Page 1

®

QuickBERT-T1 and QuickCHECK-T1

PN 1278087

July 1999 Rev.1, 9/99

© 1999 Fluke Corporation, All rights reserved. Printed in USA

All product names are trademarks of their respective companies.

635/633

Users Manual

Page 2

LIMITED WARRANTY & LI M ITATION OF LIABILITY

Each Fluke product is warrant ed to be free from defects in mat eri al and workmanship

under normal use and service. The warrant y peri od i s one year and begins on the date

of shipment. Parts , product repairs and services are warrant ed for 90 days. This warranty extends only to the original buyer or end-user customer of a Fl uke authorized reseller, and does not apply to fuses, disposable batt eri es or to any product which, in

Fluke’s opinion, has been misused, al tered, neglected or damaged by acci dent or abnormal conditions of operation or handling. Fluke warrants that software will operate

substantially in ac cordance with its funct i onal specifications for 90 days and that it has

been properly recorded on non-defective m edi a. Fl uke does not warrant that software

will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to enduser customers only but have no authority to extend a greater or di fferent warranty on

behalf of Fluke. Warranty s upport is available if product i s purchased through a Fluke

authorized sales outlet or Buyer has paid the applicable international price. Fluke reserves the right to inv oi ce Buyer for importation costs of repair/replacement parts when

product purchased in one country i s submitted for repair in another c ountry.

Fluke’s warranty obligation is limited, at Fluke’s option, to ref und of the purchase price,

free of charge repair, or replacement of a defective product whic h i s returned to a Fluke

authorized service cent er wi thin the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center or s end

the product, with a descri pt i on of the difficulty, postage and insurance prepaid (FOB Destination), to the nearest Fl uk e authorized service center. Fl uke assumes no risk for dam age in transit. Following warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destinati on). If Fluke determines that the failure was caused by

misuse, alteration, accident or abnormal condition of operat i on or handl i ng, Fluke will

provide an estimate of repair c osts and obtain authorization before commencing the

work. Following repair, the product will be returned to the Buyer transportation prepaid

and the Buyer will be billed for the repair and return transportat i on c harges (FOB Shipping Point).

THIS WARRANTY IS BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO ANY IMPLIED WARRANTY OF MERCHANTAB I LITY OR FITNESS FOR A

PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL,

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING

LOSS OF DATA, WHETHER ARISING FROM BREACH OF WARRANTY OR BASED

ON CONTRACT, TORT, RELIANCE OR ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an impli ed warranty,

or exclusion or limitation of incidental or consequent i al dam ages, the limitations and exclusions of this warranty may not apply to every buyer. If any provision of this Warranty

is held invalid or unenforceable by a court of competent jurisdiction, such holding will not

affect the validity or enforceability of any other provision.

5/94

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090 P.O. Box 1186

Everett, WA 98206-9090 5602 BD Eindhoven

U.S.A. The Netherlands

Page 3

Table of Contents

Chapter Title Page

1 Introduction ................................................................................ 1-1

1-1. Introduction .................................................................................. 1-1

1-2. Design Highlights......................................................................... 1-2

1-3. Safety Information ........................................................................ 1-3

1-4. Software Revision......................................................................... 1-3

1-5. Self Test........................................................................................ 1-3

1-6. Supplied Equipment...................................................................... 1-4

1-7. Toolpak Accessory Kit.................................................................. 1-5

1-8. View Angle Adjustment................................................................ 1-6

1-9. Accessories................................................................................... 1-6

1-10. Cleaning........................................................................................ 1-6

1-11. Environmental............................................................................... 1-6

1-12. Manual.......................................................................................... 1-6

2 Overview ..................................................................................... 2-1

2-1. Introduction .................................................................................. 2-1

2-2. Power............................................................................................ 2-1

2-3. Primary And Reference T1 Receivers........................................... 2-1

2-4. Controls ........................................................................................ 2-2

2-5. ON/OFF Switch........................................................................ 2-2

2-6. RESULTS Keys........................................................................ 2-5

2-7. BPV Error/Frame Err............................................................ 2-5

2-8. CRC Error/Bit Error.............................................................. 2-6

2-9. DS1 Freq/Clk Slips............................................................... 2-7

2-10. E-Bit Sync............................................................................. 2-8

2-11. DS1 Level (volts, peak-to-peak)/DS1 Level (dBDSX)......... 2-8

2-12. DS0 Freq/DS0 Level............................................................. 2-9

2-13. FT1 (Fractional T1)............................................................... 2-10

2-14. DTMF ................................................................................... 2-10

2-15. RESTART Key......................................................................... 2-11

2-16. TEST MODE Key..................................................................... 2-11

2-17. SIGNALING TYPE Key........................................................... 2-12

2-18. TX CLK SOURCE Key (QuickBERT-T1 only)....................... 2-12

2-19. LOOP CODE Key (QuickBERT-T1 only)................................ 2-12

2-20. CSU....................................................................................... 2-14

2-21. NIU4, NIU5 .......................................................................... 2-14

i

Page 4

635/633

Users Manual

2-22. NTWRK ............................................................................... 2-14

2-23. LINE..................................................................................... 2-14

2-24. PYLD ................................................................................... 2-14

2-25. ARM (ADTRAN)................................................................. 2-15

2-26. HTU-R (ADTRAN).............................................................. 2-15

2-27. HTU-C (ADTRAN).............................................................. 2-15

2-28. HRE1 (ADTRAN)................................................................ 2-15

2-29. HRE2 (ADTRAN)................................................................ 2-15

2-30. NREM (PairGain)................................................................. 2-15

2-31. NLOC (PairGain) ................................................................. 2-15

2-32. NDU1 (PairGain).................................................................. 2-15

2-33. NDU2 (PairGain).................................................................. 2-15

2-34. CREM (PairGain)................................................................. 2-16

2-35. CLOC (PairGain).................................................................. 2-16

2-36. CDU1 (PairGain).................................................................. 2-16

2-37. CDU2 (PairGain).................................................................. 2-16

2-38. FT1 CHANNEL SELECT Key................................................. 2-16

2-39. CHANNEL UP/DOWN Keys................................................... 2-16

2-40. ERROR INJECT Keys (QuickBERT-T1 only) ........................ 2-17

2-41. SEND LOOP UP/DOWN Keys (QuickBERT-T1 only)........... 2-17

2-42. RX INPUT Key........................................................................ 2-17

2-43. TX PATTERN Key (QuickBERT-T1 only)............................. 2-18

2-44. QRSS.................................................................................... 2-18

2-45. 1 IN 7.................................................................................... 2-19

2-46. 2 IN 8.................................................................................... 2-19

2-47. 3 IN 24.................................................................................. 2-19

2-48. ALL 0’S ................................................................................ 2-19

2-49. ALL 1’S ................................................................................ 2-19

2-50. 1:1......................................................................................... 2-19

2-51. NET55.................................................................................. 2-19

2-52. OCT55.................................................................................. 2-20

2-53. DALY55............................................................................... 2-20

2-54. USER.................................................................................... 2-20

2-55. THRU................................................................................... 2-21

2-56. TX LINE CODE Key (QuickBERT-T1 only).......................... 2-21

2-57. TX FRAME Key (QuickBERT-T1 only) ................................. 2-22

2-58. Volume Control........................................................................ 2-22

2-59. Indicators...................................................................................... 2-22

2-60. Errors LEDs.............................................................................. 2-22

2-61. Data Bits LEDs......................................................................... 2-22

2-62. Signaling Bits LEDs................................................................. 2-23

2-63. Rx Status/History LEDs........................................................... 2-23

2-64. AMI and B8ZS/HISTORY LEDs......................................... 2-23

2-65. SIGNAL PRESENT/HISTORY LEDs................................. 2-24

2-66. OUT OF FRAME/HISTORY LEDs..................................... 2-24

2-67. BLUE ALARM (AIS)/HISTORY LEDs.............................. 2-24

2-68. ONES DENSITY/HISTORY LEDs..................................... 2-25

2-69. EXCESS ZEROS/HISTORY LEDs..................................... 2-25

ii

Page 5

Contents

2-70. YELLOW ALARM/HISTORY LEDs.................................. 2-26

2-71. DS1 IDLE SIGNAL/HISTORY LEDs.................................. 2-26

2-72. PATTERN SYNC LOSS/HISTORY LED............................ 2-26

2-73. Error Inject LEDs (QuickBERT-T1 only)................................. 2-27

2-74. Receive Loop Up/Down LEDs (QuickBERT-T1 only) ............ 2-27

2-75. Send Loop Up/Down LEDs (QuickBERT-T1 only)................. 2-27

2-76. Rx Input LEDs.......................................................................... 2-27

2-77. Pattern LEDs............................................................................. 2-27

2-78. Tx Line Code LEDs (QuickBERT-T1 only)............................. 2-28

2-79. Frame LEDs.............................................................................. 2-28

2-80. Low Battery LED...................................................................... 2-28

2-81. BATTERY SAFE MODE............................................................. 2-29

2-82. BATTERY PACK......................................................................... 2-29

3 Operation .................................................................................... 3-1

3-1. Introduction .................................................................................. 3-1

3-2. Automatic Evaluation................................................................... 3-1

