. The Product

display shows “OL” when an

inappropriate pressure is applied. If “OL”

is shown on any pressure display, the

pressure should be reduced or vented

immediately to prevent Product damage

or possible personnel injury. “OL” is

shown when the pressure exceeds 110 %

of the nominal range of the sensor or

when a vacuum in excess of 2 PSI is

applied on gauge range sensors.

• Push Z to zero the pressure sensor

when vented to atmospheric pressure.

20

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 31

Pressure Calibrator

Measure Pressure

Note

To ensure accuracy of the Product, the Product

must be zeroed before a device is calibrated.

See the “Zero Function Use” section.

Media Compatibility

The Product has a unique user-accessible valve cleaning

port for easy pump service. See the “Clean the Valve

Assembly” section for how to clean these valves. Make

sure to only expose the Product to clean, dry gases.

Measure Pressure with External Modules

The Product has a digital interface to be used with

external pressure modules. These modules are available

in different ranges and types that include gauge, vacuum,

differential, and absolute. Connect the modules to the

interface and select [EXT] (external sensor). Since the

interface between the Product and the module is digital,

all accuracy and display resolution is derived from the

module. See Figure 4.

Valve

Pressure

Module

hix010.eps

Figure 4. Pressure with External Modules

21

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 32

719PRO

Users Manual

Measure and Generate Current (4 mA to 20 mA)

Use the input terminals on the front of the Product to

measure current, see Figure 5:

1. Select the mA function on the lower display and

select MEASURE. Current is measured in mA and

percentage of range. The range on the Product is set

to 0 % at 4 mA and 100 % at 20 mA.

For example:

If the current measured is shown as 75 % then the

mA value is 16 mA.

Note

The display shows “OL” when the measured

current is more than the nominal range of

current measurement (24 mA).

2. To source current, the same connections are used.

From the configuration screen, select mA source or

mA Sim-2W.

3. This function will only work on the LOWER screen. In

the source mode, the Product supplies 0 mA to

24 mA with its own internal 24-volt supply, whereas

in the simulate mode the Product acts as a two-wire

transmitter and an external 24-volt supply is

necessary.

4. Push any of the arrow softkeys to start the output

mode and use the arrow softkeys to adjust the mA

output. The function keys can also be used to step

the output in either 25 % steps (4, 8, 12, 16, 20 mA)

or 0 % (4 mA) and 100 % (20 mA). While in the mA

output mode, if the loop is opened or the compliance

is exceeded the display flashes “OL”.

22

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 33

Pressure Calibrator

Measure and Generate Current (4 mA to 20 mA)

Device

Under

Te st

4 to 20mA

24 V Loop Power

Loop

Power

Supply

4 to 20mA

SIM-2W

Device

Under

Te st

4 to 20mA

UUT

Figure 5. Measure and Generate Current

4 to 20mA

UUT

hix011.eps

23

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 34

719PRO

Users Manual

Measure Voltage

To measure voltage, use the input terminals on the front of the Product. Select the volts function on one of the displays. The

Product can measure a maximum of 30 V dc. See Figure 6.

Note

The display shows “OL” when the measured voltage is more than the nominal range of the voltage measurement

(30 V).

24

Figure 6. Voltage Measurement

Up to 30V dc

Device

Under

Te st

hix015.eps

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 35

Pressure Calibrator

Measure Temperature with an RTD

Measure Temperature with an RTD

To measure temperature with an RTD probe, select the

RTD function on one of the displays. Make sure the

correct probe type is selected. See the “Set the RTD

Probe Type” section.

The standard probe has a 10-inch insertion depth with a

¼-inch diameter stainless steel sheath. See Figure 7.

Note

The factory default type is PT100-385 so if the

Product is used with the Fluke 720 RTD Probe

(pn 4366669), it is not necessary to set the

probe type. Connect the probe to the Product

and configure the display to read temperature.

The display shows “OL” when the measured

temperature is outside the nominal

measurement range of the RTD function (below

-40 °C or above 150 °C). If a custom probe is

used, enter the R0 and coefficients with the

serial interface (see the “Remote Operation”

section).

Figure 7. Temperature Measurement with RTD Probe

RTD Probe

hix016.eps

25

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 36

719PRO

Users Manual

Pressure Switch Test

Connect a pressure switch to the Product as shown in

Figure 8.

Pressure

Switch

Use low volume tubing when possible

hix017.eps

Figure 8. Pressure Switch Connection

To do a pressure switch test:

1. Change the setup to Setup 4 (default switch test)

listed under “Setups” in the MORE configuration

menu choices. The upper display is set to [P1] ST, all

other displays are off.

Note

The pressure switch test can be done with these

functions: [P1] ST, or EXT ST.

Use low-volume tubing when possible.

2. Connect the Product to the switch with the pressure

switch terminals to the pressure switch contacts (deenergized dry contacts). The polarity of the terminals

does not matter. Connect the pump from the Product

to the input of the pressure switch.

3. Make sure the vent on the pump is open.

4. Zero the Product if necessary.

5. Close the vent after the Product is zeroed. If a

normally closed switch, the top of the display shows

“CLOSE”.

6. Apply pressure with the pump slowly until the switch

opens.

