Page 1

718Ex 30G/100G/300G

May 2004 Rev. 2, 5/09

© 2004-2009 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

Pressure Calibrator

Users Manual

®

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and service. The warranty period is

three years (one year for pump assembly) and begins on the date of shipment. Parts, product repairs, and services are warranted for 90

days. This warranty extends only to the original buyer or end-user customer of a Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in Fluke's opinion, has been misused, altered, neglected, contaminated, or damaged by accident

or abnormal conditions of operation or handling. Fluke warrants that software will operate substantially in accordance with its functional

specifications for 90 days and that it has been properly recorded on non-defective media. Fluke does not warrant that software will be error

free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers only but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is available only if product is purchased through a Fluke authorized

sales outlet or Buyer has paid the applicable international price. Fluke reserves the right to invoice Buyer for importation costs of repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair, or replacement of a defective

product which is returned to a Fluke authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return authorization information, then send the

product to that service center, with a description of the difficulty, postage and insurance prepaid (FOB Destination). Fluke assumes no risk

for damage in transit. Following warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination, alteration, accident, or abnormal condition of operation or handling,

including overvoltage failures caused by use outside the product’s specified rating, or normal wear and tear of mechanical components,

Fluke will provide an estimate of repair costs and obtain authorization before commencing the work. Following repair, the product will be

returned to the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges (FOB Shipping

Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OR

LOSSES, INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not apply to every buyer. If any provision of this Warranty is held invalid or

unenforceable by a court or other decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any

other provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

To register your product online, visit register.fluke.com

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

Page 3

Table of Contents

Title Page

Introduction..................................................................................................................... 1

How to Contact Fluke ..................................................................................................... 2

Safety Information .......................................................................................................... 2

Faults and Damage ................................................................................................... 7

Safety Regulations..................................................................................................... 8

Certification Information............................................................................................. 9

Getting Acquainted with the Calibrator ........................................................................... 9

Power Saver .............................................................................................................. 11

Zeroing with Absolute Pressure Modules ....................................................................... 11

Calibrating a P/I Transmitter........................................................................................... 13

Using the Internal Pump ............................................................................................ 13

Using an External Pump ............................................................................................ 17

External Fluke Pressure Module Compatibility ............................................................... 19

Cleaning the Pump Valve Assembly............................................................................... 20

Switch Test..................................................................................................................... 20

Maintenance................................................................................................................... 21

In Case of Difficulty.................................................................................................... 21

Cleaning .................................................................................................................... 22

i

Page 4

718Ex 30G/100G/300G

Users Manual

Calibration................................................................................................................. 22

Replacing the Battery................................................................................................ 22

Approved Batteries.................................................................................................... 23

Parts and Accessories ................................................................................................... 24

Specifications................................................................................................................. 25

Pressure Sensor Input .............................................................................................. 25

Pressure Sensor Range and Resolution ................................................................... 25

Pressure Module Input .............................................................................................. 26

DC mA Input ............................................................................................................. 26

General Specifications .............................................................................................. 26

Product Compliance Markings .................................................................................. 27

