Page 1

709/709H

Precision Loop Calibrator

Users Manual

January 2013

© 2013 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

This Fluke product will be free from defects in material and workmanship for three years from the date of purchase. This

warranty does not cover fuses, disposable batteries, or damage from accident, neglect, misuse, alteration, contamination, or

abnormal conditions of operation or handling. Resellers are not authorized to extend any other warranty on Fluke’s behalf.

To obtain service during the warranty period, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that Service Center with a description of the problem.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER WARRANTIES, SUCH AS FITNESS FOR A PARTICULAR

PURPOSE, ARE EXPRESSED OR IMPLIED. FLUKE IS NOT LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES, ARISING FROM ANY CAUSE OR THEORY. Since some states or countries

do not allow the exclusion or limitation of an implied warranty or of incidental or consequential damages, this limitation of

liability may not apply to you.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

11/99

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

Page 3

Table of Contents

Title Page

Introduction .................................................................................................................... 1

How to Contact Fluke ..................................................................................................... 2

Safety Information .......................................................................................................... 3

Symbols ......................................................................................................................... 4

Standard Equipment....................................................................................................... 6

The Product .................................................................................................................... 8

The Buttons ............................................................................................................... 8

The Selection Knob ................................................................................................... 9

Main Menu ..................................................................................................................... 9

mA Source ................................................................................................................. 10

mA Simulate .............................................................................................................. 12

mA Measure .............................................................................................................. 13

mA Measure with 24V ............................................................................................... 14

Volts Measure ........................................................................................................... 15

Calibrator Setup Menu ................................................................................................... 16

i

Page 4

709/709H

Users Manual

Auto Ramp Time ....................................................................................................... 17

Auto Step Time ......................................................................................................... 17

Step and Ramp Operation ................................................................................... 18

Automatic Step and Ramp ................................................................................... 18

Valve Test ................................................................................................................. 19

HART 250Ω Resistor ................................................................................................ 20

mA Span ................................................................................................................... 20

Contrast .................................................................................................................... 21

Auto Shutdown Time ................................................................................................. 21

HART Write Enable ................................................................................................... 22

HART Device Communication ....................................................................................... 23

HART Connections ................................................................................................... 23

In Circuit, External Loop Power ............................................................................ 24

In Circuit, Product Loop Power ............................................................................. 25

Across Circuit, Communicator Only ..................................................................... 26

Communications Setup and Selection ...................................................................... 27

Mode .................................................................................................................... 28

250Ω Resistor ...................................................................................................... 28

HART Connect ..................................................................................................... 29

Polling Loop ......................................................................................................... 29

Tag Selection ....................................................................................................... 30

Acquiring Data ...................................................................................................... 30

Disconnect from Loop .......................................................................................... 31

Function Select Menu ............................................................................................... 31

Device Setup and Data ............................................................................................. 32

Write LRV and URV Values ........................................................................................... 33

Write LRV ................................................................................................................. 33

Write URV ................................................................................................................. 34

Trim, Set, and Zero Menu .............................................................................................. 34

ii

Page 5

Contents (continued)

Trim 4 mA .................................................................................................................. 35

Trim 20 mA ................................................................................................................ 36

Set Fixed mA Output ................................................................................................. 37

PV Zero ..................................................................................................................... 38

Device Diagnostic........................................................................................................... 39

Configuration Log and Data Log ................................................................................ 40

Configuration Log ................................................................................................. 40

Data Log ............................................................................................................... 42

Maintenance ................................................................................................................... 44

Clean the Product ...................................................................................................... 45

Fuse .......................................................................................................................... 45

Battery Replacement ................................................................................................. 46

User-Replaceable Parts ................................................................................................. 47

Specifications ................................................................................................................. 49

iii

Page 6

709/709H

Users Manual

iv

Page 7

List of Tables

Table Title Page

1. Symbols ................................................................................................................................. 4

2. Standard Equipment .............................................................................................................. 6

3. Buttons .................................................................................................................................. 8

4. User-Replaceable Parts ........................................................................................................ 47

v

Page 8

709/709H

Users Manual

vi

Page 9

List of Figures

Figure Title Page

1. Standard Equipment .............................................................................................................. 7

2. Buttons .................................................................................................................................. 8

3. Main Menu ............................................................................................................................. 9

4. mA Source Connections ........................................................................................................ 11

5. mA Simulate Connections ..................................................................................................... 12

6. mA Measure Connections ..................................................................................................... 13

7. mA Measure with 24 V Connections ..................................................................................... 14

8. Volts Measure Connections ................................................................................................... 15

9. Setup Menu, Screen 1 ........................................................................................................... 16

10. Setup Menu, Screen 2 ........................................................................................................... 16

11. Auto Ramp Time Screen ....................................................................................................... 17

12. Auto Ramp Step Time Screen ............................................................................................... 17

13. Valve Test Enable Screen ..................................................................................................... 19

14. HART Resistor Enable Screen .............................................................................................. 20

15. mA Span Selection Screen .................................................................................................... 20

vii

Page 10

709/709H

Users Manual

16. Contrast Adjustment Screen ................................................................................................. 21

17. Auto Shutdown Screen ......................................................................................................... 21

18. Hart Write Enable Screen ..................................................................................................... 22

19. Password Screen .................................................................................................................. 22

20. In Circuit, External Loop Power Connections ........................................................................ 24

21. In Circuit, 709H Loop Power ................................................................................................. 25

22. Across Circuit, Communicator Only Connections ................................................................. 26

23. HART Comm. Menu Screen ................................................................................................. 27

24. Mode Selection Screen ......................................................................................................... 28

25. 250Ω Resistor Screen ........................................................................................................... 28

26. Polling Screen ....................................................................................................................... 29

27. Tag Selection Screen............................................................................................................ 30

28. Acquiring Data Screen .......................................................................................................... 30

29. Disconnect from Loop Screen ............................................................................................... 31

30. Function Select Menu ........................................................................................................... 31

31. Sample Screen ..................................................................................................................... 32

32. Write LRV and URV Screen .................................................................................................. 33

33. Write LRV Screen ................................................................................................................. 33

34. Write URV Screen ................................................................................................................ 34

35. Trim, Set, and Zero Screen ................................................................................................... 34

36. Trim 4 mA Screen ................................................................................................................. 35

37. Trim 20 mA Screen ............................................................................................................... 36

38. Set Fixed mA Output Screen ................................................................................................ 37

39. PV Zero Screen .................................................................................................................... 38

40. Self Test Screen ................................................................................................................... 39

41. Self Test Results Screen ...................................................................................................... 39

42. Data Log and Configuration Log Screen ............................................................................... 40

43. Configuration Log Screen ..................................................................................................... 40

44. Configuration Log Showing Storage Position ........................................................................ 41

viii

Page 11

Contents (continued)

45. Data Log Screen ................................................................................................................... 42

46. Logging Interval Screen ........................................................................................................ 43

47. Active Logging Screen .......................................................................................................... 43

48. Battery Replacement ............................................................................................................. 46

ix

Page 12

709/709H

Users Manual

x

Page 13

Introduction

The Fluke 709 Precision Loop Calibrator and 709H

Precision HART Loop Calibrator (the Product or the

Calibrator) can be used for installation, calibration, and

troubleshooting of field transmitters, valves, and other

control system components at process plants. Primary

functions are source and measure mA signals in the 0 mA

to 24 mA range. The Product can also produce 24 V dc loop

power.

