Page 1

Eliminating sensor

errors in loop

calibrations

Calibrating a loop is more than just

4 mA to 20 mA

Significant performance

improvement can realized by

optimizing the loop calibration

measurement system to better

accommodate the unique characteristics of the temperature

sensing element. All temperature probes and their sensing

elements are unique, with

variations in materials, construction and usage, or exposure

to different environments. This

uniqueness continues throughout the useful life of the sensor,

in the form of drift due to

mechanical shock and vibration or to contamination of the

materials when exposed to the

material they are measuring.

Only through periodic verification can these differences and

changes be accommodated,

improving total measurement

performance.

Temperature plays an important role in many industrial and

commercial processes. Examples

range from sterilization in

pharmaceutical companies,

metal heat-treatment to ensure

optimal strength in aerospace

applications, temperature

verification in a cold storage

warehouse, and atmospheric

and oceanographic research. In

all temperature measurement

applications, the sensor strongly

affects the results; unfortunately, many measurements are

made without optimizing the

system to get the best performance from the temperature

transducer.

The majority of process

temperature measurements are

performed using a sensing element connected to a transmitter.

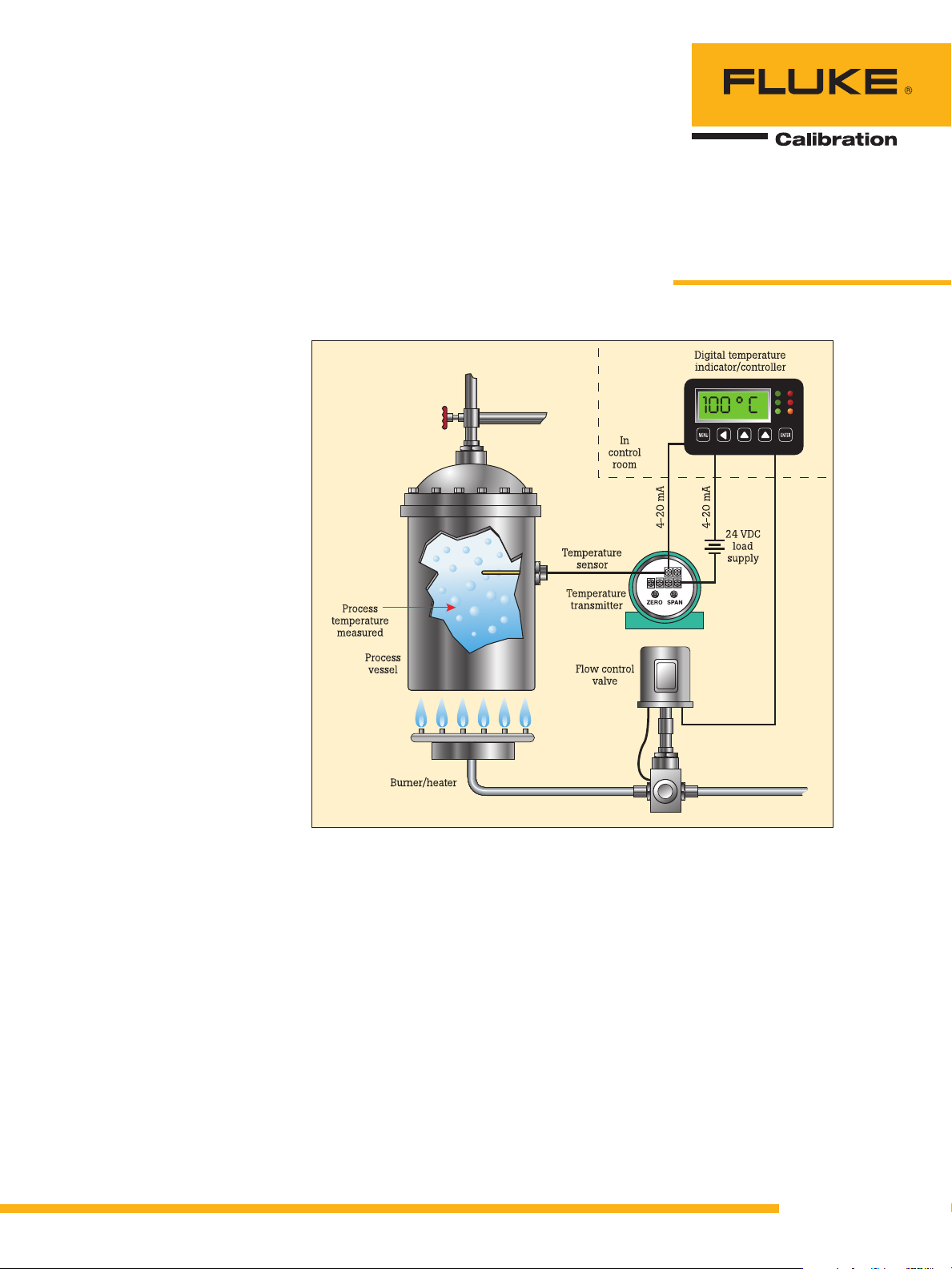

Figure 1. Diagram of a typical process temperature measurement system.

