Page 1

717 Series

Pressure Calibrators

Instruction Sheet

Introduction

The Fluke 717 Series Pressure Calibrators are compact, battery-powered, 5-digit

instruments that perform the following calibration and measurement functions:

• Calibrates P/I (pressure to current) transmitters

• Measures pressure using a 1/8-inch NPT pressure fitting and an internal

pressure sensor

• Measures pressure via a Fluke 700 Series Pressure Module

• Measures current up to 24 mA

• Sources loop voltage (to 24 V dc)

• Displays simultaneously pressure and current measurements

• Calculates mA percentage in Percent Mode

• Calculates mA error in Percent Error Mode

The 717 Pressure Calibrators (hereafter, “the Calibrator”) include:

• 717 1G

• 717 30G

• 717 100G

• 717 300G

• 717 500G

Full Scale Pressure sensor is as listed in the “Specifications” section under

“Pressure Specifications”. The Calibrator is an IEC 61010, CAT I 30 V, Pollution

Degree 2 instrument. A CAT I instrument is designed to protect against transients

from low-energy sources like, for example, electronic circuits or a copy machine.

The Calibrator comes with a holster, an installed 9 V battery, a set of test leads and

alligator clips, and a 14-language instruction sheet pack. If the Calibrator is

damaged or something is missing, contact the place of purchase immediately.

• 717 1000G

• 717 1500G

• 717 3000G

• 717 5000G

®

PN 690013 March 1998, Rev. 2, 3/06 (English)

1998-2006 Fluke Corporation. All rights reserved. Printed in USA

Page 2

Input Units

The Calibrator measures and displays pressure sensor inputs in the units listed

below:

• Psi

• inH2O@4°C

• inH2O@20°C

• cmH2O@4°C

• cmH2O@20°C

• bar

• mbar

• kPa

• inHg@0°C

• mmHg

• kg/cm

If inappropriate units are selected, the output of Fluke 700P pressure modules can

be too low to be displayed or can cause the Calibrator to display OL (overload).

Refer to Table 1 for pressure unit and range compatibility.

psi All kPa All

inH2O Through 3000 psi inHg All

cmH2O Through 1000 psi mmHg Through 3000 psi

bar 15 psi and above kg/cm2 15 psi and above

mbar Through 1000 psi

2

Table 1. Pressure Unit and Range Compatibility

Units Range Units Range

Symbols

Symbol Meaning

+

J

W

X

f

T

ON / OFF button

Earth ground

Caution: Important information. See instruction sheet

Hazardous voltage, risk of electric shock

Pressure

Double insulated

M Battery

$

P

F

Canadian Standards Association

Conforms to European Union requirements

Direct current

Page 3

Safety

A "XW Warning" identifies conditions or actions that pose hazards to the user.

A "W Caution" identifies conditions and hazards that may damage the Calibrator

or equipment under test.

XW Warnings

To avoid electric shock, injury, or damage to the Calibrator:

• Use the Calibrator only as described in this Instruction Sheet.

• Using the Calibrator in a manner not specified by the manufacturer might

impair the protection provided by the Calibrator.

• Do not use the Calibrator to make measurements in a CAT II, CAT III, or

CAT IV environment.

CAT I equipment is designed to protect against transient from high-

voltage, low-energy sources, such as electronic circuits or a copy

machine.

• Do not use the Calibrator around explosive gas, vapor, or dust.

• Inspect the Calibrator before use. Do not use it if appears damaged.

• Check the test leads for continuity, damaged insulation, or exposed metal.

Replace damaged test leads.

• Never apply more than 30 V between any two terminals, or between any

terminal and earth ground.

• Use the proper terminals, mode, and range for your measuring or sourcing

application.

• To prevent damage to the unit under test, put the Calibrator in the correct

mode before connecting the test leads.

• When making connections, connect the COM test lead before the live lead;

when disconnecting, disconnect the live lead before the COM lead.

• Never use the Calibrator with the case open.

• Make sure the battery door is closed before you use the Calibrator.

• Replace the battery as soon as the M (low battery) symbol appears to

avoid false readings that can lead to electric shock.

• Remove test leads from the Calibrator before opening the case or battery

door.

