Page 1

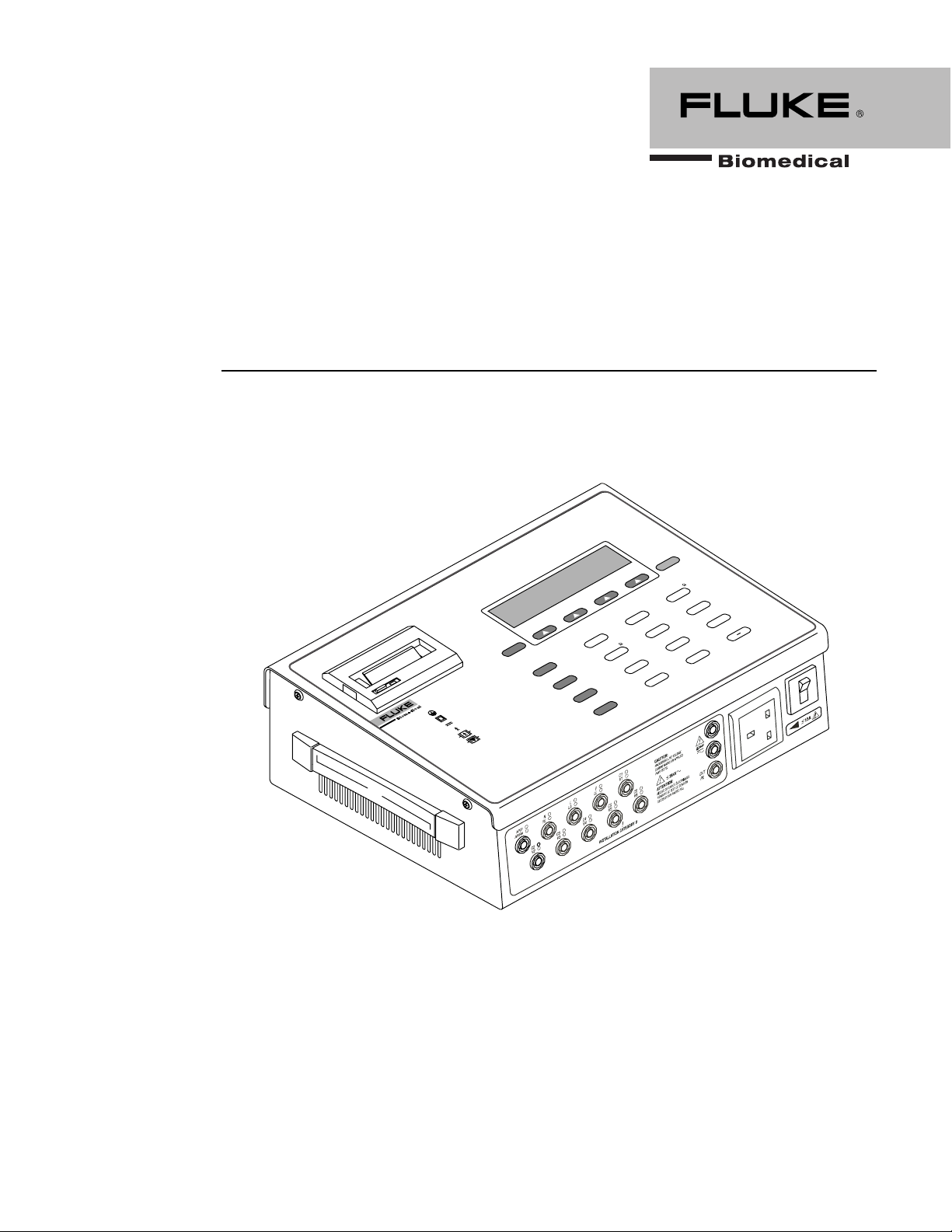

601PROXL International Safety Analyzer

Operators Manual

PREVIOUS

XL

601 Pro Series

INTERNATIONAL SAFETY ANALYZER

CLASS I PROTECTIVE EARTH

CLASS II

CLASS IP

TYPE B

DOUBLE INSULATION

TYPE BF

TYPE CF

INTERNAL POW

N-ISOLATED APPLIED PART

NO

TYPE F

TYPE T

ER SUPPLY

ISOLATED APPLIED PART

ISOLATED APPLIED PART

DIRECT CARDIAC APPLICATION

FIXED DEVICE

TRANSPORTABLE DEVICE

PN 2234222

April 2005

2005 Fluke Corporation, All rights reserved. Printed in USA.

All product names are trademarks of their respective companies.

ESC/STO

ENT

2

INSULATION-M

ENCLOSURE

5

1

KAGE-µA

EARTH

LEA

6

IEC 1010

ACCESSIBLE-V/µA

4

MAINS ON AP

LEAKAGE-µA

9

LEAKAGE-µA

7

UIVALENT

VDE EQ

DEVICE LEAK-µA

PATIENT AUXILIARY

CURRENT-µA

/

8

VDE EQUIVALENT

PATIENT LEAK-µA

baw151f.eps

TESTS

TESTS

CURRENT-A

LTS-V

0

VO

PROTECTIVE EARTH

3

PRINT HEADER

RESISTANCE-

PATIENT

LEAKAGE-µA

INT DATA

PR

P

PRESENT

VIEW

SETTINGS

Page 2

Page 3

Notices

NOTICES, WARNINGS AND CONTENT

Fluke Biomedical

A Division of Fluke Electronics

6920 Seaway Blvd.

Everett, WA 98203

USA

Customer Service and Sales

USA and Canada: 800.648.7952

Outside the USA: 775.883.3400

Sales E-Mail: sales@flukebiomedical.com

Internet: www.flukebiomedical.com

Service: 888.993.5853

Outside the USA: 425.446.5560

For additional sales or service information, contact your local Fluke Biomedical Distributor or

Fluke Electronics office

References in this manual to Bio-Tek Instruments, Inc. and DNI Nevada, refer to companies

that are now part of Fluke Biomedical.

All Rights Reserved

Copyright © 2005, Fluke Biomedical. All rights are reserved. No part of this manual may be

reproduced, transmitted, transcribed, stored in a retrieval system, translated into any

language, or transmitted in any form or by any means electronic or mechanical, including

photocopying and recording, for any purpose other than the purchaser's personal use without

written permission of Fluke Biomedical.

Manufacturing location

Fluke Biomedical

6920 Seaway Blvd

Everett, WA 98203 USA

775-883-3400

800-648-7952

Trademarks

®

IBM

, PC® and PC/AT® are registered trademarks of International Business Machines

Corporation.

Microsoft

®

and MS-DOS® are registered trademarks of Microsoft Corporation.

Restrictions and Liabilities

Information in this document is subject to change and does not represent a commitment by

Fluke Biomedical. Changes made to the information in this document will be incorporated in

new editions of the publication.

No responsibility is assumed by Fluke Biomedical Corporation for the use or reliability of

software or equipment that is not supplied by Fluke Biomedical Corporation or its affiliated

dealers.

iii

Page 4

601PRO SERIES

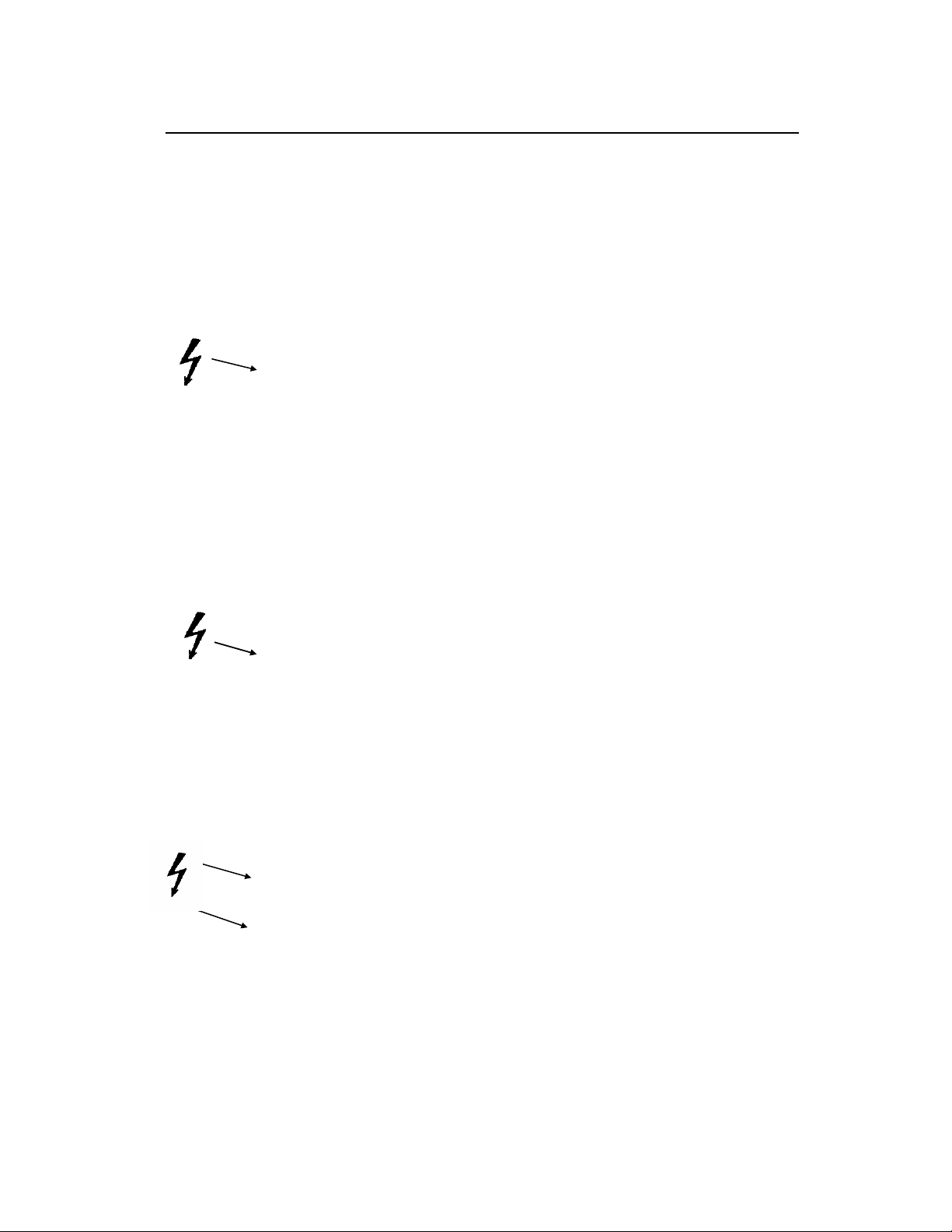

Warnings

XL

Use of this instrument is restricted to qualified personnel who recognize shock hazards

and are familiar with safety precautions used when operating electrical equipment. Read

the manual carefully before operating the 601PRO.

☛ The following warning and informational symbols can be found on the 601PRO:

Symbol Description

Caution: Risk of electric shock

Direct / Alternating Current

Protective Earth (PE)

Caution: Refer to accompanying

documentation

Off (power: disconnection from Mains)

On (Power: connection to Mains)

Equipotential/Functional Earth (FE)

iv

Page 5

NOTICES, WARNINGS AND CONTENT

☛

Exercise extreme caution when a shock hazard is present at the instrument's

measurement terminals during the following tests:

• Mains on Applied Part

• Mains on Applied Part Calibration

• Protective Earth Resistance

• Protective Earth Resistance Calibration

• Equivalent Patient Leakage

• Equivalent Device Leakage

• Equivalent Device/Patient Leakage Calibration

FOR CORRECT OPERATION, ALL GROUND-REFERENCED PERIPHERALS, SUCH AS

PRINTERS AND PCs, MUST BE DISCONNECTED.

Do not discharge a defibrillator while it is plugged into the 601PRO.

☛

☛ Only use Fluke Biomedical-supplied test leads or leads rated for 32 Amps/1000

Volts with the Protective Earth Resistance Test.

☛ Inspect the lead ends for possible wear, cracks or breaks before each use.

☛ Take leakage current measurements only after earth resistance is measured and

found to be compliant with the applied safety limit.

☛ External devices, such as printers and computers, attached to the 601PRO, may

affect the 601PRO's ability to sense Open Earth conditions on the Mains input. If

Mains voltage readings are in error, remove all external devices.

☛ If the DUT fails the Earth Resistance test, the operator must discontinue testing and

label the DUT defective.

☛ If any single test fails, the test must be immediately discontinued and the DUT

labeled defective.

☛ Prior to performing an ECG Simulation test, perform an Applied Part Leakage Test.

If the Applied Part Leakage Test yields an instrument-under-test failure, then do not

perform an ECG Simulation Test, as damage to the instrument may occur.