The 709H includes HART communication functionality and

supports a select set of HART universal and commonpractice commands. The Product can be used as a loop

calibrator or basic function communicator.

Product functions include:

• Current measurement, sourcing, and a selectable 24 V

supply

• 30 V dc measurement

• Valve test capability

• A selectable HART 250 Ω loop resistor

• Output step and ramp

1

Page 14

709/709H

Users Manual

Product features include:

• Large backlit display

• Digital selection knob with selectable decade control for

easy data entry

• Interactive menus

• Communicator mode reads basic device information,

does diagnostic tests, and can be used to trim the

calibration of most HART-enabled transmitters.

Note

All figures in this Manual show the 709H.

How to Contact Fluke

To contact Fluke, call one of the following telephone

numbers:

• Technical Support USA: 1-800-44-FLUKE

(1-800-443-5853)

• Calibration/Repair USA: 1-888-99-FLUKE

(1-888-993-5853)

• Canada: 1-800-36-FLUKE (1-800-363-5853)

• Europe: +31 402-675-200

• Japan: +81-3-6714-3114

• Singapore: +65-6799-5566

• Anywhere in the world: +1-425-446-5500

Or, visit Fluke's website at www.fluke.com.

To register your product, visit http://register.fluke.com.

To view, print, or download the latest manual supplement,

visit http://us.fluke.com/usen/support/manuals.

2

Page 15

Precision Loop Calibrator

Safety Information

Safety Information

A Warning identifies conditions and procedures that are

dangerous to the user. A Caution identifies conditions and

procedures that can cause damage to the Product or the

equipment under test.

Warning

To prevent possible electrical shock, fire, or

personal injury:

• Read all safety Information before you use

the Product.

• Use the Product only as specified, or the

protection supplied by the Product can be

compromised.

• Examine the case before you use the

Product. Look for cracks or missing

plastic. Carefully look at the insulation

around the terminals.

• Do not use test leads if they are damaged.

Examine the test leads for damaged

insulation and measure a known voltage.

• Do not use and disable the Product if it is

damaged.

• Do not use the Product around explosive

gas, vapor, or in damp or wet

environments.

• Do not touch voltages >30 V ac rms, 42 V ac

peak, or 60 V dc.

• Do not apply more than the rated voltage,

between the terminals or between each

terminal and earth ground.

• Do not connect directly to mains.

• Do not exceed the Measurement Category

(CAT) rating of the lowest rated individual

component of a Product, probe, or

accessory.

• Keep fingers behind the finger guards on

the probes.

• Remove all probes, test leads, and

accessories before the battery door is

opened.

• Remove the batteries if the Product is not

used for an extended period of time, or if

stored in temperatures above 50 °C. If the

batteries are not removed, battery leakage

can damage the Product.

• Replace the batteries when the low battery

indicator shows to prevent incorrect

measurements.

• The battery door must be closed and

locked before you operate the Product.

3

Page 16

709/709H

Users Manual

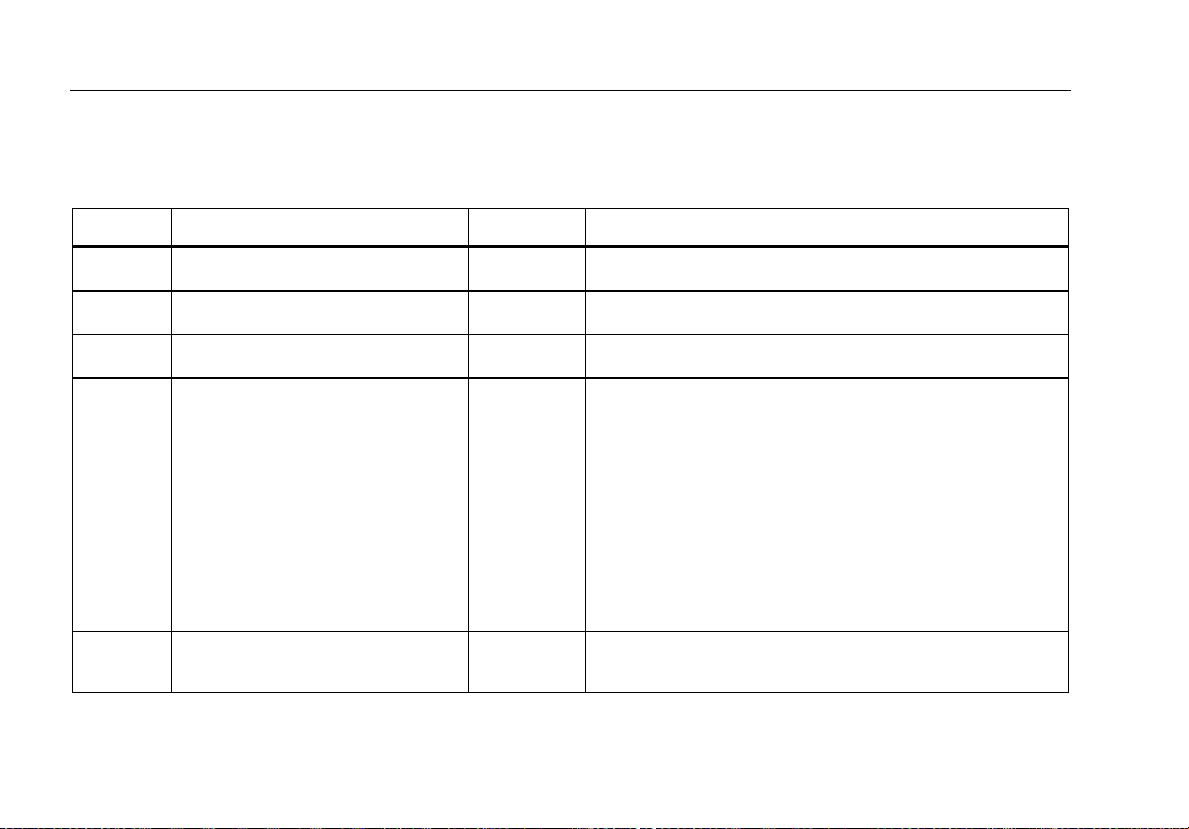

Symbols

Symbols used on the Product and in this manual are explained in Table 1.

Table 1. Symbols

Symbol Meaning Symbol Meaning

4

Earth ground

AC- alternating current

DC- direct current

Risk of danger. Important

information. See manual.

Hazardous voltage. Risk of

electrical shock.

Conforms to relevant North American Safety Standards.

Conforms to European Union directives.

Conforms to relevant Australian standards.

This product complies with the WEEE Directive

(2002/96/EC) marking requirements. The affixed label

indicates that you must not discard this

electrical/electronic product in domestic household

waste. Product Category: With reference to the

equipment types in the WEEE Directive Annex I, this

product is classed as category 9 "Monitoring and

Control Instrumentation” product. Do not dispose of this

product as unsorted municipal waste. Go to Fluke’s

website for recycling information.

Examined and licensed by TÜV Product Services.

Page 17

Precision Loop Calibrator

Symbols

Table 1. Symbols (cont.)

CAT II

CAT IV

The CAT ratings apply to the handheld accessories only. The Product is rated to 30 V maximum.

Battery.