Figure 1 shows a diagram of a

common configuration.

In many applications, it is

common to verify the elements

of the measurement system

separately, but in doing so,

significant improvements made

possible by considering the

system as a whole are ignored.

One of the main reasons the

elements are verified or calibrated separately is that it is

often considered to be more

efficient. Verifying the measurement component is done

simply and quickly with an

electronic thermocouple (TC) or

Application Note

resistance temperature detector

(RTD) simulator. This approach

does not verify the performance

of the associated temperature

probe, and assumes all probes

are identical and closely follow

some standard. In practice, no

two probes are identical; they

all vary from the ideal standard,

and over time and usage their

characteristics change. Understanding how probes vary from

the ideal will allow you to optimize the measurement system

to achieve the best performance.

From the Fluke Calibration Digital Library @ www.flukecal.com/library

Page 2

Ideal curve

Actual curve

Class A tolerance

Class B tolerance

0 °C 400 °C

Figure 2.

System accuracy improved by more than 75 %!

1.2

0.8

0.4

RSS Error ± °C

0

Figure 3. System accuracy improvement achieved with a

calibrated Pt100 Sensor.

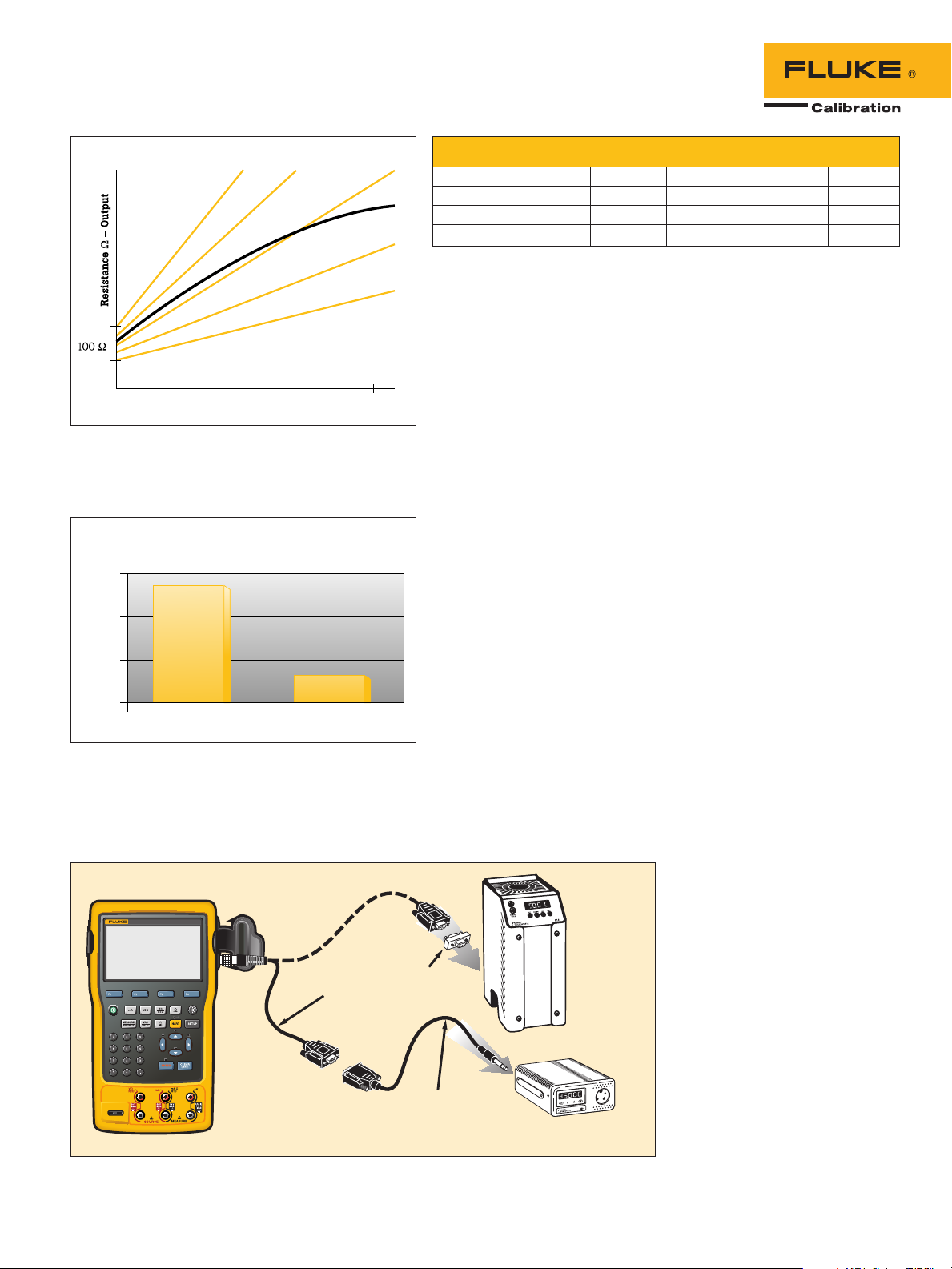

DOCUMENTING PROCESS CALIBRATOR

754

Figure 4. Connecting a Fluke 754 to a Fluke Calibration dry-well.

Temperature °C – Input

Standard Sensor Calibrated Sensor

2514 dry-well

interface cable

System accuracy comparison measuring 150 °C using a Pt100 (IEC751)

RTD with a transmitter span of 0 to 200 °C

Standard RTD Accuracy Characterized RTD Accuracy

Rosemount Model 644H ± 0.15 °C Rosemount Model 644H ± 0.15 °C

Standard RTD ± 1.05 °C Matched (calibrated) RTD ± 0.18 °C

Total system ± 1.06 °C Total system ± 0.23 °C

Total system accuracy calculated using RSS statistical method.

Table 1

Rosemount Inc. uses the

example provided in Table 1 for

information on the possible performance improvement of their

Model 644H Smart Temperature Transmitter. To achieve

this performance improvement,

the Rosemount 644H is given

information (Callendar Van

Dusen Coefficients) that allows

it to correct for the unique

performance of the temperature

sensing element, in this case a

standard IEC751 Pt100 sensor.

Dry-wells and micro-baths

are good choices for verifying

the performance of temperature probes and other related

sensors. But they do not have

the capability to calibrate the

transmitter’s output or readout and, by themselves, do

not allow the entire measurement loop to be optimized. A

heat source, combined with an

intelligent electronic process

calibrator that is capable of