• To avoid a violent release of pressure in a pressurized system, shut off the

valve and slowly bleed off the pressure before you attach or detach the

pressure sensor or Pressure Module fitting to the pressure line.

When servicing the Calibrator, use only specified replacement parts.

When using pressure pressure modules

Calibrator module connections, follow all procedures in the pressure

module instruction sheet.

When using pressure sensor connections

Calibrator or equipment to which it is attached:

• To avoid overpressure damage, do not apply pressures that exceed

ranges listed under “Pressure Specifications”.

W Caution

, to avoid damage to the

W Caution

, to avoid damage to the

Page 4

• To avoid corrosion in the pressure sensor, use the Calibrator only

with media compatible with glass, ceramic, silicon, RTV, nitrile

(Buna -N) type 303 stainless steel, and nickel.

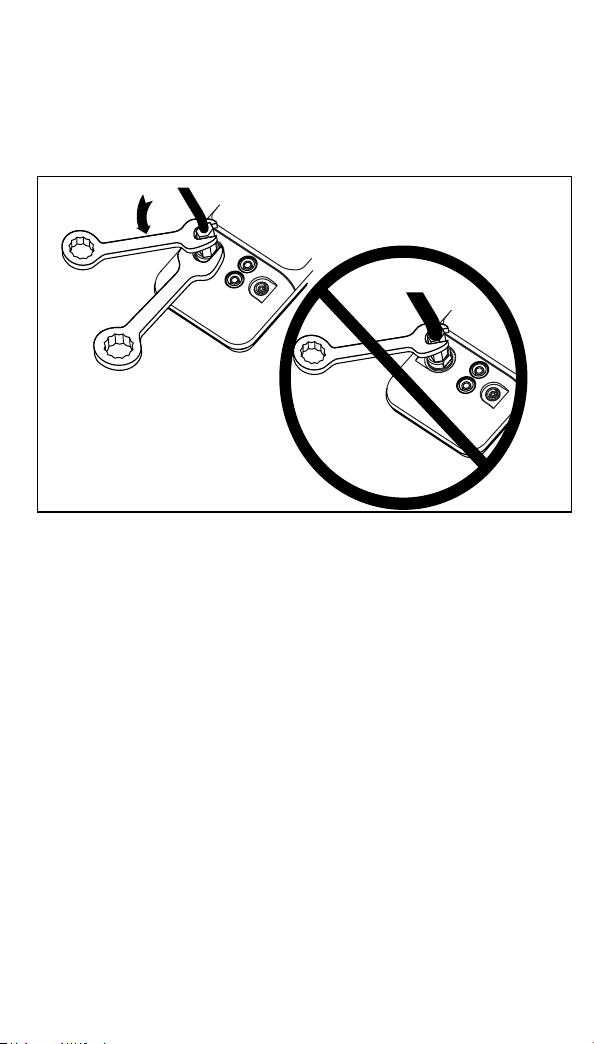

• To avoid damaging the Calibrator, do not apply torque between the

pressure fitting and the Calibrator case. See Figure 1 for the proper

technique.

