Fluke 700PTP-1 Instructions Manual

Pump Valve Assembly Cleaning Instructions

Occasionally, the 700PTP-1 may not work properly due to contamination of

the internal valve assembly. Use the following procedure to clean the valve

assembly. If the procedure does not fix the problem, a repair kit (part

number 2812587) may be ordered.

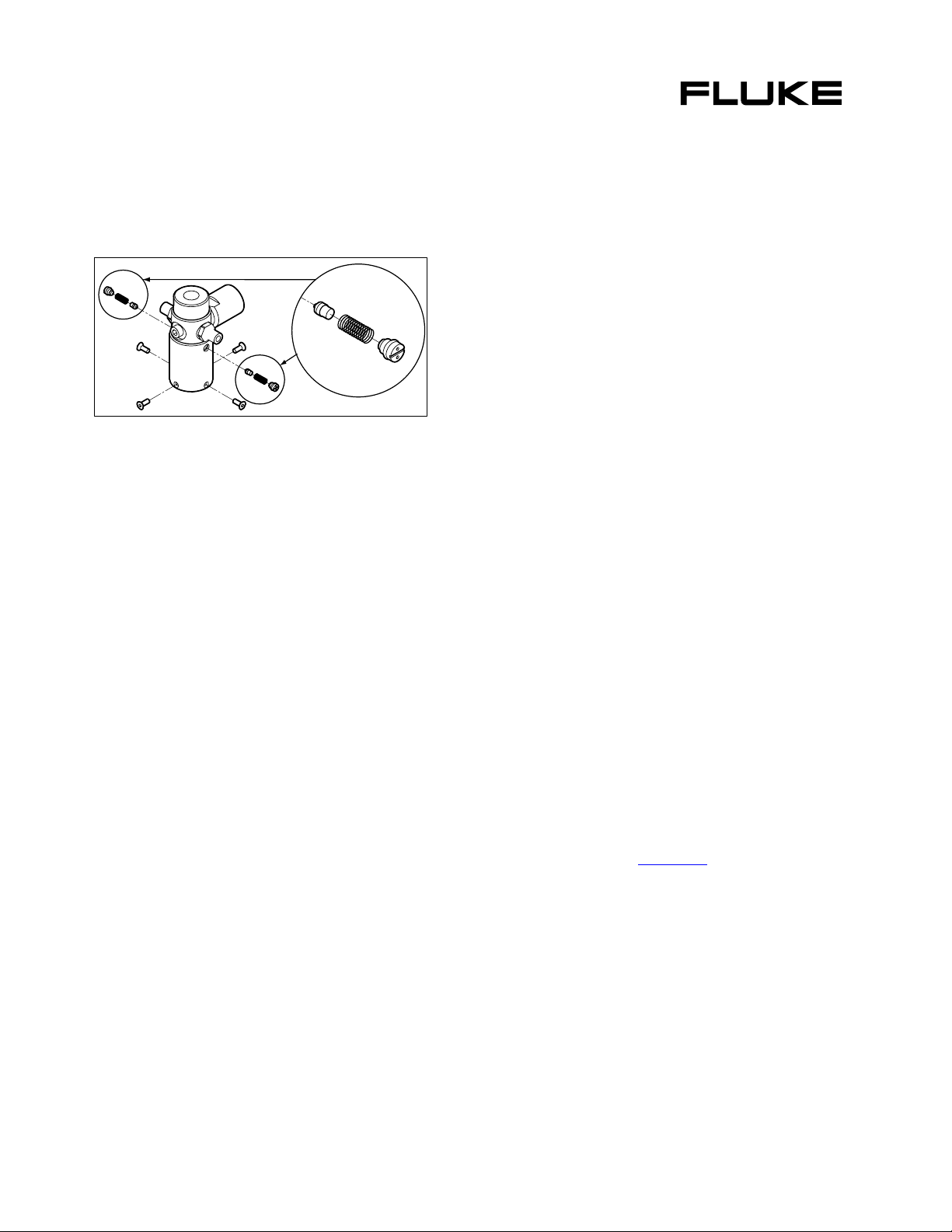

1. Using a small screwdriver, remove the 2 valve retention caps located

on opposite sides of the pump below the pressure/vacuum switch.

2. Gently remove the spring and o-ring assembly. Take care when

removing check valve as it contains several small components. See

Figure 3.

euz03f.eps

Figure 3. Cleaning the Valve Assembly

3. Set aside the valve assemblies and clean out the valve body using a

cotton swab soaked in isopropyl alcohol.

4. Repeat the process several times using a new swab until clean.

5. Operate the pump handles several times and recheck for

contamination.

6. Clean the o-ring assembly and the o-ring on the retention caps with

isopropyl alcohol and inspect the o-rings closely for any damage or

excessive wear. Replacements are included in the repair kit.

