Page 1

712B/714B

RTD/Thermocouple Calibrator

March 2015

© 2015 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

Calibration Manual

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and

service. The warranty period is three years and begins on the date of shipment. Parts, product repairs, and

services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of

a Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in

Fluke's opinion, has been misused, altered, neglected, contaminated, or damaged by accident or abnormal

conditions of operation or handling. Fluke warrants that software will operate substantially in accordance

with its functional specifications for 90 days and that it has been properly recorded on non-defective media.

Fluke does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers

only but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is

available only if product is purchased through a Fluke authorized sales outlet or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for importation costs of

repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair,

or replacement of a defective product which is returned to a Fluke authorized service center within the

warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that service center, with a description of the difficulty,

postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following

warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination, alteration, accident, or abnormal

condition of operation or handling, including overvoltage failures caused by use outside the product’s

specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair

costs and obtain authorization before commencing the work. Following repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or

limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not

apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court or other

decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any other

provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

Page 3

Table of Contents

Title Page

Introduction ............................................................................................ 1

Contact Fluke ........................................................................................ 1

Safety Information ................................................................................. 1

Symbols ................................................................................................. 2

712B Specifications ............................................................................... 3

DC mA Measurement ........................................................................ 3

Ohms Measurement .......................................................................... 3

Ohms Source ..................................................................................... 3

RTD Input and Output ....................................................................... 4

General Specifications ....................................................................... 5

714B Specifications ............................................................................... 6

Thermocouple mV Input .................................................................... 6

Thermocouple mV Output ................................................................. 6

Thermocouple mA Input .................................................................... 6

Thermocouple Input and Output ........................................................ 6

General Specifications ....................................................................... 8

Maintenance .......................................................................................... 9

Replace the Batteries ........................................................................ 9

Clean the Product .............................................................................. 9

Required Equipment .............................................................................. 10

712B Performance Verification .............................................................. 11

Verify Ohms Source .......................................................................... 11

Verify 4-Wire Ohms Measure ............................................................ 12

Verify 3-Wire Ohms Measure ........................................................... 13

Verify mA Measure ............................................................................ 14

714B Performance Verification .............................................................. 16

Verify mV Source ............................................................................... 16

Verify mV Measure ............................................................................ 17

Verify TC Measure (Type K) .............................................................. 18

Verify TC K Source ............................................................................ 18

Verify mA Measure ............................................................................ 19

712B Calibration Adjustment ................................................................. 21

Enter Manual Calibration Mode ......................................................... 21

Adjust Ohms Source .......................................................................... 21

Adjust 50 Ω Source ........................................................................ 22

Adjust 350 Ω Source ...................................................................... 22

i

Page 4

712B/714B

Calibration Manual

Adjust 500 Ω Source ...................................................................... 23

Adjust 3500 Ω Source .................................................................... 23

Adjust Trigger Current for Ohms Measure ........................................ 24

Adjust 0.1 mA Trigger Current ....................................................... 24

Adjust 0.25 mA Trigger Current ..................................................... 25

Adjust 0.5 mA Trigger Current ....................................................... 25

Adjust 1 mA Trigger Current .......................................................... 26

Adjust Ohms Measure ....................................................................... 26

Adjust 50 Ω Input ........................................................................... 27

Adjust 350 Ω Input ......................................................................... 27

Adjust 500 Ω Input ......................................................................... 28

Adjust 3500 Ω Input ....................................................................... 28

Adjust mA Measure ........................................................................... 29

Adjust 0.1 mA Input ....................................................................... 29

Adjust 24 mA Input ........................................................................ 30

Adjust External Trigger for Ohms Source .......................................... 30

Adjust 0.1 mA External Trigger ...................................................... 31

Adjust 1 mA External Trigger ......................................................... 31

Save Data and Reset the 712B System ............................................ 32

714B Calibration Adjustment ................................................................. 32

Enter Calibration Mode ...................................................................... 32

Use 8508A to Adjust the 5522A Output ............................................. 33

Adjust mV Source .............................................................................. 33

Adjust mV Measure ........................................................................... 34

Adjust Internal Cold Junction Temperature ....................................... 35

Use the Fluke 9101-256 ................................................................ 35

Use a Lag Bath .............................................................................. 37

Adjust mA Measure ........................................................................... 38

Save Data and Reset the 714B System ............................................ 39

User-Replaceable Parts and Accessories ............................................. 40

ii

Page 5

List of Tables

Table Title Page

1. Symbols ..................................................................................................... 2

2. Required Equipment for 712B Verification and Calibration Adjustment .... 10

3. Required Equipment for 714B Verification and Calibration Adjustment .... 10

4. 712B Ohms Source Limits ......................................................................... 12

5. 712B 4-Wire Ohms Measure Limits .......................................................... 13

6. 712B 3-Wire Ohms Measure Limits .......................................................... 14

7. 712B mA Measure Limits .......................................................................... 15

8. 714B mV Source Limits ............................................................................. 17

9. 714B mV Measure Limits .......................................................................... 17

10. 714B Type K Measure Limits .................................................................... 18

11. 714B TC K Source Limits .......................................................................... 19

12. 714B mA Measure Limits .......................................................................... 20

13. User-Replaceable Parts and Accessories for 712B .................................. 40

14. User-Replaceable Parts and Accessories for 714B .................................. 42

iii

Page 6

712B/714B

Calibration Manual

iv

Page 7

List of Figures

Figure Title Page

1. Replace the Batteries ................................................................................

2.

Verify 712B Ohms Source ......................................................................... 11

3.

Verify 712B 4-Wire Ohms Measure ........................................................... 12

Verify 712B 3-Wire Ohms Measure ........................................................... 13

4.

Verify 712B mA Measure .......................................................................... 15

5.

Verify 714B mV Source ............................................................................. 16

6.

Verify 714B mV Measure .......................................................................... 17

7.

Verify Type K Measure .............................................................................. 18

8.

9.

Verify mA Measure .................................................................................... 20

10.

Adjust 712B Ohms Source ........................................................................ 21

11.

Adjust 712B Trigger Current ...................................................................... 24

12.

Adjust for 712B Ohms Measure ................................................................ 26

13.

Adjust 712B mA Measure .......................................................................... 29

Adjust External Trigger for Ohms Source .................................................. 30

14.

Connect the 714B to the 8508A ................................................................ 33

15.

Adjust 714B mV Measure .......................................................................... 34

16.

Connect the 714B to the Fluke 9101-256 .................................................. 36

17.

Use Lag Bath to Adjust Cold Junction Temperature ................................. 37

18.

19.

714B and 5522A mA Channel Connections .............................................. 38

20.

User-Replaceable Parts and Accessories for 712B .................................. 41

21.

User-Replaceable Parts and Accessories for 714B .................................. 43

9

v

Page 8

712B/714B

Calibration Manual

vi 1

Page 9

Introduction

The Fluke 712B/714B RTD/Thermocouple Calibrator (the Product) is a handheld,

battery-operated instrument that measures and sources a variety of

RTDs/thermocouples. It also has an isolated channel to measure 4-20 mA.

Contact Fluke

To contact Fluke, call one of the following telephone numbers:

• Technical Support USA: 1-800-44-FLUKE (1-800-443-5853)

• Calibration/Repair USA: 1-888-99-FLUKE (1-888-993-5853)

• Canada: 1-800-36-FLUKE (1-800-363-5853)

• Europe: +31 402-675-200

• Japan: +81-3-6714-3114

• Singapore: +65-6799-5566

• Anywhere in the world: +1-425-446-5500

Or, visit Fluke's website at www.fluke.com.

To register your product, visit http://register.fluke.com.

To download manuals, or to view, print, or download the latest manual

supplement, visit http://us.fluke.com/usen/support/manuals.

Safety Information

A Warning identifies conditions and procedures that are dangerous to the user.

A Caution identifies conditions and procedures that can cause damage to the

Product or the equipment under test.

To prevent possible electrical shock, fire, or personal injury:

• Carefully read all instructions.

• Read all safety information before you use the Product.

• Use the Product only as specified, or the protection

supplied by the Product can be compromised.

• Do not use the Product around explosive gas, vapor, or in

damp or wet environments.

• Never apply more than 30 V between any two terminals, or

between any terminal and earth ground.

• Do not use the Product if it is damaged.

• The battery door must be closed and locked before you

operate the Product.

Warning

Page 10

712B/714B

Calibration Manual

Symbols

• Remove all probes, test leads, and accessories before the

battery door is opened.

• Remove the input signals before you clean the Product.

• Have an approved technician repair the Product.

• Replace the batteries when the low battery indicator shows

to prevent incorrect measurements.

For safe operation and maintenance of the Product:

• Repair the Product before use if the batteries leak.

• Remove the batteries if the Product is not used for an

extended period of time, or if stored in temperatures that

exceed the specification of the battery manufacturer. If the

batteries are not removed, battery leakage can damage the

Product.

