Page 1

6109A/7109A

Portable Calibration Baths

January 2017

© 2017 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

Operators Manual

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and

service. The warranty period is one year and begins on the date of shipment. Parts, product repairs, and

services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of

a Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in

Fluke's opinion, has been misused, altered, neglected, contaminated, or damaged by accident or abnormal

conditions of operation or handling. Fluke warrants that software will operate substantially in accordance

with its functional specifications for 90 days and that it has been properly recorded on non-defective media.

Fluke does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers

only but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is

available only if product is purchased through a Fluke authorized sales outlet or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for importation costs of

repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair,

or replacement of a defective product which is returned to a Fluke authorized service center within the

warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that service center, with a description of the difficulty,

postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following

warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination, alteration, accident, or abnormal

condition of operation or handling, including overvoltage failures caused by use outside the product’s

specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair

costs and obtain authorization before commencing the work. Following repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or

limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not

apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court or other

decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any other

provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

Page 3

Table of Contents

Title Page

Introduction ............................................................................................ 1

Contact Fluke Calibration ...................................................................... 1

Safety Information ................................................................................. 2

Symbols ................................................................................................. 3

Specifications ........................................................................................ 4

Temperature Source Specifications .................................................. 4

Input Module Option Specifications ................................................... 5

General Specifications ....................................................................... 6

Unpack the Product ............................................................................... 7

Product Overview .................................................................................. 7

Top .................................................................................................... 7

Front .................................................................................................. 9

Control Panel ..................................................................................... 10

Back ................................................................................................... 11

Input Module (Option) ........................................................................ 12

Installation ............................................................................................. 12

Product Placement ............................................................................ 12

Provide Ventilation ............................................................................. 13

Add Bath Fluid ................................................................................... 13

Attach the Probe Access Cover ......................................................... 14

Connect to Mains Power ................................................................... 14

Attach Accessories ............................................................................ 16

Fluid Overflow Accessory .............................................................. 16

Probe Clamp .................................................................................. 17

Adjustable Probe Fixture ............................................................... 18

Turn On the Product .............................................................................. 19

Set the Language, Time, and Date .................................................... 19

Set the Password .............................................................................. 20

Connect the Reference Probe and Test Sensor.................................... 20

Connect the Reference Probe ........................................................... 20

Configure the Reference Probe Coefficients ..................................... 22

Connect a Test RTD .......................................................................... 22

Configure the RTD Type .................................................................... 23

Connect a Thermocouple .................................................................. 23

Configure the Thermocouple Type .................................................... 24

Connect a 4–20 mA Transmitter ........................................................ 24

i

Page 4

6109A/7109A

Operators Manual

Configure the mA Input ...................................................................... 24

Operation ............................................................................................... 25

Display ............................................................................................... 25

Basic Operations ............................................................................... 26

Immerse Temperature Probes ....................................................... 26

Set the Setpoint ............................................................................. 26

Preset Setpoints ............................................................................ 27

Set the Cutout ................................................................................ 27

Stop Heating or Cooling ................................................................ 27

Select the Temperature Unit .......................................................... 27

Control the Bath Temperature with a Reference Probe ................ 28

Keyboard Use ................................................................................ 28

Recording Temperature ................................................................. 28

Run a Program .................................................................................. 29

Menu Guide ........................................................................................... 30

Monitor ............................................................................................... 30

Setpoint ............................................................................................. 31

Program ............................................................................................. 32

Setup ................................................................................................. 35

Remote Operation ................................................................................. 42

Setup ................................................................................................. 42

USB Device ....................................................................................... 42

RS-232 .............................................................................................. 43

Test .................................................................................................... 43

Commands ............................................................................................ 44

SCPI Conformance Information ......................................................... 44

Command Reference ........................................................................ 44

Maintenance .......................................................................................... 65

Clean the Product .............................................................................. 65

Clean Up Spills .................................................................................. 65

Check the Bath Fluid ......................................................................... 66

Drain the Bath Fluid ........................................................................... 66

Transport the Calibration Bath ........................................................... 67

Calibrate the Product ............................................................................. 67

Temperature Setpoint Calibration ...................................................... 68

Temperature Stability Calibration ...................................................... 69

Temperature Uniformity Calibration ................................................... 70

Input Module Calibration .................................................................... 71

Troubleshooting ..................................................................................... 74

Fluid Selection ....................................................................................... 76

Temperature Range .......................................................................... 76

Safety ................................................................................................ 76

Viscosity ............................................................................................ 77

Heat Capacity .................................................................................... 77

Thermal Expansion ............................................................................ 77

Lifetime .............................................................................................. 77

Disposal ............................................................................................. 78

Silicone Fluids ................................................................................... 78

Customer-Replaceable Parts and Accessories ..................................... 79

ii

Page 5

Introduction

The Fluke Calibration 7109A and 6109A Portable Calibration Baths (the Product)

accurately calibrate a variety of temperature sensors. The bath fluid volume is

large enough to immerse up to four 38 mm (1.5 inch) flanged tri-clamp probes and

a reference thermometer. The 7109A tests the temperature range of -25 °C to

140 °C. The 6109A covers the temperature range of 35 °C to 250 °C. Traceable

NVLAP accredited calibration is included. Models that equipped with the Input

Module can also measure an RTD, thermocouple, or 4-20 mA transmitter and a

reference PRT. This functionality makes the Product a complete calibration

solution.

Contact Fluke Calibration

To contact Fluke Calibration, call one of the following telephone numbers:

• Technical Support USA: 1-877-355-3225

• Calibration/Repair USA: 1-877-355-3225

• Canada: 1-800-36-FLUKE (1-800-363-5853)

• Europe: +31-40-2675-200

• Japan: +81-3-6714-3114

• Singapore: +65-6799-5566

• China: +86-400-810-3435

• Brazil: +55-11-3759-7600

• Anywhere in the world: +1-425-446-6110

To see product information or download manuals and the latest manual

supplements, visit Fluke Calibration’s website at www.flukecal.com.

To register your product, visit http://flukecal.com/register-product.

1

Page 6

6109A/7109A

Operators Manual

Safety Information

A Warning identifies conditions and procedures that are dangerous to the user. A

Caution identifies conditions and procedures that can cause damage to the

Product or the equipment under test.

Warning

To prevent possible electrical shock, fire, or personal injury:

• Read all safety information before you use the Product.

• Do not keep the Product in operation and unattended at high

temperatures.

• Use the Product only as specified, or the protection

supplied by the Product can be compromised.

• Turn the Product off and remove the mains power cord.

Stop for two minutes to let the power assemblies discharge

before you open the fuse door.

• Replace a blown fuse with exact replacement only for

continued protection against arc flash.

• Use only specified replacement fuses.

• Use only specified replacement parts.

• Disconnect the mains power cord before you remove the

Product covers.

• Disable the Product if it is damaged.

• Do not use the Product if it is altered or damaged.

• Do not heat bath fluid above its flash point unless it is

necessary, approved, and handled safely. The bath fluid or

its vapor may be flammable.

• Connect an approved three-conductor mains power cord to

a grounded power outlet.

• Use this Product indoors only.

• Do not use a two-conductor mains power cord unless you

install a protective ground wire to the Product ground

terminal before you operate the Product. Make sure that the

Product is grounded before use.

• Do not touch parts of the Product that can be hot, including

the area around the tank, the bath fluid, the overflow tube,

overflow tank, and drain tube.

2

• Refer to the bath fluid and solvent’s safety data sheets

(SDS) as these may require additional safety precautions.

• Do not spill bath fluid on the floor. Spilled bath fluid creates

a safety hazard.

Page 7

Portable Calibration Baths

Symbols

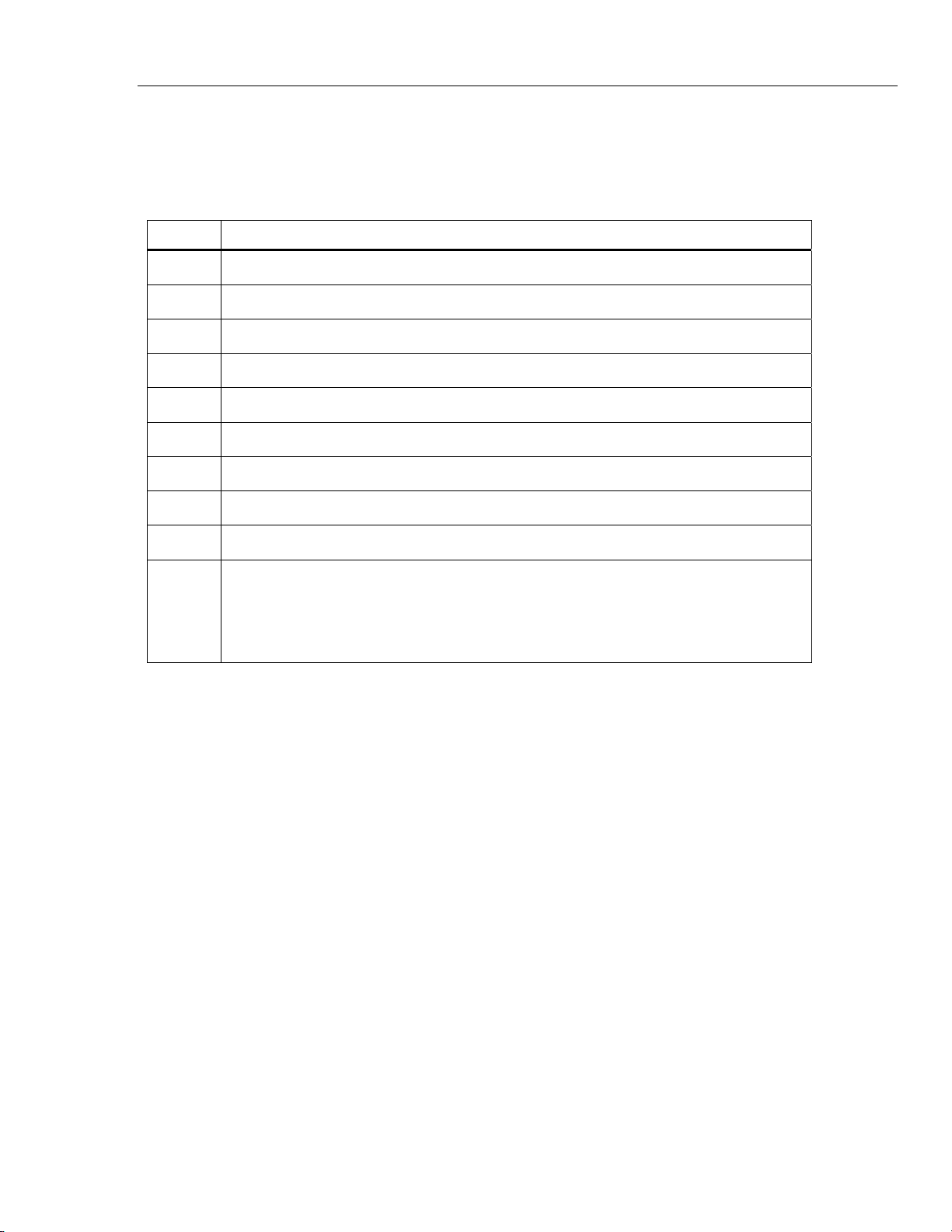

Symbols

The symbols used in this manual and on the Product are shown in Table 1.

Table 1. Symbols

Symbol Description

WARNING. HAZARDOUS VOLTAGE. Risk of electric shock.

WARNING.RISK OF DANGER.

WARNING. HOT SURFACE. Risk of burns.

Consult user documentation.

Certified by CSA Group to North American safety standards.

Conforms to European Union directives.

Conforms to relevant Australian EMC standards.

Fuse

Conforms to relevant South Korean EMC Standards.

This product complies with the WEEE Directive marking requirements. The affixed label

indicates that you must not discard this electrical/electronic product in domestic household

waste. Product Category: With reference to the equipment types in the WEEE Directive

Annex I, this product is classed as category 9 "Monitoring and Control Instrumentation"

product. Do not dispose of this product as unsorted municipal waste.