☛ If operating the 601PRO with a variable AC Supply (Variac), it is important to

perform a calibration after changing the Mains Voltage level. Calibration can be

performed from within the Mains On Applied Part, Equivalent Device Leakage, or

Equivalent Patient Leakage tests.

v

Page 6

601PRO SERIES

Nomenclature

Comparable Terminology: International and United States

INTERNATIONAL/IEC U.S./AAMI

L1 Hot

L2 Neutral

Earth Ground

Mains Line Voltage

Applied Parts Patient Leads

Enclosure/Case Chassis

Protective Earth Ground Wire

Earth Leakage Current Leakage in Ground Wire

Enclosure Leakage Chassis Leakage

XL

Patient Leakage Lead Leakage

Patient Auxiliary Leakage between Patient Leads

Mains on Applied Parts Lead Isolation

Insulation Resistance Dielectric Strength or

Insulation Resistance between

Hot and Neutral to Ground

Earth Resistance Ground Wire Resistance

vi

Page 7

NOTICES, WARNINGS AND CONTENT

Hazard Warnings

☛ Warning! Power Rating. The 601PRO's mains power input must be connected to a

power receptacle that provides voltage within the specified rating for the system.

Connection must be made via the Mains Power cord provided by Fluke Biomedical.

Use of an incompatible power receptacle or incorrect Mains Power cord may produce

electrical shock and fire hazards. Acceptable Mains Voltage ranges are 90~VAC to

132~VAC, and 180~VAC to 240~VAC 50/60 Hz. The current ratings for the 601PRO are

as follows:

Europe: <=15A (Fused by 15A circuit breaker)

United Kingdom: <=13A (Fused by 13A fused Mains Power Cord)

Australia: <=10A (Fused by 10A circuit breaker)

☛ Warning! Internal Voltage. Always turn off the power switch and unplug the power

cord before cleaning the 601PRO's outer surface.

☛ Warning! Liquids. Avoid spilling liquids on the analyzer; fluid seepage into internal

components creates a potential shock hazard. Do not operate the instrument if internal

components are exposed to fluid.

Precautions

The following precautions are provided to help you avoid damaging the system:

☛ To power up the 601PRO, place the index finger on the rocker switch and use a

☛ Caution: Service. The 601PRO should be serviced by authorized service personnel.

☛ Caution: Environmental Conditions. Do not expose the system to temperature

☛ Caution: Do Not Immerse. Clean only with a mild detergent, and wipe down

rolling motion to push from "OFF" to "ON." Do NOT forcefully push or snap the

rocker switch. This may cause the unit to shut off.

Only qualified technical personnel should perform troubleshooting and service

procedures on internal components.

extremes. Ambient temperatures should remain between 18-40°C. System

performance may be adversely affected if temperatures fluctuate above or below

this range.

with a gentle cloth.

vii

Page 8

601PRO SERIES

XL

Electromagnetic Interference and Susceptibility

☛ USA FCC CLASS A

Warning: Changes or modifications to this unit not expressly approved by the

manufacturer could void the user's authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. Like all similar equipment,

this equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause

interference, in which case the user will be required to correct the interference at his own

expense.

☛ Canadian Department of Communications Class A

User Safety

This digital apparatus does not exceed Class A limits for radio emissions from digital

apparatus set out in the Radio Interference Regulations of the Canadian Department of

Communications.

Le present appareil numerique n'met pas du bruits radioelectriques depassant les limites

applicables aux appareils numerique de la Class A prescrites dans le Reglement sur le

brouillage radioelectrique edicte par le ministere des Communications du Canada.

This device has been type tested by an independent laboratory and found to meet the

requirements of the following:

Canadian Standards Association CAN/CSA

C22.2 No.1010.1-1992, “Safety Requirements for Electrical Equipment for

Measurement, Control and Laboratory Use, Part 1: General Requirements”.

UL 3101-1

“Electrical Equipment for Laboratory Use, Part 1: General Requirements”.

viii

Page 9

NOTICES, WARNINGS AND CONTENT

Based on the testing described below, this instrument bears the CE mark.

EC Directive 89/336/EEC Electromagnetic Compatibility

☛ Emissions - CLASS A

The system has been type tested by an independent, accredited testing laboratory and

found to meet the requirements of EN 61326-1:1998 for Radiated Emissions and Line

Conducted Emissions. Verification of compliance was conducted to the limits and

methods of the following:

CISPR 16-1:1993 and CISPR 16-2:1996

☛ Immunity

The system has been type tested by an independent, accredited testing laboratory and

found to meet the requirements of EN 61326-1:1998 for Immunity. Verification of

compliance was conducted to the limits and methods of the following:

EN 61000-4-2 (1991) Electrostatic Discharge

EN 61000-4-3 (1995) Radiated EM Fields

EN 61000-4-4 (1995) Electrical Fast Transient/Burst

EN 61000-4-5 (1995) Surge Immunity

EN 61000-4-6 (1996) Conducted Disturbances

EN 61000-4-11 (1994) Voltage Dips, Short Interruptions and Variations

EC Directive 73/23/EEC Low Voltage (Safety)

The system has been type tested by an independent testing laboratory and found to meet

the requirements of EC Directive 73/23/EEC for Low Voltage. Verification of compliance

was conducted to the limits and methods of the following:

EN 61010-1 (1993) & IEC 1010-1

“Safety Requirements for Electrical Equipment for Measurement, Control and

Laboratory Use, Part 1: General requirements” (including amendments 1 & 2).

ix

Page 10

601PRO SERIES

Warranty

XL

This Warranty is limited and applies only to new products, except for computerbased software, which is covered under a separate Warranty Policy,

manufactured by Fluke Biomedical. Fluke Biomedical makes no warranty

statement regarding the condition of used products.

Fluke Biomedical warrants the instrument (hereinafter collectively referred to as

“Products” or “Product”) for a period of one (1) year from the original purchase

date against defective materials or workmanship. This Warranty is limited to the

original purchaser (the “Purchaser”) and cannot be assigned or transferred. All

claims under this Limited Warranty must be made in writing to Fluke Biomedical,

Attention: Service Department. Purchaser must ship the Product to Fluke

Biomedical, postage pre-paid. Fluke Biomedical shall either repair or replace with

new or like new, at its option and without cost to the Purchaser, any Product

which in Fluke Biomedical’s sole judgment is defective by reason of defects in the

materials or workmanship.

This Warranty is VOID if the Product has been damaged by accident or misuse, or

has been damaged by abuse or negligence in the operation or maintenance of the

Product, including without limitation unsafe operation, operation by untrained

personnel, and failure to perform routine maintenance. This Warranty is VOID if

the Product has been repaired or altered by persons not authorized by Fluke

Biomedical, or if the Product has had the serial number altered, effaced, or

removed. This Warranty is VOID if any of the Products has not been connected,

installed or adjusted strictly in accordance with written directions furnished by

Fluke Biomedical. Batteries, fuses, light bulbs, and other “consumable” items used

in any of the Products are not covered by this Warranty. Software utilized in

conjunction with any of the Products is not covered by the terms of this Warranty

but may be covered under a separate Fluke Biomedical software warranty.

We will continue to stock parts for a maximum period of five (5) years after the

manufacture of any equipment has been discontinued. Parts shall include all

materials, charts, instructions, diagrams, and accessories that were furnished with

the standard models.

THIS WARRANTY CONTAINS THE ENTIRE OBLIGATION OF FLUKE

BIOMEDICAL, AND NO OTHER WARRANTIES, EXPRESSED, IMPLIED, OR

STATUTORY ARE GIVEN. PURCHASER AGREES TO ASSUME ALL LIABILITY

FOR ANY DAMAGES AND/OR BODILY INJURY OR DEATH THAT MAY

RESULT FROM THE USE OR MISUSE OF ANY EQUIPMENT OR

INSTRUMENT BY THE PURCHASER, HIS EMPLOYEES, AGENTS, OR

CUSTOMERS, OTHER THAN THE EXPRESS WARRANTY CONTAINED

HEREIN. WE SHALL NOT BE RESPONSIBLE FOR ANY DIRECT OR

CONSEQUENTIAL DAMAGES OF ANY KIND. THIS WARRANTY SHALL NOT

BE CHANGED OR MODIFIED IN ANY WAY WITHOUT THE EXPRESS

WRITTEN PERMISSION OF AN OFFICER OF FLUKE BIOMEDICAL.

THIS WARRANTY IS VOID UNLESS THE PURCHASE REGISTRATION CARD

HAS BEEN COMPLETED AND MAILED TO US WITHIN TEN (10) DAYS OF

PURCHASE.

x

Page 11

Contents

NOTICES, WARNINGS AND CONTENT

Notices ....................................................................................................ii

Warnings ...............................................................................................iii

Nomenclature ......................................................................................... v

Hazard Warnings ................................................................................... vi

Precautions ............................................................................................. vi

Electromagnetic Interference and Susceptibility................................... vii

Safety.....................................................................................................vii

Warranty................................................................................................. ix

Chapter 1: Introduction and Description

Introduction to the 601PRO Series

Accessories........................................................................................... 1-3

Optional Accessories............................................................................1-3

Menu Structure.....................................................................................1-3

System Characteristics .........................................................................1-5

Audio Feedback ................................................................................ 1-5

Top Panel ..........................................................................................1-6

Keys Used to Enter Device Control Numbers ..................................1-7

Front Panel........................................................................................1-8

Back Panel ........................................................................................1-9

Statement of Compatibility.............................................................1-10

Chapter 2: Setting Up the 601PRO

Using Factory Default Settings ............................................................2-1

Selecting the Test Standard ..................................................................2-2

Selecting the Printer Output ................................................................. 2-3

Selecting the RS232 Baud Rate ...........................................................2-4

...................................................1-1

XL

Activating the Beeper...........................................................................2-5

Setting the Time and Date....................................................................2-6

Configuring the Enclosure Leakage for the Auto Mode Sequence......2-8

Selecting Language Options.................................................................2-9

Selecting the DC Option ....................................................................2-10

Selecting the Auto/Step Tests: Controlled Power Sequences or

601CE Conventional Test Sequences ............................................2-11

Enabling Stop on Failure.................................................................... 2-13

Configuring for Device Records or Templates ..................................2-15

xi

Page 12

601PRO SERIES

Chapter 3: Manual Mode

XL

Connecting the Device Under Test ......................................................3-1

The Power-Up Sequence......................................................................3-2

Selecting the Test Standard ..................................................................3-3

Selecting the Class/Type ...................................................................... 3-4

Saving Standard, Class, Type and Test Current...................................3-6

Using View Present Settings ................................................................3-7

Lead Type Definitions ......................................................................3-9

Manual Operation...............................................................................3-13

Additional Features.........................................................................3-14

Shortcut Key 0: Mains Voltage Test and

Dual Lead Voltage Test ..................................................................3-16

Shortcut Key 1: Current Consumption Test....................................3-17

Shortcut Key 2: Insulation Resistance Test ....................................3-18

Shortcut Key 3: Protective Earth Resistance Test ..........................3-20

Shortcut Key 4: Earth Leakage Test ............................................... 3-22

Shortcut Key 5: Enclosure Leakage Test........................................3-23

Shortcut Key 6: Patient Leakage Current Test

(IEC 601-1 or VDE 751-1 Test Standard) ...................................... 3-24

Shortcut Key 7: Mains on Applied Part Leakage Test

(IEC 601-1).....................................................................................3-26

Shortcut Key 8: Patient Auxiliary Current Test.............................. 3-28

Shortcut Key 9: IEC 1010 Accessible Voltage/

Leakage Test ...................................................................................3-30

Accessible Voltage......................................................................3-30

Accessible Leakage .....................................................................3-31

Shortcut Key /: VDE Equivalent Device Leakage Test..................3-32

Shortcut Key

- : VDE Equivalent Patient Leakage Test................3-34

Dual Lead Leakage ......................................................................... 3-36

ECG Output ....................................................................................3-37

Sample Waveforms ..................................................................... 3-38

xii

Page 13

NOTICES, WARNINGS AND CONTENT

Chapter 4: Auto/Step Modes

Selecting Auto or Step Mode Testing ..................................................4-1

Executing Auto and Step Mode Tests ..................................................4-4

Creating/Editing a Device Record or Template ...................................4-7

Chapter 5: Test Records

Sending Test Results from the 601PRO to the Host Computer ...........5-1

Test Data Record: Serial Output ..........................................................5-3

Printing Test Records...........................................................................5-3

Deleting Test Records .......................................................................... 5-3

Printing a Header...........................................................................5-5

Chapter 6: Device Records and Templates

Setup Requirements..............................................................................6-1