7. Inspect the springs for wear or loss of tension. They should be

approximately 8.6 mm long in the relaxed state. If shorter, they may

provide sufficient sealing tension. Replace if needed.

8. Once all parts have been cleaned and inspected, reinstall the o-ring

and spring assembly into the valve body.

9. Reinstall the retention caps and gently tighten each cap.

10. Seal the output port and operate the pump to at least 50 % of capacity.

11. Release the pressure and repeat several times to ensure that the

o-rings seat properly.

Replacement Parts

Hose assembly, Fluke PN 2815714

Rebuild kit, Fluke PN 2812587

Bleed Valve Assembly (Needle) Fluke PN 2844329

LIMITED WARRANTY AND LIMITATION OF LIABILITY

This Fluke product will be free from defects in material and workmanship for one year

from the date of purchase. This warranty does not cover fuses, disposable batteries,

or damage from accident, neglect, misuse, alteration, contamination, or abnormal

conditions of operation or handling. Resellers are not authorized to extend any other

warranty on Fluke’s behalf. To obtain service during the warranty period, contact your

nearest Fluke authorized service center to obtain return authorization information,

then send the product to that Service Center with a description of the problem.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER WARRANTIES, SUCH AS

FITNESS FOR A PARTICULAR PURPOSE, ARE EXPRESSED OR IMPLIED. FLUKE IS

NOT LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES OR LOSSES, ARISING FROM ANY CAUSE OR THEORY. Since some

states or countries do not allow the exclusion or limitation of an implied warranty or

of incidental or consequential damages, this limitation of liability may not apply to

you.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

Fluke-700PTP-1

Pneumatic Test Pump

Instruction Sheet

Introduction

The Fluke-700PTP-1 Pneumatic Test Pump (hereafter called the “pump”) is

a handheld device that develops precise pressure and vacuum. The pump

has the following specifications:

• Pressure to 40 bar (600 psi)

• Vacuum to -0.96 bar (-13.9 psi)

• Wetted materials: aluminum, silicon, neoprene, stainless steel,

Buna-N

• Weight: 1.03 lb (467 g)

• Dimensions: length 8.7 in (220 mm), width 4.8 in (122 mm), depth

3.5 in (89 mm)

Box Contents

• 700PTP-1 Pneumatic Test Pump

• 1/4 in NPT male to 1/4 in BSP female

• 1 m hose

• (2) 1/8 in NPT male quick connects

• 1/8 NPT female to 1/4 in BSP female

• Seal Kit

• Instruction Sheet

Contacting Fluke

To contact Fluke or for service, call one of the following telephone numbers:

USA: 1-888-44-FLUKE (1-888-443-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-675-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

Or, visit Fluke's Web site at www.fluke.com

.

®

11/99

PN 2811824

April 2007

©2007 Fluke Corporation. All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies.