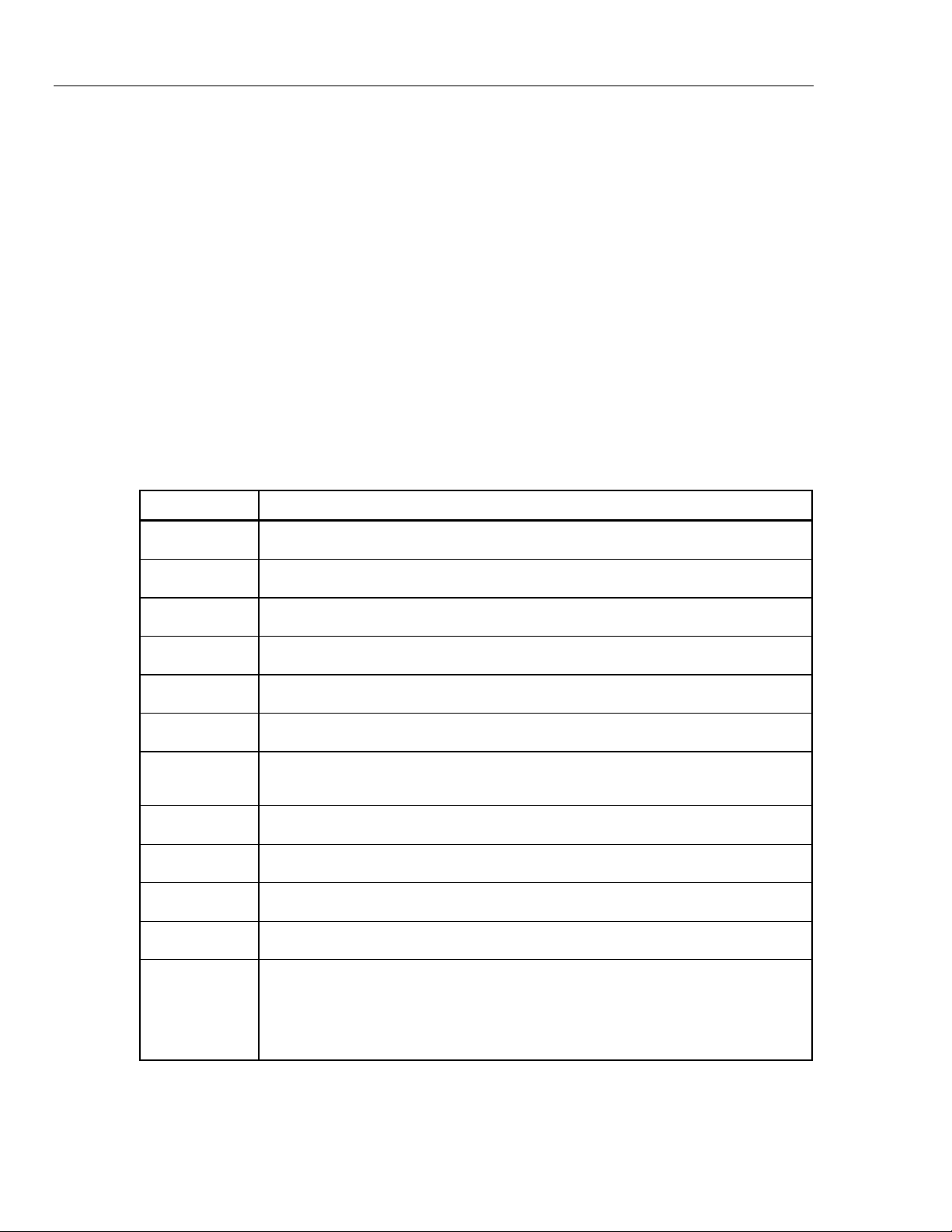

Symbols used on the Product or in this manual are shown in Table 1.

Table 1. Symbols

Symbol Description

Earth Ground

Battery

CAT II

CAT III

CAT IV

Conforms to relevant Australian Standards.

Risk of danger. Important information. See Manual.

Inspected and licensed by TÜV Product Services.

Conforms to European Union directives.

MEASUREMENT CATEGORY II is applicable to test and measuring circuits

connected directly to utilization points (socket outlets and similar points) of the low

voltage MAINS installation.

MEASUREMENT CATEGORY III is applicable to test and measuring circuits

connected to the distribution part of the building’s low-voltage MAINS installation.

MEASUREMENT CATEGORY IV is applicable to test and measuring circuits

connected at the source of the building’s low voltage MAINS installation.

Conforms to relevant North American Safety Standards.

Conforms to relevant South Korean EMC Standards.

This Product complies with the WEEE Directive (2002/96/EC) marking requirements.

The affixed label indicates that you must not discard this electrical/electronic product

in domestic household waste. Product Category: With reference to the equipment

types in the WEEE Directive Annex I, this product is classed as category 9 "Monitoring

and Control Instrumentation" product. Do not dispose of this product as unsorted

municipal waste. Go to Fluke’s website for recycling information.