3

Page 8

6109A/7109A

Operators Manual

Specifications

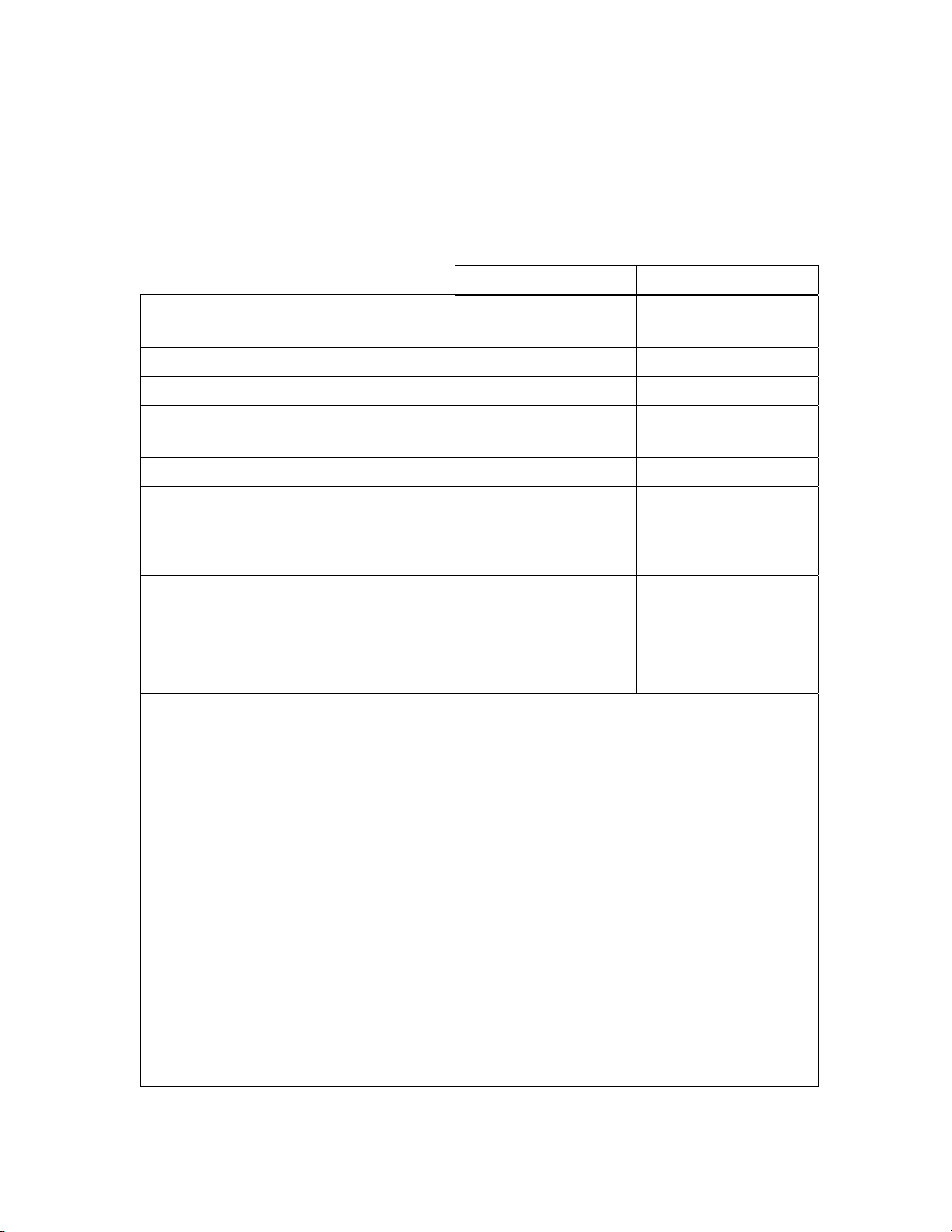

Temperature Source Specifications

The product specifications describe the Absolute Instrumental Uncertainty of the

Product at 95 % level of confidence (coverage factor k = 2) within one year from

calibration. The product specifications include environmental temperature effects

from 13 °C to 33 °C.

6109A 7109A

Range

(at 25 °C ambient temperature)

35 °C to 250 °C

-25 °C to 140 °C

(-15 °C cover off)

Accuracy: Maximum Permissible Error 0.1 °C 0.1 °C

Stability 0.015 °C 0.01 °C

Typical Uniformity

0.03 °C up to 200 °C

0.04 °C above 200 °C

0.02 °C

Repeatability 0.04 °C 0.04 °C

Typical Heating Time

Typical Cooling Time

35 °C to 100 °C:

25 minutes

100 °C to 250 °C:

45 minutes

250 °C to 100 °C:

35 minutes

100 °C to 35 °C:

55 minutes

25 °C to 140 °C:

55 minutes

-25 °C to 25 °C:

35 minutes

25 °C to -25 °C:

75 minutes

140 °C to 25 °C:

45 minutes

Typical Settling Time 15 minutes 10 minutes

Notes:

• The lower limit of the Temperature Range varies depending on the ambient temperature and whether the tank is covered.

Operating time at negative temperatures may be limited by water condensation or ice build-up, especially if the tank is

open.

• Accuracy covers all sources of error including calibration uncertainty, stability, uniformity, and repeatability.

• If the environment temperature is outside the Performance Environment Range but within the Operating Environment

Range, multiply the specification by 1.25.

• Temperature Stability and Temperature Uniformity apply with the tank covered. If the Product is operated with the tank

open, multiply the specifications by 1.25.

• Specifications are valid with fluid depth at least 130 mm and within the working volume defined as a 75 mm square

centered in the tank opening from 15 mm above the bottom of the tank to 65 mm below the surface of the fluid. The

specifications also apply with the recommended fluid in good condition. Results may vary if a different fluid is used.

• Temperature Stability is evaluated as two times the statistical standard deviation of the fluid temperature (2 sigma) during

a 15-minute period after sufficient settling time is allowed.

• Temperature Uniformity is defined as half the difference between the maximum and minimum temperatures within the

working volume.

• Repeatability includes hysteresis of the control sensor. It is defined as the difference between the maximum and

minimum observed temperatures at a setpoint near the middle of the Product Temperature Range after that setpoint is

alternately reached from both extremes of the Temperature Range.

• Cooling or heating time is measured from the time the setpoint is changed to when the fluid temperature reaches the

setpoint within the Temperature Accuracy specification. Cooling and heating times vary depending on environment

temperature, AC supply voltage, loading, and whether the tank is covered. At low ac supply voltages, heating time may be

much longer.

• Settling time is measured from the end of the cooling or heating time to the time at which the fluid reaches its ultimate

mean temperature within a tolerance equal to the Temperature Stability specification.

4

Page 9

Portable Calibration Baths

Specifications

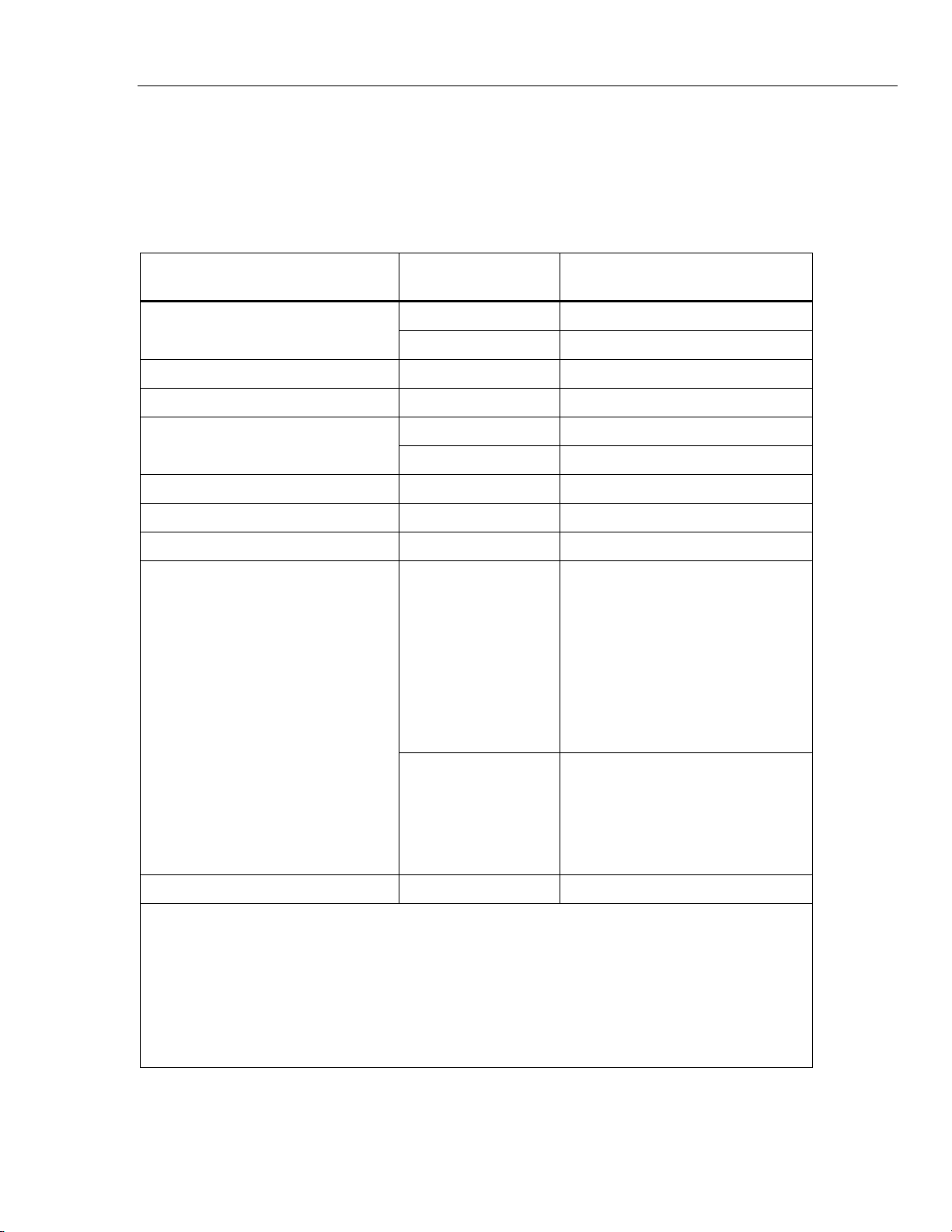

Input Module Option Specifications

The Product specifications describe the Absolute Instrumental Uncertainty of the

Product at 95 % level of confidence (coverage factor k = 2) within one year from

calibration. The Input Module specifications include calibration uncertainty,

linearity, repeatability, resolution, stability, and environmental temperature effects

from 13 °C to 33 °C.

Function Range

Maximum Permissible Error

Accuracy:

0 Ω to 42 Ω 0.0025 Ω

Reference Input Resistance

42 Ω to 400 Ω 0.006 %

Reference Input Temperature -25 °C to 250 °C 0.007 % + 0.015 °C

Resistance Sensing Current 1 mA 8 %

0 Ω to 31 Ω 0.0025 Ω

DUT 4-wire Resistance

31 Ω to 400 Ω 0.008 %

DUT 3-wire Resistance Accuracy 0 Ω to 400 Ω 0.12 Ω

Thermocouple mV -10 mV to 100 mV 0.025 % + 0.01 mV

Reference Junction Temperature 0 °C to 40 °C 0.35 °C

J: 0.44 °C

K: 0.49 °C

T: 0.53 °C

-25 °C to 250 °C

E: 0.44 °C

N: 0.57 °C

M: 0.48 °C

Thermocouple Temperature

L: 0.42 °C

U: 0.48 °C

R: 1.92 °C

S: 1.88 °C

0 °C to 250 °C

C: 0.84 °C

D: 1.12 °C

G/W: 3.34 °C

mA 0 mA to 22 mA 0.02 % + 0.002 mA

Notes

• Specifications stated in percent are percent of reading.

• If the environment temperature is outside the Performance Environment Range but within the Operating Environment

Range, multiply the accuracy specifications by 1.5.

• Reference Input Temperature Accuracy assumes a 4-wire, 100 Ω, α = 0.00392 PRT. The specification does not include

accuracy of the thermometer (see Table 4 of this manual).

• DUT Input Resistance Accuracy specification for 2-wire sensors is 0.05 Ω plus lead wire resistance.

• Thermocouple Input Temperature Accuracy specification includes Thermocouple Input mV and Reference Junction

Temperature, combined using the root-sum-square method. The specification does not include the accuracy of the

thermocouple.

5

Page 10

6109A/7109A

Operators Manual

General Specifications

Performance Environment Range ..................................... 13 °C to 33 °C

5 % to 90 % (non-condensing)

Operating Environment Range ......................................... 0 °C to 40 °C

5 % to 90 % (non-condensing)

Maximum Operating Altitude ............................................ 2000 m (6600 ft)

Storage Range ................................................................. -40 °C to 70 °C

5 % to 95 % (non-condensing)

Supply Voltage ................................................................. 115 V nominal: 100 V to 120 V ac (±10 %),

50 Hz or 60 Hz

230 V nominal: 200 V to 230 V ac (±10 %),

50 Hz or 60 Hz

1150 W

Fuses ................................................................................ 115 V nominal: 10 A, 250 V 3AG slow

230 V nominal: 5 A, 250 V 5x20 slow

4-20 mA Input Loop Power Voltage .................................. 24 V dc ±6 V

4-20 mA Fuse ................................................................... 0.05 A, 250 V 5x20 fast

Size

Width: 242 mm (9.5 in)

Depth: 400 mm (15.7 in)

Weight

6109A: 16 kg (35 lb)

Fluid Volume ..................................................................... 2.5 liters (0.66 gal)

Fluid Working Area ........................................................... 75 mm x 75 mm (3 in x 3 in)

Maximum Fluid Depth ....................................................... 154 mm

Remote Interface .............................................................. RS-232 port, 1200 to 38400 baud

USB 2.0 device port

USB 2.0 host port (for data recording)

Compliance ....................................................................... EN 61010-1 (2010), category II, degree 2

IEC 61326-1, basic

RoHS

SCPI 1999.0

Notes

[1] Size does not include the optional overflow kit or other attached accessories.

[2] Weight does not include bath fluid or accessories.

[1]

............................................................................... Height: 382 mm (15 in)

[2]

........................................................................... 7109A: 20 kg (45 lb)

6

Page 11

Portable Calibration Baths

Unpack the Product

Unpack the Product

Carefully unpack the Product. Save the shipping carton for later use in case the

Product needs to be shipped or moved to another facility. Make sure that there is

no damage to the Product. If any parts are damaged, contact Fluke Calibration. If

it is necessary to reship the Product, use the original container. To order a new

container, see Contact Fluke Calibration.

Warning

To prevent possible electrical shock, fire, or personal injury:

• Disable the Product if it is damaged.

• Do not use the Product if it is damaged or altered.

Check that all items listed below are present and have no visible damage.

• The Product

• Mains power cord (see Figure 6)

• USB cable

• Probe access cover

• Transport tank cover

• Printed safety information

• Product CD

• Report of calibration with label

• Clamp-on ferrite (-P models)

• Din connector (-P models)

• Test lead kit (-P models)

The Product CD contains:

• Operators manual in multiple languages

• USB driver

• Software distribution licenses

• Source code for public-domain software

Product Overview

This section is a reference for the Product features, parts, and user interface (UI).

