Page 1

7102

Micro-Bath

PN 3729328

December 2013

© 2013 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

User's Guide

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and

service. The warranty period is one year and begins on the date of shipment. Parts, product repairs, and

services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of

a Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in

Fluke's opinion, has been misused, altered, neglected, contaminated, or damaged by accident or abnormal

conditions of operation or handling. Fluke warrants that software will operate substantially in accordance

with its functional specifications for 90 days and that it has been properly recorded on non-defective media.

Fluke does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers

only but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is

available only if product is purchased through a Fluke authorized sales out let or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for importation costs of

repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair,

or replacement of a defective product which is returned to a Fluke authorized service center within the

warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that service center, with a description of the difficulty,

postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Followi ng

warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination, alteration, accident, or abnormal

condition of operation or handling, including overvoltage fail ures caused by use outside the product’s

specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair

costs and obtain authorization before commencing the work. Following repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or

limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not

apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court or other

decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any other

provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

To register your product online, visit register.fluke.com

Page 3

Table of Contents

Chapter Title Page

1 Before You Start .................................................................................. 1-1

1.1 Symbols Used ................................................................................. 1-1

1.2 Safety Information ........................................................................... 1-2

1.2.1 Warnings ............................................................................... 1-2

1.2.2 Cautions ................................................................................... 1-4

1.3 Authorized Service Centers ............................................................. 1-5

2 Introduction ......................................................................................... 2-1

3 Specifications and Environmental Conditions ................................. 3-1

3.1 Specifications .................................................................................. 3-1

3.2 Environmental Conditions ................................................................ 3-2

4 Quick Start ........................................................................................... 4-1

4.1 Unpacking ........................................................................................ 4-1

4.2 Setup ............................................................................................... 4-2

4.3 Power .............................................................................................. 4-2

4.4 Setting the Temperature .................................................................. 4-2

5 Installation ........................................................................................... 5-1

5.1 Bath Environment ............................................................................ 5-1

5.2 “Dry-out” Period ............................................................................... 5-1

5.3 Bath Preparation and Filling ............................................................ 5-2

5.4 Power .............................................................................................. 5-2

6 Bath Use ............................................................................................... 6-1

6.1 General ............................................................................................ 6-1

6.2 Comparison Calibration ................................................................... 6-2

6.3 Calibration of Multiple Probes.......................................................... 6-2

i

Page 4

7102

User's Guide

7 Parts and Controls .............................................................................. 7-1

7.1 Front Panel ...................................................................................... 7-1

7.2 Back Panel ...................................................................................... 7-2

7.3 Accessories ..................................................................................... 7-3

7.3.1 Transport/Pour Access Lid ....................................................... 7-3

7.3.2 Access Cover (Optional) ........................................................... 7-4

7.3.3 Probe Basket ............................................................................ 7-4

7.3.4 Stir Bar ...................................................................................... 7-4

7.3.5 Well Extender (Optional) .......................................................... 7-4

8 General Operation ............................................................................... 8-1

8.1 Changing Display Units ................................................................... 8-1

8.2 Switching to 230V Operation ........................................................... 8-1

8.3 Bath Fluid ........................................................................................ 8-1

8.3.1 Temperature Range ................................................................. 8-2

8.3.2 Viscosity ................................................................................... 8-2

8.3.3 Specific Heat ............................................................................ 8-2

8.3.4 Thermal Conductivity ................................................................ 8-2

8.3.5 Thermal Expansion ................................................................... 8-2

8.3.6 Electrical Resistivity .................................................................. 8-3

8.3.7 Fluid Lifetime ........................................................................ 8-3

8.3.8 Safety ....................................................................................... 8-3

8.3.9 Cost .......................................................................................... 8-3

8.3.10 Commonly Used Fluids .......................................................... 8-3

8.3.10.1 Water (Distilled) ............................................................... 8-4

8.3.10.2 Mineral Oil ....................................................................... 8-4

8.3.10.3 Silicone Oil (Dow Corning 200.05, 200.10, 200.20) ........ 8-4

8.3.11 Fluid Characteristics Charts ................................................... 8-4

8.3.11.1 Limitations and Disclaimer ............................................... 8-5

8.3.11.2 About the Graph .............................................................. 8-6

8.4 Stirring ............................................................................................. 8-7

8.5 Power .............................................................................................. 8-8

8.6 Thermal Electric Devices (TED) ...................................................... 8-8

8.7 Fluid Drain ....................................................................................... 8-9

8.8 Temperature Controller ................................................................... 8-9

9 Controller Operation ........................................................................... 9-1

9.1 Well Temperature ............................................................................ 9-1

9.2 Temperature Set-point ..................................................................... 9-1

9.2.1 Programmable Set-points ......................................................... 9-1

9.2.2 Set-point Value ......................................................................... 9-3

9.2.3 Temperature Scale Units .......................................................... 9-3

9.3 Scan ................................................................................................ 9-4

9.3.1 Scan Control ............................................................................. 9-4

9.3.2 Scan Rate ................................................................................. 9-4

9.4 Temperature Display Hold ............................................................... 9-4

9.4.1 Hold Temperature Display ........................................................ 9-5

9.4.2 Mode Setting ............................................................................ 9-5

9.4.3 Switch Wiring ............................................................................ 9-5

9.4.4 Switch Test Example ................................................................ 9-6

9.5 Secondary Menu ............................................................................. 9-6

9.6 Thermal Electric Device (TED) ........................................................ 9-6

9.7 Proportional Band ............................................................................ 9-7

9.8 Controller Configuration .................................................................. 9-8

ii

Page 5

Contents (continued)

9.8.1 Operating Parameters .............................................................. 9-8

9.8.1.1 High Limit ........................................................................... 9-9

9.8.1.2 Stir Speed .......................................................................... 9-9

9.8.2 Serial Interface Parameters ...................................................... 9-9

9.8.2.1 Baud Rate .......................................................................... 9-10

9.8.2.2 Sample Period ................................................................... 9-10

9.8.2.3 Duplex Mode ..................................................................... 9-10

9.8.2.4 Linefeed ............................................................................. 9-11

9.8.3 Calibration Parameters ............................................................. 9-11

9.8.3.1 R0 ...................................................................................... 9-12

9.8.3.2 ALPHA ............................................................................... 9-12

9.8.3.3 DELTA ............................................................................... 9-12

9.8.3.4 C0 and CG ......................................................................... 9-12

9.8.3.5 rCAL .................................................................................. 9-12

10 Digital Communication Interface ....................................................... 10-1

10.1 Serial Communications.................................................................. 10-2

10.1.1 Wiring ..................................................................................... 10-2

10.1.2 Setup ...................................................................................... 10-2

10.1.2.1 Baud Rate ........................................................................ 10-2

10.1.2.2 Sample Period ................................................................. 10-3

10.1.2.3 Duplex Mode ................................................................... 10-3

10.1.2.4 Linefeed ........................................................................... 10-3

10.1.3 Serial Operation ...................................................................... 10-3

10.2 Interface Commands ..................................................................... 10-3

11 Test Probe Calibration ........................................................................ 11-1

11.1 Calibrating a Single Probe ............................................................. 11-1

11.2 Stabilization and Accuracy ............................................................ 11-2

12 Calibration Procedure ......................................................................... 12-1

12.1 Calibration Points .......................................................................... 12-1

12.2 Calibration Procedure .................................................................... 12-2

12.2.1 Compute DELTA .................................................................... 12-2

12.2.2 Compute R0 & ALPHA ........................................................... 12-3

12.2.3 Accuracy & Repeatability ........................................................ 12-3

13 Maintenance ......................................................................................... 13-1

14 Troubleshooting .................................................................................. 14-1

14.1 Troubleshooting Problems, Possible Causes, and Solutions ........ 14-1

14.2 Comments ..................................................................................... 14-4

14.2.1 EMC Directive ......................................................................... 14-4

14.2.2 Low Voltage Directive (Safety) ............................................... 14-4

iii

Page 6

7102

User's Guide

iv

Page 7

List of Tables

Table Title Page

1. International Electrical Symbols ................................................................ 1-1

2. Specifications ............................................................................................ 3-1

3. Table of Various Bath Fluids ..................................................................... 8-5

4. Nominal Stirrer Motor SettingsWith Different Liquids ................................ 8-8

5. Controller Communications Commands .................................................... 10-4

v

Page 8

7102

User's Guide

vi

Page 9

List of Figures

Figure Title Page

1. 7102 Front Panel ....................................................................................... 7-1

2. 7102 Back Panel and Bottom .................................................................... 7-2

3. Bath Lids and Lid Parts ............................................................................. 7-3

4. Probe Basket ............................................................................................. 7-4

5. Stir Bar ...................................................................................................... 7-4

6. Chart of Various Bath Fluids ..................................................................... 8-6

7. Controller Operation Flowchart ................................................................. 9-2

8. Serial Cable Wiring .................................................................................... 10-2

vii

Page 10

7102

User's Guide

viii

Page 11

1.1 Symbols Used

Table 1 lists the International Electrical Symbols. Some or all of these symbols

may be used on the instrument or in this manual.