2

Page 11

RTD/Thermocouple Calibrator

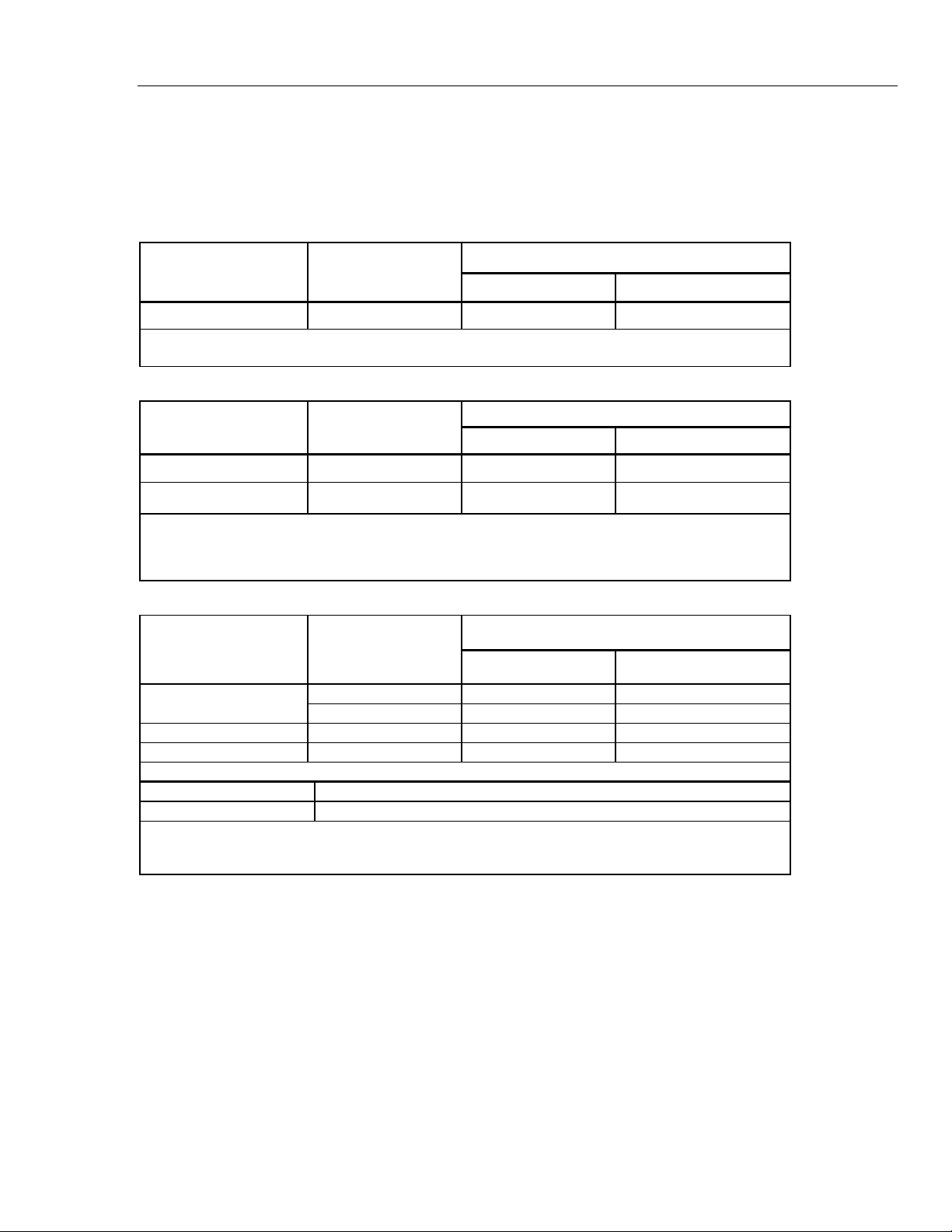

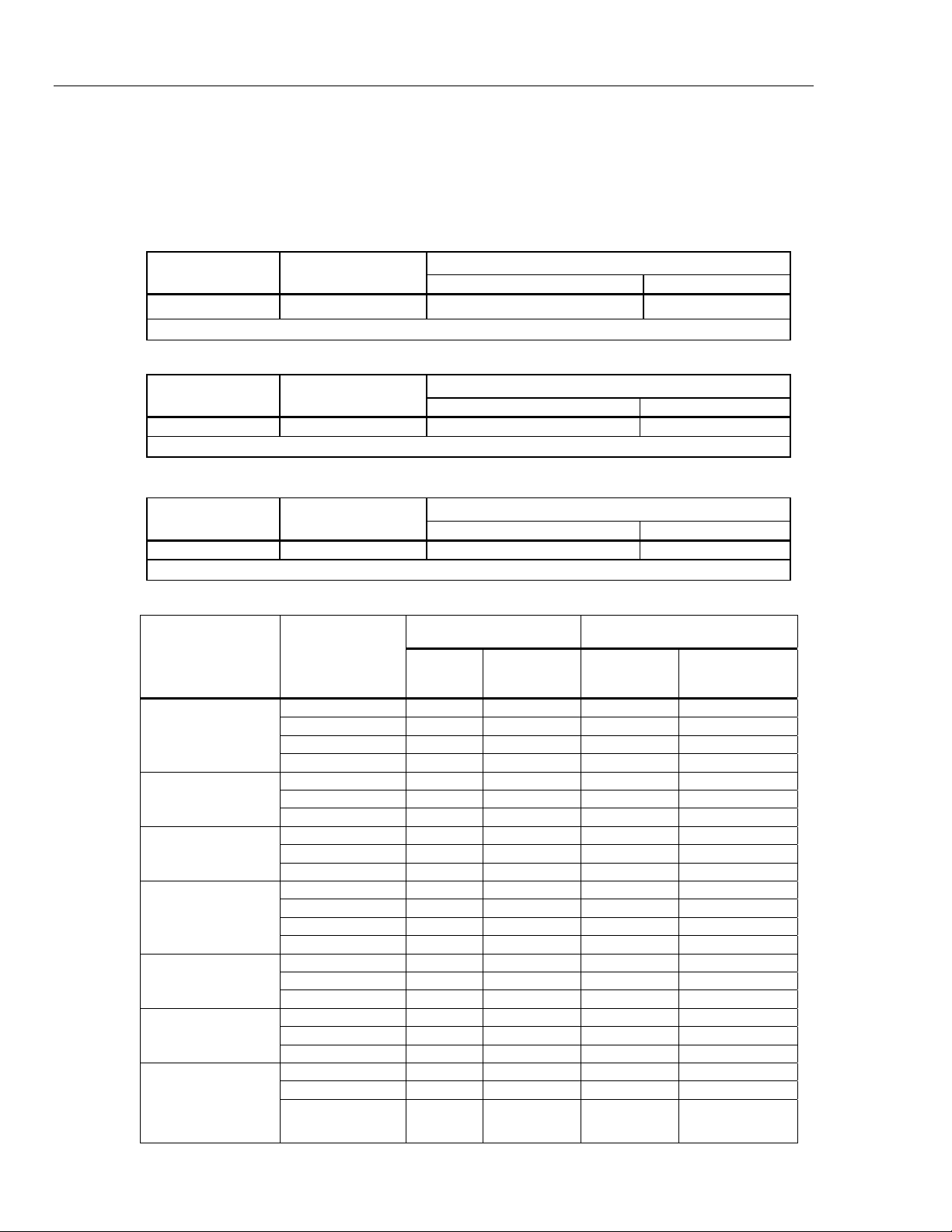

712B Specifications

712B Specifications

Specifications are based on a one year calibration cycle and apply from +18 °C

to +28 °C unless stated otherwise. All specifications assume a 5 minute warmup

period.

DC mA Measurement

Range Resolution

0-24 mA 0.001 mA

• Notes:

• Temperature coefficient: ±(0.002 % of reading + 0.002 % of range) /°C ( <18 °C or >28 °C)

Accuracy (% of Reading + Floor)

1 Year 2 Year

0.01 % + 2 μA 0.02 % + 4 μA

Ohms Measurement

Range Resolution

0.00 Ω to 400.00 Ω 0.01 Ω 0.015 % + 0.05 Ω 0.03 %+ 0.08 Ω

400.0 Ω to 4000.0 Ω 0.1 Ω 0.015 % + 0.5 Ω 0.03 %+ 0.8 Ω

• Notes:

• Reading accuracy is based on 4-wire input. For 3-wire ohm measurements, assuming all three leads are matched, add

0.05 Ω (0.00 Ω~400.00 Ω), 0.2 Ω (400.0 Ω~4000.0 Ω) to the specifications.

• Temperature Coefficient: ± (0.002 % of reading + 0.002 % of range) /°C (<18 °C or >28 °C)

Accuracy (% of Reading + Floor)

1 Year 2 Year

Ohms Source

Accuracy

Ohms Range

1.00 Ω to 400.00 Ω

400.0 Ω to 1500.0 Ω

1500.0 Ω to 4000.0 Ω

1.00 Ω to 400.00 Ω 0.01 Ω

400.0 Ω to 4000.0 Ω 0.1 Ω

• Notes:

• Supports pulsed transmitters and PLCs with pulse times as short as 5 ms.

• Temperature coefficient: ± (0.002 % of output + 0.002 % of range) /°C ( <18 °C or >28 °C)

Excitation Current from

Measurement Device

0.1 mA to 0.5 mA

0.5 mA to 3 mA

0.05 mA to 0.8 mA

0.05 mA to 0.4 mA

0.015 % + 0.1 Ω 0.03 % + 0.2 Ω

0.015 % + 0.05 Ω 0.03 % + 0.08 Ω

0.015 % + 0.5 Ω 0.03 % + 0.8 Ω

0.015 % + 0.5 Ω 0.03 % + 0.8 Ω

Resolution

(% of Output + Floor)

1 Year 2 Year

3

Page 12

712B/714B

Calibration Manual

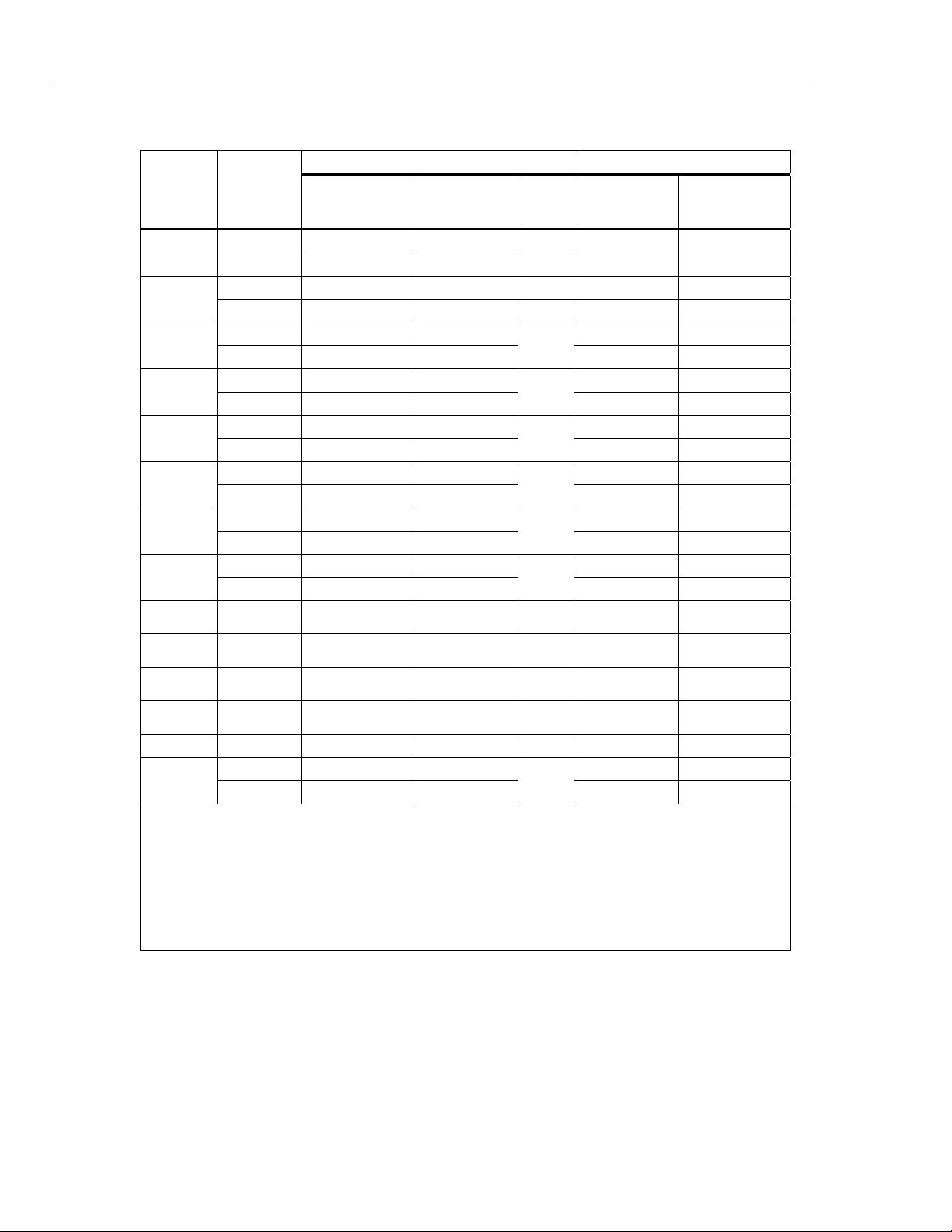

RTD Input and Output

RTD Type

(α)

