Page 1

5820A

®

Oscilloscope Calibrator

Service Manual

PN 673142

June 1999 Rev.1, 4/03

© 1999-2003 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies.

Page 2

LIMITED WARRANTY & LIMITATI O N OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under

normal use and service. The warranty period is one year and begins on the date of shipment.

Parts, product repairs and services are warranted for 90 days. This warranty extends only to the

original buyer or end-user customer of a Fluke authorized reseller, and does not apply to fuses,

disposable batteries or to any product which, in Fluke’s opinion, has been misused, altered,

neglected or damaged by accident or abnormal conditions of operation or handling.Fluke warrants

that software will operate substantially in accordance with its functional specifications for 90 days

and that it has been properly recorded on non-defective media. Fluke does not warrant that

software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user

customers only but have no authority to extend a greater or different warranty on behalf of Fluke.

Warranty support is available if product is purchased through a Fluke authorized sales outlet or

Buyer has paid the applicable international price. Fluke reserves the right to invoice Buyer for

importation costs of repair/replacement parts when product purchased in one country is submitted

for repair in another country.

Fluke’s warranty obligation is limited, at Fluke’s option, to refund of the purchase price, free of

charge repair, or replacement of a defective product which is returned to a Fluke authorized

service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center or send the

product, with a description of the difficulty, postage and insurance prepaid (FOB Destination), to

the nearest Fluke authorized service center. Fluke assumes no risk for damage in transit.

Following warranty repair, the product will be returned to Buyer, transportation prepaid (FOB

Destination). If Fluke determines that the failure was caused by misuse, alteration, accident or

abnormal condition of operation or handling, Fluke will provide an estimate of repair costs and

obtain authorization before commencing the work. Following repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and return

transportation charges (FOB Shipping Point).

THIS WARRANTY IS BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, WHETHER

ARISING FROM BREACH OF WARRANTY OR BASED ON CONTRACT, TORT, RELIANCE OR

ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or

exclusion or limitation of incidental or consequential damages, the limitations and exclusions of

this warranty may not apply to every buyer. If any provision of this Warranty is held invalid or

unenforceable by a court of competent jurisdiction, such holding will not affect the validity or

enforceability of any other provision.

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090 P.O. Box 1186

Everett, WA 98206-9090 5602 BD Eindhoven

U.S.A. The Netherlands

5/94

Page 3

Safety Information

This Calibrator complies with IEC publication 1010- 1 ( 1992-1), Safety Requirements for

Electrical Measuring, Control and Laboratory Equipment, and ANSI/ISA-S82.01-1994,

and CAN/CSA-C22.2 No. 1010.1-92. This m anual cont ains information, warnings, and

cautions that must be followed to ensure saf e oper ation and to maintain the Calibrator in

a safe condition. Use of this Calibrator in a manner not specified herein may impair the

protection provided by the Calibrator.

This Calibrator is designed for IEC 1010-1 Installat ion Cat egory II use. It is not designed

for connection to circuits rated over 4800 VA.

Warning statements identify conditions or practices t hat could r esult in personal injury

or loss of life.

Caution statements identify conditions or pr act ices t hat could result in damage to

equipment.

SYMBOLS MARKED ON THE CALIBRATOR

WARNING Risk of electric shock. Refer to the manual (see the Index for

references).

GROUND Ground terminal to chassis (earth).

Attention Refer to the manual (s ee t he Index for references). This

symbol indicates that information about usage of a feature is contained in

the manual.

AC POWER SOURCE

The Calibrator is intended to operate from an ac power source that will not apply more

than 264V ac rms between the supply conductors or bet ween eit her supply conductor

and ground. A protective ground connection by way of the grounding conductor in the

power cord is required for safe operation.

USE THE PROPER FUSE

To avoid fire hazard, use only the specified replacement f use:

• For 100 V or 120 V operation, use a 5A/250V time delay fuse ( Fluke PN 109215) .

• For 220 V or 240 V operation, use a 2.5A/250V time delay f use ( Fluke PN 851931) .

GROUNDING THE CALIBRATOR

The Calibrator uses controlled overvoltage techniques that require the Calibrator to be

grounded whenever normal mode or common mode ac volt ages or t r ansient voltages

may occur. The enclosure must be grounded through t he gr ounding conductor of the

power cord, or through the r ear panel CHASSI S G RO UND binding post.

Page 4

USE THE PROPER POWER CORD

Use only the power cord and connector appropriate for the voltage and plug

configuration in your country.

Use only a power cord that is in good condition.

Refer power cord and connector changes to qualified service personnel.

DO NOT OPERATE IN EXPLOSIVE ATMOSPHERES

To avoid explosion, do not operate the Calibrator in an atmosphere of explosive gas.

CHECK INSULATION RATINGS

Verify that the voltage applied to the unit under t est does not exceed the insulation

rating of the UUT and the interconnecting cables.

DO NOT REMOVE COVER DURING OPERATION

To avoid personal injury or death, do not remove the Calibrator cover without first

removing the power source connected to the rear panel. Do not operate the Calibrator

without the cover properly installed. Norm al calibration is accomplished with the cover

closed. Access procedures and the warnings for such procedures ar e cont ained in the

Service Manual. Service procedures are for qualified service personnel only.

DO NOT ATTEMPT TO OPERATE IF PROTECTION MAY BE IMPAIRED

If the Calibrator appears damaged or oper ates abnormally, protection may be impaired. Do

not attempt to operate t he Calibr at or under these conditions. Refer all questions of proper

Calibrator operation to qualified ser vice personnel.

Page 5

Table of Contents

Chapter Title Page

1 Introduction and Specifications........................................................ 1-1

1-1. Introduction........................................................................................... 1-3

1-2. How to Contact Fluke........................................................................... 1-4

1-3. Instruction Manuals.............................................................................. 1-4

1-4. 5820A Operators Manual................................................................. 1-4

1-5. 5820A Service Manual..................................................................... 1-5

1-6. Specifications........................................................................................ 1-5

1-7. General Specifications.......................................................................... 1-6

1-8. Volt Specifications........................................................................... 1-8

1-9. DC Volt Measure Specifications...................................................... 1-8

1-10. Edge Specifications.......................................................................... 1-9

1-11. Leveled Sine Wave Specifications................................................... 1-10

1-12. Time Marker Specifications............................................................. 1-11

1-13. Wave Generator Specifications........................................................ 1-12

1-14. 1 ns Pulse Generator Specifications................................................. 1-13

1-15. Trigger Signal Specifications (Pulse Function) ............................... 1-13

1-16. Trigger Signal Specifications (Time Marker Function)................... 1-13

1-17. Trigger Signal Specifications (Edge Function)................................ 1-14

1-18. Trigger Signal Specifications (Square Wave Voltage Function)..... 1-14

1-19. Trigger Signal Specifications (TV).................................................. 1-14

1-20. Tunnel Diode Drive Capability........................................................ 1-14

1-21. Oscilloscope Input Resistance Measurement Specifications........... 1-14

1-22. Oscilloscope Input Capacitance Measurement Specifications......... 1-14

1-23. Overload Measurement Specifications............................................. 1-15

1-24. External Reference Input Specifications.......................................... 1-15

1-25. Auxiliary Input Specifications.......................................................... 1-15

1-26. Current Output Specifications.......................................................... 1-15

2 Theory of Operation........................................................................... 2-1

2-1. Introduction........................................................................................... 2-3

2-2. Voltage Mode................................................................................... 2-7

2-3. Edge Mode........................................................................................ 2-7

2-4. Leveled Sine Wave Mode ................................................................ 2-7

2-5. Time Marker Mode .......................................................................... 2-7

i

Page 6

5820A

Service Manual

2-6. Wave Generator Mode ..................................................................... 2-8

2-7. Pulse Generator ................................................................................ 2-8

2-8. Input DC Voltage Measurement Mode ............................................ 2-8

2-9. Input Impedance Mode (Resistance)................................................ 2-8

2-10. Input Impedance Mode (Capacitance).............................................. 2-8

2-11. Current Module ................................................................................ 2-9

2-12. Overload Mode................................................................................. 2-9

2-13. Trigger.............................................................................................. 2-9

2-14. High Frequency Switching............................................................... 2-9

2-15. 5 Channel Option.............................................................................. 2-9

2-16. GHz Option Module......................................................................... 2-9

3 Calibration and Verification............................................................... 3-1

3-1. Introduction........................................................................................... 3-3

3-2. Equipment Required for Calibration and Verification......................... 3-3

3-3. Calibration Setup.................................................................................. 3-6

3-4. Calibration and Verification of Square Wave Voltage Functions........ 3-6

3-5. Overview of HP3458A Operation.................................................... 3-6

3-6. Setup for Scope Calibrator Voltage Square Wave Measurements... 3-6

3-7. Setup for Scope Calibrator Edge and Wave Gen Square Wave

Measurements................................................................................... 3-8

3-8. DC Voltage Calibration........................................................................ 3-9

3-9. AC Voltage Calibration........................................................................ 3-10

3-10. DC Measurement Calibration............................................................... 3-11

3-11. Current Calibration............................................................................... 3-11

3-12. DC Current Calibration.................................................................... 3-11

3-13. AC Current Calibration.................................................................... 3-11

3-14. Wave Generator Calibration................................................................. 3-12

3-15. Edge Amplitude Calibration................................................................. 3-12

3-16. Leveled Sine Wave Amplitude Calibration.......................................... 3-13

3-17. Leveled Sine Wave Flatness Calibration.............................................. 3-14

3-18. Low Frequency Calibration.............................................................. 3-14

3-19. High Frequency Calibration............................................................. 3-15

3-20. Pulse Width Calibration........................................................................ 3-15

3-21. MeasZ Calibration................................................................................ 3-16

3-22. Leveled Sine Wave Flatness Calibration (GHz Option)....................... 3-18

3-23. 5820A-5 Option.................................................................................... 3-18

3-24. Verification........................................................................................... 3-18

3-25. DC Voltage Verification .................................................................. 3-20

3-26. Verification at 1 MΩ.................................................................... 3-20

3-27. Verification at 50 Ω..................................................................... 3-20

3-28. AC Voltage Amplitude Verification................................................ 3-23

3-29. Verification at 1 MΩ.................................................................... 3-23

3-30. Verification at 50 Ω..................................................................... 3-24

3-31. AC Voltage Frequency Verification ................................................ 3-25

3-32. DC Measurement Verification......................................................... 3-26

3-33. Current Verification ......................................................................... 3-27

3-34. DC Current Verification .............................................................. 3-27

3-35. AC Current Verification .............................................................. 3-28

3-36. Edge Amplitude Verification........................................................... 3-30

3-37. Edge Frequency Verification............................................................ 3-30

3-38. Edge Duty Cycle Verification.......................................................... 3-31

3-39. Edge Rise Time Verification............................................................ 3-31

3-40. Edge Aberrations.............................................................................. 3-33

ii

Page 7

Contents

3-41. Tunnel Diode Pulser Drive Amplitude Verification........................ 3-34

3-42. Leveled Sine Wave Amplitude Verification.................................... 3-34

3-43. MHz Leveled Sine Wave Flatness Verification............................... 3-35

3-44. Equipment Setup for Low Frequency Flatness............................ 3-35

3-45. Equipment Setup for High Frequency Flatness........................... 3-36

3-46. Low Frequency Verification........................................................ 3-36

3-47. High Frequency Verification ....................................................... 3-37

3-48. < 600 MHz Leveled Sine Harmonic Verification........................ 3-47

3-49. Time Marker Verification ................................................................ 3-48

3-50. Wave Generator Verification........................................................... 3-50

3-51. Verification at 1 MΩ.................................................................... 3-50

3-52. Verification at 50 Ω..................................................................... 3-52