Measurement Category II is

applicable to test and measuring

circuits connected directly to

utilization points of low voltage

mains installation.

Measurement Category IV is applicable to test and measuring circuits connected at the source of the

building’s low-voltage MAINS installation.

CAT III

Double insulated

Measurement Category III is applicable to test and

measuring circuits connected to the distribution part of

the building’s low-voltage MAINS installation.

5

Page 18

709/709H

Users Manual

Standard Equipment

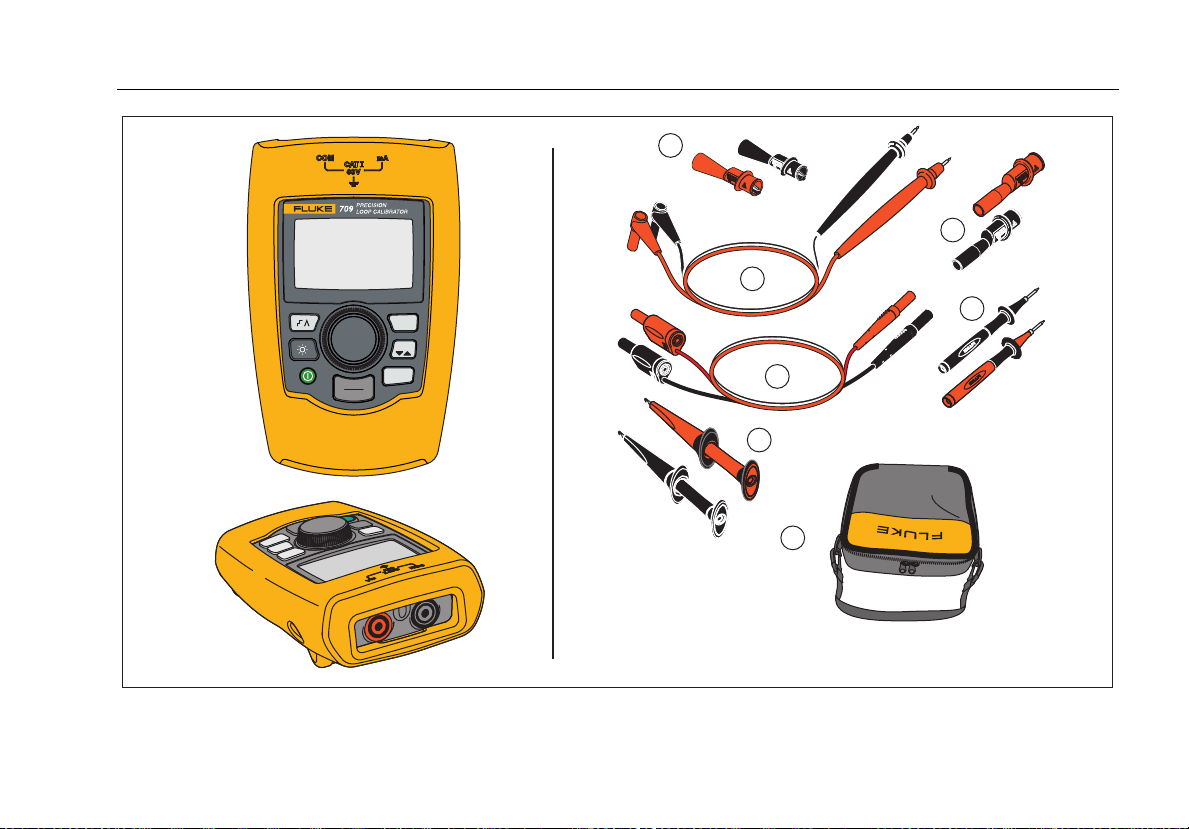

Items included with the Product are listed in Table 2 and shown in Figure 1.

Table 2. Standard Equipment

Item Description

Two AC72-1 alligator clips (709)

TL-75-4201 test leads (709)

754-8016 alligator clip set (709H)

75X-8014 stackable lead set (709H)

TP220-4201 test probes (709H)

AC280-5001 Suregrip hook clips (709H)

Soft Case

Six AAA batteries (installed)

Not Shown

6

709/709H Product Manual CD-ROM

709/709H Quick Reference Guide

709/709H Safety Information

Page 19

Precision Loop Calibrator

Standard Equipment

1

3

2

5

MENU

100%

25%

0%

EXIT

4

6

7

gzx002.eps

Figure 1. Standard Equipment

7

Page 20

709/709H

Users Manual

The Product

The subsequent sections are about the features and

functions of the Product.

The Buttons

Figure 2 and Table 3 show the location and brief

descriptions of the Product buttons.

Table 3. Buttons

Button Function

Push to enable step or ramp.

Push to turn on or turn off the backlight.

gzx001.eps

Figure 2. Buttons

8

Push to turn on and turn off the Product.

Push to set the output to 20 mA when in mA

Source or mA Simulate modes. In

Measurement mode the button does not set

the output current.

Push to step the output up or down by 25 %

increments (4, 8, 12, 16, 20 mA).

Push to set the output to 4 mA when in

mA Source or mA Simulate mode. In

Measurement mode the button does not set

the output current

Push to enter the Main menu. Push a

second time to exit the Main menu. See the

“Main Menu” section.

Page 21

Precision Loop Calibrator

The Product

The Selection Knob

The selection knob lets you select and control necessary

functions and navigate through the Product menus. Turn

the selection knob to highlight a menu item or adjust a

value. When the necessary selection is highlighted, push

the selection knob to do the selected action, or push and

hold to save any changes that have been made. Push

to go to the main screen with no action.

In the output modes (mA Source, mA Simulate):

• Push the selection knob to move the display cursor

to the next digit.

• Turn the selection knob to increment or decrement

the output in steps shown by the selected decade.

• Push , , or to set the output to preset

values.

• Push to select and stop these advanced modes.

Main Menu

Push to show the Main menu, choose the primary

operation mode of the Product, access the Product setup

menu, or to use HART mode. See Figure 3.

gzx20.eps

Figure 3. Main Menu

The first five items shown on the Main menu change the

Product operation mode accordingly and once selected,

change the Product menu to a “home” screen for the

selected function. The operation modes are explained in

the subsequent sections of this manual.

For the last two items of the Main menu, see “The

Calibrator Setup Menu” and “Hart Comm. Menu” sections.

Note

The “HART” menu items only apply to the 709H.

9

Page 22

709/709H

Users Manual

Note

Some menus have multiple screens. When this

is the case, the lower-left corner of the menu

shows when additional screens follow the

current screen. is shown when additional

screens precede the current screen. Both icons

are shown when additional screens follow and

precede the present screen.

mA Source

In the mA Source mode, the Product outputs a signal

from 0 mA to 24 mA into a load of up to 1000 Ω (750 Ω if

the internal HART resistor is switched on).

Figure 4 shows the mA Source home screen and typical

connections for this mode.

10

Page 23

Precision Loop Calibrator

The Product

To use mA Source:

1. Select mA Source from the Main menu.

2. Push the selection knob to move the decade cursor.

3. Turn the selection knob to increment or decrement

the output in steps indicated by the selected decade.

4. Push , , or to set the output to preset

values.

5. Push to select and stop these advanced modes.

When automatic step or ramp is active, one of the

subsequent icons is shown in the lower left corner:

Automatic step:

Automatic ramp:

6. Push to go to the Main menu.

7. Push again to go to the mA Source home

screen.