Range (°C)

Measure (°C) Source (°C)

1 Year 2 Year

Source

Current

1 Year 2 Year

10 Ω

Pt(385)

50 Ω

Pt(385)

100 Ω

Pt(385)

200 Ω

Pt(385)

500 Ω

Pt(385)

1000 Ω

Pt(385)

100 Ω

Pt(3916)

100 Ω

Pt(3926)

10 Ω

Cu(427)

120 Ω

Ni(672)

50 Ω

Cu(427)

100 Ω

Cu(427)

-200 to 100 1.5 3 1 mA 1.5 3

100 to 800 1.8 3.6 1 mA 1.8 3.6

-200 to 100 0.4 0.7 1 mA 0.4 0.7

100 to 800 0.5 0.8 1 mA 0.5 0.8

-200 to 100

100 to 800

-200 to 100

100 to 630

-200 to 100

100 to 630

-200 to 100

100 to 630

-200 to 100

100 to 630

-200 to 100

100 to 630

0.2 °C 0.4 °C

0.015 %+0.18 °C 0.03 %+0.36 °C 0.015 %+0.18 °C 0.03 %+0.36 °C

0.2 °C 0.4 °C

0.015 %+0.18 °C 0.03 %+0.36 °C 0.015 %+0.18 °C 0.03 %+0.36 °C

0.3 °C 0.6 °C

0.015 %+0.28 °C 0.03 %+0.56 °C 0.015 %+0.28 °C 0.03 %+0.56 °C

0.2 °C 0.4 °C

0.015 %+0.18 °C 0.03 %+0.36 °C 0.015 %+0.18 °C 0.03 %+0.36 °C

0.2 °C 0.4 °C

0.015 %+0.18 °C 0.03 %+0.36 °C 0.015 %+0.18 °C 0.03 %+0.36 °C

0.2 °C 0.4 °C

0.015 %+0.18 °C 0.03 %+0.36 °C 0.015 %+0.18 °C 0.03 %+0.36 °C

1 mA

500 μA

250 μA

250 μA

1 mA

1 mA

0.2

°C

0.4 °C

0.2 °C 0.4 °C

0.3 °C 0.6 °C

0.2 °C 0.4 °C

0.2 °C 0.4 °C

0.2 °C 0.4 °C

-100 to 260 1.5 3 1 mA 1.5 3

-80 to 260 0.15 0.3 1 mA 0.15 0.3

-180 to 200 0.4 0.7 1 mA 0.4 0.7

-180 to 200 0.2 0.4 1 mA 0.2 0.4

YSI400 15 to 50 0.2 0.4 250 μA 0.2 0.4

100 Ω

Pt(3902)

-200 to 100

100 to 500 0.015 %+0.18 °C

• Notes:

• Sensor inaccuracies not included.

• Resolution: 0.1 °C.

• Read accuracy is based on 4-wire input. For 3-wire RTD measurements, assuming all three RTD leads are

matched, add 1.0 °C (Pt10 and Cu10), 0.6 °C (Pt50 and Cu50), 0.4 °C (Other RTD types) to the specifications.

• Source Accuracy in source mode is based on 0.5 mA~3 mA (1.00 Ω~400.00 Ω), 0.05 mA~0.8 mA

(400.0 Ω~1500.0 Ω), 0.05 mA~0.4 mA (1500.0 Ω ~4000.0 Ω), excitation current (0.25 mA for Pt1000 range).

• Temperature Coefficient: ±0.05 °C /°C (<18 °C or >28 °C) for both measure and source.

• Supports pulsed transmitters and PLCs with pulse times as short as 5 ms.

0.2 °C 0.4 °C

0.03 %+0.36 °C 0.015 %+0.18 °C 0.03 %+0.36 °C

1 mA

0.2 °C 0.4 °C

4

Page 13

RTD/Thermocouple Calibrator

General Specifications

Maximum voltage applied between any

terminal and earth ground or between any

two terminals:

Operating temperature

Storage temperature

Operating altitude 2,000 meters

Storage altitude 12,000 meters

Relative Humidity (% RH operating without

condensation)

Vibration Requirements MIL-T-28800E, Class 2

Drop Test Requirements 1 meter

IP Rating IEC 60529: IP52

Electromagnetic Environment

Safety IEC 61010-1, Max 30 V to earth, Pollution Degree 2

Electromagnetic Compatibility

Power Supply 4 AA alkaline batteries/NEDA code: 15A, IEC code: LR6

Size (H x W x L) 52.5 x 84 x 188.5 mm

Weight 524 g

30 V

-10 °C to 50 °C

-20 °C to 60 °C

Non condensing

90 % (10 °C to 30 °C)

75 % (30 °C to 40 °C)

45 % (40 °C to 50 °C)

(Without condensation)

IEC 61326-1, Portable

FCC: CFR Title 47, Part 15, Subpart B

Applies to use in Korea only. Class A Equipment (Industrial

Broadcasting & Communication Equipment)

This product meets requirements for industrial (Class A)

electromagnetic wave equipment and the seller or user should

take notice of it. This equipment is intended for use in business

environments and is not to be used in homes.

5

Page 14

712B/714B

Calibration Manual

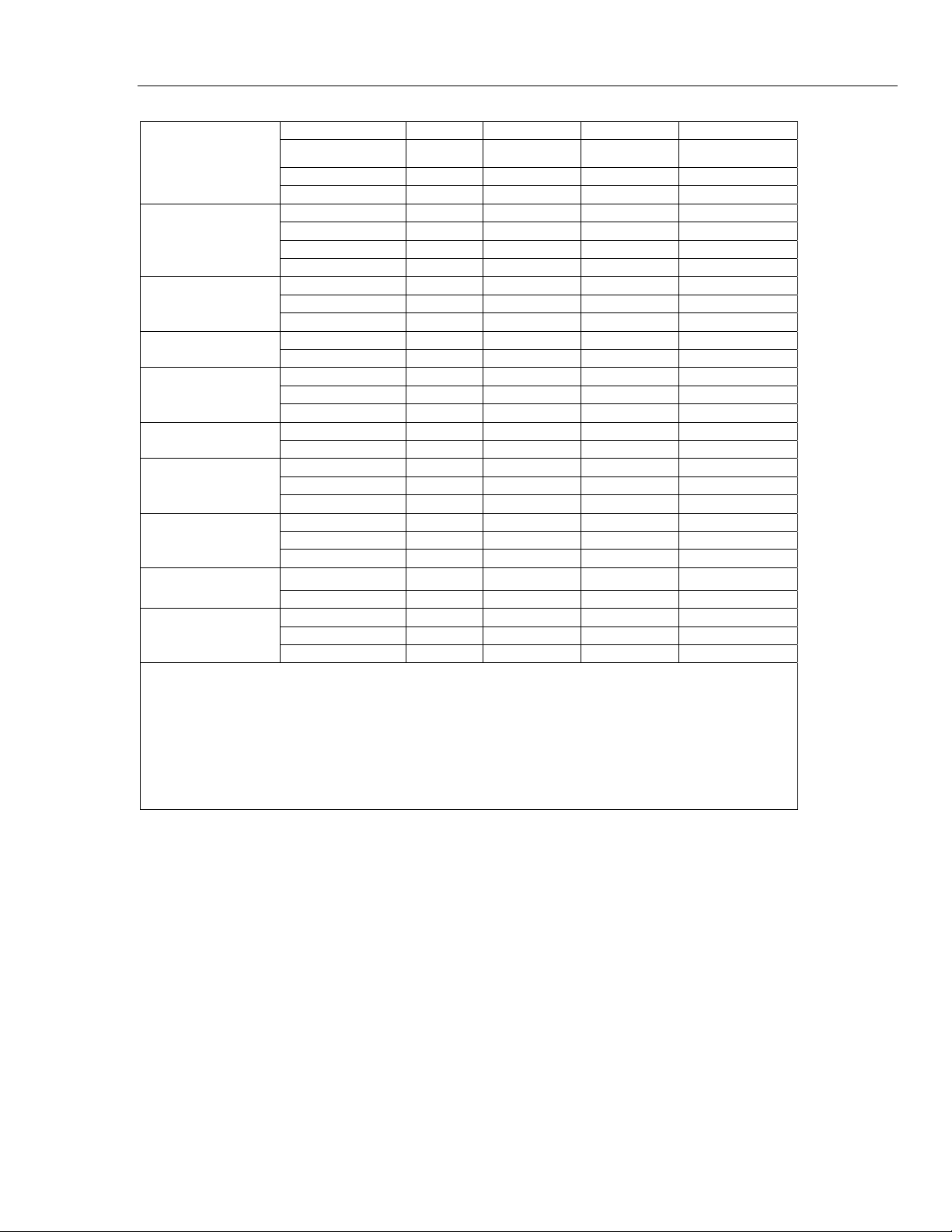

714B Specifications

Thermocouple mV Input

-10 mV to 75 mV 0.001 mV 0.015 % + 10 µV

Thermocouple mV Output

-10 mV to 75 mV 0.01 mV 0.015 % + 10 µV 0.02 % + 15 µV

Thermocouple mA Input

0 mA to 24 mA 0.001 mA 0.01 % + 2 µA 0.02 % + 4 µA

Specifications are based on a one year calibration cycle and apply from +18 °C

to +28 °C unless stated otherwise. All specifications assume a 5 minute warmup

period.