3-53. Pulse Width Verification.................................................................. 3-53

3-54. Pulse Skew Calibration and Verification......................................... 3-54

3-55. Calibration.................................................................................... 3-55

3-56. Verification .................................................................................. 3-55

3-57. Pulse Period Verification ................................................................. 3-56

3-58. MeasZ Resistance Verification........................................................ 3-56

3-59. MeasZ Capacitance Verification...................................................... 3-57

3-60. Overload Function Verification ....................................................... 3-58

3-61. Hardware Adjustments ......................................................................... 3-59

3-62. Equipment Required......................................................................... 3-59

3-63. Adjusting the Leveled Sine Wave Function..................................... 3-59

3-64. Equipment Setup.......................................................................... 3-59

3-65. Adjusting the Leveled Sine Wave VCO Balance........................ 3-60

3-66. Adjusting the Leveled Sine Wave Harmonics............................. 3-60

3-67. Adjusting the Aberrations for the Edge Function ............................ 3-61

3-68. Equipment Setup.......................................................................... 3-61

3-69. Adjusting the Edge Aberrations................................................... 3-62

(continued)

4 Maintenance........................................................................................ 4-1

4-1. Introduction........................................................................................... 4-3

4-2. Replacing the Line Fuse ....................................................................... 4-3

4-3. Cleaning the Air Filter.......................................................................... 4-4

4-4. General Cleaning.................................................................................. 4-6

4-5. Service Information.............................................................................. 4-6

5 Options................................................................................................ 5-1

5-1. Introduction........................................................................................... 5-3

5-2. 5820A-5 Option.................................................................................... 5-3

5-3. GHz Module ......................................................................................... 5-3

5-4. GHz Option Specifications............................................................... 5-3

5-5. Fast Edge Specifications .................................................................. 5-3

5-6. Leveled Sine Wave (> 600 MHz ) Specifications............................ 5-4

5-7. Time Marker Specifications............................................................. 5-5

5-8. Theory of Operation......................................................................... 5-5

5-9. Fast Edge Adjustment for the GHz Module..................................... 5-6

5-10. GHz Leveled Sine Wave Frequency Verification............................ 5-9

5-11. GHz Leveled Sine Wave Harmonics Verification........................... 5-10

5-12. Verification Tables ............................................................................... 5-11

5-13. Verification Tables for Channels 2-5 ................................................... 5-21

5-14. Leveled Sine Flatness (< 600 MHz)................................................. 5-21

5-15. Pulse Width ...................................................................................... 5-23

5-16. Edge Rise Time Verification (Channels 2-5)................................... 5-24

iii

Page 8

5820A

Service Manual

5-17. Pulse Skew........................................................................................ 5-25

5-18. Channel 2 DMM Input..................................................................... 5-25

5-19. Channel 3 DMM Input..................................................................... 5-27

5-20. Channel 4 DMM Input..................................................................... 5-28

5-21. Channel 5 DMM Input..................................................................... 5-29

5-22. Capacitance ...................................................................................... 5-30

6 Replaceable Parts............................................................................... 6-1

6-1. Introduction........................................................................................... 6-3

6-2. How to Obtain Parts.............................................................................. 6-3

6-3. List of Replacement Parts..................................................................... 6-3

Index

iv

Page 9

List of Tables

Table Title Page

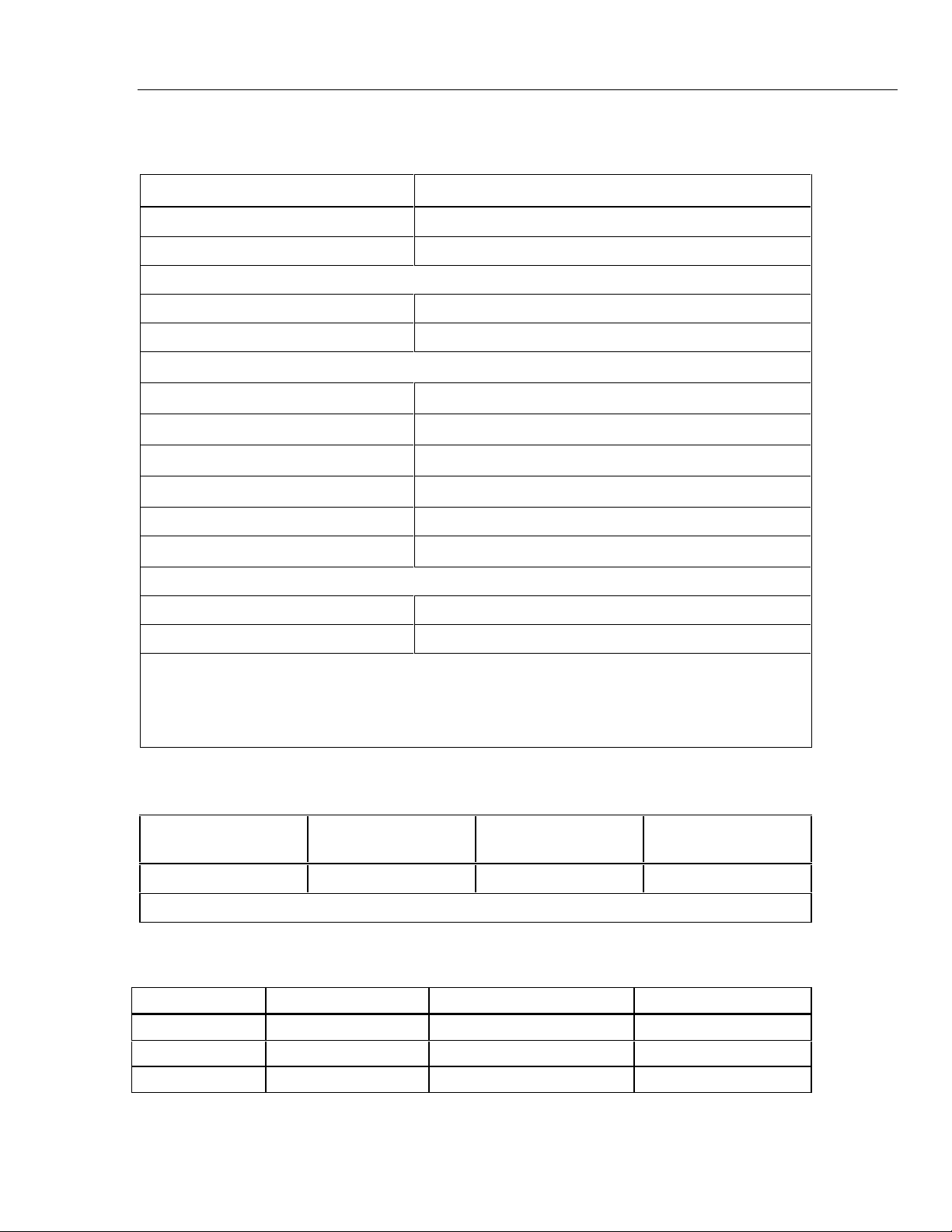

1-1. General Specifications........................................................................................... 1-6

1-2. Volt Specifications................................................................................................. 1-8

1-3. DC Volt Measure Specifications ........................................................................... 1-8

1-4. Edge Specifications................................................................................................ 1-9

1-5. Leveled Sine Wave Specifications (≤ 600 MHz ).................................................. 1-10

1-6. Time Marker Specifications................................................................................... 1-11

1-7. Wave Generator Specifications.............................................................................. 1-12

1-8. Pulse Generator Specifications.............................................................................. 1-13

1-9. Trigger Signal Specifications (Pulse Function)..................................................... 1-13

1-10. Trigger Signal Specifications (Time Marker Function)......................................... 1-13

1-11. Trigger Signal Specifications (Edge Function)...................................................... 1-14

1-12. Trigger Signal Specifications (Square Wave Voltage Function)........................... 1-14

1-13. TV Trigger Signal Specifications .......................................................................... 1-14

1-14. Tunnel Diode Drive Capability.............................................................................. 1-14

1-15. Oscilloscope Input Resistance Measurement Specifications................................. 1-14

1-16. Oscilloscope Input Capacitance Measurement Specifications .............................. 1-14

1-17. Overload Measurement Specifications .................................................................. 1-15

1-18. Auxiliary Input Performance.................................................................................. 1-15

1-19. Current Output Specifications................................................................................ 1-15

3-1. Scope Calibrator Calibration and Verification Equipment.................................... 3-3

3-2. Voltage HP3458A Settings.................................................................................... 3-7

3-3. Edge and Wave Generator HP3458A Settings....................................................... 3-8

3-4. Verification Methods for Scope Calibrator Functions........................................... 3-19

3-5. DC Voltage Verification........................................................................................ 3-21

3-6. DC Voltage Verification at 50 Ω........................................................................... 3-22

3-7. AC Voltage Amplitude Verification...................................................................... 3-24

3-8. AC Voltage Verification at 50Ω............................................................................ 3-25

3-9. AC Voltage Frequency Verification...................................................................... 3-26

3-10. DC Voltage Measurement Verification ................................................................. 3-27

3-11. DC Voltage Verification at 1 MΩ ......................................................................... 3-28

3-12. Edge and Wave Generator HP3458A Settings....................................................... 3-28

3-13. AC Current Verification......................................................................................... 3-29

3-14. Edge Amplification Verification............................................................................ 3-30

3-15. Edge Frequency Verification ................................................................................. 3-31

3-16. Edge Rise Time Verification.................................................................................. 3-33

v

Page 10

5820A

Service Manual

3-17. Edge Aberrations.................................................................................................... 3-33

3-18. Tunnel Diode Pulser Verification .......................................................................... 3-34

3-19. Leveled Sine Wave Amplitude Verification.......................................................... 3-35

3-20. Low Frequency Flatness Verification at 5.5 V...................................................... 3-37

3-21. High Frequency Flatness Verification ................................................................... 3-38

3-22. Leveled Sine Wave Harmonics Verification ......................................................... 3-48

3-23. Marker Generator Verification .............................................................................. 3-49

3-24. Wave Generator Verification at 1 MΩ .................................................................. 3-51

3-25. Wave Generator Verification at 50 Ω.................................................................... 3-52

3-25. Pulse Generator Verification: Pulse Width............................................................ 3-54

3-25. Pulse Skew ............................................................................................................. 3-55

3-25. Pulse Generator Verification: Period..................................................................... 3-56

3-26. MeasZ Resistance Verification.............................................................................. 3-57

3-27. MeasZ Capacitance Verification............................................................................ 3-58

4-1. Replacement Fuses................................................................................................. 4-3

5-1. Fast Edge Specifications........................................................................................ 5-3

5-2. Leveled Sine Wave Specifications (> 600 MHz)................................................... 5-4

5-3. Time Marker Specifications................................................................................... 5-5

5-4. Leveled Sine Wave Frequency Verification (Channels 1, 2, and 5)..................... 5-11

5-5. Fast Edge Rise Time for Channels 1, 2, and 5....................................................... 5-11

5-6. Leveled Sine Wave Harmonics Verification (Channels 1, 2, and 5)..................... 5-12

5-7. GHz Leveled Sinewave Verification: Flatness (Channels 1, 2, and 5).................. 5-14

5-8. Leveled Sine Flatness (5.5 V) (Channel 2)............................................................ 5-21

5-9. Leveled Sine Flatness (5.5 V) (Channel 3)............................................................ 5-22

5-10. Leveled Sine Flatness (5.5 V) (Channel 4)............................................................ 5-22

5-11. Leveled Sine Flatness (5.5 V) (Channel 5)............................................................ 5-23

5-12. Pulse Width............................................................................................................ 5-23

5-13. Edge Rise Time (Channel 2).................................................................................. 5-24