Symbol Description

AC (Alternating Current)

AC-DC

Chapter 1

Before You Start

Table 1. International Electrical Symbols

Battery

CE Complies with European Union directives

DC

Double Insulated

Electric Shock

Fuse

PE Ground

Hot Surface (Burn Hazard)

Read the User’s Guide (Important Information)

O Off

I On

Canadian Standards Association

OVERVOLTAGE (Installation) CATEGORY II, Pollution Degree 2

per IEC1010-1 refers to the level of Impulse Withstand Voltage

CATII

protection provided. Equipment of OVERVOLTAGE CATEGORY II

is energy-consuming equipment to be supplied from the fixed

installation. Examples include household, office, and laboratory

appliances.

C-TICK Australian EMC mark

The European Waste Electrical and Electronic Equipment (WEEE)

Directive (2002/96/

EC) mark.

1-1

Page 12

7102

User's Guide

1.2 Safety Information

Use this instrument only as specified in this manual. Otherwise, the protection

provided by the instrument maybe impaired.

The following definitions apply to the terms “Warning” and “Caution”.

• “Warning” identifies conditions and actions that may pose hazards to the

user.

• “Caution” identifies conditions and actions that may damage the instrument

being used.

1.2.1 Warnings

Warnings

To avoid personal injury, follow these guidelines.

• Disclaimer: Hart Scientific manufactures instruments for the

purpose of temperature calibration. Instruments used for

applications other than calibration are used at the discretion

and sole responsibility of the customer. Hart Scientific

cannot accept any responsibility for the use of instruments

for any application other than temperature calibration.

GENERAL

• DO NOT install an access cover without holes onto a bath

that is energized. Dangerous pressures may result from

fluids vaporizing.

• DO NOT use the instrument for any application other than

calibration work. The instrument was designed for

temperature calibration. Any other use of the unit may

cause unknown hazards to the user.

• DO NOT use the unit in environments other than those

listed in the user’s guide. Completely unattended operation

in not recommended.

• DO NOT install access cover without holes onto a bath that

is energized. Dangerous pressures may result from fluids

vaporizing.

• Follow all safety guidelines listed in the user’s manual.

• Calibration Equipment should only be used by Trained

Personnel.

• If this equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment

may be impaired or safety hazards may arise.

1-2

• Inspect the instrument for damage before each use. DO NOT

use the instrument if it appears damaged or operates

abnormally.

Page 13

• Before initial use, or after transport, or after storage in

humid or semi-humid environments, or anytime the

instrument has not been energized for more than 10 days,

the instrument needs to be energized for a “dry-out” period

of 2 hours before it can be assumed to meet all of the safety

requirements of the IEC 61010-1. If the product is wet or has

been in a wet environment, take necessary measures to

remove moisture prior to applying power such as storage in

a low humidity temperature chamber operating at 50 °C for 4

hours or more.

• The instrument is intended for indoor use only.

• Lift the instrument by the handle provided to move the

instrument. DO NOT move the instrument until the display

reads less than 25 °C (77 °F) and the unit has been drained

or the Transport Lid installed.

BURN HAZARD

• ALWAYS ensure the instrument is COOL before closing the

instrument for storage.

Before You Start

1.2 Safety Information1

• DO NOT touch the well access surface of the unit.

• DO NOT mix water and oil when exceeding temperatures of

90 °C (194 °F).

• DO NOT mix water and oil when exceeding temperatures of

90 °C (194 °F). The temperature of the well access is the

same as the actual temperature shown on the display, e.g. if

the unit is set at 125 °C and the display reads 125 °C, the

well is at 125 °C.

• Ensure the power cord is positioned in such a way as it

cannot contact hot surfaces or temperature probes. Always

inspect power cord before use for any damage to the

insulation due to contact with hot surfaces, cuts or

abrasions.

• The top sheet metal of the instrument may exhibit extreme

temperatures for areas close to the well access.

• DO NOT turn off the unit at temperatures higher than 100 °C.

This could create a hazardous situation. Select a set-point

less than 100 °C and allow the unit to cool before turning it

off.

• DO NOT remove the fluid at high temperatures. The fluid will

be the same temperature as the display temperature.

• DO NOT operate near flammable materials. Extreme

temperatures could ignite the flammable material.

• Use of this instrument at HIGH TEMPERATURES for

extended periods of time requires caution.

1-3

Page 14

7102

User's Guide

ELECTRICAL HAZARD

• These guidelines must be followed to ensure that the safety

mechanisms in this instrument will operate properly. This

instrument must be plugged into an AC only electric outlet

as listed in Section 3.1, Specifications. The power cord of

the instrument is equipped with a three-pronged grounding

plug for your protection against electrical shock hazards. It

must be plugged directly into a properly grounded threeprong receptacle. The receptacle must be installed in

accordance with local codes and ordinances or adapter

plug. DO NOT use an extension cord. Consult a qualified

electrician. Always inspect the power cord before use for

any damage to the insulation due to contact with hot

surfaces, cuts or abrasions.

• The instrument is equipped with operator accessible fuses.

If a fuse blows, it may be due to a power surge or failure of a

component. Replace the fuse once. If the fuse blows a

second time, it is likely caused by failure of a component

part. If this occurs, contact a Hart Scientific Authorized

Service Center. Always replace the fuse with one of the

same rating, voltage, and type. Never replace the fuse with

one of a higher current rating.

• Always replace the power cord with an approved cord of the

correct rating and type. If you have questions, contact an

Authorized Service Center (see Section 1.3).

• High voltage is used in the operation of this equipment.

Severe injury or death may result if personnel fail to

observe the safety precautions.

1.2.2 Cautions

To avoid possible damage to the instrument, follow these

guidelines.

• Always operate this instrument at room temperatures listed

in Section 3.2, Environmental Conditions. Allow sufficient

air circulation by leaving at least 6 inches (15 cm) of

clearance around the instrument.

• Overhead clearance is required. DO NOT place this

instrument under a cabinet or other structure.

• Never introduce any foreign material into the well.

• DO NOT change the values of the calibration constants from

the factory set values. The correct setting of these

parameters is important to the safety and proper operation

of the unit.

Cautions

1-4

• DO NOT slam the probe stems into the well. This type of

action can cause a shock to the sensor and affect the

calibration.

• DO use a ground fault interrupt device.

Page 15

1.3 Authorized Service Centers1

• DO NOT operate this instrument in an excessively wet, oily,

dusty, or dirty environment.

• The unit is a precision instrument. Although it has been

designed for optimum durability and trouble free operation,

it must be handled with care.

• Most probes have handle temperature limits. Be sure that

the probe handle temperature limit is not exceeded in the air

above the instrument.

• The instrument and any thermometer probes used with it

are sensitive instruments that can be easily damaged.

Always handle these devices with care. Do not allow them

to be dropped, struck, stressed, or overheated.

• When calibrating PRTs always follow correct calibration

procedure and calibrate from high temperatures to low

temperatures with the appropriate triple point of water

checks.

• Components and heater lifetimes can be shortened by

continuous high temperature operation.