Range Resolution

Temperature coefficient: ±(0.002 % of reading + 0.002 % of range) /°C ( <18 °C or >28 °C)

Range Resolution

Temperature Coefficient: ± (0.002 % of output + 0.002 % of range) /°C ( <18 °C or >28 °C)

Range Resolution

Temperature Coefficient: ± (0.002 % of output + 0.002 % of range) /°C ( <18 °C or >28 °C)

Accuracy (% of Reading + Floor)

1 Year 2 Year

0.02 % + 15 µV

Accuracy (% of Output + Floor)

1 Year 2 Year

Accuracy (% of Reading + Floor)

1 Year 2 Year

Thermocouple Input and Output

TC Type Range

-250 to 200 1.3 2.0 0.6 0.9

E

N

J

K

T

B

R

-200 to -100 0.5 0.8 0.3 0.4

-100 to 600 0.3 0.4 0.3 0.4

600 to 1000 0.4 0.6 0.2 0.3

-200 to -100 1.0 1.5 0.6 0.9

-100 to 900 0.5 0.8 0.5 0.8

900 to 1300 0.6 0.9 0.3 0.4

-210 to -100 0.6 0.9 0.3 0.4

-100 to 800 0.3 0.4 0.2 0.3

800 to 1200 0.5 0.8 0.3 0.3

-200 to -100 0.7 1.0 0.4 0.6

-100 to 400 0.3 0.4 0.3 0.4

400 to 1200 0.5 0.8 0.3 0.4

1200 to 1372 0.7 1.0 0.3 0.4

-250 to -200 1.7 2.5 0.9 1.4

-200 to 0 0.6 0.9 0.4 0.6

0 to 400 0.3 0.4 0.3 0.4

600 to 800 1.3 2.0 1.0 1.5

800 to 1000 1.0 1.5 0.8 1.2

1000 to 1820 0.9 1.3 0.8 1.2

-20 to 0 2.3 2.8 1.2 1.8

0 to 100 1.5 2.2 1.1 1.7

100 to 1767 1.0 1.5 0.9 1.4

Measure (°C) Source (°C)

1 Year 2 Year 1 Year 2 Year

6

Page 15

RTD/Thermocouple Calibrator

714B Specifications

-20 to 0 2.3 2.8 1.2 1.8

S

C

L

U

BP

XK

G

D

P

M

Notes:

• Sensor inaccuracies not included.

• Accuracy with external cold junction; for internal junction add 0.2 °C

• Temperature scale: ITS-90

• Compensation: NIST Monograph 175 for B, R, S, E, J, K, N, T. DIN 43710 for L, U. GOST P 8.585-2001 (Russia) for

BP and XK. ASTM E988-96 for C. ASTM E1751/E1751M − 09ԑ1 for G, D, P, M

• Resolution: 0.1 °C

• Temperature Coefficient: 0.05 °C/°C ( <18 °C or >28 °C )

0 to 200 1.5 2.1 1.1 1.7

200 to 1400 0.9 1.4 0.9 1.4

1400 to 1767 1.1 1.7 1.0 1.5

0 to 800 0.6 0.9 0.6 0.9

800 to 1200 0.8 1.2 0.7 1.0

1200 to 1800 1.1 1.6 0.9 1.4

1800 to 2316 2.0 3.0 1.3 2.0

-200 to -100 0.6 0.9 0.3 0.4

-100 to 800 0.3 0.4 0.2 0.3

800 to 900 0.5 0.8 0.2 0.3

-200 to 0 0.6 0.9. 0.4 0.6

0 to 600 0.3 0.4 0.3 0.4

0 to 1000 1.0 1.5 0.4 0.6

1000 to 2000 1.6 2.4 0.6 0.9

2000 to 2500 2.0 3.0 0.8 1.2

-200 to 300 0.2 0.3 0.2 0.5

300 to 800 0.4 0.6 0.3 0.6

100 to 300 1.6 2.4 1.2 1.8

300 to 1500 1.0 1.5 1.0 1.5

1500 to 2315 2.0 3.0 1.6 2.4

0 to 300 1.6 2.4 1.2 1.8

300 to 1500 1.0 1.5 1.0 1.5

1500 to 2315 2.0 3.0 1.6 2.4

0 to 1000 1.6 2.4 0.6 0.9

1000 to 1395 2.0 3.0 0.8 1.2

-50 to 100 1.0 1.5 0.4 0.6

100 to 1000 1.6 2.4 0.6 0.9

1000 to 1410 2.0 3.0 0.8 1.2

0.07 °C/°C for C type >1800 °C and for BP type >2000 °C

7

Page 16

712B/714B

Calibration Manual

General Specifications

Maximum voltage applied between

any terminal and earth ground or

between any two terminals:

Operating temperature

Storage temperature

Operating altitude 2,000 meters

Storage altitude 12,000 meters

Relative Humidity (% RH operating

without condensation)

Vibration Requirements MIL-T-28800E, Class 2

Drop Test Requirements 1 meter

IP Rating IEC 60529: IP52 (with TC cap)

Electromagnetic Environment

Safety IEC 61010-1, Max 30 V to earth, Pollution Degree 2

Electromagnetic Compatibility

Power Supply 4 AA alkaline batteries/NEDA code: 15A, IEC code: LR6

Size (H x W x L) 52.5 x 84 x 188.5 mm

Weight 515 g

30 V

-10 °C to 50 °C

-20 °C to 60 °C

Non condensing

90 % (10 °C to 30 °C)

75 % (30 °C to 40 °C)

45 % (40 °C to 50 °C)

(Without condensation)

IEC 61326-1, Portable

FCC: CFR Title 47, Part 15, Subpart B

Applies to use in Korea only. Class A Equipment (Industrial Broadcasting &

Communication Equipment)

This product meets requirements for industrial (Class A) electromagnetic

wave equipment and the seller or user should take notice of it. This

equipment is intended for use in business environments and is not to be

used in homes.

8

Page 17

RTD/Thermocouple Calibrator

Maintenance

Maintenance

Replace the Batteries

Warning

To prevent false readings, which could lead to possible electric

shock or personal injury, replace the batteries as soon as the

low battery indicator appears.

Figure 1 shows how to replace the batteries.

Clean the Product

To prevent personal injury or damage to the Product, use only

the specified replacement parts and do not allow water into the

case.

To avoid damaging the plastic lens and case, do not use

solvents or abrasive cleansers.

Clean the Product with a soft cloth dampened with water or water and mild soap.

Figure 1. Replace the Batteries

Warning

Caution

hnh38.eps

9

Page 18

712B/714B

Calibration Manual

Required Equipment

The equipment listed in Table 2 is necessary to do the calibration and test for the

712B. The equipment listed in Table 3 is necessary to do the calibration and test

for the 714B.

Note

Fluke 5522A and Fluke 8508A need an 8-hour warmup period

before the calibration starts. The 5522A needs to zero all the

functions weekly and zero Ohms output function every day. The

8508A needs to zero the dc V measurement function, the 4-Wire

Ohms measurement function and the DCI measurement function.

Table 2. Required Equipment for 712B Verification and Calibration Adjustment

Item Equipment QTY Comment

Fluke 5522A 1 ——

Can be replaced with other

Fluke 8508A 1

reference or equivalent

DMMs

B-36-2,BANANA PLUG

PATCH CORD (Part

number:1894785, RED, Part

Item Equipment QTY Comment

Fluke 5522A 1 The mV output should be calibrated by 8508A

Fluke 8508A 1

Fluke 9101-256 1

Fluke-75X-8014 1 Fluke Item No: 3669716

Fluke 7526A 1 -

[1] Before using the mV output function of 5522A, record the 5522A output setting by the reading of the

8508A.