26

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 37

Pressure Calibrator

Pressure Switch Test

Note

In switch-test mode the display update rate is

increased to help capture pressure input

changes. Even with this enhanced sample rate,

pressurization of the device under test should be

done slowly to ensure accurate readings.

7. When the switch is open, “OPEN” is shown on the

display. Bleed the pump slowly until the pressure

switch closes.

hix043.eps

At the top of the display “SW OPENED AT” and the

pressure that the switch was opened at is shown as in the

figure below.

hix044.eps

27

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 38

719PRO

Users Manual

8. Push the “NEXT” option to view when the switch

closed, and the deadband as seen below.

9. Push to clear the data and do another test.

10. Push to end the test and return to the standard

pressure setting.

Example:

[P1] ST will return to [P1].

Note

The previous example uses a normally-closed

switch. The basic procedure is the same for a

normally-open switch. The display reads “OPEN”

instead of “CLOSE”.

hix045.eps

hix046.eps

28

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 39

Pressure Calibrator

Transmitter Calibration

Transmitter Calibration

mA Input Function

The mA input function reads back the 4 mA to 20 mA

output from the device being calibrated. This can be done

in one of two ways:

1. Passively – Where the device under test directly

regulates or generates 4 mA to 20 mA and can be

read by the Product.

hix047.eps

2. Actively – Where the Product supplies 24 V dc loop

power to the device under test to power the device

while reading the resulting 4 mA to 20 mA signal.

hix048.eps

29

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 40

719PRO

Users Manual

Pressure-to-Current Transmitter Calibration

To calibrate a pressure-to-current transmitter (P/I):

1. Connect the Product and the pump to the transmitter.

See Figure 9.

2. Apply pressure with the pump.

3. Measure the current output of the transmitter.

4. Ensure the reading is correct. If not, adjust the

transmitter as necessary.

Note

Use low-volume tubing when possible.

Percent Error Function

The Product features a unique function which can

calculate pressure vs. milliamp error as a percentage of

the 4 mA to 20 mA loop span. The percent error mode

uses all three screens and has a unique menu structure.

It simultaneously shows pressure, mA, and percent error.

See Figure 10.