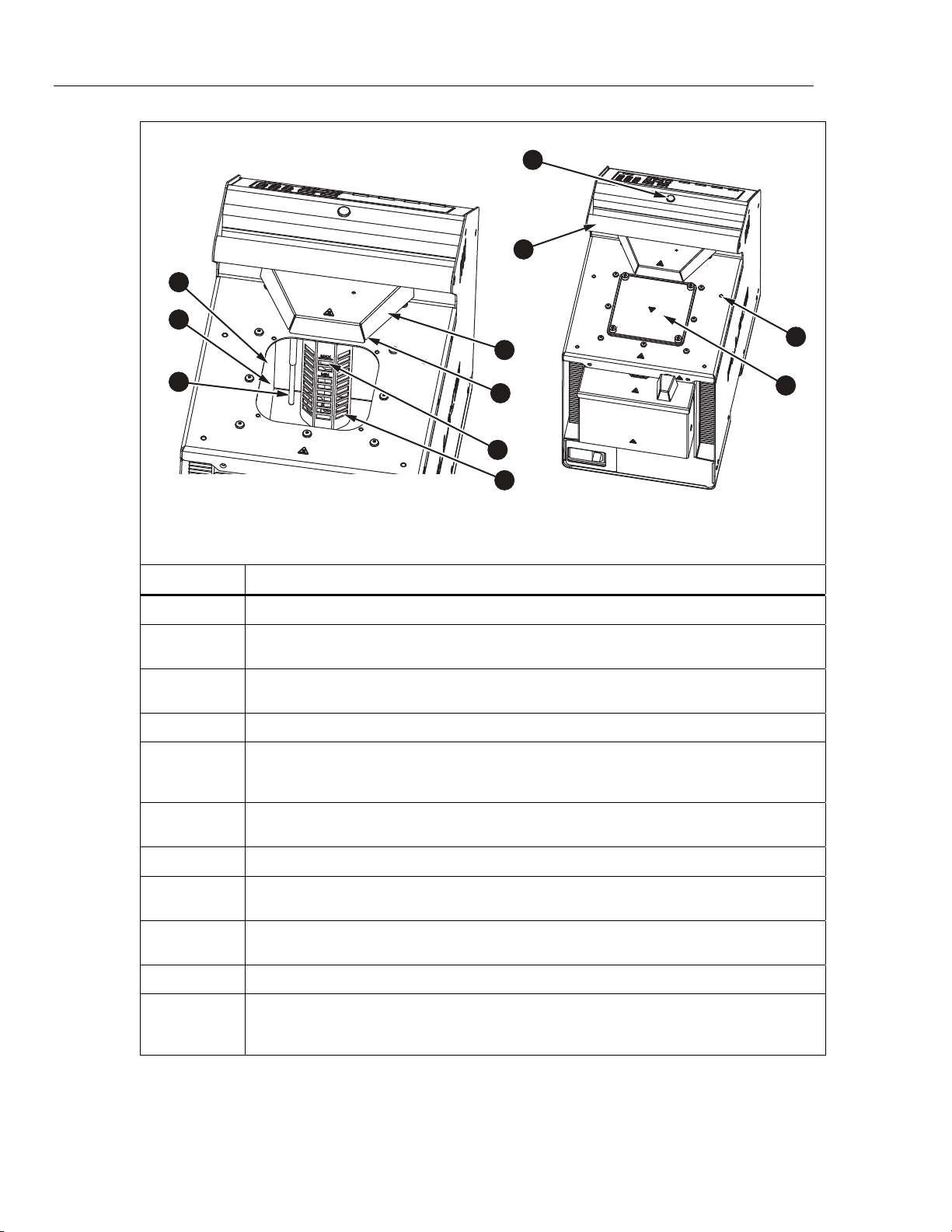

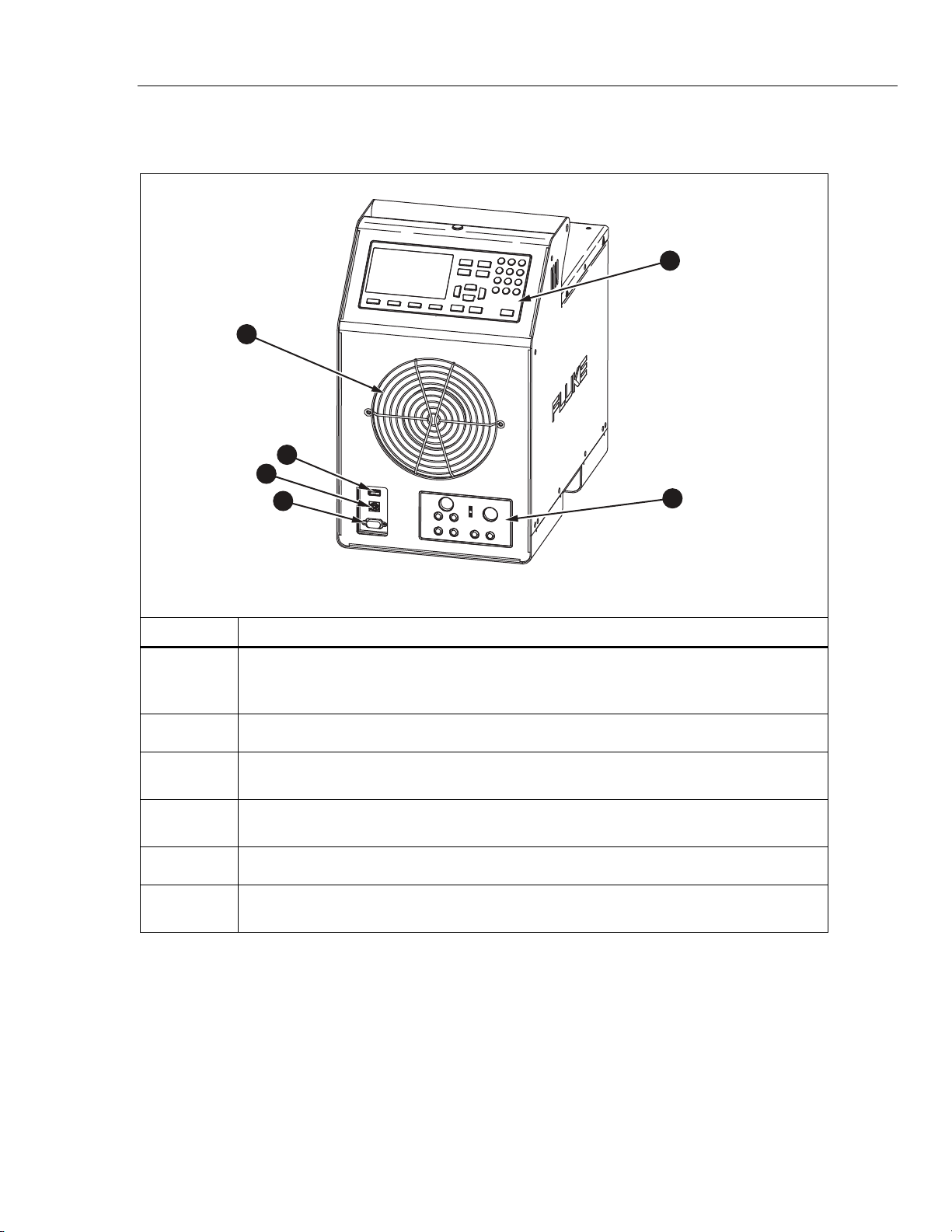

Top

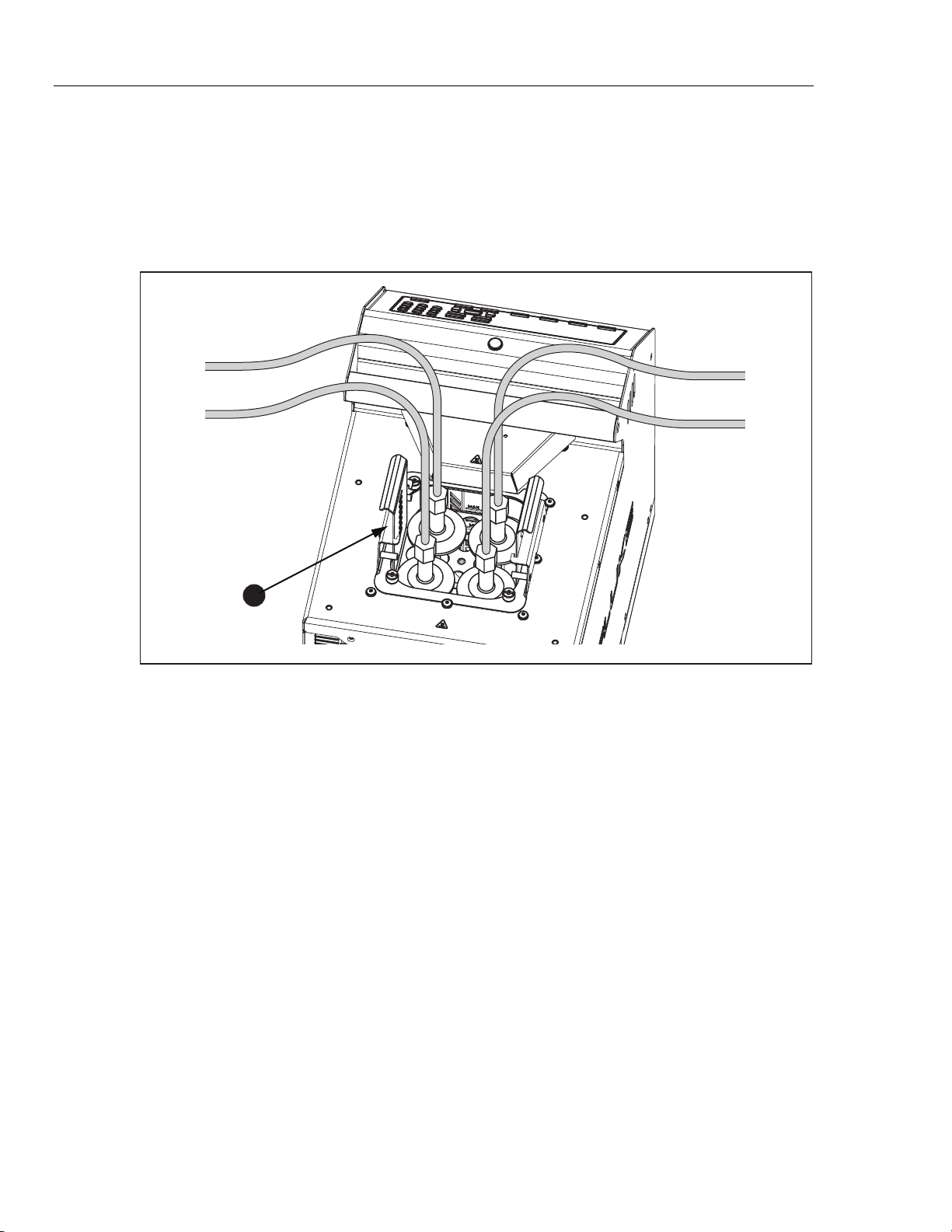

The Product top and tank are shown in Figure 1.

7

Page 12

6109A/7109A

Operators Manual

9

8

1

2

10

4

3

Number Description

Tank - The stainless steel tank contains the bath fluid.

Bath Fluid - Temperature sensors are inserted into the bath fluid for calibration. Heating

and cooling devices attached to the walls of the tank heat and cool the bath fluid.

Control Sensor - The precision platinum resistance thermometer (PRT) measures and

controls the temperature of the bath fluid.

Stir Motor Cover - Protects the stir motor.

Stir Motor (under the Stir Motor cover) - The stir motor drives the propeller that circulates

the fluid to produce a uniform temperature. The stir motor turns on when control is

enabled.

Stir Guard - Separates the working area of the tank from the stir propeller. MIN and MAX

marks on the stir guard show the correct fill levels.

5

6

7

11

icu07.eps

8

Propeller - Stirs the bath fluid.

Carrying Handle - Use the handle to lift or move the Product. There are also recessed

handles on the sides of the Product (not shown).

Ready Indicator - Changes from amber to green when the bath fluid temperature has

settled at the setpoint. Green indicates that the Product is ready for measurement.

Threaded Holes (M4) - Used to attach accessories to the Product.

Tank Cover - Isolates the bath fluid from the environment, reduces fumes, prevents

objects from falling into the tank, and keeps the fluid temperature stable. The tank cover

attaches to the top panel with four thumb screws.

Figure 1. Top of the Product

Page 13

Portable Calibration Baths

Product Overview

Front

The front of the Product is shown in Figure 2.

5

1

2

3

4

6

icu01.eps

Number Description

Fan - Cools the tank and heating devices. Keep at least 150 mm of open space around the

Product and 300 mm behind it to avoid obstruction of the air flow. Keep objects away from

the fan opening as the fan produces strong suction.

USB Host Port - Use this port to record temperature data to a memory device.

USB Device Port - Like the RS-232 Port, this USB device port can be used to control the

Product.

RS-232 Port - Like the USB Device Port, this port can be used to control the Product

remotely.

Control Panel - See Control Panel.

Process Input Module - This optional module measures electrical temperature sensors for

calibration.