calibrating the transmitter and

readout, is required if the above

performance improvement is to

be realized and maintained.

By combining the automating

and documenting capabilities

of the Fluke 754 Documenting Process Calibrator with

Fluke Calibration’s intelligent

and stable family of field drywells and micro-baths, you

have the capability to test the

entire loop. This combination of

equipment allows you to easily

verify the characteristics of the

temperature sensor and measurement electronics. Using this

information, the entire loop can

be adjusted to optimize system

measurement performance.

Below are some examples of

how to optimize the performance of your measurement

system using these instruments.

The Fluke 754 is connected

to a Fluke Calibration dry-well

or micro-bath by way of a serial

RS-232 interface cable. Version

2.3 or greater firmware for the

754 is required. The firmware

version is displayed briefly on

the display of the 754 during

power-up. If you do not have

the required firmware, contact

your authorized Fluke distributor for information regarding an

upgrade. The serial cable may

be obtained from either your

authorized Fluke distributor or

directly from your Fluke Calibration representative. The heat

Null modem

Fluke Calibration

Dry-well

(DB9)

source is connected to the 754

pressure port and is accessed

by the 754 TC/RTD source

key. Due to the length of these

tests, it is recommended that a

fully charged battery or battery

eliminator for the 754 be used.

A diagram of the connection of

Fluke Calibration

3.5 mm

interface cable

Fluke Calibration

Dry-well (3.5 mm)

this equipment is pictured in

Figure 4.

In many process applications,

the instrumentation of choice

for temperature measurements

2 Fluke Corporation Eliminating sensor errors in loop calibrations

Page 3

is a transmitter that accepts the

output from the temperature

sensor and drives a 4-20 mA

signal back to the PLC, DCS or

indicator. This example describes

one method for verifying performance and offers to optimize

this measurement to improve

performance.

To perform this test, the RTD

sensor is removed from the

process and inserted in to the

dry-block calibrator. The mA

connections from the transmitter are connected directly to

the 754 Documenting Process

Calibrator (see Figure 5). In

most applications, this solution

provides adequate performance.

But if your application includes

a uniquely-shaped sensor, you

might want to consider the use

of a micro-bath. If increased

heat source accuracy is needed,

the use of a reference thermometer combined with the 754’s

User-Entered Values feature can

be used. See application note

1263925 for more information

on 754 User-Entered Values.

