Page 1

Fluke-700LTP-1

Low-Pressure Test Pump

Instruction Sheet

®

Introduction

The Fluke-700LTP-1 Low-Pressure Test Pump is a

portable, dual source of vacuum and pressure. Each pump

incorporates a vacuum and pressure selector and fine

adjustment control. The pump has the following

specifications:

• Output pressure: 0 to 100 psi / 0 to 6.9 bar

• Output vacuum: 0 to -13 psi / 0 to -900 mbar

• Exposed Materials: Aluminum, silicon, neoprene,

stainless steel, Buna-N

• Adjustment: Fine volumetric pressure and vacuum

adjuster

• Dimensions: 150 mm x 100 mm

• Weight: 226 grams or .5 lbs (pump only)

Box Contents

• Fluke 700LTP-1 Low-pressure Test Pump

• 1/8 in NPT male/female tee

• (2) 1 m hoses

• (4) 1/8 in NPT male quick connects

• (2) 1/8 NPT female to 1/4 in BSP female

• Seal Kit

• Instruction Sheet

Contacting Fluke

To contact Fluke or for service, call one of the following

telephone numbers:

USA: 1-888-44-FLUKE (1-888-443-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-675-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

Or, visit Fluke's Web site at www.fluke.com

.

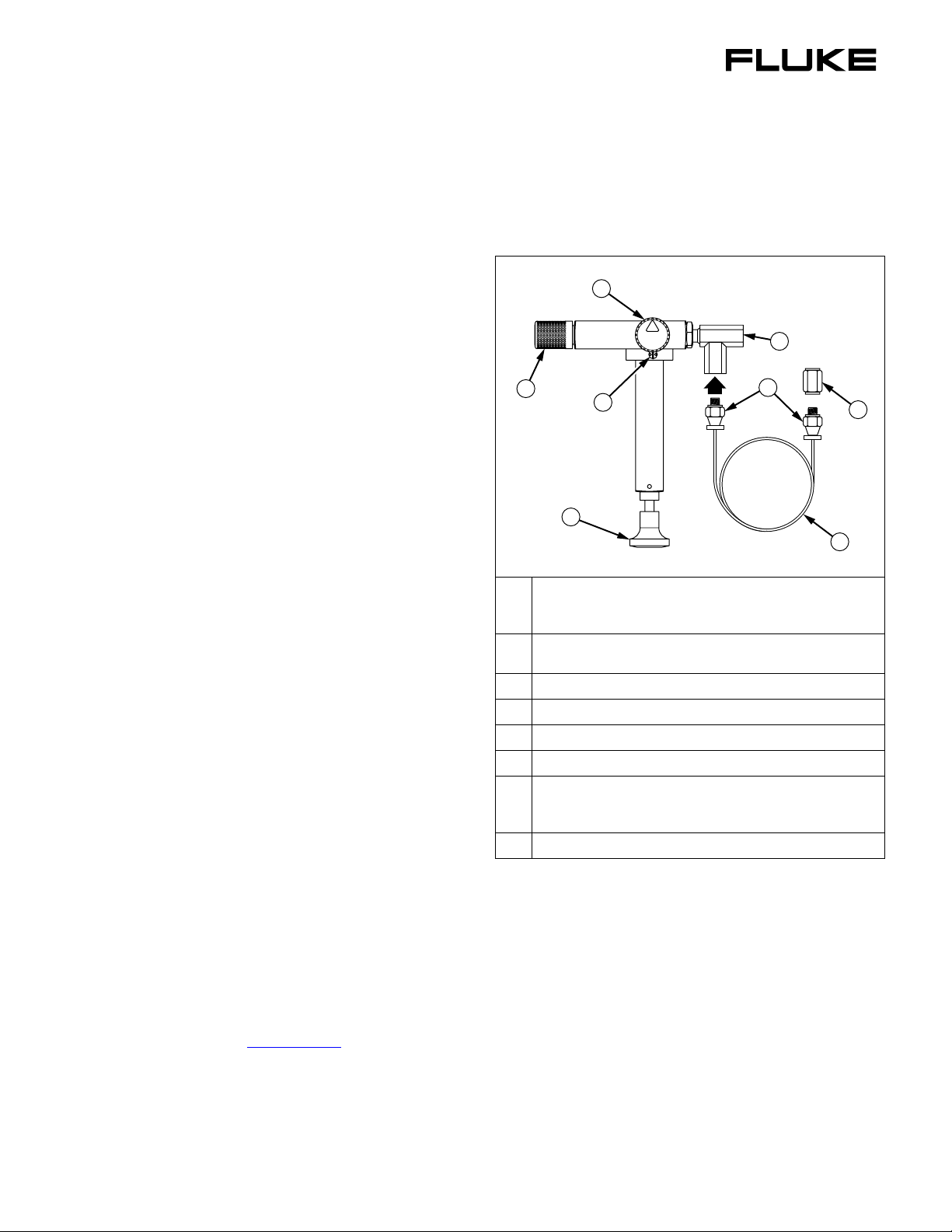

1

3

2

Pressure/vacuum release valve- Turn valve counterclockwise for vacuum, clockwise for pressure and

A

centered for release.