3-3. Framing Evaluation................................................................... 3-1

3-4. Pattern Evaluation..................................................................... 3-2

3-5. Line Code Evaluation ............................................................... 3-2

3-6. Evaluating Live Traffic................................................................. 3-2

3-7. Capturing and Displaying DTMF Digits....................................... 3-6

3-8. Performing a BIT Error Rate Test (BERT)

(Quick BERT-T1 only)................................................................. 3-7

3-9. Performing Fractional T1 BERT................................................... 3-9

3-10. Performing Clock-Slip Measurements.......................................... 3-11

Appendices

A Specifications.................................................................................. A-1

Index

(continued)

iii

Page 6

635/633

Users Manual

iv

Page 7

List of Tables

Table Title Page

2-1. Loop Code Types............................................................................... 2-13

2-2. Signaling Bits Displayed Based on Framing and Signaling Type...... 2-23

A-1. Mechanical Specifications................................................................. A-1

A-2. Electrical Specifications..................................................................... A-2

v

Page 8

635/633

Users Manual

vi

Page 9

List of Figures

Figure Title Page

1-1. QuickBERT-T1 Test Set.................................................................... 1-1

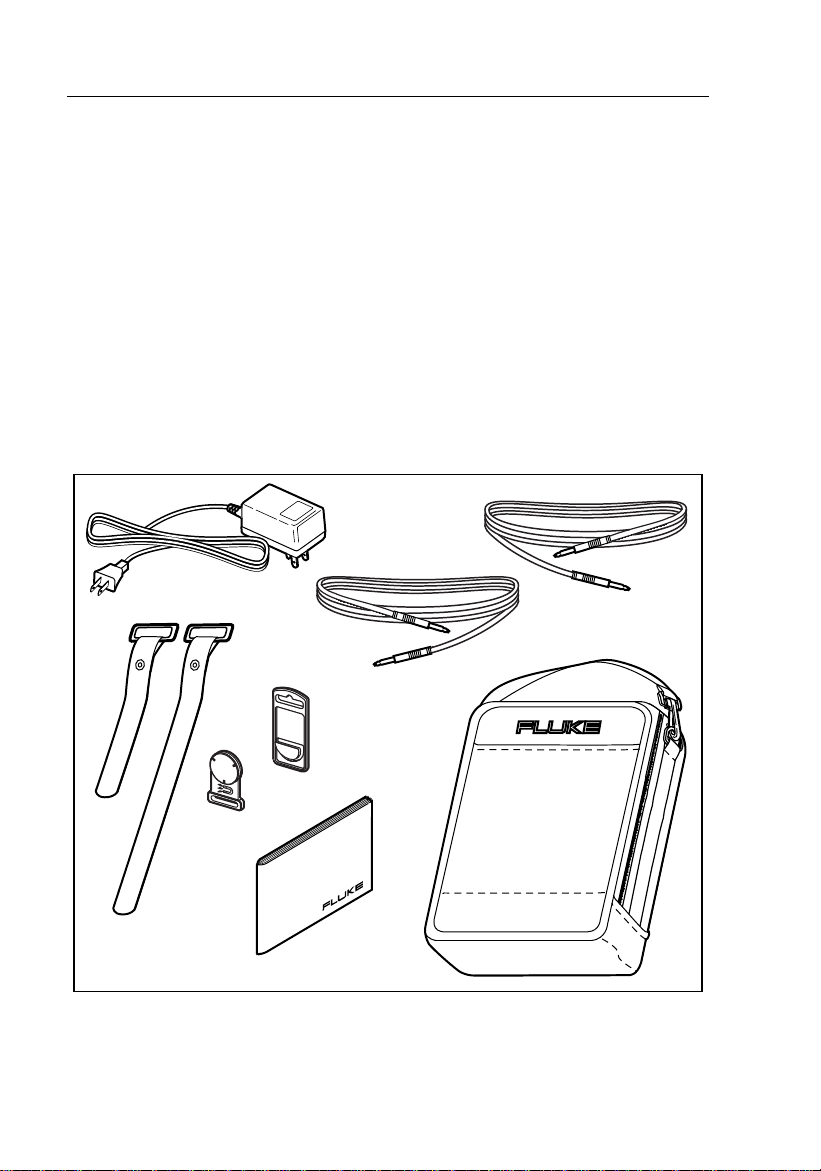

1-2. Supplied Equipment........................................................................... 1-4

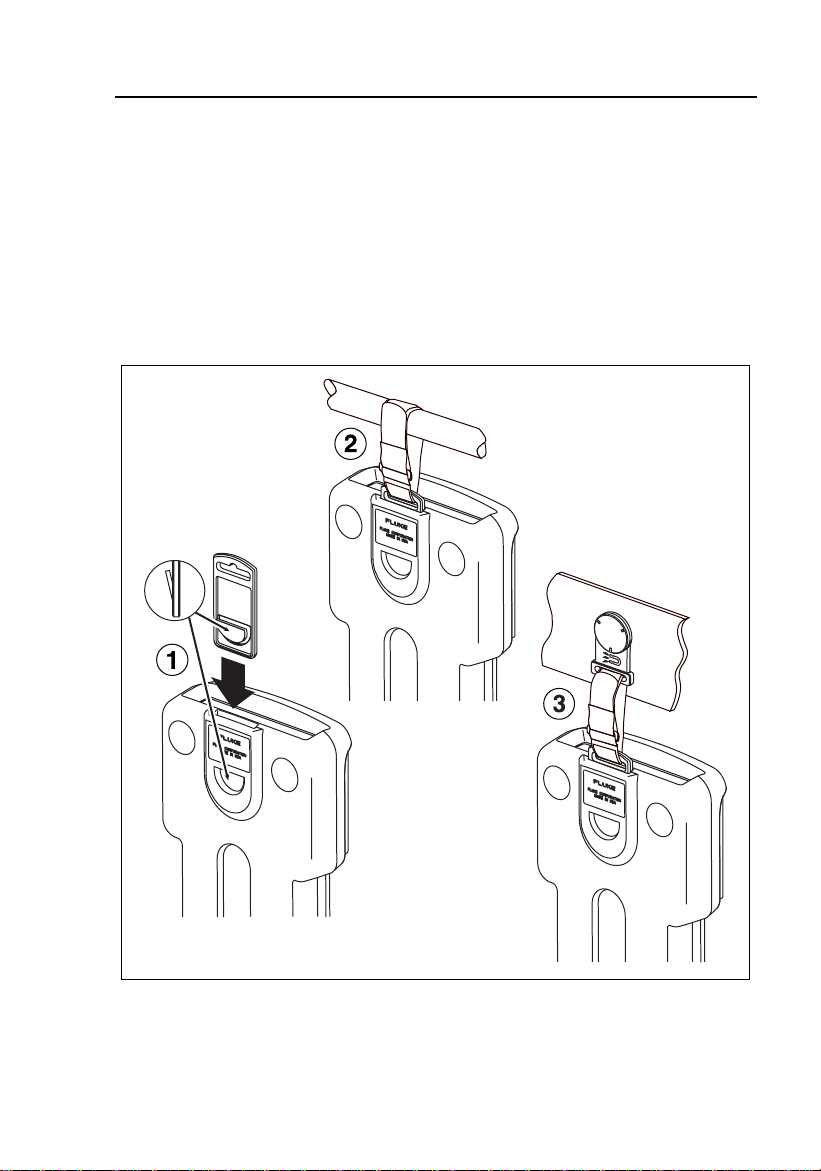

1-3. ToolPak Accessory Kit ...................................................................... 1-5

2-1. QuickBERT-T1 Front Panel.............................................................. 2-3

2-2. QuickCHECK-T1 Front Panel........................................................... 2-4

3-1. Live-Traffic Monitoring..................................................................... 3-3

3-2. Capturing and Displaying DTMF Digits............................................ 3-6

3-3. Performing an Out-of-Service BERT................................................. 3-7

3-4. Performing an End-to End, Out-of-Service BERT ............................ 3-9

3-5. Clock-Slip Measurements.................................................................. 3-11

vii

Page 10

635/633

Users Manual

viii

Page 11

Chapter 1

Introduction

1-1. Introduction

This chapter of the manual contains general information about the Fluke 635

QuickBERT-T1 and 633 QuickCHECK-T1. These units are compact,

handheld, fully-featured T1 test sets designed to thoroughly verify the

performance parameter of a T1 facility.

LOW BATTERY

RESULTS

ERRORS

BIT ERR

BPV ERR

FRM ERR

635 QUICKCHECK - T1

CRC ERR

FREQDEV

RESTART

SIGNALING

TEST

MODE

LOOP

CODE

TxClk

SOURCE

DATA BITS

1234

CHANNEL

5678

SIGNALING BITS

ABCD

FT1 CHANNEL

SELECT

Rx STATUS

AMI

B8ZS

SIGNAL PRESENT

OUT OF FRAME

BLUE ALARM (AIS)

ONES DENSITY

EXCESS ZEROS

TYPE

Figure 1-1. QuickBERT-T1 Test Set

PATTERN

QRSS

YELLOW ALARM

DS1 IDLE SIGNAL

PATTERN SYNC LOSS

HISTORY

1 IN 7

2 IN 8

3 IN 24

ERROR INJECT

LOGIC

ALL 0'S

ALL 1'S

BPV FRAME

RECEIVE

1 : 1

NET55

OCT55

DALY55

USER

LOOP UP LOOP DOWN

SEND

DSX

MON

THRU

RX

Rx INPUT

TX

Tx LINE CODE

AMI

BRDG

TERM

B8ZS

FRAME

NONE

D4

TX

ESF

SLC96

RX

abn05f.eps

1-1

Page 12

633/635

Users Manual

1-2. Design Highlights

The QuickBERT-T1 and QuickCHECK-T1 are designed to allow users to

easily analyze and correct the common problems arising in T1 networks.