Figure 2. Front of the Product

9

Page 14

6109A/7109A

Operators Manual

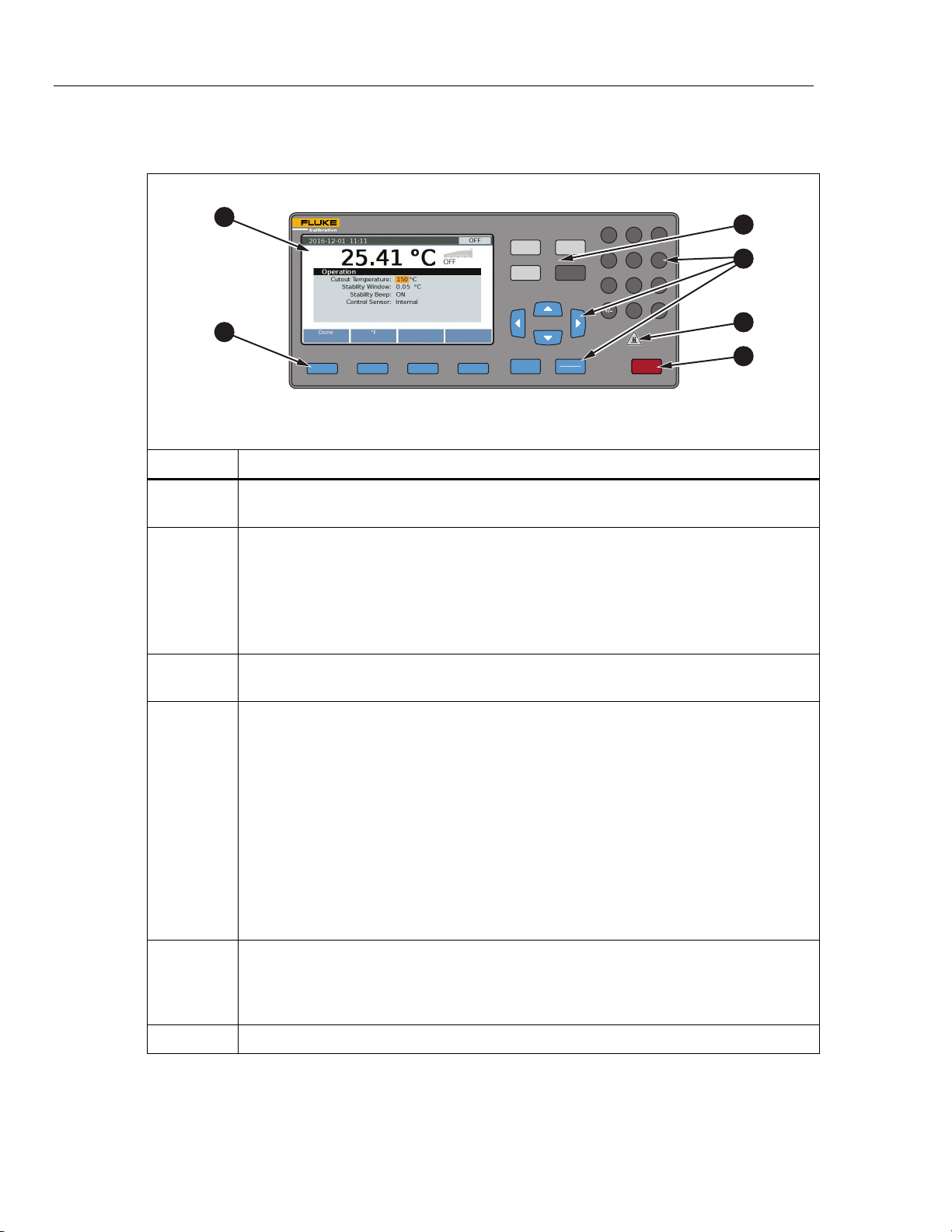

Control Panel

The control panel is shown in Figure 3.

1

2

F1 F2 F3 F4

PORTABLE CALIBRATION BATH

6109A

35˚C TO 250˚ C

MONITOR

SETPOINT

BACK

PROGRAM

SETUP

SELECT

ENTER

798

46

5

3

2

1

.

0

STOP

3

4

5

6

icu05.eps

Number Description

Display - Shows the information about the operation of the Product such as the fluid

temperature and setpoint.

Softkeys - These keys correspond to the display icons directly above each key. The

functions change with the status of the display. In many menus is labeled Done.

It returns the screen to the first menu.

As you type numbers for settings, acts as a backspace key. This deletes the last

digit in the number. If a setting accepts a number in exponential notation, works

as an exponent key.

Mode Keys - , , , and access different groups of settings. Some

mode keys light up when the mode is active.

Other Keys - Controls used to operate the Product. There are numbers, cursor keys,

and to make menu choices.

- Returns the UI to the prior menu.

and - Use to move the cursor up or down.

and - Use to move the cursor left or right.

Number keys (0-9) - Use the ten number keys to enter decimal numbers. If a setting

accepts an exponential number, a special exponent key is shown as one of the softkeys.

Push to save the number.

- Change a selected item. After the setting is changed, push to save the new

value. Settings that have only binary states, such as ON or OFF, are changed and

saved with a single push.

Hot Warning Indicator - This indicator lights up if the fluid temperature is ≥60 °C. This

warns that the bath fluid, tank cover, and area around the tank are hot and should not

be touched. If the Product is switched off, the indicator stays on until the Product

reaches a safe temperature. It flashes at a slow rate to conserve energy.

- Immediately disables heating and cooling and switches off the stir motor.

Figure 3. Control Panel

10

Page 15

Portable Calibration Baths

Product Overview

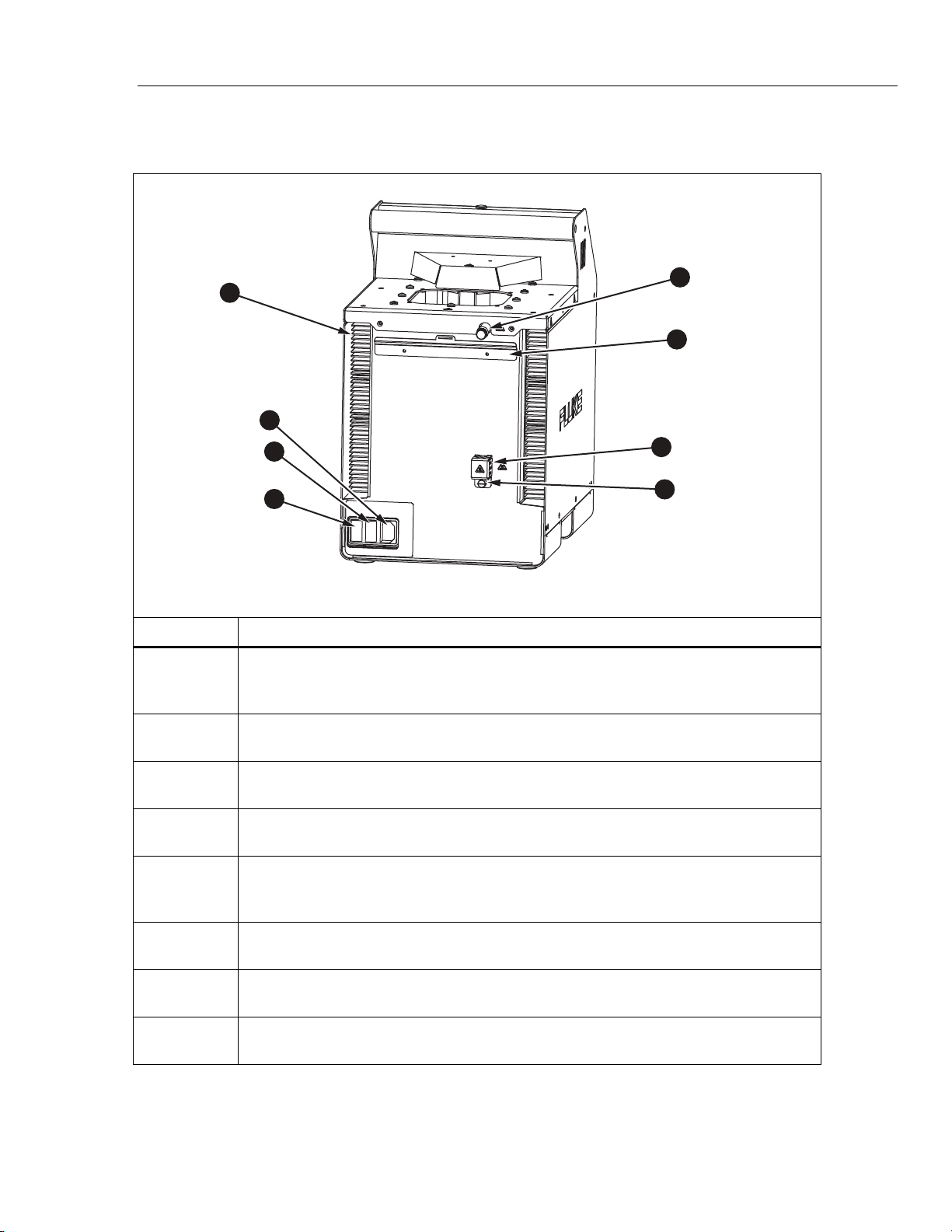

Back

The back of the Product is shown in Figure 4.

1

2

3

4

Number Description

Fan Vents - As the Product cools, a heavy air stream flows from the fan vents. Keep at

least 300 mm of open space behind the Product to avoid an obstructed air flow. There

are also ventilation slots on the sides of the Product (not shown).

5

6

7

8

icu09.eps

Mains Power Socket - A grounded male three-prong connector that accepts the mains

power cord. Connect the Mains power cord here.

Power Switch - Toggle this switch to I to turn on the Product. Toggle this switch to O to

turn off the Product.

Fuses - Protect the Product from excessive current. If a fuse appears to be blown,

contact Fluke Calibration for assistance. See Contact Fluke Calibration.

Overflow Tube - Directs excess bath fluid into the optional overflow container. If the

overflow kit is not used, keep the overflow tube plugged and reduce the fluid level to

allow for thermal expansion.

Overflow Container Mounting Bracket – Holds the optional overflow container (not

shown).

Drain Cover - Keep the drain plug (not shown) on tight and the drain cover in place for

normal operation.

Drain Tube - The drain tube (not visible) makes it easy to remove the bath fluid for

replacement or Product transport.

Figure 4. Back of the Product

11

Page 16

6109A/7109A

Operators Manual

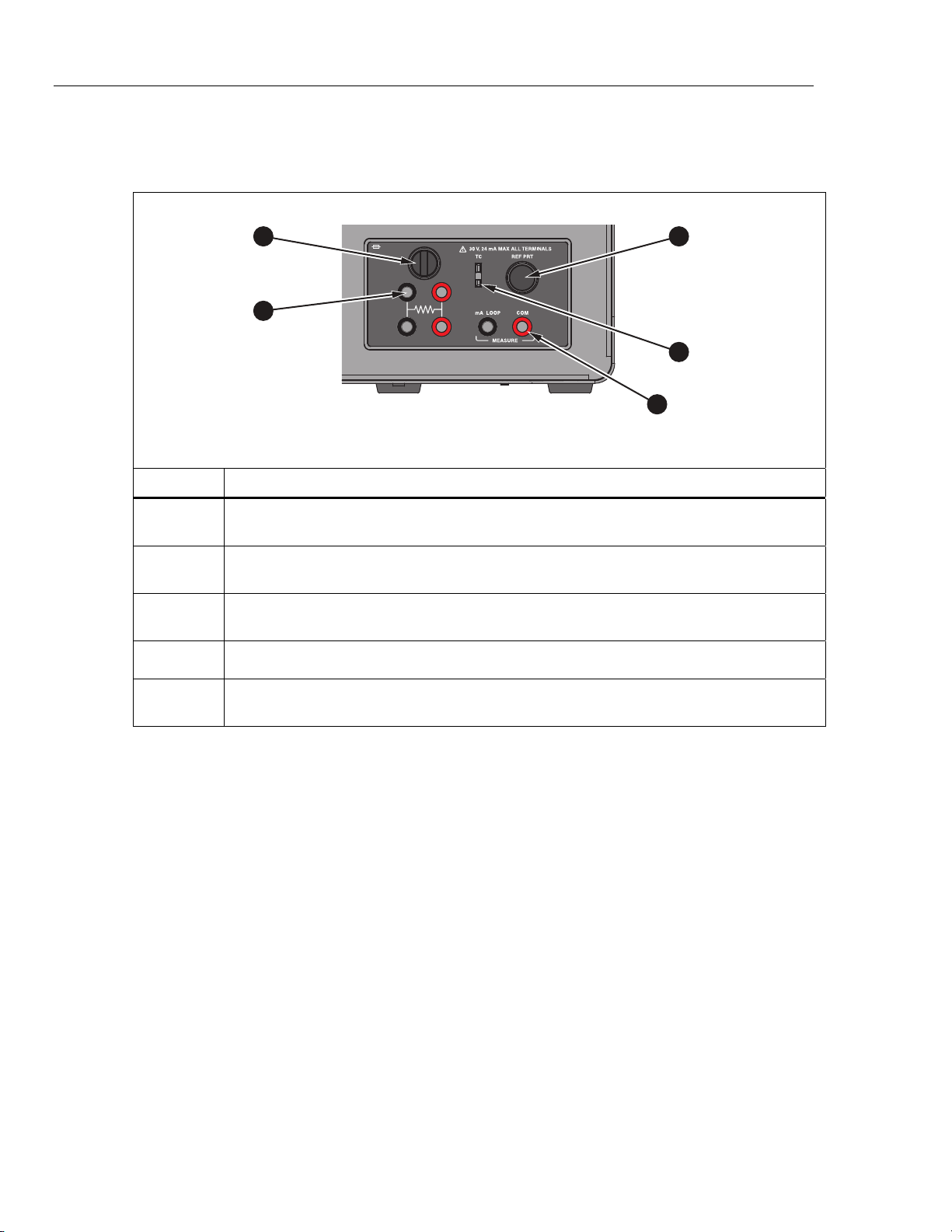

Input Module (Option)

The 7109A-P and 6109A-P come with an Input Module that measures various

types of temperature sensors. This optional input module is shown in Figure 5.

1

2

Number Description

Current Fuse - Protects the Input Module and connected devices from accidental short

circuit. Replace the fuse only with the same type: 5 mm × 20 mm, 50 mA, fast-acting.

RTD Terminals - A test RTD connects to these terminals. The graphic on the panel shows

the circuit diagram for a four-wire RTD.

Reference PRT Connector - A reference probe plugs into this socket. The connector

accepts a Fluke INFO-CON plug with a memory device that stores probe coefficients.

Thermocouple Input - A miniature thermocouple connector.

F 50 mA 250V

3

4

5

icu02.eps

Transmitter Terminals - A 4-20 mA transmitter connects to the two transmitter terminals

labeled mA LOOP and COM.

Installation

The subsequent sections explain safe and correct Product installation.

Product Placement

To prevent possible electrical shock, fire, or personal injury, do

not restrict access to the Product mains power cord. The mains

power cord is the mains disconnecting device.

Place the unpacked Product on a clean, sturdy, flat surface in a spacious location

with good environmental control. There must be at least 150 mm (6 inches) of

space around the front and sides and 300 mm of open space behind the Product

for the ventilation and cooling fans to operate properly. The environment must

maintain a steady, moderate temperature and dissipate up to 1000 W of heat

produced by the Product. Avoid air drafts and temperature fluctuations that could

adversely affect the temperature stability of the Product.