Hold in

fixed

position

Figure 1. Proper Tightening Method

qo001f.eps

Getting Acquainted

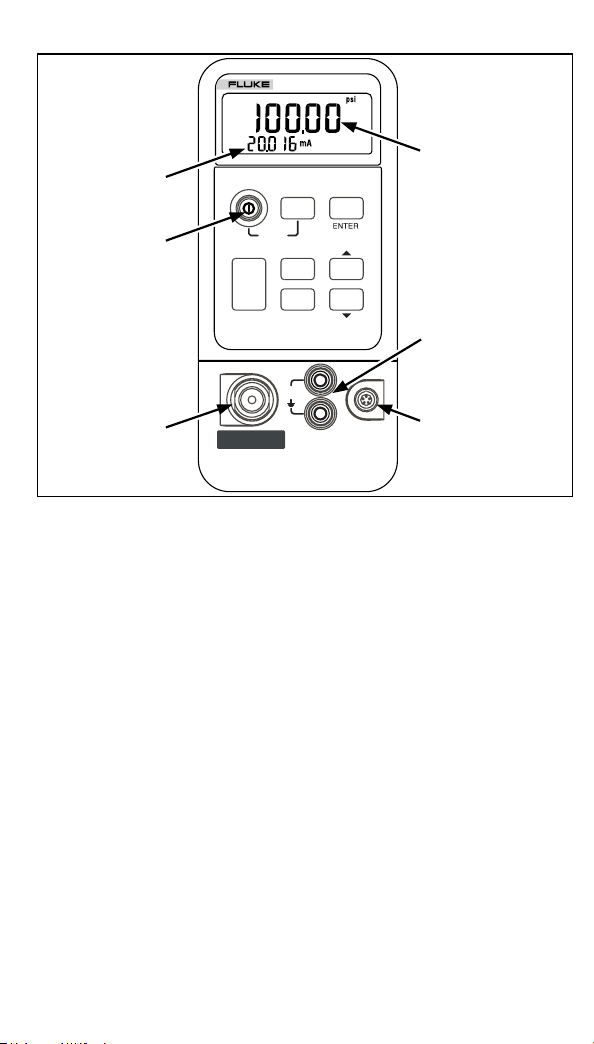

Press O to turn the Calibrator ON and OFF. The Calibrator displays pressure and

current measurements simultaneously.

The upper part of the display shows the applied pressure.

Press U to select a different unit. When you turn the Calibrator OFF, the next

time you turn the Calibrator back ON it returns to the pressure unit you last used.

The lower part of the display shows the current (up to 24 mA) applied to the

current (mA) inputs. See Figure 2.

Power Saver

The Calibrator automatically turns off after 30 minutes of inactivity. To reduce this

time or disable this feature:

1. With the Calibrator OFF, press O.

2. P.S. xx is displayed, where xx is the turn-off time in minutes. OFF means the

power saver is disabled.

3. Press h (W) to decrease or a (

4. To disable, press h until the display shows OFF.

The Calibrator resumes normal operation after 2 seconds.

Z) to increase the turn-off time.

Page 5

Current mA

measurement

On/Off Button

ZERO

LOOP

POWER

717 100G

HOLD

UNITS

MIN

MAX

SWITCH

TEST

PRESSURE

CALIBRATOR

DAMP

mA

MODE

BAROMETRIC ADJ.

HOLD

Pressure

measurement

Current input

Pressure

module input

Pressure

sensor input

RANGE

-12 TO 100 PSI

RANGE

-83 TO 690 kPa

MAX 200 PSI 1.4 mP

I 69 mPa

mA

30V

MAX

a

COM

Figure 2. The Pressure Calibrator (717 100G is Shown)

qo005f.eps

Page 6

Pushbutton Functions

Button Function

Press to select a pressure unit. All units are available when the

pressure sensor input is used. For higher pressure module inputs,

U

D

ENTER

Z

N

S

Z

a

h

Y

inappropriate units are not available.

Press

Press to toggle pressure reading damping on and off. With

damping on, the display does not update as quickly.

Press to confirm selection of 0% and 100% output parameters.

Press to zero the pressure display. (Vent pressure to atmosphere

before pressing.)

With an absolute pressure module, see instructions below.

Press to read the minimum pressure and current readings since

power was turned on or the registers were cleared. Press again to

read the maximum pressure and current readings since power was

turned on. Press and hold to clear the MIN/MAX registers.

Press to perform switch test.

Press to toggle the mA display mode between mA, mA

Percent, and mA Percent Error.

Press h to freeze the display.

The

again to resume normal operation.

In ZERO mode, press to decrease barometric pressure.

on while pressing U to source loop voltage.

O

gsymbol appears on the display. Press h

Switch Test

To perform a switch test, do the following:

This example uses a normally closed switch. The procedure is the same for

an open switch but the display reads OPEN instead of CLOSE.

1. Connect the Calibrator mA and COM terminals to the switch using the

pressure switch terminals and connect an external pump between the

Calibrator and the pressure switch using a tee fitting. The polarity of the

terminals does not matter.

2. Make sure the vent on the pump is open and zero the Calibrator if necessary.

Close the vent after zeroing the Calibrator.

3. Press S to enter pressure switch test mode. The Calibrator will display

CLOSE instead of a mA measurement.

4. Apply pressure with the pump slowly until the switch opens.

In the switch test mode, the display update rate is increased to help capture

changing pressure inputs. Even with the enhanced sample rate, pressuring

the device under test should be done slowly to ensure accurate readings.