• Valve Test is shown in the lower center when

the valve test function has been enabled on the

Setup menu. See the “Valve Test” section of this

manual.

• 250Ω is shown in the lower right corner when

the HART resistor has been enabled on the

setup menu.

4 mA to 20 mA

Input Device,

Recorder/Indicator,

etc.

4 mA to 20 mA

gzx003.eps

Figure 4. mA Source Connections

11

Page 24

709/709H

Users Manual

mA Simulate

In the mA Simulate mode, the Product functions like a

2-wire transmitter and controls the loop current from an

external power supply. This function can test a loop

with the transmitter removed.

Figure 5 shows the mA Simulate home screen and typical

connections for this mode.

To use mA Simulate:

1. Select mA Simulate from the Main menu.

2. Push the selection knob to move the decade cursor.

3. Turn the selection knob to increment or decrement

the output in steps indicated by the selected decade.

4. Push , , or to set the output to preset

values.

5. Push to select and stop these advanced modes.

When automatic step or ramp is active, one of the

subsequent icons is shown in the lower left corner:

• Automatic step:

• Automatic ramp:

6. Push to go to the Main menu.

7. Push again to go to the mA Simulate home

screen.

• Valve Test is shown in the lower center when

the valve test function has been enabled on the

Setup menu. See the “Valve Test” section of this

manual.

• 250Ω is shown in the lower right corner when

the HART resistor has been enabled on the

setup menu.

Power Supply

30 V dc Max

4 mA to 20 mA

4 mA-20 mA

Input Device

gzx004.eps

Figure 5. mA Simulate Connections

12

Page 25

Precision Loop Calibrator

The Product

mA Measure

In the mA Measure mode, the Product shows the loop

current measurement. This mode is without 24 V.

Figure 6 shows the mA Measure home screen and typical

connections for this mode.

To use mA Measure:

Select mA Measure from the Main menu. Once selected,

the Product changes to the mA Measure home screen.

250Ω is shown in the lower right corner when the HART

resistor has been enabled on the setup menu.

4 mA-20 mA

Output Device

4 mA to 20 mA

Figure 6. mA Measure Connections

gzx005.eps

13

Page 26

709/709H

Users Manual

mA Measure with 24V

In the mA Measure with 24V mode, the Product outputs

24 V dc as it shows the loop current. The mode can

power a transmitter without a separate power supply.

Figure 7. mA Measure with 24 V Connections

Figure 7 shows the home screen and typical connections

for this mode.

gzx006.eps

14

Page 27

Precision Loop Calibrator

The Product

To use mA Measure with 24 V:

1. Select mA Measure with 24 V from the Main menu.

Once selected, the Product changes to the mA

Measure with 24 V home screen.

Voltage

Output Device

250Ω is shown in the lower right corner when the HART

resistor has been enabled on the setup menu.

Volts Measure

In the Volts Measure mode, the Product shows the loop

voltage. Figure 8 shows the Volts Measure home screen

and typical connections for this mode.

To use the Volts Measure mode:

Select Volts Measure from the Main menu. Once

selected, the Product changes to the Volts Measure

home screen.

gzx007.eps

Figure 8. Volts Measure Connections

15

Page 28

709/709H

Users Manual

Calibrator Setup Menu

The Calibrator Setup Menu has two screens. To go to

the second screen, select Other Parameters from the

first screen. Screen 1 is shown in Figure 9 and screen 2

is shown in Figure 10.

gzx21.eps

Figure 9. Setup Menu, Screen 1

Figure 10. Setup Menu, Screen 2

Note

The “HART Write Enable” menu item only is

shown on the 709H.

gzx22.eps

16

Page 29

Precision Loop Calibrator

Calibrator Setup Menu

Auto Ramp Time

The Auto Ramp Time function sets the full-scale ramp

time for the mA ramp feature. The value can be set from

5 seconds to 300 seconds. Push the selection knob to

move the decade cursor. Turn the selection knob to

adjust the value in steps indicated by the decade

selected. See Figure 11.

gzx23.eps

Figure 11. Auto Ramp Time Screen

Auto Step Time

The Auto Step Time function sets the step interval time

for the mA Auto Step feature. The value can be set from

5 seconds to 300 seconds. Push the selection knob to

move the decade cursor. Turn the selection knob to

adjust the value in steps indicated by the decade

selected. See Figure 12.

gzx24.eps

Figure 12. Auto Ramp Step Time Screen

17

Page 30

709/709H

Users Manual

Step and Ramp Operation

For step and ramp operation, the percent keys can be

used to set the milliamp output to 0 % of span, 100 % of

span, or step the output by 25 % of span.

Hands-free operation is possible with . Set the

Product to automatically and continuously step or ramp

the milliamp output from 0 % to 100 % and back.

The 100 % value is always 20 mA, but the 0 % value can

be 0 mA or 4 mA. This depends on how the mA span is

set. The 25 % step size is 5 mA or 4 mA accordingly.

To use the manual step function:

1. Use the Main menu to set the Product to source or

simulate current.

2. Push to set the output to 0 % of span.

3. Push to set the output to 100 % of span.

4. Push to step the output in 25 % of span

increments, from 0 % of span to 100 % of span and

back.

Automatic Step and Ramp

To use the automatic step and automatic ramp functions:

1. Use the Main menu to set the Product to source or

simulate current.

2. The Product has separate auto ramp and step times.

Use the menu to set the ramp or step time.

3. Push once to continually step the output from

0 % of span to 100 % of span and back in increments

of 25 % of span at the specified interval.

4. Push once more to go to auto ramp.

5. Push one of the percent keys, and twice, to turn

off the auto step and ramp.

6. Push twice to continually ramp the output from

0 % of span to 100 % of span over the specified

interval, and then back over the specified interval.

7. Push one of the percent keys or once more, to

turn off the auto step and ramp.

18

Page 31

Precision Loop Calibrator

Calibrator Setup Menu

Valve Test

The Valve Test function turns on or off the valve test

feature. See Figure 13.

Figure 13. Valve Test Enable Screen

gzx25.eps

The valve test verifies correct operation of valves. In

valve test, the output can be stepped to these values:

• 3.8 mA

• 4.0 mA

• 4.2 mA

• 8.0 mA

• 12.0 mA

• 16.0 mA

• 19.8 mA

• 20.0 mA

• 20.2 mA

The valve test mA values are not affected by the mA span

setting.

1. Use the Main menu to set the Product to source or

simulate current.

2. If valve test is not enabled, use the menu to enable it.

3. Push or to step the output to verify the

proper valve operation.

4. Use the menu to disable valve test when done.

19

Page 32

709/709H

Users Manual

HART 250Ω Resistor

The HART 250Ω Resistor Enable function turns on and

turns off the HART resistor. See the “HART Resistor”

section of this manual. See Figure 14.

gzx26.eps

Figure 14. HART Resistor Enable Screen

The Product can insert a 250 Ω resistor in series with the

power supply in order to use a HART communicator. The

HART resistor is enabled through the menu.

To get to the second Calibrator Setup Screen, highlight

Other Parameters and push the selection knob.

mA Span

mA Span is the first item on the second Calibrator Setup

Menu.