Figure 5. Input Module Option

Warnings

12

Page 17

Portable Calibration Baths

Installation

Provide Ventilation

Warning

To prevent personal injury:

• Read the bath fluid safety data sheet (SDS) and take

necessary precautions. Some fluids are corrosive, toxic, or

irritate the skin, eyes, nose, and respiratory organs.

• Use a ventilation system to remove vapor.

• Do not use fluids that are corrosive to stainless steel.

Harmful substances such as benzene and formaldehyde can be produced above

a certain temperature. The safety data sheet for a silicone fluid typically states

149 °C for this temperature.

Bath fluid vapors present a fire hazard, especially when the bath fluid is operated

above its flash point. Bath fluid vapors tend to condense onto surrounding

surfaces. This can contaminate materials and inhibit laboratory cleanliness. If

enough condensation accumulates on the floor, the floor becomes slippery and

creates a safety hazard.

For appropriate fume extraction use a ventilation duct of at least 75 mm

(3 inches) in diameter with an air flow rate between 1.4 cubic meters and

1.7 cubic meters per minute (50 cfm to 60 cfm). Place the inlet of the ventilation

duct near the top of the tank.

Add Bath Fluid

The choice of bath fluid is important for the Product to achieve full temperature

range and performance specifications. Table 2 lists the recommended bath fluid

for each model.

Fluke 5012 Silicone, 10 centistoke Fluke 5014 Silicone, 50 centistoke

Table 2. Recommended Bath Fluids

7109A 6109A

13

Page 18

6109A/7109A

Operators Manual

MAX level, 154 mm MIN level, 128 mm

Other bath fluids can be used, but the temperature range may be more limited.

Temperature stability and uniformity also varies when other fluids are used. As a

rule, bath fluid viscosity should be no greater than 50 centistokes at any

operating temperature. See Fluid Selection for more information.

Silicone fluid expands as it is heated. This can cause the bath fluid to spill out of

the tank. Use the optional overflow kit or fill the tank to a lower level. The stir

guard has marks MAX and MIN to show the proper fill levels. Fill the tank to the

MIN level if the plug is left in the overflow tube. Fill to the MAX level if the

overflow kit is used. Table 3 gives the recommended fill levels as measured from

the bottom of the tank.

Table 3. Fluid Fill Levels

Overflow Kit Installed Overflow Tube Plugged

Note

Remove the plug from the overflow tube if the tank is filled to

maximum depth.

To add bath fluid:

1. Remove the tank cover.

2. Pour the bath fluid in through the tank opening.

3. Replace the cover and tighten its thumb screws.

4. Clean up any drips or spills. Do not get fluid on the control panel.

Attach the Probe Access Cover

Keep the tank covered when you operate the Product to ensure temperature

stability, uniformity, and accuracy. Use the provided probe access cover. The

cover holes fit many types of temperature sensors. Use the thumb screws to

fasten the cover to the top panel. Make sure the rubber gasket is properly

seated.

Connect to Mains Power

To prevent possible electrical shock, fire, or personal injury,

connect the factory-supplied three-conductor mains power cord

to a properly-grounded power outlet. Do not use a twoconductor adapter or extension cord, as it will break the

protective ground connection.

Use the provided mains power cord to connect the Product to a 150 V ac or

230 V ac outlet (this depends on the model). The circuit, outlet, and mains power

cord must all be rated at 115 V ac, 10 A at 230 V ac.

Warning

14

Page 19

Portable Calibration Baths

Installation

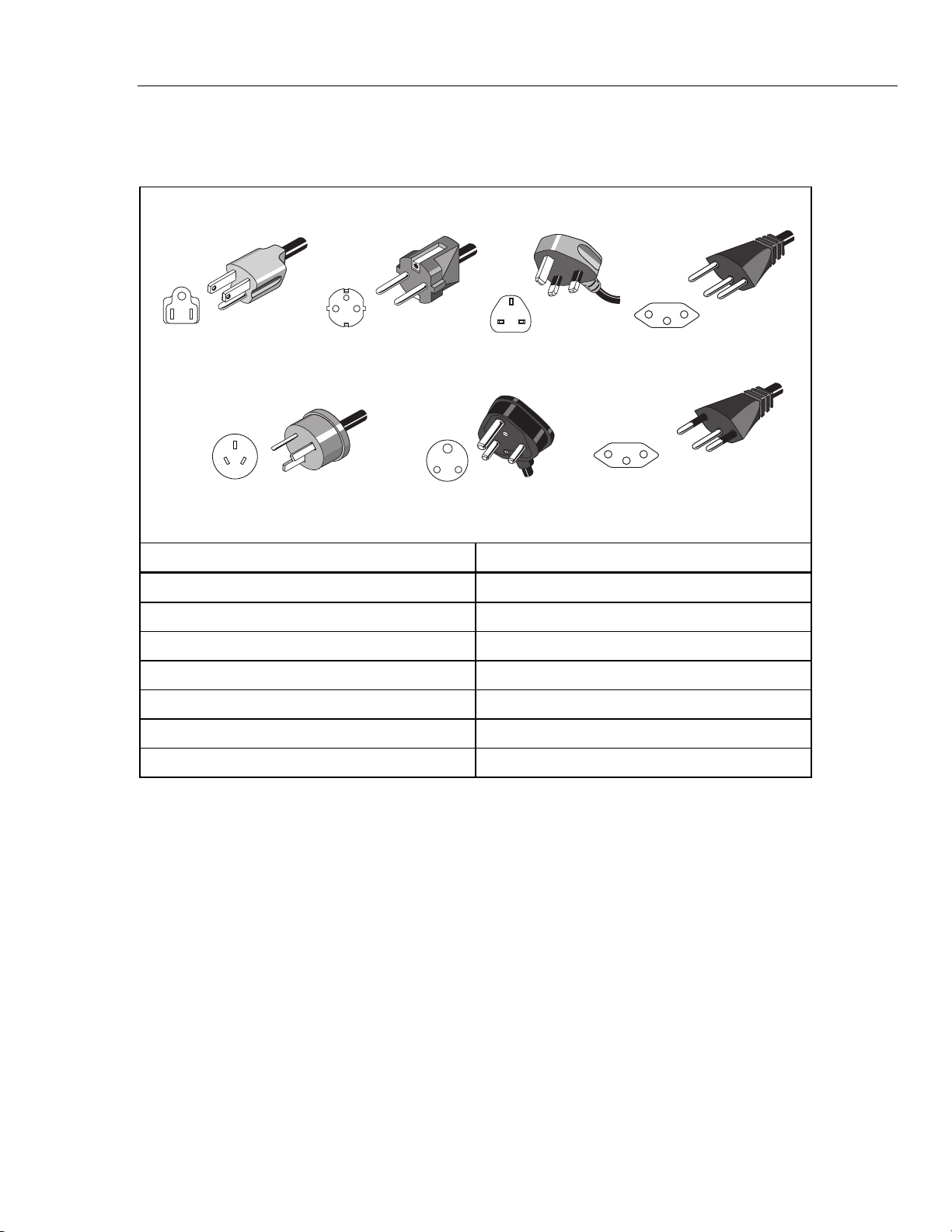

The Product comes with the appropriate line power plug for the country of

purchase. If a different type is necessary, refer to Figure 6 for the correct mains

line power plug types available from Fluke Calibration.

Universal EuroNorth American/Japan United Kingdom

LC-1

Australia/China

LC-6

LC-3

LC-4

South Africa Brazil

LC-7 LC-42

Type Fluke Calibration Part Number

North America LC-1

Universal Euro LC-3

United Kingdom LC-4

LC-5

Swiss

hhp004.eps

Switzerland LC-5

Australia LC-6

South Africa LC-7

Brazil LC-42

Figure 6. Available Mains Power Cord Types

15

Page 20

6109A/7109A

Operators Manual

Attach Accessories

Fluid Overflow Accessory

Accessory attachment is explained in the subsequent sections.

Fluke Calibration recommends the fluid overflow accessory kit (model 7109-

2083) to avoid spills caused by thermal expansion of the fluid or an overfilled

tank.

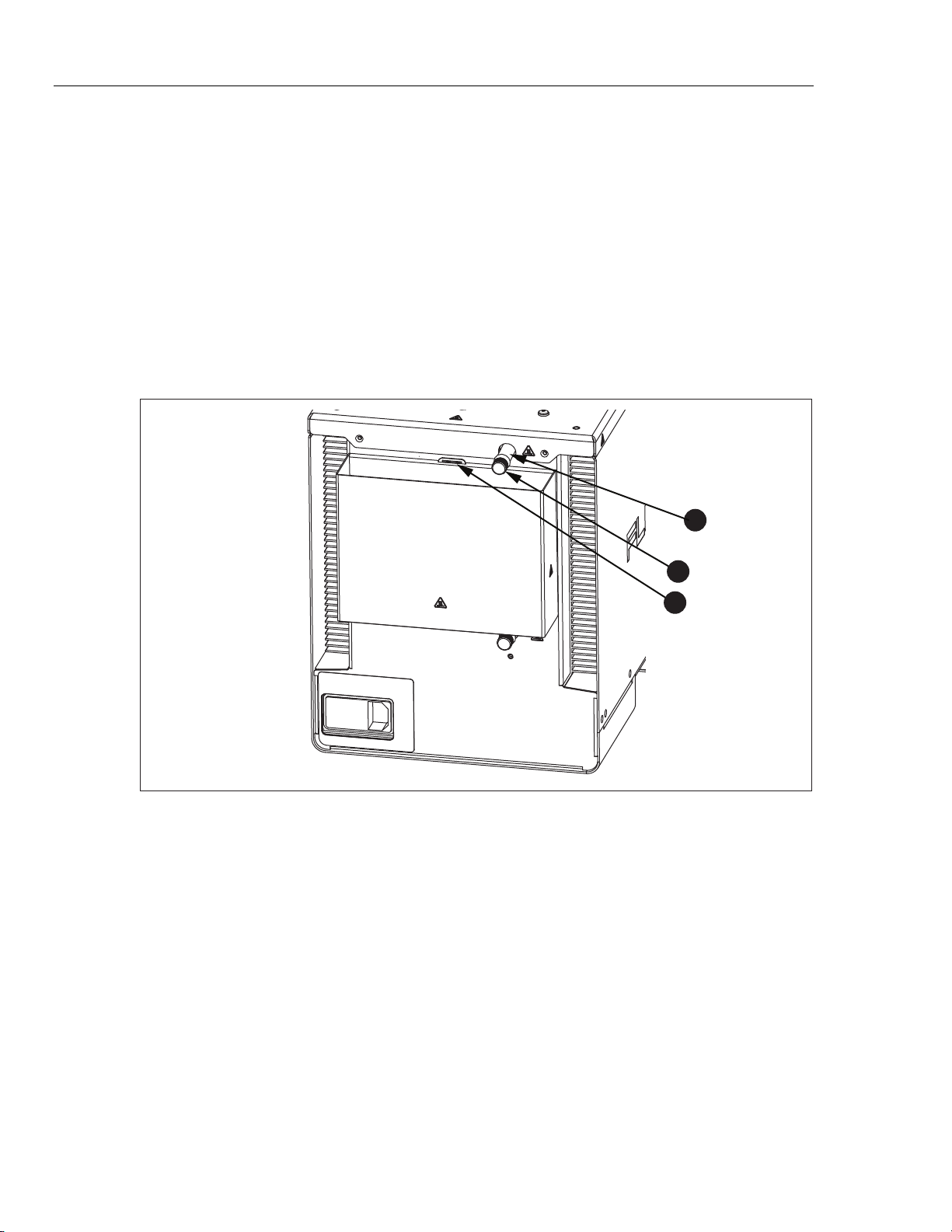

To install the bath fluid overflow accessory, see Figure 7:

1. Remove the plug from the overflow tube .

2. Place the overflow container onto the mounting bracket and align it below

the overflow tube.

3. Place the cover (not shown) on the overflow container.

Figure 7. Fluid Overflow Accessory

1

2

3

icu03.eps

16

Page 21

Portable Calibration Baths

Installation

Probe Clamp

Use the probe clamp accessory (Model 7109-2051, purchased separately) to

hold temperature probes in place while they are calibrated. The post of the probe

clamp screws into any of the four the M4 size threaded holes located near the

corners of the top panel. See Figure 8.