Experienced and inexperienced users alike can determine the integrity,

configuration parameters, and general performance of a T1 circuit when using

these units. Features include the following.

•

Is handheld and battery powered

•

Transmits all standard T1 bit error rate test (BERT) patterns and loop

codes (QuickBERT-T1 only)

•

Transmits HDSL loop codes (QuickBERT-T1 only)

•

Has the ability to insert logic, BPV, and frame bit errors (QuickBERT-T1

only)

•

Performs BERT and Fractional T1 BERT (Nx56 and Nx64)

•

Captures and displays DTMF digits

•

Measures DS1 frequency, level, and clock slips

•

Displays standard T1 alarms

•

Displays major T1 performance parameters

•

Displays AMI or B8ZS line coding

•

Measures DS 0 level and frequency

•

Monitors voice using internal speaker (or headset)

•

Displays DS0 data and signaling bits

•

Automatically synchronizes to and displays the T1 framing type, line

coding, and BERT pattern

1-2

Page 13

Introduction

Safety Information

1-3. Safety Information

W Warnings and Precautions

To avoid possible electric shock or personal injury, and to

avoid possible damage to the Test Set or to the equipment

under test, follow these guidelines:

•

Before using the Test Set inspect the case. Do not use the Test Set if it is

damaged.

•

Inspect the test cables for damaged in sulation or exposed metal. Check the

cables for continuity. Replace damaged test cables, before using the Test

Set.

•

Do not operate the Test Set around explosive gas, vapor, or dust.

•

Do not operate the Test Set with the case (or part of the case) removed.

•

Recharge the battery as soon as the low battery indicator appears. With a

low battery, the Test Set might produce false readings.

•

When servicing the Test Set, use only specified replacement parts.

1

1-4. Software Revision

To view the software revision number and the date of release, press and hold

RESTART

the

key while powering up the unit.

1-5. Self Test

After the startup screen, a self test will activate and the version build date will

be displayed. To perform an LED test, press and hold the

while powering up the unit.

RX INPUT

key

1-3

Page 14

633/635

Users Manual

1-6. Supplied Equipment

The QuickBERT-T1 and QuickCHECK-T1 come with the following items.

•

Carrying case

•

ToolPak

•

A/C power adapter

•

Two bantam-to-bantam cables

•

Users manual

•

Trimmer tool (used to adjust display view angle)

The 635-1 version of the QuickBERT-T1 also comes with a cable kit, which

includes the following items.

•

Two bantam-to-310 cables

•

Two bantam-to-alligator clip cables

•

One bantam-to-RJ48 cable.

TM

Accessory Kit

A/C Power Adapter

Bantam-toBantam Cables

1-4

ToolPack

Users Manual

Figure 1-2. Supplied Equipment

Carrying Case

abn01f.eps

Page 15

Introduction

Toolpak Accessory Kit

1-7. Toolpak Accessor y Kit

The QuickBERT-T1 and QuickCHECK-T1 come with a ToolPak accessories

kit. This kit includes a universal hanger, hook-and-loop straps, and a magnet.

The universal hanger attaches to the unit and can be used by itself on a nail or

hook, with a piece of rope or stiff wire. Two hook-and-loop straps are used

with the universal hanger and can be wrapped around a pipe or beam. The

ToolPak’s magnet is used with the universal hanger and is strong enough to

securely hold the test set.

Hanger inserts

into slot with tab

extension facing

out, for proper use.

1

Figure 1-3. ToolPak Accessory Kit

abn03f.eps

1-5

Page 16

633/635

Users Manual

1-8. View Angle Adjustment

VIEW ANGLE

The

recessed control used to vary the display’s view angle.

In order to prevent damage to the test set, use only an isulated, flat-

bladed tool to adjust the display’s view angle.

control, located on the top panel of the test set, is a

Note

1-9. Accessories

Additional cables and headsets for use with the Q uickBERT-T1 and

QuickCHECK-T1 are available from Fluke Corporation. For information,

please contact customer service at 888-993-5853.

1-10. Cleaning

When cleaning the display surface, use a soft cloth (such as a gauze) with mild

soap and water.

1-11. Environmental

Do not exceed the operating temperature limits of 32° to 122° F. Protect your

unit from exposure to direct sunshine or high temperature/humidity for

prolonged periods of time. These conditions may cause degradation to t he

display.

1-12. Manual

This manual is arranged so you can quickly and easily find the information you

need. The following is an overview of the contents of this manual.

•

Chapter 1, Introduction, familiarizes you with QuickBERT-T1 and

QuickCHECK-T1 highlights.

• Chapter 2, Overview, describes the QuickBERT-T1 and QuickCHECK-T1

controls, indicators, and connectors.

• Chapter 3, Operation, provides common test i nstructions.

1-6

Page 17

Introduction

Manual

•

Appendix A, Specifications, provides the specifications of the

QuickBERT-T1 and QuickCHECK-T1.

References to front panel keys are designated in upper case bold letters.

1

1-7

Page 18

633/635

Users Manual

1-8

Page 19

Chapter 2

Overview

2-1. Introduction

This chapter of the manual contains information to familiarize you with

QuickBERT-T1 and QuickCHECK-T1 controls and indicators. Refer to

Appendix A for test set specifications. Figure 2-1 and 2 -2 illustrate all control

and indicator locations.

2-2. Power

The primary power source for the QuickBERT-T1 and QuickCHECK-T1 is a

rechargeable, NiMH (nickel metal hydride) battery pack. An auxiliary power

connector is available for use with an A/C power adapter (which is provided

with the unit). The

jack and the RX bantam jack on the top panel of the unit. During battery

operation, the LOW BATTERY LED will illumi nate to indicate that the

battery pack has nearly exhausted its charge and that the test set should be

recharged.

If the test set is not turned off before the battery is co mpletely

exhausted, the unit will shut down to prevent battery damage. If this

occurs, the unit will resume normal operation once recharge is

performed.

ON/OFF

switch is located between the power (9 VDC)

Note

2-3. Primary And Reference T1 Receivers

The QuickBERT-T1 and QuickCHECK-T1 are equipped with two T1

receivers: primary (Rx) and reference (REF). The test set performs analysis on

the signal present at the Rx receiver. The REF receiver provides the clock

reference for performing clock-slip measurements.

On the QuickBERT-T1, the REF receiver functions as the transmit clock

source when external (EXT) clock is selected. For additio nal information on

clock-source selection, see section 2-18.

2-1

Page 20

633/635

Users Manual

RX INPUT

The

connection from a T1 line to the RX jack, the

appropriately. For additional information on the

settings, see section 2-42.

A bantam jack is provided for the REF T1 receiver. This jack is automatically

terminated by the test set.

key is provided for the Rx T1 receiver. Before making a

RX INPUT

RX INPUT

key should be se t

key and its

2-4. Controls

The QuickBERT-T1 is equipped with 19 pushbutton keys and one switch. The

TX PATTERN, TX LINE CODE

RESTART

The QuickCHECK-T1 is equipped with 9 pushbutton keys and one switch. The

RESTART

The following is a list of the controls which are defined in sections 2-5 through

2-58. An asterisk is placed next to those controls that are only applicable to the

QuickBERT-T1. The remaining controls are included on both units.

key is red. All remaining pushbutton keys are black.

key is red. All remaining pushbutton keys are black.

ON/OFF Switch CHANNEL UP/DOWN Keys

RESULTS Keys ERROR INJECT Keys*

TX FRAMING

, and

keys are yellow. The

RESTART Key SEND LOOP UP/DOWN Keys*

TEST MODE Key RX INPUT Key

SIGNALING TYPE Key TX PATTERN Key*

TXCLK SOURCE Key* TX LINE CODE Key*

LOOP CODE Key* TX FRAME Key*

FT1 CHANNEL SELECT Key Volume Control

2-5. ON/OFF Switch

This switch is located on the top panel of the test set and is used to apply and

remove power from the unit.