30

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 41

Pressure Calibrator

Transmitter Calibration

hix018.eps

Figure 9. Pressure-to-Current Transmitter Connections

31

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 42

719PRO

Users Manual

hix019.eps

Figure 10. Percent Error Function Connection

32

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 43

Pressure Calibrator

Transmitter Calibration

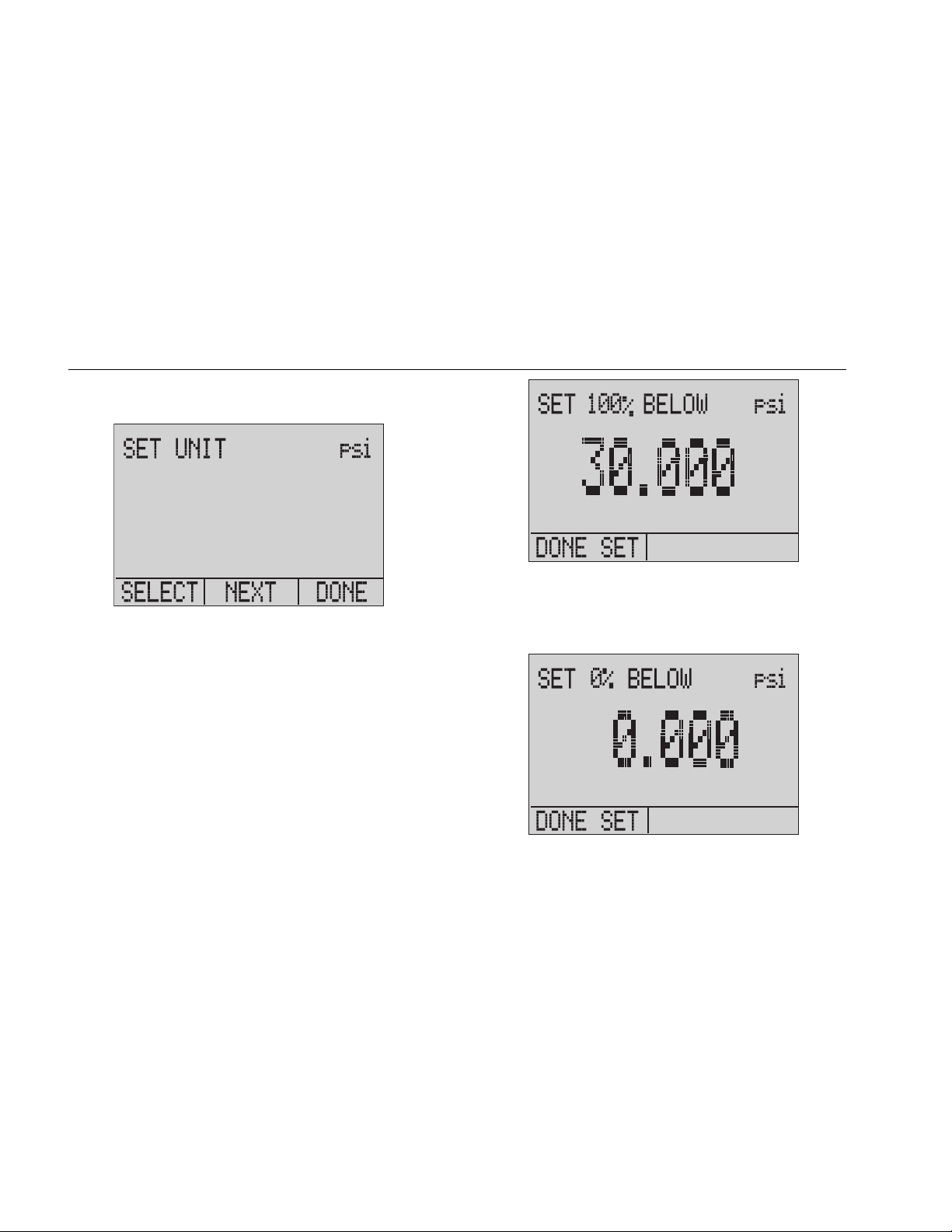

Example:

A pressure transmitter under test is 30 psi (2 Bar) FullScale and regulates a corresponding 4 mA to 20 mA

signal. Program a 0 psi to 30 psi pressure span into the

Product and the Product calculates and shows the

deviation or %Error from the expected 4 mA to 20 mA

output. This eliminates the need for manual calculations

and helps when it is difficult to set an exact pressure with

an external pump.

To use the %ERROR function:

1. From the Main Menu, push .

2. Push .

3. Push to start the %ERROR option.

4. Push to configure the option. The first option sets

the Port.

5. Push to scroll through the port choices.

6. When finished, push .

7. Loop Power can be toggled on/off as seen below.

Push when done.

hix049.eps

hix050.eps

33

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 44

719PRO

Users Manual

8. Push to toggle through the unit options, and push

to move on.

hix052.eps

9. Use the arrow keys to set the 100 % point of the

desired pressure range, select DONE SET when

finished.

34

hix051.eps

10. Use the arrow keys to set 0 % point and select

DONE SET when finished and the % ERROR mode

will be ready to use.

hix053.eps

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 45

Pressure Calibrator

Minimum and Maximum Storage Capability

Note

The 0 % and 100 % point will be saved in nonvolatile memory until they are changed again by

the user for the internal sensors, and external

pressure modules. When an external module is

used, the 0 % and 100 % are set to low and full

scale of the module until the user changes it, or

if it was previously saved.

