Page 1

How to Prime the Test Pump

Fluke Corporation

Fluke Europe B.V.

Before you connect the Pump to the Unit Under Test (UUT), the

Pump must be filled with fluid and primed for use. Follow the

directions below to prepare the Pump for use.

1. Fill the Pump with fluid:

a. Remove the Reservoir Filler Cap (item .)

b. Fill the Hydraulic Fluid Reservoir approximately two-thirds full

(66 cc) with distilled water, mineral oil, or hydraulic oil.

Note

If water is used in the Pump, use only DISTILLED water

and drain the water out of the Pump after use.

c. Install the Reservoir Filler Cap (item .) Tighten by hand.

2. Prime the Pump:

a. Adjust the Vernier Fine Adjustment Knob (item ) to the

approximate middle-range.

b. Turn the Pressure Bleed Knob (item ) clockwise until it

stops in the full closed position.

c. Squeeze the handles together to pump fluid. Pump fluid until

fluid shows at the Pump Port.

d. Attach the fluid hose to the Pump.

e. Squeeze the handles together until fluid shows at the end of

the hose.

f. Attach the fluid hose to the Unit Under Test (UUT) and

squeeze the Pump handles until pressure increases.

g. Bleed the trapped air from the Pump. Pressurize the Pump to

1,000 psi then slowly turn the Pressure Bleed Knob (item )

counter-clockwise to release pressure.

Notes

• As the pressure rises it will be hard to squeeze the

handles together. Use the Handle Limiter (item

limit the travel of the handles which will make them

easier to squeeze together. To toggle the Handle

Limiter on or off, squeeze the handles together and

push the Handle Limiter (item

• The rate at which the pressure increases is directly

related to the test configuration (hose length and

volume of UUT.)

) in or out.

) to

Replacement Parts

Rebuild Kit, Fluke PN 4097836

Hydraulic Fluid Reservoir Rebuild Kit, Fluke PN 2844341

Handle Assembly Rebuild Kit, Fluke PN 2844352

LIMITED WARRANTY AND LIMITATION OF LIABILITY

This Fluke product will be free from defects in material and workmanship for

one year from the date of purchase. This warranty does not cover fuses,

disposable batteries, or damage from accident, neglect, misuse, alteration,

contamination, or abnormal conditions of operation or handling. Resellers ar e

not authorized to extend any other warranty on Fluke’s behalf. To obtain

service during the warranty period, contact your nearest Fluke authorized

service center to obtain return authorization information, t he n s end t he prod uc t

to that Service Center with a description of the problem.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER WARRANTIES,

SUCH AS FITNESS FOR A PARTICULAR PURPOSE, ARE EXPRESSED OR

IMPLIED. FLUKE IS NOT LIABLE FOR ANY SPECIAL, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, ARISING

FROM ANY CAUSE OR THEORY. Since some states or countries do not

allow the exclusion or limitation of an implied warranty or of incidental or

consequential damages, this limitation of liability may not apply to you.

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

11/99

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

Fluke-700HTP-2

Hydraulic Test Pump

Instruction Sheet

Introduction

The Fluke 700HTP-2 Hydraulic Test Pump (the Pump or Product) is a

portable source of high pressure.

Safety

W Warning

To prevent personal injury, use the Product only as

specified, or the protection supplied by the Product can be

compromised.

Pump Specifications

• Maximum pressure: 10,000 psi (690 bar)

• Hydraulic media: distilled water, mineral based hydraulic oil, or up

to hydraulic oil 100 (30 W).

• Wetted materials: 303 stainless steel, aluminum, polyurethane,

PTFE, nitrile, and nylon.

• Weight: 1.29 lb (0.58 kg)

• Dimensions: length 9.5 in (241 mm), width 6.1 in (155 mm), depth

2.6 in (66 mm)

Box Contents

• Model 700HTP-2 Hydraulic Test Pump with a 1/4-inch NPT tee

installed.

• Two 1/4-inch NPT male to 1/4-inch BSP female adapters.

• One 1/4-inch NPT male to 1/4-inch NPT male fitting.

• One 1/4-inch NPT male to 1/8-inch NPT male fitting.

• Instruction Sheet

How to Contact Fluke

To contact Fluke, call one of the following telephone numbers:

• Technical Support USA: 1-800-44-FLUKE

(1-800-443-5853)

• Calibration/Repair USA: 1-888-99-FLUKE

(1-888-993-5853)

• Canada: 1-800-36-FLUKE

(1-800-363-5853)

• Europe: +31 402-675-200

• Japan: +81-3-6714-3114

• Singapore: +65-738-5655

• Anywhere in the world: +1-425-446-5500

Or, visit Fluke's website at www.fluke.com

To register your product, visit http://register.fluke.com.

To view, print, or download the latest manual supplement, visit

http://us.fluke.com/usen/support/manuals

.

.