Once connections are made,

you are ready to acquire transmitter configuration (if you

have a transmitter with HART

communications), set the test

parameters, and configure the

calibrator for mA measurement

and dry-well control as the

sourcing parameter.

Pressing the HART key on

the 754 allows the calibrator to acquire the transmitter

configuration from a transmitter with HART communication

capability. Following is a sample

of this acquired configuration

information.

Pressing the HART key on

the 754 again presents the

following screen with several

options for configuring the calibrator to the correct parameters

for this test. For the purposes

of this example, we’ll use the

transmitter configured to output

a 4-20mA signal; therefore the

correct configuration of the 754

is to measure mA and source

temperature via the dry-well.

Pressing the AS FOUND soft

key on the 754 provides access

to parameters needed to configure an automated test. Below

is a typical definition that will

test the measurement system

from 50°C to 150°C sourcing

temperatures using a dry-well

in ascending order.

After the test has been

defined, the Fluke 754 will take

over and run the test recording the sourced temperature,

measured output of the transmitter, in mA. At the end of the

test, the results will be displayed on the screen, allowing

the test technician to evaluate

the results and take corrective

action if needed. Following is

Figure 5. Fluke 754 and Fluke Calibration dry-well calibrating a

4-20 mA transmitter and temperature sensor.

an example of the results.

One method of optimizing

this system to minimize error

is to shift the URV or LRV of

the transmitter to the values

measured by the 754. With a

transmitter with HART capabilities, this is easily done via

the 754, by simply entering

new values in the HART SETUP

3 Fluke Corporation Eliminating sensor errors in loop calibrations

Page 4

screen below. With an analog

transmitter, you will need to

mechanically adjust the Zero

and Span adjustments when

sourcing the appropriate temperature values. The 754 has

a convienent menu key that

allows you to easily set the correct value on the dry-well with

a single button press.

a sensor and the ability to

perform curve-fitting of the

collected data.

The method of characterizing a probe is similar to the

procedure above, but rather

than measuring the output of

the transmitter, the output of

the sensor is connected directly

to the 754. An example of data

collected by a 754 on a temper-

Calibrating and adjusting

measurement systems using

characterized sensors and

ature sensor is shown below.

Data like this can be entered

calibration constants

Another method of reducing

uncertainty and optimizing temperature measurement systems

is to carefully characterize the

temperature sensor, calculate

correction coefficients and load

these correction coefficients into

the measurement equipment.

This is the method used in the

Rosemount 644H example on

the previous page. This method

does a better job of reducing

the error in the measurement

system that comes from the

sensor. But it requires transmitters that have a correction

into Fluke Calibration’s software

using the screens in Figure 6

and then unique CVD constants

calculated for that probe.

These coefficients can then

be entered into a suitable

measurement device that allows

its linearizations to match the

characteristics of the probe.

or linearization algorithm that

can accommodate the sensor.

For example, Platinum RTDs

typically use the CallendarVan Dusen (CVD) equation for

linearizing the sensor’s output.

A characterized sensor will

provide unique CVD coefficients

that can be input into the transmitter, allowing its conversion

algorithm to more closely match

the unique characteristics of the

Summary

Using a dry-well in combination with a process calibrator

allows measurement systems

to be verified and adjusted to

optimize measurement performance. By verifying the entire

measurement system, unique

characteristics of the sensing

element can be combined with

the measurement electronics

sensor.

The Fluke 754 connected

with a dry-well can help

to collect the necessary

information to characterize the

sensor, but additional software

and resources will be needed

to take this data and generate

new CVD constants. Examples

of the required software include

Fluke Calibration’s TableWare.

Other software that could

be used include Mathcad,

Mathematica, Maple or Excel.

But these packages require

considerable knowledge of

the equations used to linearize

4 Fluke Corporation Eliminating sensor errors in loop calibrations

Figure 6. TableWare software from Fluke Calibration calculates unique

CVD constants that match the characteristics of the probe.

to minimize measurement

error. This can result in a

significant reduction in measurement errors. The Fluke 754

Documenting Process Calibrator, combined with a Fluke

Calibration dry-well makes this

process faster and easier.

Fluke Calibration. Precision, performance, confidence.

Fluke Calibration

PO Box 9090,

Everett, WA 98206 U.S.A.

For more information call:

In the U.S.A. (877) 355-3225 or Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or Fax (905) 890-6866

From other countries +1 (425) 446-5500 or Fax +1 (425) 446-5116

Web access: http://www.flukecal.com

©2004-2011 Fluke Corporation. Specifications subject to change without notice.

Printed in U.S.A. 11/2011 2148146C A-EN-N

Modification of this document is not permitted without written permission from Fluke Corporation.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

™

Loading...

Loading...