• If a mains supply power fluctuation occurs, immediately

turn off the bath. Power bumps from brown-outs and blackouts can damage the instrument. Wait until the power has

stabilized before re-energizing the bath.

Before You Start

• Fluids may expand at different rates. Allow for fluid

expansion inside the well as the instrument heats.

Otherwise, the fluid may overflow the well and leak into the

instrument.

1.3 Authorized Service Centers

Please contact one of the following authorized Service Centers to coordinate

service on your Hart product:

Fluke Corporation

Hart Scientific Division

799 E. Utah Valley Drive

American Fork, UT 84003-9775

USA

Phone: + 1.801.763.1600

Telefax: +1.801.763.1010

E-mail: support@hartscientific.com

1-5

Page 16

7102

User's Guide

Fluke Nederland B.V.

Customer Support Services

Science Park Eindhoven 5108

5692 EC Son

NETHERLANDS

Phone: +31-402-675300

Telefax: +31-402-675321

E-mail: ServiceDesk@fluke.nl

Fluke Int’l Corporation

Service Center - Instrimpex

Room 2301 Sciteck Tower

22 Jianguomenwai Dajie

Chao Yang District

Beijing 100004, PRC

CHINA

Phone: +86-10-6-512-3436

Telefax: +86-10-6-512-3437

E-mail: xingye.han@fluke.com.cn

Fluke South East Asia Pte Ltd.

Fluke ASEAN Regional Office

Service Center

60 Alexandra Terrace #03-16

The Comtech (Lobby D)

118502

SINGAPORE

Phone: +65-6799-5588

Telefax: +65-6799-5589

E-mail: anthony.ng@fluke.com

When contacting these Service Centers for support, please have the following

information available:

1-6

• Model Number

• Serial Number

• Voltage

• Complete description of the problem

Page 17

The Hart Scientific 7102 Micro-Bath may be used as a portable instrument or

bench top temperature calibrator for calibrating thermocouple and RTD

temperature probes. The 7102 is small enough to use in the field, and accurate

enough to use in the lab. With an ambient temperature of 23 °C (74 °F),

calibrations may be done over a range of −5 °C to 126 °C (23 °F to 259 °F). The

resolution of the 7102 temperature display is 0.01 degrees.

Chapter 2

Introduction

The Micro-Bath calibrator features:

• Convenient handle

• RS-232 interface

• Switchable AC Input (115 VAC or 230 VAC)

• Optional well extender to extend well depth

Built in programmable features include:

• Temperature scan rate control

• Temperature switch hold

• Eight Set-point memory

• Adjustable readout in °C or °F

The temperature is accurately controlled by Hart’s hybrid analog/digital controller.

The controller uses a precision platinum RTD as a sensor and controls the well

temperature with a solid state relay (triac) driven heater.

The LED front panel continuously shows the current well temperature. The

temperature may be easily set with the control buttons to any desired

temperature within the specified range. The calibrator’s multiple fault protection

devices insure user and instrument safety and protection.

The 7102 Micro-Bath was designed for portability, low cost, and ease of

operation. Through proper use, the instrument will continuously provide accurate

calibration of temperature sensors and devices. The user should be familiar with

the safety guidelines and operating procedures of the calibrator as described in

the instruction manual.

2-1

Page 18

7102

User's Guide

2-2

Page 19

Chapter 3

Specifications and Environmental

Conditions

3.1 Specifications

Table 2. Specifications

Range −5 to 125 °C (23 to 257 °F)

Accuracy ±0.25 °C

Stability ±0.015 °C at −5 °C (oil, 5010)

±0.03 °C at 121 °C (oil, 5010)

Uniformity ±0.02 °C

Resolution 0.01 °C/F

Operating Temperature 5 to 45 °C (41 to 113 °F)

Heating Time 25 °C to 100 °C (77 °F to 212 °F): 30 minutes

Cooling Time 25 °C to 0 °C (77 °F to 32 °F): 30 minutes

Well Size 2.5" dia. x 5.5" deep (64 x 139 mm)

(access opening is 1.9" [48 mm] in diameter )

Exterior Dimension 12" H x 7.2" W x 9.5" D (31 cm x 18 cm x 24 cm)

Weight 15 lb. (6.8 kg) with fluid

Power 115 VAC ( ±10 %), 1.8 A, or 230 VAC ( ±10 %), 0.9

A, switchable, 50/60 Hz, 200 W

Readout Switchable °C or °F

Controller Digital controller with data retention

Thermal Electric Devices (TED) 150 W

Cooling Fan and Thermal Electric Devices (TED)

Fault Protection Sensor burnout and short protection

Safety Overvoltage (Installation) Category II, Pollution

Fuse Rating 115 V: 250 V 3A SB (slow blow)

Degree 2 per IEC 61010-01

230 V: 250 V 1.6 A T (time delay)

3-1

Page 20

7102

User's Guide

3.2 Environmental Conditions

Although the instrument has been designed for optimum durability and troublefree operation, it must be handled with care. The instrument should not be

operated in an excessively dusty or dirty environment. Maintenance and cleaning

recommendations can be found in the Maintenance Section of this manual.

• The instrument operates safely under the following conditions:

• ambient temperature range: 5 − 45 °C (41 − 113 °F)

• ambient relative humidity: maximum 80 % for temperature <31 °C, decreasing

linearly to 50 % at 40 °C

• mains voltage within ± 10 % of nominal

• vibrations in the calibration environment should be minimized

• altitudes less than 2,000 meters

3-2

Page 21

Caution:

READ SECTION 6 ENTITLED BATH USE before placing the bath

in service. Incorrect handling can damage the bath and void the

warranty.

Chapter 4

Quick Start

4.1 Unpacking

Unpack the Micro-Bath carefully and inspect it for any damage that may have

occurred during shipment. If there is shipping damage, notify the carrier

immediately.

Verify that the following components are present:

• 7102 Micro-Bath

• Transport/Pour Access Lid

• Probe Basket

• Stir Bar

• Power Cord

• User’s Guide

• Report of Calibration

• Calibration Label

• Access Cover, optional

• Well Extender, optional

4-1

Page 22

7102

User's Guide

4.2 Setup

Caution:

DO NOT operate this instrument without fluid.

Place the calibrator on a flat surface with at least 6 inches of free space around

the instrument. Plug the power cord into a grounded mains outlet. Observe that

the nominal voltage corresponds to that indicated on the back of the calibrator.

Carefully insert the probe basket into the well. Fill the well with the appropriate

fluid. The set-point temperature and the number of and size of probes determine

the fluid level. Be sure to keep the fluid level an adequate distance below the top

of the well to prevent overflowing the fluid when the probes are inserted. For

example, placing200.05 oil at room temperature (25 °C) into the bath and heating

the unit to 125 °C, causes a 1-inch (2.54 cm) expansion of the fluid inside the

well.

Keep the fluid level at least 1.9 cm (0.75 inches) below the top of the well at

all times. With the probe (probes) in the well fill the tank 3/4 full. Heat to the

maximum temperature of the fluid. Slowly fill the well to 2.54 cm (1 inch) below

the top of the basket at the maximum temperature of the fluid.

Turn on the power to the calibrator by toggling the switch on the power entry

module. The fan should begin blowing air through the instrument and the

controller display should illuminate after 3 seconds. After a brief self test the

controller should begin normal operation. If the unit fails to operate please check

the power connection.

The display shows the well temperature and the well TEDs start operating to

bring the temperature of the well to the set-point temperature. Insure that the fluid

is being stirred.

4.3 Power

Plug the Micro-Bath power cord into a mains outlet of the proper voltage,

frequency, and current capability. Refer to Section 3.1, Specifications, for power

details. Turn the bath on using the rear panel “POWER” switch. The Micro-Bath

will turn on and begin to heat to the previously programmed temperature setpoint. The front panel LED display will indicate the actual bath temperature.

4.4 Setting the Temperature

Section 9.2 explains in detail how to set the temperature set-point on the

calibrator using the front panel keys. The procedure is summarized here.

