Page 1

Victoreen® 6000-529

Mammographic Ion Chamber

March 2005

Manual No. 6000-529-1 Rev. 2

©2004, 2005 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies

Users Manual

Page 2

Fluke Biomedical

Radiation Management Services

6045 Cochran Road

Cleveland, Ohio 44139

440.498.2564

120 Andrews Road

Hicksville, New York 11801

516.870.0100

www.flukebiomedical.com/rms

Page 3

Table of Contents

Section 1: General Information................................................................................... 1-1

1.1 Introduction .................................................................................................. 1-1

1.2 Application ................................................................................................... 1-1

1.3 Specifications............................................................................................... 1-1

1.4 Receiving Inspection.................................................................................... 1-3

1.5 Storage ........................................................................................................ 1-3

1.6 Procedures, Warnings and Cautions ........................................................... 1-3

1.7 Installation.................................................................................................... 1-4

1.8 Electrical Interface ....................................................................................... 1-4

1.9 Setup ........................................................................................................... 1-4

Section 2: Theory of Operation................................................................................... 2-1

2.1 Theory of Operation..................................................................................... 2-1

2.2 Sample Applications .................................................................................... 2-1

Section 3: Maintenance, Calibration and Troubleshooting...................................... 3-1

3.1 Maintenance ................................................................................................ 3-1

3.2 Calibration.................................................................................................... 3-1

3.3 Troubleshooting ........................................................................................... 3-1

i

Page 4

(Blank Page)

Page 5

General Information

Introduction

1

Section 1

General Information

1.1 Introduction

The Model 6000-529 Mammographic Ion Chamber is an ion chamber especially designed to measure low

energy x

1.2 Application

The Model 6000-529 Mammographic Ion Chamber is specifically designed for measurement of exposure

rate from the output of mammographic x-ray tubes.

-ray exposure as encountered in mammography.

1.3 Specifications

Volume 3.3 cm3

Size 41 mm x 14 mm high

Window Material Polycarbonate

2

Window Thickness 9.5 mg/cm

Sensitivity 1 nC/R, nominal (0.087 nC/Gy)

Energy Dependence Within ± 5% from 0.2 mm AI HVL to 5.0 mm AI

Angular Response ± 2% for radiation incidence of up to 30° from normal

Max. Exposure Rate 13 R/min at 300 V bias for 99% collection efficiency

Accessories Custom carrying case and detachable acrylic stem

Cable Length 10 meters

Cable Termination BNC signal and banana HV or BNC Triax

Weight 128 g

1-1

Page 6

Victoreen 6000-529

V

Operators Manual

Figure 1-1. Model 6000-529 Ion Chamber (shown with handle attached)

Model 6000-529 Energy Response

(normalized to 0.3 mm AI HVL)

Response

alue Layer (mm AI)

Half-

Figure 1-2. Model 6000-529 Energy Response

1-2

Page 7

General Information

Receiving Inspection

1.4 Receiving Inspection

Upon receipt of the package:

1. Inspect the cartons (s) and contents for damage. If damage is evident, file a claim with the carrier

and notify Fluke Biomedical, Radiation Management Services at 440.248.9300.

2. Remove the contents from the packing material.

3. Verify that all items listed on the packing list have been received and are in good order.

1.5 Storage

The storage requirements for this instrument are listed below.

1. The instrument shall be stored in a cool, dry location.

2. If the instrument is taken from its current location and is to be placed in a new location with a

different ambient temperature, allow the instrument to reach the new location’s ambient

temperature before applying power.

1.6 Procedures, Warnings and Cautions

1

The equipment described in this manual is intended to be used for the detection and measurement of

ionizing radiation. It should be used only by persons who have been trained in the proper interpretation of

its readings and the appropriate safety procedures to be followed in the presence of ionizing radiation.

Although the equipment described in this manual is designed and manufactured in compliance with all

applicable safety standards, certain hazards are inherent in the use of electronic and radiometric

equipment.

Warnings and Cautions are presented throughout this document to alert the user to potentially

hazardous situations. A Warning is a precautionary message preceding an operation that has the

potential to cause personal injury or death. A Caution is a precautionary message preceding an operation

that has the potential to cause permanent damage to the equipment and/or loss of data. Failure to comply

with Warnings and Cautions is at the user's own risk and is sufficient cause to terminate the warranty

agreement between Fluke Biomedical, Radiation Management Services and the customer.