PN 4096896

September 2011

2011 Fluke Corporation. All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies.

Page 2

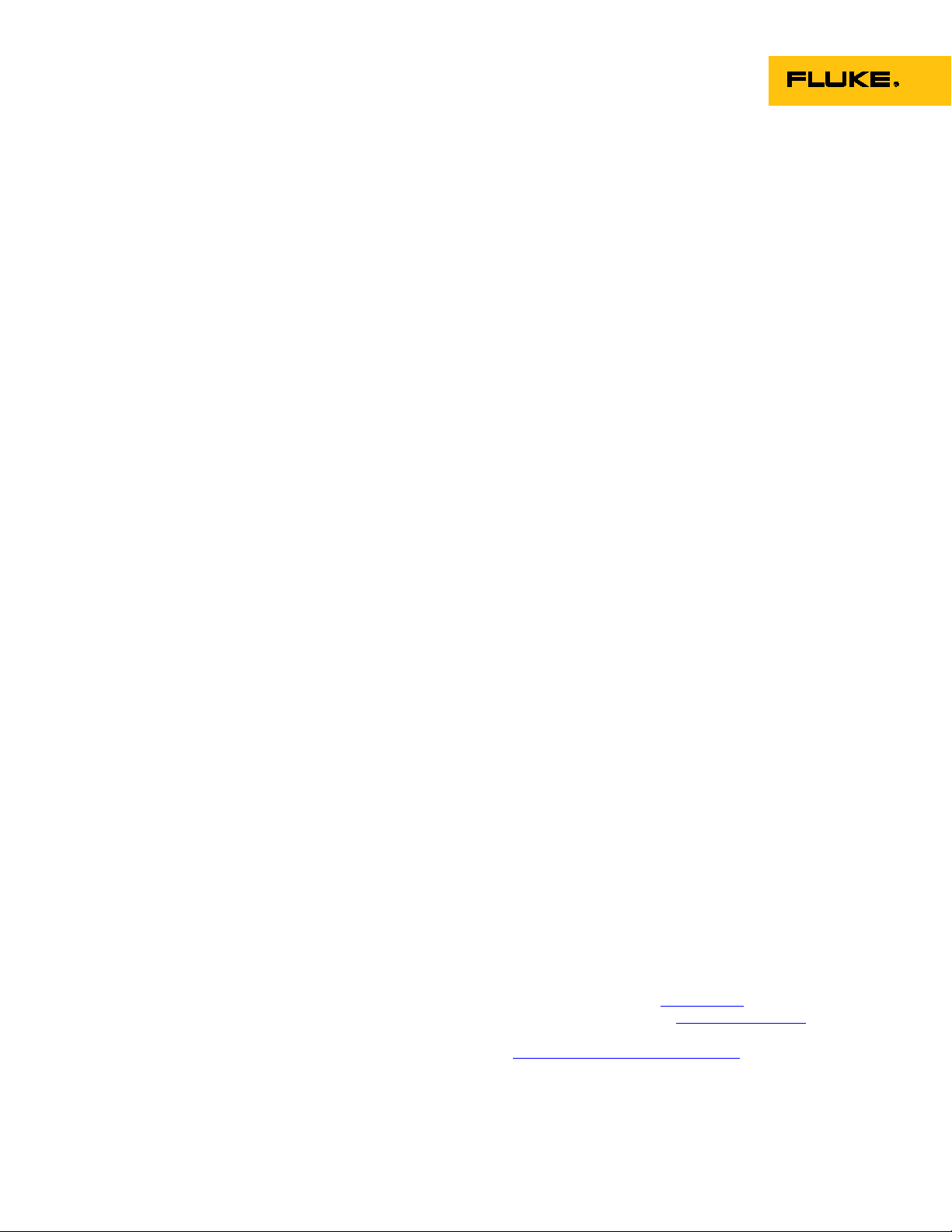

Features

gsp001.eps

No. Item Function

Master

Instrument Port

Test Pressure

Port

Pressure Relief

Valve Port

Vernier Fine

Adjustment Knob

Hydraulic Fluid

Reservoir

1/4-inch NPT Tee

Fitting

Port for Fluke 700 Series Pressure

Module, 1/4-inch NPT female.

Port for pressure instrument under

test, 1/4-inch NPT female.

Port for an optional Fluke 700PRV-1

Pressure Relief Valve (plugged).

Lets you adjust the applied pressure

in small increments.

Holds 100 cc of mineral based

hydraulic oil, distilled water, or

hydraulic oil.

For master and test ports.

Handle Limiter Limits the travel of the handles.

Reservoir Filler

Cap

Pressure Bleed

Knob

Cap which seals the hydraulic fluid

reservoir. Install before you pump.

Lets you release pressure in small

increments.

Reservoir Nut Remove nut to clean reservoir.

