Page 1

Transmitter Calibration

754

DOCUMENTING PROCESS CALIBRATOR

with the Fluke 750 Series

Documenting Process Calibrator

Application Note

The precision sourcing and measurement

capabilities of the rugged Fluke Documenting

Process Calibrator (DPC) make it an ideal choice

for the calibration of process instrumentation.

The following examples show how to address transmitter calibrations quickly and effectively using the

Fluke 753 or 754 Documenting Process Calibrators.

Calibrating a 2 Wire Thermocouple

Transmitter with the Fluke 750 Series

Documenting Process Calibrators

The transmitter in this example is a 2 wire transmitter (needs loop power). The input stimulus for

this device is from a type K thermocouple with an

input range of 100 °C to 300 °C at 0 % and 100 %.

The output drawn against loop power is 4-20 mA

at 0 % and 100 % with a tolerance of 0.25 %. The

steps below show how to: 1) perform a three point

ascending (3↑) As Found (pre-adjustment) test at

0-50-100 %, and Tag the results, 2) adjust the

zero and span (span = 100 %) of the transmitter,

then 3) perform a three point ascending As Left

(post-adjustment) test at 0-50-100 %, Tag those

results and review them in memory.

Rosemount 444

1. Connect a type K miniconnector into the “TC” input

of the DPC and connect to

the thermocouple input of

the transmitter (Figure 1). It

is necessary that you use the

correct type of mini-connector for this connection to the

DPC.

2. Connect the center two terminals of the DPC to the connections on the transmitter

where loop power is applied

(Figure 1).

Note: If you prefer to use house

loop power rather than supplying

loop power from the DPC, connect

these two leads in series with the

loop supply to the transmitter.

3. Once your connections are

made, starting from the DPC

power up state (or measure

screen), select the “mA” button to measure milliamps

(Figure 2).