5-14. Edge Rise Time (Channel 3).................................................................................. 5-24

5-15. Edge Rise Time (Channel 4).................................................................................. 5-24

5-16. Edge Rise Time (Channel 5).................................................................................. 5-24

5-17. Pulse Skew ............................................................................................................. 5-25

5-18. Levsine Amplitude................................................................................................. 5-25

5-19. DC Voltage 1 MΩ.................................................................................................. 5-25

5-20. AC Voltage 1 MΩ.................................................................................................. 5-26

5-21. Edge Amplitude...................................................................................................... 5-26

5-22. Levsine Amplitude................................................................................................. 5-27

5-23. DC Voltage 1 MΩ.................................................................................................. 5-27

5-24. AC Voltage 1 MΩ.................................................................................................. 5-27

5-25. Edge Amplitude...................................................................................................... 5-27

5-26. Levsine Amplitude................................................................................................. 5-28

5-27. DC Voltage 50 Ω ................................................................................................... 5-28

5-28. AC Voltage 50 Ω ................................................................................................... 5-28

5-29. Edge Amplitude...................................................................................................... 5-29

5-30. Levsine Amplitude................................................................................................. 5-29

5-31. DC Voltage 1 MΩ.................................................................................................. 5-29

5-32. AC Voltage 1 MΩ.................................................................................................. 5-29

5-33. Edge Amplitude...................................................................................................... 5-30

5-34. Capacitance (Channels 2-5) ................................................................................... 5-30

6-1. 5820A Manuals...................................................................................................... 6-4

6-2. Front Panel Module List of User Replaceable Parts.............................................. 6-4

6-3. Rear Panel Module List of Replaceable Parts........................................................ 6-7

6-4. Chassis Module List of Replaceable Parts............................................................. 6-9

6-5. Single Channel Without GHz Option List of Replaceable Parts........................... 6-12

6-6. Single Channel With GHZ Option List of Replaceable Parts................................ 6-15

vi

Page 11

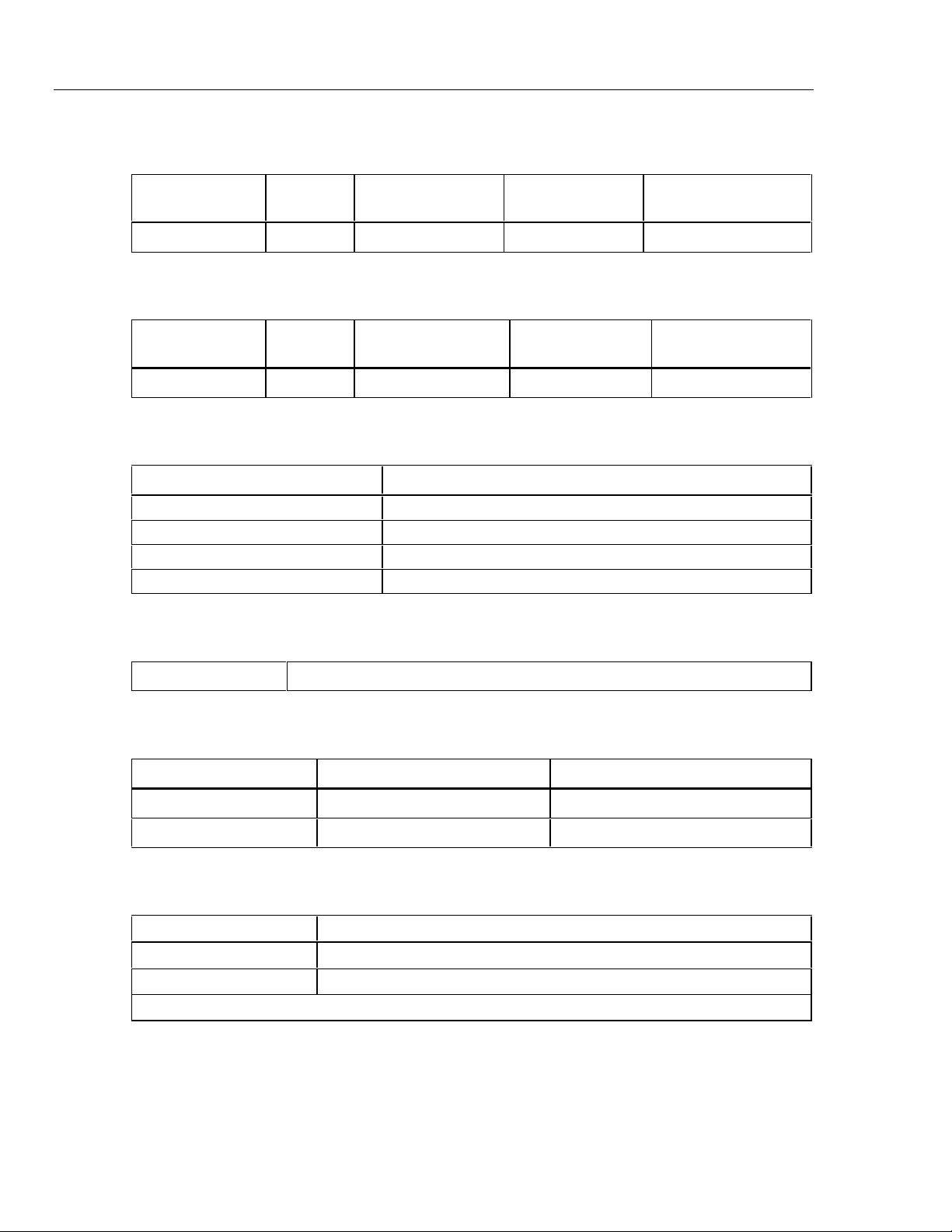

List of Figures

Figure Title Page

1-1. 5820A Multi-Product Calibrator............................................................................ 1-3

1-2. 5820A Calibrator Dimensional Outline................................................................. 1-6

2-1. Signal Diagram of Chassis..................................................................................... 2-4

2-2. Block Diagram of Scope Module........................................................................... 2-5

2-3. Signal Diagram of Scope Module.......................................................................... 2-6

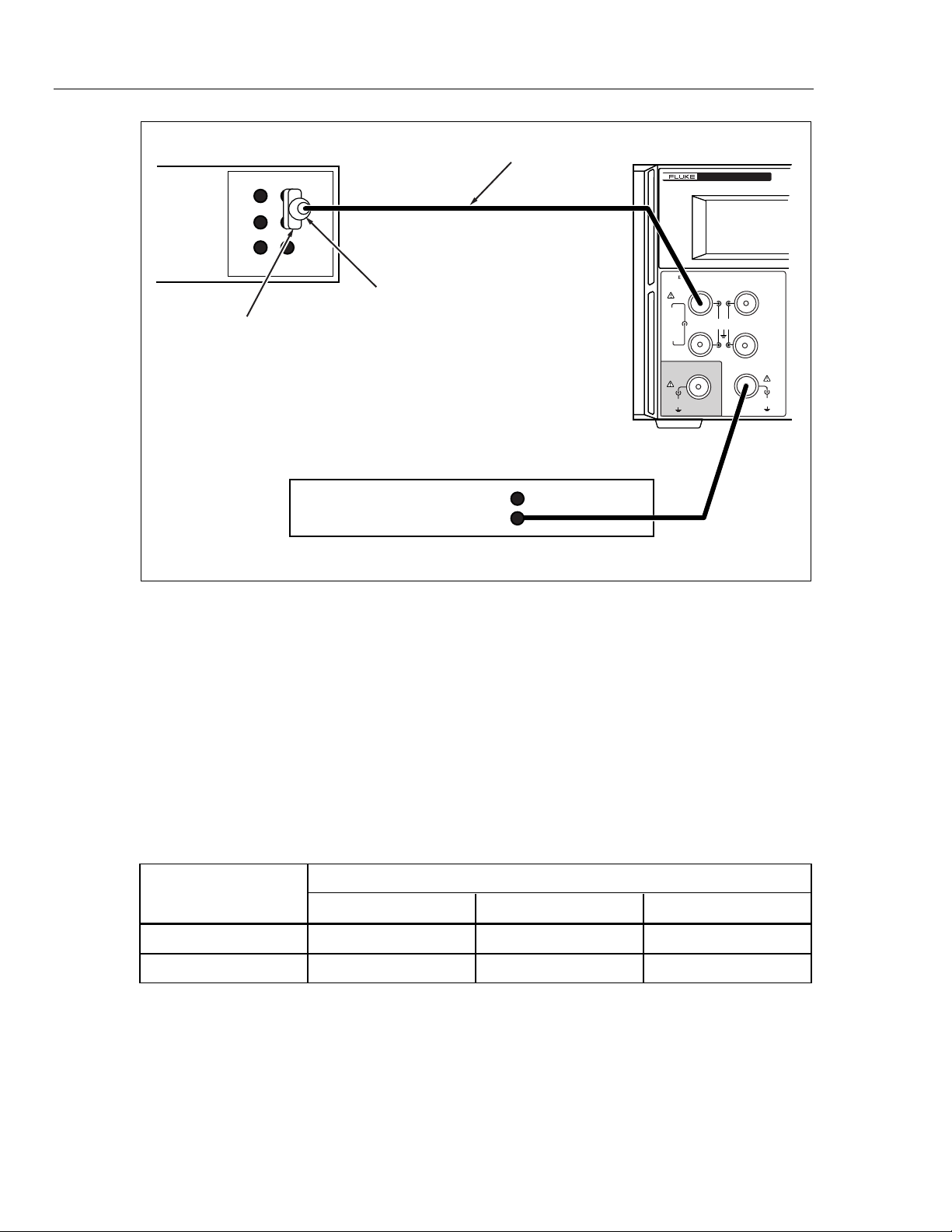

3-1. Setup for Scope Calibrator Voltage Square Wave Measurements ........................ 3-8

3-2. Setup for Scope Calibrator Edge and Wave Gen Square Wave Measurements.... 3-9

3-3. Connecting the Calibrator Mainframe to the 5790A AC Measurement Standard. 3-14

3-4. Setup for MeasZ Calibration.................................................................................. 3-17

3-5. Setup for AC Voltage Frequency Verification ...................................................... 3-26

3-6. Setup for Edge Rise Time Verification.................................................................. 3-32

3-7. Setup for Leveled Sine Wave Harmonics Verification.......................................... 3-47

3-8. Setup for Wave Generator Function...................................................................... 3-50

3-9. Setup for Overload Function Verification............................................................. 3-58

3-10. Adjusting the Leveled Sine Wave Balance............................................................ 3-60

3-11. Adjusting the Leveled Sine Wave Harmonics....................................................... 3-61

3-12. Adjusting Short-Term Edge................................................................................... 3-63

4-1. Accessing the Fuse................................................................................................. 4-4

4-2. Accessing the Air Filter ......................................................................................... 4-5

5-1. GHz Block Diagram............................................................................................... 5-6

5-2. Fast Edge Full Wave Form..................................................................................... 5-7

5-3. Porch ...................................................................................................................... 5-8

5-4. Bullet on the Porch................................................................................................. 5-8

5-5. Critically Triggered Edge at Porch Height Level I................................................ 5-9

5-6. Critically Distorted Edge at Porch Height Level II................................................ 5-9

5-7. Setup for Leveled Sine Wave Harmonics Verification.......................................... 5-10

6-1. Final Assembly....................................................................................................... 6-5

vii

Page 12

5820A

Service Manual

viii

Page 13

Chapter 1

Introduction and Specifications

Title Page

1-1. Introduction........................................................................................... 1-3

1-2. How to Contact Fluke........................................................................... 1-4

1-3. Instruction Manuals.............................................................................. 1-4

1-4. 5820A Operators Manual................................................................. 1-4