Using the Device Information Record Utility ...................................... 6-1

Connecting the 601PRO and the Host Computer.................................6-2

Sending Device Information Records from the 601PRO

to the Host Computer ...........................................................................6-2

Receiving Device Information Records from the Host Computer ....... 6-3

Device Information Record: Definition of Fields ................................6-5

Device Information Record Format .....................................................6-6

Deleting Device Records and Templates .............................................6-7

Chapter 7: Testing Devices

Permanently Wired Devices.................................................................7-1

Portable Devices ..................................................................................7-2

Portable Devices in Isolated Power Systems .......................................7-2

Testing Three-Phase Portable Devices.................................................7-2

Testing Conductive Surfaces................................................................7-3

Detachable Power Supply Cable ..........................................................7-3

Battery-Powered Equipment ................................................................7-3

xiii

Page 14

601PRO SERIES

Chapter 8: Standards and Principles

Chapter 9: Custom Standards

Chapter 10: Computer Control

XL

Accessing System Setup.......................................................................8-2

Selecting the Test Standard ..................................................................8-2

Referring to Test Limits for the Selected Standard..............................8-2

Defining/Editing a Custom Standard ...................................................9-1

Tests Available in a Custom Standard .................................................9-4

Custom Standard Controlled Power Sequence.....................................9-5

Setup Requirements............................................................................10-1

Establishing Computer Control..........................................................10-2

Connecting the 601PRO and the Host Computer........................10-2

Sending the Command from the Host Computer ........................10-2

Command Protocol.............................................................................10-2

Computer Control Commands............................................................10-4

Chapter 11: Error Messages, Troubleshooting, and Support

Error Codes ........................................................................................11-1

Errors and Suggested Corrective Actions ..........................................11-2

Troubleshooting .................................................................................11-3

Technical Assistance ..........................................................................11-3

Service................................................................................................11-3

Shipping Requirements ............................................................... 11-3

Appendix A: Specifications

Appendix B: Keyboard Options/Barcode Keyboard Wedge

Appendix C: Printer Maintenance

Appendix D: Test Data Record ASCII Character Formats

xiv

Page 15

Introduction and Description

Chapter

1

1. Introduction to the 601PRO SeriesXL

2. Accessories

3. Optional Accessories

4. Menu Structure

5. System Characteristics

6. Statement of Compatibility

1. Introduction to the 601PRO SeriesXL

The 601PRO SeriesXL (601PRO) is an automated electrical safety analyzer that

meets stringent international standards for electrical safety testing of hospital

and laboratory electromedical equipment.

The 601PRO conducts electrical safety testing in accordance with IEC 601-1,

VDE 751, VDE 701, HEI 95, IEC 1010, AAMI, and AS/NZS 3551

requirements, flags failures, and simulates performance, ECG, and arrhythmia

waveforms. The 601PRO stores 1000 device records. Test results, which are

automatically analyzed and saved in non-volatile memory, can be printed using

the internal ZY column thermal printer or an attached external printer, or

uploaded to a PC using the serial port.

The 601PRO offers automatic, manual, computer control, or step mode

operation.

The 601PRO will accept device information that is input using an external

keyboard, integrated keypad, or barcode keyboard wedge.

1-1

Page 16

601PRO SERIES

XL

Available electrical safety tests include:

♦ Mains Voltage

♦ Dual Lead Voltage

♦ Dual Lead Leakage

♦ Current Consumption

♦ Insulation Resistance

♦ Protective Earth Resistance

♦ Earth Leakage Current

♦ Enclosure Leakage Current

♦ Patient Leakage Current

♦ Mains on Applied Part Leakage

♦ Patient Auxiliary Current

♦ Accessible Voltage

♦ Accessible Leakage

♦ Equivalent Device Leakage

♦ Equivalent Patient Leakage

Available ECG performance waveforms include:

♦ Square wave: 0.125, 2 Hz

♦ Sine wave: 10, 40, 50, 60, 100 Hz

♦ Triangle wave: 2 Hz

♦ ECG complex: 30, 60, 120, 180, 240 BPM

♦ Pulse: 30, 60 BPM

♦ A-Fib, A-Flutter, A-Tach, Idioventricular,

PVC1, R-on-T, Run, V-Fib, V-Tach

1-2

Page 17

INTRODUCTION AND DESCRIPTION

2. Accessories

The following accessories are shipped standard with the 601PRO. To order

additional quantities, contact your Fluke Biomedical equipment dealer, and use

the Fluke Biomedical Part Numbers provided.

Description Quantity

Supplied

Probe/Safety Lead, Red 1 2213252

Probe/Safety Lead, Black 1 2213241

Adapter, Banana/Alligator 5 2212941

Operators Manual 1 2234222

Large Clamp, Red 1 2004125

Warranty Card 1 2241856

Printer Paper Roll (original) 1 2248719

Printer Paper Roll (new style) 1 2248743

Part #

3. Optional Accessories

The following optional accessories are available for the 601PROXL. To order,

contact a Fluke Biomedical equipment dealer and use the Fluke Biomedical

part numbers provided.

Description Part #

Carry Case 2234065

RS232 Cable (9M-9F) 2238659

Printer Cable 2238072

Barcode, Keyboard, Wedge 2248255

Adapter, Banana, ECG 2212657

Keyboard English 2213184

Powercord Set Australian 2238603

Powercord Set Schuko 2238015

Powercord Set US 120 V 2286644

Powercord Set UK 2238570

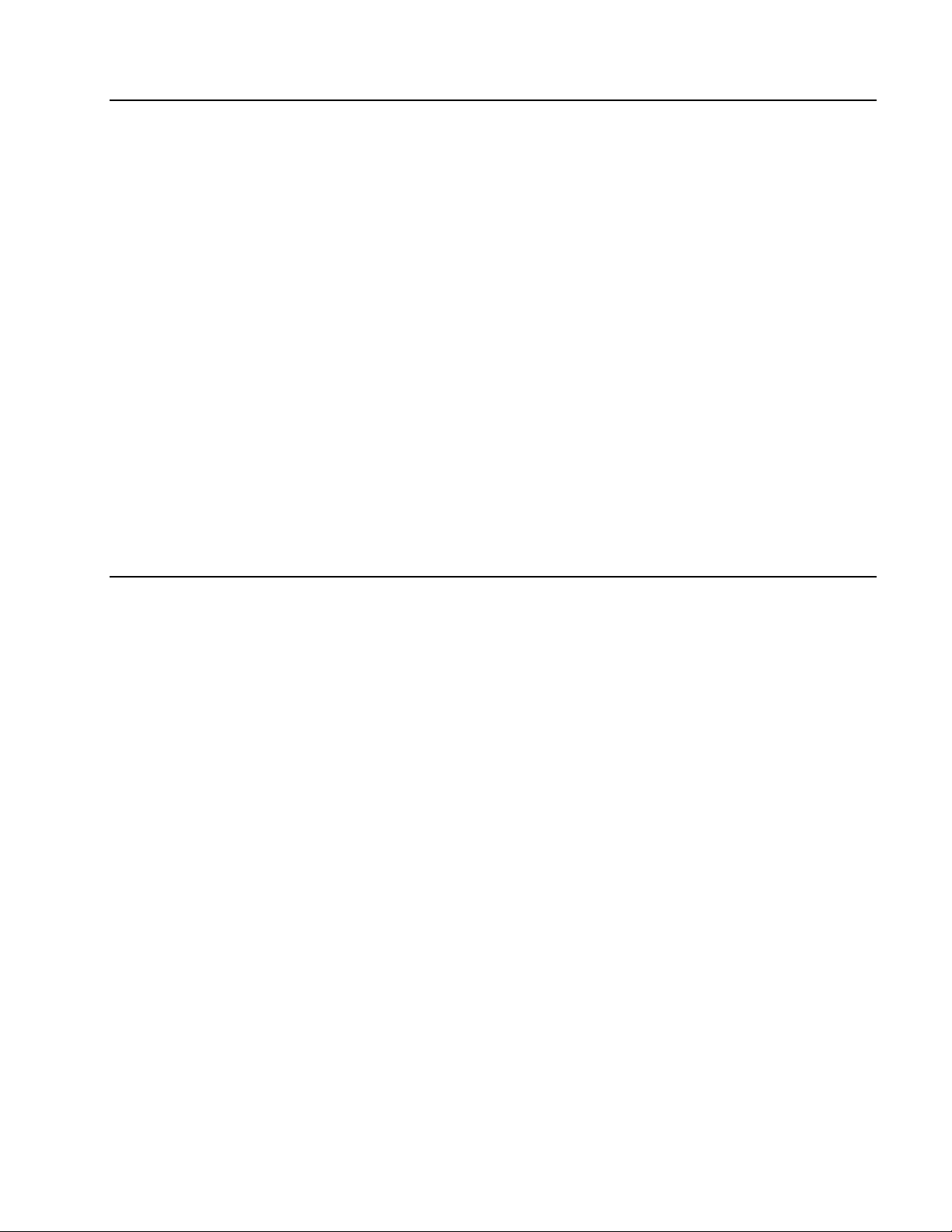

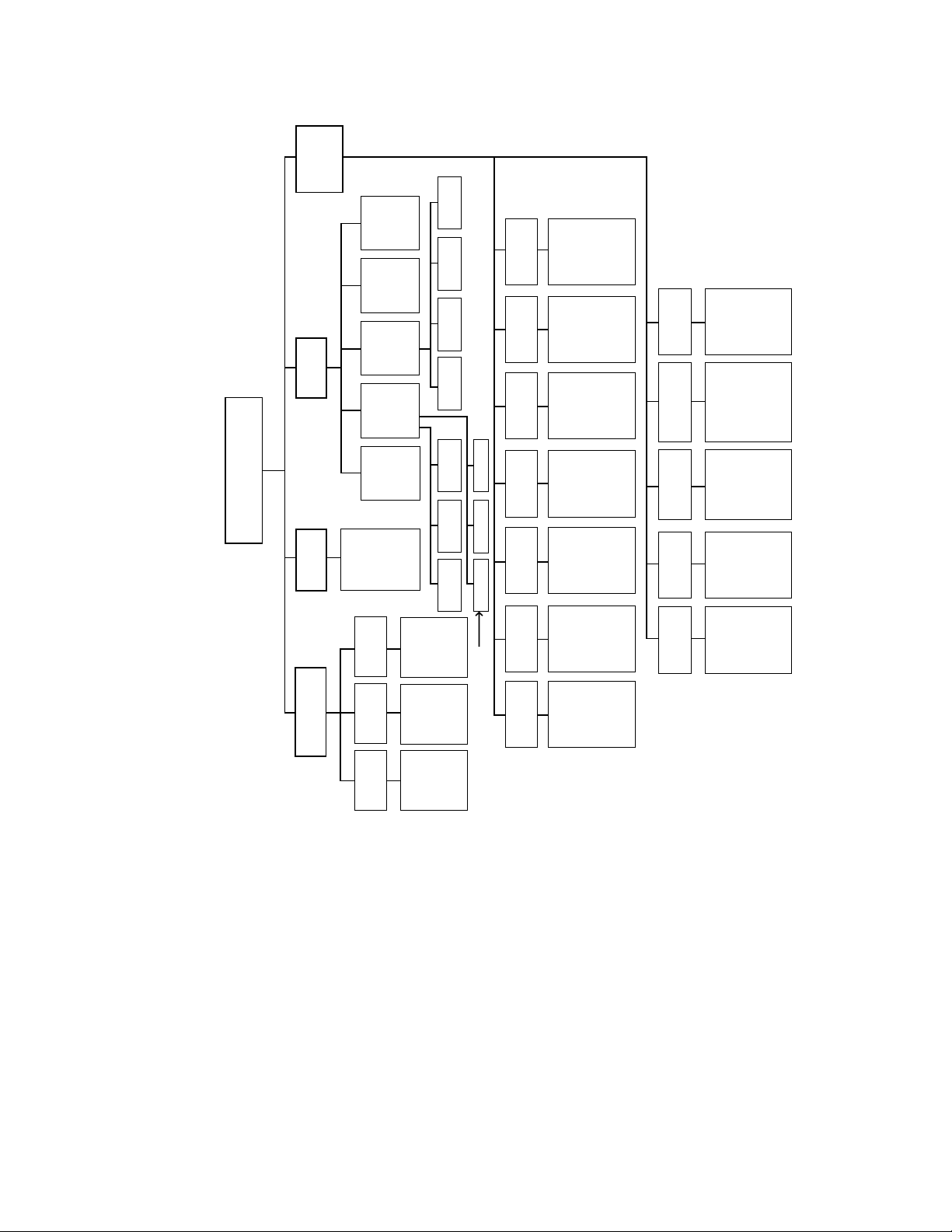

4. Menu Structure

A layout showing various system functions is provided on the following page.