Adequate warnings are included in this manual and on the product itself to cover hazards that may be

encountered in normal use and servicing of this equipment. No other procedures are warranted by Fluke

Biomedical. It shall be the owner's or user's responsibility to see to it that the procedures described here

are meticulously followed, and especially that Warnings and cautions are heeded. Failure on the part of

the owner or user in any way to follow the prescribed procedures shall absolve Fluke Biomedical and its

agents from any resulting liability.

Indicated battery and other operational tests must be performed prior to each use to assure that the

instrument is functioning properly. If applicable, failure to conduct periodic performance tests in

accordance with ANSI N323-1978 (R1983) Radiation Protection Instrumentation Test and Calibration,

paragraphs 4.6 and 5.4, and to keep records thereof in accordance with paragraph 4.5 of the same

standard, could result in erroneous readings or potential danger. ANSI N323-1978 becomes, by this

reference, a part of this operating procedure.

1-3

Page 8

Victoreen 6000-529

Operators Manual

1.7 Installation

CAUTION

Ensure all power is removed prior to installing the

Model 6000-529 Ion Chamber.

Installation of the Model 6000-529 consists of connecting the ion chamber to a Model 4000M+, 4000+,

6000B, 6000M, RAD-CHECK® Plus, or any medical grade electrometer.

The Model 6000-529 may also be used with the Model 6000-531 preamplifier for interfacing with the 4000

or 6000 series of instruments. Refer to the 6000-531 manual for interface details.

A handle is also included with the ion chamber for supporting the ion chamber for in-air measurements.

1.8 Electrical Interface

Final electrical interface connections between the preamplifier, the Ion Chamber, and the host instrument

are listed in Table 2-1.

Table 2-1. Electrical Interface Connections

Connector Description

BNC Ion Chamber Output

HV (BIAS) Ion Chamber High Voltage

1.9 Setup

Because the Model 6000-529 Ion Chamber may be used with many commercially available electrometers

and dosimeters, please refer to the applicable instrument manual for set up and calibration.

1-4

Page 9

Theory of Operation

Theory of Operation

2

Section 2

Theory of Operation

2.1 Theory of Operation

An ionization chamber consists of a defined volume of air in which ions produced by radiation passing

through the chamber can be collected and measured. The Model 6000-529 is a parallel plate ion

chamber, consisting of a guarded center electrode placed near a conductive plate that serves as a

window as well as an electrode. A potential difference in the range of approximately 200 - 300 volts is

placed across the plates of the ion chamber (the high voltage applied to the ion chamber will depend on

the host instrument used). When ionizing radiation passes through the chamber, ion pairs are produced,

each pair consisting of one positive and one negative ion. Under the influence of the electric field

produced by the potential between the plates, the ions move toward their oppositely charged plate. Upon

arrival, they are neutralized by the free charges on the plates, taking an electron from the negative plate

and adding an electron to the positive plate. This causes a current to flow through the external electronics

connected to the plates, the magnitude of which is proportional to the rate of exposure to radiation.

The sensitivity of an ion chamber depends on the number of air molecules in the chamber, in fact these

quantities are directly proportional. The number of molecules is a function of volume, temperature, and

pressure. The volume of air in the chamber is fixed, but since it communicates with the atmosphere,

temperature and pressure will vary. The chambers are calibrated at Fluke Biomedical at a temperature of

22°C and a pressure of 760 mmHg. A correction factor should be applied to the reading given by the ion

chamber, based on the ambient temperature and barometric pressure at the time the measurement is

made. For diagnostic x-ray use, this is usually unnecessary since the errors are on the order of 0.3% per

degree Celsius and 0.1% per mmHg. However, if you are using the 6000-529 at an elevation greatly

different than sea level, the error could be significant. The correction factor is calculated by the following

expression:

760 T +

cf =

P

Where T is the temperature in degrees Celsius and P is the pressure in mmHg.

x

273.16

295.16

2.2 Sample Applications

Beam Quality Measurements

Beam quality is an indication of the penetrating ability of diagnostic x-rays. The quantity being measured

is the half-value layer (HVL) and is reported is units of millimeters of aluminum. The HVL is defined as the

thickness of an absorbing material (aluminum in this case) required to reduce the intensity of the x-ray

beam to one half its unattenuated intensity. Also, by definition of the HVL, radiation scatted by the

absorber must not be included in the measurement, thereby necessitating care to be taken in setting up

the measurement geometry.