1. Press “SET” twice to access the set-point value.

2. Press “UP” or “DOWN” to change the set-point value.

3. Press “SET” to store the new set-point.

4-2

4. Press “EXIT” to return to the temperature display.

When the set-point temperature is changed the controller switches the heater on

or off to raise or lower the temperature. The displayed well temperature gradually

changes until it reaches the set-point temperature. The well may require 25

minutes to reach the set-point depending on the span. Another 10 to 15 minutes

is required to stabilize within ±0.03 °C of the set-point. Ultimate stability may take

20 to 30 minutes more of stabilization time.

Page 23

Caution:

READ SECTION 6 ENTITLED BATH USE before placing the bath

in service. Incorrect handling can damage the bath and void the

warranty.

Chapter 5

Installation

5.1 Bath Environment

The 7102 Micro Bath is a precision instrument which should be located in an

appropriate environment. The location should be free of drafts, extreme

temperatures and temperature changes, dirt, etc. The surface where the bath is

placed must be level.

Because the bath is designed for operation at high temperatures, keep all

flammable and meltable materials away from the bath. Although the bath is well

insulated, top surfaces do become hot. Beware of the danger of accidental fluid

spills. The bath should be placed on a heat-proof surface such as concrete with

plenty of clear space around the bath.

If the bath is operated at high temperatures, a fume hood should be used to

remove any vapors given off by hot bath fluid.

5.2 “Dry-out” Period

Before initial use, after transport, and any time the instrument has not been

energized for more than 10 days, the bath will need to be energized for a “dryout” period of 1-2 hours before it can be assumed to meet all of the safety

requirements of the IEC 61010-1.

5-1

Page 24

7102

User's Guide

5.3 Bath Preparation and Filling

The 7102 Micro Bath is not provided with a fluid. Various fluids are available from

Hart Scientific and other sources. Depending on the desired temperature range,

any of the following fluids, as well as others, may be used in the bath:

• Water (distilled)

• Ethylene glycol/water

• Mineral oil

• Silicone oil

Fluids are discussed in detail in Section 8.3.

Remove the access lid from the bath and check the tank for foreign matter (dirt,

remnant packing material, etc.). Thoroughly dry the inside of the well with paper

towels before filling.

Fill the bath with clean unpolluted fluid. Under-filling may reduce bath

performance. The fluid should never exceed a height of 1.9 cm (0.75 inches)

below the top of the basket. Carefully monitor the bath fluid level as the bath

temperature rises to prevent overflow or splashing. Remove excess hot fluid if

necessary with caution.

200.05 Silicon Oil expands 2.54 cm (1 inch) for a 100

temperature.

5.4 Power

With the bath power switch off, plug the bath into an AC mains outlet of the

appropriate voltage, frequency, and current capacity. Refer to Section 3.1,

Specifications, for power details.

Note:

°

C increase in

5-2

Page 25

Caution:

Read before placing the bath in service

Chapter 6

Bath Use

The information in this section is for general information only. It

is not designed to be the basis for calibration laboratory

procedures. Each laboratory will need to write their own

specific procedures.

6.1 General

Be sure to select the correct fluid for the temperature range of the calibration.

Bath fluids should be selected to operate safely with adequate thermal properties

to meet the application requirements. Also, be aware that some fluids expand

and could overflow the bath if not watched. Refer to Section 8.3, Bath Fluid, and

subsequent subsections for information specific to fluid selection and to the

MSDS sheet specific to the fluid selected. Generally, baths are set to one

temperature and used to calibrate probes only at that single temperature. This

means that the type of bath fluid does not have to change. Additionally, the bath

can be left energized reducing the stress on the system.

The bath generates extreme temperatures. Precautions must be taken to prevent

personal injury or damage to objects. Probes may be extremely hot or cold when

removed from the bath. Cautiously handle probes to prevent personal injury.

Carefully place probes on a heat/cold resistant surface or rack until they are at

room temperature. It is advisable to wipe the probe with a clean soft cloth or

paper towel before inserting it into another bath. This prevents the mixing of

fluids from one bath to another. If the probe has been calibrated in liquid salt,

carefully wash the probe in warm water and dry completely before transferring it

to another fluid. Always be sure that the probe is completely dry before inserting

it into a hot fluid. Be aware that cleaning the probe can be dangerous if the probe

has not cooled to room temperature. Additionally, high temperature fluids may

ignite the paper towels if the probe has not been cooled.

6-1

Page 26

7102

User's Guide

Warning:

Some of the high temperature fluids react violently to water or

other liquid mediums.

For optimum accuracy and stability, allow the bath adequate

stabilization time after reaching the set-point temperature.

6.2 Comparison Calibration

Comparison calibration involves testing a probe (unit under test, UUT) against a

reference probe. After inserting the probes to be calibrated into the bath, allow

sufficient time for the probes to settle and the temperature of the bath to stabilize.

One of the significant dividends of using a bath rather than a dry-well to calibrate

multiple probes is that the probes do not need to be identical in construction. The

fluid in the bath allows different types of probes to be calibrated at the same time.

However, stem effect from different types of probes is not totally eliminated. Even

though all baths have horizontal and vertical gradients, these gradients are

minimized inside the bath work area. Nevertheless, probes should be inserted to

the same depth in the bath liquid. Be sure that all probes are inserted deep

enough to prevent stem effect. From research at Hart Scientific, we suggest a

general rule-of-thumb for immersion depth to reduce the stem effect to a

minimum: 15 x the diameter of the UUT + the sensor length. Do not submerge

the probe handles. If the probe handles get too warm during calibration at high

temperatures, a heat shield could be used just below the probe handle. This heat

shield could be as simple as aluminum foil slid over the probe before inserting it

in the bath or as complicated as a specially designed reflective metal apparatus.

When calibrating over a wide temperature range, better results can generally be

achieved by starting at the highest temperature and progressing down to the

lowest temperature.

Probes can be held in place in the bath by using probe clamps or drilling holes in

the access cover. Other fixtures to hold the probes can be designed. The object

is to keep the reference probe and the probe(s) to be calibrated as closely

grouped as possible in the working area of the bath. Bath stability is maximized

when the bath working area is kept covered.

In preparing to use the bath for calibration start by:

• Placing the reference probe in the bath working area.

• Placing the probe to be calibrated, the UUT, in the bath working area as close

as feasibly possible to the reference probe.

6.3 Calibration of Multiple Probes

Fully loading the bath with probes increases the time required for the

temperature to stabilize after inserting the probes. Using the reference probe as

the guide, be sure that the temperature has stabilized before starting the

calibration.

6-2

Page 27

The user should become familiar with the bath and its parts:

7.1 Front Panel

Figure 1 on this page.

Chapter 7

Parts and Controls

Figure 1. 7102 Front Panel

Controller Display – The digital display is an important part of the temperature

controller because it not only displays set and actual temperatures but also

displays various calibrator functions, settings, and constants. The display shows

temperatures in units according to the selected scale °C or °F.

Controller Keypad – The four button keypad allows easy setting of the set-point

temperature. The control buttons (SET, DOWN, UP, and EXIT) are used to set

the calibrator temperature set-point, access and set other operating parameters,

and access and set calibration parameters.

Setting the control temperature is done directly in degrees of the current scale. It

can be set to one-hundredth of a degree Celsius or Fahrenheit.

The functions of the buttons are as follows:

SET – Used to display the next parameter in the menu and to store parameters

to the displayed value.

DOWN – Used to decrement the displayed value of parameters.

UP – Used to increment the displayed value.

7-1

Page 28

7102

User's Guide

EXIT – Used to exit a function. Any changes made to the displayed value are

ignored. Holding the EXIT button for approximately 0.5 seconds exits back to the

main display.

7.2 Back Panel

Figure 2 on next page.

Power Cord – Underneath the calibrator is the removable power cord inlet that

plugs into an IEC grounded socket.

7-2

Figure 2. 7102 Back Panel and Bottom

Page 29

Parts and Controls

7.3 Accessories 7

Power Switch – The power switch is located on the power entry module (PEM).

The PEM also houses the fuses and the dual voltage selector. The PEM allows

the unit to be field switchable for 115 VAC ( ±10 %) or 230 VAC ( ±10 %)

operation.