1-3

Page 18

601PRO SERIES

XL

SETUP

SYSTEM

(CHAPTER 2)

PRINT

(CHAPTER 2)

PRINTDELETE

(CHAPTER 9)

SUMMARY

LEAKAGE

ENCLOSURE

CONFIGURE

ENCLOSURE

LEAKAGE FOR

USE DURING

AUTO MODE

SEQUENCE

TEST

TEST

ENABLE

STANDARDS

EDIT

CUSTOM

STANDARD

MAIN MENU

CLASS/TYPE UTILITIES

TESTS/

AUTOMODES

TEST

DEVICE

SYSTEM

SELECT

ALL VALID

CLASS/TYPES

MANUAL

STEP

RECORDS

OR

RECORDS

TEMPLATES

TEST

FOR THIS

PRESENT

STANDARD

(CHAPTER 3)

(CHAPTER 4)

(CHAPTER 5)

(CHAPTER 6)

CREATE

(CHAPTER 3)

(CHAPTER 3)

SELECT

TEST AND

ADVANCE TO

SELECTED

SCREEN

ENTER

CONTROL

NO. TO

STEP

THROUGH

TRANSMIT

(CHAPTER 4)

RECEIVE

EDIT DELETE ALLDELETE

TRANSMIT

CHAPTER 4

EACH TEST

DATE

FORMAT

TIME

FORMAT

BEEPER

RS232

OUTPUT

PRINTER

TEST

STANDARD

SET DATE

TO EITHER

MM-DD-YYORDD-MM-YY

SET CLOCK

TO EITHER

12-HOUR OR

24-HOUR

FORMAT

ACTIVATE OR

DEACTIVATE

BEEPER

CONFIGURE

RS232 SERIAL

PORT FOR:

- EXTERNAL

RS232

SELECT AND

SET UP

PRINTER

INTERFACE

SELECT FROM

- IEC 601-1

- VDE 701-1

- VDE 751-1

- HEI 95

FORMAT

DEVICE

- IEC 1010

- AAMI

- AS/NZS 3551

- CUSTOM

DEV RECS/

TEMPLATES

ON

STOP

FAILURE

SELECT

AUTO/STEP

SEQUENCES

DC

LANGUAGE

CONFIGURE

FOR DEVICE

RECORDS OR

TEMPLATES

AUTOMATICALLY

STOPS AN AUTO

MODE SEQUENCE

WHEN A TEST

FAILS

SELECT

CONTROLLED

POWER

SEQUENCE

OR 601CE

ENABLE DC

READINGS

SELECT

KEYBOARD

OR DISPLAY

LANGUAGE:

CONVENTIONAL

TEST

SEQUENCE

- ENGLISH

- FRENCH

- GERMAN

- ITALIAN

1-4

AUTO

(CHAPTER 4)

ENTER

CONTROL

NO. TO

PERFORM

COMPLETE

TEST

baw007f.eps

Page 19

INTRODUCTION AND DESCRIPTION

5. System Characteristics

The 601PRO uses a membrane keypad for selection of tests or menu options.

The keys are grouped by color and functionality. The red keys below the

display are used to access menu options. These include the

SOFT KEYS, and the enter key. The black keys allow the operator to

four

gain access to additional functions. These include the

present settings

key, the print header key, and the print data key.

previous key, the

esc/stop key, the view

The red keys numbered 0 through

– are used to enter information and can also

be used to gain quick access to the manual tests.

AUDIO FEEDBACK

• A one-beep signal indicates that a key has been pressed.

• A two-beep-per-second signal indicates high voltage or current generated

by the 601PRO is present.

1-5

Page 20

601PRO SERIES

XL

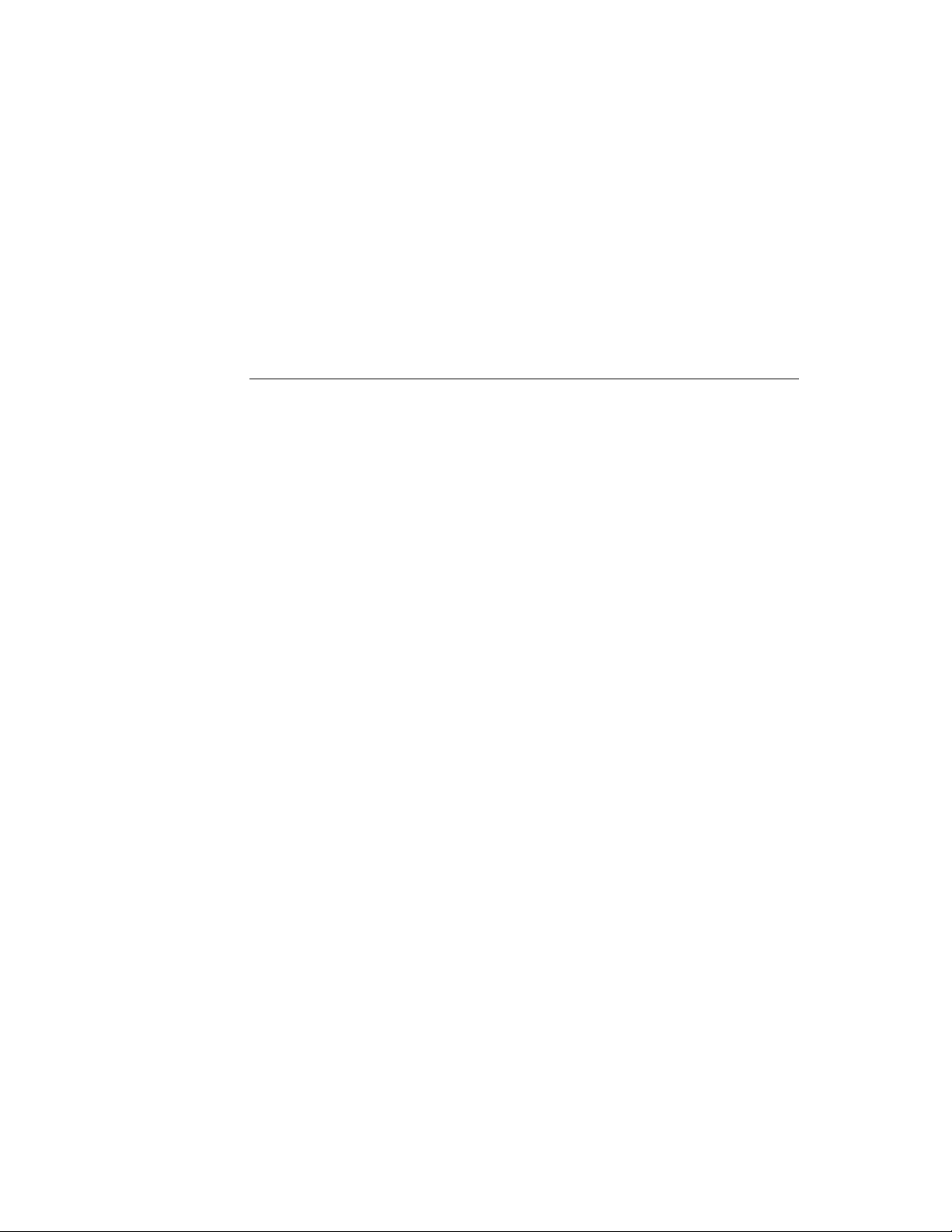

A

601 Pro Series

XL

INTERNATIONAL SAFETY ANALYZER

CLASS I PROTECTIVE EARTH

CLASS II

CLASS IP

TYPE B NON-ISOLATED APPLIED PART

TYPE BF ISOLATED APPLIED PART

TYPE CF

TYPE F

TYPE T

DOUBLE INSULATION

INTERNAL POWER SUPPLY

ISOLATED APPLIED PART

DIRECT CARDIAC APPLICATION

FIXED DEVICE

TRANSPORTABLE DEVICE

E

F

Figure 1-1: 601PRO Top Panel Illustration

B

G H

PREVIOUS

ESC/STOP

VIEW PRESENT

SETTINGS

PRINT HEADER

PRINT DATA

C

VOLTS-V

PROTECTIVE EARTH

RESISTANCE-

34

PATIENT

LEAKAGE-µA

IEC 1010

ACCESSIBLE-V/µA

9

TESTS

TESTS

CURRENT-A

10

EARTH

LEAKAGE-µA

MAINS ON AP

LEAKAGE-µA

76

VDE EQUIVALENT

DEVICE LEAK-µA

/

INSULATION-M

2

ENCLOSURE

LEAKAGE-µA

5

PATIENT AUXILIARY

CURRENT-µA

8

VDE EQUIVALENT

PATIENT LEAK-µA

ENT

D

Baw152f.eps

Top Panel: Identifying 601PRO Components

Use the drawing of the 601PRO top panel, displayed above, to locate the

following components.

A Printer

Optional 24-character printer for

immediate hard copy of results.

B Previous Key

C

Soft Keys 1-4

Returns user to the previous screen.

Make dynamic assignments based on

current screen.

Enter Key

D

Advances to the next menu or

saves/selects options.

E

Esc/Stop Key

Discontinues current test and returns

operator to the

the DUT outlet.

F

View Present

Settings Key

Advances to View Present Settings

screen when at the

Displays current settings and allows

operator to edit test standard, class/type,

and lead assignments (see page 3-7).

G

Print Header Key

Sends device information fields to

enabled printer.

H

Print Data Key

Sends displayed test data to printer.

MAIN MENU. Turns off

MAIN MENU.

1-6

Page 21

INTRODUCTION AND DESCRIPTION

Keys Used to Enter Device Control Numbers

The keys described below (0 through –) can be used to enter test control

numbers in the auto/step modes of operation. These keys are also referred to as

test-shortcut keys and can be used to initiate manual tests.

0 Volts In single lead mode, displays mains voltage.

In dual lead mode, displays voltage between

RED and BLACK test leads.

1 Current Measures the current consumption (in

amperes) of the device under test.

2

3 Protective Earth

4 Earth Leakage Is measured between the DUT “Protective

5 Enclosure Leakage In single-lead mode, measures the enclosure

6

Patient

7 Mains on

8 Patient Auxiliary

9 IEC 1010

Insulation Tests insulation resistance (mains to case or

applied parts to case).

Measures the earth resistance using a 1A test

Resistance

Leakage

Applied Part

Leakage

Current

Accessible

Voltage/Leakage

current (unless 10A or 25A is selected).

Earth” terminal and the “Protective Earth”

terminal of the 601PRO.

leakage (RED test lead to DUT protective

earth on the 601PRO).

Measures the patient leakage current (applied

part to earth.

Applies 110% mains voltage to selected

applied part and measures leakage to earth in

both normal and reverse polarity. Does not

apply to patient auxiliary selections.

Measures the leakage and biasing current

between applied parts.

Selects the IEC 1010 Test Load. Measures

accessible voltage through the RED jack to

601PRO earth. Allows access to the

accessible leakage test.

/ VDE Equivalent

Device Leakage

– VDE Equivalent

Patient Leakage

Selects the IEC 601 test load. Applies 110%

of mains voltage between L1/L2 and earth.

Selects the IEC 601 test load. Applies 110%

of mains voltage to the selected applied part

and measures the leakage.