1-5. 5820A Service Manual..................................................................... 1-5

1-6. Specifications........................................................................................ 1-5

1-7. General Specifications.......................................................................... 1-6

1-8. Volt Specifications........................................................................... 1-8

1-9. DC Volt Measure Specifications...................................................... 1-8

1-10. Edge Specifications.......................................................................... 1-9

1-11. Leveled Sine Wave Specifications................................................... 1-10

1-12. Time Marker Specifications............................................................. 1-11

1-13. Wave Generator Specifications........................................................ 1-12

1-14. 1 ns Pulse Generator Specifications................................................. 1-13

1-15. Trigger Signal Specifications (Pulse Function) ............................... 1-13

1-16. Trigger Signal Specifications (Time Marker Function)................... 1-13

1-17. Trigger Signal Specifications (Edge Function)................................ 1-14

1-18. Trigger Signal Specifications (Square Wave Voltage Function)..... 1-14

1-19. Trigger Signal Specifications (TV).................................................. 1-14

1-20. Tunnel Diode Drive Capability........................................................ 1-14

1-21. Oscilloscope Input Resistance Measurement Specifications........... 1-14

1-22. Oscilloscope Input Capacitance Measurement Specifications......... 1-14

1-23. Overload Measurement Specifications............................................. 1-15

1-24. External Reference Input Specifications.......................................... 1-15

1-25. Auxiliary Input Specifications.......................................................... 1-15

1-26. Current Output Specifications.......................................................... 1-15

1-1

Page 14

5820A

Service Manual

1-2

Page 15

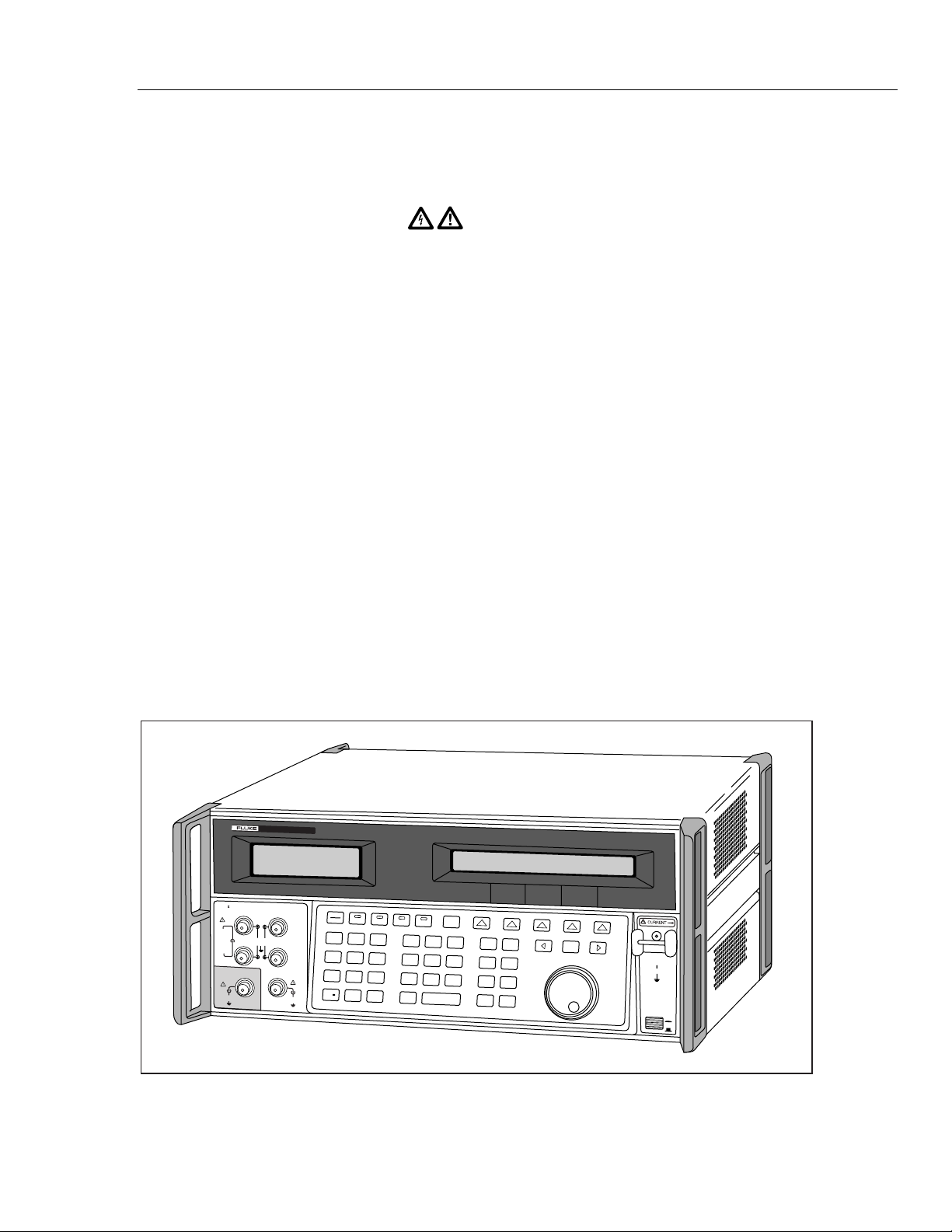

1-1. Introduction

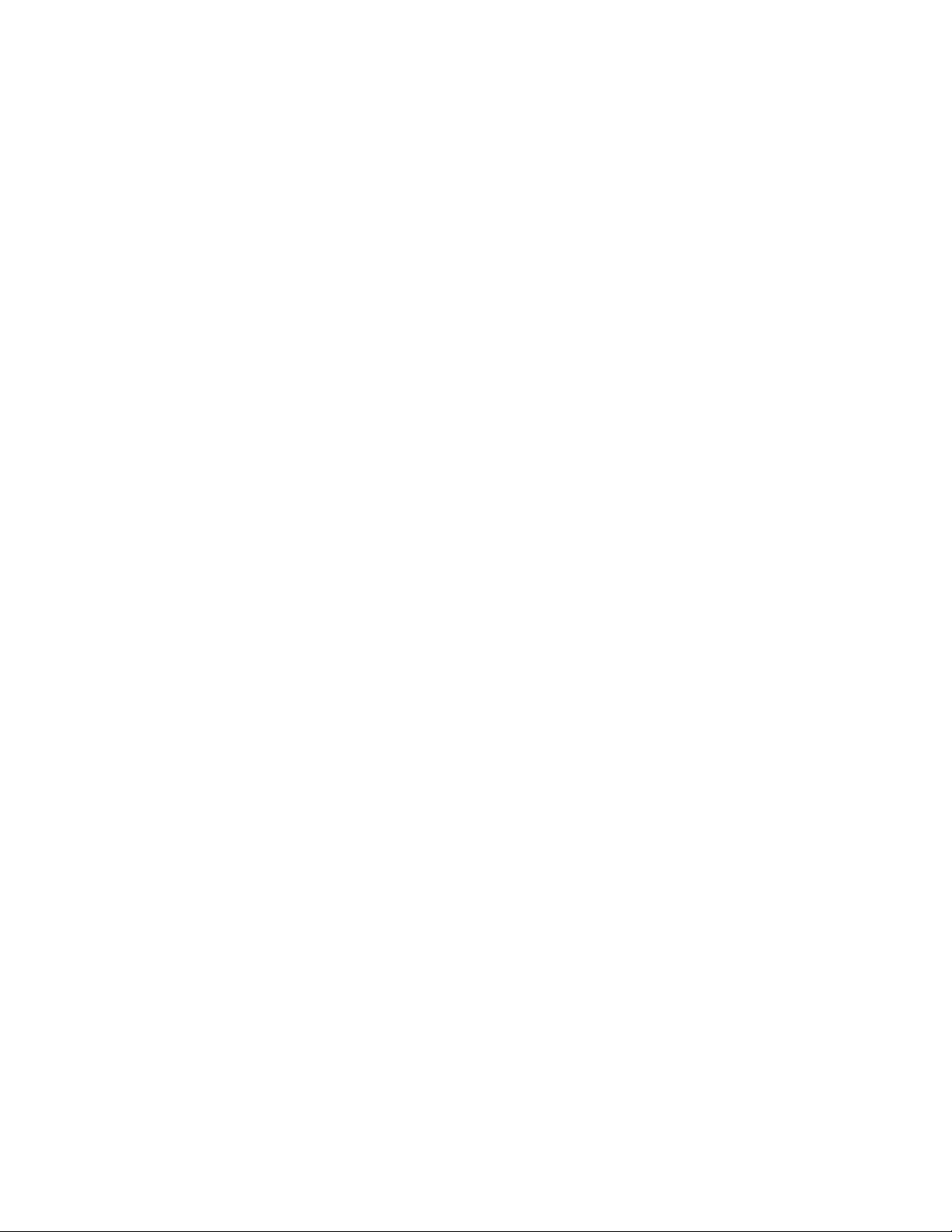

The Fluke Model 5820A Oscilloscope Calibrator (Figure 1-1) is a precise instrument that

calibrates analog and digital oscilloscopes. Specifications are provided in this chapter.

To prevent electric shock or other possible injuries, t he 5820A

Calibrator must be operated in the way specif ied by this manual

or other documentation provided by Fluke.

Input voltages exceeding 30 V dc may cause damage to the

instrument. Do not apply voltages except in voltage

measurement mode.

Features of the 5820A Calibrator include the following:

• Automatic meter error calculation.

• % and keys that change the output value to pre-determined cardinal values

for various functions.

Warning

WCaution

Introduction and Specifications

Introduction

1

• Programmable entry limits that prevent invalid amounts from being entered.

• Edge, Leveled Sine, Pulse, Marker, and Wave Generation modes.

• Accurate oscilloscopic input impedance measurement.

• Tunnel Diode Pulse compatibility.

• DC Volt Measure Mode.

• Current Mode generates both DC and low frequency ac current.

• 1 ns to 500 ns pulse width capability with skew controlled trigger.

OSCILLOSCOPE

5820A

CALIBRATOR • 2GHz

CAT

SOURCE/MEASURE

EXT TRIG

CHAN 1

130V

PK

MAX

SOURCE

30V DC

MAX

MEASURE

CHAN 1-5

AUX

INPUT

CHAN 2

20V PK

MAX

CHAN 3

CHAN 4

EXT TRIG

20V PK

MAX

CHAN 5

20V PK

MAX

OPR

STBY

VOLT

EDGE

789

456

123

+

/

0•

LEVSINE

PREV

MARKER

MENU

NEW

µ

V

REF

m

n

dBm

k

sec

Hz

M

ENTER

MORE

MODES

CHAN

MULT

RESETCE

SETUP

AUX

INPUT

DIV

x

÷

EDIT

FIELD

100 mA MAX

20V PK MAX

POWER

I

O

Figure 1-1. 5820A Oscilloscope Calibrator

yh001f.eps

1-3

Page 16

5820A

Service Manual

• External reference.

• Auxiliary input.

• 5-channel output (5-Channel Option). The 5-Channel Option allows you to calibrate

up to five oscilloscope channels simultaneously without changing cables.

• Simultaneous output of a signal and a trigger signal.

• 600 MHz, Leveled Sine wave output.

• Optional 600 MHz - 2.1 GHz, Leveled Sine wave output with 150 ps fast edge.

• Standard IEEE-488 (GPIB) interface, complying with ANSI/IEEE Standards

488.1-1987 and 488.2-1987.

• EIA Standard RS-232-C serial data interface for printing, displaying, or transferring

internally stored calibration constants, and for remote control of the 5820A.

• Pass-through RS-232-C serial data interface for communicating with the Unit Under

Test (UUT).