Serial Port – A DB-9 male connector is present for interfacing the calibrator to a

computer or terminal with serial RS-232 communications.

Fan – The fan inside the calibrator runs continuously when the unit is being

operated to provide cooling for the instrument. Slots at the top and around the

two corners of the calibrator are provided for airflow. The area around the

calibrator must be kept clear to allow adequate ventilation. The airflow is directed

out the back.

7.3 Accessories

7.3.1 Transport/Pour Access Lid

A transport/pour access lid (Figure 3) is provided so the fluid being does not have

to be removed when transporting. The lid doubles as a pour spout.

Figure 3. Bath Lids and Lid Parts

7-3

Page 30

7102

User's Guide

7.3.2 Access Cover (Optional)

An aluminum access cover (Figure 3) is available for optimum stability. Holes

should be drilled in the access cover to allow insertion of the probes into the well.

The holes must be within the guide ring for the probes to fit into the probe basket.

Warning:

DO NOT install an access cover without holes (like the optional

cover) onto a bath that is energized. Dangerous pressures may

result from fluids vaporizing.

7.3.3 Probe Basket

A probe basket (Figure 4) is provided as a guide for the probes and to prevent

bumping of the stir bar.

7-4

Figure 4. Probe Basket

7.3.4 Stir Bar

The stir bar (Figure 5) sits in the bottom of the well for mixing the fluid providing

better accuracy, uniformity, and stability.

Figure 5. Stir Bar

7.3.5 Well Extender (Optional)

An optional well extender is available for increasing the depth of the well. This

extender screws onto the well and is equipped with an O-ring. Thread the

extender down until the O-ring makes a good seal. Some fluids may expand up

to 6.35 cm (2.5 inches). Therefore, when using the well extender keep in mind

how much the fluid you are using will expand. Do not overfill the well.

Page 31

8.1 Changing Display Units

The 7102 can display temperature in Celsius or Fahrenheit.

The temperature units are shipped from the factory set to Celsius.

To change to Fahrenheit or back to Celsius there are two ways:

1. Press “SET” and “UP” simultaneously. This will change the display units.

2. Press the “SET” key three times from the temperature display to show

Chapter 8

General Operation

Un = C

or

• Press the “UP” or “DOWN” key to change units.

• Press “SET” to store changes.

8.2 Switching to 230V Operation

The 7102 is switchable from 115 VAC to 230 VAC 50/60 Hz. Switching the

voltage can change the calibration, so the unit should be calibrated after

changing the input voltage.

To change from 115 VAC to 230 VAC:

• Unplug the unit.

• With a small straight slot screwdriver remove the fuse holder located on the

back of the bath. Replace the two fuses (3 amp 250 V) with 1.6 amp 250 V

fuses.

• Replace the fuse holder with the “230V” in the display window.

Note:

Use 3 amp fuses for 115 V and 1.6 amp for 230V only. DO NOT

PLUG THE UNIT INTO 230 V IF THE FUSE HOLDER READS 115 V.

8-1

Page 32

7102

User's Guide

8.3 Bath Fluid

Many fluids work with the 7102 bath. Choosing a fluid requires consideration of

many important characteristics of the fluid. Among these are temperature range,

viscosity, specific heat, thermal conductivity, thermal expansion, electrical

resistivity, fluid lifetime, safety, and cost.

8.3.1 Temperature Range

One of the most important characteristics to consider is the temperature range of

the fluid. Few fluids work well throughout the complete temperature range of the

bath. The temperature at which the bath is operated must always be within the

safe and useful temperature range of the fluid. The lower temperature range of

the fluid is determined by the freeze point of the fluid or the temperature at which

the viscosity becomes too great. The upper temperature is usually limited by

vaporization, flammability, or chemical breakdown of the fluid. Vaporization of the

fluid at higher temperatures may affect temperature stability because of cool

condensed fluid dripping into the bath from the lid.

8.3.2 Viscosity

Viscosity is a measure of the thickness of a fluid, how easily it can be poured and

mixed. Viscosity affects the temperature stability of the bath. With low viscosity,

fluid mixing is better which creates a more uniform temperature throughout the

bath. This improves the bath response time which allows it to maintain a more

constant temperature. For good control the viscosity should be less than ten

centistokes. Twenty centistokes is about the upper limit of allowable viscosity.

Viscosities greater than this cause very poor control stability and may also

overheat or damage the stirring motor. With oils viscosity may vary greatly with

temperature.

When using fluids with higher viscosities the controller proportional band may

need to be increased to compensate for the reduced response time. Otherwise

the temperature may begin to oscillate.

8.3.3 Specific Heat

Specific heat is the measure of the heat storage ability of the fluid. Specific heat,

to a small degree, affects the control stability. It also affects the heating and

cooling rates. Generally, a lower specific heat means quicker heating and

cooling. The proportional band may require some adjustment depending on the

specific heat of the fluid.

8.3.4 Thermal Conductivity

Thermal conductivity measures how easily heat flows through the fluid. Thermal

conductivity of the fluid affects the control stability, temperature uniformity, and

probe temperature settling time. Fluids with higher conductivity distribute heat

more quickly and evenly improving bath performance.

8-2

Page 33

8.3.5 Thermal Expansion

Thermal expansion describes how the volume of the fluid changes with

temperature. Thermal expansion of the fluid used must be considered since the

increase in fluid volume as the bath temperature changes may cause overflow.

Excessive thermal expansion may also be undesirable in applications where

constant liquid level is important. Many fluids including oils have significant

thermal expansion.

8.3.6 Electrical Resistivity

Electrical resistivity describes how well the fluid insulates against the flow of

electric current. In some applications, such as measuring the resistance of bare

temperature sensors, it may be important that little or no electrical leakage occur

through the fluid. In such conditions choose a fluid with very high resistivity.

8.3.7 Fluid Lifetime

Many fluids degrade over time because of evaporation, water absorption, gelling,

or chemical breakdown. Often the degradation becomes significant near the

upper temperature limit of the fluid, substantially reducing the fluid’s lifetime.

8.3.8 Safety

When choosing a fluid always consider the safety issues associated. Obviously

where there are conditions of extreme hot or cold there can be danger to people

and equipment. Fluids may also be hazardous for other reasons. Some fluids

may be considered toxic. Contact with eyes, skin, or inhalation of vapors may

cause injury. A proper fume hood must be used if hazardous or bothersome

vapors are produced.

General Operation

8.3 Bath Fluid 8

Fluids may be flammable and require special fire safety equipment and

procedures. An important characteristic of the fluid to consider is the flash point.

The flash point is the temperature at which there is sufficient vapor given off so

that when there is sufficient oxygen present and an ignition source is applied the

vapor will ignite. This does not necessarily mean that fire will be sustained at the

flash point. The flash point may be either of the open cup or closed cup type.

Either condition may occur in a bath situation. The closed cup temperature is

always the lower of the two. The closed cup represents the contained vapors

inside the tank and the open cup represents the vapors escaping the tank.

Oxygen and an ignition source will be less available inside the tank.

Environmentally hazardous fluids require special disposal according to applicable

federal or local laws after use.

8.3.9 Cost

Cost of bath fluids may vary greatly, from cents per gallon for water to hundreds

of dollars per gallon for synthetic oils. Cost may be an important consideration

when choosing a fluid.

Warning:

Fluids at high temperatures may pose danger from BURNS,

FIRE, and TOXIC FUMES. Use appropriate caution and safety

equipment.

8-3

Page 34

7102

User's Guide

8.3.10 Commonly Used Fluids

Below is a description of some of the more commonly used fluids and their

characteristics.

8.3.10.1 Water (Distilled)

Water is often used because of its very low cost, availability, and excellent

temperature control characteristics. Water has very low viscosity and good

thermal conductivity and heat capacity which makes it among the best fluids for

control stability at low temperatures. Temperature stability is much poorer at

higher temperatures because water condenses on the lid, cools and drips into

the bath. Water is safe and relatively inert. The electrical conductivity of water

may prevent its use in some applications. Water has a limited temperature range,

from a few degrees above 0 °C to a few degrees below 100 °C. At higher

temperatures evaporation becomes significant. Water used in the bath should be

distilled or softened to prevent mineral deposits. Consider using an algaecide

chemical in the water to prevent contamination.