1-7

Page 22

601PRO SERIES

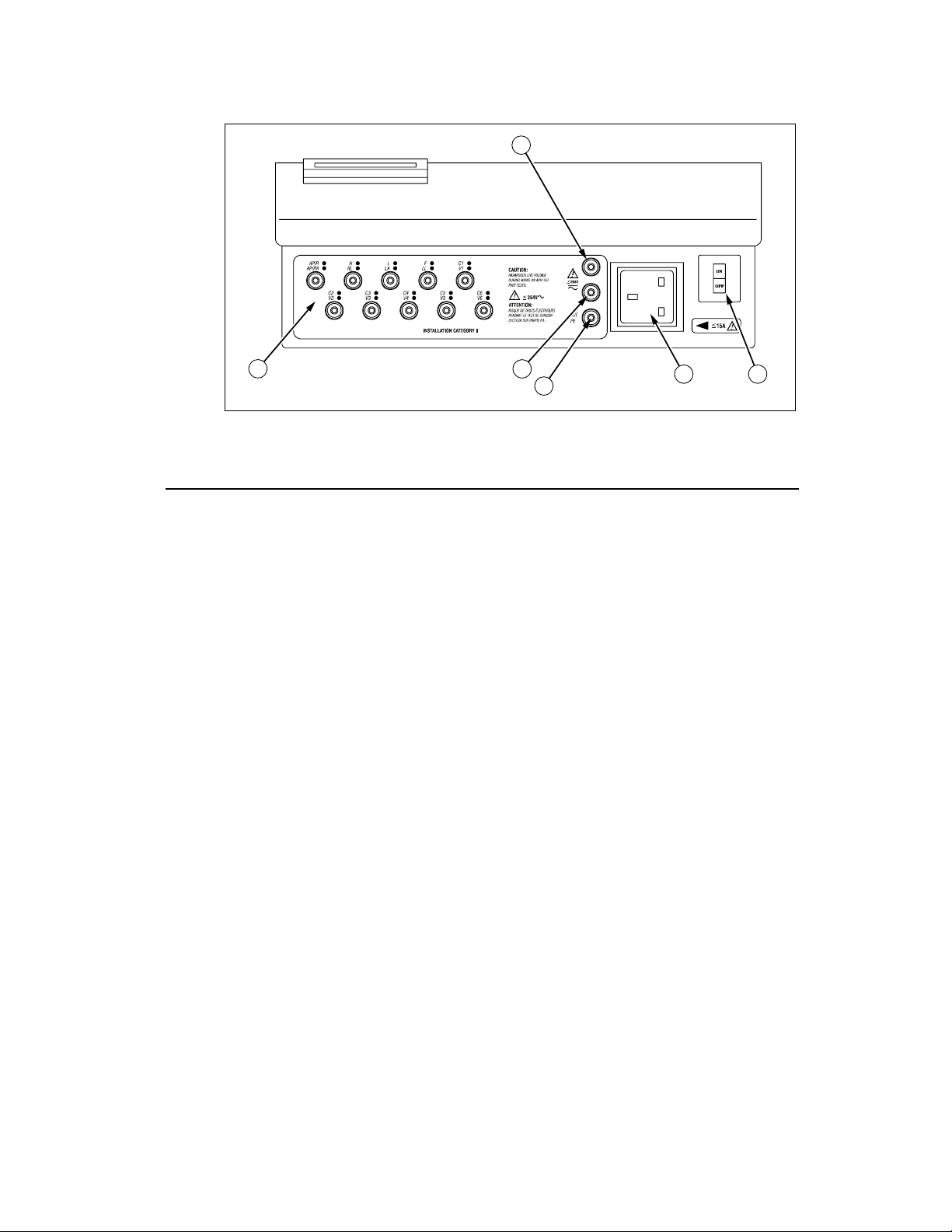

XL

B

A

Front Panel

A Applied Part

B Red Input

C Black Input

D Green Input

E Power Outlet Allows standard power plug connection

C

D

Figure 1-2: 601PRO Front Panel Illustration

The jacks allow direct connection to

Terminal

banana jacks, or 4mm-to-alligator

adapters provided.

Single test lead connection.

Terminal

Used for dual lead testing in combination

Terminal

with red test lead.

Protective Earth of Device Under Test.

Terminal

of the Device Under Test. 120V @ 15A

or 240V @ 15A maximum.

E F

baw154f.eps

1-8

F On-Off Switch /

Circuit Breaker

Power up the 601PRO, I=ON, 0=OFF;

built-in ISA circuit breaker.

Note: To power up the 601PRO, place

the index finger on the rocker switch and

use a rolling motion to push from "OFF"

to "ON." Do NOT forcefully push or

snap the rocker switch. This may cause

the unit to shut off.

Page 23

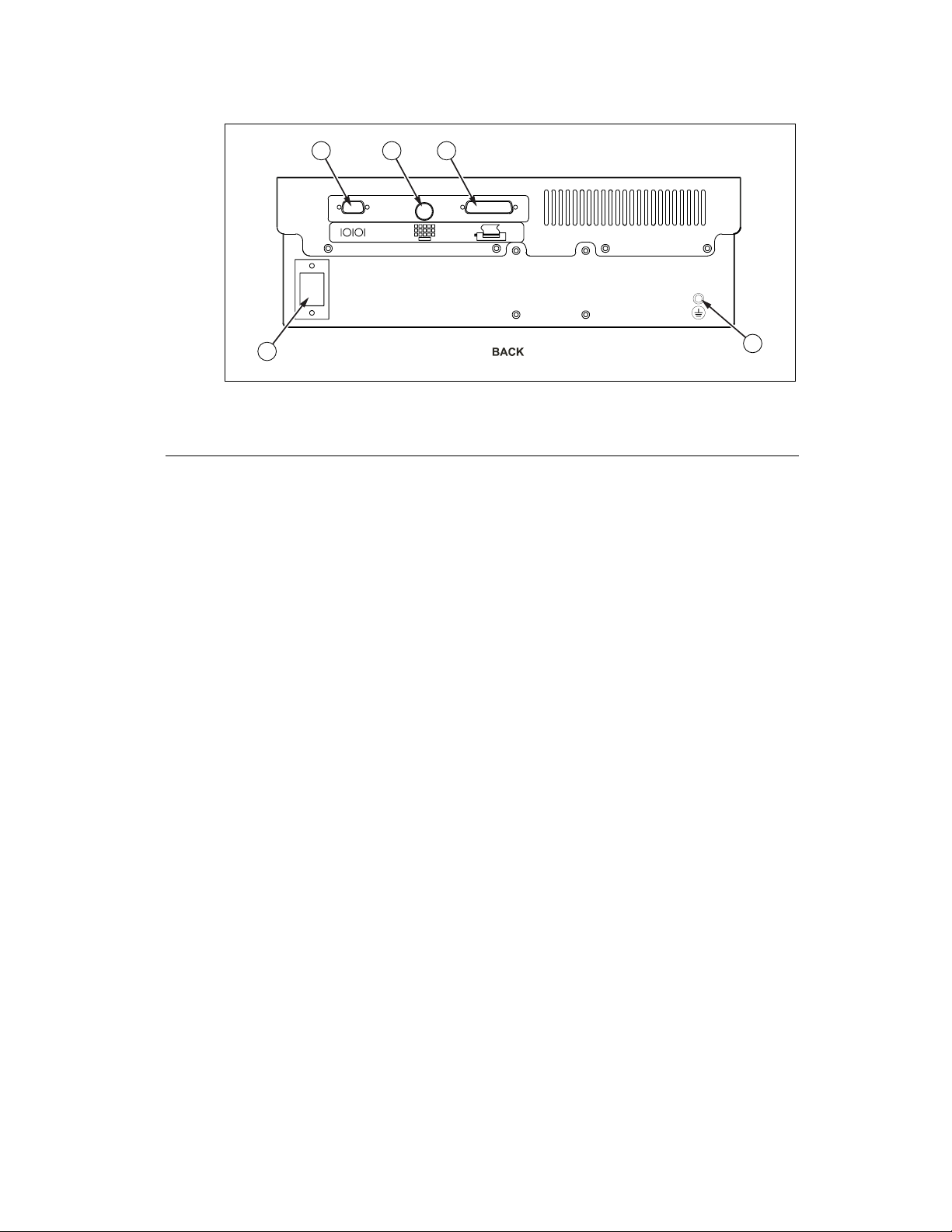

INTRODUCTION AND DESCRIPTION

D

Back Panel

A RS232 Connection Allows bi-directional computer control.

B Keyboard Input Allows the use of an external keyboard

A

B C

E

baw155f.eps

Figure 1-3: 601PRO Back Panel Illustration

Serial D-9 female connector.

for data input. DIN 5 socket.

C Printer Connector Allows for an external parallel printer.

D-25 female connector.

D Power Cord

Connection

E Protective Earth

Connection

120V/15A or 240V/15A power cord

connection.

Provides a direct connection to the

power cord ground.

1-9

Page 24

601PRO SERIES

6. Statement of Compatibility

XL

The 601PRO is compatible with and has the same base features as the previous

601PRO safety analyzer. It also has some new features that include the

following:

• Because of new features in this version of the 601PRO, the Device Record

Format has been changed. If old format device records are transmitted to

the 601PRO Series

via RS232, they will be accepted. However, when

XL

receiving device records from the 601PRO, the new format will always be

used. Refer to Chapter 6 for details.

• Custom standard names are fixed. Any old-style device record received via

RS232 must be updated to reflect this change. Refer to Chapter 9 for more

details.

• Supports all computer control commands from the previous 601PRO.

Some of the commands no longer have meaning in the new 601PRO and

have been given fixed responses. New commands have been added to

support new features on the instrument. Refer to Chapter 10 for complete

details.

• Due to new features, the RS232 result output format has changed. It is very

similar to the old format but has extra fields for the new features. The

transfer utility is no longer required or supported. Refer to Chapter 5

for complete details.

• Because the 601PRO now supports IEC 601, IEC 1010, and AAMI test

loads, some changes in computer control commands have been made. All

existing (previous) commands use the 601 test load. New commands have

been created to support the new loads. Refer to Chapter 10 for details.

• Unlike previous versions of the 601PRO, the 601PRO Series

XL

standard D9M-D9F serial cable.

uses a

1-10

Page 25

Setting Up the 601PRO

Chapter

2

This chapter describes the factory default settings and how to change them,

and provides instructions for one-time customization of the 601PROXL using

SYSTEM SETUP key and the Select Setup Function menu.

the

1. Using Factory Default Settings

2. Selecting the Test Standard

3. Selecting the Printer Output

4. Selecting the RS232 Baud Rate

5. Activating the Beeper

6. Setting the Time and Date

7. Configuring the Enclosure Leakage for the Auto

Mode Sequence

8. Selecting Language Options

9. Selecting the DC Option

10. Selecting the Auto/Step Tests: Controlled Power

Sequences or 601CE Conventional Test

Sequences

11. Enabling Stop on Failure

12. Configuring for Device Records or Templates

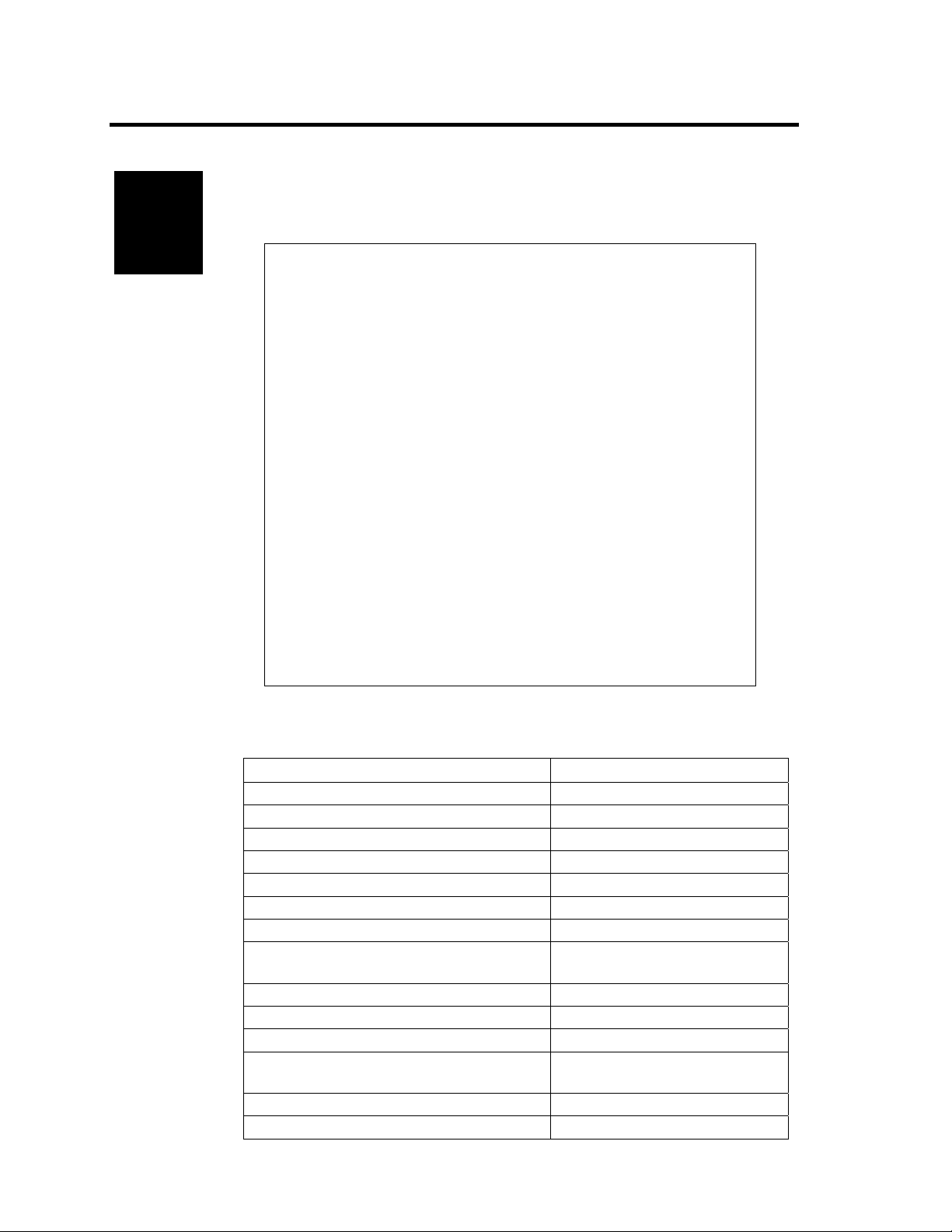

1. Using Factory Default Settings

The factory default settings are shown below.