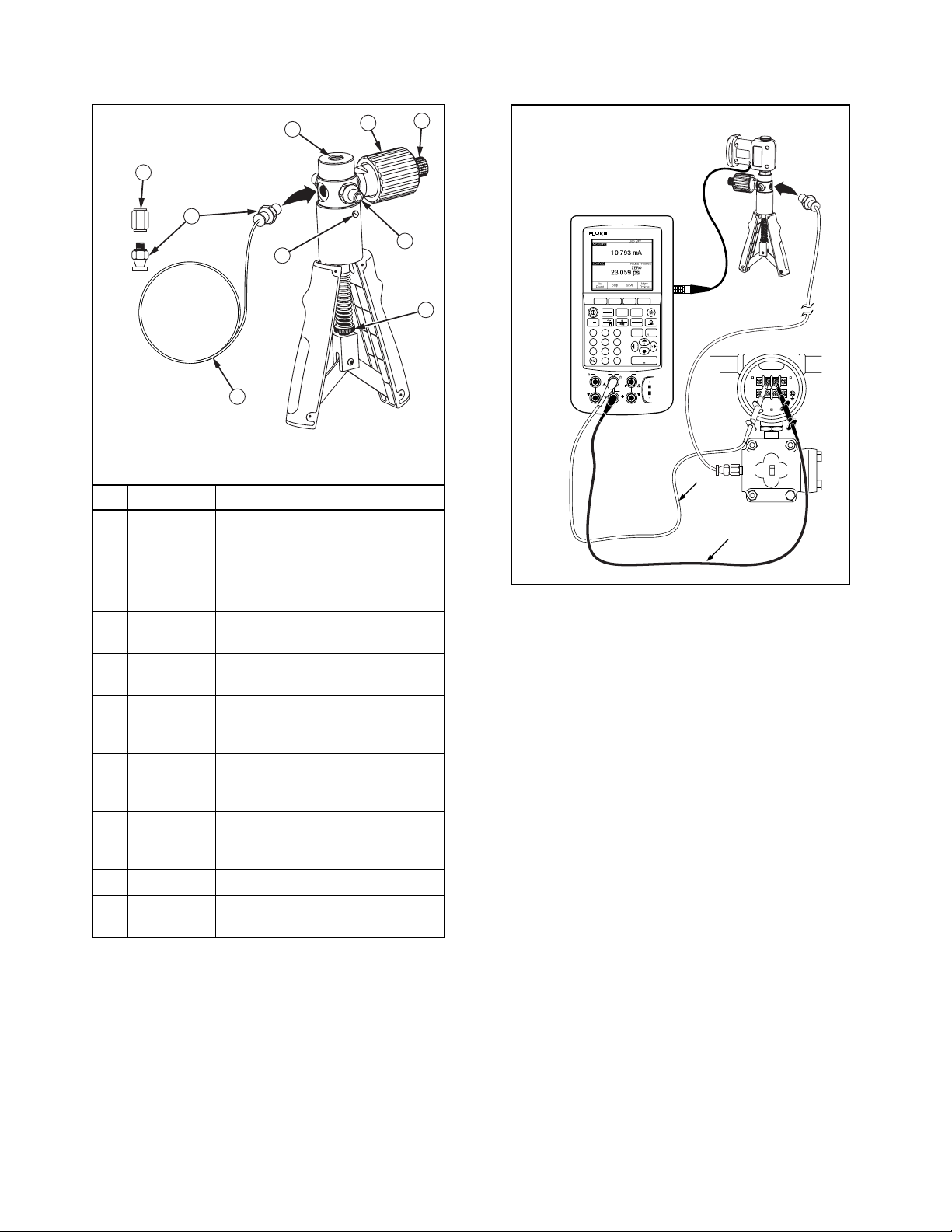

Features

8

Using the Pump

1

7

6

Test Pump

Pressure

Module

4

9

3

No. Item Function

Master

A

B

C

D

E

F

instrument port

Pressure /

vacuum button

Test pressure

port hose

Quick

Connects

Maximum

stroke limiter

Pressure

release valve

Port for Fluke 700 Series Pressure Module

Push in from this side for vacuum, and from

the other side for pressure. Use a small

screwdriver.

Flexible hose to pressure instrument under

test

1/8 in NPT male

To limit the pressure from the hand pump,

tighten these nuts to shorten the compression

stroke.

Unscrew to vent pressure from the pump.

Tighten the valve to close the valve before

applying pressure.

Fine

G

adjustment

To precisely adjust the applied pressure

knob

H Adapter 1/8 in NPT female to 1/4 in BSP female

I

(2) Clean out

ports

See “Pump Valve Assembly Cleaning

Instructions”

Figure 1. Features

2

5

euz01f.eps

DOCUMENTING PROCESS CALIBRATOR

743

Calibrator

MEAS

SETUP

mA

SOURCE

TC

V

V

RTD

Hz

RANGE

CLEAR

789

(ZERO)

456

123

RTD

30V

MAX

mA mA

SOURCE

30V

MAX

ENTER

0

.

VV

RTD

CAT

MEAS

300V

TC

MAX

30V

MAX

Red

Black

SIGNAL

+

–

TEST

UUT

euz02c.eps

Figure 2. Using the Pump

WWarning

To avoid a violent release of pressure, always

depressurize the system slowly using the pressure

release valve (item F) before detaching any

pressure line from the pump. Do not connect the

pump to an external pressure source.

1. Attach a 700 Series Pressure Module (hereafter called “pressure

module”) to the master instrument port. Use Teflon tape or other

sealing medium on all NPT thread connections to eliminate leakage.

2. Connect the test pressure port hose (item C) to the pressure input of

the pressure instrument under test.

3. Make sure the pressure/vacuum button (item B) is in the desired

position.

4. Unscrew the pressure release valve (item F) to vent pressure from

the pump.

5. Zero the pressure module. The zeroing procedure depends on which

pressure module and calibrator is in use.

6. Turn the fine adjustment knob (item G) to mid-range.

7. Tighten the pressure release valve (item F). Do not over tighten.

8. To limit the maximum pressure that can be developed by the pump,

tighten the maximum-stroke limiting adjustment nuts (item E). This

also reduces the amount of pressure increase per stroke.

9. To apply very low pressures, use the fine adjustment knob only (item

G).

10. Squeeze the handles together to apply incrementally higher pressure.

For pressure over 7 bar (100 psi), use two hands.

11. Adjust the pressure using the fine adjustment knob (item G).

Loading...

Loading...