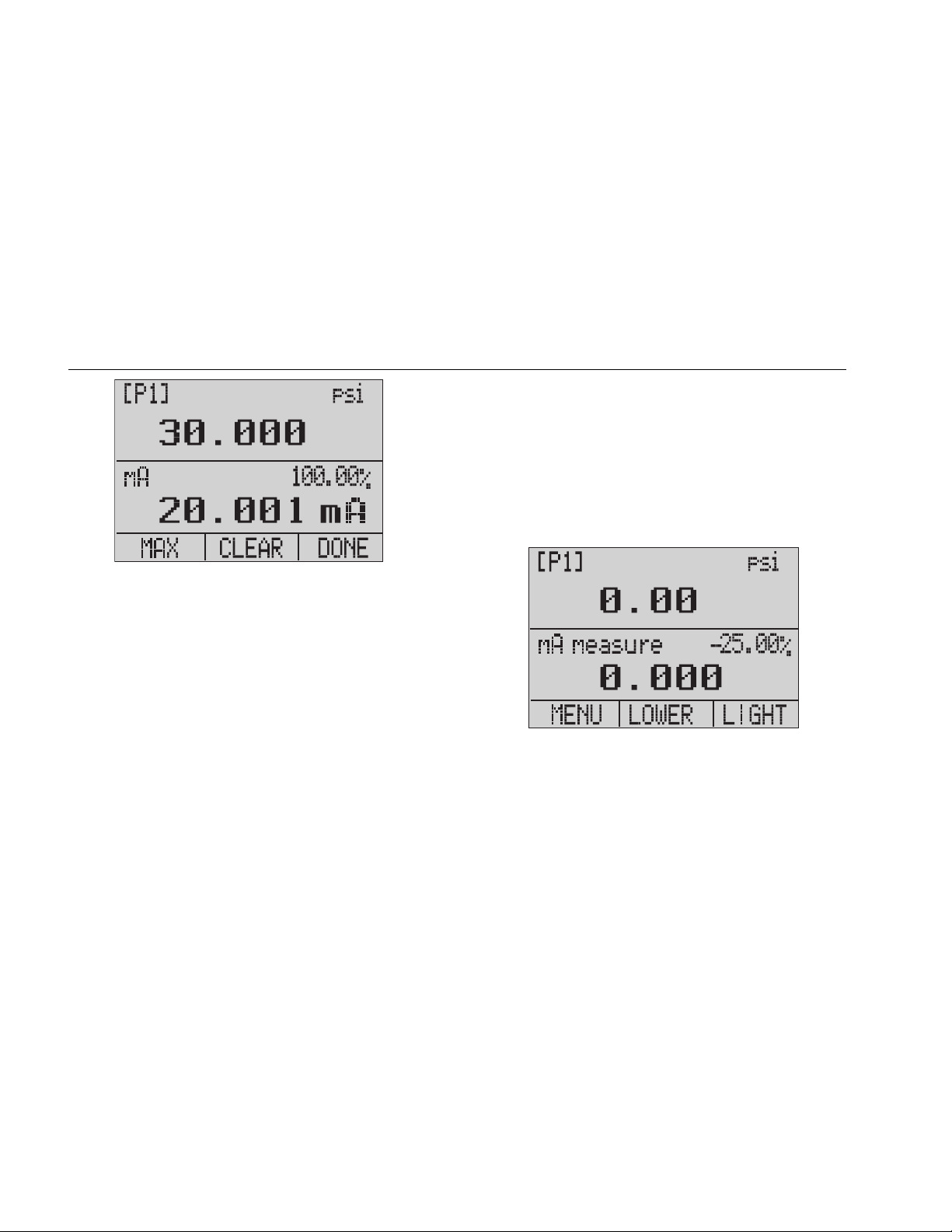

hix054.eps

Minimum and Maximum Storage Capability

The Product has a min/max feature to capture the

minimum and maximum values of any displayed

parameter.

Step through the menu options to access the min/max

function. “MIN/MAX” is shown on the display above .

Push to toggle the display through the min/max values

that are stored in the min/max registers. These readings

are live so that the new min/max values will be recorded

while in this mode.

hix055.eps

35

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 46

719PRO

Users Manual

hix056.eps

To reset the min/max registers, push for “CLEAR”.

These registers are also cleared at power-up or when the

configuration is changed.

Factory Setups

The Product is loaded with five commonly used factory

setups. To access these SETUPS, select from the MORE

configurations options. These setups are shown below.

Note

Any of these setups can be changed and saved.

Setup 1: The upper display is set to [P1] mode and the

lower is set to mA, middle is off.

hix057.eps

36

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 47

Pressure Calibrator

Factory Setups

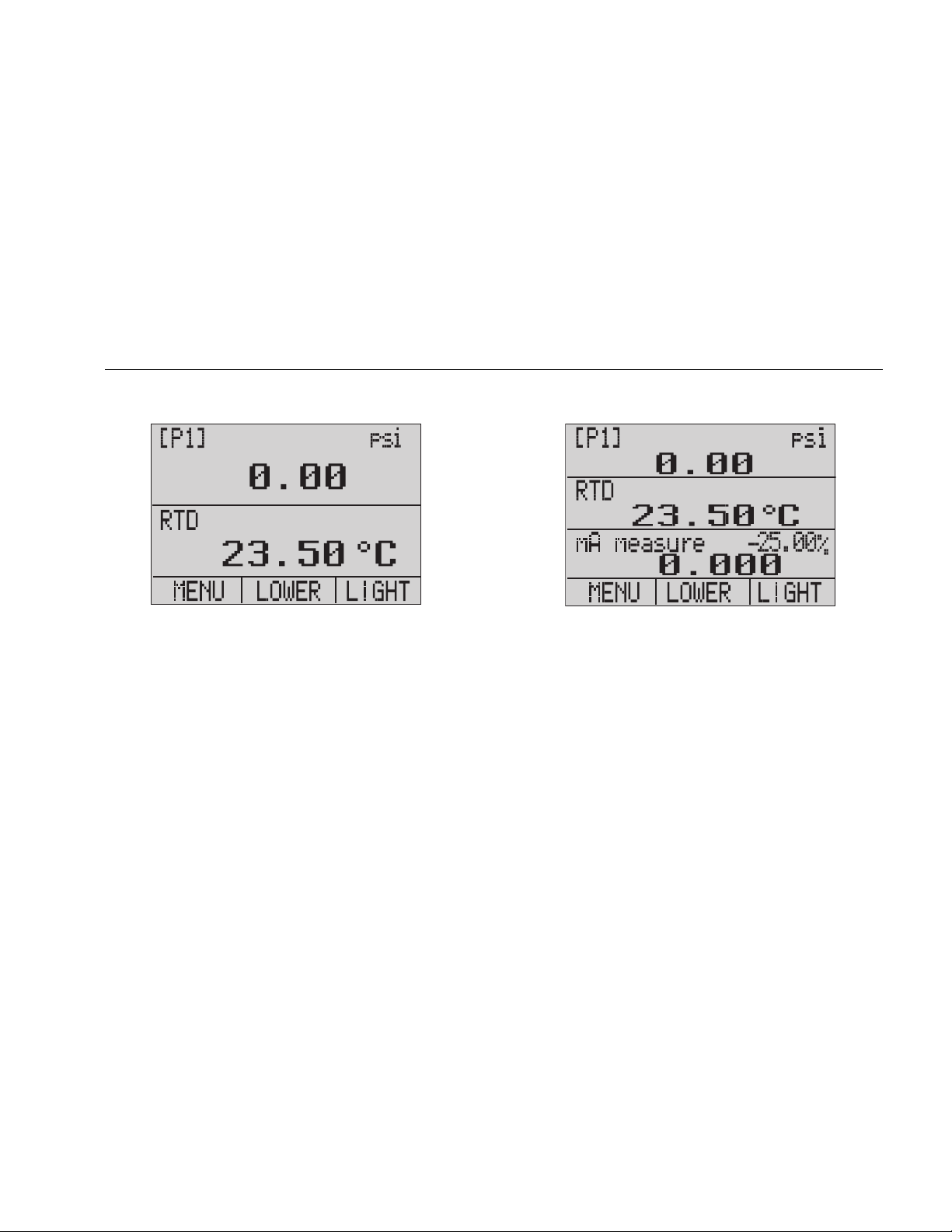

Setup 2: The upper display is set to [P1] mode and the

lower is set to RTD, middle is off.