ii

Page 5

List of Tables

Table Title Page

1. International Electrical Symbols .................................................................. 3

2. Pushbutton Functions.................................................................................. 10

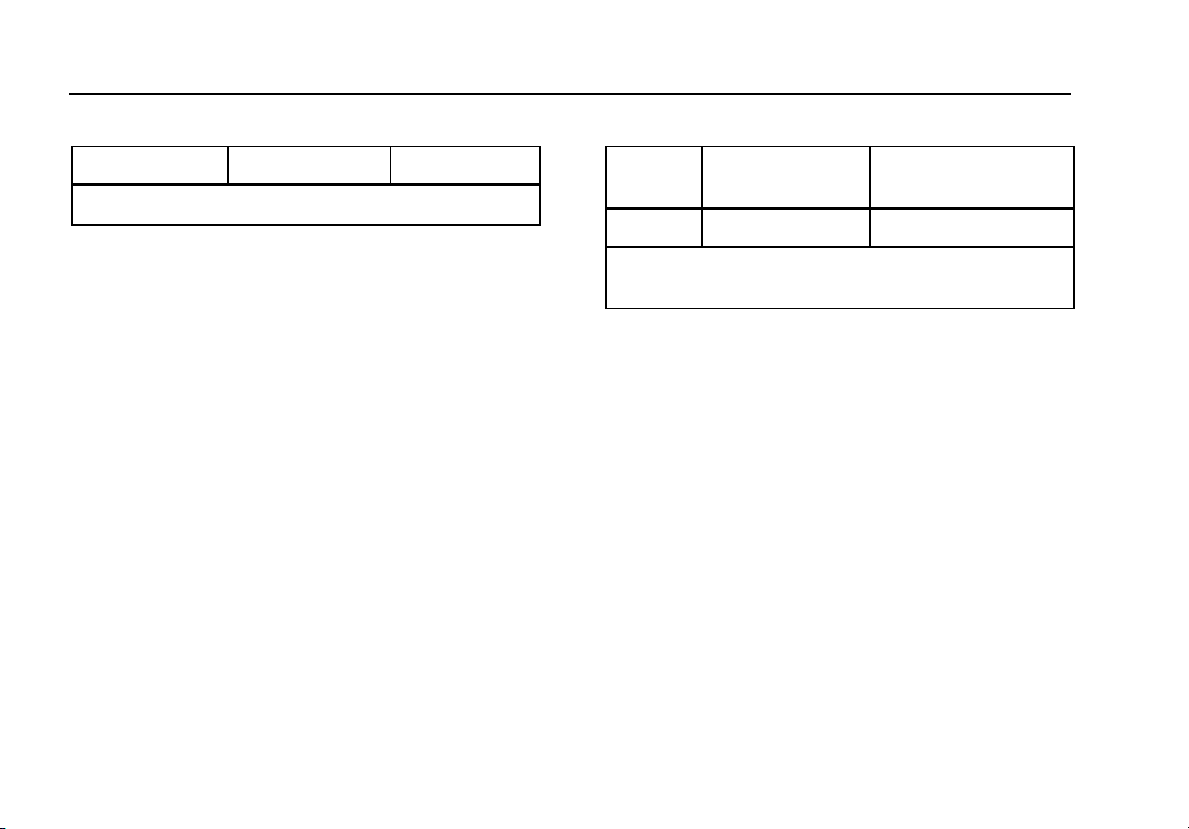

3. Pump Features ............................................................................................ 12

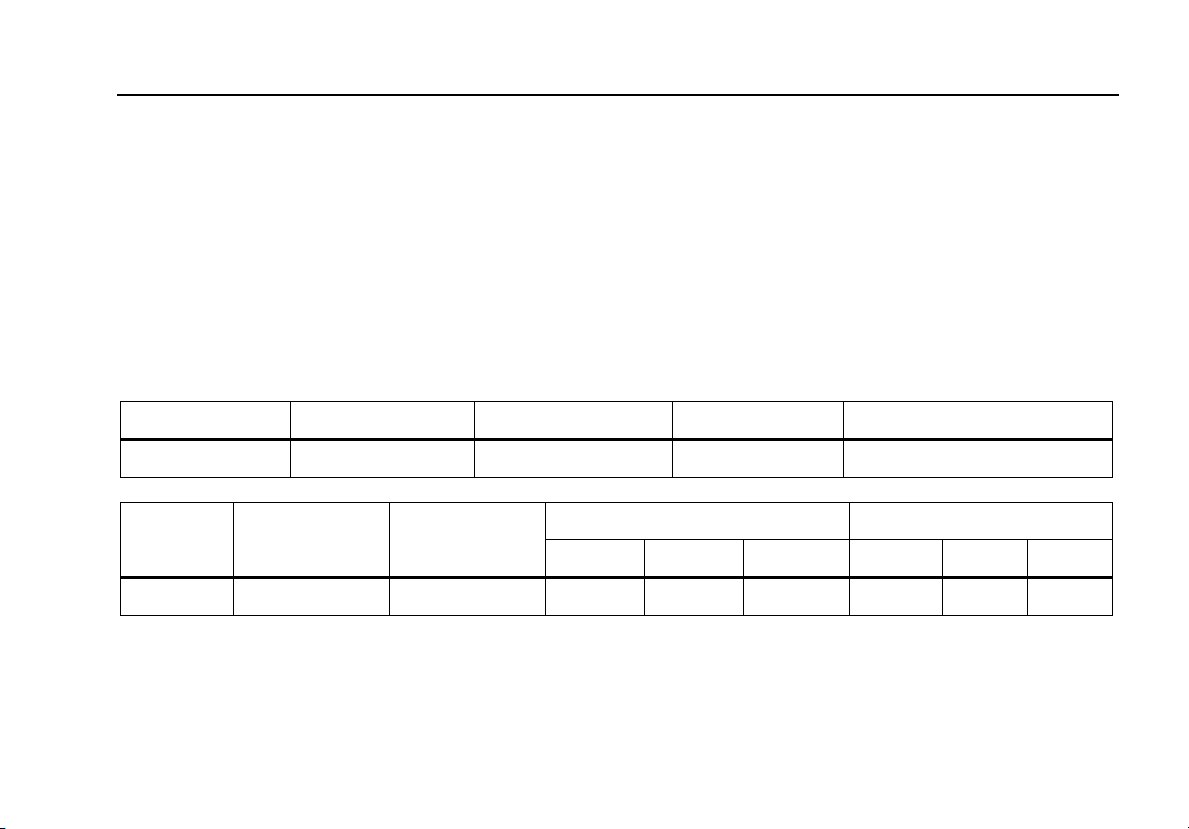

4. Recommended Pressure Modules .............................................................. 17

5. Fluke Pressure Module Compatibility .......................................................... 19

6. Replacement Parts and Accessories........................................................... 24

iii

Page 6

718Ex 30G/100G/300G

Users Manual

iv

Page 7

List of Figures

Figure Title Page

1. Connection Technique................................................................................. 7

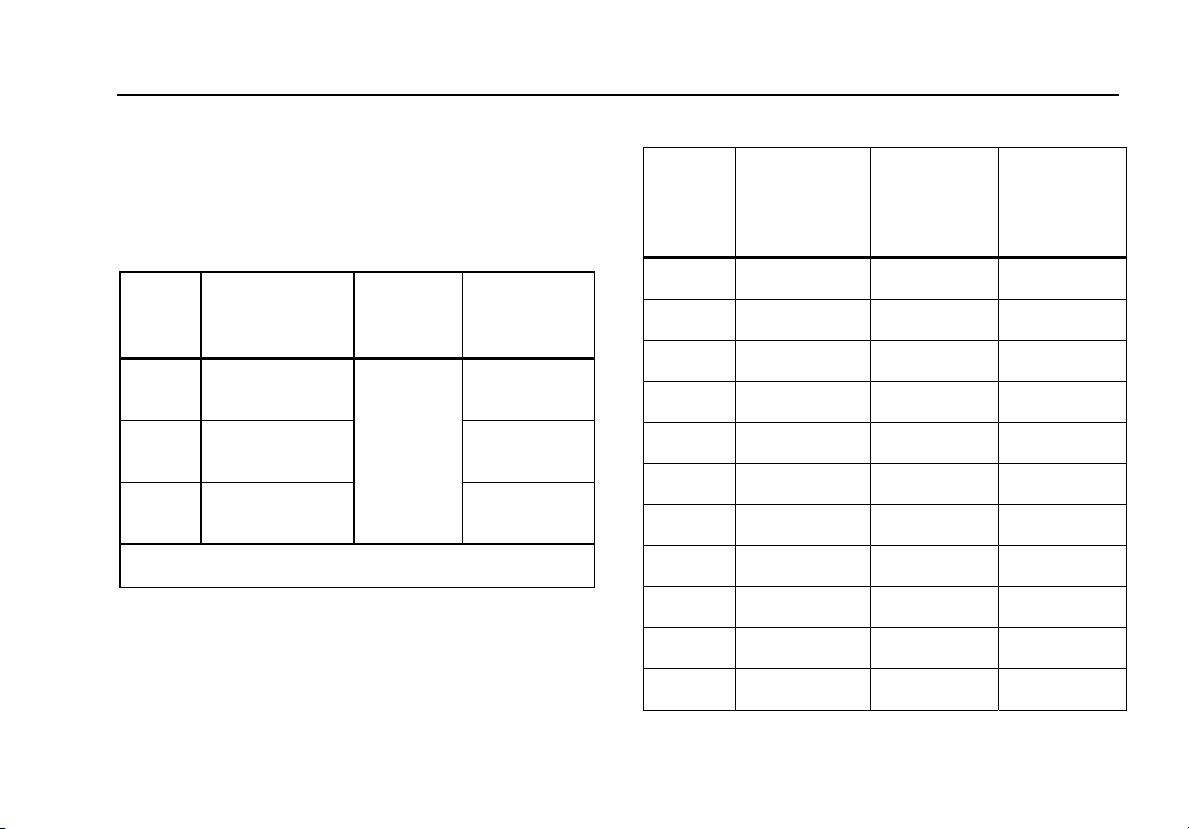

2. Front Panel Features................................................................................... 9

3. Pump Features ............................................................................................ 12

4. Internal Pressure Sensor with Internal Pump .............................................. 15

5. Pressure Module with Internal Pump........................................................... 16

6. Pressure Module with External Pump.......................................................... 18

7. Battery Replacement ................................................................................... 22

v

Page 8

718Ex 30G/100G/300G

Users Manual

vi

Page 9

718Ex 30G/100G/300G

Pressure Calibrator

Introduction

XWWarning

Read Safety Information before using the

Calibrator.