2-2

Page 21

ERRORS

BIT ERR

BPV ERR

FRM ERR

CRC ERR

FREQDEV

RESTART

635 QUICKBERT - T1

TEST

SIGNALING

MODE

DATA BITS

1234

SIGNALING BITS

ABCD

Rx STATUS PATTERN

AMI

B8ZS

SIGNAL PRESENT

OUT OF FRAME

BLUE ALARM (AIS)

ONES DENSITY

EXCESS ZEROS

YELLOW ALARM

DS1 IDLE SIGNAL

PATTERN SYNC LOSS

HISTORY

ERROR INJECT

LOGIC

BPV FRAME

LOOP UP LOOP DOWN

RECEIVE

SEND

Rx INPUT

DSX

MON

TYPE

CHANNEL

5678

TERM

BRDG

TxClk

SOURCE

FT1 CHANNEL

SELECT

QRSS

1 IN 7

2 IN 8

3 IN 24

ALL 0'S

ALL 1'S

1 : 1

NET55

OCT55

DALY55

USER

THRU

RX

Tx LINE CODE

AMI

FRAME

NONE

D4

ESF

SLC96

RX

LOOP

CODE

B8ZS

LOW BATTERY

TX

TX

RESULTS

Overview

Controls

2

Figure 2-1. QuickBERT-T1 Front Panel

abn02f.eps

2-3

Page 22

633/635

Users Manual

ERRORS

BIT ERR

BPV ERR

FRM ERR

CRC ERR

FREQDEV

RESTART

633 QUICKCHECK - T1

TEST

SIGNALING

MODE

TYPE

CHANNEL

DATA BITS

12345678

SIGNALING BITS

ABCD

Rx STATUS PATTERN

AMI

B8ZS

SIGNAL PRESENT

OUT OF FRAME

BLUE ALARM (AIS)

ONES DENSITY

EXCESS ZEROS

YELLOW ALARM

DS1 IDLE SIGNAL

PATTERN SYNC LOSS

HISTORY

FT1 CHANNEL

SELECT

QRSS

1 IN 7

2 IN 8

3 IN 24

ALL 0'S

ALL 1'S

1 : 1

NET55

OCT55

DALY55

RX

LOW BATTERY

RESULTS

2-4

FRAME

NONE

D4

DSX

MON

Rx INPUT

TERM

BRDG

ESF

SLC96

RX

Figure 2-2. QuickCHECK-T1 Front Panel

abn04f.eps

Page 23

Overview

Controls

2

2-6. RESULTS Keys

These keys are used to scroll through the paired results parameters that appear

on the display screen. To go from one pair of results to the next, use the

RESULTS UP/DOWN

BPV Error 0

Frame Err 0

T1 RB Int CSU

The five Error LEDs will illuminate solid if currently detecting an error and

will flash to indicate an error has previously been detected but is not currently

being detected (history). Sections 2-7 through 2-14 provide detailed

descriptions of the paired parameters.

keys (located to the right of the display screen).

abn06f.eps

2-7. BPV Error/Frame Err

BPV Error 0

Frame Err 0

T1 RB Int CSU

abn07f.eps

BPV Error

The test set records a bipolar violation (BPV) if it detects a vio lation of the

alternate mark inversion (AMI) line-coding scheme (that is standard for T1

transmission). BPVs are recorded if the T1 signal is live traffic or a B ERT

pattern. The red BPV ERR LED will illuminate solid to indicate a BPV error is

present and will flash to indicate a history of BPV errors.

Frame Err

The test set automatically synchronizes with D4, ESF, o r SLC¨96 framing.

When frame synchronization is achieved, the proper green Frame LED will

illuminate. The unit will now register a ny errors that occur in the framing bit

sequence (as defined for that particular framing format). Frame errors are

recorded if the T1 signal is live traffic or a BERT pattern. The red FRM ERR

2-5

Page 24

633/635

Users Manual

LED will illuminate solid to indicate a frame error is present and will flash to

indicate a history of frame errors.

2-8. CRC Error/Bit Error

BPV Error 0

Frame Err 0

T1 RB Int CSU

abn07f.eps

CRC Error

If the test set establishes frame sync with an ESF-framed signal, it will detect

and count cyclic redundancy check (CRC) errors. The CRC is a check-sum

message that is transmitted in the facility data link (FDL) associated with ESF

framing. The red CRC ERR LED will illuminate solid to indicate a CRC erro r

is present and will flash to indicate a history of CRC errors.

Bit Error

In order to record a bit error, the test set has to be synchronized with a test

pattern. Therefore, bit errors are registered only if a BERT pattern is present.

Pattern synchronization is indicated by the green Pattern LEDs. Each time the

unit detects an errored bit in the pattern it is receiving, one bit error is recorded.

The red BIT ERR LED will illuminate solid to indicate a bit error is present

and will flash to indicate a history of bit errors.

2-6

Page 25

Overview

Controls

2

2-9. DS1 Freq/Clk Slips

DS1 Freq 1544000Hz

Clk Slips 0

T1 RB Int CSU

abn09f.eps

DS1 Freq

When the DS1 frequency result is selected (using the RESULTS keys), the test

set displays the frequency (in Hz) of the DS1 signal. If the DS1 frequency

deviates from the nominal (1.544 MHz ± 50 Hz), the red FREQDEV LED

illuminates to indicate that a DS1 frequency deviation is occurring. A

frequency deviation of greater than ± 50 Hz indicates that the clock source is

becoming unstable and has an unacceptable variation.

Clk Slips

In order for a T1 circuit to perform properly, the TX clock (from the CPE)

must be synchronized with the receive clock (from the central office). If a

variation of these clocks exists, errors will result. The clock-slip parameter is

used to verify clo ck synchroniza tion. The test setup for a clock-sli p

measurement between the Tx and Rx side of a T1 span is described in section

3-10 of this manual.

Timing tests may also be performed to either side of the span when a T1

reference clock (stratum) is used. If a bipolar clock or a T1 signal is present at

both the REF and RX receivers, the test set compares the two inputs and

declares clock slips (if they are out of phase). If an external reference clock is

not available, the unit will automatically compare the receiver clock to the

internal, 5-ppm, 1.544-MHz clock source.

Clock slips is a loop-timing parameter that shows the total number of clock

counts that the reference and receiver clocks have deviated from since the test

began (or from the last restart). A positive number indicates that the reference

clock is faster than the receive clock. A negative number indicates that the

receive clock is faster than the reference clock.

2-7

Page 26

633/635

Users Manual

Note

If no reference clock measurement is being made, remove the plug

from the REF jack to extend battery life.

2-10. E-Bit Sync

E-Bit Sync Yes

T1 E-Bit Int CSU

abn10f.eps

If E-Bit is the selected signaling type (chosen with t he

SIGNALING TYPE

key), the E-Bit Sync results screen will display Yes or No to indicate whether

or not the span is in E-Bit sync. If E-Bit is not the selected signaling type, the

E-Bit Sync results screen is not accessible.

2-11. DS1 Level (volts, peak-to-peak)/DS1 Level (dBDSX)

DS1 Level 6.00vp-p

DS1 Level 0.00dBD

T1 RB Int CSU

abn10f.eps

DS1 Level (volts, peak-to-peak)

When monitoring an in-service span, it may be useful to read the level o f the

T1 signal in volts, peak-to-peak; therefore, the DS1 level may be viewed both

in dBDSX and volts, peak-to-peak. See section 3-6.

2-8

Page 27

DS1 Level (dBDSX)

Overview

Controls

2

When the DS1 level result is selected (using the

displays the level of the DS1 signal in dBDSX. A DS1 signal is transmitted at

a 0 dBDSX level. The reading, therefore, indicates the loss (in dB) from the

point of transmission to the point of measurement.

RESULTS

keys), the test set

2-12. DS0 Freq/DS0 Level

DS0 Freq 1004.0Hz

DS0 Level 0.0dBm

T1 RB Int CSU

abn12f.eps

DS0 Frequency

DS0 frequency is a measurement of the analog frequency for the DS0 that is

currently being monitored. For example, a test tone that is being received (in

the selected DS0) will be measured and the received frequency will be

displayed. The test set demodulates the digitally-encoded signal on t he selected

channel and presents it through the speaker (and the headset jack). If the DS0

frequency result is selected (using the

analog signal present on the channel i s displayed in Hz. (This result display is

only available if a channel has been selected for monitoring.)

RESULTS

keys), the fr equency of the

DS0 Level

DS0 level is a measurement of the analog signal level for the DS0 that is

currently being monitored. For example, a test tone that is being received will

be measured and the received level (or amplitude) will be displayed. The test

set demodulates the digitally-encoded signal on the selected channel and drops

the channel to the speaker (and the headset jack). If the DS0 level result is

selected (using the

dBm. If you know the level at which the tone signal is inserted, the insertion

loss of the channel may be determined. (This result display is only available if

a channel has been selected for monitoring.)

RESULTS

keys), the level of the signal is displayed in

2-9

Page 28

633/635

Users Manual

Note

The test set develops the analog signal level from the decoded digital

signal. Therefore, the isolation resistors at a DSX monitor jack do not

affect eh DSO-level reading. See the note under step 7b in section 3-6.

2-13. FT1 (Fractional T1)

FT1 01 02 03 04 05

06 07 08 09 10 11 12

F64 CCIS Rx CSU

abn13f.eps

If F64 or F56 is selected as the test mode, you can view the Fractional T1

channels (01-24) on the FT1 results screens. There are two FT1 results screens:

one with channels 01-12 and one with channels 13-24. The selected channel(s)

will blink. For information on how to select channels for Fractional T1, see

section 2-38.

2-14. DTMF

DTMF - - No Digits - -

F64 CCIS Rx CSU

abn14f.eps

The DTMF results screen allows you to view DTMF digits for a selected

channel. For information on how to capture and display DTMF digits, see

section 3-7. (This result display is only available if a channel has been selected

for monitoring.)