hix058.eps

Setup 3: The upper display is set to [P1] mode and the

middle is set to RTD, lower is mA.

hix059.eps

37

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 48

719PRO

Users Manual

Setup 4: The lower display is set to [P1] switch test, the

other displays are off.

hix062.eps

Setup 5: The upper display is set to [P1], the middle

display is set to [EXT] and the lower display is set to RTD.

hix060.eps

38

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 49

Pressure Calibrator

Custody Transfer / Flow Calibration

Custody Transfer / Flow Calibration

The Product is ideal for flow computer calibration. Every

manufacturer of flow computers has a different calibration

procedure, but most call for calibration of three

parameters: static pressure, differential pressure and

temperature. To facilitate these measurements, recall

setup #5 on the Product.

1. Connect the Product to the static and differential

pressures. ([P1], EXT) Then connect the RTD sensor

to the Product.

2. With the reading of the RTD, static, and differential

pressures, make sure the flow computer has the

correct reading. If not, adjust the flow computer as

necessary.

Remote Operation

Remote Interface

The Product can be remotely controlled with a PC

terminal or by a computer program that runs the Product

in an automated system. It uses an RS-232 serial port

connection for remote operation.

Note

To use the remote control option, a custom

miniature circular to USB interface cable, PN

4401616 must be purchased separately. To

contact Fluke refer to the “Contact Fluke”

section.

With this connection the user can write programs on the

PC, with Windows languages like Visual Basic to operate

the Product, or use a terminal program similar to Hyper

Terminal, to enter single commands. Typical RS-232

remote configurations are shown in Figure 11.

39

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 50

719PRO

Users Manual

Figure 11. Typical Remote Connection

USB Port

hix020.eps

40

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 51

Pressure Calibrator

Remote Operation

Set up the RS-232 Port for Remote Control

Note

The RS-232 connection cable should not exceed

15 m unless the load capacitance measured at

connection points is less than 2500 pF.

Serial parameter values:

• 9600 baud

• 8 data bits

• 1 stop bit

• no parity

• Xon/Xoff

• EOL (End of Line) character or CR (Carriage Return)

or both

Note

To use the remote control option, a custom

miniature circular to USB interface cable, PN

4401616, must be purchased separately.

Connect the Product to the computer, attach the

miniature circular connector end of the cable to the

pressure module port on the right side of the Product and

the USB connector to the computer. The Product should

be turned off prior to making the connection and then

turned on.

For remote operation of the Product, connect it to a COM

port on the PC as in Figure 11. Use a terminal emulator

program and follow the subsequent procedure:

1. Start the terminal emulator program.

2. Select New Connection.

3. For Name enter “Fluke 719PRO”. Select the serial

port that the Product is connected to.

4. Enter the above information for port settings.

5. Select ASCII setup from File/Properties/Settings and

mark these choices:

• Echo typed characters locally

• Wrap lines that exceed terminal width

6. Select Ok.

7. To see if the port works enter *IDN?. This command

will return information on the Product.

41

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 52

719PRO

Users Manual

Change Between Remote and Local Operation

There are three modes of operation of the Product: Local,

Remote, and Remote with Lockout. Local mode is the

default mode. Commands may be entered with the

keypad on the Product or with a computer. In Remote

mode the keypad is disabled and commands may only be

entered with a computer. If [GO TO LOCAL] is chosen

from the display menu, the Product restores keypad

operation. In Remote with Lockout, the keypad cannot be

used.

To switch modes:

1. To enable Remote mode, enter the serial command

REMOTE at the computer terminal.

2. To enable Remote with Lockout, enter “REMOTE

LOCKOUT” in either order.

3. To switch back to local operation enter LOCAL at the

terminal. This command also turns off LOCKOUT if it

is on. For more information on commands, refer to

the “Remote Commands” section.

Command Use and Types

Refer to the “Remote Commands” section for all available

commands. The Product may be controlled by commands

and queries. All commands may be entered with upper or

lower case. The commands are divided into the

categories listed below:

Calibrator Commands

Only the Product uses these commands. For example:

VAL?

asks for the values displayed on the Product display.

Common Commands

Standard commands used by most devices. These

commands always begin with an “*”.

For example:

*IDN?

tells the Product to return its identification.

42

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 53

Pressure Calibrator

Remote Operation

Query Commands

Commands that ask for information, they always end with

a “?”. For example:

FUNC?

returns the current modes of the Product displays.

Compound Commands

Commands that contain more than one command on one

line. For example:

RTD_TYPE PT385_100;RTD_TYPE?

Sets the Product to RTD type PT385_100 and queries it

to verify. It will return:

PT385_100

Character Processing

The data entered into the Product is processed as

follows:

• ASCII characters are discarded if their decimal

equivalent is less than 32 (space), except 10 (LF)

and 13 (CR):

• Data is taken as 7-bit ASCII

• The most significant data bit is ignored.