[2] The absolute uncertainties of the DMM’s dc voltage need to be better than 10 ppm+0.2 μV in the range of

0 mV and 100 mV.

[3] The accuracy (MAX) of standard sensors should be better than 0.05 °C.

[4] The accuracy (MAX) of the TC sensor should be better than 0.05 °C.

number: 1894724, BLACK)

Or

Fluke-75X-8014,

STACKABLE LEAD SET

(Part number: 3669716)

Table 3. Required Equipment for 714B Verification and Calibration Adjustment

Pure copper cables

with the mini plug

J TYPE and K TYPE

TC Sensor

[4]

1

1

2 sets

Can be replaced with other reference or

equivalent DMMs

Can be replaced with a lag bath and standard

sensors

Used for the calibration of the mV input function

and mV source function

Used for verification and calibration adjustment

of the temperature function

[3]

Used for all the function

calibration and verification

test

[2]

.

[1]

.

10

Page 19

RTD/Thermocouple Calibrator

712B Performance Verification

712B Performance Verification

Verify that the 712B performance is within the 1 or 2 year specifications as

desired.

Turn the 712B on and let it warm up for 5 minutes.

Verify Ohms Source

1. Make connections between the 712B and the 8508A, as shown in Figure 2.

Fluke 8508A

Fluke 712B

Figure 2. Verify 712B Ohms Source

hwp011.eps

2. Set the 8508A to 4-wire ohms measurement mode. Set the resolution of

Ohms measurement mode to 7 1/2-digits or above. Set the range of Ohms

measurement mode as shown in Table 4.

3. Set the 712B to Ohms Source mode.

a. Push .

b. Push until Ohms is highlighted.

c. Push again.

d. Push as necessary to enter Source mode.

4. Set the 712B to output the resistance values at the first column in Table 4.

5. Wait approximately 10 seconds until the 8508A shows a stable reading, and

verify that the 8508A readings are within the appropriate limits in Table 4.

Note

The 8508A must be set to 4-Wire measurement and in the requested

range to maintain currents that are within 712B’s limits.

6. Disconnect the 712B from the 8508A.

11

Page 20

712B/714B

5522A

CALIBRATOR

Calibration Manual

Table 4. 712B Ohms Source Limits

Source (Ω)

1 0.950 1.050 0.920 1.080 2k range, 4W

10 9.949 10.052 9.917 10.083 2k range, 4W

100 99.935 100.065 99.890 100.110 2k range, 4W

390 389.892 390.109 389.803 390.197 2k range, 4W

1000 999.35 1000.65 998.90 1001.10 20k range, 4W

4000 3998.90 4001.10 3998.00 4002.00 20k range, 4W

1 Yr. Lower

Limit (Ω)

1 Yr. Upper

Limit (Ω)

2 Yr. Lower

Limit (Ω)

2 Yr. Upper

Limit (Ω)

8508A Range

Verify 4-Wire Ohms Measure

1. Push to set the 712B to Ohms Measure mode.

2. Push until 4W shows on the screen.

3. Make the connections between the 712B and the 5522A, as shown in

Figure 3.

4. Set the 5522A to output the Ohms value at the second column in Table 5.

5. Wait approximately 10 seconds for a stable output of the 5522A, and verify

that the 712B readings are within

the limits shown.

Fluke 712B

Figure 3. Verify 712B 4-Wire Ohms Measure

Fluke 5522A

hwp003.eps

12

Page 21

RTD/Thermocouple Calibrator

5522A

CALIBRATOR

712B Performance Verification

Table 5. 712B 4-Wire Ohms Measure Limits

Range (Ω) Applied Ω from

5522A (Ω)

400 1 0.95 1.05 0.92 1.08

400 10 9.95 10.05 9.92 10.08

400 100 99.94 100.06 99.89 100.11

400 390 389.89 390.11 389.80 390.20

4000 1000 999.4 1000.6 998.9 1001.1

4000 4000 3998.9 4001.1 3998.0 4002.0

1 Yr. Lower

Limit (Ω)

1 Yr. Upper

Limit (Ω)

2 Yr. Lower

Limit (Ω)

2 Yr. Upper

Limit (Ω)

Verify 3-Wire Ohms Measure

1.

Push

2.

Push

3.

Make the connections between the 712B and the 5522A, as shown in

Figure

4.

Set the 5522A to

Table 6.

5.

Wait approximately 10 seconds for a stable output of the 5522A, and verify

that the 712B readings are within

to set the 712B to Ohms Measure mode.

until 3W shows on the screen.

4

.

output the Ohms value at the second column

the limits shown.

in

Fluke 712B

Figure 4. Verify 712B 3-Wire Ohms Measure

Fluke 5522A

hwp018.eps

13

Page 22

712B/714B

Calibration Manual

Table 6. 712B 3-Wire Ohms Measure Limits

Range (Ω)

400 1 0.90 1.10 0.87 1.13

400 100 99.89 100.11 99.84 100.16

4000 1000 999.2 1000.8 998.7 1001.3

Applied Ω

from 5522A (Ω)

1 Yr. Lower

Limit (Ω)

1 Yr Upper

Limit (Ω)

2 Yr. Lower

Limit (Ω)

2 Yr Upper

Limit (Ω)

Verify mA Measure

1.

Make the connections between the 712B, 8508A, and 5522A, as

shown in Figure 5.

2.

Set the 8508A to DCI measurement mode, set the range of the DCI

measurement mode to 20 mA and the resolution of DCI measurement

mode to 7 1/2-digits.

3.

Adjust the mA source output of 5522A and make that 8508A shows

as the first column in the Table 7, and verify that the 712B readings

are within the limits shown.

14

Page 23

RTD/Thermocouple Calibrator

5522A

CALIBRATOR

712B Performance Verification

Fluke 8508A

Fluke 5522A

Fluke 712B

Figure 5. Verify 712B mA Measure

hwp004.eps

Table 7. 712B mA Measure Limits

DC Current

Display from

8508A (mA)

1 Yr. Lower Limit

(mA)

1 Yr Upper Limit

(mA)

2 Yr. Lower Limit

(mA)

2 Yr Upper Limit

(mA)

0.100 0.098 0.102 0.096 0.104

19.000 18.996 19.004 18.992 19.008

15

Page 24

712B/714B

Calibration Manual

714B Performance Verification

Verify mV Source

Verify that the 714B performance is within the 1 or 2 year specifications as

desired.

Turn the 714B on and let it warm up for 5 minutes.

1. Make connections between the 714B and the 8508A with copper wire, as

shown in Figure 6.

Fluke 8508A

Fluke 714B

Pure Copper Cables

Pure Copper TC Miniplug

Figure 6. Verify 714B mV Source

hwp006.eps

2. Set the 714B to Source mV mode.

a. Push .

b. Push until mV is highlighted.

c. Push again.

d. Push as necessary to enter Source mode.

3. Set the 714B to output the mV values in Table 8.

4. Check that the 8508A readings are within the appropriate limits in Table 8.

Table 8. 714B mV Source Limits

Range (mV) Sourced (mV)

-10 to 75 -9.5 -9.511 -9.489 -9.517 -9.483

-10 to 75 10 9.989 10.012 9.983 10.017

-10 to 75 40 39.984 40.016 39.977 40.023

-10 to 75 70 69.980 70.020 69.971 70.029

1 Yr. Lower

Limit (mV)

1 Yr Upper

Limit (mV)

2 Yr. Lower

Limit (mV)

2 Yr Upper

Limit (mV)

16

Page 25

RTD/Thermocouple Calibrator

5522A

CALIBRATOR

714B Performance Verification

Verify mV Measure

1. Make connections between the 714B and the 5522A with copper wire, as

shown in Figure 7.

Fluke 5522A

Fluke 714B

Pure Copper Cables

Pure Copper TC Miniplug

Figure 7. Verify 714B mV Measure

hwp007.eps

2. Push to set the 714B to mV Measure mode.

3. Set the 5522A to the first value in Table 9.

4. Output the mV values in Table 9 and verify that the 714B readings are within

the limits shown.

Table 9. 714B mV Measure Limits

Sourced (mV)

-9.5 -9.511 -9.489 -9.517 -9.483

10 9.989 10.012 9.983 10.017

40 39.984 40.016 39.977 40.023

70 69.980 70.020 69.971 70.029

1 Yr. Lower Limit

(mV)

1 Yr Upper Limit

(mV)

2 Yr. Lower Limit

(mV)

2 Yr Upper Limit

(mV)

Verify TC Measure (Type K)

1. Set the 714B to Type K Measure mode.

2. Set the 7526A to TC Out Type K.

3. Use K type TC sensor to connect the 7526A and the 714B, as shown in

Figure 8.