2-10

Page 29

Overview

Controls

2-15. RESTART Key

Bit errors, BPV errors, CRC errors, frame errors, clock slip s, and errored

seconds are cleared to "0" when the

results is being displayed when the

to be displayed, but "0" will be displayed until an error of that type occurs.

Any red Error LEDs that are flashing (to indicate errors of that type) will be

turned off when the

are cleared when the

Always press the RESTART key after connecting the test set to the

line under test. The unit might detect invalid errors when first

connected due to receiver sensitivity.

RESTART

RESTART

RESTART

RESTART

key is pressed. All Status and History LEDs

key is pressed.

Note

key is pressed. If one of these

key is pressed, it will continue

2

Pressing the

Bits LEDs, Signaling Type LEDs, LOW BATTERY LED, or Channel

Selection display. In addition, pr essing the

to enter the auto-evaluate mode (see section 3 -2 for ad ditional information on

automatic evaluation).

RESTART

key does not af fect the Signalin g Bits LEDs, Data

RESTART

key causes the test set

2-16. TEST MODE Key

TEST MODE

The

(fractional T1, 64k), or F56 (fractional T1, 56k). W hen the T1 mode is

selected, you can perform a T1 in-service or out-of-service BERT. For both the

F64 and F56 test modes, the receiver performs T1 in-service or out-of-service

testing on only the active channels and ignores the data on all other channels.

When F64 mode is selected, all 8 bits in each active channel are used by the

receiver for BERT. When the F56 mode is selected, only the first 7 bits in each

active channel are used by the receiver for BERT.

The transmitter (QuickBERT-T1 only) sends the BERT pattern on the active

channel(s). The received signal is simply passed through in the inactive

channels and if there is not a received signal present, the inactive channels are

filled with idle code (FF Hex). (Channels can be selected with the

CHANNEL SELECT

key allows you to select one of three test modes: T1, F64

FT1

key.)

2-11

Page 30

633/635

Users Manual

2-17. SIGNALING TYPE Key

When the test set is in frame sync, either the D4, ESF, or SLC96 green

Framing LED illuminates. For further analysis, the unit provides the abilit y to

view the state of the signaling bits and data bits for a selected DS0 channel.

There are four yellow Signaling Bits LEDs provided for this purpose (A, B, C,

D). The D4 and SLC96 framing modes make provision for two signaling bits

(A, B). The ESF framing mode makes provisio n for four signaling bits (A, B,

C, D). In order to display the state of the signaling bits, the test set must be set

up for the proper signaling format (robbed bit, CCIS, or E-Bit) being used on

the T1 line under test.

The robbed bit (RB) scheme uses "robbed" data bits to transmit the signaling

states. In common channel interoffice signaling (CCIS), a complete channel

(DS0) is used to transmit signaling bits, thu s leaving the eight data bits

available to transmit data (clear channel). The E-Bit selection is p r ovided to

define a proprietary common channel signaling scheme.

2-18. TX CLK SOURCE Key (QuickBERT-T1 only)

This key is used to select one of three transmit clock sources: Rx (recovered),

Int (internal), and Ext (external). When Rx is selected, the QuickBERT-T1

recovers the clock from the received bit stream and uses the received clock as

the timing element for the transmit data. When Int is selected, the 1.544 MHz

internal oscillator is used to clock the transmitter. When Ext is selected, the

QuickBERT-T1 recovers the bipolar clock from the external clock that is

applied to the REF bantam jack and uses this clock as the transmit timing

element.

2-19. LOOP CODE Key (QuickBERT-T1 only)

This key is used to select the type of loop code to be transmitted by the

QuickBERT-T1. See Table 2-1 for a list of the codes transmitted by the

QuickBERT-T1 when the corresponding selections are made and the

LOOP UP

either ADTRAN, Inc. or PairGain Technologies, Inc. loop codes. Sections 2-20

through 2-37 provide detailed descriptions of the loop-code types.

2-12

SEND LOOP DOWN

or

key is pressed. The HDSL loop codes are

SEND

Page 31

Table 2-1. Loop Code Types

Overview

Controls

2

Loop Code

Loop-Up Code Loop-Down Code

Type

CSU 10000 (IN-BAND) 100 (IN-BAND)

NIU4 1100 (IN-BAND) 1110 (IN-BAND)

NIU5 11000 (IN-BAND) 11100 (IN-BAND)

NTWRK (ESF) 11111111010010 00 (OU T-B AN D ) 11111111001001 00 (OU T-B AN D )

LINE (D4) 10000 (IN-BAND) 100 (IN-BAND)

LINE (ESF) 1111111101110000 (OUT-BAND) 1111111100011100 (OUT-BAND)

PYLD (ESF) 11111111001010 00 (OU T-B AN D ) 11111111010011 00 (OU T-B AN D )

ARM 11000 (IN-B AN D) 11100 (IN-BAN D)

HTU-R 11000111010000 10 (IN-B AN D ) 10010011100100 11 (IN-B AN D )

HTU-C 11010011110100 11 (IN-B AN D ) 10010011100100 11 (IN-B AN D )

HRE1 11000111010000 01 (IN-B AN D ) 10010011100100 11 (IN-B AN D )

HRE2 11000111010101 00 (IN-B AN D ) 10010011100100 11 (IN-B AN D )

NREM 11111111000000 10 (IN-B AN D ) 11100 (IN-BAND)

NLOC 11111111000111 10 (IN-B AN D ) 11100 (IN-BAND)

NDU1 1111111100000100 (IN-BAND) 11100 (IN-BAND)

NDU2 1111111100000110 (IN-BAND) 11100 (IN-BAND)

CREM 00111111000111 10 (IN-B AN D ) 11100 (IN-BAND)

CLOC 00111111000000 10 (IN-B AN D ) 11100 (IN-BAND)

CDU1 0011111100000100 (IN-BAND) 11100 (IN-BAND)

CDU2 0011111100000110 (IN-BAND) 11100 (IN-BAND)

2-13

Page 32

633/635

Users Manual

2-20. CSU

This selection is made to loop up/down a CSU, typically on the far end of a T1

span (see Chapter 3).

2-21. NIU4, NIU5

This selection is made to loop an NIU. The NIU (sometimes called smart jack)

is part of the network equipment and belongs to the service provider. Most

modern NIUs respond to the NIU5 code. Older NIUs only respond to the NIU4

code.

2-22. NTWRK

This selection is only valid in ESF framing. The NTWRK loop code is

transmitted "out of band" (in the facilit y data link (FDL) of the ESF signal).

The distant ESF CSU will respond by looping the DS1 signal back at a point

that includes the entire CSU. The NTWRK loop code may be used in

conjunction with the LINE loop code to determine whether a fault exists in the

facility or the CSU. In order to activate the NTWRK loop code, ESF framing

must be selected (using the

TX FRAME

key).

2-23. LINE

If ESF framing and LINE loop code are selected, pressing the

UP

SEND LOOP DOWN

or

the FDL of the ESF signal). The distant ESF CSU will respond by looping the

entire DS1 signal at a point that does not include the CSU circuitry. The LINE

loop code may be used in conjunction with the NTWRK loop code to

determine whether a fault exists in the facility or the CSU. The LINE loop

code may also be sent in band when D4 framing is selected.

key will transmit LINE code "out of band" (in

SEND LOOP

2-24. PYLD

If ESF framing and PYLD loop code are selected, pressing the

UP

SEND LOOP DOWN

or

(in the FDL of the ESF signal). The distant ESF CSU will respond by looping

only the payload (the customer data) of the ESF signal. The FDL will not be

looped back, as with the NTWRK or the LINE loop codes. Because the FDL

isregenerated at the distant CSU, the PYLD loop code is useful in determining

which side of a T1 facility is faulty.

2-14

key will transmit the PYLD code "out of band"

SEND LOOP

Page 33

2-25. ARM (ADTRAN)

Overview

Controls

2

When ARM is selected and the

ADTRAN HDSL equipment is armed, enabling the HDSL elements to be

looped. When ARM is selected and the

all ADTRAN HDSL equipment is disarmed.

SEND LOOP UP

SEND LOOP DOWN

key is pressed, all

key is pressed,

2-26. HTU-R (ADTRAN)

This selection causes the HTU-R (remote-end HDSL unit) to transition from an

armed state to a loopback state.

2-27. HTU-C (ADTRAN)

This selection causes the HTU-C (central -office HD SL unit) to transition from

an armed state to a loopback state.

2-28. HRE1 (ADTRAN)

This selection causes the HRE1 (HDSL range extender 1; sometimes referred

to as a "doubler") to transition from an armed state to a loopback state.

2-29. HRE2 (ADTRAN)

This selection causes the HRE2 (HDSL range extender 2; sometimes referred

to as a "doubler") to transition from an armed state to a loopback state.

2-30. NREM (PairGain)

This selection causes the NREM (network remote) to transition to a loopback

state.

2-31. NLOC (PairGain)

This selection causes the NLOC (network local loop) to transition to a

loopback state.

2-32. NDU1 (PairGain)

This selection causes the NDU1 (network doubler 1) to transition to a loopback

state.