Figure 8. Probe Clamp Accessory

icu14.eps

17

Page 22

6109A/7109A

Operators Manual

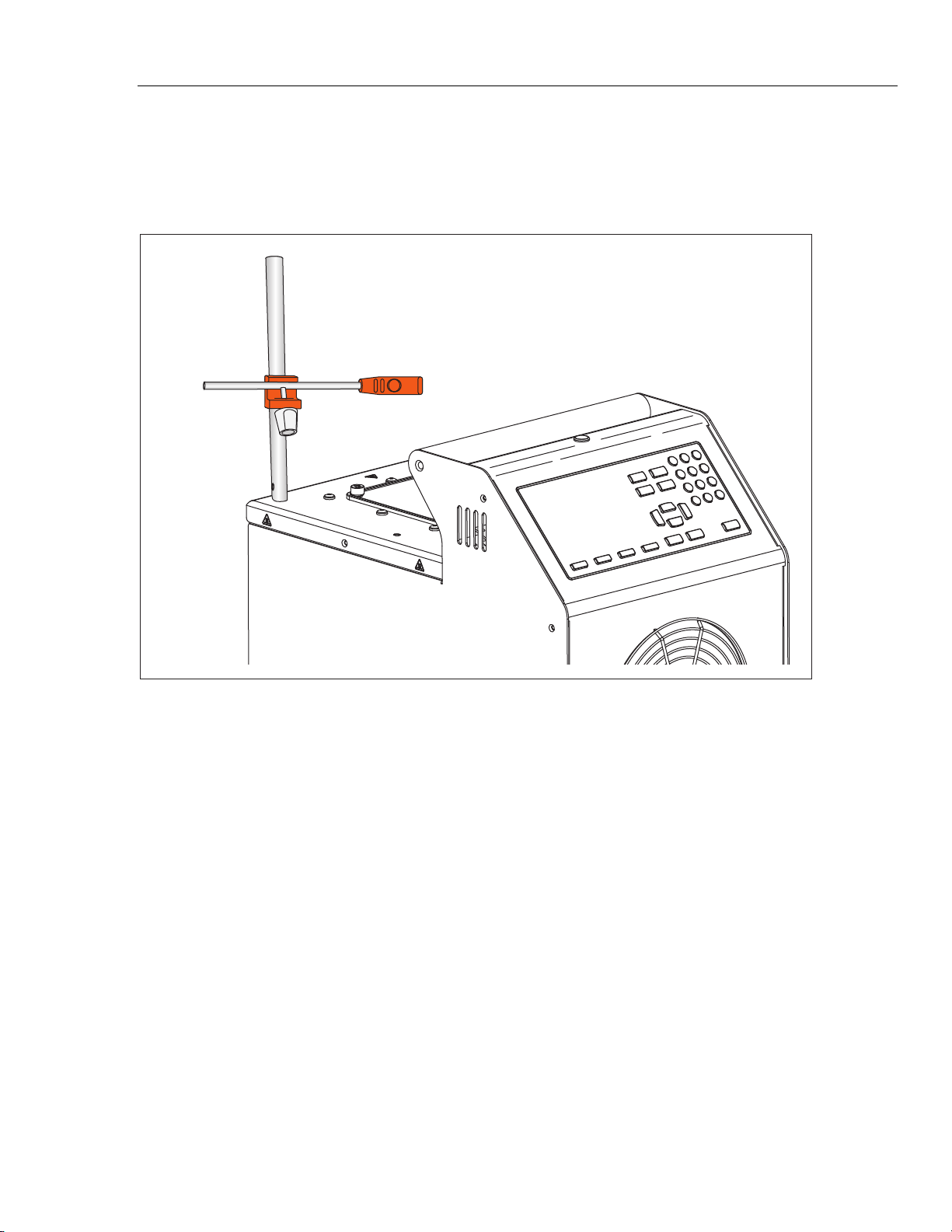

Adjustable Probe Fixture

Use the adjustable probe fixture (model 7109-2027) to hold up to four tri-clamp

temperature sensors. The device fits inside the tank opening and attaches to the

top panel of the Product with four thumb screws. The height of the platform can

be adjusted for proper immersion of the stems and flanges of the temperature

sensors. To adjust the height, slightly squeeze the tabs inward on the height

adjustment bracket shown in Figure 9.

1

Figure 9. Adjustable Probe Fixture

icu08.eps

18

Page 23

Portable Calibration Baths

Turn On the Product

Turn On the Product

Push the power switch on the back panel of the Product to the I side to turn on

the Product. The Product can take up to 40 seconds for the Product to become

fully operational.

Set the Language, Time, and Date

Set the display language, time, date, and other operator preferences in the Setup

Instrument screen. The UI is available in:

• English

• French

• German

• Portuguese

• Spanish

• Russian

• Simplified Chinese

• Japanese

• Korean

To change the language, time, or date:

1. Push .

2. Push .

3. Push to move the focus to an item.

4. Push .

5. Push to move the selection to the necessary value.

6. Push to save the change.

7. Push the (Done) to return to the first screen.

19

Page 24

6109A/7109A

Operators Manual

Set the Password

The Product ships from Fluke Calibration with minimal security settings. Except

for calibration parameters, any settings are easily changed.

To change the security level and set a new password to prevent unauthorized

use:

1. Push .

2. Push .

3. Push (More).

4. Push (Password).

5. Use the number keys to type in the factory password 1234.

6. Push to access the Password screen.

7. Push to edit the password.

8. Use the number keys to type in a new password.

9. Push save the new password.

10. Push to move to the Security setting.

11. Push to change the security level.

12. Push (Done) to return the first screen.

Note

Make sure to save the new password and do not lose it.

Connect the Reference Probe and Test Sensor

The 7109A-P and 6109A-P include the Input module to which a reference

thermometer and one DUT (Device Under Test) sensor can be connected.

Temperatures show on the display and are automatically recorded as a program

runs. This section explains how to set up these models to operate the sensor

inputs.

Connect the Reference Probe

A reference probe provides improved temperature accuracy and serves as a

reference standard to test other sensors. For best results, use a high-quality,

100 Ω, four-wire, platinum resistance thermometer (PRT) calibrated with low

uncertainty such as Fluke 5615-6. Table 4 shows how a reference probe can be

used to improve temperature accuracy.

Table 4. Typical Accuracy with a Fluke 5615 as a Reference Probe

Temperature Expanded Uncertainty (k = 2)

-25 °C 0.020 °C

20

0 °C 0.022 °C

140 °C 0.031 °C

250 °C 0.043 °C

Page 25

Portable Calibration Baths

Connect the Reference Probe and Test Sensor

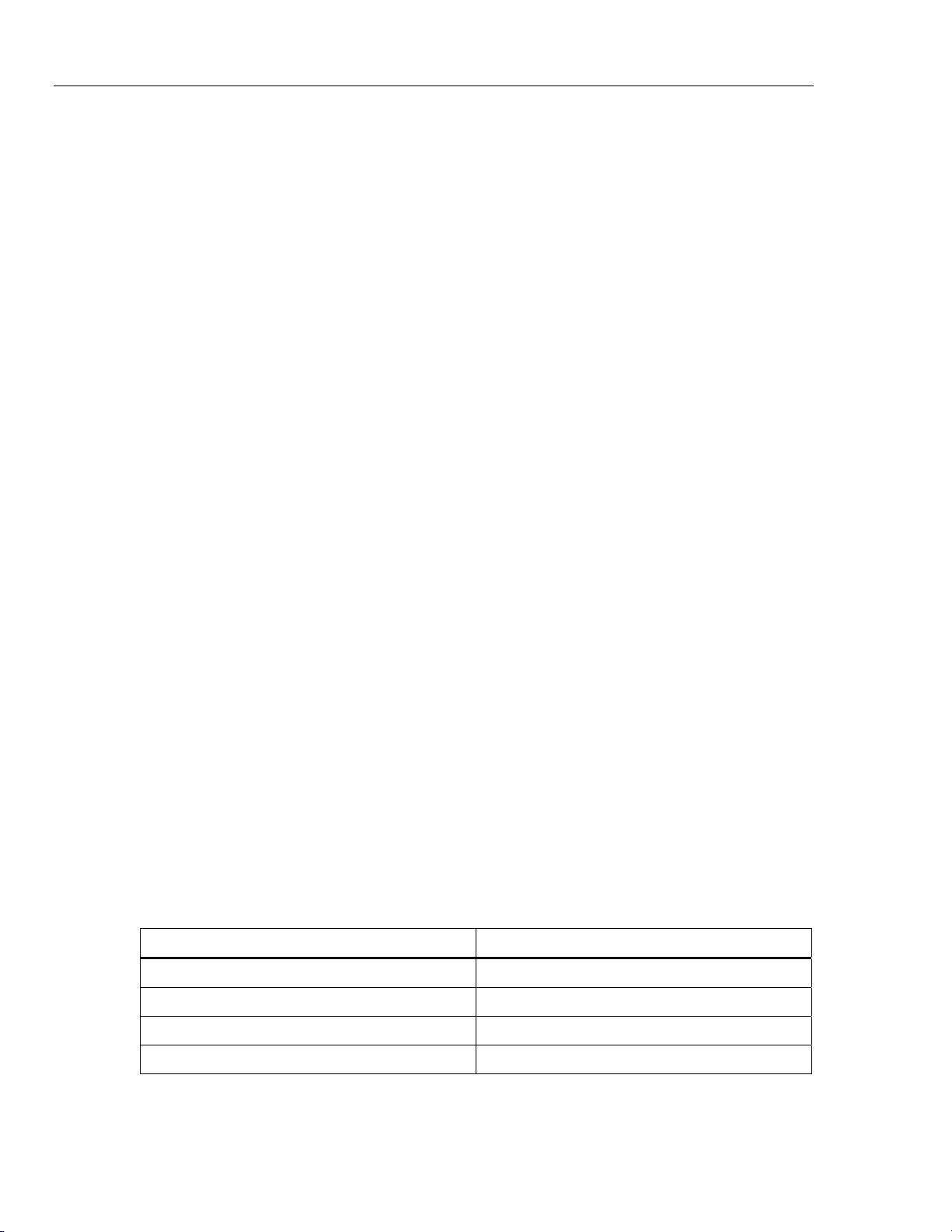

Use the provided clamp-on ferrites to reduce radio-frequency emissions and to

ensure electromagnetic compatibility with other equipment. Loop a section of

cable near the connector through the ferrite as shown in Figure 10. Fluke

Calibration also recommends a ferrite for the test sensor.

1

2

3

icu10.eps

Number Description

Connector

Clamp-on Ferrite

Probe

Figure 10. Ferrite Installation

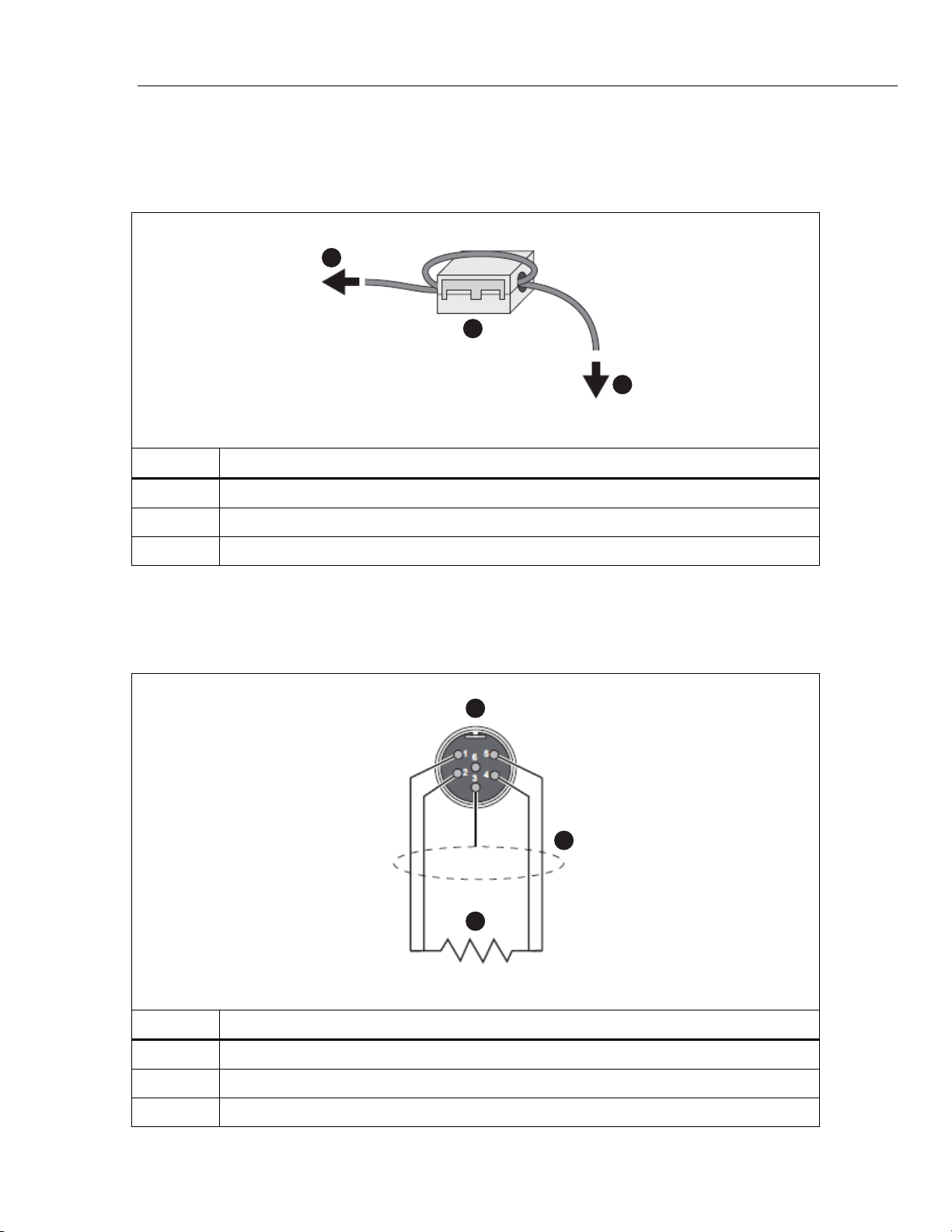

The reference probe plugs into the REF PRT input. It requires a 6-pin DIN

connector wired as shown in Figure 11.

1

2

3

icu11.eps

Number Description

Probe Connector

Shield

PRT Sensor

Figure 11. Reference Probe Connections

21

Page 26

6109A/7109A

Operators Manual

Configure the Reference Probe Coefficients

Probe coefficients must be configured for the PRT temperature to be accurately

measured. If the reference probe has a properly-programmed INFO-CON

connector, probe coefficients are automatically configured when the probe is

connected to the Product. The connection icon shows at the top of the display to

show that the probe coefficients were successfully transferred from the

connector. To view the probe coefficients and verify that they are correct, go to

the Reference Probe menu:

1. Push .

2. Push (Probe Function).

3. Push (Reference Probe).

4. Push or to step through the list.

5. Push (Done) to return the first screen.

If the reference probe does not have a programmed INFO-CON connector, enter

the probe coefficients manually. Get the values from the reference PRT’s report

of calibration. Push (Test Calculation) to test the probe coefficients and

see that they produce correct temperatures.

When properly connected and configured, the temperature of the reference

probe shows on the display under Reference in Monitor mode.