The Fluke Model 718Ex 30G, 718Ex 100G, and 718Ex

300G Pressure Calibrators (hereafter called Calibrator)

can do the following:

Calibrate P/I (pressure to current) transmitters.

• Measure pressure via a 1/8-inch NPT pressure fitting

and an internal pressure sensor or via Fluke 700PEx

Series Pressure Modules.

• Measure current up to 24 mA.

• Simultaneously display pressure and current

measurements.

• Perform switch testing.

The Calibrator is for use ONLY in Ex-hazardous areas.

The Calibrator makes 5-digit pressure readings in the

following units: psi, inH

cmH2O at 4 °C, cmH2O at 20 °C, bar, mbar, kg/cm2, inHg,

and mmHg. Full-scale pressure sensor input is as follows:

• Model 718Ex 30G: 30 psi (206.85 kPa, 2.0685 bar).

OL appears at 33 psi.

• Model 718Ex 100G: 100 psi (689.5 kPa, 6.895 bar).

OL appears at 120 psi.

• Model 718EX 300G: 300 psi (2068 kPa, 20.68 bar).

OL appears at 360 psi.

The Calibrator measures pressure sensor inputs in the

units shown under Pressure Sensor Range and

Resolution.

For Pressure Modules, full-scale readings for all pressure

ranges can be made in psi, kPa, and inHg units. To avoid

display overflow, full-scale readings are limited to

O at 4 °C, inH2O at 20 °C, kPa,

2

1

Page 10

718Ex 30G/100G/300G

Users Manual

1000 psi in cmH2O, mbar, and mmHg units, and 3000 psi

in inH

O units. Pressures of at least 15 psi must be

2

measured for meaningful readings in bar and kg/cm2

units.

The Calibrator is supplied with:

• a holster

• one installed 9 V alkaline battery

• one set of TL75 test leads

• one set of AC72A alligator clips

• a Control Drawing

• a CD-Rom

If the Calibrator is damaged or something is missing,

contact the place of purchase immediately. Contact a

Fluke distributor for information about accessories. See

Contacting Fluke. To order replacement parts or spares,

see Parts and Accessories.

How to Contact Fluke

To contact Fluke, call one of the following telephone

numbers:

Technical Support USA: 1-800-44-FLUKE

(1-800-443-5853)

Calibration/Repair USA: 1-888-99-FLUKE

(1-888-993-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-675-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

Or, visit Fluke's website at www.fluke.com

To register your product, visit http://register.fluke.com.

To view, print, or download the latest manual supplement,

visit http://us.fluke.com/usen/support/manuals

.

.

Safety Information

A Warning identifies conditions and actions that pose

hazard(s) to the user; a Caution identifies conditions and

actions that may damage the Calibrator or the equipment

under test.

Safety and electrical symbols used in this manual and on

the Calibrator are displayed in Table 1.

2

Page 11

Pressure Calibrator

Safety Information

Table 1. International Electrical Symbols

Symbol Meaning

+

J

Power ON/OFF

Earth ground

( Conforms to ATEX requirements.

M

X

W

T

)

P

f

~

;

3

Battery

Hazardous Voltage

Risk of Danger. Important information. Refer to manual.

Double insulated

Conforms to relevant Canadian and US Standards.

Conforms to relevant European Union directives.

Pressure

Do not dispose of this product as unsorted municipal waste. Go to Fluke’s website for recycling

information.

Conforms to relevant Australian standards.

Page 12

718Ex 30G/100G/300G

Users Manual

XW Warning

To avoid electric shock, injury, or damage to the Calibrator:

• Use the Calibrator only as described in this User Manual and the Fluke 718Ex CCD (Concept Control

Drawing) or the protection provided by the Calibrator may be impaired.

• Inspect the Calibrator before use. Do not use it if it appears damaged.

• Check the test leads for continuity, damaged insulation, or exposed metal. Replace damaged test leads.

• When using probes, keep fingers behind the finger guards on the probes

• Never apply more than 30.0 V between the input terminals, or between any terminal and earth ground.

• Applying more than 30.0 V to the input terminals invalidates the Calibrator’s Ex Approval and may

result in permanent damage to the unit so it can no longer be used.

• Use the proper terminals, mode, and range for the measuring or sourcing application.

• To prevent damage to the unit under test, be sure the Calibrator is in the correct mode before

connecting the test leads.

• When making connections, connect the COM test probe before the live test probe. When

disconnecting, disconnect the live probe before the COM probe.

• Never use the Calibrator with the red holster removed.

• Never open the Calibrator case. Opening the case invalidates the Calibrator’s Ex Approval.

• Make sure the battery door is closed before using the Calibrator.

• Replace the battery as soon as the B (low battery) symbol appears to avoid false readings that can

lead to electric shock. Remove the Calibrator from the Ex-hazardous area before opening the battery

door.

4

Page 13

Pressure Calibrator

Safety Information

• Remove test leads from the Calibrator before opening the battery door.

• This equipment is specified for use in measurement category I (CAT I) pollution degree 2 environments

and should not be used in CAT II, CAT III, or CAT IV environments. Voltage transients should not

exceed 300 volts for the CAT I applications where this product is used. Measurement transients are

defined in IEC1010-1 as 2 µs rise time with a 50 μs duration at 50 % of the maximum amplitude height.

• Measurement Category I (CAT I) is defined for measurements performed on circuits not directly

connected to the mains.

• Turn off circuit power before connecting the Calibrator mA and COM terminals in the circuit. Place

Calibrator in series with the circuit.

• When servicing the Calibrator, use only specified replacement parts. Do not open the Calibrator case.

Opening the case invalidates the Calibrator’s Ex Approval.

• Do not allow water inside the case.

• Do not use in a damp or wet environment.

• When using the Calibrator’s internal pressure sensor, do not connect a pressure module at the

Calibrator to avoid misleading readings. If both a pressure module and the internal pressure sensor are

connected, the Calibrator displays ONLY the pressure module measurement. To avoid misleading

readings, disconnect the pressure module connector at the Calibrator.

• To avoid a violent release of pressure in a pressurized system, shut off the valve and slowly bleed off

the pressure before attaching or detaching the internal pressure sensor or pressure module fitting to

the pressure line.

• To avoid overpressure damage, do not apply pressure to the internal pressure sensor input that

exceeds the following:

5

Page 14

718Ex 30G/100G/300G

Users Manual

• Model 718Ex 30G: 30.000 psi, 206.85 kPa, or 2.0685 bar. OL appears at 33 psi.

• Model 718Ex 100G: 100.00 psi, 689.5 kPa, or 6.895 bar. OL appears at 120 psi.

• Model 718EX 300G: 300.00 psi, 2068 kPa, or 20.68 bar. OL appears at 360 psi.