• Extensive automatic internal self testing and diagnostics of analog and digital

functions.

1-2. How to Contact Fluke

USA and Canada: 1-888-99-FLUKE (1-888-993-5853)

Europe: +31 402-675-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

For additional information about Fluke, its products, and services, visit Fluke’s web site

at: www.fluke.com

1-3. Instruction Manuals

The 5820A Manual Set provides complete information for operators and service or

maintenance technicians. The set includes:

• 5820A Operators Manual (PN 802154)

• 5820A Service Manual (PN 673142)

The 5820A Operators Manual ships with the instrument. The 5820A Service Manual is

optional. Order additional copies of the manuals separately using the part number

provided. For ordering instructions, refer to the Fluke Catalog, or ask a Fluke sales

representative. These manuals are also available on Fluke's web site www.fluke.com.

1-4. 5820A Operators Manual

The 5820A Operators Manual provides complete information for installing the 5820A

Oscilloscope Calibrator and operating it from the front panel keys and in remote

configurations. The manual also provides a glossary of calibration, specifications, and

error code information. The 5820A Operators Manual includes the following topics:

1-4

• Installation

• Operating controls and features, including front panel operation

• Remote operation (IEEE-488 bus or serial port remote control)

Page 17

• Serial port operation (printing, displaying, or transferring data, and setting up for

serial port remote control)

• Operator maintenance, including verification procedures and calibration approach

for the 5820A

• Accessories

• Error Messages

1-5. 5820A Service Manual

This 5820A Service Manual includes: product specifications, appropriate theory of

operation, calibration and verification procedures, maintenance information, and options.

1-6. Specifications

The following paragraphs describe the details for the 5820A specifications. All

specifications are valid after allowing a warm-up period of 30 minutes, or twice the time

the 5820A has been turned off. (For example, if the 5820A has been turned off for 5

minutes, the warm-up period is 10 minutes.)

All specifications apply for the temperature and time period indicated. For temperatures

outside of tcal + 5 °C (tcal is the ambient temperature when the 5820A was calibrated),

the temperature coefficient is less than 0.1 times the 1-year specification per °C (limited

to 0 °C - 50 °C).

Introduction and Specifications

Specifications

1

If you ordered the GHz Option, the following specification tables are supplemented by

the tables with similar headings in Chapter 5:

• Edge Specifications

• Leveled Sine Wave Specifications

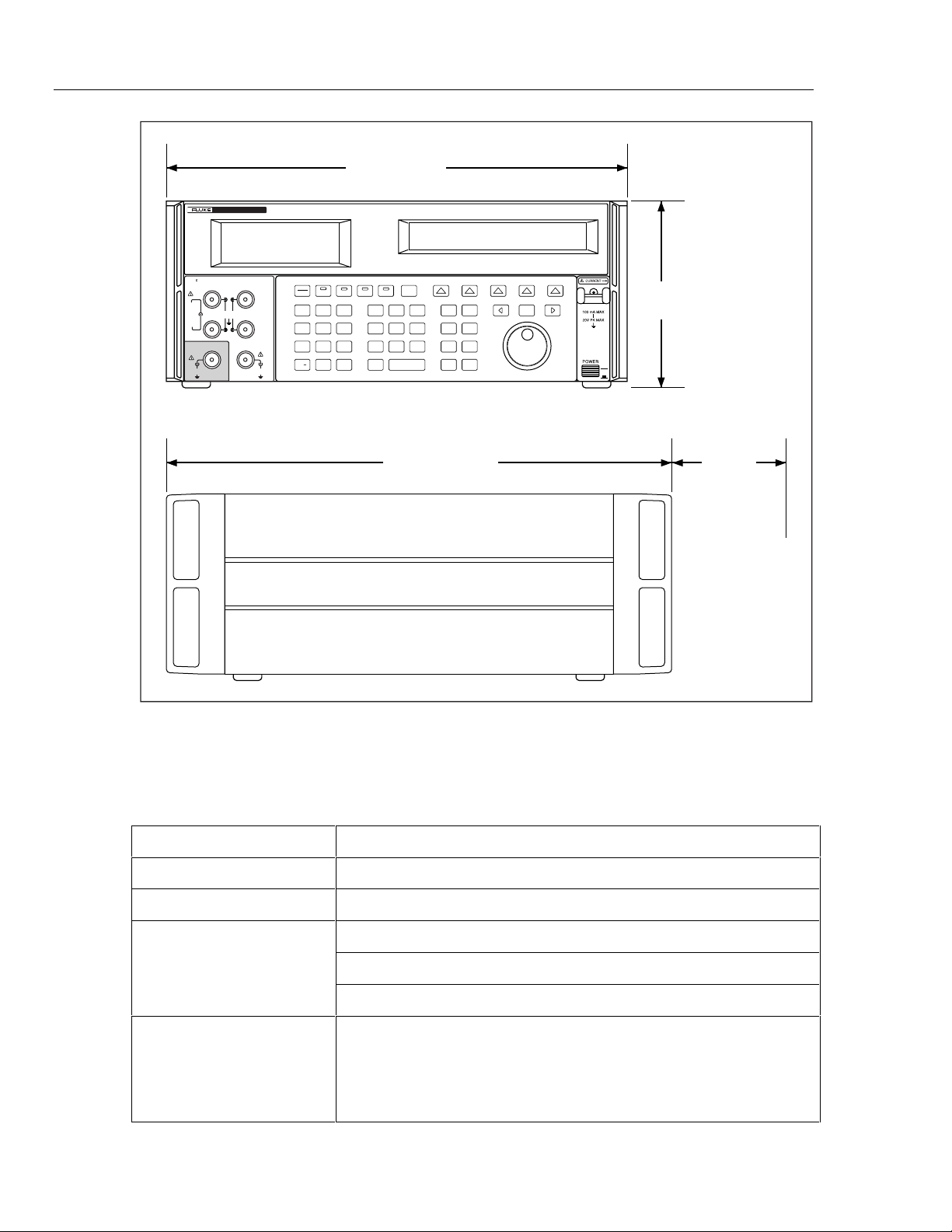

Refer to Figure 1-2 for the dimensional outline of the 5820A Calibrator.

1-5

Page 18

5820A

Service Manual

EXT TRIG

130V

PK

MAX

SOURCE

30V DC

MAX

MEASURE

CHAN 1-5

AUX

INPUT

CAT

20V PK

CHAN 1

CHAN 3

MAX

OSCILLOSCOPE

5820A

CALIBRATOR • 2GHz

SOURCE/MEASURE

20V PK

MAX

CHAN 2

CHAN 4

EXT TRIG

CHAN 2

CHAN 4

CHAN 5

20V PK

MAX

OPR

STBY

VOLT EDGE LEVSINE MARKER

789

456

123

+

0•

/

43.2 cm (17 in)

PREV

µ

m

k sec

M

MENU

NEW

V

REF

dBm

n

Hz

ENTER

CE

MORE

MODES

CHAN

MULTxDIV

RESET

SETUP

INPUT

AUX

÷

EDIT

FIELD

I

O

17.8 cm

(7 in)

47.0 cm (18.5 in) 6.4 cm

(2.5 in)