2-33. NDU2 (PairGain)

This selection causes the NDU2 (network doubler 2) to transition to a loopback

state.

2-15

Page 34

633/635

Users Manual

2-34. CREM (PairGain)

This selection causes the CREM (customer remote) to transition to a loopback

state.

2-35. CLOC (PairGain)

This selection causes the CLOC (customer local loop) to transition to a

loopback state.

2-36. CDU1 (PairGain)

This selection causes the CDU1 (customer doubler 1) to transition to a

loopback state.

2-37. CDU2 (PairGain)

This selection causes the CDU2 (customer doubler 2) to transition to a

loopback state.

2-38. FT1 CHANNEL SELECT Key

When in F64 or F56 test mode, the FT1 channels will be selected by scrolling

through the DS0s using the

two-character display. To select the displayed channel for F64 or F56 BERT,

press the

on the display screen (shown below) if FT 1 is selected as the result type (using

the

FT1 CHANNEL SELECT

RESULTS

keys).

CHANNEL UP/DOWN

key. The selected channel(s) will blink

keys and vie wing the

FT1 01 02 03 04 05

06 07 08 09 10 11 12

F64 CCIS Rx CSU

abn15f.eps

To clear or deselect all channels for F64 or F56 BERT, select no channel

(shown as "--" on the two-character display). Then, press the

SELECT key momentarily. To select all channels, press and hold the FT1

CHANNEL SELECT key for approximately two seconds.

FT1 CHANNEL

2-39. CHANNEL UP/DOWN Keys

These keys are used to select the DS0 channel for data and signaling drop to

the Signaling Bits and Data Bits LEDs. The selected DS0 will also be dropped

2-16

Page 35

Overview

Controls

to the speaker (and headset jack). The DS0 channel selection (1-24) is shown

on the display that is located to the left of the

These keys are also used with Fractional T1 to select fractional channels.

CHANNEL UP/DOWN

keys.

2-40. ERROR INJECT Keys (QuickBERT-T1 only)

2

The three

errors into the data stream. When you press the

momentarily, the LED will flash and one error will be injected. When you

press and hold the

LED will illuminate solid and the selected error will be injected at an error rate

of 1.0E-4. Pressing the

inject rate and turn the LED off.

ERROR INJECT

ERROR INJECT

ERROR INJECT

keys allow insertion of logic, BPV, or frame

ERROR INJECT

key for approximately two seconds, the

key again will discontinue the error

key

2-41. SEND LOOP UP/DOWN Keys (QuickBERT-T1

only)

Various circuit elements in a T1 span respond to loop codes. This allows one

person to perform an out-of-service BERT. Press the

transmit the loop-up code (which has been selected by the

The SEND LOOP UP LED will illuminate to indicate the code is b eing

transmitted. Once the device is looped, the RECEIVE LOOP UP LED will

illuminate for approximately 3 seconds (5 seconds for HDSL loop codes) to

indicate that the device has successfully looped up. Press the

DOWN

LOOP CODE

indicate the code is being transmitted. The RECEIVE LOOP DOWN LED will

illuminate for approximately 3 seconds (5 seconds for HDSL loop codes) to

indicate that the device has successfully looped down. Table 2-1 lists all of the

loop-code types supported by the QuickBERT-T1. When monitoring a span, if

the QuickBERT-T1 detects a loop code, the RECEIVE LOOP UP LED will

illuminate to indicate a pre-loop condition.

key to transmit the loop-down code (which has been selected by the

key). The SEND LOOP DOWN LED will illuminate to

SEND LOOP UP

LOOP CODE

SEND LOOP

key to

key).

2-42. RX INPUT Key

Before making a connection to the RX jack, the

appropriately. This key allows you to choose between three different T1

terminations: DSX MON for monitoring in-service or out-of-service lines

through a DSX Monitor jack; TERM typically for out-of-service testing; and

BRDG for monitoring in-service or out-of-service lines. The following

paragraphs describe each termination mode.

RX INPUT

key should be set

2-17

Page 36

633/635

Users Manual

DSX MON - The DSX Monitor Mode is typically used to monitor in-service

T1 spans through a DSX monitor jack that is resistor-isolated from the span.

When DSX MON is selected, the receiver is terminated into 100 ohms. Due to

the loading effect of the 100-ohm termination in series with the isolation

resistors, there is approximately a 20 dB line drop seen by the receiver. See

Chapter 3.

TERM - The Terminate Mode is used when the span is being terminated by the

QuickBERT-T1 or QuickCHECK-T1. It is typically used for an out-of-service

BERT (see section 3-8).

BRDG - The Bridge Mode is typically used to monitor in-service T-spans that

do not have a DSX monitor jack. The test set assumes a bridged connection

consists of a direct connection to one side of the span, and that the connection

is not resistor-isolated to the receive connector of the test set. The receiver is

set to the high-impedance state of greater than 1000 ohms.

2-43. TX PATTERN Key (QuickBERT-T1 only)

TX PATTERN

The

transmitted by the QuickBERT-T1. Twelve patterns are available for selection.

The yellow Pattern LEDs illuminate to indicate that t he corresponding pattern

is being transmitted. To change the pattern, s imply press the

key.

key controls the data content of the signal being

TX PATTERN

Since the transmitter and receiver of the QuickBERT-T1 are totally

independent, the pattern being transmitted is not necessarily the pattern being

received. So while the yellow Pattern LEDs indicate the pattern being

transmitted, the green Pattern LEDs indicate the pattern being received. No

selection is necessary for the received pattern.

The QuickBERT-T1 automatically evaluates the signal present at the receiver

and the appropriate LED illuminates ind icating pattern synchronization has

been achieved. Sections 2-44 through 2-55 provide detailed descriptions of the

individual patterns.

2-44. QRSS

The quasi-random signal source (QRSS) pattern is modified 220-1

pseudorandom pattern which allows a maximum of 14 sequential zeros and 20

sequential ones. The QRSS pattern is the most widely used pattern to test DS1

facilities. It provides a random set of stresses including long strings of zeros

and ones. Unless B8ZS is invoked, QRSS violates the ones-density

requirements when framed.

2-18

Page 37

Overview

Controls

2

2-45. 1 IN 7

This pattern is a sequence of a one and seven zeros in the following form: 0100

0000. The maximum number of sequential zeros is eight, when transmitted

framed, and seven when transmitted unframed. This pattern is useful when

testing for mis-optione d AMI /B 8ZS eq uipment.

2-46. 2 IN 8

This pattern is a sequence of two ones in eight bits in the following form: 0100

1000. The maximum number of sequential zeros is four, either framed or

unframed. This pattern is used to verify error-free transmission in B8ZSoptioned systems.

2-47. 3 IN 24

This pattern is a sequence of three ones in 24 bits in the following form: 0100

0100 0000 0000 0000 0100. The maximum number of sequential zeros is 15.

This pattern is used to stress timing recovery in AMI-optioned systems.

2-48. ALL 0’S

This pattern is a sequence of all zeros. This pattern is useful for testing B8ZS

circuits.

2-49. ALL 1’S

This pattern is a sequence of all ones. “All ones” require the maximum power

to regenerate. This pattern is used to make loss measurements of the DS1

signal.

2-50. 1:1

This pattern is a sequence of alternating ones and zeros.

2-51. NET55

This pattern is a repeating pattern of 55 bytes according to the following

hexadecimal sequence.

01 01 03 01 01 01 00 01 01 01 01 01 01 03 01 01 01 01 07 01

01 01 01 55 55 55 55 AA AA AA AA 01 01 01 01 01 01 FF FF FF

FF FF FF 80 01 80 01 80 01 80 01 80 01 80 01

This pattern creates a variety of stress on the circuits. Some service providers

require end-to-end testing using the 55 patterns.

2-19

Page 38

633/635

Users Manual

2-52. OCT55

This pattern is a modified 220-1 pseudorandom pattern which allows a

maximum number of 14 sequential zeros and 20 sequential ones.

01 01 01 01 01 01 00 01 01 01 01 01 01 03 01 01 01 01 07 01

01 01 01 55 55 55 55 AA AA AA AA 01 01 01 01 01 01 FF FF FF

FF FF FF 80 01 80 01 80 01 80 01 80 01 80 01

This pattern creates a variety of stress on the circuits. Some service providers

require end-to-end testing using the 55 patterns.

2-53. DALY55

This pattern is a repeating pattern of 55 bytes according to the following

hexadecimal sequence.

01 01 01 01 01 01 80 01 01 01 01 01 01 03 01 01 01 01 07 01

01 01 01 55 55 55 55 AA AA AA AA 01 01 01 01 01 01 FF FF FF

FF FF FF 80 01 80 01 80 01 80 01 80 01 80 01

This pattern creates a variety of stress on the circuits. Some service providers

require end-to-end testing using the 55 patterns.

2-54. USER

This pattern is a 64-bit user-programmable pattern, with a default pattern of

1:16. The 1:16 pattern is a repeating 16-bit pattern in the following form: 0100

0000 0000 0000.

When the unit is turned on, it automatically reverts to the de fault pattern. To

set the user pattern to something other than the default, proceed with the

following steps.

1. Press the

LOOP CODE

key and

RESULTS DOWN

key simultaneously.