To perform a beam quality measurement, one makes several exposure (or air kerma) measurements with

the Model 6000-529 ionization chamber, while increasing the thickness of an absorbing material from

zero to a sufficient quantity to reduce the reading to less than one half the reading measured with no

absorber. A logarithmic interpolation formula is then used to interpolate between the measurement made

2-1

Page 10

Victoreen 6000-529

Operators Manual

with enough aluminum to give a reading just below one-half the unattenuated reading and that made with

aluminum to give a reading just greater than one-half the unattenuated reading.

When making beam quality measurements at mammographic energies, it is recommended that you use

99% pure aluminum. Alloy 1100 aluminum has been used, however studies show that an error as great

as 7.5% may result.

To perform a beam quality test, follow these steps:

1. Raise the compression paddle to its highest position. Mount the 6000-529 ionization chamber on a

ring stand so there is approximately 5 cm of space between the bottom of the chamber and table.

The chamber should be centered in the beam laterally, and approximately 4 cm from the chest wall.

2. Collimate the beam, using the light field, so that the entire chamber is included in the beam. The

field should be approximately 6 cm x 6 cm. If necessary, relocate the chamber such that it is

centered in the field.

3. Set the kVp selector at a kVp setting that is frequently used for making mammograms. Set manual

timing, and set the mAs to provide an exposure reading of at least 500 mR. Refer to the instruction

manual for the electrometer or other instrument used to measure charge generated in the 6000-529

chamber.

4. Make an exposure. Note the reading and label it X

. If you are using an electrometer that reads in

0

nC or some other instrument that would normally require the application of a correction factor, you

may note the raw reading without corrections. This is so because all subsequent readings are

normalized to X

.

0

5. Place a sheet of aluminum 0.2 mm thick on the compression paddle. Using the collimator light, be

sure the entire ionization chamber is in the shadow of the aluminum sheet. Make an exposure.

Record the reading and label it X

exposure. Label it t

.

1

; also record the thickness of aluminum used to make the

1

6. Place an additional 0.01 mm of aluminum on top of the aluminum absorber(s) already in place.

Make an exposure. Record the reading, labeling it with sequential indices. Also, record the total

thickness of aluminum used in making the measurement, labeling it as t

number of filtered exposures taken so far. If X

is less than one half of X0 proceed to step 7,

N

where N is the total

N

otherwise, repeat step 6.

7. It is now assumed that you have compiled a list of data pairs, labeled "t

" and "Xi"- If N is the total

i

number of filtered exposures, then the half-value layer may then be calculated using the following

formula:

It is recommended that the HVL be in the following range:

If your calculated HVL is lower than this range, you may be in violation of Federal or State regulation. For

more information, see American College of Radiology Medical Physicist's Manual.

2-2

Page 11

Theory of Operation

Sample Applications

2

Measuring Breast Entrance Exposure and Mean Glandular Dose

Breast entrance exposure is the radiation exposure that would be measured at the point of radiation entry

to the breast, free-in-air with the breast removed from the beam. Mean glandular dose is the dose to

glandular tissue in a typical 50-50 adipose-glandular composition breast, compressed to a thickness of

4.5 cm, and averaged over the extent of the glandular tissue.

To measure entrance exposure, follow these recommended steps:

1. Set up the x-ray machine for a typical mammographic technique. Place a loaded cassette in the

cassette holder, of the size and type consistent with the examination being simulated. Set the

machine in the AEC mode and set the density control to the position most commonly used for the

examination.

2. Place a mammographic phantom on the cassette holder assembly at the position normally

occupied by the breast. Be sure the phantom completely covers the AEC sensor. Now, place the

Model 6000-529 ionization chamber just to the side of the phantom. The entrance window of the ion

chamber should be flush with the top of the phantom, and the chamber should be placed as close

as possible to the chest wall edge of the x-ray field being sure that the entire chamber is in the field

and that it does not shadow the AEC sensor. Now, lower the compression paddle until it contacts

the phantom and chamber. Take care not to put any mechanical stress on the chamber.