For Cable

Access

Figure 1-2. 5820A Calibrator Dimensional Outline

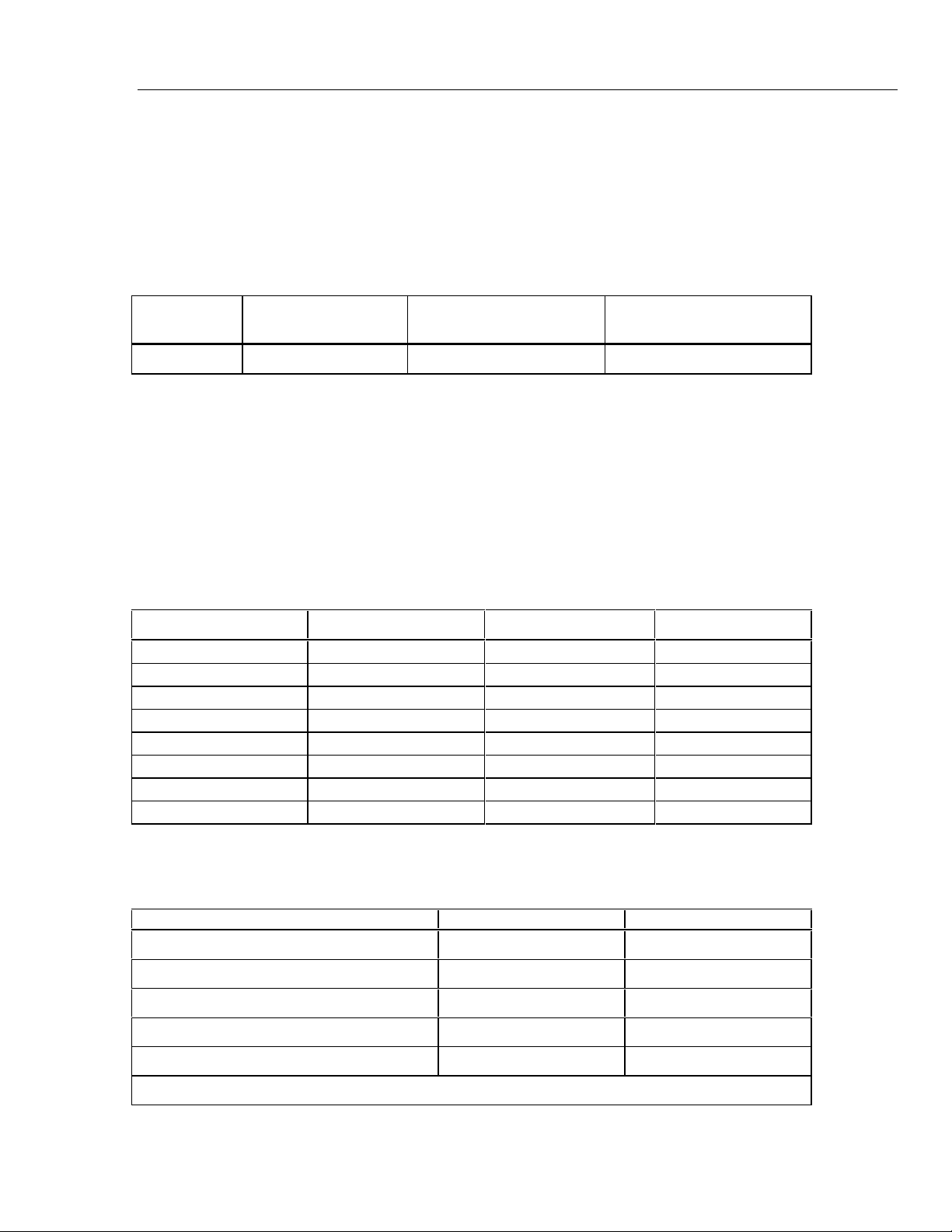

1-7. General Specifications

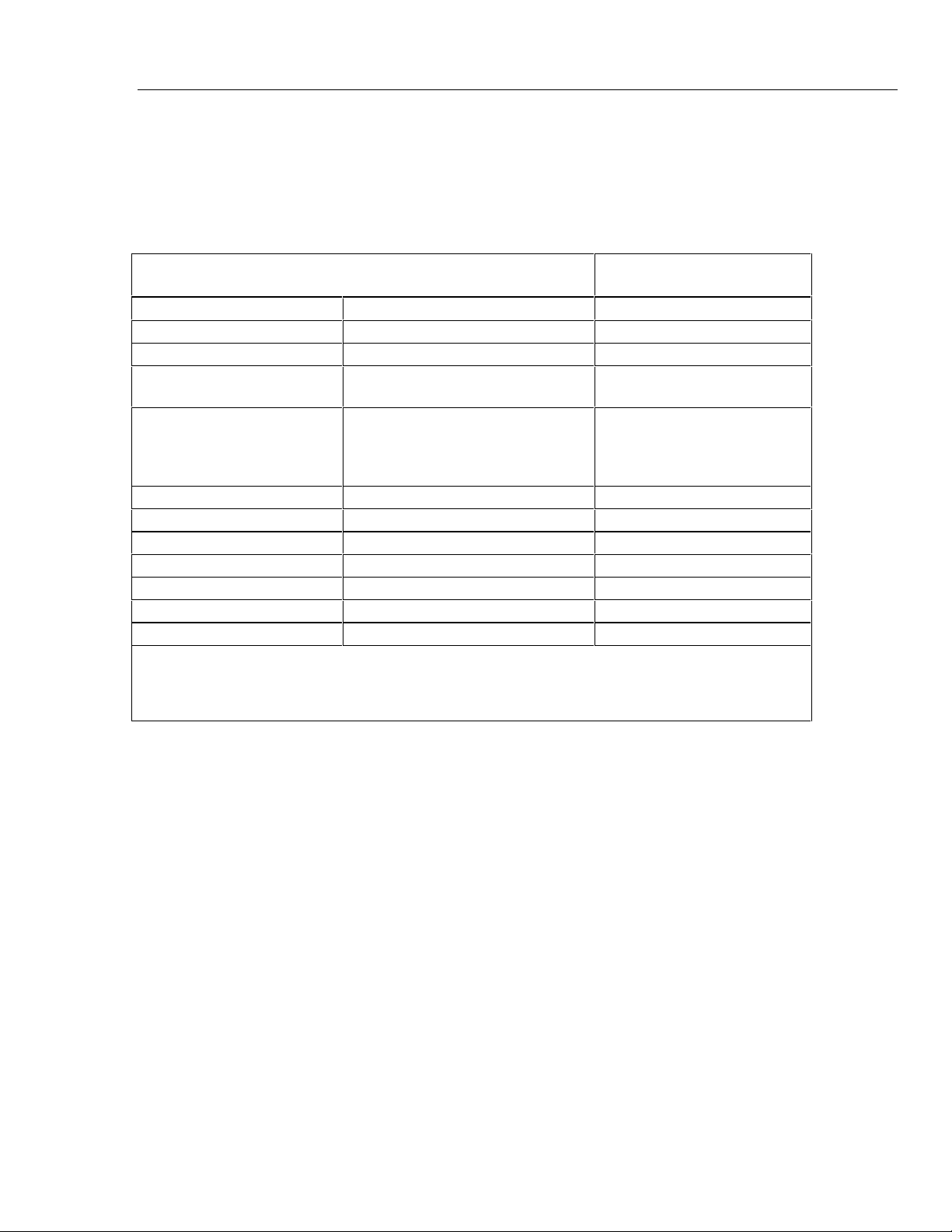

Table 1-1. General Specifications

Warmup Time Twice the time since last warmed up, to a maximum of 30 minutes

Settling Time 5 seconds or faster for all functions and ranges

Standard Interfaces IEEE-488 (GPIB), RS-232

Temperature Performance Operating: 0 °C to 50 °C

yh003f.eps

1-6

Electromagnetic

Compatibility

Calibration (tcal): 15 °C to 35 °C

Storage: -20 °C to 70 °C

Designed to operate in Standard Laboratory environments where the

Electromagnetic environment is highly controlled. If used in areas with

Electromagnetic fields > 1 V/m, there could be errors in output values.

From 80 -252 MHz, the current output is susceptible to a field strength of

> 0.165 V/M.

Page 19

Introduction and Specifications

General Specifications

Temperature Coefficient Temperature Coefficient for temperatures outside tcal ±5 °C is 0.1X/°C of

1-year specification.

Relative Humidity Operating: < 80 % to 30 °C, < 70 % to 40 °C,< 40 % to 50 °C

Storage: < 95 %, noncondensing

Altitude Operating: 3,050 m (10,000 ft) maximum

Nonoperating: 12,200 m (40,000 ft) maximum

Safety Designed to comply with IEC 1010-1 (1992-1); ANSI/ISA-S82.01-1994;

CAN/CSA-C22.2 No. 1010.1-92

Interface Impedance The 5820A is designed to drive both 50 Ω and 1MΩ loads.

Analog Low Isolation 20 V

EMC Complies with EN 61326-1

Line Power Line Voltage (selectable): 100 V, 120 V, 220 V, 240 V

Line Frequency: 47 to 63 Hz

1

Line Voltage Variation: ± 10 % about line voltage setting

Power Consumption 250 VA

Dimensions Height: 17.8 cm (7 inches), standard rack increment, plus 1.5 cm

(0.6 inch) for feet on bottom of unit;

Width: 43.2 cm (17 inches), standard rack width

Depth: 47.3 cm (18.6 inches) overall.

Weight 20 kg (44 pounds)