17

Page 26

712B/714B

Calibration Manual

Fluke 714B

K Type

OUTPUT

100V MAX

20V PK

MAX

CURRENT

20V PK

MAX

7526A

VOLTS

4

7526A

PRECISION PROCESS CALIBRATOR

mA

100mA MAX

HI

LO

W RTD/

INPUT

HI

LO

HI

LO

SENSE

RTD/

OUTPUT

TC

INPUT/OUTPUT

20V PK

MAX

TC Miniplug

Figure 8. Verify Type K Measure

hwp015.eps

4. Set the 7526A to the values in Table 10 and verify that the 714B readings are

within the limits shown.

Table 10. 714B Type K Measure Limits

5522A Sourced

(°C)

1 Yr. Lower Limit

(°C)

1 Yr Upper Limit

(°C)

2 Yr. Lower Limit

(°C)

2 Yr Upper Limit

(°C)

-180 -180.9 -179.1 -181.2 -178.8

0 -0.5 0.5 -0.6 0.6

1300 1299.1 1300.9 1298.8 1301.2

Verify TC K Source

1. Set the 714B to type K Source mode.

2. Set the 7526A to TC IN Type K

3. Maintain the connections in Figure 8.

4. Set the 714B to the values in Table 11 and verify that the 7526A readings are

within the limits shown.

Table 11. 714B TC K Source Limits

714B Sourced

(°C)

-100 -100.5 -99.5 -100.6 -99.4

0 -0.5 0.5 -0.6 0.6

800 799.5 800.5 799.4 800.6

1 Yr. Lower Limit

(°C)

1 Yr Upper Limit

(°C)

2 Yr. Lower Limit

(°C)

2 Yr Upper Limit

(°C)

18

Page 27

RTD/Thermocouple Calibrator

5522A

CALIBRATOR

714B Performance Verification

Verify mA Measure

1. Connect the 5522A, 8508A, and 714B, as shown in Figure 9.

2. Set the 8508A to DCI measurement mode, set the range of the DCI

measurement mode to 20 mA and the resolution of DCI measurement mode

to 7 1/2-digits.

3. Set the 5522A to source and make sure that 8508A shows the first dc current

in Table 12.

4. Output the dc current values in Table 12 and verify that the 714B readings

are within the limits shown.

Fluke 8508A

Fluke 714B

Figure 9. Verify mA Measure

Table 12. 714B mA Measure Limits

Fluke 5522A

hwp010.eps

DC current display from

8508A (mA)

0.100 0.098 – 0.102 0.096 – 0.104

19.000 18.996 – 19.004 18.992 – 19.008

1 Yr. Limit (mA) 2 Yr. Limit (mA)

19

Page 28

712B/714B

Calibration Manual

712B Calibration Adjustment

Enter Manual Calibration Mode

This section describes how to adjust for the 712B.

To enter manual calibration mode:

1. Power off the Product.

2. Push and hold down and at the same time.

3. Push and then release .

4. Release and .

The Welcome screen shows.

5. After a warmup period of approximately 5 minutes, start the calibration

adjustment.

Adjust Ohms Source

Before the calibration adjustment, set the 8508A to 4-Wire Ohms measurement

mode, set the resolution of Ohms measurement mode to 7 1/2-digits or above,

and use two sets of banana plug patch cords to connect the 712B and the 8508A,

as shown in Figure 10.

Fluke 712B

Figure 10. Adjust 712B Ohms Source

Fluke 8508A

hwp01.jpg

hwp011.eps

20

Page 29

RTD/Thermocouple Calibrator

712B Calibration Adjustment

Adjust 50 Ω Source

1. Set the range of 8508A 4-Wire measurement to 2 kΩ.

2. Push on the 712B to enter the 50 Ω Source calibration mode.

3. Wait approximately 10 seconds until the 8508A shows a stable reading.

4. Use the arrow keys to input the reading into the 712B.

5. Confirm the input.

Adjust 350 Ω Source

1. Push to enter 350 Ω Source calibration mode.

2. Wait approximately 10 seconds until the 8508A shows a stable reading.

3. Input the reading into the 712B.

4. Confirm the input.

hwp02.jpg

hwp03.jpg

21

Page 30

712B/714B

Calibration Manual

Adjust 500 Ω Source

1. Set the range of 8508A 4-Wire measurement to 20 kΩ.

2. Push to enter 500 Ω Source calibration mode.

3. Wait approximately 10 seconds until the 8508A shows a stable reading.

4. Input the reading into the 712B.

5. Confirm the input.

Adjust 3500 Ω Source

1. Push to enter 500 Ω Source calibration mode.

2. Wait approximately 10 seconds until the 8508A shows a stable reading.

3. Input the reading into the 712B.

4. Confirm the input.

hwp04.jpg

hwp05.jpg

22

Page 31

RTD/Thermocouple Calibrator

712B Calibration Adjustment

Adjust Trigger Current for Ohms Measure

Before the calibration adjustment, set the 8508A to DCI measurement mode,

set the resolution of DCI measurement mode to 7 1/2-digits, and use one set

of banana plug patch cords to connect the 712B and the 8508A, as shown in

Figure 11.

Fluke 8508A

Fluke 712B

Figure 11. Adjust 712B Trigger Current

Adjust 0.1 mA Trigger Current

1. Set the range of the 8508A dc mA measurement to 2 mA.

2. Push on the 712B to enter 0.1 mA trigger current calibration mode.

3. Wait approximately 15 seconds until the 8508A shows a stable reading.

4. Input the reading into the 712B.

5. Confirm the input.

hwp002.eps

hwp06.jpg

23

Page 32

712B/714B

Calibration Manual

Adjust 0.25 mA Trigger Current

1. Push on the 712B to enter 0.25 mA trigger current calibration mode.

2. Wait approximately 15 seconds until the 8508A shows a stable reading.

3. Input the reading into the 712B.

4. Confirm the input.

Adjust 0.5 mA Trigger Current

1. Push on the 712B to enter 0.5 mA trigger current calibration mode.

2. Wait approximately 15 seconds until the 8508A shows a stable reading.

3. Input the reading into the 712B.

4. Confirm the input.

hwp07.jpg

hwp08.jpg

24

Page 33

RTD/Thermocouple Calibrator

5522A

CALIBRATOR

712B Calibration Adjustment

Adjust 1 mA Trigger Current

1. Push on the 712B to enter 1 mA trigger current calibration mode.

2. Wait approximately 15 seconds until the 8508A shows a stable reading.

3. Input the reading into the 712B.

4. Confirm the input.

Adjust Ohms Measure

Before the calibration adjustment, set the 5522A to Ohms source output mode,

and use two sets of banana plug patch cords to connect the 712B and the 5522A,

as shown in Figure 12.

Fluke 712B

Fluke 5522A

hwp09.jpg

Figure 12. Adjust 712B Ohms Measure

hwp003.eps

25

Page 34

712B/714B

Calibration Manual

Adjust 50 Ω Input

1. Set the 5522A to output 50 Ω.

2. Wait approximately 10 seconds for a stable output of the 5522A.

3. Confirm the reading on the 712B.

Adjust 350 Ω Input

1. Push on the 712B to enter 350 Ω input calibration mode.

2. Set the 5522A to output 350 Ω.

Wait approximately 10 seconds for a stable output of the 5522A.

3. Confirm the reading on the 712B.

hwp10.jpg

hwp11.jpg

26

Page 35

RTD/Thermocouple Calibrator

712B Calibration Adjustment

Adjust 500 Ω Input

1. Push on the 712B to enter 500 Ω input calibration mode.

2. Set the 5522A to output 500 Ω.

Wait approximately 10 seconds for a stable output of the 5522A.

3. Confirm the reading on the 712B.

Adjust 3500 Ω Input

1. Push on the 712B to enter the 3500 Ω input calibration mode.

2. Set the 5522A to output 3500 Ω.

Wait approximately 10 seconds for a stable output of the 5522A.

3. Confirm the reading on the 712B.

hwp12.jpg

hwp13.jpg

27

Page 36

712B/714B

5522A

CALIBRATOR

Calibration Manual

Adjust mA Measure

Before the calibration adjustment, set the 5522A to mA (dc) source output mode,

and use one set of banana plug patch cords to connect the 712B and the 5522A,

as shown in Figure 13.

Fluke 5522A

Fluke 712B

Adjust 0.1 mA Input

1. Set the 5522A to output 0.1 mA.

2. Push on the 712B to enter 0.1 mA input calibration mode.

Wait approximately 10 seconds for a stable output of the 5522A.

3. Confirm the reading on the 712B.

Figure 13. Adjust 712B mA Measure

hwp022.eps

hwp14.jpg

28

Page 37

RTD/Thermocouple Calibrator

5522A

CALIBRATOR

712B Calibration Adjustment

Adjust 24 mA Input

1. Set the 5522A to output 24 mA.

2. Push on the 712B to enter 24 mA input calibration mode.

Wait approximately 10 seconds for a stable output of the 5522A.

3. Confirm the reading on the 712B.

Adjust External Trigger for Ohms Source

Before the calibration, set the 5522A to mA (dc) source output mode, and use

one set of banana plug patch cords to connect the 712B and the 5522A, as

shown in Figure 14.