This will display the current user pattern. Twenty bits will be displayed on

each of the top three lines. Four bits will be displayed in the first four

character positions of the bottom line. Also displayed on the bottom line

will be "User ← →".

2-20

Page 39

Overview

Controls

2

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 User ←

2. Press the

CODE

will blink.

3. Press the

UP

4. Press and hold the

clear all bits (in the current length of the pattern) to "1."

5. When on the last character of the pattern, press the

key to delete the last character.

6. Press and hold the

to clear all bits (in the current length of the pattern) to "0 ."

7. Press the

one bit that is set to "0."

8. To exit the user pattern setup, press the

previously displayed results and setups will be displayed.

TX CLK SOURCE

key to scroll to the right through the bits. The currently selected bit

RESULTS UP

key toggles between "0" and "1.")

RESTART

key to scroll to the left and the

key to select either "0" or "1." (The

RESULTS UP

RESULTS DOWN

key to erase all bits and start with a pattern length of

key for approximately two seconds to

key for approximately two seconds

TEST MODE

→

abn16f.eps

LOOP

RESULTS

RESULTS DOWN

key. The

2-55. THRU

When this pattern is selected, the Rx signal is passed through the test set and

transmitted back out the Tx jack. This is the only time that Rx and Tx are not

independent. When this pattern is selected, signal monitoring continues and

pattern sync still takes place.

2-56. TX LINE CODE Key (QuickBERT-T1 only )

The line-coding scheme should be set to AMI or B8ZS according to the

configuration of the T1 facility bein g tested. The selection is made by pressin g

the TX LINE CODE key. The line-code selection affects the transmitted

signal, not the received signal. The QuickBERT-T1 automatically evaluates the

received signal and determines the line coding. See section 3-2 for additional

information on the automatic-evaluation function of the QuickBE RT-T1.

2-21

Page 40

633/635

Users Manual

2-57. TX FRAME Key (QuickBERT-T1 only)

Four possible framing selections are available with the QuickBERT-T1

(NONE, D4, ESF, SLC96). If NONE is selected, the QuickBERT-T1 will

transmit the selected pattern unframed. That is, no framing bits are generated

and no channels (DS0s) are defined. The full bandwidth of the T1 is used for

data (in this case, the selected pattern). If D4 is selected, the Q uickBERT-T1

will frame the selected pattern in 24 channels and 12 frames (as defined by

®

AT&T

24-frame, 24-channel format (per AT&T specification 62411). SLC96 is a

special framing format that can be used when testing digital loop carriers

(conforming to TR-TSY-00008).

specification 62411). The ESF selection generates a T1 signal in the

Note

Sometimes D4 framing is referred to as SF or super frame.

2-58. Volume Control

If the receiver of the QuickBERT-T1 or QuickCHECK-T1 is in frame sync

(indicated by the green Frame LEDs), a channel may be selected for audible

monitoring. The demodulated audio signal for the selected channel (DS0) is

dropped to an internal speaker. The volume control, located on the right side of

the unit, is used to adjust the audio volume. A headset jack (for use with a

customer-supplied headset) is also provided for noisy environments. See

Appendix A for a description of the headset jack specifications.

2-59. Indicators

Status, alarm, framing, signal presence, and coding information can be

monitored from front-panel LEDs. Detailed descriptio ns of these front-panel

LEDs are described in the following paragraphs.

2-60. Errors LEDs

The Errors LEDs are labeled BIT ERR, BPV ERR, FRM ERR, CRC ERR, and

FREQDEV. All of these LEDs illuminate solid to indicate errors are present

and flash to indicate error history. Additional in formation on these errors can

be viewed usin g the RESULTS keys. Detailed descriptions of each of these

parameters are described earlier in this chapter.

2-61. Data Bits LEDs

The received data for the selected DS0 channel is dropped to the eight Data

Bits LEDs. The Data Bits LEDs are labeled 1 through 8, indicating the data-bit

2-22

Page 41

Overview

Indicators

positions. The first bit received for each DS0 byte is displayed in bit position 1

(least significant bit). If no channel is selected, the Data Bits LEDs will be off.

2

2-62. Signaling Bits LEDs

The signaling for the selected DS0 channel is dropped to the Signaling Bits

LEDs. These LEDs are labeled A, B, C, and D. The Signaling Bits LEDs will

be off if no channel is selected. Table 2-2, shown below, lists the signaling

bits.

Table 2-2. Signaling Bits Displayed Based on Framing and Signaling Type

Framing Detected Signaling Type Selected Signaling Bits

D4 Robbed Bit A, B

ESF Robbed Bit A, B, C, D

SLC96 Robbed Bit A, B

D4 CCIS or E-Bit A, B

ESF CCIS A, B

ESF E-Bit A, B, C, D

None Not Applicable None

2-63. Rx Status/History LEDs

The Rx Status LEDs provide a visual indication of an alarm condition. The

corresponding History LEDs provide a visual indication of the history of an

alarm condition.

2-64. AMI and B8ZS/HISTORY LEDs

Line coding is assumed to be AMI u ntil a B 8ZS substitution is detected. The

AMI and B8ZS LEDs automatically indicate the line coding present at the

receiver. However, in order to distinguish between AMI and B8ZS, the data at

the receiver must include at least one string that contains at least eight

consecutive zeros. If live traffic is being monitored, it is lo gical to assume that

eight zeros will transmit within a reasonable time period. However, if a pattern

is transmitted, refer to section 2-43 to ensure that the particular pa ttern being

received allows eight consecutive zeros. Monitor the green Pattern LEDs to

determine if a pattern is being recognized b y the test set.

2-23

Page 42

633/635

Users Manual

Note

An out-of –service T1 usually has framed all ones or a keep-alive

signal present. The test set cannot detect B8ZS in this condition. In

order to make a declaration of line coding, eight consecutive zeros or

a B8ZS substitution (for eight zeros) must be received .

The AMI LED illuminates only when AMI line coding is detected without

B8ZS currently being detected. The B8ZS LED illuminates only when B8ZS

(a zero substitution) is currently being detected. The B8ZS HISTORY LED

illuminates to indicate a previously-received B8ZS substitution and will remain

illuminated until the

RESTART

key is pressed.

2-65. SIGNAL PRESENT/HISTORY LEDs

The SIGNAL PRESENT LED illuminates if a signal is detected by the Rx T1

receiver. The SIGNAL PRESENT LED turns off when 192 consecutive zeros

(bit times without a pulse) are detected by the Rx T1 receiver.The SIGNAL

PRESENT LED illuminates again when the next “1” is detected by the Rx T1

receiver.

The SIGNAL PRESENT HISTORY LED illuminates if a signal was detected

and then lost (192 consecutive zeros were detected by the Rx T1 receiver).

Once the SIGNAL PRESENT HISTORY LED illuminates, it will remain

illuminated until the

RESTART

key is pressed.

2-66. OUT OF FRAME/HISTORY LEDs

The OUT OF FRAME LED illuminates whenever an out-of-frame condition is

detected. The test set must have previously detected D4, ESF, or SLC96

framing before an out-of-frame condition will be d eclared. For D4 or SLC96

framing, an out-of-frame condition is defined as 2 out of 4 FT (terminal

framing) bits in error. For ESF framing, an out-of-frame condition is defined as

2 out of 4 FPS (framing pattern sequence) bits in error. The OUT OF FRAME

LED will remain illuminated as long as the out-of-frame condition exists.

The OUT OF FRAME HISTORY LED illuminates when an out-of-frame

condition is detected and then clears. Once the OU T OF FRAME LED

illuminates, it will remain illuminated until the

RESTART

key is pressed.

2-67. BLUE ALARM (AIS)/HISTORY LEDs

A blue alarm is declared if an out-of-frame condition exists and 14 or less

zeros are counted in 13,895 bit times. The BLUE ALARM LED is unlit if the

2-24

Page 43

Overview

Indicators

out-of-frame condition clears, or if 15 or more zeros are counted in 13,895 or

less bit times.

The BLUE ALARM (AIS) HISTORY LED illuminates when a blue alarm is

detected and then clears. Once the BLUE ALARM (AIS) HISTORY LED

illuminates, it will remain illuminated until the

RESTART

key is pressed.

2

2-68. ONES DENSITY/HISTORY LEDs

In accordance with T1 standards (Pub 62411 and ANSI T1.403), a DS1 signal

should maintain a minimum density of 1s bits. In the T1 transmission scheme

(AMI), a one is represented by pulses of alternating polarity and a zero is

represented by the absence of a pulse. T1 circuit elements depend on a

minimum number of pulses to retain timing and regenerate proper clocking. If

a signal contains too many consecutive zero bits (no pulses) these circuits

cannot recover timing and bit errors occur. According to the accepted

standards, a ones-density violation occurs when there are less than N ones

within 8(N+1) bit times where N=1-23. If the test set detects this condition, the

ONES DENSITY LED will illuminate and remain illuminated until the

violation clears. Some test patterns are intent ionally generated to violate onesdensity requirements to determine a failure point of network equipment (see

section 2-43). If the DS1 is a B8ZS circuit and the circuit is provisioned

properly, ones-density violations should not occur.