3. Connect the chamber cable to an electrometer, NERO, 4000M+ or other charge-measuring

instrument. Follow the instructions accompanying the instrument for details of instrument operation.

4. Make an exposure. Record the reading from the electrometer or other instrument. Apply whatever

corrections are necessary to yield an accurate exposure reading. If you are using the Model 6000531 preamplifier, and have set it up according to the instructions, the only correction that may be

necessary would be air density correction (see section page 2-1). If you are using a charge-reading

electrometer, you should multiply the electrometer reading (in nanocoulombs) by the calibration

factor (in Roentgens per nanocoulombs) listed on the calibration report that accompanied the

chamber. Record the result.

5. Repeat step 4 three more times. Average all four results. The final result is the breast entrance

exposure. You should now repeat the procedure for all other clinically used techniques.

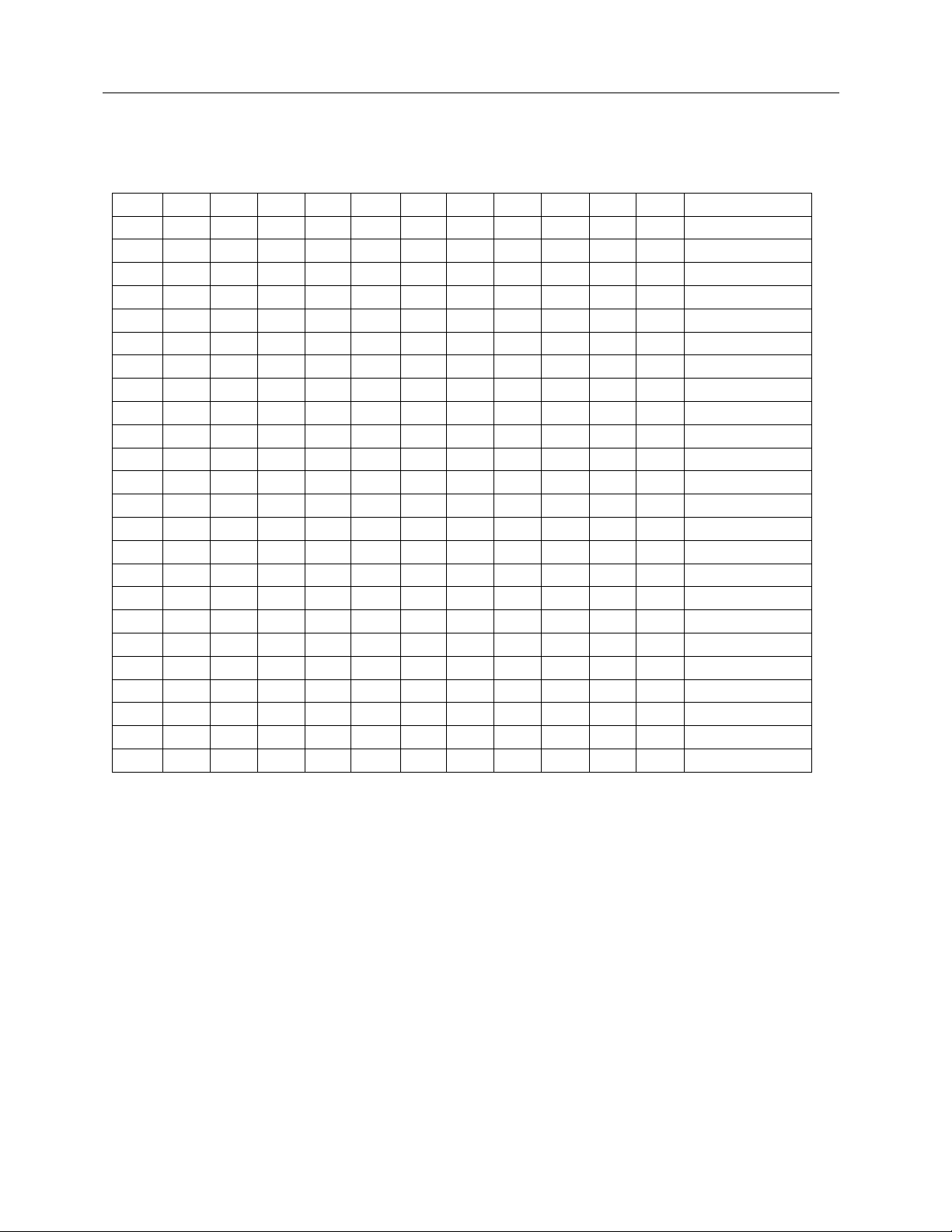

6. To compute mean glandular dose, refer to Table 2-1. In the column labeled "HVL", locate the value

closest to the half-value-layer you measured in step 4 for the kVp setting used in making the