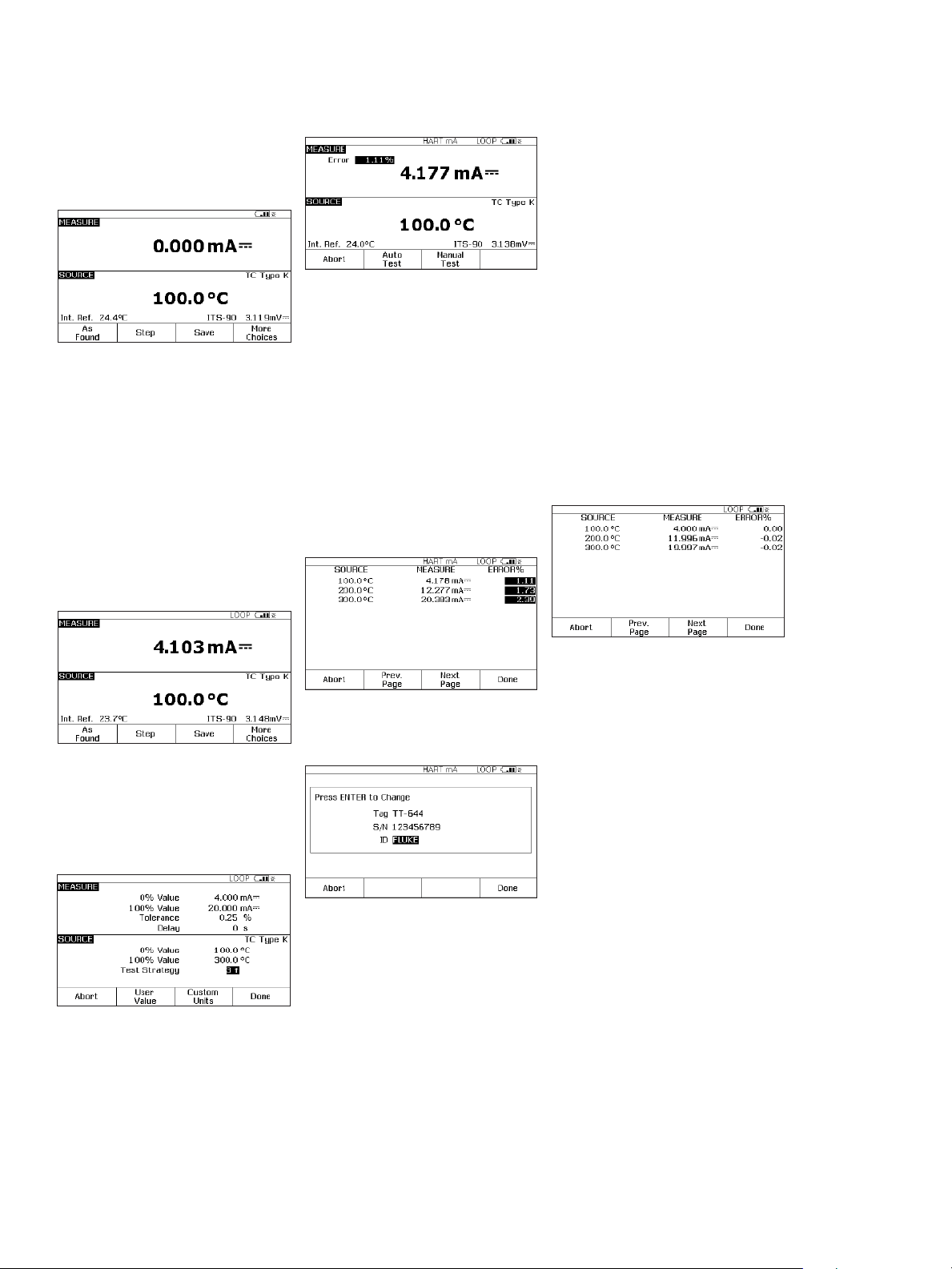

Figure 2.

4. Next depress the “MEAS/

SOURCE” button; now you are

in the source screen.

Since you want to source a

thermocouple, press “TC/RTD”

once. Press ENTER to select

TC. Use the down arrow to

move the cursor to “K” and

then press “ENTER.” Select

“Linear T” and press ENTER.

The DPC will respond with

????? asking for a temperature to source. Depress “100”

and “ENTER” (Figure 3).

Figure 3.

Figure 1.

TEST DC PWR

++

––

Fluke DPC

Page 2

5. Next press the “MEAS/

SOURCE” button once and

you will be in the split screen

mode (Figure 4).

Figure 4.

Note: Skip to step 7 if you are

measuring current in series using

the house loop power source

mentioned in step (2).

6. Next, depress the “SETUP”

button on the DPC. The cursor

should begin on loop power.

Depress “ENTER,” down

arrow until the DPC cursor

is on Enabled and depress

“ENTER.” Next depress the

“Done” softkey (Figure 5).

Figure 7.

8. Select “Auto Test,” and watch

the DPC take 0 %, 50 % and

100 % measurements of current (4, 12 and 20 mA nominal) while sourcing 100 °C,

200 °C and 300 °C.

9. Once the DPC has completed

this evaluation, it will display

the post test summary screen

with the SOURCE, MEASURE

and ERROR columns. Failures

in the error column will be

in reverse video (Figure 8).

Depress “Done.”

0.25 %. As long as the error

exceeds .25 % the error window in the measure half of

the screen will be in reverse

video. Adjust the zero on the

transmitter until the error is

less than 0.25 %. Next, select

“Go to 100 %” and adjust the

transmitter span in the same

way. You may also “Go to

50 %” to check linearity at

mid-span.

12. After adjustment is complete,

select “As Left,” “Done” and

“Autotest.” Watch the 0-50100 % evaluations. If the

adjustment was successful,

all the errors in the post run

summary should be in normal

video (or less than .25 %)

(Figure 10).

Figure 5.

7. At this point depress

“As Found” and select

“Instrument” and press

“ENTER,” then fill in the

template, use the default

“Delay=0 seconds.”)

Figure 6.

Depress “DONE.” You should

now see the split screen and

are presented with soft key

choices of “Abort,” “Auto

Test,” and “Manual Test”

(Figure 7).

Figure 8.

10. Now you are presented with

the Tag entry screen (Figure 9).

Figure 9.

Press the “ENTER” key to edit

the entries. Depress “Done”

when complete until the split

screen reappears with the

soft key options of “As Left,”

“Adjust,” “Save” and “More

Choices” on the display of the

DPC.

11. At this point, select “Adjust”

and the DPC will source 0 %

and measure for 4 mA to

Figure 10.

13. Select “Done,” “Done,” and

“Done” again and you are

done!

