Page 1

Limited Warranty

700PCK Pressure Module

Each Fluke product is warranted to be free from defects in material and

workmanship under normal use and service. The warranty period is one year

and begins on the date of shipment. Parts, product repairs, and services are

warranted for 90 days. This warranty extends only to the original buyer or enduser customer of a Fluke authorized reseller, and does not apply to fuses,

disposable batteries, or to any product which, in Fluke's opinion, has been

misused, altered, neglected, contaminated, or damaged by accident or

abnormal conditions of operation or handling. Fluke warrants that software will

operate substantially in accordance with its functional specifications for 90

days and that it has been properly recorded on non-defective media. Fluke

does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused

products to end-user customers only but have no authority to extend a greater

or different warranty on behalf of Fluke. Warranty support is available only if

product is purchased through a Fluke authorized sales outlet or Buyer has paid

the applicable international price. Fluke reserves the right to invoice Buyer for

importation costs of repair/replacement parts when product purchased in one

country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the

purchase price, free of charge repair, or replacement of a defective product

which is returned to a Fluke authorized service center within the warranty

period.

To obtain warranty service, contact your nearest Fluke authorized service

center to obtain return authorization information, then send the product to that

service center, with a description of the difficulty, postage and insurance

prepaid (FOB Destination). Fluke assumes no risk for damage in transit.

Following warranty repair, the product will be returned to Buyer, transportation

prepaid (FOB Destination). If Fluke determines that failure was caused by

neglect, misuse, contamination, alteration, accident, or abnormal condition of

operation or handling, including overvoltage failures caused by use outside the

product’s specified rating, or normal wear and tear of mechanical components,

Fluke will provide an estimate of repair costs and obtain authorization before

commencing the work. Following repair, the product will be returned to the

Buyer transportation prepaid and the Buyer will be billed for the repair and

return transportation charges (FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN

LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE

LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA,

ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied

warranty, or exclusion or limitation of incidental or consequential damages, the

limitations and exclusions of this warranty may not apply to every buyer. If any

provision of this Warranty is held invalid or unenforceable by a court or other

decision-maker of competent jurisdiction, such holding will not affect the

validity or enforceability of any other provision.

In Case of Difficulty

For service or calibration, call your nearest authorized Fluke Service

Center.

To contact Fluke, call one of the following telephone numbers:

USA: 1-888-99-FLUKE (1-888-993-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-675-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

Or, visit Fluke's Web site at www.fluke.com.

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090 P.O Box 1186

Everett WA 98206-9090 5602 B.D. Eindhoven

USA The Netherlands

Calibration Kit

Instruction Sheet

Introduction

Use this Windows software program and interface unit to

verify and calibrate Fluke 700 Series Pressure Modules for

zero and span errors at ambient temperature. You will need a

pressure calibrator or dead weight tester that is at least 4X

more accurate than the pressure module under test.

You do not use a 74x or 75x during this procedure. The PC

communicates directly with the pressure module through the

interface unit.

Safety Specifications

Designed to IEC-1010-1 Overvoltage Category II, ANSI/ISAS82.01-1994.

Box Contents

Box contains an interface unit with serial interface cable,

serial to USB adapter, software CD, power supply, line cord,

soft case, and instruction sheet.

Loading the Software

With Microsoft Windows running, click on the CD/DVD drive

where the CD is installed. Double click on the file 7pck.exe.

Follow the instructions to load the program onto your PC.