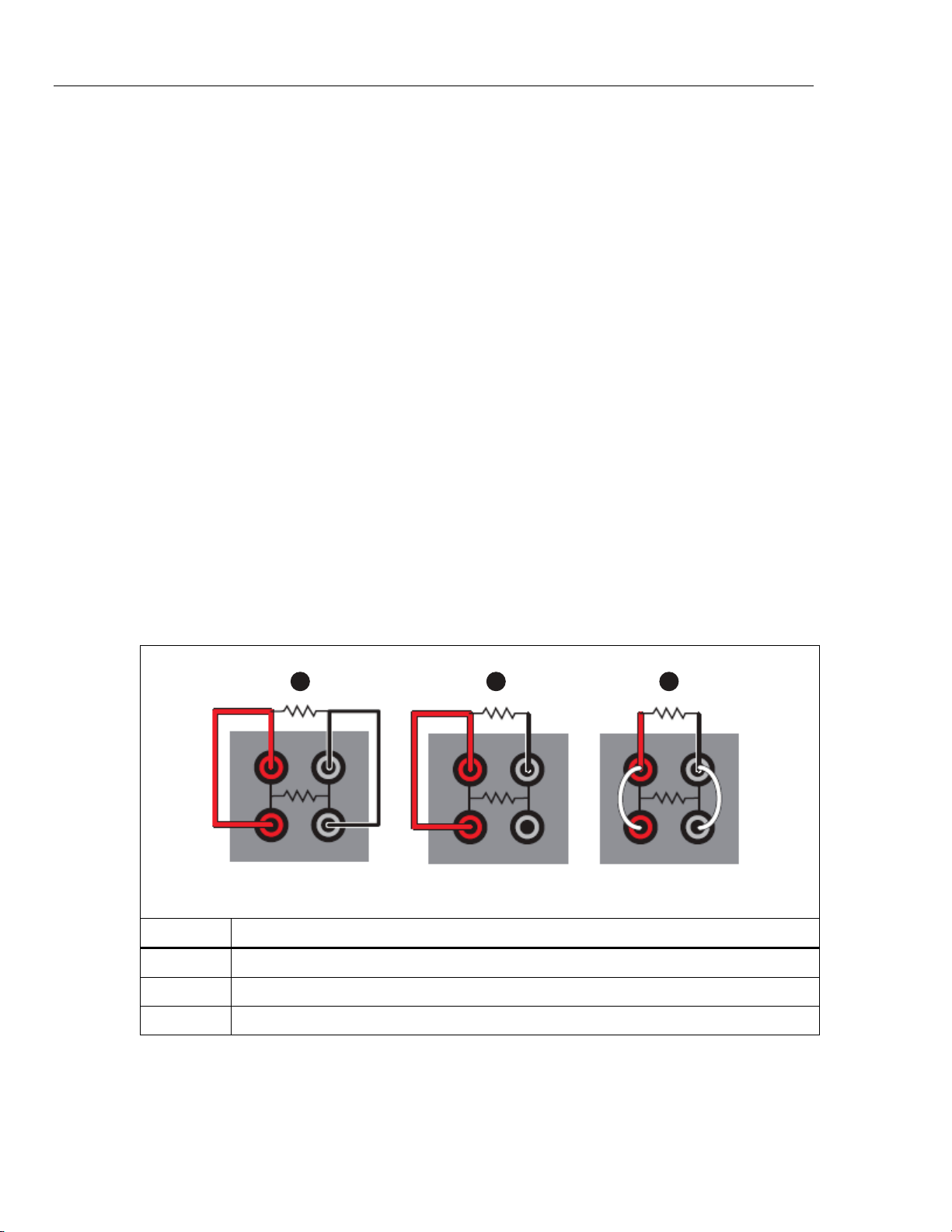

Connect a Test RTD

The Input Module measures the resistance of a four-wire, three-wire, or two-wire

RTD. The RTD connects to the set of four banana terminals on the Input Module.

See Figure 12.

1 2 3

icu12.eps

Number Description

4-wire RTD

3-wire RTD

2-wire RTD

Figure 12. Test RTD Connections

22

Page 27

Portable Calibration Baths

Connect the Reference Probe and Test Sensor

Configure the RTD Type

To configure the test RTD to accurately measure the temperature or the

resistance of the RTD:

1. Push .

2. Push (Probe).

3. Push (DUT).

4. Push to edit the DUT Type.

5. Push or to move the highlight to RTD.

6. Push to save the DUT Type.

7. Push to move the highlight to the Wires control.

8. Push to enter edit mode.

9. Push or to move the highlight to the correct number of wires.

10. Push to save.

11. Push to move the highlight to the RTD Type control.

12. Push to enter edit mode.

13. Push or to move the highlight to the correct type.

14. Push to save.

15. Push (Done) to return the first screen.

When properly connected and configured, the temperature or resistance of the

test RTD shows on the display under DUT in Monitor mode.

Connect a Thermocouple

The Input Module measures temperature from a thermocouple and automatically

applies reference junction compensation. The thermocouple connects directly to

the miniature thermocouple connector labeled TC. Do not use an external

reference junction. The positive wire connects to the smaller blade of the

connector.

23

Page 28

6109A/7109A

Operators Manual

Configure the Thermocouple Type

To configure the thermocouple type to measure the temperature of the

thermocouple accurately:

1. Push .

2. Push (Probe).

3. Push (DUT).

4. Push to edit the DUT type.

5. Push or to move the highlight to the Thermocouple control.

6. Push to save the DUT Type.

7. Push to move the highlight to the Thermocouple Type control.

8. Push to enter edit mode.

9. Push or to move the highlight to the correct type.

10. Push to save.

11. Push (Done) to return the first screen.

When properly connected and configured, the temperature of the thermocouple

shows on the display under DUT in Monitor mode.

Connect a 4–20 mA Transmitter

The Input Module measures current from a 4–20 mA loop transmitter. The Input

Module also provides dc voltage to power the transmitter. The transmitter wires

connect to the two banana terminals labeled mA LOOP and COM. If Loop Power

mode is OFF, the Input Module measures current that flows into the red COM

terminal. If Loop Power is on, positive dc voltage is supplied from the red COM

terminal to the black mA LOOP terminal, and the Input Module measures current

that flows into the black mA LOOP terminal.

Configure the mA Input

Configure the Input Module to measure the transmitter current. If the transmitter

has a separate power supply, set Loop Power to OFF. If the Product must supply

power to the transmitter, set Loop Power to ON.

1. Push .

2. Push (Probe).

3. Push (DUT).

4. Push to edit the DUT type.

5. Push or to move the highlight to the mA control.

6. Push to save the DUT Type.

24

7. Push to move the highlight to the Loop Power control.

8. Push to switch Loop Power ON or OFF.

9. Push (Done) to return the first screen.

Use the Offset, Span, and Unit settings to convert the transmitter measurement

to another unit such as temperature.

When properly connected and configured, readings from the transmitter show on

the display under DUT in Monitor mode.

Page 29

Portable Calibration Baths

Operation

Operation

This section explains how to operate the Product after it is set up.

The user interface (UI) and basic key actions are explained in the subsequent

sections.

Display

The display is explained in Figure 13.

8

1

2

3

4

5

Number Description

Date and Time - The present date and time from the internal, battery-operated clock of

the Product.

Bath Fluid Temperature - The temperature of the bath fluid as measured by the internal

control sensor.

7

6

9

icu06.eps

Setpoint - The Product heats or cools to maintain the fluid temperature at the setpoint.

Reference Temperature (-P models only) - If sensors are connected to the input

module and are properly configured, the reference temperature and test sensor reading

show on the home screen.

Test Sensor reading (-P models only) - This is the temperature that the DUT presently

reads.

Control Indicator - Shows Stable when the bath fluid temperature is at the setpoint and

the Product is ready for temperature measurement.

Connection Indicator (-P models only) - The connection indicator shows when a

reference probe is connected and its probe coefficients have successfully been

transferred to the Product.

Recording Indicator - Shows when recording is on.

Heating Status - Shows these states: Off, Heating, Cooling, or Cutout. Cutout indicates

that the bath fluid temperature has exceeded the cutout temperature setting.

Temperature control can only resume after you push and the bath fluid cools

below the cutout temperature.

Figure 13. The Display

25

Page 30

6109A/7109A

Operators Manual

Basic Operations

Immerse Temperature Probes

Common operations are explained in the subsequent sections.

For best results:

• Check that the bath fluid level is between the MIN and MAX marks on the stir

guard.

• See that the bath fluid stirs well when you enable temperature control.

• Keep the bath fluid covered as much as possible to ensure good temperature

stability and uniformity and to reduce fumes. Use the provided probe access

cover or a custom cover.

• Immerse sensors in the bath fluid so that the tips of the probes are at least

15 mm above the bottom of the tank and 65 mm below the surface of the

fluid. When you test the tri-clamp temperature sensors, immerse their flanges

just below the surface of the bath fluid to ensure good thermal equilibration of

the temperature sensor with the bath fluid.

• If you use a reference probe, place it in the center of the working area.

• Use the optional probe clamps to hold sensors vertical at the proper height.

Set the Setpoint

1. Push . The setpoint field changes to edit mode.

2. Enter the setpoint temperature with the number keys.

3. Push to save the setpoint.

4. Push (Ramp) to specify a temperature ramp rate.

5. Push to edit the Ramp Rate.

6. Use the number keys to type a rate (in °C or °F per minute).

7. Push to save the new value.

8. Push to move the focus to Ramp Enable.

9. Push to enable the ramp rate.

10. Push (Done).

11. Push or the Enable softkey to heat or cool the bath fluid to the setpoint.

If ramp rate is enabled, the rate of change is controlled until the temperature

reaches the setpoint. The Product may reduce heating power as it approaches

the setpoint to minimize overshoot.

When the temperature reaches the setpoint, the control indicator changes to

Stable and the ready indicator turns green. The temperatures of the sensors can

then be measured and compared.

26

Page 31

Portable Calibration Baths

Operation

Preset Setpoints

Use presets to set the setpoint to frequently-used temperatures. To define

presets:

1. Push .

2. Push (Presets) to see the list of preset setpoints.

3. Push as needed to choose one of the numbered setpoints.

4. Push (Edit) to edit the setpoint.

5. Use the number keys to type temperature.

6. Push to save the new value.

7. Push (Done) after all presets have been defined.

To recall a preset:

1. Push .

2. Push (Presets) to see the list of preset setpoints,

3. Push as needed to choose one of the numbered setpoints.

4. Push to activate the chosen preset. The Setpoint field on the display

shows that the setpoint has changed to match the selected preset.

Set the Cutout

The cutout is a safety device that prevents overheating of the Product and bath

fluid in the event of operator error or product malfunction. For each test, set the

cutout to 5 °C to 15 °C above the maximum temperature at which the Product will

operate. Do not set the cutout higher than the maximum safe temperature of the

fluid.

1. Push .

2. Push (Operation).

3. Push to edit the Cutout Temperature.

4. Use the number keys to type in a temperature.

5. Push to save the new temperature.

Stop Heating or Cooling

Push to turn off heating and cooling and the stir motor.

Select the Temperature Unit

To change the temperature to degrees Fahrenheit or degrees Celsius:

1. Push .

2. Push (Operation).

3. Push (°C or °F).

4. Push to see temperatures in the selected unit of measurement.

Note

In some regions, the Product may not have this option.

27

Page 32

6109A/7109A

Operators Manual

Control the Bath Temperature with a Reference Probe

Keyboard Use

The 7109A-P and 6109A-P allow measurements from the reference probe to be

used to control the fluid temperature with more accuracy. Set up the reference as

explained in Configure the Reference Probe Coefficients.

1. Push .

2. Push (Operation).

3. Push several times to move the highlight to Control Sensor.

4. Push to switch the value to Reference.

5. Push to view the control temperature.

When the reference probe controls temperature, the display shows the fluid

temperature in gray and the Reference temperature in black.

When the reference probe is used, the settling time and temperature variation

may be slightly greater.

Use the keyboard to enter or change filename characters. To use the keyboard:

1. Use the direction keys to choose a letter.

2. Push to add the letter to the filename.

3. Repeat until the filename is complete. Push (Backspace) to delete a

letter.

Recording Temperature

The recording function stores temperature readings in a file on a USB memory

device. To use this device:

1. Insert a Linux-compatible, FAT32-formatted memory device into the USB

host port on the front panel.

2. Wait for the device to be recognized.

3. Push .

4. Push (Recording).

5. Push (Filename).

6. Push to specify the filename.

7. Push (Save) to save the filename. See Keyboard Use.

8. Push (Start Recording) to record temperature. Observe that the

recording icon shows at the top of the display.

9. Push (Stop Recording) to stop recording.

10. Wait at least 5 seconds after you stop recording before you remove the USB

memory device. This allows time for all the data to be written and the file

closed.

28

Page 33

Portable Calibration Baths

Operation

The extension “.txt” is automatically appended to the filename when the file is

created. If the file already exists, new data is appended to the end of the file. The

file is placed in a folder determined by the serial number of the Product:

\Fluke\7109_6109\<product serial number>\Data\

Each line in the file contains the date and time, fluid temperature, its unit of

measurement, reference probe reading, its unit of measurement, DUT reading,

and its unit of measurement. Fields are separated by commas. If reference probe

or DUT readings are not available, the field is empty.

Run a Program

A program instructs the Product to step through a sequence of setpoints to

automatically test sensors at multiple temperatures.

To set up a program:

1. Push .

2. Push (New).

3. Push to specify the program name. See Keyboard Use.

4. Push (Save) to save the program name.

5. Push (Edit Setpoints) to specify the setpoints.

6. Push or to choose an existing setpoint or to add a new setpoint.

7. Push to edit the setpoint temperature.

8. Use the number keys to type the setpoint temperature.

9. Push to save the setpoint.

10. Push after all setpoints have been defined.

11. Push several times to move the highlight to Dwell Time.

12. Push to edit the Dwell Time.

13. Use the number keys to type in a time in minutes.

14. Push to save the value.

15. Push (Save) to save the program.

If the Input Module (7109A-P or 6109A-P) is installed, the module can collect the

sensor readings and produce a test report. To turn on program report:

1. Push .

2. Push or to choose a program.

3. Push (SELECT).

4. Push (Options).

5. Push to move the highlight to Program Report.

6. Push to change Program Report to ON.

7. Push to move to Pass Tolerance.

8. Push to change the number.

9. Use the number keys to type in the new number.

10. Push to save the value.

29

Page 34

6109A/7109A

Operators Manual

To run a program:

1. Push .

2. Push or to choose a program.

3. Push (Select).

4. Push (Run Program).

After the program completes, to view the reports:

1. Push .

2. Push (Reports).

3. Push or to choose the report.

4. Push (View).

5. Push (Done) to exit.

A program report can also be exported to a file on a USB memory device.