Description Factory Default Setting

Test Standard IEC 601-1 (Class I, BF)

Number of Applied Parts 0 (To change, refer to Chapter 3)

Printer Output Internal

RS232 9600 Baud

Beeper On

Time Format 24 hour

Date Format MDY

Enclosure Leakage (multiple readings

during the Auto Mode sequence)

Keyboard Language English

Display/Print Language English

DC Readings Off

Auto/Step Sequences: Controlled Power

Sequence

Stop on Failure Off

DEV RECS / TEMPLATES DEVICE REC

Off

On

2-1

Page 26

601PRO SERIESXL

2. Selecting the Test Standard

The Select Test Standard option allows the operator to choose among

IEC 601-1, VDE 701-1, VDE 751-1, HEI 95, IEC 1010, AAMI,

AS/NZS 3551, or custom standards.

Refer to Chapter 8, Standards and Principles, for a detailed discussion of IEC

601-1, VDE 701-1, VDE 751-1, HEI 95, IEC 1010, AAMI, and AS/NZS 3551

standards and their selection.

• At the 601PRO

Setup Function

• At the

Select Test Standard menu, select a test standard, or press *MORE

for additional standards.

MAIN MENU, press SYSTEM SETUP to access the Select

menu. Press TEST STANDARD:

baw008f.eps

2-2

☛ Note: To enable/disable the test standards that appear at the

Standard

*MORE

Enable Test Standard menu.

menu, press UTILITIES at the MAIN MENU, then

, then ENABLE STANDARDS. Press YES or NO at the

Once the selection is made, the 601PRO will automatically return

MAIN MENU where the selected standard is displayed.

to the

Default Setting: IEC 601-1

baw009f.eps

Select Test

Page 27

SETTING UP THE 601PRO

3. Selecting the Printer Output

Before testing, choose whether to use the optional internal printer, an external

printer, or no printer.

• From the 601PRO

Select Setup Function menu. Press PRINTER OUTPUT:

• At the

Printer Output menu, use the SOFT KEYS to select a printer

interface:

MAIN MENU, press SYSTEM SETUP to access the

baw026f.eps

baw010f.eps

⇒ The EXTERNAL ASCII ONLY setting is for older (and some newer)

printers that will interpret and print basic ASCII characters.

⇒ The EXTERNAL HP PCL3 printer setting is for any HP printer that

supports PCL3 (Printer Control Language, Version 3). The control

sequence feature configures the printer and then downloads ASCII

characters to it.

☛ Note: Follow the printer manufacturer’s instructions for handling page

ejects and printing using form-feed commands.

• Press

Default Setting: Internal

previous or enter to save the settings and return to the MAIN MENU.

2-3

Page 28

601PRO SERIESXL

4. Selecting the RS232 Baud Rate

To select the baud rate for the RS232 serial port:

• From the 601PRO

Select Setup Function menu. Press RS232:

At the 601PRO

RS232 Settings menu, press a SOFT KEY to select a baud rate:

MAIN MENU, press SYSTEM SETUP to access the

baw027f.eps

Default Setting: 9600

• Press

enter to save the setting and return to the Select Setup Function

menu. Press

previous to return to the MAIN MENU.

baw011f.eps

2-4

Page 29

SETTING UP THE 601PRO

5. Activating the Beeper

To activate/deactivate the beeper:

• From the 601PRO

Select Setup Function menu. Press *MORE until the following menu is

displayed, then press

MAIN MENU, press SYSTEM SETUP to access the

BEEPER:

• Press a

SOFT KEY to select ON or OFF at the Key and Error Beeper

menu:

baw012f.eps

baw025f.eps

Selecting

an error occurs. Selecting

OFF will silence the beep that sounds when a key is pressed or when

OFF will not disable the beeper during lead

calibration or when performing tests using the beeper as a warning.

Default Setting: ON

• Press enter to save the settings and return to the Select Setup Function

menu. Press

previous to return to the MAIN MENU.

2-5

Page 30

601PRO SERIESXL

6. Setting the Time and Date

The time and date are used to record testing times and their associated dates.

The clock can be set in either 12-hour or 24-hour format. The date format is

either MM-DD-YY or DD-MM-YY.

To set the time format:

• From the 601PRO

Select Setup Function menu. Press *MORE until the following menu is

displayed, then press

MAIN MENU, press SYSTEM SETUP to access the

TIME FORMAT:

To set the time:

• At the following menu, press a

24 HOUR format. Press the cursor SOFT KEY to change cursor position

and enter the time of day using the

SOFT KEY to select either the 12 HOUR or

test-shortcut keys.

baw028f.eps

2-6

Default Setting: 24 HOUR

• Press

enter to save the settings and return to the Select Setup Function

menu. Press

previous to return to the MAIN MENU.

baw013f.eps

Page 31

SETTING UP THE 601PRO

To set the date format:

• From the 601PRO

Select Setup Function menu. Press *MORE until the following menu is

displayed, then press

MAIN MENU, press SYSTEM SETUP to access the

DATE FORMAT:

To set the date:

• At the following menu, press a

DD/MM/YY. Press a SOFT KEY to move the cursor in either direction. Use

test-shortcut keys to enter the date.

the

SOFT KEY to select either MM/DD/YY or

baw029f.eps

Default Setting: MDY

• Press

enter to save the settings and return to the Select Setup Function

menu. Press

previous to return to the MAIN MENU.

baw014f.eps

2-7

Page 32

601PRO SERIESXL

7. Configuring the Enclosure Leakage for the Auto Mode

Sequence

To take multiple Enclosure Leakage readings when performing tests in

Auto mode:

• From the 601PRO

MAIN MENU, press SYSTEM SETUP to access the

Select Setup Function menu. Press *MORE until the following menu is

displayed, then press

ENCLOSURE LEAKAGE:

• At the following menu, press YES.

Default Setting: NO

baw015f.eps

baw016f.eps

2-8

• Press

enter to save the setting and return to the Select Setup Function

menu. Press

previous to return to the MAIN MENU.

baw017f.eps

Thereafter, whenever an

Auto sequence, readings will be continually taken until NEXT-> is pressed.

Enclosure Leakage test is performed as part of an

The last reading taken will then be used to determine Pass/Fail.

☛ Note: If running a custom standard auto sequence while multiple leakage

readings are enabled, the operator may experience a delay of up to

30 seconds when taking DC readings before the next test begins.

Refer to Chapter 4, Auto/Step Modes, for more information.

Page 33

SETTING UP THE 601PRO

8. Selecting Language Options

The Language option allows the operator to select an English, French,

German, or Italian external keyboard, and also to select the print and display

language. Supported keyboards are described in Appendix B. To configure the

Language option:

• From the 601PRO

MAIN MENU, press SYSTEM SETUP to access the

Select Setup Function menu. Press *MORE until the following menu is

displayed, then press

LANGUAGE:

• At the following menu, press a

SOFT KEY to select a keyboard language:

• Press enter. At the following menu, press a SOFT KEY to select a

print/display language:

baw015f.eps

baw018f.eps

Default Setting: ENGLISH

• Press

enter to save the settings and return to the Select Setup Function

menu. The unit will immediately be reconfigured with the new selections.

previous to return to the MAIN MENU.

Press

baw019f.eps

2-9

Page 34

601PRO SERIESXL

9. Selecting the DC Option

The DC option permits the operator to disable all DC readings, allowing the

Auto/Step sequences to run faster. This applies to all sequences, including

Custom, and all modes

and

readings disabled

• To enable/disable DC readings: From the 601PRO MAIN MENU, press

• Press YES or NO at the following menu:

(Auto/Step/Manual), except for IEC 1010 sequences

Computer Control. The 601PRO SERIES

units are supplied with DC

XL

.

SYSTEM SETUP to access the Select Setup Function menu. Press

*MORE until the following menu is displayed, then press DC:

baw030f.eps

Default Setting: No

baw020f.eps

2-10

Page 35

SETTING UP THE 601PRO

10. Selecting the Auto/Step Tests: Controlled Power

Sequences or 601CE Conventional Test Sequences

The Auto/Step Sequences option allows the operator to choose between the

controlled power sequences or the conventional test sequences popular in the

older 601PRO CE units.

To run conventional test sequences, it is necessary to disable the controlled

power sequences for IEC 601 and HEI 95

function, press

*MORE at the Select Setup Function menu as shown:

Auto/Step sequences. To access this

baw031f.eps

This will display the following:

• Press YES or NO at the following menu:

Default Setting: Yes

baw001f.eps

baw021f.eps

2-11

Page 36

601PRO SERIESXL

For the controlled power sequences, refer to Chapter 8, Standards and

Principles, pages 8-5 and 8-6 for IEC 601 test limits, and page 8-12 for HEI 95

test limits.

Although the conventional test sequences are performed in a different order,

the results and printed output are in the same order as the controlled power

sequences. See Chapter 8, pages 8-7 through 8-9 for IEC 601 test limits, and

page 8-13 for HEI 95 test limits.

The 601PRO, not the device record, determines which sequence is used. The

601PRO SERIES

disabled.

units are supplied with the controlled power sequences

XL

☛ Note: The setup options that are defined are

not saved with the

device records.

Startup and Power Off Delays have been inserted into the conventional test

sequences to allow customization of the sequence. Long or short delays can be

programmed into a device record, considering the specific device under test.

The Power Off Delay, for all sequences, has a range of 1 to 9999 seconds. The

Startup Delay has a range of 0 to 9999 seconds.

☛ Note: In

Auto/Step mode, Startup and Power Off delays are

performed, regardless of the tests enabled.

2-12

Page 37

SETTING UP THE 601PRO

11. Enabling Stop on Failure

The Stop On Failure option allows the operator to stop the execution of an

Auto sequence when a failed reading is encountered. To access this option,

SYSTEM SETUP at the MAIN MENU, then press *MORE at the Select

press

Setup Function

menu as shown:

baw031f.eps

This will display the following:

• Press YES or NO at the following menu:

baw002f.eps

baw022f.eps

2-13

Page 38

601PRO SERIESXL

• If YES is selected: During an Auto sequence, when a reading is taken that

is outside the limit for the current test, the sequence will stop and a “UNIT

FAILED” message will appear with an error beep. Pressing any key will

put the operator in

Manual mode at the test during which the failure had

occurred.

When a test is executed in an

Auto sequence that utilizes multiple lead

types (Insulation Resistance, Patient Leakage, Patient Auxiliary Current, or

Mains on Applied Part), the 601PROXL will cycle through all of the leads

prior to determining whether a limit has been exceeded. If a failure is

detected, the operator will be placed in

Manual mode at the failed test. The

outlet configuration will be that of the failed condition. If the test uses

applied parts, the applied part lead will be the last one tested, which is not

necessarily the lead that failed.

☛ Note:

Stop on Failure does not apply to Accessible Voltage and

Accessible Leakage tests for IEC 1010.

NO is selected: The Auto sequence will execute until completion. The

• If

Pass/Fail determination is performed when all tests are completed.