To review your results

in memory, select the “More

Choices” soft key, the “Review

Memory” soft key and move your

cursor to the applicable result and

press enter. Select “As Found”

or “As Left,” then “ENTER” and

review the setup for the test,

select “Next Page” for the results,

and press “Tag” for its associated

label. Select “Done” and “Done”.

Move your cursor to the applicable

“As Left” result and press “ENTER”

and review the test setup, select

“Next Page” for the results, and

press “Tag” for its associated

label. When you are finished

reviewing results, press “Done”

until right-most soft key label

changes to “More Choices.”

2 Fluke Corporation 750 Series Documenting Process Calibrators

Page 3

3 and 4 Wire RTD Sourcing for the Fluke 750 Series

754

DOCUMENTING PROCESS CALIBRATOR

TEST DC PWR

++

––

Fluke DPC

C-2

C-1

S-3

S-2

S-4

S-1

Documenting Process Calibrators

One of the most frequently asked application questions pertaining to

the 750 Series Documenting Process Calibrators is, “How do I hook

up the test leads to the DPC to source 3 and 4 wire RTDs?” For 3 and

4 wire RTD measurement, the DPC has embedded hookup diagrams

that easily show you how to connect the DPC. However, for 3 and 4

wire RTD source, the DPC does not offer that assistance.