• Upper or lower case is acceptable.

43

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 54

719PRO

Users Manual

Response Data Types

The data returned by the Product can be divided into four

types:

Integer

For most computers and controllers they are decimal

numbers that range from -32768 to 32768. For example:

FAULT? could return 110

Refer to Table 8 for more information on error codes.

Floating

Floating numbers have up to 15 significant figures and

exponents. For example:

CPRT_COEFA? returns 3.908300E-03

Character Response Data (CRD)

Data returned as keywords. For example:

RTD_TYPE? returns PT385_100

Indefinite ASCII (IAD)

Any ASCII characters followed by a terminator. For

example:

*IDN? returns FLUKE,719PRO,1234567,1.00

Calibrator Status

Error Queue

If an error occurs due to invalid input or buffer overflow,

its error code is sent to the error queue. The error code

can be read from the queue with the command FAULT?.

The error queue holds 15 error codes. When it is empty,

FAULT? returns 0. The error queue is cleared when

power is reset or when the clear command *CLS is

entered.

Input Buffer

The Product stores all received data in the input buffer.

The buffer holds 250 characters. The characters are

processed on a first in, first out basis.

44

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 55

Pressure Calibrator

Remote Operation

Remote Commands and Error Codes

Tables 5, 6, 7, and 8 list all commands, and their

descriptions, that are accepted by the Product.

Table 5. Common Commands

Command Description

*CLS

*IDN?

*RST

(Clear status) Clears the error

queue.

Identification query. Returns the

manufacturer, model number,

serial number, and firmware

revision level of the Product.

Resets the Product to the

power up state.

Command

CPRT_COEFA

CPRT_COEFA?

CPRT_COEFB

CPRT_COEFB?

CPRT_COEFC

CPRT_COEFC?

CPRT_R0

CPRT_R0?

Table 6. Calibrator Commands

Sets the custom RTD

coefficient A

Returns the custom RTD

coefficient A

Sets the custom RTD

coefficient B

Returns the custom RTD

coefficient B

Sets the custom RTD

coefficient C

Returns the custom RTD

coefficient C

Sets the custom RTD R0

resistance

Returns the custom RTD R0

resistance

Description

45

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 56

719PRO

Users Manual

Command

Description

Command

Description

DAMP Turns Damp on or off.

DAMP? Returns if DAMP is on/off

DISPLAY

DISPLAY?

ERROR_LOOP

ERROR_LOOP?

ERROR_MODE

ERROR_MODE?

ERROR_PORT

ERROR_PORT?

Turns on/off the displays

specified in the command

Returns which displays are

on/off

Turns loop power on or off in

percent error mode

Returns the current state of

loop power in error mode

Turns percent error mode on

or off

Returns whether percent

error mode is on or off

Set the pressure port for

percent error mode

Returns the pressure port for

percent error mode

FAULT?

FUNC

FUNC?

HART_ON Turns the hart resistor on.

HART_OFF Turns the hart resistor off.

HART?

HI_ERR

HI_ERR?

IO_STATE Set the Product's mA state.

IO_STATE? Return the Product's mA state.

Returns the most recent

error code

Sets the display mode as

specified in the command

Returns the current mode of

the upper, middle, and lower

display

Returns the current state of

the Hart resistor.

Sets the 100 % of span limit

for percent error mode

Returns the 100 % of span

limit for percent error mode

46

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 57

Pressure Calibrator

Remote Operation

Command Description

LOCAL

LOCKOUT

LO_ERR

LO_ERR

MOTOR_ON Turns the motor on.

MOTOR_OFF Turns the motor off.

MOTOR?

OHMS?

OUT

OUT?

Returns user to manual operation of

the Product

Locks out the keypad of the Product in

remote operation

Sets the 0 % of span limit for percent

error mode

Returns the 0 % of span limit for

percent error mode

Returns the current state of the Hart

resistor

Returns ohms value measured from

the RTD

Set the Product to output the

requested current.

Returns the value of the current being

simulated.

Command Description

PRES_UNIT

PRES_UNIT?

PUMP_LIMIT

PUMP_LIMIT?

REMOTE Puts the Product in remote mode

RTD_TYPE Sets the RTD type

RTD_TYPE? Returns the RTD type

SIM

Set the pressure unit for the indicated

display

Returns the pressure from the

indicated display

Sets the approximate value at which

the pump will turn off.

Returns the approximate value at

which the pump will turn off.

Set the Product to simulate the

requested current.

47

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 58

719PRO

Users Manual

Command Description

SIM?

ST_CLOSE?

ST_DEAD?

ST_OPEN?

ST_START Starts a switch test

Returns the value of the current being

simulated.

Returns pressure value at which the

switch closed

Returns pressure value of the

deadband of the switch

Returns pressure value at which the

switch opened

Table 7. Parameter Units

Units Meaning

CEL Temperature in degrees Celsius

CUSTOM Custom RTD type

DCI Current function

DCV Voltage measure function

EXT

External pressure measurement

function

FAR Temperature in degrees Fahrenheit

TEMP_UNIT

Set the RTD to read in °F or °C on the

indicated display

TEMP_UNIT? Returns the unit the RTD is set to

VAL? Returns the measured values

ZERO_MEAS Zeros the pressure module

ZERO_MEAS?