8.3.10.2 Mineral Oil

Mineral oil or paraffin oil is often used at moderate temperatures above the range

of water. Mineral oil is relatively inexpensive. At lower temperatures mineral oil is

quite viscous and control may be poor. At higher temperatures vapor emission

becomes significant. The vapors may be dangerous and use of a fume hood is

highly recommended. As with most oils mineral oil will expand as temperature

increases so be careful not to fill the bath too full that it overflows when heated.

The viscosity and thermal characteristics of mineral oil is poorer than water so

temperature stability will not be as good. Mineral oil has very low electrical

conductivity. Use caution with mineral oil since it is flammable and may also

cause serious injury if inhaled or ingested.

8.3.10.3 Silicone Oil (Dow Corning 200.05, 200.10, 200.20)

Silicone oils are available which offer a much wider operating temperature range

than mineral oil. Like most oils, silicone oils have temperature control

characteristics which are somewhat poorer than water. The viscosity changes

significantly with temperature and thermal expansion also occurs. These oils

have very high electrical resistivity. Silicone oils are fairly safe and non-toxic.

Silicone oils are fairly expensive.

8.3.11 Fluid Characteristics Charts

Table 3 on page 25 and Figure 6 on page 26 have been created to provide help

in selecting a heat exchange fluid media for your constant temperature bath.

These charts provide both a visual and numerical representation of most of the

physical qualities important in making a selection. The list is not all inclusive.

There may be other useful fluids not shown in this listing.

The charts include information on a variety of fluids which often used as heat

transfer fluid in baths. Because of the temperature range some fluids may not be

useful with your bath.

8-4

Page 35

8.3.11.1 Limitations and Disclaimer

The information given in this manual regarding fluids is intended only to be used

as a general guide in choosing a fluid. Though every effort has been made to

provide correct information we cannot guarantee accuracy of data or assure

suitability of a fluid for a particular application. Specifications may change and

sources sometimes offer differing information. Hart Scientific cannot be liable for

any personal injury or damage to equipment, product or facilities resulting from

the use of these fluids. The user of the bath is responsible for collecting correct

information, exercising proper judgment, and insuring safe operation. Operating

near the limits of certain properties such as the flash point or viscosity can

compromise safety or performance. Your company’s safety policies regarding

flash points, toxicity, and such issues must be considered. You are responsible

for reading the MSDS (material safety data sheets) and acting accordingly.