1-7

Page 20

5820A

Service Manual

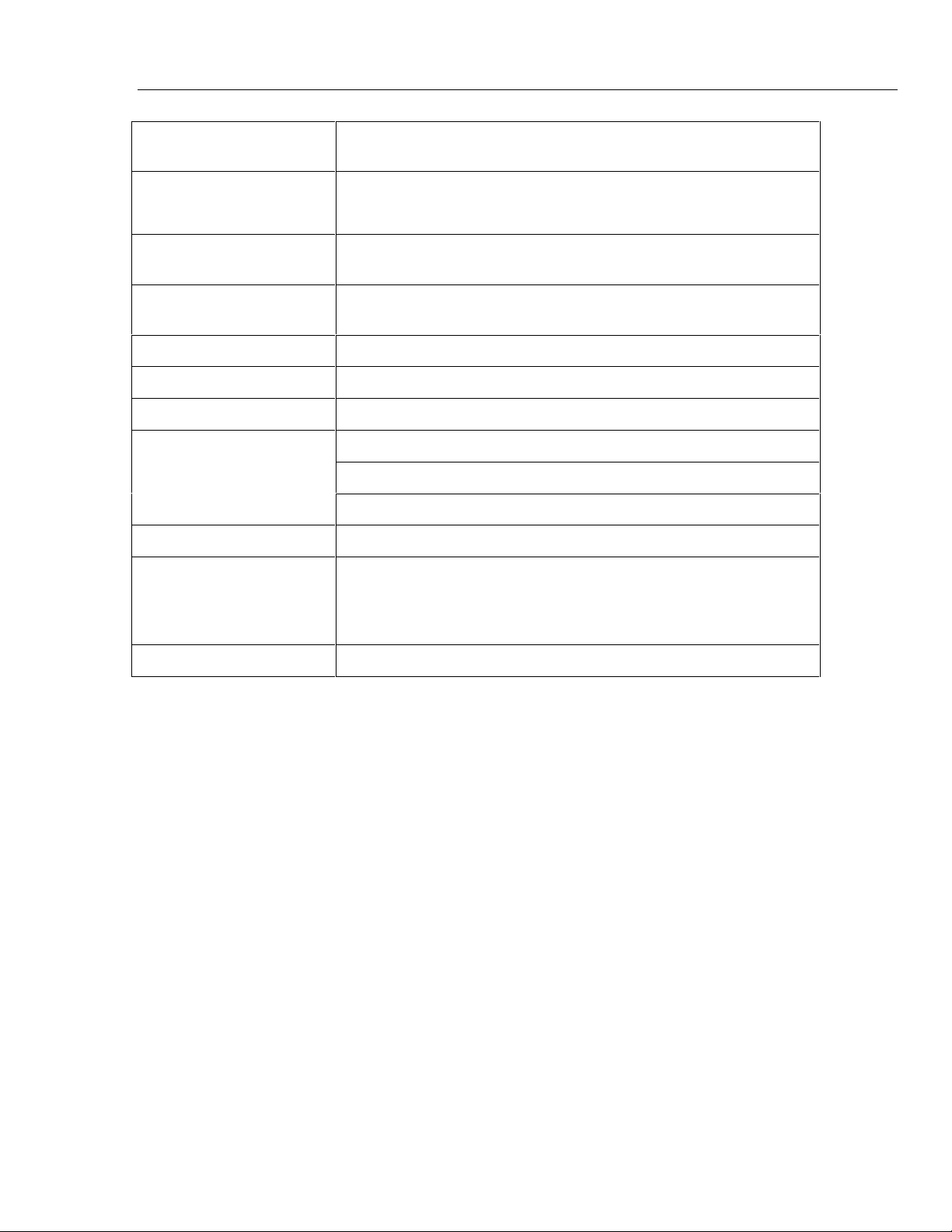

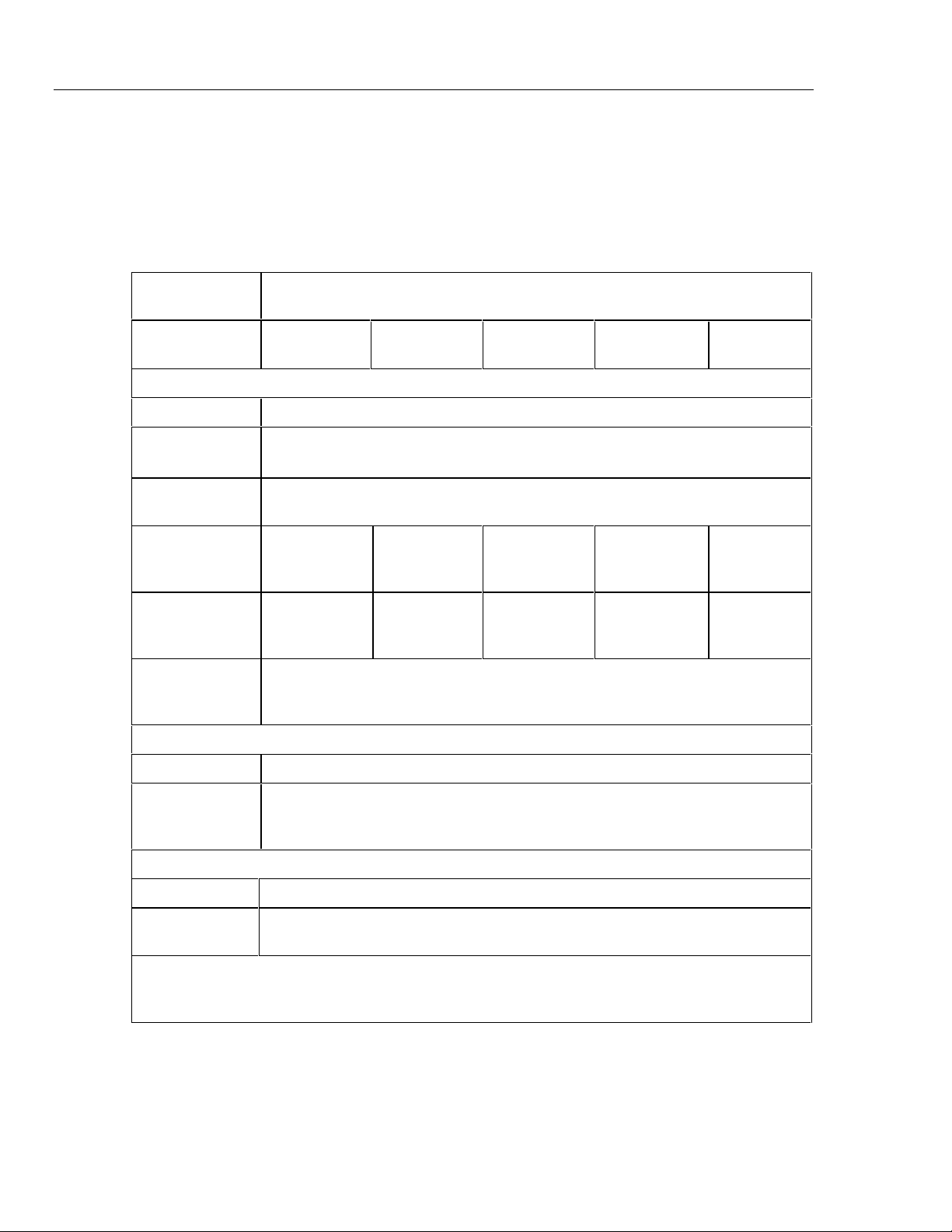

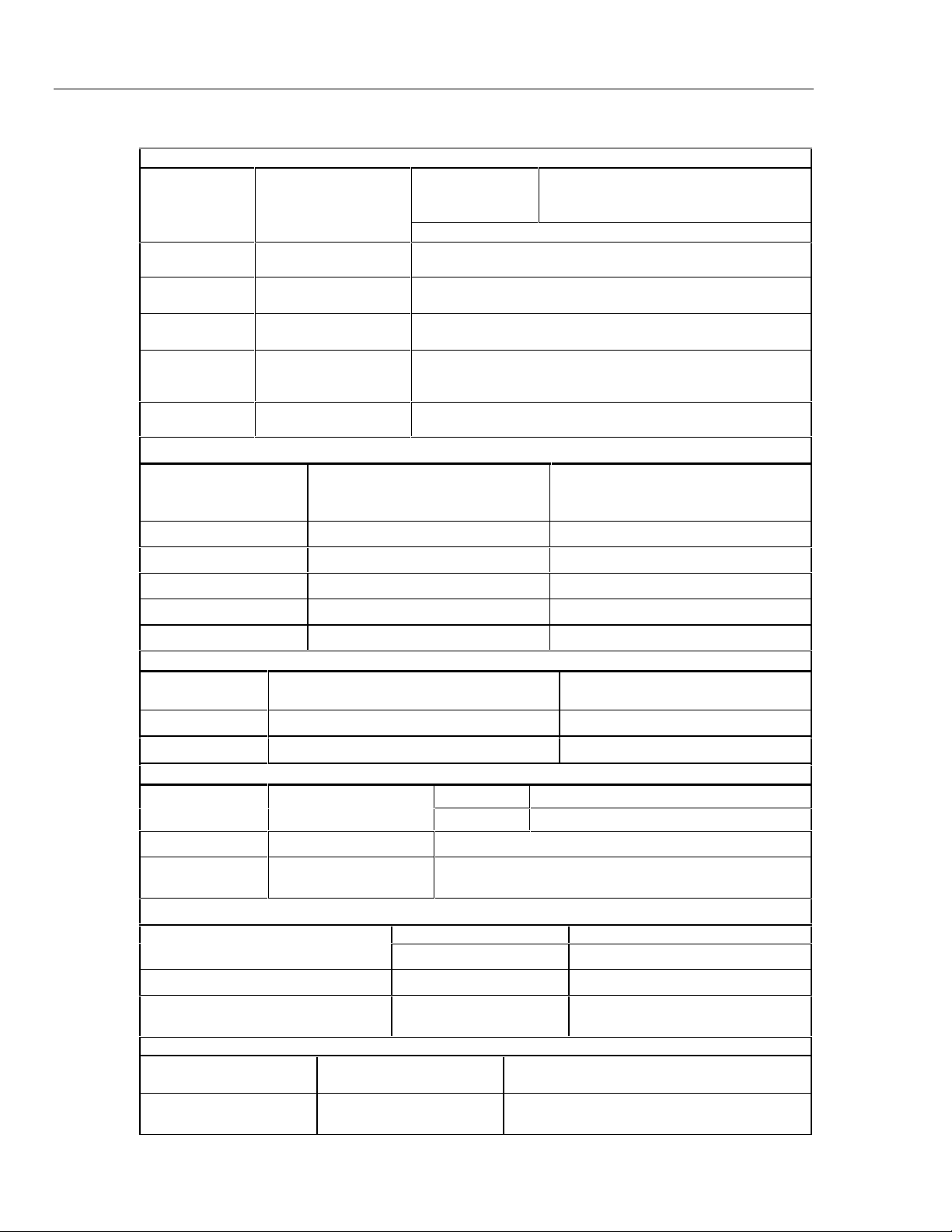

1-8. Volt Specifications

Table 1-2. Volt Specifications

Volt Function

Load

Amplitude Characteristics

Range

range resolution

Resolution

Adjustment Range Continuous

1-Year Absolute Uncertainty, tcal ± 5 °C ± (0.25% of

Sequence 1-2-5 (e.g., 10 mV, 20 mV, 50 mV)

Range 10 Hz to 10 kHz

1-Year Absolute Uncertainty, tcal ± 5 °C ± (0.33 ppm of setting)

1mV to 24.999 mV

25 mV to 109.99 mV

110 mV to 2.1999 V

2.2 V to 10.999 V

11 V to 130 V

Square Wave Frequency Characteristics

0 V to ± 6.6 V 0 V to ± 130 V ±1 mV to

output

+ 40 µV)

DC Signal Square Wave Signal [1]

into

50 Ω

into

1 MΩ

± (0.025%

of output +

25 µV)

into

50 Ω

±6.6 V p-p

1 µV

10 µV

100 µV

1 mV

10 mV

± (0.25%

of output

+ 40 µV)

into

1 M Ω

±1 mV to

±130 V p-p

± (0.05%

of output

+ 5 µV) [2]

Typical Aberration (from 50% of

leading/trailing edge)

25 mV to 130 V: within 4 µs

10 mV to 25 mV: within 8 µs

1 mV to 10 mV: within 14 µs

[1] Positive or negat i v e, zero referenced square wave.

[2] Above 1 kHz,

± (0.25% of output + 40 µV). As sumes connectors and cables are in good condition.

< (0.5% of output + 100 µV)

WCaution

Input voltages exceeding 30 V dc may cause damage to the

instrument.