Insert a memory device into the USB host port on the front panel. Wait for the

device to be recognized.

1. Push .

2. Push (Reports).

3. Push or to choose the report.

4. Push (Export).

Menu Guide

This section explains each of the items in the user interface menu system. The

menus are arranged into separate menu trees associated with the mode keys.

Most menus contain a softkey labeled Done. This returns the menu system to

the home screen of the active mode. Push to move to the prior menu.

Some menus require the password before settings can be changed.

Monitor

Use Monitor mode to view and record temperature data.

(Monitor) Recording

Control recording to a USB memory device.

The memory device must be Linux-compatible and formatted as FAT32.

(Monitor > Recording) Start Recording/Stop Recording

Enable or disable temperature recording.

30

Insert a memory device into the USB host port and set the filename

before you turn on recording.

Page 35

Portable Calibration Baths

Menu Guide

(Monitor > Recording) Filename

Specify the filename for recording data to the memory device.

The filename can have up to 20 characters. The extension “.txt” is

automatically added to the filename when the file is created.

(Monitor) View Graph

Plot temperature over time.

The graph scales automatically to best fit the data.

For the 7109A-P and 6109A-P, the , , and softkeys

select which parameter to plot—either the control sensor, reference

probe, or DUT sensor.

(Monitor) Statistics

Show moving average and standard deviation of temperature readings.

(Monitor > Statistics) Time Window

Select the time window for the moving average and standard deviation.

(Monitor > Statistics) Reset Statistics

(Monitor) Delta Temperature/DUT Reading (-P models)

Setpoint

Use Setpoint mode to set the temperature of the Product:

1. Push to change the setpoint.

2. Type in a new temperature using the number keys.

3. Push to save the number.

4. Push again to enable temperature control.

(Setpoint) Enable/Disable

Clear the statistical buffers and set a new starting point for subsequent

statistics.

Select the parameter to be shown in the DUT field on the Monitor screen.

• DUT Reading is the immediate indication from the test sensor.

• Delta Temperature is the difference between the DUT reading and the

reference probe temperature. Delta T is only valid if the Reference

and DUT are both configured to read temperature.

Enable or disable temperature control.

This does the same thing as when is pushed twice after , or

.

(Setpoint) Presets

Select a preset for recall or edit.

Push or to move the focus to one of the presets in the list and

to recall that setpoint.

31

Page 36

6109A/7109A

Operators Manual

Program

(Setpoint > Presets) Edit

Change the temperature of the selected preset.

(Setpoint) Ramp Rate

Set the rate at which the Product heats or cools.

• Ramp Rate is the rate of change when heating or cooling. The setting

is only effective when Ramp Enable is ON. The actual rate may be

limited by the Product’s heating and cooling capacity.

• Ramp Enable enables or disables Ramp Rate. If Ramp Enable is

OFF, the Product heats or cools at the maximum possible rate.

(Setpoint) Edit Setpoint

Change the setpoint.

This does the same as when you push .

Use Program mode to create and run an automatic setpoint program.

When is pushed, a list of defined programs is shown. Use or to select

a program.

(Program) Select

Choose the program to run or edit.

does the same.

When you push , a list of defined setpoints is shown.

The softkeys change with the state of the program execution.

(Program > Select) Run Program

Start the selected program.

This function shows only if a program is not running.

(Program > Select) Pause Program

Pause the program.

This function shows only if a program is running.

After the program is paused, it can be continued later.

(Program > Select) Continue Program

Continue program execution.

This function only appears if a program is paused.

32

Page 37

Portable Calibration Baths

Menu Guide

(Program > Select) Stop Program

Stop the program.

This function only appears if a program is running.

Once stopped, a program cannot be continued.

(Program > Select) Edit

Change the selected program.

A list of program parameters shows:

• Program Name identifies which program is selected or running.

• Setpoints indicate the number of setpoints that have been defined. It

cannot be changed directly. Use Edit Setpoint to add, delete, or

change setpoints.

• Cycles defines the number of cycles completed before the program is

finished.

• Order controls the order of setpoints. If Order is Linear, the program

setpoints step from first to last in one cycle. The next cycle starts with

the first setpoint again. If Order is Up/Down, the sequence is from first

to last, then backwards last to first to complete one cycle.

• Dwell Time is number of minutes the temperature is held at each

setpoint before it advances to the next setpoint. The timer begins

when the control indicator changes to Stable and the ready indicator

is green.

• Ramp Rate overrides the Setpoint mode Ramp Rate as a program

runs.

• Ramp Enable overrides the Setpoint mode Ramp Enable as a

program runs.

Push (Save) to save the program.

33

Page 38

6109A/7109A

Operators Manual

(Program > Select > Edit) Edit Setpoints

Add, delete, or change program setpoints.

A list of program setpoints is shown. Push or and then to

choose a setpoint to change.

Move to Add and push to add a new setpoint to the end of the list.

(Program > Select > Edit > Edit Setpoints) Insert

Add a setpoint just above the highlighted setpoint.

(Program > Select > Edit > Edit Setpoints) Delete

Delete the highlighted setpoint.

(Program > Select > Edit > Edit Setpoints) Move Up

Exchange the highlighted setpoint with the one just above it.

(Program > Select > Edit) Save

Save the program to memory.

(Program > Select) Options

Change general program and report settings.

If Program Beep is ON, the Product beeps when the program finishes.

In the 7109A-P and 6109A-P, settings to manage reports are also

available.

• Report determines whether a test report is created. Readings are

captured at the end of the dwell time and added to the report.

• Standard determines the source for the reference temperature. If

Standard is Reference (and a reference probe is connected and

configured) the recorded reference temperature will come from the

reference probe. Otherwise the reference will be the internal control

sensor.

• Pass Tolerance specifies the maximum acceptable difference

between the DUT temperature and the reference temperature.

34

Page 39

Portable Calibration Baths

Menu Guide

(Program) New

Create a new program.

See (Program > Select) Edit for a list of program parameters.

Up to eight programs can be defined.

(Program) Delete

Delete the selected program.

(Program) Reports (7109A-P and 6109A-P)

Select a report for view or export.

A list of stored test reports appears. Push or to select a report.

(Program > Reports) View

View the selected report.

(Program > Reports) Export

Export the selected report to a file on a USB memory device.

The memory device must be Linux-compatible and FAT32-formatted.

Setup

The filename is created automatically from the program name and the time the

program finished. The extension is “.csv”. The file is placed in a folder on the

memory device that is dependent to the serial number of the Product:

\Fluke\7109_6109\<product serial number>\Report\

(Program > Reports) Delete

Delete the selected report.

The Setup menu contains operator preferences and instrument settings.

(Setup) Operation

Change settings related to temperature control.

• The cutout is a safety device that prevents overheating of the Product

and bath fluid in the event of operator error or product malfunction. If

the fluid temperature exceeds the Cutout Temperature, power is

immediately removed from the heating and cooling devices.

Temperature control can only resume after the operator pushes

and the fluid cools below the cutout temperature. Set the Cutout

Temperature at 5 °C to 15 °C above the maximum temperature at

which the Product is operated and no higher than the maximum safe

temperature of the bath fluid.

• Stability Window controls when the control indicator becomes Stable

and the ready indicator turns green. The control temperature must

remain near the setpoint within the Stability Window tolerance for at

least 1 minute.

35

Page 40

6109A/7109A

Operators Manual

• Stability Beep controls whether the beeper sounds when the control

indicator changes to Stable.

• Control Sensor (7109A-P and 6109A-P only) selects which

temperature sensor is used for temperature control. This feature is

useful to improve the temperature accuracy. The usual configuration

(Internal) uses the internal PRT. When set to Reference, the Product

heats or cools the tank so that the reference probe temperature

matches the setpoint.

(Setup > Operation) °C/°F

Select the temperature unit.

Fahrenheit is only available in some regions of the world.

(Setup) Instrument

View or change configuration and user preferences.

• Language selects the language for the user interface. Options are

English, French, German, Portuguese, Spanish, Russian, Simplified

Chinese, Japanese, and Korean.

• Time Format selects the format for the time shown on the display.

Options are 24-hour and 12-hour format.

• Time changes the clock’s time.

• Date Format selects the format of dates shown on the display. Options

are YYYY-MM-DD (default), MM-DD-YYYY, DD.MM.YYYY,

DD/MM/YYYY, and YYYY/MM/DD.

• Date changes the clock’s date.

• Decimal selects the decimal character used in numbers shown on the

display. Options are period and comma.

(Setup > Instrument) English

Change the UI language to English.

(Setup > Instrument) Remote

Change settings related to the remote interface.

• Termination selects the line termination characters for transmitted

messages. The options are CR, LF, and CR/LF.

• Serial Baud Rate selects the bit rate for the RS-232 port.

• Serial Monitor turns on automatic transmission of temperature readings.

The fluid temperature is sent at intervals of one second. Temperature is in

°C or °F and depends on the temperature unit setting. Serial Monitor is

always OFF after power on.

(Setup > Instrument) More...

36

Access additional instrument settings.

Page 41

Portable Calibration Baths

Menu Guide

• Temperature Resolution selects the number of decimal places in

temperatures shown on the display.

• Display Brightness sets the brightness of the backlight, which may need

to be adjusted depending on ambient light.

• Screen Saver causes the display to turn off after a period of time without

operator actions. Push any key to turn the display on again. The Product

continues to operate and control temperature while the display is dark.

• Key Beep controls whether the Product beeps each time a key is pushed.

• Stability Beep controls whether the Product beeps when the ready

indicator turns green. This setting is also located in the Setup Operation

menu.

(Setup > Instrument > More) Control

Change temperature control parameters.

Depending on the fluid used, the Product may achieve slightly better

temperature stability after fine-tuning the control parameters. This should

only be done by a knowledgeable technician when necessary. Incorrect

values could cause the bath temperature to oscillate or drift.

The password is required to change these settings.

• Stir Speed sets the speed of the stir motor. The normal speed is 2000

revolutions per minute (RPM). When bath fluids are used that have low

viscosity, the operator might want to decrease the stir speed to reduce

spatter.

Note

The stir motor only runs when temperature control is enabled.

• Proportional Band controls the gain of the control function. A larger value

decreases gain and a smaller proportional band increases gain.

• Integral Time controls the settling time of the control function.

• Derivative Time controls stability compensation.

(Setup > Instrument > More > Control) Default

Change the control parameters back to factory default values.

(Setup > Instrument > More) Password

Change the security settings.

The password is required to access this menu. The default password is

1234.

The password is the security code required by any protected menu,

including this one.

IMPORTANT: Do not lose your password. If you do lose your

password, contact Fluke Calibration.

37

Page 42

6109A/7109A

Operators Manual

Security determines which menus and functions require the password.

Regardless of the Security setting, these menus are protected:

• Setup > Instrument > More > Control

• Setup > Instrument > More > Password

• Setup > Instrument > More > Service > System Status > Update Firmware

• Setup > Instrument > More > Service > Bath Calibration

• Setup > Instrument > More > Service > Input Calibration (-P models)

• Setup > Instrument > More > Memory > Clear Settings

• Setup > Instrument > More > Memory > Clear Data

• Setup > Probe > Reference Probe > Program Probe (-P models)

When Security is ON, these additional menus are protected:

• Program > Select > Edit

• Program > Select > Options

• Program > New

• Program > Delete

• Program > Reports > Delete

• Setup > Operation

• Setup > Instrument

• Setup > Probe > Reference Probe (-P models)

• Setup > Probe > DUT (-P models)

(Setup > Instrument > More > Password) Default

Change the password back to the factory default (1234).

(Setup > Instrument > More) Service

View or change service related parameters.

Product information is shown (Model, Serial Number, Firmware Version,

Bath Calibration date, and Input Calibration date (-P models)).

(Setup > Instrument > More > Service) System Status

View information about the condition of the Product.

The System Status screen shows the results of the latest self-check. A

self-check is performed when the Product is switched on.

(Setup > Instrument > More > Service > System Status) Self Check

38

Repeat the system self-check.

Subsystems and components are tested. When completed, the System

Status screen shows updated results.

(Setup > Instrument > More > Service > System Status) Diagnostics

View data about the Product operation.

The diagnostics indicators can be helpful when the Product is serviced

and for troubleshooting issues.

Page 43

Portable Calibration Baths

Menu Guide

• Heating is the relative size of the signal that controls the heating devices. A

negative number indicates cooling.

• Cutout Code indicates the specific cause of a cutout event. This number is

normally 0.

• Stir Tachometer shows the actual speed of the stir motor in RPM.

• Stir Power is the relative size of the signal controlling the stir motor speed.

Because stir power increases with load, it can reveal a change in fluid

viscosity. An increase of 1 % or greater suggests that fluid should be checked

and perhaps replaced.

• Typical Stir Power provides a reference to determine whether the load on the

stir motor has increased significantly. The value is set in the Bath Calibration

menu.

• Ambient Temperature shows the air temperature inside the Product.

• Remote Error shows the latest error message if any occurred at the time of

remote operation.

(Setup > Instrument > More > Service > System Status) Update Firmware

Update the Product firmware.

A valid firmware update file must be stored on the memory device

plugged in to the USB host port.

(Setup > Instrument > More > Service) Memory

Manage data stored in memory.

The Memory screen shows how many user-defined programs and test

reports are stored in memory.

(Setup > Instrument > More > Service > Memory) Clear Data

Clear all setpoint programs and test reports from memory. The default

setpoint program remains in memory.

This function requires the password.

(Setup > Instrument > More > Service > Memory) Clear Settings

Change all settings to factory defaults.

The settings affected are preset setpoints, operation settings, and