Returns the zero offset of the

pressure module

48

LOWER Designates Lower display

MA Milliamps of current

MEASURE Measure state

MEAS_LOOP Measure with loop power state

MIDDLE Designates Middle display

OHM Resistance in ohms

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 59

Pressure Calibrator

Remote Operation

Units Meaning

PCT_ERR Percent Error

PERCENT Percent

PT385_100 100 Ohm 385 Platinum RTD type

PT392_100 100 Ohm 392 Platinum RTD type

PTJIS_100 100 Ohm JIS Platinum RTD type

P1 P1 pressure measurement function

RTD Temperature measure function

ST_P1 Switchtest mode with P1

ST_EXT Switchtest mode with external module

SOURCE Source state

SIM Simulate state

UPPER Designates Upper display

V Voltage

Error Number Error Description

100

101 Too many digits entered

102

103

104

105

106

107 Pressure not selected

Table 8. Error Codes

A non-numeric entry was received

where it should be a numeric entry

Invalid units or parameter value

received

Entry is above the upper limit of the

allowable range

Entry is below the lower limit of the

allowable range

A required command parameter was

missing

An invalid command parameter was

received

49

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 60

719PRO

Users Manual

Error Number Error Description

108 Invalid sensor type

109 Pressure module not connected

110 An unknown command was received

111 Bad Parameter received

112 The serial input buffer overflowed

113

114 The serial output buffer overflowed

Too many entries in the command

line

Enter Commands

Commands for the Product may be entered in upper or

lower case. There is at least one space required between

the command and parameter, all other spaces are

optional. Almost all commands for the Product are

sequential. Any overlapped commands are indicated as

such. This section briefly explains each of the commands

and describe their general use, which include any

parameters that may be entered with the command as

well as what the output of the command is.

Common Commands

*CLS

Clears the error queue. Also terminates all pending

operations. When programs are written, use before each

procedure to avoid buffer overflow.

*IDN?

Returns the manufacturer, model number, serial number,

and firmware revision of the Product. For example:

*IDN? returns FLUKE,719PRO,1234567,1.00

50

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 61

Pressure Calibrator

Remote Operation

Calibrator Commands

CPRT_COEFA

Use this command to entere a custom RTD into the

Product. The numeric value entered after the command is

set as the first coefficient of the polynomial used by the

custom RTD.

For example:

CPRT_COEFA 3.908300E-03 enters 3.908300e-3 as

coefficient A.

CPRT_COEFA?

Returns the number that was entered for the first

coefficient of the polynomial used in the custom RTD.

With the example above, CPRT_COEFA? returns:

3.908300E-03

CPRT_COEFB

This command is used to enter a custom RTD into the

Product. The numeric value entered after the command

will be set as the second coefficient of the polynomial

used by the custom RTD.

For example:

CPRT_COEFB –5.774999E-07 enters –5.774999E-07

as coefficient B.

CPRT_COEFB?

Returns the number which was entered for the second

coefficient of the polynomial used in the custom RTD.

With the example above, CPRT_COEFB? returns:

-5.774999E-07

CPRT_COEFC

This command is used to enter a custom RTD into the

Product. The numeric value entered after the command

will be set as the first coefficient of the polynomial used

by the custom RTD.

For example:

CPRT_COEFC –4.183000E-12 enters –4.183000E-12

as coefficient C.

CPRT_COEFC?

Returns the number that was entered for the third

coefficient of the polynomial used in the custom RTD. The

example above CPRT_COEFC? returns:

–4.183000E-12

51

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 62

719PRO

Users Manual

CPRT_R0

Sets the 0 ° resistance, R0, in the custom RTD. The value

must be entered with a unit label. Refer to Table for

assistance.

For example:

CPRT_R0 100 OHM sets R0 to 100 Ω.

CPRT_R0?

Returns the value for the resistance in custom RTD. The

above example returns:

1.000000E+02, OHM

DAMP

Turns on or off the damping function.

For example:

If DAMP ON is sent, this will turn on the damping

function.

DAMP?

Returns the current state of the damping function.

For example:

If DAMP? is sent, it will return ON if the damping function

is on.

DISPLAY

Turns on or off the indicated display.

For example:

If DISPLAY LOWER is sent ON, this will turn on the lower

display.

DISPLAY?

Returns the current state of the each of the displays.

For example:

If DISPLAY? is sent, it will return ON, ON, ON if the all

the displays are on.

52

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 63

Pressure Calibrator

Remote Operation

FAULT?

Returns the error code number of an error that has

occurred. The command may be entered when the

previous command did not do what it was meant to do.

For example, if a value for current output is entered that is

bigger than the supported range (0 mA -24 mA) FAULT?

returns:

103 which is the code number for an entry over range.

Refer to Tables 5, 6, 7, and 8 for more information on

error code numbers.

ERROR _LOOP

Turns on or off loop power in percent error mode.

For example:

To set loop power on, send ERROR_LOOP ON.

ERROR _LOOP?

Returns the current state of loop power in percent error

mode.