The mA Span function sets the step interval for the mA

Auto Step feature. The value can be set from 5 seconds

to 300 seconds. See the “Step and Ramp Operation”

section of this manual. See Figure 15.

gzx27.eps

Figure 15. mA Span Selection Screen

20

Page 33

Precision Loop Calibrator

Calibrator Setup Menu

Contrast

The Contrast function adjusts the display contrast. Turn

the selection knob to adjust the contrast. The range is

shown by the bar graph. Higher contrast is shown by a

longer bar. The sample normal and reverse video

selections let you evaluate both text modes. See

Figure 16.

gzx28.eps

Figure 16. Contrast Adjustment Screen

Auto Shutdown Time

The Auto Shutdown Time function sets or turns off the

time before the Product automatically shuts itself down if

the keypad is not used. The value can be set to

Disabled, or from 1 minute to 30 minutes. See Figure 17.

gzx29.eps

Figure 17. Auto Shutdown Screen

21

Page 34

709/709H

Users Manual

HART Write Enable

HART Write Enable is the last function in the Calibrator

Setup Menu. See Figure 18.

gzx30.eps

Figure 18. Hart Write Enable Screen

This function is available only on the 709H. It protects the

Write LRV, Write URV, Device Diagnostic, Trim 4mA,

Trim 20mA, Set Fixed Output, and PV Zero functions.

The default setting is ON, but it may be turned off to

protect the Product against unauthorized use.

Before the setting is changed, a password is required.

The password is set to 617 at the factory. The range of

values that can be set is 000 to 999. See Figure 19.

The write-enable selection is saved only when the correct

password is given. Otherwise an error message is shown.

Push the selection knob to move the decade cursor. Turn

the selection knob to adjust the value in steps indicated

by the decade selected. Push and hold the selection knob

to save the write enable setting. Push to restore the

previous HART-enable selection and go to the Main

screen.

gzx31.eps

Figure 19. Password Screen

22

Page 35

Precision Loop Calibrator

HART Device Communication

HART Device Communication

The HART functions are only available in the 709H.

Auto shutdown is disabled when the HART menus are

used. Auto shutdown is restored to its previous state

when you exit the HART menus.

Note

Loop current trim is supported for transmitter

devices, but is not supported for actuator

devices.

These functions can be disabled with the HART Write

Enable selection on the Product:

• write LRV

• write URV

• device diagnostic

• trim 4 mA

• trim 20 mA

• fixed output

PV zero functions can be disabled with the HART Write

Enable selection on the Calibrator Setup menu. See the

“Calibrator Setup Menu” section of this manual. If these

functions are necessary, they must be enabled before

you enter the HART menus.

HART Connections

See the subsequent sections for HART connections.

23

Page 36

709/709H

Users Manual

In Circuit, External Loop Power

In mA Measure mode, the Product is in circuit and loop

power is supplied externally. In Figure 20, the 250 Ω

24 V

Supply

Figure 20. In Circuit, External Loop Power Connections

4 mA to 20 mA

HART resistor is enabled. If the loop already has 250 Ω,

do not enable the HART resistor.

gzx008.eps

24

Page 37

Precision Loop Calibrator

HART Device Communication

In Circuit, Product Loop Power

In mA Measure with 24V mode, the Product is in circuit

and loop power is supplied by the Product. In Figure 21,

Figure 21. In Circuit, 709H Loop Power

the 250 Ω HART resistor is enabled. If the loop already

has 250 Ω, do not enable the HART resistor.

gzx009.eps

25

Page 38

709/709H

Users Manual

Across Circuit, Communicator Only

In Communicator Only mode, the Product is across the

circuit and loop power is supplied externally. In Figure 22,

24 V

Supply

4 mA to 20 mA

Figure 22. Across Circuit, Communicator Only Connections

26

when in Communicator Only mode, there must be 250 Ω,

resistance present in the loop.

RL ≥ 250 Ω

gzx010.eps

Page 39

Precision Loop Calibrator

HART Device Communication

Communications Setup and Selection

For all Main screen operation modes, except mA

Measure with 24V or Volts Measure, the operation

mode is set to mA Measure when you enter the HART

Comm. Menu.

The operation mode remains the same as the main

screen when it is Measure with 24V. If Volts Measure

was selected from the Main menu, the menu defaults to

communicator mode only and the 250 Ω resistor selection

shows n/a.

The 250 Ω resistor selection cannot be edited in

communicator mode.

The mode and resistor will change from the last

selections made in the HART Comm. Menu when you

exit the menu.

The mode and 250 Ω resistor settings must correspond to

how the test leads are connected before you connect.

See Figure 23.

Figure 23. HART Comm. Menu Screen

Select a function from the menu and push the selection

knob to do the function. Push to disconnect from

HART mode and go to the function home screen without

action.

An error is shown and no action is taken if the measured

input is out of range, OL or -OL.

250Ω Resistor, and HART CONNECT functions are

described in subsequent sections.

gzx32.eps

27

Page 40

709/709H

Users Manual

Mode

The Mode function from the HART. Comm. Menu lets

you select what mode to work in. See Figure 24.

gzx33.eps

Figure 24. Mode Selection Screen

Use the selection knob to choose the necessary mode:

• mA Measure- The Product is in circuit and loop

power is supplied externally.

• mA Measure with 24V- The Product is in circuit and

the loop power is supplied by the Product.

• Communicator Only- The Product is across the

circuit and the loop power is supplied externally. The

250Ω resistor selection defaults to n/a (not

applicable).

250Ω Resistor

The 250Ω Resistor function lets you turn the 250 Ω

resistor on or off. Use the selection knob to change the

resistor to the highlighted selection and return to the

Setup and Selection screen. See Figure 25.

gzx34.eps

Figure 25. 250Ω Resistor Screen

28

Page 41

Precision Loop Calibrator

HART Device Communication

HART Connect

The HART Connect function locates the HART device in

the loop. Before an operation with a HART device, the

device must be located on the loop. This is done by

polling all of the possible device addresses and selecting

a device from those addresses that respond to the

search.

If a HART protocol revision 5 or earlier device is found on

the loop, polling stops at poll address 15. If not found, the

Product continues to poll address 63. Polling stops after

10 devices are found on the loop.

If multiple devices are found on the loop, a tag list is

shown. From the list, select the correct device. If only one

device is found on the loop, it becomes the selected

device by default.

When a selected device is found, all relevant data is read

from the device and the operations described in the

“Function Select Menu” and “Device Setup and Data”

sections of this manual become available.

Polling Loop

The Polling Loop function searches the loop for HART

devices. This function starts immediately. The screen

changes to show the string of dots that is extended once

per second to as the operation progresses. See

Figure 26.

Figure 26. Polling Screen

The number of devices found on the loop during polling is

shown.

The selection knob can be pushed to stop polling early if

it is known that all of the devices on the loop have been

found. Push to stop polling, disconnect from HART

mode, and go to the function home screen.

An error is shown if no device is found.

If multiple devices are found, a list of tags is shown. Use

the list of tags to select the necessary device.

If only one device is found, the tag selection step is

skipped.

gzx35.eps

29

Page 42

709/709H

Users Manual

Tag Selection

The tag selection screen lists all of the long tag names

found during polling. Tag names can span two lines if

necessary to show all of the text.

If the long tag name is not available, or it is blank, a short

tag name is used. If the short tag name is blank, the text

Poll address x is used.