Note

Note

Page 7

5. OPEN is displayed once the switch is open. Bleed the pump slowly until the

pressure switch closes. The recall icon appears on the display.

6. Press S to read the pressure values for when the switch opened, for when

it closed, and for the deadband

7. Hold S for 3 seconds to reset Switch Test mode; hold any other key for 3

seconds to exit.

Zeroing with Absolute Pressure Modules

To zero, adjust the Calibrator to read a known pressure as follows:

1. Press and hold Z.

2. Press

a

Z (

) to increase or Y ( h)to decrease the Calibrator reading

to equal the applied pressure.

3. Release Z to exit the zeroing procedure.

For all but the 700PA3 module, the known pressure can be barometric, if it is

accurately known. An accurate pressure standard can also apply a pressure within

range for any absolute pressure module. To convert measurement units:

• 1 bar = 750 mmHg (1 mmHg = 0.0013332 bar)

• 1 psi = 2.036 inHg (1 inHg = 0.49115 psi).

Sourcing Loop Voltage

To use the Calibrator to supply loop power (24 V dc) to a current transmitter that

is disconnected from the system:

1. With power off, hold down Uwhile pressing OON.

The LOOP POWER icon appears on the display.

2. With the transmitter disconnected from normal loop power, connect the

Calibrator in series with the instrument current loop as shown in Figure 3.

In addition to mA, the current can be displayed in two alternative modes:

• Percent Mode- The current is displayed as a percentage based on a 4-20 mA

scale.

• Percent Error Mode- Transmitter current output error is displayed. Error is

calculated based on a configurable zero and span pressure and a 4-20 mA

scale.

3. Measure loop current in the mA measurement display.

4. Press O OFF to deactivate the 24 V dc supply when you are done sourcing

loop voltage.

SIGNAL

+

–

TEST

Figure 3. Sourcing Connections

qo007f.eps

Page 8

Percent Error Setup

Press and hold a. After 3 seconds the set icon and 0% appears on the lower

display. Use

then press D(ENTER) key to confirm selection. Press a. 100% is displayed

on the lower display. Use

calculation. Press D (ENTER) to confirm the selection and exit.

Wand

to adjust the 0% point for the Percent Error calculation,

X

Wand

to adjust the 100% point for the Percent Error

X

Calibrating a P/I Transmitter

To calibrate a P/I (pressure to current) transmitter:

1. Open the pump vent and zero the Calibrator before applying pressure.

Repeat frequently to ensure accuracy.

2. Apply a pressure to the transmitter and measure the transmitter’s current

loop output. OL (overload) is displayed at full scale.

3. Connect the Calibrator to the transmitter as shown in Figure 4 or Figure 5.

The Calibrator recognizes only the pressure module if both types of

connection are in place.

Page 9

PRESSURE

717 100G

CALIBRATOR

HOLD

UNITS

DAMP

ENTER

LOOP

POWER

MIN

mA

MODE

MAX

BAROMETRIC ADJ.

ZERO

SWITCH

HOLD

TEST

Black

100psi 689kPa

RANGE

MAX 200 PSI 1.4 mP

RANGE

-12

-83

mA

mA

30V

MAX

COM

COM

O 100 PSI

MAX

O 690 kPa

MAX

a

T

mPa

T

I 69

+

Red

SIGNAL

–

TEST

Figure 4. Connecting to an Internal Pressure Sensor

qo002f.eps

Page 10

Calibrating a P/I Transmitter (Cont.)

SIGNAL

+

Red

Pressure

Module

–

TEST

Black

ZERO

RANGE

100psi 689kPa

-12 TO 100 PSI

RANGE

-83 TO 690 kPa

MAX 200 PSI 1.4 mP

POWER

I 69 mPa

LOOP

a

717 100G

HOLD

UNITS

MIN

MAX

SWITCH

TEST

30V

MAX

PRESSURE

CALIBRATOR

DAMP

ENTER

mA

MODE

BAROMETRIC ADJ.

HOLD

mA

COM

Figure 5. Connecting to a Pressure Module

qo006f.eps

Page 11

Maintenance

XW Warning

To avoid electric shock, personal injury, or damage to the Calibrator:

• Do not service this product other than as described in this

Instruction Sheet unless you are a qualified technician and have

the required equipment and service information.