Fluke 712B

Fluke 5522A

hwp15.jpg

Figure 14. Adjust External Trigger for Ohms Source

hwp005.eps

29

Page 38

712B/714B

Calibration Manual

Adjust 0.1 mA External Trigger

1. Set the 5522A to output 0.1 mA.

2. Push on the 712B to enter 0.1 mA external trigger calibration mode.

3. Wait approximately 10 seconds for a stable output of the 5522A.

4. Confirm the reading on the 712B.

Adjust 1 mA External Trigger

1. Set the 5522A to output 1 mA.

2. Push on the 712B to enter 1 mA external trigger calibration mode.

3. Wait approximately 10 seconds for a stable output of the 5522A.

4. Confirm the reading on the 712B.

hwp16.jpg

hwp17.jpg

30

Page 39

RTD/Thermocouple Calibrator

714B Calibration Adjustment

Save Data and Reset the 712B System

After the calibration procedure described above is done, push to confirm and

store the calibration data. The 712B system is automatically reset.

hwp18.jpg

714B Calibration Adjustment

Enter Calibration Mode

To enter manual calibration mode:

1. Power off the Product.

2. Push and hold down and at the same time.

3. Push and then release .

4. Release and .

The Welcome screen shows.

5. After a warmup period of approximately 5 minutes, start the calibration

adjustment.

hwp19.jpg

hwp20.jpg

31

Page 40

712B/714B

Calibration Manual

Use 8508A to Adjust the 5522A Output

Adjust mV Source

To use the 8508A to calibrate the 5522A output:

1. Connect the voltage output terminals of the 5522A with the voltage input

connectors of the 8508A via the pure copper cables.

2. Set the resolution of DCV measurement mode to 7 1/2-digits or above.

3. Adjust the output of the 5522A until the reading of the 8508A is -10 mV

±0.2 μV, and record the voltage setting of the 5522A (=Voltage

-10mV

Setting).

4. Adjust the output of the 5522A until the reading of the 8508A is 75 mV

±0.2 μV, and record the voltage setting of the 5522A (=Voltage

Setting).

75mV

Note

The two voltage setting records are used to calibrate the UUT.

To calibrate the 714B mV Source function:

1. Connect the 714B TC mini plug and the 8508A with pure copper cables, as

shown in Figure 15.

Fluke 8508A

Fluke 714B

Pure Copper Cables

Pure Copper TC Miniplug

Figure 15. Connect the 714B to the 8508A

2. Push to enter -10 mV Source calibration mode.

3. Input the reading on the 8508A to the 714B.

hwp006.eps

32

hwp21.jpg

Page 41

RTD/Thermocouple Calibrator

5522A

CALIBRATOR

714B Calibration Adjustment

4. Push to enter the 75 mV source calibration mode.

5. Input the new reading on the 8508A to the 714B.

6. Push to confirm.

Adjust mV Measure

1. Connect the 714B TC mini plug to the 5522A with pure copper cables, as

shown in Figure 16.

Fluke 714B

Pure Copper Cables

hwp22.jpg

Fluke 5522A

Pure Copper TC Miniplug

Figure 16. Adjust 714B mV Measure

The 5522A outputs the value (Voltage

-10mV

Setting).

hwp007.eps

33

Page 42

712B/714B

Calibration Manual

The 5522A outputs the value (Voltage

2. After approximately 10 seconds, push to calibrate the value.

Adjust Internal Cold Junction Temperature

Use the Fluke 9101-256 or a lag bath to calibrate the internal cold junction

temperature.

Use the Fluke 9101-256

To use the Fluke 9101-256 to calibrate the internal cold junction temperature:

Setting).

75mV

hwp23.jpg

hwp24.jpg

34

1. Connect the Fluke 9101-256 and the 714B via the J type thermocouple

sensor, as shown in Figure 17.

Page 43

RTD/Thermocouple Calibrator

714B Calibration Adjustment

Fluke 714B

J TYPE TC Sensor

Fluke 9101-256

hwp008.eps

Figure 17. Connect the 714B to the Fluke 9101-256

2. After the J type thermocouple is inserted, wait approximately 5 minutes for

the temperature reading to stabilize.

3. Push to calibrate the cold junction temperature.

hwp25.jpg

35

Page 44

712B/714B

Calibration Manual

Use a Lag Bath

To use a lag bath to calibrate the internal cold junction temperature:

1. Connect the lag bath and the 714B via the J type thermocouple sensor, and

immerse the thermocouple and a precision mercury thermometer in the

mineral oil lag bath, as shown in Figure 18.

2. After the thermocouple is inserted, wait approximately 5 minutes for the

temperature reading to stabilize.

3. Record the reading on the standard sensor, and input the reading to the

714B.

4. Push to calibrate the cold junction temperature.

Fluke 714B

J Type

TC Sensor

Figure 18. Use Lag Bath to Adjust Cold Junction Temperature

Fluke 1551A Ex

Thermometer

Note

The mercury thermometer can be replaced with other standard

temperature sensors. The temperature of the lag bath should be

within

±2°

C of ambient temperature.

hwp009.eps

36

Page 45

RTD/Thermocouple Calibrator

5522A

CALIBRATOR

714B Calibration Adjustment

Adjust mA Measure

1. Connect the 5522A and the 714B via the Fluke-75X-8014 cable, as shown in

Figure 19.

The 5522A outputs 0.1 mA.

Fluke 714B

Figure 19.714B and 5522A mA Channel Connections

Fluke 5522A

hwp26.jpg

hwp023.eps

37

Page 46

712B/714B

Calibration Manual

2. Push . The 5522A outputs 24mA.

3. Push to adjust.

Save Data and Reset the 714B System

After the calibration procedure described above is done, push to confirm and

store the calibration data. The 714B system is automatically reset.

hwp28.jpg

hwp27.jpg

hwp29.jpg

38

Page 47

RTD/Thermocouple Calibrator

User-Replaceable Parts and Accessories

User-Replaceable Parts and Accessories

Warning

To prevent possible electrical shock, fire, or personal injury,

use only specified replacement parts.

User-replaceable parts for the 712B are listed in Table 13 and shown in

Figure 20. User-replaceable parts for the 714B are listed in Table 14 and shown

in Figure 21. For more information about these items, contact a Fluke

representative. See the “Contact Fluke” section of this manual.

Table 13. User-Replaceable Parts and Accessories for 712B

Item Description Part Number

Case top 4307068

Decal 4307164

Keypad 4307147

Keypad support 4307112

Screw, M2.2 x 0.8, 5 MM, PAN, PHILLIPS 2032777

LCD mask 4307101

LCD protect rubber 4307208

LCD 4313462

Support LCD gasket 4307213

Screw, M3 x 0.5,5MM, PAN, PHILLIPS 2032811

Case seal rubber 4307186

Case bottom assembly 4307079

Screw, M3, 13.5 mm, PAN, PHILLIPS 2388382

Battery door seal rubber 4307199

AA battery 376756

Not Shown

Not Shown

Not Shown

Not Shown

[1] See www.fluke.com for more information about the test leads and alligator clips available for your

region.

Pad, battery door 4417921

Battery door assembly 4376901

Bail stand 4307093

Quick Reference Guide 4285042

754-8016 alligator clip set 4253535

Stackable test lead set 3669716

Test Leads variable

Alligator Clips variable

[1]

[1]

39

Page 48

712B/714B

Calibration Manual

1

10

2

6

3

4

5

8

9

7

11

12

13

14

15

16

17

19

18

hqu46.eps

Figure 20.User-Replaceable Parts and Accessories for 712B

40

Page 49

RTD/Thermocouple Calibrator

User-Replaceable Parts and Accessories

Table 14. User-Replaceable Parts and Accessories for 714B

Item Description Part Number

Not Shown

Not Shown

[1] See www.fluke.com for more information about the test leads and alligator clips available for your region.

Case top 4307120

Decal on case top 4307173

TC cap 4369726

Keypad 4307158

Keypad support 4307112

Screw, M2.2 x 0.8, 5 mm, PAN, Philips 2032777

TC plate 4307381

Screw, M3-0.5 x 5 mm, Philips 2032811

LCD mask 4307135

LCD protect rubber 4307208

LCD 4313462

Support LCD gasket 4307213

Case seal rubber 4307186

Case bottom assembly 4307079

Screw, M3, 13.5 mm, PAN, Philips 2388382

Battery door seal rubber 4307199

AA battery 376756

Pad, battery door 4417921

Battery door assembly 4376901

Bail stand 4307093

Quick Reference Guide 4285039

TC plugkit, K type 773135

Test Leads, not shown variable

Alligator Clips

[1]

41

Page 50

712B/714B

Calibration Manual

2

3

4

5

6

7

1

9

10

11

8

12

13

14

15

16

17

18

19

20

21

22

hrk46.eps

Figure 21. User-Replaceable Parts and Accessories for 714B

42

Loading...

Loading...