Use the selection knob to go to the necessary tag. See

Figure 27.

gzx36.eps

Figure 27. Tag Selection Screen

Acquiring Data

The Acquiring Data screen is shown while the Product

acquires all of the configuration data from the device. The

string of dots extends once per second to show the

operation progress. flashes in the upper-right corner to

show a live HART connection.

The screen in Figure 28 shows the name of the tag that is

accessed.

gzx37.eps

Figure 28. Acquiring Data Screen

Push to stop data acquisition, disconnect from HART

mode, and go to the function home screen.

When data acquisition is complete, the Function Select

Menu is shown.

30

Page 43

Precision Loop Calibrator

HART Device Communication

Disconnect from Loop

The Disconnect from Loop screen is shown before the

Product returns to the function home screen so the

Product can be disconnected from the Loop. See

Figure 29 .

gzx38.eps

Figure 29. Disconnect from Loop Screen

Function Select Menu

The Function Select menu is shown in Figure 30.

gzx39.eps

Figure 30. Function Select Menu

The tag name is truncated to fit on one line when

necessary. flashes in the upper-right corner to show a

live connection.

Use the selection knob to choose the necessary action.

Push to disconnect from HART mode and go to the

function main screen.

31

Page 44

709/709H

Users Manual

Device Setup and Data

The Device Setup and Data screen spans 11 screens

with the format shown in Figure 31.

gzx40.eps

Figure 31. Sample Screen

This screen shows all of the data retrieved from the data

acquisition procedure.

The tag name is truncated to fit on one line when

necessary. flashes in the upper-right corner to show a

live connection.

Each screen holds a maximum of 6 data points. An item

can span more than one line when necessary to show the

full text. If a data item is not supported in the HART

device, it is marked n/a (not available). Data items that

change dynamically in the HART device are updated as

often as possible on the screens.

Turn the selection knob to go from screen to screen.

Push to go to the Function Select menu.

32

Page 45

Precision Loop Calibrator

Write LRV and URV Values

Write LRV and URV Values

Note

For the screens in this section, tag names can

be truncated to fit on one line if necessary.

flashes in the upper-right corner to show a live

connection.

If the HART write commands are not active, these

functions are not available and an error message is

shown instead of the screen in Figure 32.

gzx41.eps

Figure 32. Write LRV and URV Screen

Use the selection knob to choose the necessary function.

Push the selection knob to choose the highlighted action

and go to the corresponding screen. These screens are

explained in the “Write LRV” and “Write URV” sections.

Push to go to the Function Select menu.

Write LRV

The Product warns you to change the loop to MANUAL

before you proceed. Push the selection knob to proceed.

Push to go to the Write LRV and Write URV menu.

The present LRV value and units are shown. See

Figure 33.

gzx42.eps

Figure 33. Write LRV Screen

1. Push the selection knob to move the decade cursor.

2. Turn the selection knob to increment or decrement

the value in steps indicated by the selected decade.

3. Push and hold the knob to send the new value to the

HART device. An error is shown if the HART device

rejects the value.

33

Page 46

709/709H

Users Manual

4. Push to go to the Function Select menu. A

reminder to change the loop to AUTOMATIC is

shown first.

Write URV

The Product warns you to change the loop to MANUAL

before you proceed. Push the selection knob to proceed.

Push to go to the LRV and URV menu.

The present URV value and units are shown. See

Figure 34.

gzx43.eps

Figure 34. Write URV Screen

1. Push the selection knob to move the decade cursor.

2. Turn the selection knob to increment or decrement

the value in steps indicated by the selected decade.

3. Push and hold the knob to send the new value to the

HART device, remaining on this display. An error is

shown if the HART device rejects the value.

4. Push to go to the LRV and URV menu. A prompt

to change the loop to AUTOMATIC is shown first.

Trim, Set, and Zero Menu

Note

For the screens in this section, tag names can

be truncated to fit on one line if necessary.

flashes in the upper-right corner to show a live

connection.

If the HART write commands are not enabled, these

functions are not available and an error message is

shown instead of the screen shown in Figure 35.

gzx44.eps

Figure 35. Trim, Set, and Zero Screen

34

Page 47

Precision Loop Calibrator

Trim, Set, and Zero Menu

Use the selection knob to select and start the necessary

action. Push to go to the Function Select menu.

Trim 4 mA

If the operation mode is Communicator Only, this

function is not available and an error message is shown.

A prompt to change the loop to MANUAL before you

proceed is shown. Push the selection knob to proceed.

Push to go to the Trim, Set and Zero menu.

While the HART device is changed to fixed output mode,

An error is shown if the HART device rejects the mode

change command. When the mode change is successful,

the screen in Figure 36 is shown.

gzx45.eps

Figure 36. Trim 4 mA Screen

While the output to settles at 4 mA, the screen shows the

Product measurement. The measurement is updated

once a second.

1. Push the selection knob to trim the HART device.

Stay on this screen to evaluate the result. An error is

shown if the HART device rejects the trim command.

2. Push to change the HART device to normal

output mode and go to the Trim, Set, and Zero menu.

A warning to change the loop to AUTOMATIC is

shown first. An error is shown if the device rejects the

mode change command.

35

Page 48

709/709H

Users Manual

Trim 20 mA

If the operation mode is Communicator Only, this

function is not available and an error message is shown.

A warning to change the loop to MANUAL before you

proceed is shown. Push the selection knob to proceed.

Push to go to the Trim, Set and Zero menu.

While the HART device is changed to fixed output mode,

an error is shown if the HART device rejects the mode

change command. When the mode change is successful,

the screen in Figure 37 is shown.

gzx46.eps

Figure 37. Trim 20 mA Screen

As the output to settles at 20 mA, the screen shows the

Product measurement. The measurement is updated

once a second.

1. Push the selection knob to trim the HART device.

Stay on this screen to evaluate the result. An error is

shown if the HART device rejects the trim command.

2. Push to change the HART device to normal

output mode and go to the Trim, Set, and Zero menu.

A prompt to change the loop to AUTOMATIC is

shown first. An error is shown if the device rejects the

mode change command.

36

Page 49

Precision Loop Calibrator

Trim, Set, and Zero Menu

Set Fixed mA Output

If the operation mode is Communicator Only, this

function is not available and an error message is shown.

A warning to change the loop to MANUAL before you

proceed is shown. Push the selection knob to proceed.

Push to go to the Trim, Set and Zero menu.

As the HART device is changed to fixed output mode, an

information screen is shown. An error is shown if the

HART device rejects the mode change command. When

the mode change is successful, the screen in Figure 38 is

shown.

gzx47.eps

Figure 38. Set Fixed mA Output Screen

This screen is used to set a fixed output and monitor the

result with the Product measurement. The measurement

is updated once a second.

The range of values that can be set is 3.0 mA to 21.0 mA.

1. Use the selection knob to select and increment or

decrement the value in steps shown by the selected

decade.

2. Push and hold the selection knob to send the new

value to the HART device and stay on this screen.

An error is shown if the HART device rejects the

value.

3. Push to change the HART device to normal

output mode and go to the Trim, Set, and Zero menu.

A warning to change the loop to AUTOMATIC is

shown first. An error is shown if the device rejects the

mode change command.

37

Page 50

709/709H

Users Manual

PV Zero

A warning to change the loop to MANUAL before you

proceed is shown. Push the selection knob to proceed.

Push to go to the Trim, Set, and Zero menus.

