Page 1

Product Compliance Markings

P ( II 1 G Eex ia IIC T4

0344

) I.S. Class I Div. 1 Groups A-D T4

221839 AEx ia IIC T4

Ta = 0 °C… + 50 °C

Ex Cerification by Mensor Corporation, San Marcos, TX USA

EMC: Complies with EN61326, Criteria C.

Limited Warranty

Each Fluke product is warranted to be free from defects in material and

workmanship under normal use and service. The warranty period is one year

and begins on the date of shipment. Parts, product repairs and services are

warranted for 90 days. This warranty extends only to the original buyer or end

user customer of a Fluke authorized reseller, and does not apply to fuses,

disposable batteries or to any product which, in Fluke’s opinion, has been

misused, altered, neglected or damaged by accident or abnormal conditions of

operation or handling. Fluke warrants that software will operate substantially in

accordance with its functional specifications for 90 days and that it has been

properly recorded on nondefective media. Fluke does not warrant that software

will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused

products to enduser customers only but have no authority to extend a greater or

different warranty on behalf of Fluke. Warranty support is available if product is

purchased through a Fluke authorized sales outlet or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for

importation costs of repair/replacement parts when product purchased in one

country is submitted for repair in another country.

Fluke’s warranty obligation is limited, at Fluke’s option, to refund of the purchase

price, free of charge repair, or replacement of a defective product which is

returned to a Fluke authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center

or send the product, with a description of the difficulty, postage and insurance

prepaid (FOB Destination), to the nearest Fluke authorized service center. Fluke

assumes no risk for damage in transit. Following warranty repair, the product

will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that the failure was caused by misuse, alteration, accident or

abnormal condition of operation or handling, Fluke will provide an estimate of

repair costs and obtain authorization before commencing the work.

Following repair, the product will be returned to the Buyer transportation prepaid

and the Buyer will be billed for the repair and return transportation charges (FOB

Shipping Point).

THIS WARRANTY IS BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN

LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE

LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, WHETHER ARISING

FROM BREACH OF WARRANTY OR BASED ON CONTRACT, TORT,

RELIANCE OR ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied

warranty, or exclusion or limitation of incidental or consequential damages, the

limitations and exclusions of this warranty may not apply to every buyer. If any

provision of this Warranty is held invalid or unenforceable by a court of

competent jurisdiction, such holding will not affect the validity or enforceability of

any other provision.

®

700PEx Series Pressure Modules

Instruction Sheet

Introduction

The Fluke 700PEx Series Pressure Modules allow you to

measure pressure with Fluke intrinsically safe calibrators

such as the 718Ex. Read this sheet before using the

pressure modules. This instruction sheet contains

specifications and information about how to avoid damaging

the pressure modules and describes how to safely use them

in hazardous locations. Refer to your calibrator’s Users

Manual

The pressure modules measure pressure using an internal

microprocessor. They receive operating power from and

send digital information to the intrinsically safe calibrators.

• Gage pressure modules have one pressure fitting and

• Differential pressure modules have two pressure fittings

• Absolute pressure modules measure relative to a

In Case of Difficulty

For service or calibration, call your nearest authorized Fluke

Service Center.

For application or operation assistance or information on

Fluke products, call:

Or, visit Fluke's Web site at www.fluke.com

To register your product, visit register.fluke.com

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090 P.O. Box 1186

Everett, WA 98206-9090 5602 B.D. Eindhoven

USA The Netherlands

Box Contents

Each pressure module comes with an installed strap and

instruction sheet. All pressure modules, with the exception of

the 700P29Ex, come with 1/4 NPT to 1/4 ISO metric

adapters.

for complete operating instructions.

measure pressure with respect to atmospheric pressure.

and measure the difference between the applied

pressure on the high fitting versus the low fitting. A

differential pressure module functions like a gage

module when the low fitting is open.

vacuum.

USA: 1-888-99-FLUKE (1-888-993-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-675-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

.

PN 2106534

(English)

May 2004

2004 Fluke Corporation. All rights reserved. Printed in USA

Page 2

Safety Information

In this instruction sheet a Warning identifies conditions and

actions that pose hazards to the user. A Caution identifies

conditions and actions that may damage the pressure

module or equipment under test. International symbols used

in this instruction sheet are identified later in the

section. Read the entire instruction sheet and the 700PEx

CCD (Concept Control Drawing) before using the pressure

module.