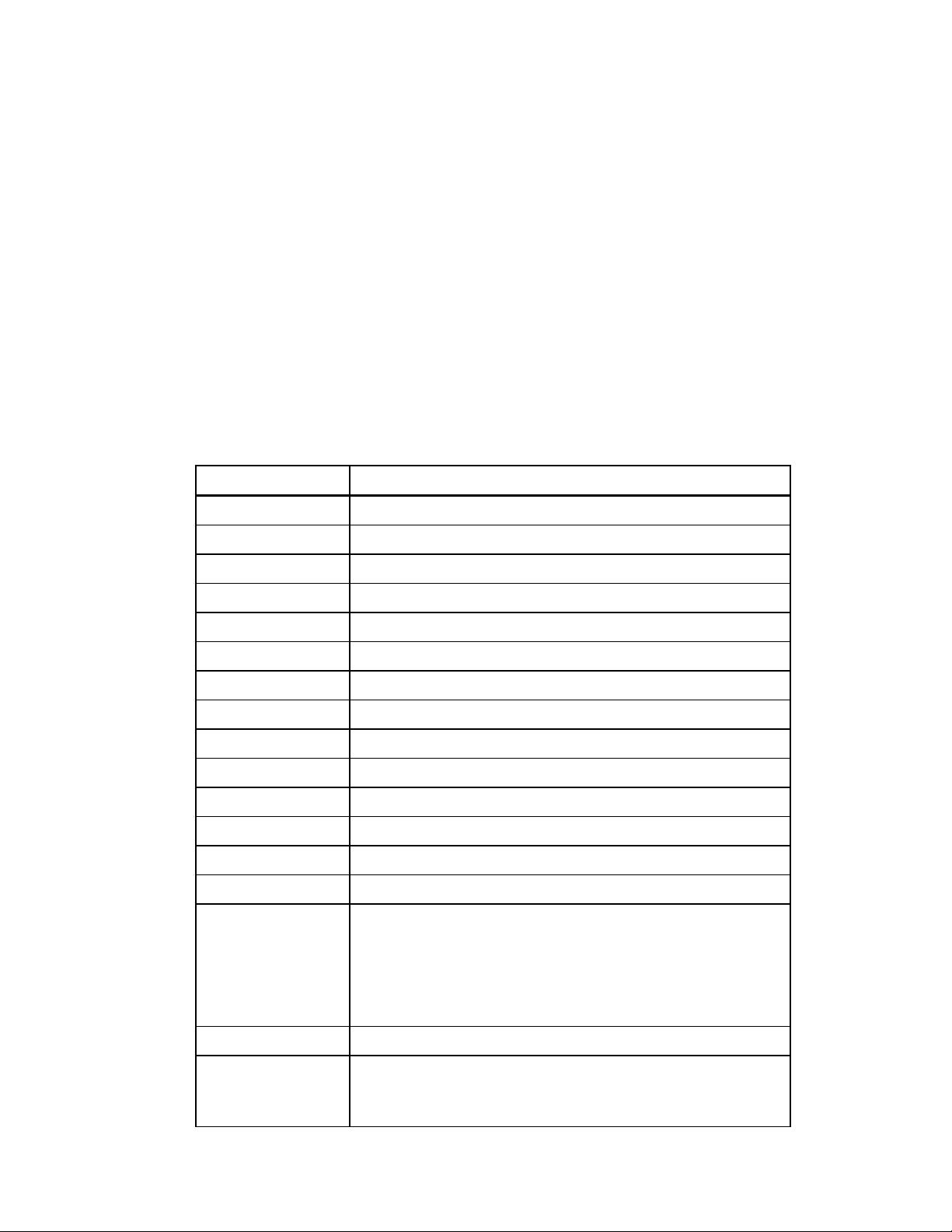

Table 3. Table of Various Bath Fluids

General Operation

8.3 Bath Fluid 8

8-5

Page 36

7102

User's Guide

8-6

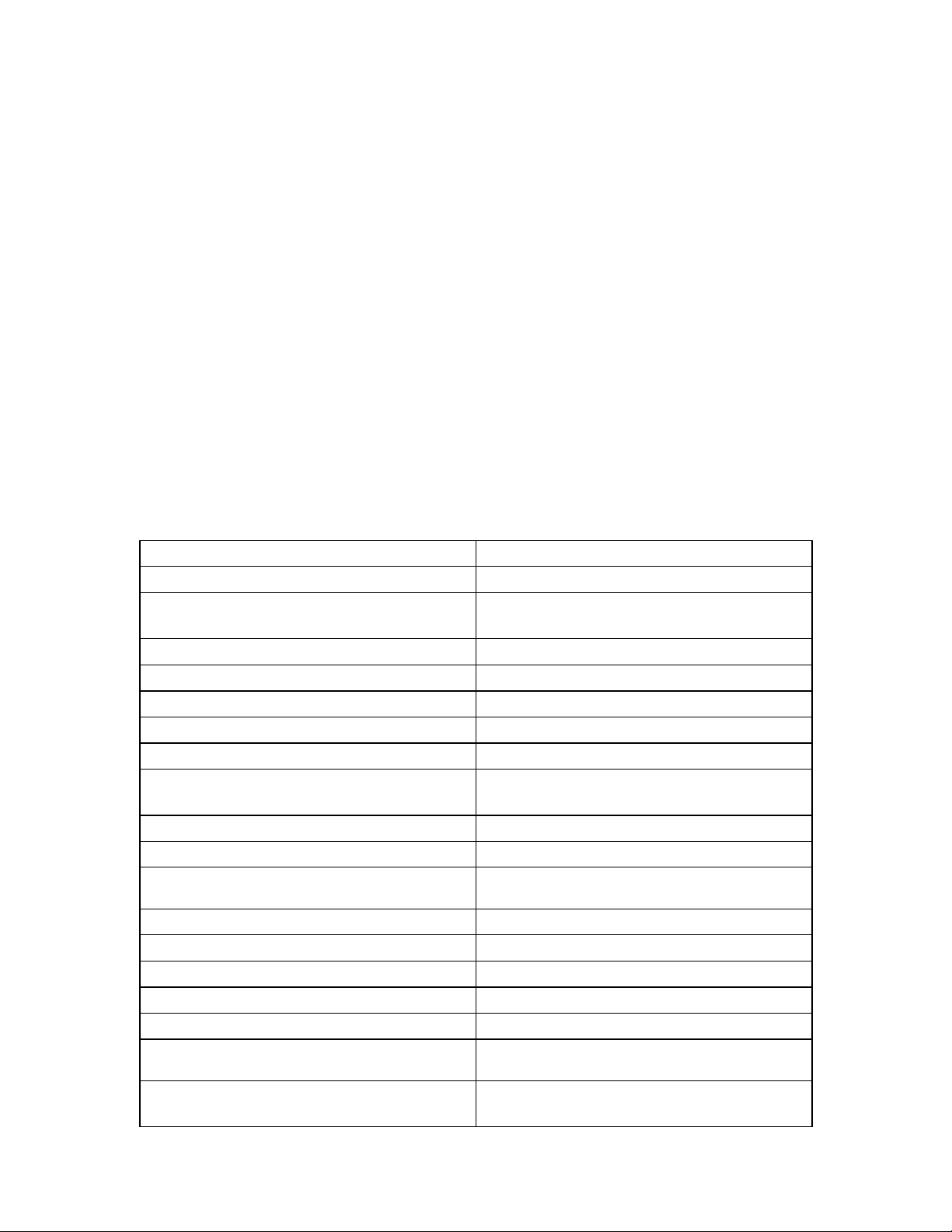

Figure 6. Chart of Various Bath Fluids

8.3.11.2 About the Graph

The fluid graph visually illustrates some of the important qualities of the fluids

shown.

Temperature Range: The temperature scale is shown in degrees Celsius. The

fluids’ general range of application is indicated by the shaded bands. Qualities

including pour point, freeze point, important viscosity points, flash point, boiling

point and others may be shown.

Freezing Point: The freezing point of a fluid is an obvious limitation to stirring.

As the freezing point is approached high viscosity may also limit performance.

Page 37

General Operation

8.4 Stirring 8

Pour Point: This represents a handling limit for the fluid.

Viscosity: Points shown are at 50 and 10 centistokes viscosity. When viscosity

is greater than 50 centistokes stirring is very poor and the fluid is unsatisfactory

for bath applications. Optimum stirring generally occurs at 10 centistokes and

below.

Fume Point: A fume hood should be used. This point is very subjective in nature

and is impacted by individual tolerance to different fumes and smells, how well

the bath is covered, the surface area of the fluid in the bath, the size and

ventilation of the facility where the bath is located and other conditions. We

assume the bath is well covered at this point. This is also subject to company

policy.

Flash Point: The point at which ignition may occur. The point shown may be

either the open or closed cup flash point. Refer to the flash point discussion in

Section 8.3.8.

Boiling Point: At or near the boiling point of the fluid, the temperature stability is

difficult to maintain. Fuming or evaporation is excessive. Large amounts of heater

power may be required because of the heat of vaporization.

Decomposition: The temperature may reach a point at which decomposition of

the fluid begins. Further increasing the temperature may accelerate

decomposition to the point of danger or impracticality.

8.4 Stirring

Stirring of the bath fluid is very important for stable temperature control. The fluid

must be mixed well for good temperature uniformity and fast controller response.

The stirrer is adjusted for optimum performance. Table 4 on page 27 shows

nominal stirrer motor settings for several fluids.

If the stirrer does not function properly, the instrument will oscillate and not meet

published specifications.

If the bath is used with the probe basket removed, stir motor settings

need to be changed so that a small vortex can be seen in the liquid.

Note:

8-7

Page 38

7102

User's Guide

Warning:

Do not mix water and oil when exceeding temperatures of 90 °C

Table 4. Nominal Stirrer Motor Settings with Different Liquids

Liquid Stir Motor Setting Temperature

Distilled Water 15 5 °C to 90 °C

(41 °F to 194 °F)

Ethylene Glycol 15 −5 °C to 90 °C

(25 °F to 194 °F)

200.05 Oil 15 −5 °C to 125 °C

( −23 °F to 258 °F)

200.10 Oil 15 25 °C to 125 °C

(77 °F to 258 °F)

8.5 Power

Power to the bath is provided by an AC mains supply and passes through a filter

to prevent switching spikes from being transmitted to other equipment. Refer to

Section 3.1, Specifications, for power details.

To turn on the bath, switch the control panel power switch to the ON position.

The stir motor will turn on, the LED display will begin to show the bath

temperature, and the heater will turn on or off until the bath temperature reaches

the programmed set-point.

When powered on the control panel display will briefly show a four digit number.

This number indicates the number of times power has been applied to the bath.

Also briefly displayed is data which indicates the controller hardware

configuration. This data is used in some circumstances for diagnostic purposes.

8.6 Thermal Electric Devices (TED)

The power to the bath is precisely controlled by the temperature controller to

maintain a constant bath temperature. Power is controlled by periodically

switching the TEDs on for a certain amount of time using power transistors.

8-8

Page 39

8.7 Fluid Drain

The fluid may be drained from the 7102 by tightly screwing the transport/pour

access lid onto the top of the bath and pouring the liquid into an appropriate

container.

8.8 Temperature Controller

The bath temperature is controlled by Hart Scientific’s unique hybrid

digital/analog temperature controller. The controller offers the tight control

stability of an analog temperature controller as well as the flexibility and

programmability of a digital controller.

The bath temperature is monitored with a platinum resistance sensor in the

control probe. The signal is electronically compared with the programmable

reference signal, amplified, and then fed to a pulse-width modulator circuit which

controls the amount of power applied to the bath heater.

The bath is operable within the temperature range given in the specifications. For

protection against solid-state relay failure or other circuit failure, a bi-metallic cutout automatically turns off the heater anytime the bath temperature exceeds the

maximum temperature.

The controller allows the operator to set the bath temperature with high

resolution, adjust the proportional band, monitor the heater output power, and

program the controller configuration and calibration parameters. The controller

may be operated in temperature units of degrees Celsius or Fahrenheit. The

controller is operated and programmed from the front control panel using the four

key switches and digital LED display. The controller is equipped with a serial RS232 digital interface for remote operation. Operation using the digital interfaces is

discussed in Section 10.

General Operation

8.7 Fluid Drain 8

When the controller is set to a new set-point the bath heats or cools to the new

temperature. Once the new temperature is reached the bath usually takes 15 –

20 minutes for the temperature to settle and stabilize. There may be a small

overshoot or undershoot.

8-9

Page 40

7102

User's Guide

8-10

Page 41

This chapter discusses in detail how to operate the bath temperature controller

using the front control panel. Using the front panel key-switches and LED display

the user may monitor the well temperature, set the temperature set-point in

degrees C or F, monitor the heater output power, adjust the controller

proportional band, and program the calibration parameters, operating

parameters, and serial interface configuration. Operation of the functions and

parameters are shown in the flowchart in Figure 7 on page 32. This chart may be

copied for reference.

In the following discussion a button with the word SET, UP, EXIT or DOWN

inside indicates the panel button while the dotted box indicates the display

reading. Explanation of the button or display reading are to the right of each

button or display value.

Chapter 9

Controller Operation

9.1 Well Temperature

The digital LED display on the front panel allows direct viewing of the actual well

temperature. This temperature value is what is normally shown on the display.

The units, C or F, of the temperature value are displayed at the right. For

example,

100.00C Well temperature in degrees Celsius

The temperature display function may be accessed from any other function by

pressing the “EXIT” button.