Fine adjustment control- Turn in or out to increase or

B

decrease pressure accordingly.

Master and test port tee

C

Quick-fit connectors

D

Hose

E

1/8 in NPT female to 1/4 in BSP female fitting

F

Pump Handle. If the pump has not been used for a

while, there may be some resistance on the first

G

stroke.

Cleanout ports (2)- See cleanout instructions

H

8

7

Figure 1. Features

4

5

eus01f.eps

Guidelines for Use

1. Connect a pressure calibrator or pressure module to

the quick-fit connector (item D) at the end of one of the

flexible hoses (item E).

2. Connect the unit under test to the quick-fit connector

(item D) at the end of the second flexible hose (item

E), choosing correct adapters (item F) and seals.

3. Turn the fine adjustment control to mid-range.

6

4. Set control valve to pressure.

5. Operate handle (item G) until the pressure is close to

the required value.

PN 2811813 April 2007 © 2007 Fluke Corporation. All rights reserved. Printed in U.S.A. 1

Page 2

Fluke-700LTP-1

Instruction Sheet

• The pressure may settle for up to one minute after

increasing pressure due to the thermodynamic

effects, settling of seals and expansion of the

flexible hose.

• On very high resolutions such as 1 mbar or 0.1

inches of water, small movements of the tubing

may result in noticeable pressure changes.

Notes

6. Turn the fine adjustment control (item B) in to increase

pressure or out to decrease pressure until required

pressure is reached.

7. Reduce pressure by careful use of the pressure release

valve (item A).

8. Achieve vacuum using the above procedure with the

pressure / vacuum selector (item A) in the vacuum

position.

When testing for leaks, you may notice that air is drawn in

or expelled from around the pressure / vacuum selector.

This is normal operation.

If the pump appears to lose pressure, then the procedure

above should be repeated, ensuring new seals are used,

adapters are tightened sufficiently and the pressure release

valve (item A) is tightened firmly. The connections to the

handheld test system are sealed with o-ring or bonded

seals and should not leak.

Pump Valve Assembly Cleaning

Instructions

Occasionally, the 700LTP-1 may not work properly due to

contamination of the internal valve assembly. Use the

following procedure to clean the valve assembly. If the

procedure does not fix the problem, a rebuild kit (2812587)

may be ordered.

1. Using a small screwdriver, remove the 2 valve retention

caps located on opposite sides of the pump below the

pressure/vacuum switch.

2. Gently remove the spring and o-ring assembly. This

includes several small components. Remove with care.

See Figure 2.

eus02f.eps

Figure 2. Disassembly

3. Set aside the valve assemblies and clean out the valve

body using a cotton swab soaked in isopropyl alcohol.

4. Repeat the process several times using a new swab

until clean.

5. Operate the pump handles several times and recheck

for contamination.

6. Clean the o-ring assembly and the o-ring on the

retention caps with isopropyl alcohol and inspect the orings closely for any damage or excessive wear.

Replacements are included in the repair kit.

7. Inspect the springs for wear or loss of tension. They

should be approximately 8.6 mm long in the relaxed

state. If shorter, they may provide sufficient sealing

tension. Replace if needed.

8. Once all parts have been cleaned and inspected,

reinstall the o-ring and spring assembly into the valve

body.

9. Reinstall the retention caps and gently tighten each

cap.

10. Seal the output port and operate the pump to at least

50 % of capacity.

11. Release the pressure and repeat several times to

ensure that the o-rings seat properly.

Replacement Parts

• Hose Assembly, Fluke PN 2815714

• Rebuild Kit, Fluke PN 2812587

LIMITED WARRANTY AND LIMITATION OF LIABILITY

This Fluke product will be free from defects in material and workmanship for

one year from the date of purchase. This warranty does not cover fuses,

disposable batteries, or damage from accident, neglect, misuse, alteration,

contamination, or abnormal conditions of operation or handling. Resellers are

not authorized to extend any other warranty on Fluke’s behalf. To obtain

service during the warranty period, contact your nearest Fluke authorized

service center to obtain return authorization information, then send the

product to that Service Center with a description of the problem.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER WARRANTIES,

SUCH AS FITNESS FOR A PARTICULAR PURPOSE, ARE EXPRESSED

OR IMPLIED. FLUKE IS NOT LIABLE FOR ANY SPECIAL, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, ARISING

FROM ANY CAUSE OR THEORY. Since some states or countries do not

allow the exclusion or limitation of an implied warranty or of incidental or

consequential damages, this limitation of liability may not apply to you.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

11/99

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

2

Loading...

Loading...