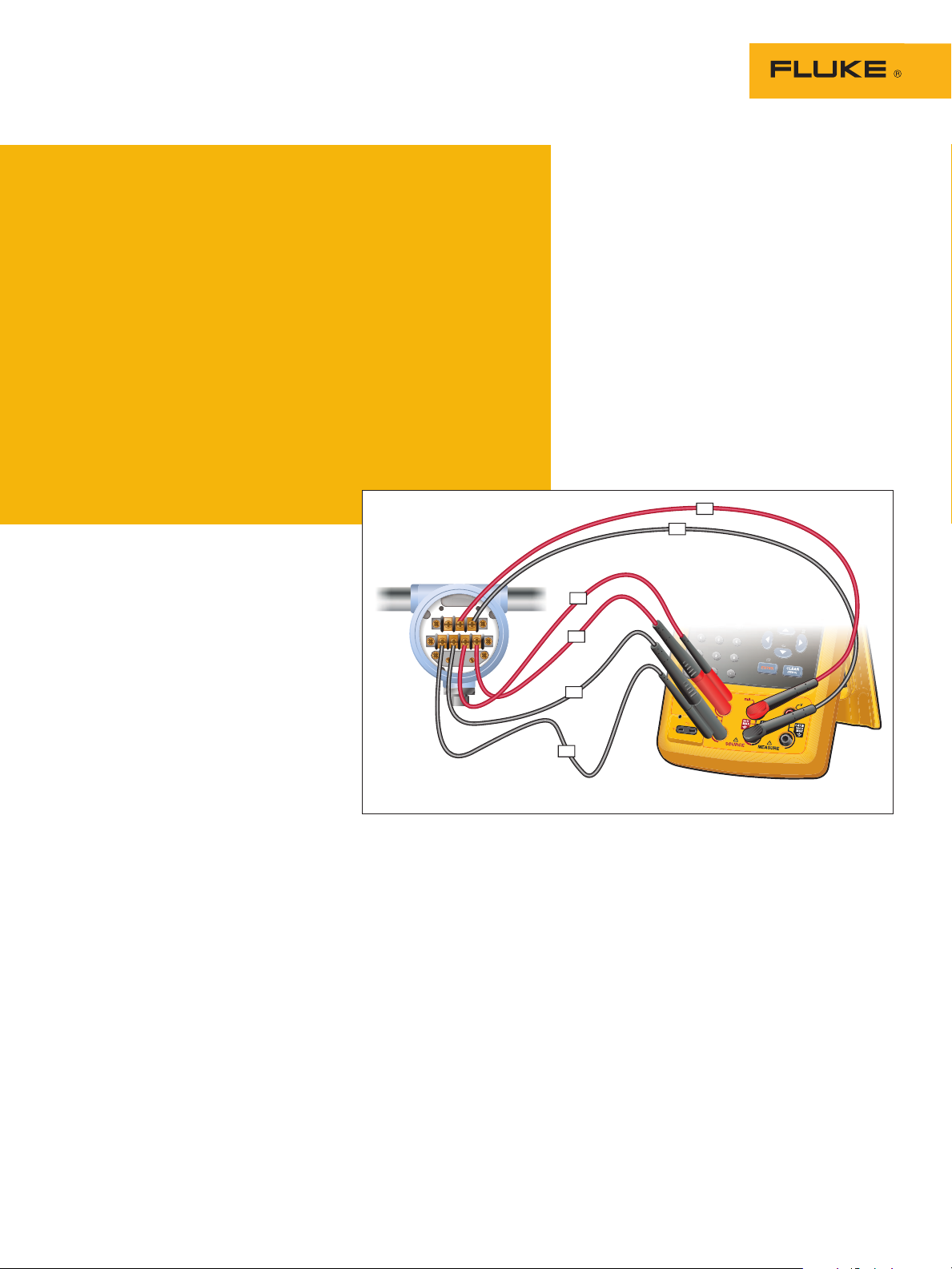

The example shown below (Figure 11) depicts the hookup for a 3

and 4 wire Rosemount 444 RTD Transmitter. You will need an additional pair of TL22 test leads and AC20 industrial test clips to complete

all the connections necessary for this application. In order to double

the available connections to the source terminals on the DPC, you also

will need to utilize the short black jumpers supplied with the Documenting Process Calibrator.

1. Make the RTD source

connections, S1, S2, S3 and

S4 (omit S3 and S4 for 2 wire

RTDs and S4 for 3 wire RTDs;

S4 is only needed for 4 wire

RTD sourcing).

2. Next, connect the loop power

and current measurement

connections, C1 and C2.

Figure 11.

3. Once the connections are

made as per the diagram in

Figure 11, enable the loop

24 volt power from the setup

screen, source the pertinent

RTD for the specific transmitter being evaluated, and set

the measure mode to mA.

4. At this point, enter the split

screen mode of the DPC and

perform the As Found, Adjust

and As Left tests as you did

in the previous thermocouple

transmitter example.

Fluke Corporation 750 Series Documenting Process Calibrators 3

Page 4

754

DOCUMENTING PROCESS CALIBRATOR

Pressure Button

Calibration of an I to P (Current to

Pressure) with the Fluke 750 Series

Documenting Process Calibrators

A common device in the Fluke DPC workload

is the I to P. The I to P device is used to convert electrical loop analog control of 4-20 mA

to pneumatic analog loop control of 3-15 PSI.

The device in this example is an I to P with

current input values of 4-20 mA for 0 % and

100 % with output range of 3-15 PSI for 0 %

and 100 %, +/- 2 %. This step-by-step example describes how to: 1) perform a three point

ascending (3↑) As Found (pre-adjustment) test

at 0-50-100 %, Tag the results, 2) Adjust the

zero and span (span = 100 %) of the I to P,

then 3) perform a three point ascending As

Left (post-adjustment) test at 0-50-100 %, Tag

those results and review them in memory.

1. Connect the pressure module

to the DPC. Connect the output of the I to P to the input

of the pressure module. If you

are using a differential pressure module, make sure (for

this example) that it is a 15

PSI module and connect to

the input labeled “H”

(Figure 12).

2. Connect from the center two

banana type connections of

the DPC to the input of the I

to P where control current is

supplied (Figure 12).

3. Once your connections are

made, assuming you are in

the power up state (or measure screen), select the “Pressure” button (directly above

the “Range” button) (Figure

13).

4. Next depress the “MEAS/

SOURCE” button; now you are

in the source screen

(Figure 14).

Figure 13.

Figure 12.

DOCUMENTING PROCESS CALIBRATOR

754

+

Pressure

Module

Since you want to source a

current, depress “mA.” Depress

“ENTER” which chooses “Source

mA” when given the choice of

“Source mA” or “Simulate Transmitter.” When the DPC responds

with ????? asking for a current to

source, depress “4” and “ENTER.”

5. Next depress the “MEAS/

SOURCE” button once and you

should be in the split screen

mode (Figure 15).

Figure 15.

Figure 14.

4 Fluke Corporation 750 Series Documenting Process Calibrators

Page 5

6. At this point depress “As

Found”, select “Instrument”

and press “ENTER,” then fill

in the template as shown in

figure 16.

9. Now you see the Tag entry

screen (Figure 18).

Figure 18.