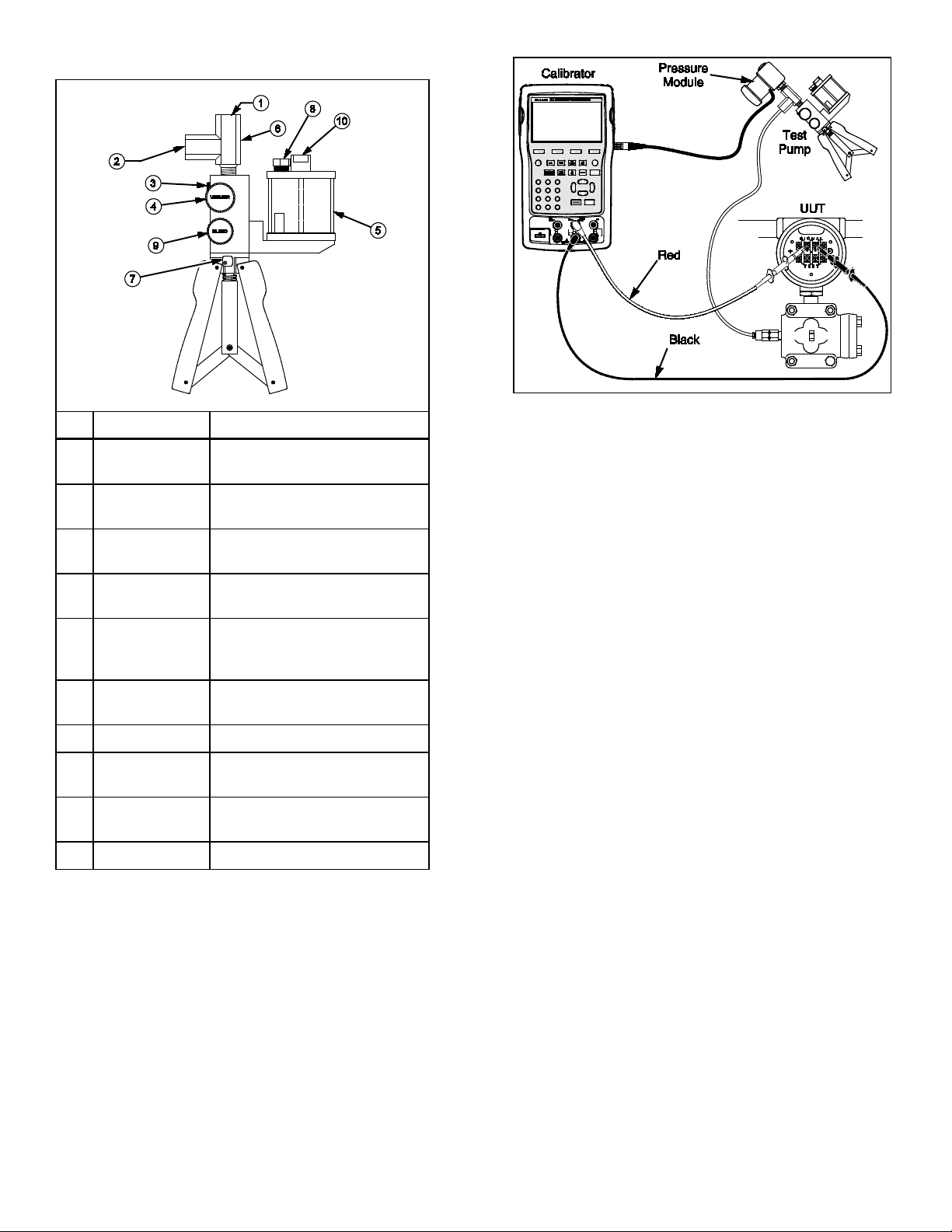

Figure 1. Test Configuration

gsp002.eps

How to Operate the Test Pump

W Warning

To prevent a violent release of pressure, open the

Pressure Bleed Knob (item ) very slowly

disconnect pressure lines. Do not connect the Pump to

an external pressure source.

W Caution

To prevent damage when a Pressure Module or Pressure

Instrument is connected that could be damaged by

pressures of 690 bar (10,000 psi), install and correctly

set a relief valve in the system or an optional Fluke

700PRV-1 Pressure Relief Valve on the Pump.

1. Connect a 700 Series Pressure Module (the Pressure Module)

to the Master Instrument Port (item .) To connect to a 700P

High Pressure Module (700P29, P30, or P31) install a male

1/4-inch NPT Adapter. Use Teflon

NPT thread connections to prevent leaks.

2. Fill and Prime the Pump. See “How to Prime the Test Pump”.

3. Connect the Pressure Module to the calibrator as shown in

Figure 1.

4. Connect the input of the Pressure Unit Under Test (UUT) to the

Test Pressure Port (item ) on the Test Pump.

5. Loosen the Pressure Bleed Knob (item ) to release pressure

from the Pump.

6. Use the Calibrator to zero the Pressure Module. Refer to the

Users Manual for instructions.

7. Turn the Vernier Fine Adjustment Knob (item ) to the

middle-range.

8. Turn the Pressure Bleed Knob (item ) clockwise until it stops

in the full closed position.

9. Squeeze the handles together to pump fluid which will increase

pressure. See the Notes in step 2 of the “How to Prime the Test

Pump” procedure.

W Caution

To prevent damage, do not let the pressure increase to

more than the pressure rating of the equipment under

test. Pressure can increase quickly if the pressurized

volume is small.

10. For incremental pressure adjustments, use the Vernier Fine

Adjustment Knob.

11. Once the test is done, slowly turn the Pressure Bleed Knob

(item ) counter-clockwise to release pressure.

®

tape or equivalent on the

before you

Loading...

Loading...