Default Setting: No

2-14

Page 39

SETTING UP THE 601PRO

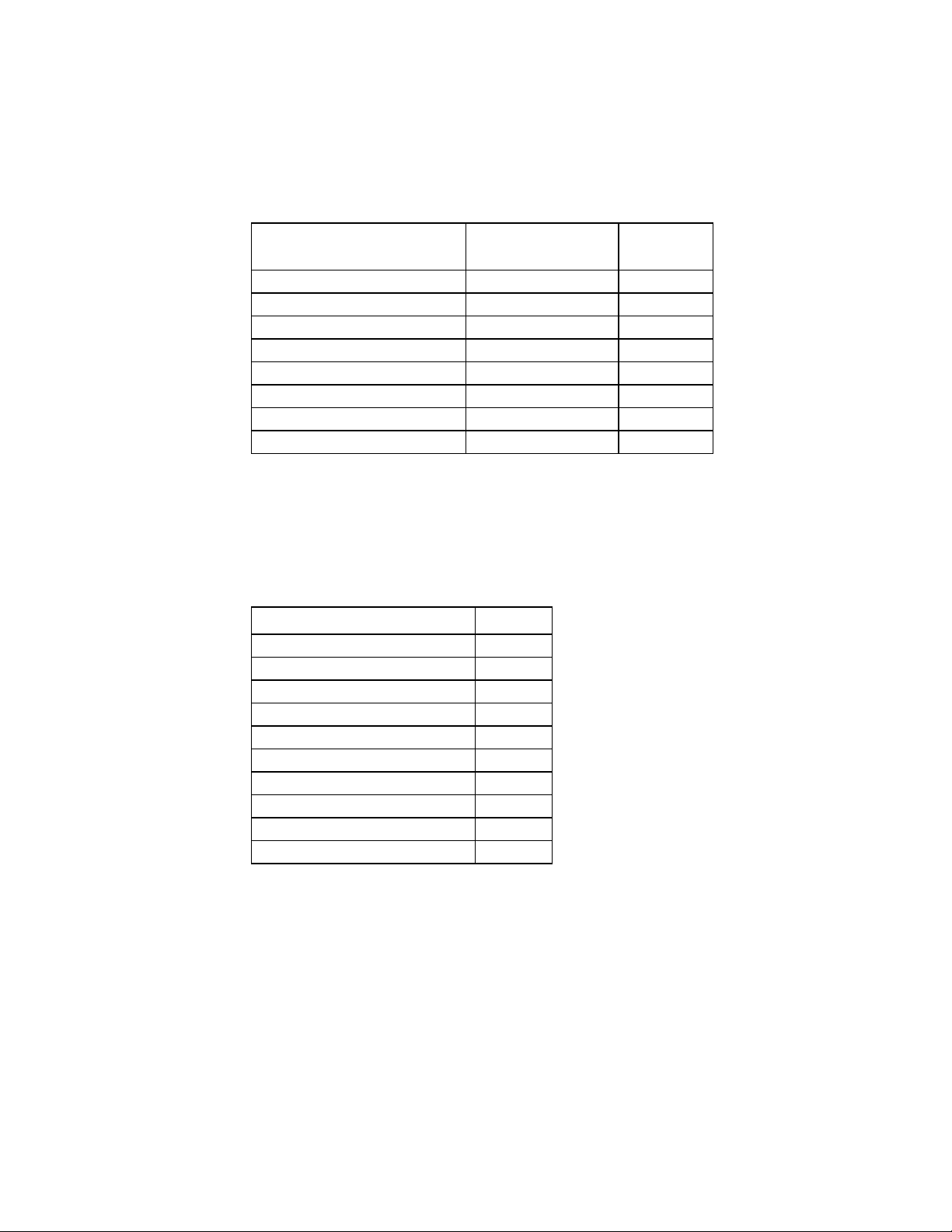

12. Configuring for Device Records or Templates1

To speed up the process of entering test variables into the 601 Pro before

executing the tests, Device Records and Templates are available to store these

variables for quick recall.

Device Records store test variables for each specific piece of equipment to be

tested. These records not only store test variables, but specific equipment

information such as serial number, control number and location of each device

tested as well. Templates on the other hand, do NOT store the specific

equipment information, but require this information to be keyed in at the end of

each test for the test report when running an AUTO/STEP sequence.

Up to a combined total of 1000 Device Records and Templates can reside

together in the 601Pro’s memory. As indicated in the table below, a Device

Record is stored and recalled by the equipment control number. A Template

however, is identified by its name.

All the information stored in a Device Record and a Template is listed in the

following table.

Field Device Record Template

Field to Store by Control Number Name

Standard Yes Yes

Class and Type Yes Yes

Applied Current Yes Yes

Startup Delay Yes Yes

Pause Before Power Off Yes Yes

Power Off Delay Yes Yes

Number of Applied Part Leads Yes Yes

Applied Part Names and Types Yes Yes

Serial Number Yes No

Location Yes No

Device Type Yes Yes

Device Manufacturer Yes Yes

Procedure ID Yes Yes

The advantage of using Templates over Device Records is the reduction of

601Pro memory required to store information on the equipment tested. For

instance, one template can be used to test all devices in your inventory that

have the same model number or require the same test protocol. It’s also easy to

initiate a test sequence for devices using the same template by simply pressing

YES at the “Repeat Auto/Step Sequence?” prompt.

You can print a list of Device Records or Templates by pressing PRINT LIST

in the Device Record or Template Utilities.

1

Templates are available on units operating with V2.00 and later firmware

2-15

Page 40

601PRO SERIESXL

To select between using Device Records or Templates, press SYSTEM SETUP

at the

Function

Press DEV REC or TEMPLATES to make your selection at the following

menu:

MAIN MENU. Next, press *MORE three times at the Select Setup

to display the following menu.

baw131f.eps

baw132f.eps

2-16

Page 41

Manual Mode

Chapter

3

This chapter provides a brief overview of 601PRO operation and describes the power-up

sequence. It also explains how to set up the 601PRO's designation for the classification

and type of instrument to be tested, and how to run a simple test using the applicable test

standard.

1. Connecting the Device Under Test

2. The Power-Up Sequence

3. Selecting the Test Standard

4. Selecting the Class/Type

5. Saving Standard, Class, Type and Test Current

6. Using View Present Settings

7. Manual Operation

1. Connecting the Device Under Test

Before starting the test(s), ensure that the 601PRO and the device being tested are

connected properly. Refer to Figure 3-1 when connecting the Device Under Test

(DUT) to the 601PRO. Applied Parts are optional, depending on the device being

tested.

Warning: Before operating the 601PRO, read the Warnings section on

pages vii through xi

.

When the device and the 601PRO have been connected, power up both units. (The

DUT may also be turned to ON when the

MAIN MENU is displayed and the 601PRO

outlet is OFF.)

Note: This is good electrical practice and prevents pitting or arcing of

☛

the 601PRO outlet or the power connector of the DUT.

Once the DUT has been plugged into the 601PRO and turned on, the operator may

freely move from test to test without changing the power switch of the DUT.

To protective

R

E

Z

Y

L

A

N

A

Y

T

E

F

A

S

L

A

XL

N

IO

T

A

N

R

601Pro

E

T

IN

P

TO

/ S

C

S

T

E

N

SE

E

S

R

G

P

IN

T

W

T

IE

E

V

S

D

A

E

H

T

IN

R

P

M

N

IO

T

A

L

U

2

S

E

IN

R

A

SU

u

E

LO

G

C

A

N

K

Y

E

A

R

E

5

L

IA

XIL

T A

U

N

T uA

E

A

N

R

T

E

R

R

U

IEN

R

C

1

T

T

U

N

A

8

C

P

E

A

A

H

L

T

u

u

A

R

K

E

IV

A

A

G

U

E

E

A

Q

K

L

T

A

E E

4

P

D

LE

IEN

-

V

A

T

A

A

N

S

T

L

O

V

R

0

A

E

E

E

C

TIV

N

C

E

T

TE

IS

O

S

R

3

E

P

R

R

E

TA

A

T D

IN

R

P

P

u

O

E

S

G

IN

H

A

T

A

K

M

A

T

E

A

N

7

L

E

E u

AL

G

IV

A

U

K

Q

A

E

E

LE

E

D

/

V

IC

T

A

V

N

E

u

IE

E

D

T

G

A

A

P

K

A

E

6

L

/uA

10

V

10

LE

C

IB

IE

S

S

E

9

C

C

A

Figure 3-1: Device Under Test (DUT) Connections to the 601PRO

earth or

enclosure

3-1

Page 42

601PRO SERIES

2. The Power-Up Sequence

XL

The 601PRO immediately begins a self-check routine at power-up while the

following instrument identification screen is displayed:

Power-up tests include internal self-checks and wall outlet checks. If any of the

power-up tests fail, the 601PRO displays an error message. Refer to Chapter 11,

Error Messages, Troubleshooting, and Support, for additional information.

baw133f.eps

baw003f.eps

When diagnostics are completed, the

MAIN MENU will appear:

baw004f.eps

To repeat the self-check routine at any time, press UTILITIES from the MAIN MENU,

SYSTEM TEST.

then

☛ Note: At power-up, the 601PRO determines the polarity of the Mains power. If

the Mains polarity is normal (normal for a grounded neutral system), L2 in

the DUT Outlet will be opened whenever a NO L2 condition exists, but if

the Mains polarity is reversed, L1 in the DUT Outlet will be opened

whenever a NO L2 condition exists. This ensures that the highest Mains

voltage remains connected to the device under test for a NO L2 singlefault condition. The operator will not be notified at power-up if the Mains

Voltage is reversed.

☛ Note: At power-up, the number of applied parts will be set to zero (0) for all

standards except VDE 751, which will default to five (5) applied parts.

The current source will default to 1 Amp.

3-2

Page 43

MANUAL MODE

3. Selecting the Test Standard

☛ Note: Chapter 8, Standards and Principles, provides further instructions for

determining and selecting the test standard.

• From the 601PRO

• At the

Select Setup Function menu, press TEST STANDARD:

MAIN MENU, press SYSTEM SETUP.

At the Select Test Standard menu, use one of the SOFT KEYS to select a test

standard, or press

*MORE for additional options.

Once the selection is made, the 601PRO will automatically return to the MAIN

MENU

.

baw008f.eps

baw032f.eps

☛ Note: Changing the test standard may change the instrument's current

Class/Type setting.

3-3

Page 44

601PRO SERIES

4. Selecting the Class/Type

☛ Note: Class/Type is not used by custom standards, and hence, is not available.

XL

The CLASS/TYPE selection sets the Type of EQUIPMENT that is being tested. This

affects the limits for the Protective Earth Resistance, Insulation Resistance L1, L2Case, Earth Leakage, and Enclosure Leakage Tests.

The class/type should be set to the instrument's classification and type before testing.

The 601PRO defaults to the

Class/Type setting for the most recently used test

standard.

Class/Type option allows the operator to choose all valid class/type selections

The

for the present test standard. If the device under test has applied part leads, then they

should be entered via the

accessible from the

view present settings key. The Class/Type option is

MAIN MENU.

If the device to be tested conforms to IEC 601-1, its class/type can easily be

identified by symbols marked on the instrument.

Manual mode, the Test Load used for measurements is set by the test standard

In

selection with the following exceptions:

⇒ The VDE Equivalent Device and VDE Equivalent Patient Leakage tests use

the IEC 601-1 Test Load exclusively.

⇒ The Accessible Voltage and Accessible Leakage tests use the IEC 1010 Test

Load exclusively. When a VDE or IEC 1010 test is selected, the Test Load is

switched to the test-specific load. When a test other than a VDE or IEC 1010

is selected, the Test Load specified by the current test standard (using the

Select Test Standard menu) is used.

3-4

Page 45

MANUAL MODE

Determine the class/type for the instrument by using the following chart:

Class/Type Definitions

Class I

Class I I

Protective Earth.

(There is no symbol

for Class I

instruments.

However, they

generally have a

protective earth

terminal.)

Double insulation (all

plastic case)

Class IP

Type B

Internal Power Supply

Non-Isolated Applied

Part

Type BF

Isolated Applied Part

Type CF

Type F

Type T

Isolated Applied Part,

suitable for direct

cardiac application

Fixed Device

Transportable Device

3-5

Page 46

601PRO SERIES

Press the SOFT KEY below the desired CLASS/TYPE, or press *MORE for additional

options.

☛ Note: When the CLASS/TYPE is changed, the lead types are not changed.

XL

• At the 601PRO MAIN MENU, press CLASS/TYPE:

baw005f.eps

baw006f.eps

☛ Note: Once the selection is made, the 601PRO will automatically return to the

MAIN MENU.

5. Saving Standard, Class, Type and Test Current

The Standard, Class, and Type can be saved in non-volatile memory by running a

manual test that is applicable to that configuration. For example, make a selection

VIEW PRESENT SETTINGS menu. Next, press the 0 button to run a mains

under

Voltage test. Press

PREVIOUS to end the test and now the parameter will be saved. It

will remain as the default after cycling power off and back on.

☛ Note: With units operating with V2.00 or later firmware, the Protective Earth

Resistance Test Current will also be saved as above by running a manual

test.