• When measuring the pressure of potentially hazardous gases, care must be taken to minimize the

possibility of leakage:

• Confirm that all pressure connections are properly sealed.

• Confirm that the Pressure/Vacuum Release Control is in the closed position (fully clockwise) and

the Pressure/Vacuum switch is in the + position (fully clockwise).

• If the Calibrator has been dropped or subjected to rough handling, remove the Calibrator to a safe

area and check for leaks to confirm the integrity of the internal pneumatic components.

• Do not use a Model 718Ex (including 718Ex 300G) to measure potentially hazardous gases at pressure

greater than 100 psi (6.9 bar).

W Caution

To avoid mechanically damaging the Calibrator:

• Do not apply torque between the pressure fitting and the Calibrator case. See Figure 1 for the proper

use of tools.

• To avoid damage to the pump, use with dry air and non-corrosive gases only.

6

Page 15

Pressure Calibrator

Safety Information

Faults and Damage

Applying a voltage greater than 30 V to the input of the

Calibrator invalidates its Ex Approval and may impair its

safe operation in an Ex-hazardous area.

If there is any reason to suspect that the safe operation of

the Calibrator has been affected, it must be immediately

withdrawn from use, and precautionary measures must be

taken to prevent any further use of the Calibrator in an Exhazardous area.

Hold in

fixed

position

Fully observe all instructions, warnings, and cautions

contained in this manual. In case of doubt due to

translation and/or printing errors, refer to the original

English users manual.

wh001f.eps

Figure 1. Connection Technique

7

Page 16

718Ex 30G/100G/300G

Users Manual

The safety features and integrity of the unit may be

compromised by any of the following:

• External damage to the housing

• Internal damage to the Calibrator

• Exposure to excessive loads

• Incorrect storage of the unit

• Damage sustained in transit

• Correct certification is illegible

• Using the product with the red holster removed

• Functioning errors occur

• Permitted limitations are exceeded

• Functioning errors or obvious measurement

inaccuracies occur which prevent further

measurement by the Calibrator

• Opening the case

Safety Regulations

The use of the Calibrator meets the requirements of the

regulations providing that the user observes and applies

the requirements as stated in the regulations and that

improper and incorrect use of the unit is avoided.

• Use must be restricted to the specified application

parameters.

• Do not open the Calibrator.

• Do not remove or install the battery within the

Ex-hazardous area.

• Do not carry additional batteries within the

Ex-hazardous area.

• Use only type-tested batteries. The use of any other

batteries will invalidate the Ex-certification and present

a safety risk.

• Do not use the Calibrator in an Ex-hazardous area

unless it is completely and securely fitted in its

accompanying red holster.

• Only use the Calibrator in circuits with compatible

entity parameters.