For example:

If ERROR_LOOP? is sent, it will return ON if loop power is

on in error mode.

ERROR_ MODE

Turns percent error mode on and off.

For example:

To turn on percent error mode, send ERROR_MODE ON.

ERROR _ MODE?

Returns the current state of percent error mode.

For example:

If ERROR_MODE? is sent, it will return ON if the Product is

in percent error mode.

53

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 64

719PRO

Users Manual

ERROR_ PORT

Sets the pressure port for percent error.

For example:

To set the pressure port for percent error to [P1], send

ERROR_ PORT P1.

ERROR _ PORT?

Returns the current pressure port for percent error mode.

For example:

If ERROR _PORT? is sent, it will return P1 if the pressure

port in percent error is [P1].

FUNC

Sets the display indicated in argument one to the function

indicated in argument 2.

For example:

To set the lower display to RTD mode send FUNC

LOWER,RTD.

FUNC?

Returns the current mode of all displays. For example, if

the Product is set to [P2] ST on the upper display, [P1] on

the middle, and RTD on the lower, FUNC? returns:

ST_P2,P1,RTD

HART_ON

Turns on the Hart resistor.

HART_OFF

Turns off the Hart resistor.

HART?

Returns the state of the Hart resistor.

For example:

If the Hart resistor was on HART? returns ON.

HI_ERR

Sets the 100 % point for the percent error mode

calculation in the current engineering units.

For example:

To set the 100 % point to 100 psi, send HI_ERR 100.

HI_ERR?

Returns the 100 % point for the percent error mode

calculation.

For example:

If the 100 % point is set to 100 psi, HI_ERR? returns

1.000000E+02, PSI.

54

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 65

Pressure Calibrator

Remote Operation

IO_STATE

Sets the input/output/simulate state of the mA function of

the Product. Does not put the Product into mA if it is not

in mA already.

For example:

If the Product is in mA simulate mode, IO_STATE

MEASURE would put it in measure mode.

IO_STATE?

Returns the input/output/simulate state of the mA function

of the Product.

For example:

If the Product was in mA simulate mode IO_STATE?

would return SIM.

LOCAL

Restores the Product to local operation if it was in remote

mode. Also clears LOCKOUT if the Product was in

lockout mode.

LOCKOUT

Send this command to set the lockout state, when the unit

is in REMOTE or if it goes to remote it prohibits use of the

keypad. The lockout state can only be cleared by if the

LOCAL command is sent.

LO_ERR

Sets the 0 % point for the percent error mode calculation

in the current engineering units.

For example:

To set the 0 % point to 20 psi, send LO_ERR 20.

LO_ERR?

Returns the 0 % point for the percent error mode

calculation.

For example:

If the 0 % point is set to 20 psi, LO_ERR? returns

2.000000E+01, PSI.

MOTOR_ON

Turns on the motor.

55

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 66

719PRO

Users Manual

MOTOR_OFF

Turns off the motor.

MOTOR?

Returns the state of the motor.

For example:

If the motor was on, MOTOR? returns ON.

OHMS?

Returns the raw ohm value from the RTD.

For example:

If when a P100-385 is measured at 0 °C, OHMS? returns

1.000000E+02, OHM.

OUT

This command also switches the Product into mA output

mode. A number and a unit must be entered after the

command.

For example:

OUT 5 MA sets the current output at 5 mA

OUT?

Returns the output of the Product.

With the above example, OUT? returns 5.000000E-03, A

PRES_UNIT

Used to set the pressure unit for the indicated display.

For example:

To set the pressure unit to psi on the lower display, send

PRES_UNIT LOWER, PSI.

PRES_UNIT?

Returns the pressure unit used when pressure is

measured for each of the 3 displays.

PUMP_LIMIT

Sets the approximate pressure in psi at which the pump

will turn off.

For example:

PUMP_LIMIT 50 sets the approximate value that the

pump will shut off at to 50 psi

56

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 67

Pressure Calibrator

Remote Operation

PUMP_LIMIT?

Returns the pump limit. The above example with

PUMP_LIMIT? returns:

50.000

REMOTE

Puts the Product into remote mode. From the remote

mode, the keypad can be used to get back to local mode

unless the command LOCKOUT was entered before

REMOTE. Then the keypad is locked out, and the LOCAL

command must be sent to get back to local operation.

RTD_TYPE

Sets the RTD type. The subsequent list shows RTD types

the way they should be entered after the command:

PT385_100; PT392_100; PTJIS_100; CUSTOM;

For Example:

RTD_TYPE PT385_100 sets RTD type to PT100-385

RTD_TYPE?

Returns the RTD type.

For example:

If the RTD type is PT385_100, RTD_TYPE?, PT100_385

is returned.

SIM

Sets the output for current simulation. This command also

switches the Product into mA simulation mode. A number

and a unit must be entered after the command.

For example:

SIM 5 MA sets the current simulation at 5 mA

SIM?

Returns the output of the current simulation. With the

example above, the output would be: 5.000000E-03, A

ST_START

Starts a switch test.

57

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 68

719PRO

Users Manual

ST_CLOSE?

Returns the pressure that the switch closed at in the

current pressure units.

ST_OPEN?

Returns the pressure that the switch opened at in the

current pressure units.

ST_DEAD?