In case of doubt (due to translation and/or printing errors)

refer to the original English instruction sheet.

XW Warning

To avoid electric shock, injury, or damage to the

pressure module:

• Use the pressure module only as described

in this instruction sheet and the Fluke

700PEx CCD (Concept Control Drawing)

otherwise the protection provided by the

pressure module may be impaired.

• Inspect the pressure module before use. Do

not use it if it appears damaged.

• Check the cable for damaged insulation. Do

not use the pressure module if the cable

appears damaged.

• Never use the pressure module with the case

open. Opening the case invalidates Ex

Approval.

• This equipment is specified for use in

measurement category I (CAT I) pollution

degree 2 environments and should not be

used in CAT II, CAT III, or CAT IV

environments. Voltage transients should not

exceed 300 volts for the CAT I applications

where this product is used. Measurement

transients are defined in IEC1010-1 as 2 µs

rise time with a 50 µs duration at 50 % of the

maximum amplitude height.

• Measurement Category I (CAT I) is defined

for measurements performed on circuits not

directly connected to the mains.

Symbols

Symbols

The following symbols are used on the pressure module or in

this instruction sheet.

Table 1. Symbols

P

)

W

(

Conforms to relevant European directives.

Conforms to relevant Canadian and US standards.

Risk of danger. Important information. See Manual.

Certified as meeting “instrinsically safe” standards of

European approval agencies.

Faults and Damage

If there is any reason to suspect that the safe operation of

the pressure module has been affected, it must be

immediately withdrawn from use and precautionary

measures must be taken to prevent any further use of the

pressure module in an Ex hazardous area.

XW Warning

The safety features and integrity of the pressure module

may be compromised by any of the following:

• External damage to the housing

• Internal damage to the pressure module

• Exposure to pressure loads in excess of the

maximum rated pressure

• Incorrect storage of the unit

• Damage sustained in transit

• Correct certification is illegible

• Functioning errors occur

• Permitted limitations are exceeded

• Functioning errors or obvious measurement

inaccuracies occur which prevent further

measurement by the pressure module

Safety Regulations

The use of the 700PEx pressure modules meets the

requirements of the regulations providing that the user

observes and applies the requirements as laid down in the

regulations and that incorrect use of the unit is avoided. Use

must be restricted to the specified application parameters.

Protecting Yourself from Pressure Releases

XW Warning

• To avoid injury due to the release of high

pressure, use only adapters and fittings

rated to withstand the appropriate pressure.

Ensure that all adapters and fittings are

securely connected.

• To avoid a violent release of pressure in a

pressurized system, slowly bleed off the

pressure before you attach or remove the

pressure module from the pressure line.

• When measuring the pressure of potentially

hazardous media, care must be taken to

minimize the possibility of leakage. Confirm

that all pressure connections are properly

sealed.

Avoiding Mechanical Damage

To avoid damaging the pressure modules, never apply more

than 10 ft.-lbf. of torque between the module fittings or

between the fittings and the body of the module. Figure 1

shows the correct way and incorrect ways to use a wrench

when applying torque to the pressure module fitting.

f

Pressure.

Page 3

1. Connect the pressure module to the intrinsically safe

R

A

7

N

0

P

0

G

R

P

E

0

E

S

4

S

U

R

E

1

M

5

O

1

D

0

P

U

0

L

E

S

k

P

ID

a

1

/G

b

a

r

calibrator and select the measure pressure function.

2. Press the [ZERO] key.

3. Enter the value from the precision barometer.

Note

Low range pressure modules may be sensitive to

gravity. For best results, pressure modules 30 psi

and below should be held at the same physical

orientation from the time they are zeroed until the

measurement is complete.

Figure 1.

Avoiding Overpressure Damage

Applying pressure in excess of the burst pressure specified

on the pressure modules can destroy the pressure modules.

WCaution

Exceeding the maximum rated pressure

may affect total uncertainty. If you

suspect the module has been over

pressured, use the performance test to

check it.

Avoiding Corrosion Damage

To avoid corrosion damage, use only with specified media as

shown below:

• Isolated: any medium that is compatible with type 316

stainless steel.

• Non-Isolated: dry, non-corrosive gasses only.

Pressure Calibration Kit

The Fluke-700PCK Pressure Calibration Kit makes it

possible to calibrate pressure modules at ambient

temperature with a precision pressure calibrator better than

the module specification. A PC running Windows

required. The kit is an optional accessory available from your

distributor or Fluke.