8

Page 17

Pressure Calibrator

Getting Acquainted with the Calibrator

Certification Information

E

( II 1 G EEx ia IIC T4

Permitted for Zone 0 Equipment Group II, gas group

IIC hazardous atmospheres, temperature class T4

Class I Div. 1 Groups A-D T4 Intrinsically

F

Safe AEx ia IIC T4

Permitted for Division 1 hazardous atmospheres, Gas

Groups A-D, temperature class T4

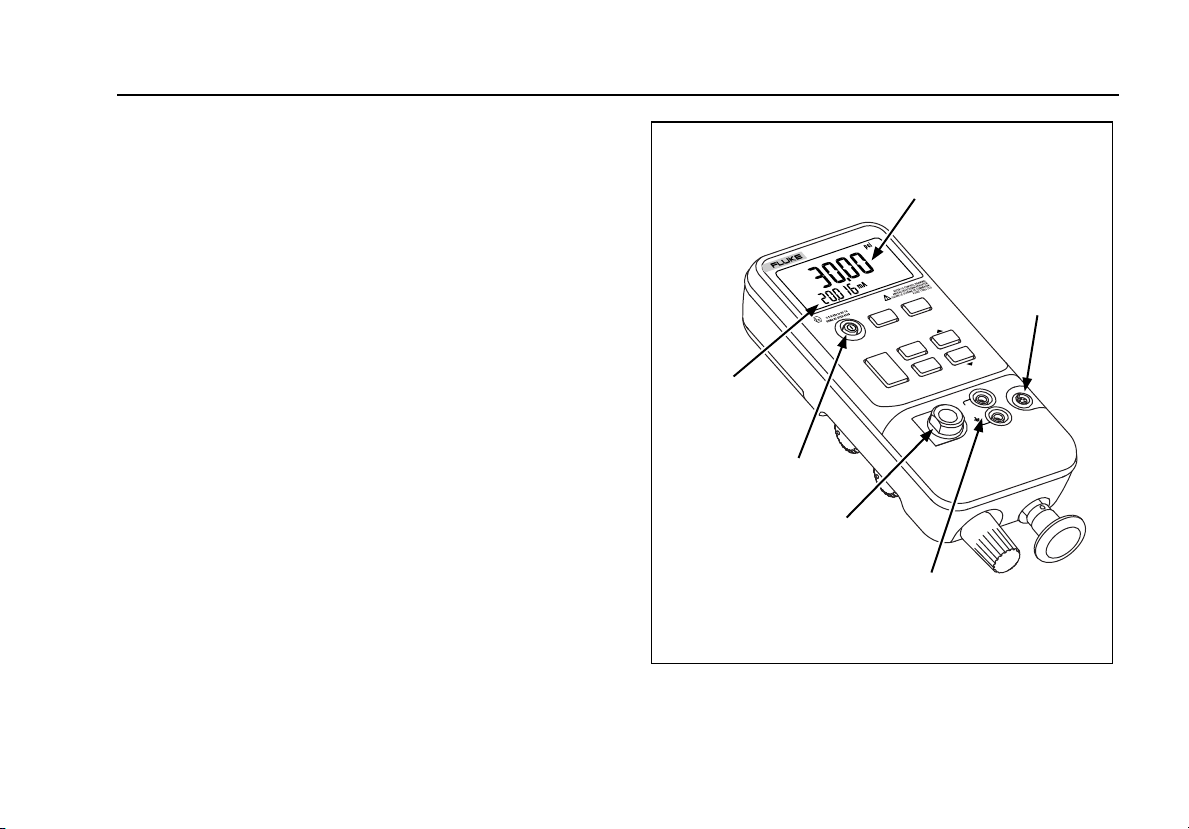

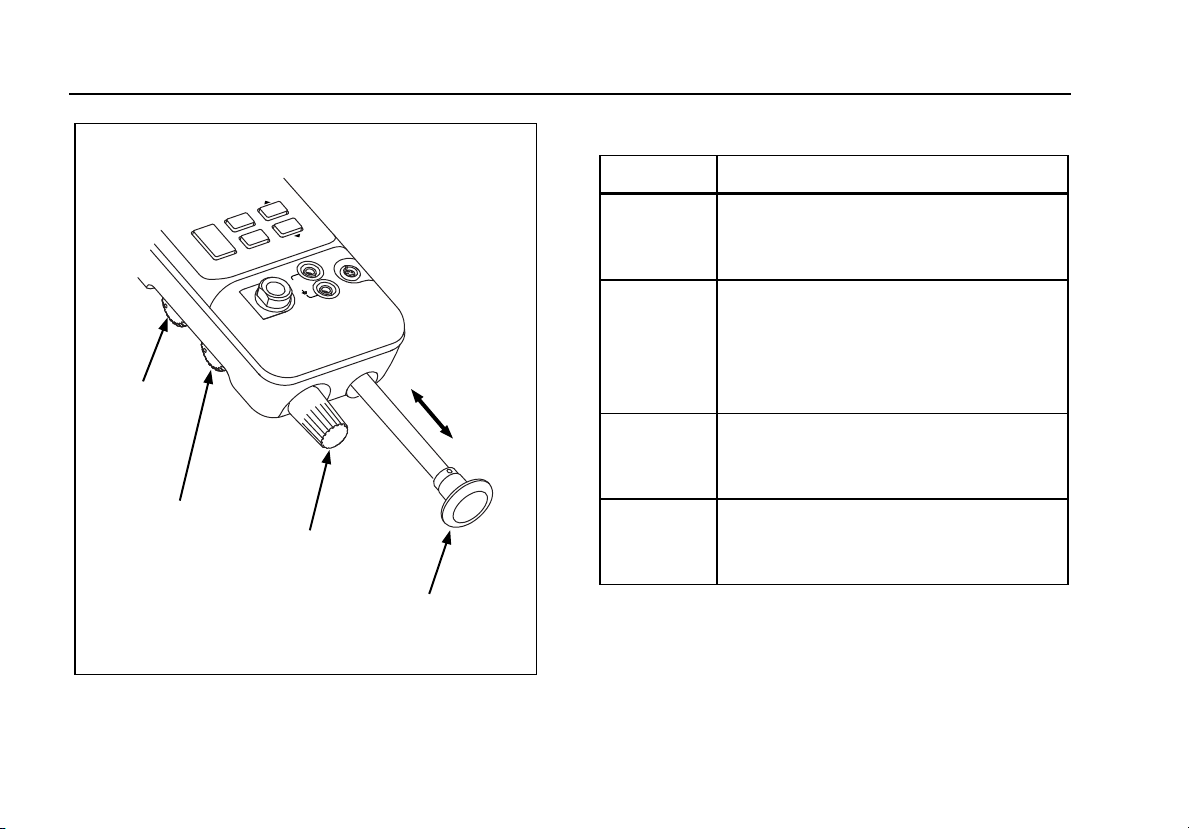

Getting Acquainted with the Calibrator

Press O to turn the Calibrator on and off. The Calibrator

displays pressure and current measurements

simultaneously. See Figure 2.

Current mA

measurement

On/Off Button

718Ex 100G

LD

HO

PRESSURE

CALIBRATOR

)

LR110460

AEx ia IIC T4

I.S. Class 1

Div 1 Group A-D

Pressure

measurement

DAMP

UNITS

CLR

ETRIC ADJ.

MIN

BAROM

MAX

HOLD

SWITCH

TEST

ZERO

RANGE

100psi 689kPa

200psi 1379kPa

module input

mA

30V

24mA

MAX

COM

MAX

Pressure

FLUKE 700PEx

ONLY

The upper part of the display shows the applied pressure

or vacuum. Vacuum is shown as a negative value. Press

to select a different unit. When cycling the power off

U

and on, the Calibrator retains the unit last used.

The lower part of the display shows the current (up to

Pressure

sensor input

Current

input

24 mA) applied to the current (mA) inputs.

Pushbutton operation is described in Table 2. Pump

features are shown in Figure 3 and described in Table 3.

Figure 2. Front Panel Features

alz005f.eps

9

Page 18

718Ex 30G/100G/300G

Users Manual

Table 2. Pushbutton Functions

Pushbutton Description

U

D

Z

N

Press to select a different pressure unit. All units are available when the pressure sensor input is used. For

higher pressure module inputs, inappropriate (out-of-range) units are not available.

Turns pressure reading damping on and off. With damping on, the Calibrator averages several

measurements before displaying a reading.

Press to zero the pressure display. Vent pressure to atmosphere before pressing this pushbutton. For an

Absolute Pressure Module, see Zeroing with Absolute Pressure Modules.

Press to read the minimum pressure and current readings since power was turned on or c was pressed.

Press again to read the maximum pressure and current readings since power was turned on or

pressed.

S Use for pressure switch test. See Switch Test.

c

h

10

Press to clear the MIN, MAX, and switch test memories

Press h to freeze the display. The

normal operation.

symbol appears on the display. Press

g

again to resume

h

c

was

Page 19

Pressure Calibrator

Zeroing with Absolute Pressure Modules

Power Saver

The Calibrator automatically turns off after 30 minutes of

inactivity. To reduce this time or disable this feature:

1. With the Calibrator OFF, press O.

P.S. xx is displayed, where xx is the turn-off time in

minutes. OFF means the power saver is disabled.

2. Press

3. To disable, press

The Calibrator resumes normal operation after 2 seconds.

h to decrease or c to increase the turn-off

time.

h until the display shows OFF.

Zeroing with Absolute Pressure Modules

For zeroing, adjust the Calibrator to read a known

pressure. This can be barometric pressure, if it is

accurately known. An accurate pressure standard can also

apply a pressure within range for any Absolute Pressure

Module. Adjust the Calibrator reading as follows:

1. Press and hold

2. Press

3. Release

Press the

measurement display unit.

h to increase or h to decrease the

Calibrator reading to equal the applied pressure.

U button to convert to any convenient

Z.

Z to exit the zeroing procedure.

11

Page 20

718Ex 30G/100G/300G

Users Manual

IN

M

X

A

M

SWITCH

O

R

E

Z

A

R

0psi 689kP

10

Pressure/

Vacuum

Switch

Pressure/Vacuum

Release

Control

LR

C

A

IC

R

T

E

M

O

R

A

B

LD

O

H

TEST

E

G

N

a

30V

2

379kP

0psi 1

A

20

M

Fine

Adjustment

Knob

Table 3. Pump Features

Item Description

.

J

D

A

m

A

m

4

X

A

M

O

C

a

X

x

E

700P

KE

M

LY

N

FLU

O

Pressure

Vacuum

Switch

Pressure

Vacuum

Release

Control

Rotate forward (clockwise) for pressure,

backward (counter-clockwise) for

vacuum.

Rotate fully backward (counterclockwise) to release all pressure or

vacuum. (Rotate slightly for partial

release.) Rotate fully forward (clockwise)

to close valve.