The screen shown in Figure 39 prompts you to set the PV

process input signal to zero and then monitors the result

with the Product measurement. The measurement is

updated once a second.

When the operation mode is Communicator Only, the

mA measurement is not available and the message mA

not available, in Comm. Only mode is shown instead.

gzx48.eps

Figure 39. PV Zero Screen

1. Push the selection knob to zero the HART device,

and stay on this screen to evaluate the result. An

error is shown if the HART device rejects the zero

command.

2. Push to go to the Trim, Set, and Zero menu. A

prompt to restore the PV process input signal to

normal operation configuration and change the loop

to AUTOMATIC is shown first.

38

Page 51

Precision Loop Calibrator

Device Diagnostic

Device Diagnostic

Note

For the screens in this section, tag names can

be truncated to fit on one line if necessary.

flashes in the upper-right corner to show a live

connection.

If the HART write commands are not active, this function

is not available and an error message is shown.

A warning to change the loop to MANUAL before you

proceed is shown. Push the selection knob to proceed.

Push to go to the Function Select menu.

Push the selection knob to select and start the self test.

See Figure 40.

gzx49.eps

Figure 40. Self Test Screen

As the self test is done, the bottom line of the screen

changes to Testing and a string of dots extends once per

second to show the operation progress.

At the end of the self test, the screen in Figure 41 is

shown. It shows No errors or the first error is reported.

gzx50.eps

Figure 41. Self Test Results Screen

The lower-left corner shows when additional errors

follow the present error. is shown when additional

errors precede the present error. and show when

additional errors follow and precede the present error.

39

Page 52

709/709H

Users Manual

Turn the selection knob to step between errors.

1. Push to go to the Function Select menu. A

reminder to change the loop to AUTOMATIC is

shown first.

Configuration Log and Data Log

Configuration Log and Data Log are only available when

connected to a HART device. Use the selection knob to

choose either the Configuration Log or Data Log. See

Figure 42.

gzx51.eps

Figure 42. Data Log and Configuration Log Screen

Configuration Log

Configuration data for a maximum of 20 tags can be

stored for later recall. The configuration data saved is the

same as that shown on the Device Data screen.

The initial Configuration Log screen spans more than one

screen and shows a list of the tags held in storage. If a

storage position is not used, the tag name area shows

<empty>. See Figure 43.

gzx52.eps

Figure 43. Configuration Log Screen

After a storage position is selected, data can be saved or

recalled from it. It can be erased or sent to the USB port.

The data can also be uploaded to a PC with the

709H/TRACK Windows Software.

40

Page 53

Precision Loop Calibrator

Device Diagnostic

It is recommended that you use a Lemo to USB cable

with 709H/TRACK Software. It has a USB/Serial adapter

that uses an FTDI chipset. This combination gives

consistent and reliable communication between the

Product and PC. The USB Drivers are included on the

709H/TRACK Software CD.

Use the selection knob to highlight and select the correct

storage location.

Push to go to the Log Select menu.

When a storage position is selected, the menu in

Figure 44 is shown. Select the necessary action.

gzx53.eps

Figure 44. Configuration Log Showing Storage

Position

The number and contents of the storage position are

shown at the top. The tag number is <empty> if the

storage position is empty.

Use the selection knob to highlight and select the correct

function. Push to go to the Log Select menu.

SAVE operation:

• If the position is empty, save the present device

configuration data into the storage position.

• If the position is in use, confirm that the existing data

is to be replaced with the present tag data before you

save it into the storage position.

RECALL operation:

• If the position is empty, an error message is shown.

• If the position is in use, the data is shown in a

sequence of screens identical to the Device Data

screen.

ERASE operation:

• If the position is empty, an error message is shown.

• If the position is in use, confirm that the existing data

is to be permanently deleted before doing so.

41

Page 54

709/709H

Users Manual

SEND operation:

• If the position is empty, an error message is shown.

• If the position is in use, send the data to the RS232

port in a report format.

Data Log

Process data can be stored for a single tag for later

upload to a PC with the 709H/TRACK Windows Software.

See the “Configuration Log” section of this manual for

more.

Data can be logged in multiple sessions, but all sessions

must be from the same HART device as determined by

the long tag name. A different logging interval can be

selected for each session. Each data sample has the

Product measurement, device mA, and all four process

variables.

There are 9810 records available. Each data sample uses

one record. Each session uses two records for overhead

data that is common to all of the data samples in that

session. There can be from 1 to 99 sessions.

The total number of data samples that can be logged is

9810 less 2 times the number of sessions started and

stopped. See Figure 45.

gzx54.eps

Figure 45. Data Log Screen

The number of free records is shown on the first line. If

data has already been logged, the tag number is shown

below it.

The present battery voltage is shown at the bottom so

that you can tell if the batteries should be changed before

a log session starts. The log is stopped before the

Product is turned off when the battery reaches its low

voltage automatic shutoff limit of 5.6 V.

• Use the selection knob to highlight and select the

correct function.

• Push the knob to do the operation. Push to

return to the Log Select menu.

42

Page 55

Precision Loop Calibrator

Device Diagnostic

START operation:

• If no free records or free sessions remain, or the

present HART device does not match the HART

device already logged, an error message is shown.

• Otherwise, proceed to interval selection described

below.

ERASE operation:

• If there is no logged data, an error message is

shown.

• Otherwise, confirm that the present data is to be

permanently erased before doing so.

Select the logging interval. See Figure 46.

gzx55.eps

Figure 46. Logging Interval Screen

Turn the selection knob to move the highlight and select

the necessary interval. Push the selection knob to start

logging at that interval. Push to go to the first data log

screen.

While logging, the screen in Figure 47 is shown to

monitor progress.

gzx56.eps

Figure 47. Active Logging Screen

Push to stop logging and go to the first data log

screen.

43

Page 56

709/709H

Users Manual

The data items shown are:

• The top line indicates is logging is in progress

(Logging) or is stopped (Stopped). Logging stops

automatically when storage is full or before the

Product is turned off when the battery reaches its low

voltage automatic shutoff limit of 5.6 V.

• Interval is the item previously selected.

• Elapsed is the time since the log was started,

updated each time a new sample is saved.

• Records used is the total number used to date for all

sessions, updated each time a new sample is saved.

• Records free is the total number that remain

unused, updated each time a new sample is saved.

• 709H is the present measurement, updated as often

as possible.

• PV mA is the last HART device measurement,

updated as often as possible.

Maintenance

Warning

For safe operation and maintenance of the

Product:

• Repair the Product before use if the

battery leaks.

• Be sure that the battery polarity is

correct to prevent battery leakage.

• Remove the input signals before you

clean the Product.

• Use only specified replacement parts.

• Have an approved technician repair the

Product.

44

Page 57

Precision Loop Calibrator

Maintenance

Clean the Product

Clean the Product and pressure modules with a soft cloth

dampened with water or water and mild soap.

Caution

To prevent possible damage to the Product:

• Do not use solvents or abrasive

cleansers.

• Do not allow water into the case.

Fuse

The Product is protected from overcurrent condition by an

internal self-resetting fuse. The fuse will automatically

reset within a few seconds. The fuse cannot be repaired

manually.

45

Page 58

709/709H

Users Manual

Battery Replacement

Replace the batteries when the battery indicator is shown

on the display.