3-6

Page 47

MANUAL MODE

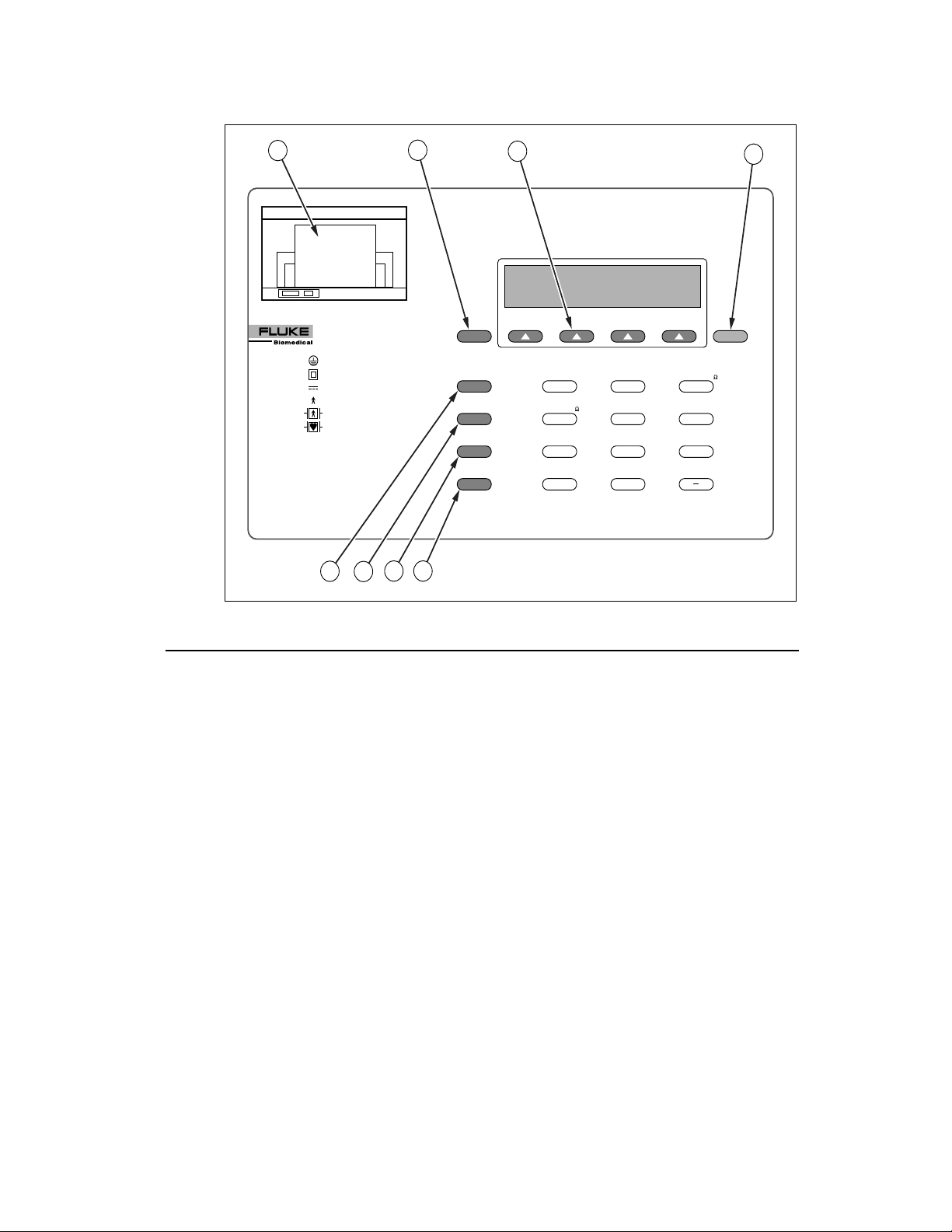

6. Using View Present Settings

• The view present settings key allows the operator to inspect or alter the

currently selected test standard, class/type, or current source. This is also the only

way to edit the Lead selection (Applied Part Type).

From the

• Press the

MAIN MENU or the manual Patient Auxiliary Current test:

view present settings key from the top panel.

PREVIOUS

TESTS

TESTS

ESC/STOP

VIEW PRESENT

SETTINGS

PRINT HEADER

PRINT DATA

VOLTS-V

PROTECTIVE EARTH

RESISTANCE-

34

PATIENT

LEAKAGE-µA

IEC 1010

ACCESSIBLE-V/µA

9

CURRENT-A

10

EARTH

LEAKAGE-µA

MAINS ON AP

LEAKAGE-µA

76

VDE EQUIVALENT

DEVICE LEAK-µA

/

INSULATION-M

2

ENCLOSURE

LEAKAGE-µA

5

PATIENT AUXILIARY

CURRENT-µA

8

VDE EQUIVALENT

PATIENT LEAK-µA

ENT

To change the test standard, press SELECT STANDARD:

baw153f.eps

baw034f.eps

3-7

Page 48

601PRO SERIES

XL

• Use a SOFT KEY to select a test standard, or press *MORE for further options:

baw158f.eps

☛ Note: Altering the test standard may change the Protective Earth Resistance

current setting.

☛ Note: Once the selection is made, the 601PRO will automatically return to the

MAIN MENU.

• To change the class/type, press the

CLASS/TYPE at the following menu:

view present settings key, and press

baw035f.eps

3-8

• Use a

SOFT KEY to select a class/type, or press *MORE for further options:

baw033f.eps

☛ Note: When the CLASS/TYPE is changed, the LEAD types are NOT changed.

☛ Note: Once the selection is made, the 601PRO will automatically return to the

MAIN MENU.

Page 49

MANUAL MODE

To choose the current source to be used for the Protective Earth Resistance test, press

view present settings key, and press AMPERES at the following menu:

the

baw036f.eps

The test current displayed in the upper right corner will toggle between the available

currents.

• Press enter to return to the

Lead Type Definitions

MAIN MENU.

The CLASS/TYPE selection sets the Type of EQUIPMENT that is being

tested. This affects the limits for the Protective Earth Resistance, Insulation

Resistance L1, L2-Case, Earth Leakage, and Enclosure Leakage Tests.

When Applied Part Types are defined, this affects the limits as well as which

tests are being performed on each of the individual leads. The operator

should consider the following possible scenarios when defining Applied Part

Types:

CONDITION 1:

If ALL of the Applied Parts are defined with the SAME Type as the

EQUIPMENT Type, then the leads will be tested TOGETHER.

CONDITION 2:

If ALL of the Applied Parts are defined with the SAME Type, but with a

different type than the EQUIPMENT Type, then the Applied Parts will be

tested INDIVIDUALLY.

3-9

Page 50

601PRO SERIES

XL

CONDITION 3:

If at least one Applied Part is defined with a DIFFERENT Type than any of

the leads or the EQUIPMENT Type, then the Applied Parts will be tested

INDIVIDUALLY.

1. To view or change the lead types, press the

while at the

2. Press

MAIN MENU.

EDIT LEADS at the following menu:

view present settings key

baw037f.eps

3. Enter the

Number of Applied Part Leads using the numeric keys:

3-10

baw038f.eps

This selection allows the user to define the number of applied parts to be

tested during the Mains on Applied Part, Insulation Resistance, Patient

Auxiliary Current, and Patient Leakage tests. This screen will only

appear when the selected test standard is one of the following:

♦ IEC 601-1

♦ HEI 95

♦ Custom 1-4*

♦ AAMI*

♦ AS/NZS 3551

enter.

Press

*Note: When using the AAMI or Custom test standard, only the applied

parts can be assigned; the Type cannot be changed.

Page 51

MANUAL MODE

4. Make lead type assignments at the Define Lead and Select Type menu:

baw039f.eps

This selection allows the operator to define the Types for each of the

applied parts during the following tests: Mains on Applied Part,

Insulation Resistance – Applied Part, Patient Leakage, and Patient

Auxiliary Current. The Limits applied to the leads will be set based on

the Type selected.

Use the following procedure to test a defibrillator with two paddles, Type

BF, and three ECG leads, RA, LA and LL, all of which are Type CF.

(This is an example of Condition 3 described on page 3-10.)

Assuming that the ECG leads will be connected to the 601PRO applied

part terminals with the identical names, the paddles would have to be

connected to the RL and any V terminal. Define the lead types using the

following steps:

1. The first lead that appears for definition is RA. Since RA is Type CF,

TYPE CF:

press

baw040f.eps

Press enter to advance to the next lead (RL).

2. Since RL is Type BF, press

enter to advance to the next lead (LA).

Press

TYPE BF:

baw041f.eps

3-11

Page 52

601PRO SERIES

XL

3. Since LA is Type CF, press

TYPE CF.

enter to advance to the next lead (LL).

Press

baw042f.eps

4. Since LL is Type CF, press

enter to advance to the next lead (V1-V6).

Press

TYPE CF.

baw043f.eps

5. Since the V lead is Type BF, press

TYPE BF.

3-12

baw044f.eps

☛ Note: The applied parts are always assigned left to right,

beginning with the top row.

Page 53

MANUAL MODE

7. Manual Operation

The 601PRO can be used to perform individual tests manually (Manual mode)

without the need to perform an automated sequence (

Auto mode).

☛ Note: In Chapter 8, Standards and Principles, a table of limits for each test

standard, Class, Type, and DUT Outlet configuration is available. In

Manual mode, tests that are not part of the currently selected standard

will operate, but the limits will be displayed as

Inv (invalid).

The operator may perform any of the available tests by selecting

TESTS/AUTOMODES option. The following will be displayed:

MANUAL from the

baw045f.eps

Press the *MORE key to view all possible tests.

☛ Note: The IEC-1010 Accessible Leakage Current and Accessible Voltage tests

appear in the menus only when the IEC-1010 test standard is the currently

selected standard. Similarly, the VDE Equivalent Device Leakage Current

and VDE Equivalent Patient Leakage Current appear in the menus only

when the appropriate VDE test standard is the currently selected standard.

3-13

Page 54

601PRO SERIES

When in the MAIN MENU or any manual test, the operator may also select a manual test

by pressing the

XL

test-shortcut keys as indicated in the following table.

Test-Shortcut

Key

0 Mains Voltage and Dual Lead Voltage

1 Current Consumption

2 Insulation Resistance

3 Protective Earth Resistance

4 Earth Leakage Current

5 Enclosure Leakage Current

6 Patient Leakage Current

7 Mains on Applied Part Leakage Current

8 Patient Auxiliary Current

9 IEC 1010 Accessible Voltage and

IEC 1010 Accessible Leakage Current

/

-

VDE Equivalent Device Leakage Current

VDE Equivalent Patient Leakage Current

Manual Test Selected

In addition to the above tests, Dual Lead Leakage and ECG Output can be accessed

through

*MORE until the tests are displayed. These tests are not accessible from the testshortcut

the manual test menus by pressing TESTS/AUTOMODES, then MANUAL, then

keys.

3-14

Additional Features

• From the

MAIN MENU or any manual test, press the print header key to print a

test header to the selected printer.

• When the

MAIN MENU is displayed, the DUT outlet is OFF (L1, L2 and Earth

are open).

• The current standard is displayed on the

selecting

present settings

SYSTEM SETUP then TEST STANDARD, or by pressing the view

key. Refer to Chapter 8, Standards and Principles, for details.

• The current class/type is displayed on the

selecting

CLASS/TYPE or by pressing the view present settings key. Refer to

page 3-8 in this chapter, or Chapter 2, Setting Up the 601PRO, for details.

MAIN MENU and may be changed by

MAIN MENU and may be changed by

Page 55

MANUAL MODE

• In tests where the condition of the DUT outlet can be changed, its status is shown

on the display and may be modified by pressing the appropriate

SOFT KEY on

the 601PRO. The following menu is displayed:

baw046f.eps

• SOFT KEY 1 cycles the polarity from Normal Polarity to DUT Off to

Reverse Polarity, or from Reverse Polarity to DUT Off to Normal

Polarity.

SOFT KEY 2 changes the earth line from Earth (closed earth) to No

•

Earth (open earth).

SOFT KEY 3 changes the L2 line from L2 (closed L2) to No L2 (open

•

L2).

• In all modes, when changing tests, the configuration of the DUT outlet will not

change unless the present condition is invalid for the new test selected. For

example, if L2 is open in a patient leakage test, and an enclosure leakage test is

selected, L2 will remain open. If a Mains On Applied Part test were selected

instead of Enclosure Leakage, L2 would automatically close, because its

connection is required for this test.

• The V1 through V6 Applied Part/ECG terminals on the 601PRO control panel

are all internally connected together and act as a single applied part.

Manual and Step modes, the insulation resistance test is performed for one

• In

minute only. In

Auto mode, the insulation resistance test is performed for 12

seconds.

• The

• The

• The

• The

Important: Inv (Invalid) will appear next to the reading if the selected test is not

enter key advances to the next menu or saves/selects options.

print data key sends displayed test data to the printer.

previous key returns the operator to the previous screen.

esc/stop key discontinues the current test and returns the operator to the

MAIN MENU.

applicable to the test standard and class/type chosen, and outlet fault

conditions are present.

3-15

Page 56

601PRO SERIES

Shortcut Key 0: Mains Voltage Test and Dual Lead Voltage Test

XL

This test can be initiated either from the test-shortcut keys or the MAIN MENU. The