Fine

Adjustment

Knob

Internal

Pump

Rotate either direction for precise

adjustment of applied pressure or

vacuum. Full rotation is about 30 turns.

Increase pressure on the inward stroke.

In vacuum mode, decrease pressure on

the outward stroke.

Internal Pump

12

Figure 3. Pump Features

alz009f.eps

Page 21

Pressure Calibrator

Calibrating a P/I Transmitter

Calibrating a P/I Transmitter

To calibrate a P/I (pressure to current) transmitter, apply a

pressure to the transmitter and measure the transmitter’s

current loop output. Pressure can be applied with the

Calibrator’s internal pump or with an external pump.

XW Warning

To avoid a violent release of pressure or vacuum,

always depressurize the system slowly using the

pressure/vacuum release control before detaching

any pressure line.

When measuring the pressure of potentially

hazardous gases, care must be taken to

minimize the possibility of leakage:

• Confirm that all pressure connections are

properly sealed.

• Confirm that the Pressure/Vacuum

Release Control is in the closed position

(fully clockwise) and the

Pressure/Vacuum switch is in the +

position (fully clockwise).

• If the Calibrator has been dropped or

subjected to rough handling, remove the

Calibrator to a safe area and check for

leaks to confirm the integrity of the

internal pneumatic components.

Using the Internal Pump

The internal pump can provide 30 psi (2.0685 bar) for

Model 718Ex 30G, 100 psi (6.895 bar) for Model 718Ex

100G, or 300 psi (20.68 bar) for Model 718Ex 300G.

The preferred use for the internal pump is shown in Figure

4, where the Calibrator displays pressure measured with

the internal sensor and provided by the internal pump.

The internal pump can also be used with certain Fluke

700PEx Series Pressure Modules. In this case, pressure

measured by the pressure module is displayed by the

Calibrator. Appropriate pressure modules for each

Calibrator model are identified in Table 4. Figure 5 shows

the internal pump being used with a pressure module.

XW Warning

If both a pressure module and the internal

sensor are connected, the Calibrator displays

ONLY the pressure module measurement.

13

Page 22

718Ex 30G/100G/300G

Users Manual

To use the Calibrator’s internal pump, refer to Figure 3 and

perform the following steps:

1. Depressurize the line before connecting the

Calibrator.

2. Connect the pressure transmitter under test to the

Calibrator internal sensor as shown in Figure 4 (for

internal pressure sensor measurements) or Figure 5

(for pressure module measurements.)

Note

To avoid leaks, use Teflon tape or similar sealant

on all pressure connections.

3. Make sure the pressure/vacuum switch on the

Calibrator is in the desired position. Forward

(clockwise) is for pressure; backward (counterclockwise) is for vacuum.

4. Turn the pressure/vacuum release control backward

(counter-clockwise) to vent pressure/vacuum from the

pump.

5. Press Zto zero the pressure display.

6. Turn the fine adjustment knob to mid-range.

7. Turn the pressure/vacuum release control forward

(clockwise) to close the release valve.

8. Work the pump handle in and out to apply

incrementally larger pressure/vacuum changes.

Shorten the stroke to apply smaller increments of

pressure/vacuum change.

9. To make very small pressure/vacuum changes, use

the fine adjustment knob.

Note

This knob adjusts a small internal reservoir to

vary the total volume. With larger external

pressure/vacuum volumes, this control will adjust

pressure or vacuum within a smaller range.

10. Depressurize the system before disconnecting the

pressure line.

14

Page 23

Pressure Calibrator

Calibrating a P/I Transmitter

718Ex 100G

HOLD

PRESSURE

CALIBRATOR

)

LR110460

AEx ia IIC T4

I.S. Class 1

Div 1 Group A-D

Internal Pressure Sensor Reading

Black

DAMP

UNITS

CLR

MIN

BAROMETRIC ADJ.

MAX

HOLD

MAX

ZERO

RANGE

100psi 689kPa

30V

MAX

200psi 1379kPa

MAX

mA

FLUKE 700PEx

ONLY

Red

+

SIGN AL

–

TEST

External

Loop Supply

alz002f.eps

Figure 4. Internal Pressure Sensor with Internal Pump

15

Page 24

718Ex 30G/100G/300G

Users Manual

PRESSURE

CALIBRATOR

718Ex 100G

HOLD

Pressure Module Reading

16

+

SIGN AL

–

TEST

DAMP

ITS

N

U

)

LR110460

AEx ia IIC T4

p A-D

u

I.S. Class 1

Div 1 Gro

CLR

MIN

BAROMETRIC ADJ.