Performance Test

If you need to check that the pressure module meets its total

uncertainty specification, use a dead weight tester or suitable

pressure calibrator. Proceed as follows to verify that a

pressure module is operating within specification:

1. Read the pressure value with no externally applied

pressure to make sure the 0% of scale is correct. When

reading the pressure, press the [ZERO] key to remove

any zero offset.

2. Connect the pressure module to a precision pressure

source.

3. Zero as described earlier in the appropriate “Zeroing”

sections.

• 700P29Ex: use only with a medium that is compatible

with Hastelloy C276 and type 316 Stainless Steel.

Recommended Measurement Technique

For best results, the modules should be pressurized to full

scale and then vented to zero pressure (atmosphere) prior to

zeroing and making measurements.

Zeroing Gage and Differential Modules

1. Connect the pressure module to the intrinsically safe

calibrator and select the measure pressure function.

2. Position the module in the same orientation for which it

will be used.

3. Vent both high and low side measurement ports to

atmosphere.

4. Press the [ZERO] key.

Zeroing Absolute Modules

1. Connect the pressure module to the intrinsically safe

calibrator and select the measure pressure function.

2. Apply a vacuum to achieve a pressure below the rated

resolution of the pressure module being zeroed.

3. Press the [ZERO] key, and enter 0.0 as the applied

pressure.

Alternative procedure if a local precision barometer is

4. Set the precision pressure source to 20% of the

pressure module’s maximum rated pressure.

5. Make sure the reading agrees with precision pressure

source value within the total uncertainty specification in

Table 2.

6. Set the precision pressure source to 40, 60, 80, and

100%. Then reverse the order from 100, 80, 60, 40, and

20% of maximum rated pressure. Repeat step 5 at each

test point.

7. If temperature sensitivity is of concern, repeat steps 1

through 5 at various controlled temperatures.

Cleaning

WCaution

• Measuring substances that

leave residue in the sensor

may cause permanent

damage to the Pressure

Module.

• Periodically wipe the Pressure

Module with a damp cloth and

mild detergent. Do not use

abrasives or solvents to clean

the Pressure Module.

available. Do not use the weather service or airport reports.

®

software is

Page 4

(0 to 50 °C)