• Remove any input signals prior to removing test leads and opening

case.

• When servicing the Calibrator, use only specified replacement

parts.

• Do not allow water to get in the case.

For maintenance procedures not described in this Instruction Sheet, contact a

Fluke Service Center.

In Case of Difficulty

• Check the battery, test leads, and pressure tubing. Replace as necessary.

• Review this Instruction Sheet to make sure you are using the Calibrator

correctly.

If the Calibrator needs repair, and the Calibrator is under warranty, see the

warranty statement for terms. If the warranty has lapsed, the Calibrator will be

repaired and returned for a fixed fee.

Cleaning

Periodically wipe the case with a damp cloth and detergent; do not use abrasives

or solvents.

Calibration

Calibrate your Calibrator yearly to ensure that it performs to specification. A

Calibration Manual (Fluke PN 686540) is available.

Replacing the Battery

XW Warning

To avoid false readings, which could lead to electric shock or injury,

replace the battery as soon as M (low battery indicator) appears on

the display.

Use only a single 9 V battery, properly installed, to power the

Calibrator.

The Calibrator uses a single 9 V, alkaline battery (ANSI/NEDA 1604A or IEC

6LR61).

To replace the battery (see Figure 5):

1. Turn the Calibrator OFF and remove the test leads from the terminals.

2. Remove Calibrator from its holster.

3. Remove the battery door on the back of the Calibrator as shown.

4. Lift the battery from the battery receptacle.

5. Attach the replacement battery to the leads, place the battery back in the

battery receptacle.

6. Secure the battery door.

7. Return the Calibrator to its holster.

Page 12

Figure 6. Battery Installation

it07f.eps

Page 13

Replacement Parts and Accessories

1

2

3

4

5

6

7

8

9

13

12

11

16

15

10

14

qo004f.eps

Item Part or Accessory No. Qty

A 717 case top for 300G and below

A 717 case top for 500G and above

B 717 1G Top Case Decal

B 717 30G Top Case Decal

B 717 100G Top Case Decal

B 717 300G Top Case Decal

B 717 500G Top Case Decal

B 717 1000G Top Case Decal

B 717 1500G Top Case Decal

B 717 3000G Top Case Decal

B 717 5000G Top Case Decal

C Keypad

D Spacer for pressure input

E O-ring for pressure input

F 9 V battery, ANSI / NEDA 1604A or IEC LR61

G Case bottom

2546258 1

2546264 1

2546993 1

2547000 1

2547017 1

2547021 1

2547039 1

2547042 1

2547056 1

2547063 1

2547074 1

2113087 1

687449 1

146688 1

614487 1

2397526 1

Figure 7. Replacement Parts and Accessories

Page 14

Item Part or Accessory No. Qty

H Case screw

I Battery door fasteners

J Non-skid foot

K Battery door

L Alligator clips

M Test lead set

N Holster, Yellow

O 717 30G LCD Bezel

P 717 100G LCD Bezel

P 717 300G LCD Bezel

P 717 500G LCD Bezel

P 717 1000G LCD Bezel

P 717 1500G LCD Bezel

P 717 3000G LCD Bezel

P 717 5000G LCD Bezel

P 717 1G LCD Bezel

Q Instruction sheets (14)

832246 3

948609 2

824466 2

609930 1

AC72 1

TL75 1

2074033 1

663997 1

1638728 1

2545073 1

2545099 1

2545105 1

2545110 1

2545122 1

2545131 1

2545064 1

690013 --

Figure 7. Replacement Parts and Accessories (cont.)

Specifications

Accuracy is specified for 1 year after calibration at operating temperatures of −10

°C to + 55 °C.

Pressure Specifications

Model Range SI Range Metric Max SI Max Metric

717-1G (-1 to 1) PSI (-7 to 7) kPa 5 PSI

717-30G (-12 to 30) PSI (-83 to 207) kPa 60 PSI

717-100G (-12 to 100) PSI (-83 to 690) kPa 200 PSI

717-300G (-12 to 300) PSI

717-500G (0 to 500) PSI

717-1000G (0-1000) PSI

717-1500G (0-1500) PSI

(-83 to 2068) kPa

or 2.1 mPa

3447 kPa or

3.4 mPa

6895 kPa or

6.9 mPa

10342 kPa or

10.3 mPa

375 PSI

1000 PSI

2000 PSI

3000 PSI

34.5 kPa

413 kPa

1379 kPa or

1.4 mPa

2586 kPa or

2.6 mPa

6895 kPa or

6.9 mPa

13790 kPa

or 13.8 mPa

20684 kPa

or 20.7 mPa

Page 15

Pressure Specifications (cont.)