MAX

HOLD

MAX

ZERO

RANGE

100psi 68

9kPa

200psi 1379kPa

mA

V

30

MAX

LY

N

FLUKE 700PEx

O

MAX

Pressure Module

External

Loop Supply

Black

Red

alz010f.eps

Figure 5. Pressure Module with Internal Pump

Page 25

Pressure Calibrator

Calibrating a P/I Transmitter

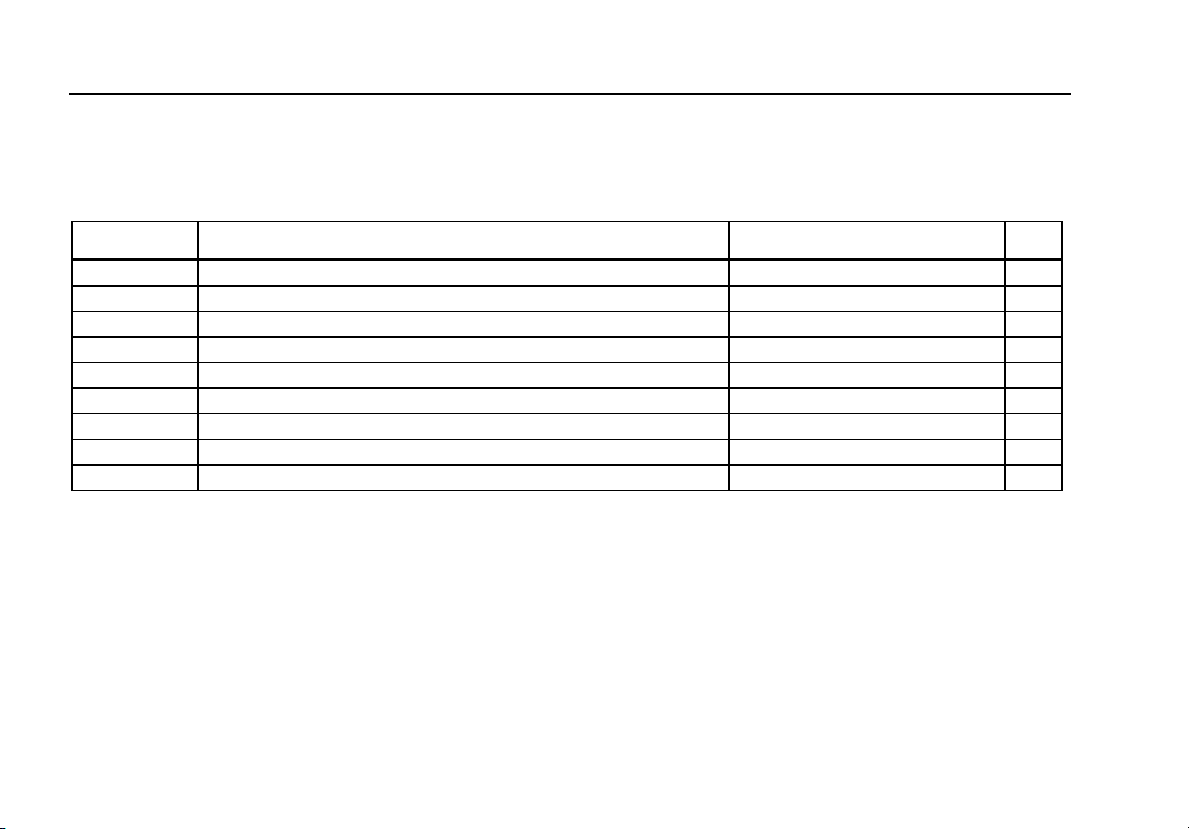

Table 4. Recommended Pressure Modules

External

Pressure

Module

700P01Ex X X X X

700P24Ex X X X X

700P05Ex X X X X

700P06Ex X X X

700P27Ex X X

700P09Ex X

700PA4Ex X X X X

700P29Ex X

Pump

718Ex

30G/100G/

300G

Internal Pump

718Ex

30G

718Ex

100G

718Ex

300G

Using an External Pump

XW Warning

To avoid damage to the Calibrator and possible

release of pressure, do not connect the internal

sensor to an external pressure source that

exceeds 30 psi for Model 718Ex 30G, 100 psi for

Model 718Ex 100G, or 300 psi for Model 718Ex

300G.

To develop higher pressure or vacuum, use an external

pump. Use a Fluke 700PEx Pressure Module connected to

the pressure module input on the Calibrator. Pressure

modules are listed in Table 4. Make overall connections as

shown in Figure 6.

Refer to setup and operating instructions included with the

pressure module and pump.

17

Page 26

718Ex 30G/100G/300G

Users Manual

Pressure Module

+

SIGNAL

TEST

Red

PRESSURE

CALIBRATOR

718Ex 100G

OLD

H

–

1

)

046

11

LR

x ia IIC

E

A

I.S

iv 1 G

D

DAMP

UNITS

0

MIN

4

T

MAX

lass 1

-D

A

. C

roup

SWITCH

O

R

TEST

E

Z

E

G

N

A

R

100psi 689kPa

CLR

ETR

M

ARO

B

HOLD

200psi 1379kPa

J.

AD

IC

V

0

3

X

A

M

MAX

Pressure

Module Reading

mA

FLUKE 700PEx

ONLY

Black

External

Loop Supply

18

Figure 6. Pressure Module with External Pump

alz006f.eps

Page 27

Pressure Calibrator

External Fluke Pressure Module Compatibility

External Fluke Pressure Module Compatibility

If inappropriate units are selected, the output of Fluke

700PEx pressure modules can cause the Calibrator

display to overflow (OL), or display values that are too low

to be read. Refer to Table 5 for appropriate unit and range

compatibility.

Table 5. Fluke Pressure Module Compatibility

Pressure Unit Module Compatibility

psi Available on all pressure ranges

inH20 All ranges through 3000 psi

cmH20 All ranges through 1000 psi

bar 15 psi and above

mbar All ranges through 1000 psi

kPa Available on all pressure ranges

inHg Available on all pressure ranges

mmHg All ranges through 1000 psi

kg/cm2 15 psi and above

19

Page 28

718Ex 30G/100G/300G

Users Manual

Cleaning the Pump Valve Assembly

1. Using a small screwdriver, remove the two valve

retention caps located in the oval-shaped opening on

the back side of the Calibrator.

2. Gently remove the spring and o-ring assembly.

3. Set aside the valve assemblies in a safe area and

clean out the valve body using a cotton swab soaked

in IPA (isopropyl alcohol).

4. Repeat this process several times using a new cotton

swab each time until there is no remaining residue.

5. Pump the unit several times and check again for

residue.

6. Clean the o-ring assembly and the o-ring on the

retention caps with IPA and inspect the o-rings closely

for any cuts, nicks, or wear. Replace if needed.

7. Inspect the springs for wear or loss of tension. They

should be approximately 8.6 mm long in the relaxed

state. If they are shorter than that, they may not allow

the o-ring to seat properly. Replace if needed.

8. Once all parts have been cleaned and inspected,

reinstall the o-ring and spring assemblies into the

valve body.

9. Reinstall the retention caps and gently tighten the

cap.

10. Seal the output of the Calibrator and pump up the unit

to at least 50 % its rated pressure.

11. Release the pressure and repeat several times to

ensure that the o-rings seat properly.

The Calibrator is now ready to use.

Switch Test

To perform a switch test, follow these steps:

Note

This example used a normally closed switch. The

procedure is the same for an open switch but the

display reads OPEN instead of CLOSE.

1. Connect the Calibrator mA and COM terminals to the

switch using the pressure switch terminals and

connect the pump from the Calibrator to the pressure

switch. The polarity of the terminals does not matter.

2. Make sure the vent on the pump is open and zero the

Calibrator if necessary. Close the vent after zeroing

the Calibrator.

20

Page 29

Pressure Calibrator

Maintenance

3. Press

Calibrator will display CLOSE instead of a mA

measurement.

4. Apply pressure with the pump slowly until the switch

opens.

In the switch test mode, the display update rate is

increased to help capture changing pressure

inputs. Even with this enhanced sample rate,

pressuring the device under test should be done

slowly to ensure accurate readings.

5. OPEN is displayed once the switch is open. Bleed the

pump slowly until the pressure switch closes. RCL

appears on the display.

6. Press

switch opened, for when it closed, and for the

deadband.

7. Hold

press

to enter pressure switch test mode. The

S

Note

S to read the pressure values for when the

Sfor three seconds to exit the switch test or

c to reset the switch test.

Maintenance

XW Warning

To avoid possible electric shock, personal

injury, or sudden release of pressure, review

Safety Information before proceeding.

For maintenance procedures not described in this manual,

or if the Calibrator needs repair, contact a Fluke Service

Center. See Contacting Fluke.

In Case of Difficulty

• After removing the Calibrator from the Ex-hazardous

area, check the battery, test leads, pressure module,

and pressure tubing. Follow replacement and

connection instructions properly.

• Review this manual and control drawing to make sure

the Calibrator is used correctly.