To replace the batteries:

1. Remove the holster.

2. Turn the Product over so the display is face down.

3. With a flat-head screwdriver, remove the battery door

screws.

4. Remove the batteries.

5. Replace the old batteries. Note the correct polarity as

the new batteries are installed.

6. Attach the battery door.

7. Tighten the two battery door screws.

8. Put the Product back into the holster. See Figure 48.

46

Figure 48. Battery Replacement

gzx011.eps

Page 59

Precision Loop Calibrator

User-Replaceable Parts

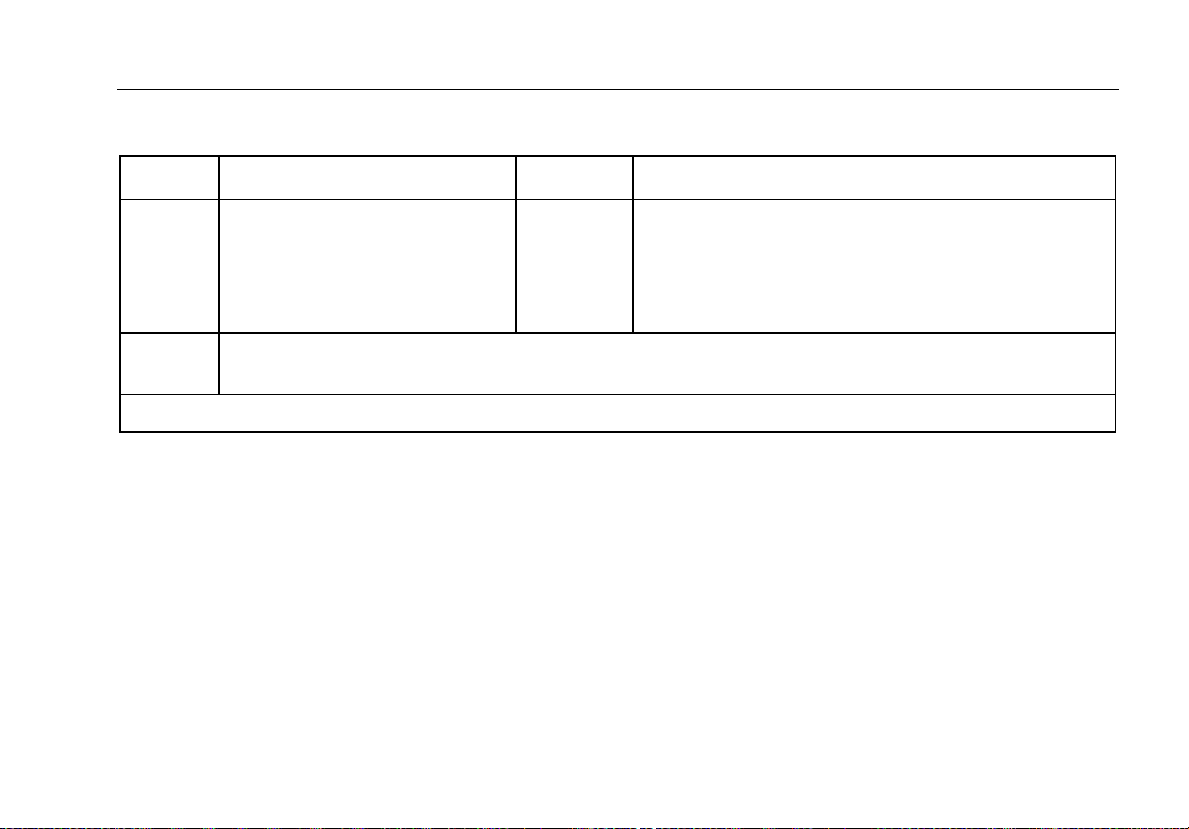

User-Replaceable Parts

User-replaceable parts are shown in Table 4. For more information about these items and their prices, contact a Fluke

representative. See the “Contact Fluke” section.

Table 4. User-Replaceable Parts

Item Fluke Part Number

Fluke-709-2005, Knob 4282155

Fluke-709-2001, Case Top 4252536

Fluke-709-2002, Case Bottom 4252549

Fluke-709-2003, Battery Door 4257167

Fluke-709-2004, Connector Panel 4257171

Fluke-709-2006, Holster, Fluke-709 4241437

Fluke-709H-2006, Holster, Fluke-709H 4241443

Fluke-709-2007, Bail, Fluke709/709H 4241455

Fluke-709-8003, Keypad, Fluke-709/709H 4252551

TL75-4201 ,TEST LEADS 855742

47

Page 60

709/709H

Users Manual

Table. User-Replaceable Parts (cont.)

Item Fluke Part Number

AC280-5001-01,175-277-011, AC280 SUREGRIP HOOK CLIP,BLACK,BULK 2063165

AC280-5001,175-277-013,SUREGRIP HOOK CLIP,RED,BULK 1613782

AC72-1-01, ALLIGATOR CLIP,30V, 2MM JACK, RED BOOT 4209063

AC72-1-02, ALLIGATOR CLIP,30V, 2MM JACK, BLACK BOOT 4209074

TP220-4201,TEST PROBES,RED 2047206

TP220-4201-01,TEST PROBES,BLACK 2063129

FLUKE-754-8016,ALLIGATOR CLIP SET, EXTENDED TOOTH 3765923

FLUKE-75X-8014,CABLE ASSEMBLY, STACKABLE LEAD SET 3669716

CD, Users Manual, Fluke 709/709H 4240654

Safety Sheet, Fluke-709/709H 4240668

Quick Reference Guide, Fluke-709/709H 4255201

709H/TRACK, Datalogging Software & Cable 4281225

SOFTCASE,POLYESTER,BLK/YEL,10.00,7.50,3.00, C115 2643273

48

Page 61

Precision Loop Calibrator

Specifications

Specifications

Ranges

mA .................................................... 0 mA to 24 mA

Volts .................................................. 0 V dc to 30 V dc

Resolution

mA Ranges ....................................... 1 μA

Voltage Range .................................. 1 mV

Accuracy ................................................ 0.01 % ±2 LSD all ranges (@23 °C ±5 °C)

Stability ................................................... 20 ppm of F.S. /°C from -10 °C to 18 °C and 28 °C to 55 °C

Operating Temp Range .......................... -10 °C to 50 °C (14 °F to 122 °F)

Storage Temp Range ............................. -20 °C to 60 °C (-4.0 °F to 140 °F)

Altitude ................................................... 3000 meters

Ingress Protection Rating ....................... IEC 60529: IP40

Humidity Range ...................................... 10 % to 95 % non-condensing

Display ................................................... 128 x 64 pixels, LCD Graphic with backlight, 8.6 mm high digits

Power ..................................................... Six AAA alkaline batteries

Battery Life (Alkaline Batteries) .............. ≥40 hours continuous use (measure mode)

Loop Compliance Voltage ...................... 24 V dc @ 20 mA

Loop Drive Capability ............................. 1200 Ω without HART resistor, 950 Ω with HART resistor

49

Page 62

709/709H

Users Manual

Electromagnetic Environment ................. IEC 61326-1 (portable equipment)

Dimensions (LxWxD) .............................. (152 x 93 x 44) mm, (6.0 x 3.7 x 1.7) in

Weight ..................................................... 0.3 kg (9.5 oz)

50

Loading...

Loading...