The ONES DENSITY HISTORY LED illuminates when a ones-density

condition is detected and then clears. Once the ON ES DENSITY HISTORY

LED illuminates, it will remain illuminated until t he

pressed.

RESTART

key is

2-69. EXCESS ZEROS/HISTORY LEDs

In accordance with T1 standards (Pub 62411 and ANSI T1.403), a DS1 signal

should maintain a minimum density of 1s bits. In the T1 transmission scheme

(AMI), a one is represented by pulses of alternating polarity and a zero is

represented by the absence of a pulse. T1 circuit elements depend on a

minimum number of pulses to retain timing and regenerate proper clocking. If

a signal contains too many consecutive zero bits (no pulses) these circuits

cannot recover timing and bit errors occur. According to the accepted

standards, an excess-zeros violation occurs when DS1 has more than 15

consecutive zeros in the datastream. If the test set detects this co ndition, the

EXCESS ZEROS LED will illuminate and remain illuminated until the

violation clears. Some test patterns are intent ionally generated to violate the

excess-zeros requirement to determine a failure point of network equipment

2-25

Page 44

633/635

Users Manual

(see sections 2-43). If the DS1 is a B8ZS circuit and the circuit is provisioned

properly, excess-zero violations should not occur.

The EXCESS ZEROS HISTORY LED illuminates when an excess-zeros

condition is detected and then clears. Once the EXCESS ZEROS HISTORY

LED illuminates, it will remain illuminated until t he

pressed.

RESTART

key is

2-70. YELLOW ALARM/HISTORY LEDs

A yellow alarm is a signal transmitted by a network terminal to inform the far

end that it has lost communication with the network. A yellow alarm can be

caused by trouble on the network or by interrupted transmission at the

customer location. If the test set detects the yellow alarm code at the receiver,

the YELLOW ALARM LED will illuminate and remain illuminated until the

condition clears.

The YELLOW ALARM HISTORY LED illuminates when a yellow alarm

condition is detected and then clears. Once the YELLOW ALARM HISTORY

LED illuminates, it will remain illuminated until t he

pressed.

RESTART

key is

2-71. DS1 IDLE SIGNAL/HISTORY LEDs

The DS1 IDLE SIGNAL LED illuminates whenever a DS1 idle condition is

detected (as defined in ANSI T1.403-1995 Annex D). DS1 idle is the

occurrence of 00010111 in all 24 DS0 channels. The DS1 IDLE SIGNAL

LED remains illuminated until the DS1 idle condition clears.

The DS1 IDLE SIGNAL HISTORY LED illuminates when a DS1 idle code is

detected and then clears. Once the DS1 IDLE SIGNAL HISTORY LED

illuminates, it will remain illuminated until the

RESTART

key is pressed.

2-72. PATTERN SYNC LOSS/HISTORY LED

If the test set has obtained synchronization, the corresponding gre en Pattern

LED will illuminate. If the pattern is interrupted and the unit declares a loss of

pattern sync, the PATTERN SYNC LO SS LED will illuminate and the Pattern

LED will turn off. If pattern sync is re-established, the Pattern LED will again

illuminate, and the PATTERN SYNC LOSS LED will remain illuminated until

the RESTART key is pressed.

2-26

Page 45

Overview

Indicators

2

2-73. Error Inject LEDs (QuickBERT-T1 only)

These three LEDs illuminate to indicate that a logic, BPV, or frame bit error

has been injected. When the

the LED will flash and one error will be injected. When the

key is pressed and held for approximately two seconds, the LED will

constantly illuminate and inject the selected error at an error rate of 1.0E-4.

Pressing the

turn the LED off.

ERROR INJECT

ERROR INJECT

key again will discontinue t he error inject and

key is momentarily pressed,

ERROR INJECT

2-74. Receive Loop Up/Down LEDs (QuickBERT-T1

only)

When looping up a device, if the pattern receiver detects the returned loop

code and is able to achieve pattern sync, the QuickB ERT-T1 assumes the

device has been looped and the RECEIVE LOOP UP LED illuminates for 3

seconds. For loop-down code, the Rx pattern receiver is loaded with the code.

If after 5 seconds the Rx pattern receiver loses sync, the span is assumed to be

taken out of loop and the RECEIVE LOOP DOWN LED illuminates for 3

seconds.

Note

When moitoring a span, if the QuickBERT-T1 detects a loop code, the

RECEIVE LOOP UP LED will illuminate to indicate a pre-loop

condition.

2-75. Send Loop Up/Down LEDs (QuickBERT-T1 only)

When the

appropriate LED will illuminate indicating that the selected loop code is being

transmitted.

SEND LOOP UP

SEND LOOP DOWN

or

key is pressed the

2-76. Rx Input LEDs

The appropriate Rx Input LED (DSX MON, TERM, or BRDG) will illuminate

to indicate the currently-selected termination mode.

2-77. Pattern LEDs

T1 facilities are being called upon to transport various combinations of voice,

analog and digital data, and video signals via the 192-bit payload of the DS1

frame. Specially-designed BERT patterns, when used under controlled

conditions, provide a means of emulating certain payload signal characteristics.

Use of one or more test patterns, with characteristics similar to those of the

2-27

Page 46

633/635

Users Manual

expected customer payload, can provide an accurate estimate of the actual inservice network performance.

The QuickBERT-T1 and QuickCHECK-T1 have the ability to obtain pattern

sync with the following patterns: QRSS, 1 IN 7, 2 IN 8, 3 IN 24, ALL ZEROS,

ALL ONES, 1:1, NET55, OCT55, and DALY55. (The QuickBERT-T1 can

also obtain pattern sync with a customizable USER pattern.) When the test set

obtains pattern sync, a green Pattern LED will illuminate to indicate which

pattern is being received. See section 2-43 for detailed descriptions of the

individual patterns.

With the QuickBERT-T1, a pattern can be selected using the

key. The pattern selected for transmit is indicated b y the yello w Pattern LEDs.

Selecting a new transmit pattern will not necessarily affect the pattern being

detected at the receiver (indicated by the green pattern LEDs).

TX PATTERN

2-78. Tx Line Code LEDs (QuickBERT-T1 only)

TX LINE CODE

The

T1 will use in transmitting the selected pattern. If the AMI selection is made,

the QuickBERT-T1 will allow any amount of zeros to b e transmitted. If the

B8ZS selection is made, a B8ZS substitution will be made for a string of 8

consecutive zero bits in the pattern. The yellow LED corresp onding to the

chosen line code will illuminate. Changing the line code selection will not

necessarily affect the line coding being detected at the receiver (green LED).

key is used to select the line code that the QuickBERT-

2-79. Frame LEDs

The QuickBERT-T1 and QuickCHECK-T1 have the ability to detect NONE,

D4, ESF, and SLC96 framing. If any of these frame formats are detected by the

Rx T1 receiver, the corresponding green LED illuminates. Otherwise, they will

remain o ff.

When transmitting (QuickBERT-T1 only), choose the frame format by using

TX FRAME

the

according to the selection indicated by the yellow LEDs. Changing the

transmit frame format selection will not affect the receiver.

key. The QuickBERT-T1 will frame the selected pattern

2-80. Low Battery LED

This LED illuminates to indicate that the battery life is nearly exhausted and

that the battery should be recharged.

2-28

Page 47

Overview

Battery Safe Mode

2

2-81. Battery Safe Mode

In order to protect the battery pack from being damaged by a complete

discharge, the QuickBERT-T1 and QuickCHECK-T1 incorporate a Battery

Safe mode. If the test set is left on, the power supply will shut down internally

to prevent a complete discharge. When the unit has entered the Battery Safe

mode, it will no longer respond to the

Safe mode, you must recharge the battery.

ON/OFF

switch. To exit the Battery

2-82. Battery Pack

The QuickBERT-T1 and QuickCHECK-T1 incorporate a NiMH rechargeable

battery pack. This battery pack provides a working voltage of 3.6 V at 1 amp

for 3 hours, and has a battery life of approximately 4.75 hours of continuous

operation (with a fully-charged battery pack). The charging voltage is 9-12

VDC and the rated current is 1 amp. A regulated or unregulated 12-V, 1-amp,

DC power adapter may be used for charging. A 12-V, fused, automotive,

cigarette lighter adapter may also be used where AC is not available.

The NiMH battery packs are not serviceable. To charge, connect the unit’s 12V power source to the DC jack. A full charge takes five hours. The bi-color

LED located on the top panel of the unit indicates the charging status of the

battery pack. The LED illuminates red to indicate the battery pack has entered

the charging state. The LED illuminates green to indicate the battery pack is

fully charged and has entered the “top off” or “trickle” charge state. If the

battery pack is absent from the unit, the LED will re main off.

2-29

Page 48

633/635

Users Manual

2-30

Page 49

Chapter 3

Operation

3-1. Introduction

This chapter of the manual includes operation procedures for the most

commonly used tests of the QuickBERT-T1 and QuickCHECK-T1 test sets.

3-2. Automatic Evaluation

When the

incoming signal for framing type, line coding, and BERT patterns. The test set

first determines the frame type that is currentl y being used on the line (D4,

ESF, SLC96, or NONE). Once the frame type has been detected, it determines

the pattern that is being transmitted on the line (see section 2-43 for a list of