If the Calibrator needs repair, and the Calibrator is under

warranty, see the warranty statement for terms. If the

warranty has lapsed, the Calibrator can be repaired and

returned for a fixed fee.

21

Page 30

718Ex 30G/100G/300G

Users Manual

Cleaning

Periodically wipe the case with a damp cloth; do not use

abrasives or solvents.

Calibration

Fluke recommends that the Calibrator be calibrated once

yearly to ensure that it performs according to its

specifications. A calibration manual is available.

Call 1-800-526-4731 from the U.S.A. and Canada. In other

countries, contact a Fluke Service Center.

Replacing the Battery

XW Warning

• To avoid false readings, which could lead to

possible electric shock or personal injury,

replace the battery as soon as the battery

indicator B appears.

• Remove the Calibrator from the Ex-hazardous

area before opening the battery door.

• Use only the battery types listed in the

Approved Battery Table.

Hex Head

Wrench

When

alkaline battery. Refer to Figure 7.

appears on the display, replace the 9 V

B

22

Figure 7. Battery Replacement

alz008f.eps

Page 31

Pressure Calibrator

Maintenance

Approved Batteries

Battery Manufacturer Type

Alkaline, 9 volt Duracell 6LR61/MN1604

Alkaline Ultra, 9 volt Duracell 6LR61/MX1604

Alkaline Energizer, 9 volt Eveready 6LR61/522

Alkaline Power Line Industrial Battery, 9 volt Panasonic 6LR61.9V

23

Page 32

718Ex 30G/100G/300G

Users Manual

Parts and Accessories

Refer to Table 6 for a list of replacement parts and accessories.

Table 6. Replacement Parts and Accessories

Model No. Description Part Qty

AC72 Alligator clips (Black) 1670652 1

AC72 Alligator clips (Red) 1670641 1

BT1 9 V battery, ANSI/NEDA 1604A or IEC 6LR61 822270 or see Battery Table 1

Holster Holster, Red 2096118 1

- Battery Door Assembly 2117013 1

- Test lead set 855742 1

- 718Ex CD-ROM (contains Users Manual) 2097427 1

- 71X Series Calibration Manual 686540 Opt

- 718Ex Control Drawing 2117024 1

24

Page 33

Pressure Calibrator

Specifications

Specifications

Specifications are based on a one year calibration cycle

and apply for ambient temperature from +18 °C to +28 °C

unless stated otherwise. Counts are the number of

increments or decrements of the least significant digit.

Pressure Sensor Input

Max Non-

Model Range Accuracy

30G

-12 to 30 psi

(-83 to 207 kPa)

100G

300G

-12 to 100 psi

(-83 to 690 kPa)

-12 to 300 psi

±0.05 %

of range

(-83 to 2068 kPa)

Temperature coefficient: 0.01 % of range per °C for temperature

ranges -10

°

C to 18 °C and 28 °C to 55 °C

destructive

Pressure

60 psi

(413 kPa)

200 psi

(1.4 mPa)

375 psi

(2.6 mPa)

Pressure Sensor Range and Resolution

O

O

O

2

O

2

2

Model 718Ex

100G Range

and

Resolution

-12.00 to

100.00 psi

-332.2 to

2768.0 inH2O

-332.8 to

2772.9 inH2O

-843.6 to

7030.0 cmH2O

-845.2 to

7043.0 cmH2O

-0.8274 to

6.8950 bar

-827.4 to

6895.0 mbar

-82.74 to

689.50 kPa

-24.43 to

203.60 inHg

-620.6 to

5171.5 mmHg

-0.8437 to

7.0306 kg/cm2

Displayed

Pressure

Units

psi

inH2O at

4 °C

inH2O at

20 °C

cmH2O at

4 °C

cmH2O at

20 °C

bar

mbar

kPa

inHg

mmHg

kg/cm2

Model 718Ex

30G Range and

Resolution

-12.000 to

30.000 psi

-332.16 to

830.40 inH

-332.75 to

831.87 inH

-843.6 to

2109.0 cmH

-845.2 to

2113.0 cmH

-0.8274 to

2.0685 bar

-827.4 to

2068.5 mbar

-82.74 to

206.85 kPa

-24.432 to

61.080 inHg

-620.6 to

1551.4 mmHg

-0.8437 to

2.1090 kg/cm

2

2

Model 718Ex

300G Range

and

Resolution

-12.00 to

300.00 psi

-332.2 to

8304 inH2O

-332.8 to

8318.7 inH2O

-843.6 to

21090 cmH2O

-845.2 to

21129 cmH2O

-0.8274 to

20.685 bar

-827.4 to

20685 mbar

-82.74 to

2068.5 kPa

-24.43 to

610.8 inHg

-620.6 to

15514.5 mmHg

-0.8437 to

21.0918 kg/cm

2

25

Page 34

718Ex 30G/100G/300G

Users Manual

Pressure Module Input

Range Resolution Accuracy

(determined by Pressure Module)

DC mA Input

Range Resolution

24 mA 0.001 mA 0.02 + 2

Accuracy, ±(% of

Reading + Counts)

Temperature coefficient: 0.005 % of range per °C for

temperature ranges -10

°

C to 18 °C and 28 °C to 55 °C

General Specifications

Maximum voltage applied between either mA terminal and earth ground or between the mA terminals: 30 V

Pressure sensor media: Non-corrosive gasses only

Storage temperature: -40 °C to 71 °C

Operating temperature: -10 °C to 55 °C

Relative humidity: 95 % up to 30 °C, 75 % up to 40 °C, 45 % up to 50 °C, and 35 % up to 55 °C

EMC: Complies with EN61326, Criteria C

Pollution Degree 2

26

Page 35

Pressure Calibrator

Specifications

Product Compliance Markings

( II 1 G EEx ia IIC T4

E

F

Ta = -10 °C +55 °C

; Conforms to relevant Australian standards.

Manufactured by Martel Electronics Inc., 1F Commons Drive, Londonderry, NH USA

Additional Safety Information: Complies with CAN/CSA C22.2 No. 1010.2:1995. Complies with ANSI/ISA S82.01-1995.

Complies with IEC 61010-1-95 CAT I, 30 V

Entity Parameters:

Vo, Uo Io Po

7.14 V 1.09 mA 1.9 mW 13.5 μF 240 μF 1000 μF 1.0 H 3.0 H 8.0 H

Kema 04ATEX1061 X

Class I Div. 1 Groups A-D T4

AEx ia IIC T4

Vi, Ui Ii Pi Ci Li

30 V 250 mA 1.88 W 0 μF 0 mH

Co Lo

IIC IIB IIA IIC IIB IIA

Power requirements: See Approved Batteries.

Size: 66 mm H x 94 mm W x 216 mm L (2.60 in H x 3.70 in W x 8.5 in L)

Weight: 992 g (35 oz)

27

Page 36

718Ex 30G/100G/300G

Users Manual

28

Loading...

Loading...