9.2 Temperature Set-point

The temperature set-point can be set to any value within the range and resolution

as given in the specifications. Be careful not to exceed the safe upper

temperature limit of any device inserted into the well.

Setting the temperature involves selecting the set-point memory and adjusting

the set- point value.

9.2.1 Programmable Set-points

The controller stores 8 set-point temperatures in memory. The set-points can be

quickly recalled to conveniently set the calibrator to a previously programmed

temperature set-point.

To set the temperature one must first select the set-point memory. This function

is accessed from the temperature display function by pressing “SET”. The

number of the set-point memory currently being used is shown at the left on the

display followed by the current set-point value.

9-1

Page 42

7102

User's Guide

9-2

Figure 7. Controller Operation Flowchart

Page 43

Controller Operation

9.2 Temperature Set-point 9

100.00C Well temperature in degrees Celsius

Access set-point memory

1. 25 Set-point memory 1, 25 °C currently used

To change the set-point memory press “UP” or “DOWN”.

4. 125. New set-point memory 4, 125 °C

Press “SET” to accept the new selection and access the set-point value.

Accept selected set-point memory

9.2.2 Set-point Value

The set-point value may be adjusted after selecting the set-point memory and

pressing “SET”.

4 125. Set-point 4 value in °C

If the set-point value is correct, hold “EXIT” to resume displaying the well

temperature. Press “UP” or “DOWN” to adjust the set-point value.

125.00 New set-point value

When the desired set-point value is reached press “SET” to accept the new value

and access the temperature scale units selection. If “EXIT” is pressed instead of

“SET”, any changes made to the set-point are ignored.

Accept new set-point value

9.2.3 Temperature Scale Units

The temperature scale units of the controller can be set by the user to degrees

Celsius ( °C) or Fahrenheit ( °F). The selected units are used in displaying the

well temperature, set-point, and proportional band.

Press “SET” after adjusting the set-point value to change display units.

Un= C Scale units currently selected

Press “UP” or “DOWN” to change the units.

Un= F New units selected

9-3

Page 44

7102

User's Guide

9.3 Scan

The scan rate can be set and enabled so that when the set-point is changed the

bath heats or cools at a specified rate (degrees per minute) until it reaches the

new set-point. With the scan disabled the bath heats or cools at the maximum

possible rate.

9.3.1 Scan Control

The scan is controlled with the scan on/off function that appears in the main

menu after the set-point function.

Sc=OFF Scan function off

Press “UP” or “DOWN” to toggle the scan on or off.

Sc=On Scan function on

Press “SET” to accept the present setting and continue.

Accept scan setting

9.3.2 Scan Rate

The next function in the main menu is the scan rate. The scan rate can be set

from .1 to 99.9 °C/min. The maximum scan rate however is actually limited by the

natural heating or cooling rate of the instrument. This is often less than

100 °C/min, especially when cooling.

The scan rate function appears in the main menu after the scan control function.

The scan rate units are in degrees C per minute.

Sr= 10.0 Scan rate in °C/min

Press “UP” or “DOWN” to change the scan rate.

Sr= 2.0 New scan rate

Press “SET” to accept the new scan rate and continue.

Accept scan rate

9.4 Temperature Display Hold

The 7102 has a display hold function which allows action of an external switch to

freeze the displayed temperature and stop the set-point from scanning. This is

useful for testing thermal switches and cut-outs. The instrument must be

powered off before attaching thermal switches or cut-outs. This section explains

the functions available for operating the temperature hold feature. An example

follows showing how to set up and use the hold feature to test a switch.

9-4

Page 45

Controller Operation

9.4 Temperature Display Hold 9

9.4.1 Hold Temperature Display

The hold feature is enabled by simply pressing the “UP” button when the

temperature is displayed. The hold temperature display shows the hold

temperature on the right and the switch status on the left. For the status “c”

means the switch is closed and “o” means the switch is open. The status flashes

when the switch is in its active position (opposite the normal position). The hold

temperature shows what the temperature of the well was when the switch

changed from its normal position to its active position. While the switch is in the

normal position the hold temperature will follow the well temperature.

If the Scan Control is “OFF” and the Hold Temperature Display is being used, the

temperature at which the switch is activated does not affect the set-point

temperature. However, if the Scan Control is “ON” and the Hold Temperature

Display is being used, the temperature at which the switch is activated is stored

as the new set-point temperature.

Operation of the hold temperature display is outlined below.

143.50C Well temperature display

Access hold display

c 144.8 Switch status and hold temperature

To return to the normal well temperature display press “DOWN”.

9.4.2 Mode Setting

The Hold Function is always in the automatic mode. In this mode the normal

position is set to whatever the switch position is when the set-point is changed.

For example, if the switch is currently open when the set-point is changed, the

closed position then becomes the new active position. The normal position will be

set automatically under any of the following conditions, (1) a new set-point

number is selected, (2)the set-point value is changed, (3) a new set-point is set

through the communications channels.

9.4.3 Switch Wiring

The thermal switch or cut-out is wired to the calibrator at the two terminals on the

back of the Micro-Bath labeled “DISPLAY HOLD”. The switch wires may be

connected to the terminals either way. Internally the black terminal connects to

ground. The red terminal connects to +5V through a 100 kW resistor. The

calibrator measures the voltage at the red terminal and interprets +5V as open

and 0V as closed.

9-5

Page 46

7102

User's Guide

9.4.4 Switch Test Example

This section describes a possible application for the temperature hold feature

and how the instrument is set up and operated.

Suppose you have a thermal switch which is supposed to open at about 75 °C

and close at about 50 °C and you want to test the switch to see how accurate

and repeatable it is. You can use the temperature hold feature and the scan

function to test the switch. Measurements can be made by observing the display

or, preferably, by collecting data using a computer connected to the RS-232 port.

To set up the test do the following steps.

1. Connect the switch wires to the terminals on the back of the Micro-Bath and

place the switch in the well.

2. Enable set-point scanning by setting the scan to “ON” in the primary menu

(see Section 9.3.1).

3. Set the scan rate to a low value, say 1.0 °C/min. (see Section 9.3.2). If the

scan rate is too high you may lose accuracy because of transient temperature

gradients. If the scan rate is too low the duration of the test may be longer

than is necessary. You may need to experiment to find the best scan rate.

4. Set the first program set-point to a value above the expected upper switch

temperature, say 90 °C.

5. Set the second program set-point to a value below the expected lower switch

temperature, say 40 °C, in the program menu.

6. Collect data on a computer connected to the RS-232 port. Refer to Section

9.8.2, Serial Interface Parameters, for instructions on configuring the RS-232

communications interface.

9.5 Secondary Menu

Functions which are used less often are accessed within the secondary menu.

The secondary menu is accessed by pressing “SET” and “EXIT” simultaneously

and then releasing. The first function in the secondary menu is the heater power

display. (See Figure 7 on page 32.)

9.6 Thermal Electric Device (TED)

The temperature controller controls the temperature of the well by pulsing the

TED on and off. The total power being applied to the TED is determined by the

duty cycle or the ratio of TED on time to the pulse cycle time. By knowing the

amount of heating the user can tell if the calibrator is heating up to the set-point,

cooling down, or controlling at a constant temperature. Monitoring the percent

heater power will let the user know how stable the well temperature is. With good

control stability the percent heating power should not fluctuate more than ±5 %

within one minute.

9-6

Page 47

Controller Operation

9.7 Proportional Band 9

The heater power display is accessed in the secondary menu. Press “SET” and

“EXIT” simultaneously and release. The heater power will be displayed as a

percentage of full power.

100.00C Well temperature

+ Access heater power in secondary menu

SEC Flashes

12.0 P Heater power in percent

To exit out of the secondary menu hold “EXIT”. To continue on to the proportional

band setting function press “EXIT” momentarily or “SET”.

9.7 Proportional Band

In a proportional controller such as this the heater output power is proportional to

the well temperature over a limited range of temperatures around the set-point.

This range of temperature is called the proportional band. At the bottom of the

proportional band the heater output is 100 %. At the top of the proportional band

the heater output is 0. Thus as the temperature rises the heater power is

reduced, which consequently tends to lower the temperature back down. In this