Figure 16.

Press “DONE.” You should

now see the split screen,

with soft key choices of

“Abort,” “Auto Test” and

“Manual Test.”

7. Select “Manual Test,” and

watch the DPC start at 0 %.

Once the reading has settled,

depress “accept point.” Perform the 50 % and 100 %

measurements the same way.

8. Once the 753/754 has completed this evaluation, it

will display the post test

summary screen with the

SOURCE, MEASURE and

ERROR columns. Failures

appear in reverse video in

the Error column (Figure 17).

Depress “Done.”

Figure 17.

Press the “ENTER” key to edit

the entries. Depress “Done”

when complete until the split

screen reappears with the

soft key options of: “As Left,”

“Adjust,” “Save,” and ”More

Choices.”

10. At this point, select “Adjust”

and the DPC will source 0 %

(4 mA) and measure for 3 PSI

to 2 %. As long as the error

exceeds 2 % the Error window in the measure half of

the screen will be in reverse

video. Adjust the zero on the

I to P until the error is less

than 2 %. Next select “Go to

100 %” and adjust span in

the same way. Select “Go to

50 %” and evaluate linearity.

11. After adjustments are complete, select “As Left,” “Done”

and “Manual Test” and repeat

step (8). If the adjustment

was successful, all the errors

in the post run summary

should be in normal video

(Figure 19).

Figure 19.

12. Select “Done,” “Done,” and

“Done” again and you are

done!

To review your results in

memory, select the “More

Choices” soft key, then the

“Review Memory” soft key.

Move your cursor to the

applicable result and press

ENTER. Select “As Found”

or “As Left,” then “ENTER.

Press “Next Page” for the

results, and press “Tag” for its

associated label. Select “Done”

and “Done” and move your

cursor to the applicable “As

Left” result and press “enter.”

Review the setup for the test,

select “Next Page” for the

results, and press “Tag” for

its associated label. When you

are finished reviewing results,

press “Done” until right-most

soft key label changes to

“More Choices.”

Fluke Corporation 750 Series Documenting Process Calibrators 5

Page 6

+

754

DOCUMENTING PROCESS CALIBRATOR

Hand Pump

Pressure

Module

754

DOCUMENTING PROCESS CALIBRATOR

Pressure Button

Calibration of a Pressure Transmitter

(Pressure to Current or P to I) with

the Fluke 750 Series Documenting

Process Calibrators

A common device in the Fluke DPC workload is the pressure transmitter or P to I

device. The P to I device is used to convert

pneumatic analog loop control signals of

3-15 PSI or other measured pressures to

electrical loop analog control signals of

4-20 mA. The device in this example is a

P to I with pressure input values of 3-15

PSI for 0 % and 100 % with output range

(drawn from loop power) of

4-20 mA for 0 % and 100 %, +/- 2 %.

In this step-by-step example we will:

1) perform a three point ascending (3↑)

As Found (pre-adjustment) test at 0-50100 %, and Tag the results, 2) adjust the

zero and span (100 %) of the P to I, then

3) perform a three point ascending As Left

(post-adjustment) test at 0-50-100 %, tag

those results and review them in memory.

Figure 20.

1. Connect the pressure module

to the DPC. Connect the input

of the P to I and the output

of a pressure hand pump

to the input of the pressure

module using a “T” connector

(Figure 20). If you are using a

differential pressure module,

ensure (for this example) it is

a 15 PSI module and connect

to input labeled “H.”

2. Connect from the center 2

banana type connections of

the DPC to the input of the P

to I where loop power

is supplied (Figure 20).

3. Next, depress the “SETUP” button on the DPC. The cursor

should begin on loop power.

Depress “ENTER,” down

arrow to Enabled and depress

“ENTER.” Next depress the

“Done” softkey.

4. Once your connections are

made, assuming you are

in the power up state (or

measure screen), select the

mA button.

5. Next depress the “MEAS/

SOURCE” button; now you are

in the source screen (Figure

21).

Figure 21.

6. Since we wish to source

a pressure (using a hand

pump) depress the pressure

button, (directly above the

HART or range button)

(Figure 22).

7. Next depress the “MEAS/

SOURCE” button once and

you should be in the split

screen mode (Figure 23).

Figure 23.

6 Fluke Corporation 750 Series Documenting Process Calibrators

Figure 22.