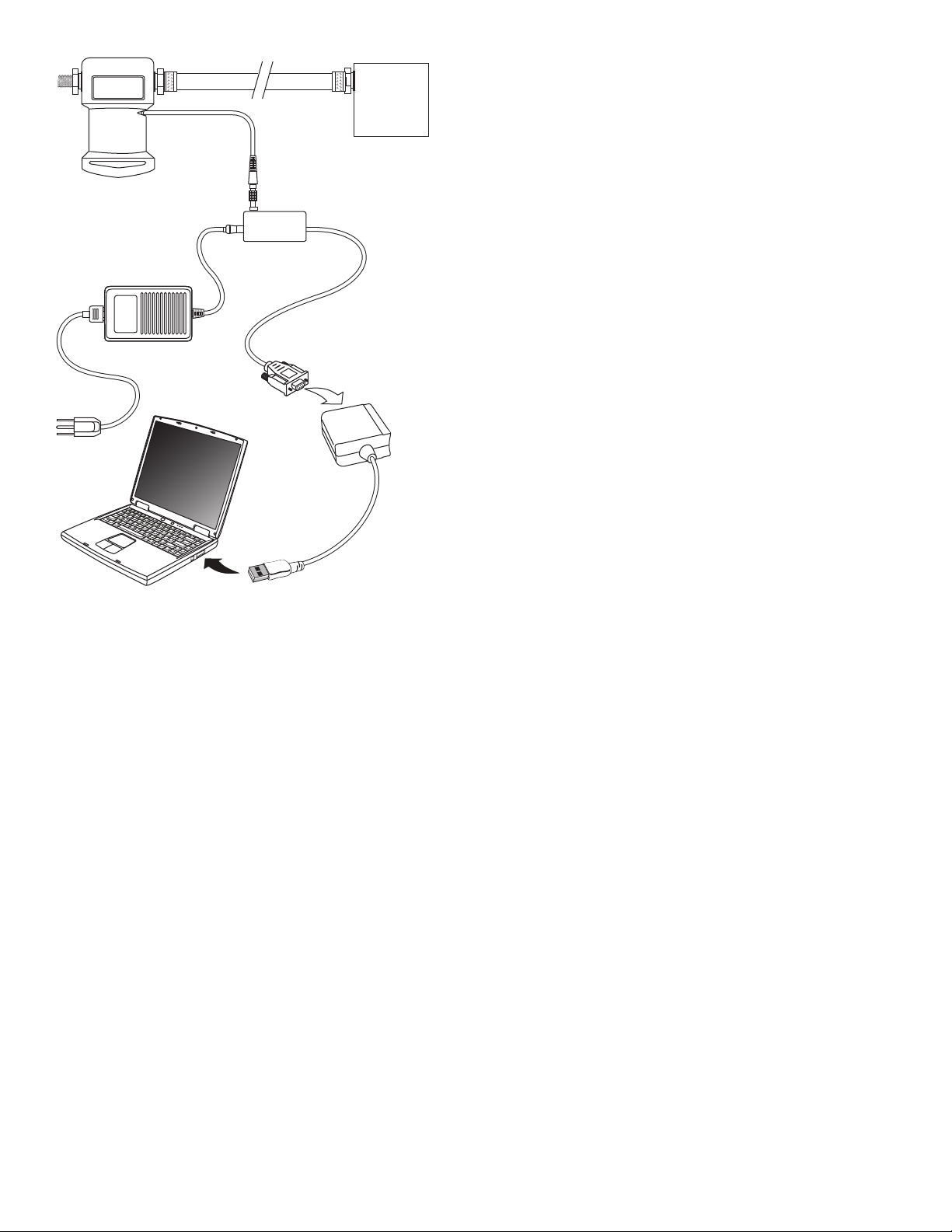

Connecting 700PCK to the Module

Plug the pressure module into the interface unit, connect the

interface unit power supply to line power (90 to 270V ac), and

connect the USB cable to an available USB port on your PC

as shown on the next page. Connect the pressure module to

the pressure calibrator or dead weight tester.

In the 700PCK directory, double click on 700pck.exe to start

the program. Select the desired communications port under

Com Port. Click on Connect. If the connection is not

successful, try another Com Port.

PN 200086

May 1995 Rev.3, 8/12

©1995-2012 Fluke Corporation. All rights reserved. Printed in USA

All product names are trademarks of their respective companies.

Page 2

Pressure

Calibrator

Pressure Module

Interface

Line Power

Unit

9-Pin to

USB

Connector

USB

Port

Zero Pressures

In verification and calibration, these instructions refer to a

zero pressure.

In verification, for standard (positive-only reading), vacuum,

or dual-range modules this is equivalent to venting to the

atmosphere. For absolute modules, it is best to apply a

known vacuum pressure as low as possible, but any precisely

known pressure will work.

In calibration, for standard (positive-only reading) and vacuum

modules, the module or pressure calibrator should be vented

to atmosphere. For absolute modules, a known vacuum must

be applied. For dual or compound-range modules, a negative

pressure should be applied that is close to the negative full

span.

As Found Verification

Proceed as follows to collect verification data for the module

before you adjust it. Before you verify the module, exercise it

by applying full scale pressure, then venting to atmosphere.

As found data is saved in a file named “nnnnnnn.fnd,” where

“nnnnnnn” is the serial number of the pressure module. You

can import this file into a database or spreadsheet program.

1. Click on As Found Verification.

2. Apply each requested pressure. Where a zero pressure

is called for, refer to Zero Pressures above.

Wait for the reading to settle (to typically less than 1

count change in 5 seconds) before you go on to each

next step.

3. Click on Done to save the data to a text file.

If Verification Fails by More than 1%

If the pressure module is more than 1% out of tolerance, it

needs full calibration over temperature at a Fluke Service

Center, and possibly repair. Check for tolerance exceeding

1% of full scale by comparing the results of As Found

Verification with the pressure module specifications.

Calibration Adjustment

Using the calibration adjustment procedure, you create new

calibration coefficients and download them into the pressure

module. Before you calibrate the module, exercise it by

applying full scale pressure, then venting to atmosphere.

Proceed as follows to adjust a module:

1. Click on Calibration Adjustment.

2. Apply a zero pressure (refer to Zero Pressures above).

Wait for the reading to settle (to typically less than 1

count change in 5 seconds) before you go on to the next

step.

3. Apply full scale pressure ±5% as requested by the

program. Again, wait for the reading to settle.

4. Test the module by applying any pressure between zero

and full scale. The module is now working with the

updated constants.

5. In cases where the zero error was large, you may have

to perform calibration adjustment twice. To repeat the

calibration adjustment, click on Calibration Adjustment

again, before clicking on Disconnect.

6. Click on Save to Module to download the new constants

and make the changes permanent (until you adjust it

again).

As Left Verification

Proceed as follows to collect verification data for the module

after you have adjusted it. Before you verify the module,

exercise it by applying full scale pressure, then venting to

atmosphere. As left data is saved in a plain text file named

“nnnnnnn.lft,” where “nnnnnnn” is the serial number of the

pressure module. You can import this file into a database or

spreadsheet program.

1. Click on As Left Verification.

2. Apply each requested pressure. Where a zero pressure

is called for, refer to Zero Pressures.

Wait for the reading to settle (to typically less than 1

count change in 5 seconds) before you go on to each

next step.

3. Click on Done to save the data to a text file.

As found data is stored as "nnnnnnn.fnd" where "nnnnnnn" is

the seven or eight-digit serial number. The only difference

between "as found verification" and "as left verification" is that

the file extension is changed to ".lft". All files are stored in the

"data" subdirectory of the working directory.

NOTE

When using the 700PCK with 700P22, 700P23,

or 700P24 Pressure Modules, derate module

specification to 0.1% if electromagnetic field

strength exceeds 2.5 V/m (above 3 V/m not

specified).

Loading...

Loading...