Temp

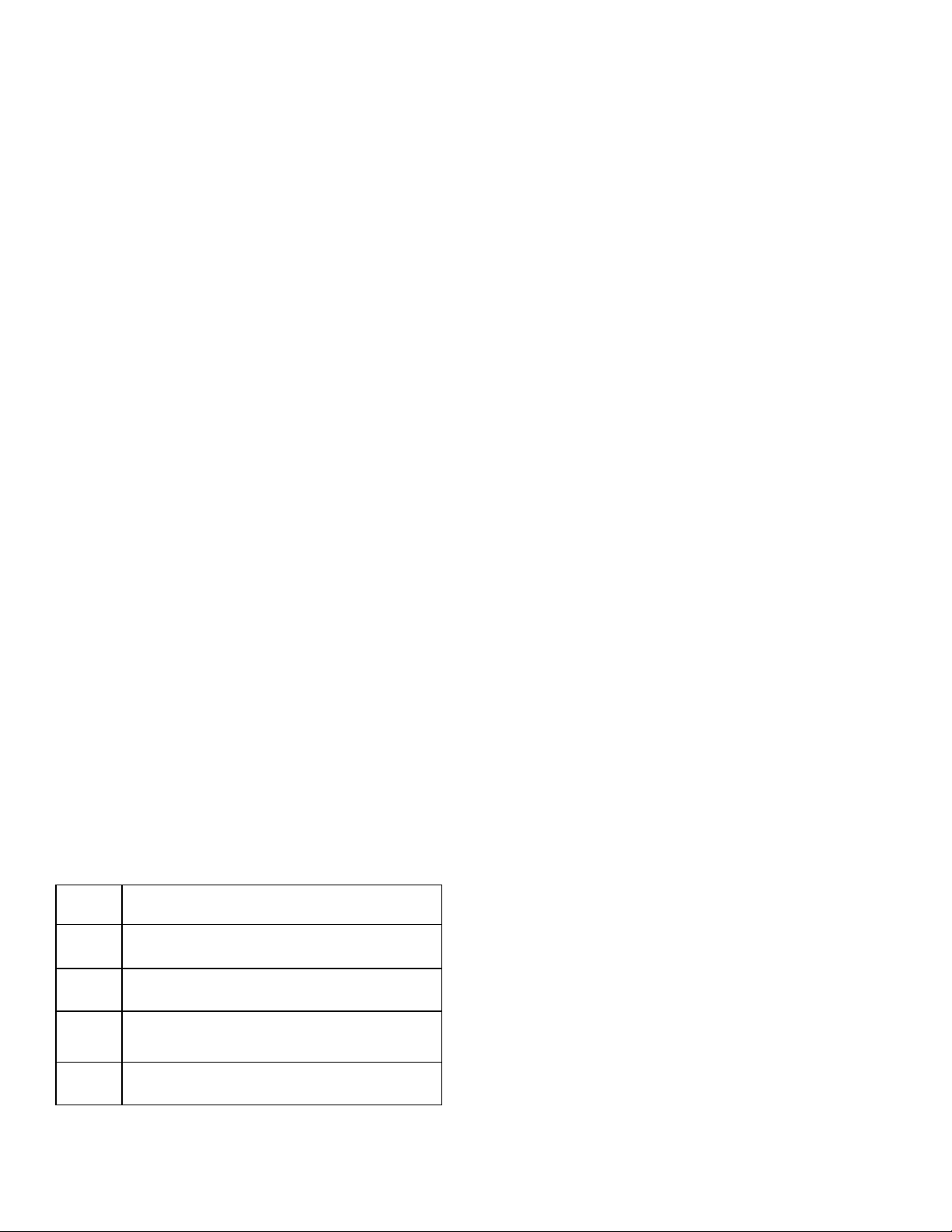

Total

Uncertainty

Model

Maximum

Rated

Pressure

(Range)

Table 2. Specifications 1 (% of Maximum Rated Pressure)

2

Type

Isolated or

Nonisolated

Reference

Uncertainty

(23 ° ± 3 °C)

Stability

(1 Year)

Burst pressure: 3X maximum rated pressure, including common mode pressure (700P29Ex and 700P09Ex: 2x).

Specifications reflect a confidence interval of 95%.

700P01Ex 0 to 10 in H2O

0 to 2.49 kPa

0 to 0.02 bar

700P24Ex 0 to 15.000 psi

0 to 100.00 kPa

0 to 1.0000 bar

700P05Ex 0 to 30.000 psi

0 to 200.00 kPa

0 to 2.0000 bar

700P06Ex 0 to 100.00 psi

0 to 700.00 kPa

0 to 7.0000 bar

700P27Ex 0 to 300.00 psi

0 to 2000.00 kPa

0 to 20.000 bar

700P09Ex 0 to 1500.0 psi

0 to 10000.0 kPa

0 to 100.000 bar

700P29Ex4 0 to 3000 psi

0 to 20680 kPa

0 to 207 bar

700PA4Ex 0 to 15.000 psi

0 to 100.00 kPa

0 to 1000.0 mbar

1. Use of pressure zero function is required to achieve these specifications.

2. Available pressure units are determined by the calibrator being used.

3. Accuracy specifications apply for 1 year for 0 to 100% of full span from 0 to 50 °C. Typical uncertainty is 1% of full span from -10 °C to 0 °C.

Maximum altitude: 2000 m. Humidity range: 0 to 80 %.

4. Only use with Group 2 Fluids compatible with Hastelloy C276 and type 316 Stainless Steel.

5. The maximum line (common mode) pressure shall not exceed the maximum rated pressure.

Differential

Differential

High Pressure

Absolute Isolated 0.050 % 0.010 % 0.010 %

5

Hi: Nonisolated

Low: Nonisolated

5

Hi: Isolated

Low: Nonisolated

Gage Isolated

Gage Isolated

Gage Isolated

Gage Isolated

Gage,

Isolated 0.050 % 0.010 % 0.020 %

0.200 % 0.050 % 0.050 %

0.025 % 0.010 % 0.015 % 0.050 %

0.025 % 0.010 % 0.015 %

0.025 % 0.010 % 0.015 %

0.025 % 0.010 % 0.015 %

0.025 % 0.010 % 0.015 %

0.300 %

0.050 %

0.050 %

0.050 %

0.050 %

0.080 %

0.070 %

3

Table 3. Entity Parameters

Vmax, Ui Imax, Ii Pi Ci Li

8.7 V 598 mA 1.2 W 5.72 µF 0 mH

Loading...

Loading...