entrance exposure measurement. Now, for Mo/Mo tubes, find the column labeled by the same kVp.

Alternatively for W/AI tubes, locate the column labeled “W/AI." The number located at the

intersection of the column thus located and the row designated by the proper HVL should be noted.

This number, when multiplied by the entrance exposure in Roentgens will give mean glandular

dose in millirads.

2-3

Page 12

Victoreen 6000-529

Operators Manual

Table 4-1. Glandular Dose for 4.5 cm Breast Thickness - 50% Adipose/50% Glandular

Breast Tissue (in mrad/R)

Mo/Mo Target-Filter X-Ray Tube Voltage (kVp)

HVL 23 24 25 26 27 28 29 30 31 32 33 W/AI Target-Filter

Combination

0.23 109

0.24 113 116

0.25 117 120 122

0.26 121 124 126 128

0.27 126 128 130 132 134

0.28 130 132 134 136 138 139

0.29 135 137 139 141 142 143 144

0.30 139 141 143 145 146 147 148 149 170

0.31 144 146 147 149 150 151 152 153 154 175

0.32 148 150 151 153 154 155 156 158 159 160 160 180

0.33 153 154 155 157 158 159 160 162 163 164 164 185

0.34 157 159 160 161 162 163 164 166 167 168 168 190

0.35 163 164 166 167 168 169 170 171 172 172 194

0.36 168 170 171 172 173 174 175 176 176 199

0.37 174 175 176 177 178 178 179 180 204

0.38 179 180 181 182 182 183 184 208

0.39 184 185 186 186 187 188 213

0.40 189 190 191 192 192 217

0.41 194 195 196 196 221

0.42 200 200 225

0.43 204 230

0.44 234

0.45 238

2-4

Page 13

Maintenance, Calibration and Troubleshooting

Maintenance

Section 3

Maintenance, Calibration and Troubleshooting

3.1 Maintenance

The Model 6000-529 Ion Chamber requires no routine maintenance, other than routine inspection of the

chamber for damage.

3.2 Calibration

The Model 6000-529 Ion Chamber is accompanied by the chamber's sensitivity on the calibration report.

If this report is not available, the ion chamber may be returned to Fluke Biomedical so that a new

sensitivity factor may be obtained, or by the customer by intercomparison with a know ion chamber.

3

Obtain the value of chamber sensitivity in

dimensions of exposure per unit charge or air

Kerma per unit charge (see the calibration report

which accompanied the chamber), and the charge

calibration factor for the host instrument in

dimensions of charge per displayed exposure unit,

prior to referring to the applicable preamplifier

manual.

NOTE

3.3 Troubleshooting

Extreme care must be used when troubleshooting a

system that has power applied. All standard

troubleshooting precautions apply.

Once a problem has been located, remove all

power before continuing with the repair.

Personnel performing the troubleshooting must be

familiar with the operation of the system and the

location of each piece of equipment used.

Troubleshooting consists of checking the wiring and verifying inputs/outputs are present on all

connectors. If a problem develops with the Ion Chamber, return the chamber to Fluke Biomedical.

WARNING

WARNING

CAUTION

3-1

Page 14

Victoreen 6000-529

Operators Manual

NOTE

If a problem cannot be resolved by applying the

troubleshooting procedures described above,

contact Fluke Biomedical at 440.248.9300 for

assistance.

3-2

Page 15

(Blank Page)

Page 16

Fluke Biomedical

Radiation Management Services

6045 Cochran Road

Cleveland, Ohio 44139

440.498.2564

120 Andrews Road

Hicksville, New York 11801

516.870.0100

www.flukebiomedical.com/rms

Loading...

Loading...