Page 7

8. At this point depress “As

Found”, select “Instrument”

and press “ENTER,” then fill

in the template per Figure 24.

Figure 24.

Depress “DONE.” You should

now see the split screen and

are presented with soft key

choices of “Abort,” “Auto

Test,” and “Manual Test.”

9. Select Manual Test, and

watch the DPC for the

prompt: “Go to 3 PSI”

(Figure 25).

if you are sourcing 3.120 PSI

(1% of span above nominal),

the DPC will look for a mA

reading of 4.160 mA (also 1%

of span above nominal). In

order to make a proper evaluation of the device you need

only to get reasonably close

to the nominal pressure values with the hand pump. The

remaining source pressure

error is compensated for by

the DPC during mA measure

calculations.

10. Once the DPC has completed

this evaluation, it will display

the post test summary screen

with the SOURCE, MEASURE

and ERROR columns (Figure

26). Depress “Done.”

Figure 26.

Press the “ENTER” key to

edit the entries, press “Done”

when complete until the split

screen reappears with the

soft key options of: “As Left,”

“Adjust,” “Save,” and “More

Choices.”‘

12. At this point, select “Adjust”

and the DPC will source

0%, instruct you to “Go to

3 PSI” and measure for 4 mA

to 2%. As long as the error

exceeds 2% the Error window in the measure half of

the screen will be in reverse

video. Adjust the zero on the

P to I until the error is less

than 2 %. Next select “Go to

100 %” and adjust span in

the same way.

13. After adjustment is complete,

select “As Left,” “Done” and

“Manual Test” and repeat

step (9). If the adjustment

was successful, all the errors

in the post run summary

should be in normal video

(Figure 28).

Figure 25.

At that point using the hand

pump, pump until the DPC

display is reasonably close

to 3 PSI and depress “Accept

Point.” Now the DPC should

display “Go to 9 PSI.” Again,

using the hand pump, pump

up reasonably close to 9 PSI

and depress “Accept Point.”

When the DPC responds with

“Go to 15 PSI” pump to that

value and “Accept Point.”

It is important to understand

a key feature of the DPC at

this point. When the error

is being calculated on the

measured mA by the DPC,

it will make the calculation

based on the deviation of

the amount of pressure being

sourced. What this means is,

11. Now you are presented with

the Tag entry screen (Figure

27).

Figure 28.

14. Select “Done,” “Done,” and

“Done” again and you are

done!

Figure 27.

To review your results in memory, select “More

Choices” soft key, “Review Memory” soft key, move your

cursor to the applicable and press “ENTER” and review

the setup for the test, select “Next Page” for the results,

depress “Tag” for its associated label. Select “Done” and

“Done” next move your cursor to the applicable “As Left”

result and depress “ENTER” and review the setup for the

test, select “Next Page” for the results, depress “Tag”

for its associated label. When you are finished reviewing results, press “Done” until right-most soft key label

changes to “More Choices.”

Fluke Corporation 750 Series Documenting Process Calibrators 7

Page 8

Note on Uploading Results to Your PC

If you are using a 743/744 or 753/754, you may choose an

instrumentation management software package from this list:

Fluke DPC/TRACK2

AMS from Emerson Process

Management, (formerly

Fisher-Rosemount).

™

PRM (Plant Resource

Manager) from Yokogawa

Electric Corporation.

On Time Support

Process/Track

All trademarks are the property of their respective holders.

Additional information is available for download from

www.fluke.com on these products

• Pressure Calibration Application Note

• Custom Units Application Note

• Switch Test Application Note

• HART Calibration Application Note

• Process Tools Accessories

E

G

M

A

N

E

N

A

T

M

S

Y

Y

T

S

I

L

A

U

Q

ISO 9001

C

E

R

T

I

F

I

T

E

M

‚

1

0

0

9

O

E

S

I

D

T

T

E

O

E

M

8 Fluke Corporation 750 Series Documenting Process Calibrators

Fluke. Keeping your world

up and running.

Fluke Corporation

PO Box 9090, Everett, WA 98206 U.S.A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2010-2011 Fluke Corporation.

Specifications subject to change without notice.

Printed in U.S.A. 8/2011 3792201B A-EN-N

Modification of this document is not permitted

without written permission from Fluke Corporation.

®

Loading...

Loading...