Model Range SI Range Metric Max SI Max Metric

20684 kpa or

20.7 mPa

34474 kPa or

34.5 mPa

± ( % of Reading + Counts)

6000 PSI

10000 PSI

Accuracy,

717-3000G (0-3000) PSI

717-5000G (0-5000) PSI

Accuracy: Pressure Accuracy is +/- 0.05% of range

Temperature coefficient:

0.01 % of range per °C for temperature ranges of between −10 °C to

18 °C and 28 °C to 55 °C.

Pressure Display, Pressure Module Input

Range Resolution Accuracy

Refer to the Instruction Sheet for the pressure module

DC mA Input

Range

24 mA 0.001 mA 0.015 + 2

Overload protection:

Fuseless overvoltage protection

Temperature coefficient:

0.005 % of range per °C for temperature ranges of between −10 °C to

18 °C and 28 °C to 55 °C.

Loop Supply

24 V dc nominal

Resolution

41369 kPa

or 41.4 mPa

68948 kPa

or 69 mPa

General Specifications

Maximum voltage applied between either an mA terminal and earth ground or

between the mA terminals:

30 V

Storage temperature:

−40 °C to 60 °C

Operating temperature:

−10 °C to 55 °C

Operating altitude:

3000 meters maximum

Relative humidity:

95 % up to 30 °C;

75 % up to 40 °C;

45 % up to 50 °C;

35 % up to 55 °C

Vibration:

Random 2 g, 5 Hz to 500 Hz, per MIL -PRF_28800F, Class 2

Shock:

1 meter drop, per IEC 61010-1

Page 16

Safety Compliance:

IEC 61010-1 2nd Edition CAT I, 30 V;

Pollution Degree 2

CSA C22.2 No. 1010.1;

ANSI/ISA S82.02. Maximum Transient Overvoltage: 240 VAC for 10

Seconds.

CE:

Complies with EN 61326 Class A; EN61010-1

Protection Class: Class II, Double Insulated

Power requirements:

Single 9 V battery (ANSI/NEDA 1604A or IEC 6LR61)

Size:

34.9 mm H x 87 mm W x 187 mm L

(1.55 in H x 3.41 in W x 7.35 in L);

With holster and Flex-Stand: 52 mm H x 98 mm W x 201 mm L (2.06 in H x

3.86 in W x 7.93 in L)

Weight:

369 g (13 oz);

With holster and Flex-Stand: 624 g (22 oz)

Contacting Fluke

To contact Fluke for product information, operating assistance, service, or to get

the location of the nearest Fluke distributor or service center, call:

USA: 1-888-99-FLUKE (1-888-993-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-675-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

Or visit Fluke's web site at: www.fluke.com

Register your Calibrator at: http://register.fluke.com

Address correspondence to:

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090, P.O. Box 1186,

Everett, WA 98206-9090 5602 BD Eindhoven

U.S.A. The Netherlands

Limited Warranty & Limitation Of Liability

This Fluke product will be free from defects in material and workmanship for 3 years from

the date of purchase. This warranty does not cover fuses, disposable batteries, or damage

from accident, neglect, misuse, alteration, contamination, or abnormal conditions of

operation or handling. Resellers are not authorized to extend any other warranty on Fluke’s

behalf. To obtain service during the warranty period, contact your nearest Fluke authorized

service center to obtain return authorization information, then send the product to that

Service Center with a description of the problem.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER WARRANTIES, SUCH AS FITNESS

FOR A PARTICULAR PURPOSE, ARE EXPRESSED OR IMPLIED. FLUKE IS NOT LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES,

ARISING FROM ANY CAUSE OR THEORY. Since some states or countries do not allow the

exclusion or limitation of an implied warranty or of incidental or consequential damages,

this limitation of liability may not apply to you.

.

.

11/99

Loading...

Loading...