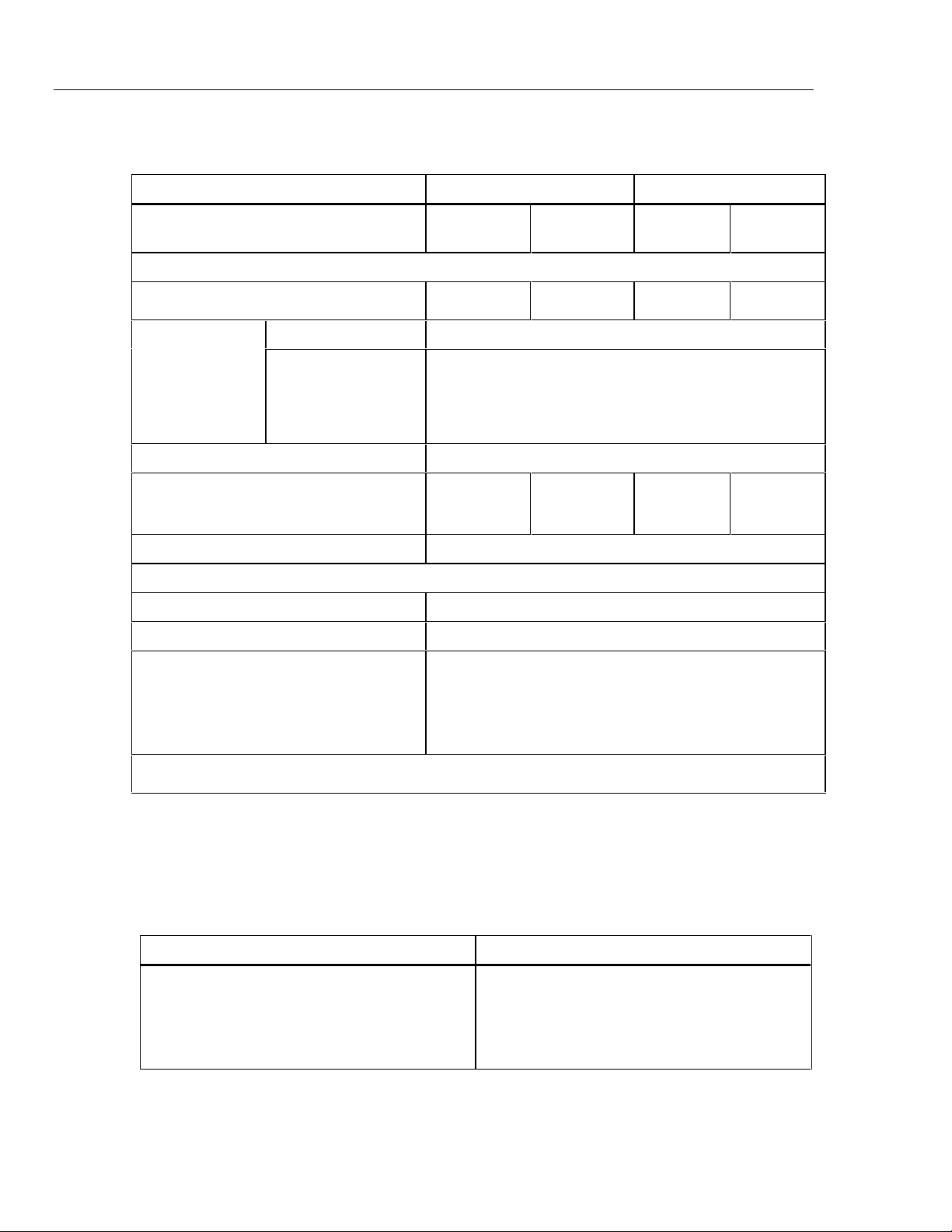

1-9. DC Volt Measure Specifications

Table 1-3. DC Volt Measure Specifications

Voltage Range Voltage Accuracy

DCV ± 10 V maximum with 1 mV resolution 0 to ± 5.99 V - 0.05% ± 1 mV

6 to ± 10 V – 0.25% ± 10 mV

> 1 MΩ input impedance (measure voltage across

1 MΩ input resistor)

1-8

Page 21

Introduction and Specifications

General Specifications

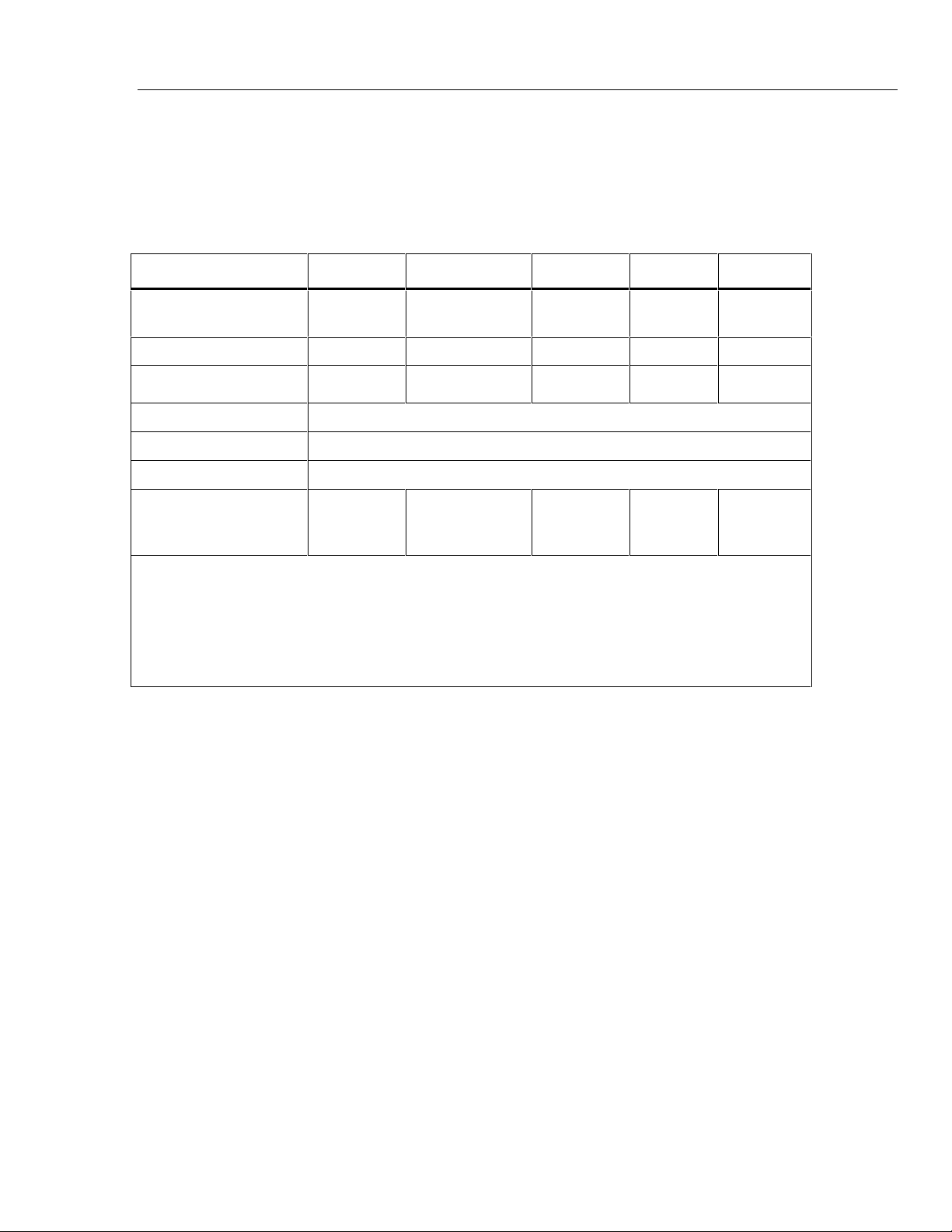

1-10. Edge Specifications

Note

The GHz Option offers a Fast Edge function. The specifications for the

Fast Edge function can be found in Chapter 5.

Table 1-4. Edge Specifications

1-Year Absolute

Edge Characteristics into 50 Ω Load

Rise Time ≤ 300 ps +0, -100 ps

Amplitude Range (p-p) 4.0 mV to 2.5 V ± (2 % of output + 200 µV)

Resolution 4 digits

Adjustment Range ± 10 % around each sequence

value (indicated below)

Sequence Values 5 mV, 10 mV, 25 mV, 50 mV,

60 mV, 80 mV, 100 mV, 200 mV,

250 mV, 300 mV, 500 mV, 600 mV,

1 V, 2.5 V

Frequency Range [1] 1 kHz to 10 MHz ± (0.33 ppm of setting)

Typical Jitter, edge to trigger < 3 ps (p-p)

Leading Edge Aberrations[2] within 2 ns from 50 % of rising edge < (3 % of output + 2 mV)

2 to 5 ns < (2 % of output + 2 mV)

5 to 30 ns < (1 % of output + 2 mV)

after 30 ns < (0.5 % of output + 2 mV)

Typical Duty Cycle 45 % to 55 %

[1] Frequency range above 2 MHz has rise time specification 350 ps typical.

Uncertainty, tcal ± 5 °C

1

[2] The leading edge aberrations below 250 mV are typical. All readings are referenced to a Tek11801

with an SD26 module or a Tek820 oscilloscope with a 8 GHz bandwidth option.

1-9

Page 22

5820A

Service Manual

1-11. Leveled Sine Wave Specifi cat ions

Note

The GHz Option offers an extended 600 MHz to 2.1 GHz Leveled Sine

Wave range. If the GHz Option is installed, see the Leveled Sine Wave

Specifications (> 600 MHz ) table in Chapter 5.

Table 1-5. Leveled Sine Wave Specifications (≤ 600 MHz )

Leveled Sine

Wave Frequency Range

Characteristics

into 50 Ω

Amplitude Characteristics

Range (p-p) 5 mV to 5.0 V

Resolution < 100 mV:3 digits

Adjustment

Range

1-Year Absolute

Uncertainty,

tcal ± 5 °C

Flatness [1]

(relative to

50 kHz)

Short-Term

Amplitude

Stability

Frequency Characteristics

Resolution 10 kHz

50 kHz

(reference)

≥ 100 mV:4 digits

continuously adjustable

± (2 % of

output +

300 µV)

not applicable ± (1.5 % of

50 kHz to

100 MHz

± (3.5 % of

output +

300 µV)

output +

100 µV)

100 MHz to

300 MHz

± (4 % of

output +

300 µV)

± (2 % of

output+

100 µV)

≤ 1 %[2]

300 MHz to

500 MHz

± (5.5 % of

output +

300 µV)

± (3.5 % of

output +

100 µV)

500 MHz to

600 MHz

± (6 % of

output +

300 µV)

± (4 % of

output +

100 µV)

1-10

1-Year Absolute

Uncertainty,

tcal ± 5 °C

Distortion Characteristics [3]

2nd Harmonic ≤ -33 dBc

3rd and Higher

Harmonics

[1] As measured near Oscilloscope bandwidth frequency.

[2] Within one hour after reference amplitude setting, provided temperature varies no more than ± 5 °C.

[3] Harmonics above 500 MHz are typical.

± 0.33 ppm

≤ -38 dBc

Page 23

1-12. Time Marker Specifi cat ions

If you ordered the GHz Option, the following specification table is

superseded by the table with the same heading in Chapter 5.

Table 1-6. Time Marker Specifications

Time Marker into 50 Ω

5 s to

50 ms

Note

20 ms to

100 ns

Introduction and Specifications

50 ns to

20 ns 10 ns

General Specifications

5 ns to 2

ns

1

Wave Shape spike or

square

Typical Output Level > 1 V p-p [1] > 1 V p-p [1] > 1 V p-p [1] >1 V p-p [1] > 1 V p-p

Typical Jitter (p-p) < 10 ppm < 1 ppm < 1 ppm < 1 ppm < 1 ppm

Sequence 5-2-1 from 5 s to 2 ns (e.g., 500 ms, 200 ms, 100 ms )

Adjustment Range At least ± 10 % around each sequence value indicated above.

Amplitude Resolution 4 digits

1-Year Absolute

Uncertainty, tcal ± 5 °C

[3]

[1] Typical rise time of square wave and 20%-pulse (20 % duty cycle pulse) is < 1.5 ns.

[2] With 10 MHz external reference selected, the uncertainty becomes that of the external clock plus 5 µHz.

[3] Time marker uncertainty is ± 50 ppm when measured off of cardinal points:

5 s, 2 s, 1 s, 500 ms, 200 ms, 100 ms, 50 ms, 20 ms, 10 ms, 5 ms, 2 ms, 1 ms, 500 µs, 200 µs, 100µs,

50 µs, 20 µs, 10 µs, 5 µs, 2 µs, 1 µs, 500 ns, 200 ns, 100 ns, 50 ns, 20 ns, 10 ns, 5 ns and 2 ns

± (2.5 ppm

+ 5 µHz) [2]

spike, square,

or 20%-pulse

± 0.33 ppm ± 0.33 ppm ± 0.33 ppm ± 0.33 ppm

spike or

square

square or

sine

sine

1-11

Page 24

5820A

Service Manual

1-13. Wave Generator Specifi cat ions

Amplitude

Range into 1 MΩ: 1.8 mV to 55 V p-p

Wave Generator

Characteristics

Table 1-7. Wave Generator Specifications

Square Wave and Sine Wave

into 50 Ω or 1 MΩ

into 1 MΩ: 1.8 mV to 55 V p-p

Triangle Wave

into 50 Ω or 1 MΩ

into 50 Ω: 1.8 mV to 2.5 V p-p

1-Year Absolute Uncertainty,

tcal ± 5 °C, 10 Hz to 10 kHz

Sequence 1-2-5 (e.g., 10 mV, 20 mV, 50 mV) 1-2-5 (e.g., 10 mV, 20 mV, 50 mV)

Typical DC Offset Range 0 to ± (≥40 % of p-p amplitude) [1] 0 to ± (≥40 % of p-p amplitude) [1]

Ramp Linearity [2] better than 0.1 % 10 Hz to 10 kHz

Frequency

Range 0.01 Hz to 100 kHz 0.01 Hz to 100 kHz

Resolution 4 or 5 digits depending upon

1-Year Absolute Uncertainty,

tcal ± 5 °C [5]

[1] The DC offset plus the wave signal must not exceed 30 V rms.

[2] Applies to the 10 % to 90 % of the triangle waveform 500 mV p-p to 10 V p-p.

[3] No specification below 10 Hz or above 10 kHz.

[4] With 10 MHz external reference selected, the uncertainty becomes that of the external clock plus 5 µHz.

[5] Uncertainties below 10 Hz are typical.

[6] Square wave rise/fall time typically less than 500 ns.

± (3 % of p-p output + 100 µV) ± (3 % of p-p output + 100 µV)

frequency

± (2.5 ppm + 5 µHz) [4] ± (2.5 ppm + 5 µHz) [4]

into 50 Ω: 1.8 mV to 2.5 V p-p

[3]

4 or 5 digits depending upon

frequency

1-12

Page 25

1-14. 1 ns Pulse Generator Specif i cations

Table 1-8. Pulse Generator Specifications

Introduction and Specifications

General Specifications

1

Pulse Generator Characteristics

Typical Rise/fall Time ≤ 500 ps

Typical Available Amplitudes 1.5 V, 600 mV, 150 mV,60 mV,15 mV

Pulse Width

Range [1] 1 ns to 500 ns

Uncertainty 5% ± 200 ps

Pulse Period

Pulse width < 1 ns 20 ms to 200 ns

1 ns ≤ Pulse width ≤ 9.9 ns 20 ms to 200 ns

10 ns ≤ Pulse width ≤ 79.9 ns 20 ms to 2 µs

80 ns ≤ Pulse width ≤ 500 ns 20 ms to 10 µs

Resolution 4 or 5 digits depending upon frequency and width

1-Year Absolute Uncertainty, tcal ± 5 °C ± 0.33 ppm

Pulse Skew with Trigger[3]

Range [2] +30 ns to -10ns with 250 ps resolution

Uncertainty [4] ± 500 ps

[1] May generate pulses below 1ns but pulse width accuracy is not specified.

[2] Assumes that trigger used in divide by 1 mode. Other divide modes are not specified.

[3] Pulse skew measured from 30% of trigger signal amplitude to 30% of pulse range amplitude.

[4] Uncertainty specification applies only for pulse periods that are 3 µs or greater in duration.

Otherwise, skew uncertainty is typical.

Positive pulse into 50 Ω

1-15. Trigger Signal Specif ications (Pulse Function)

Table 1-9. Trigger Signal Specifications (Pulse Function)

Pulse Period Division Ratio Amplitude into 50 Ω

(p-p)

20 ms to 200 ns off/1/10/100 ≥ 1 V ≤ 2 ns

Skew between Pulse and Trigger programmable from -10 ns to +30 ns

Typical Rise Time

1-16. Trigger Signal Specif ications (Time Marker Function)

Table 1-10. Trigger Signal Specifications (Time Marker Function)

Pulse Period Division Ratio [1] Amplitude into 50 Ω (p-p) Typical Rise Time

5 s to 750 ns off/1 ≥ 1 V ≤ 2 ns

34.9 ms to 7.5 ns off/10 ≥ 1 V ≤ 2 ns

34.9 ms to 2 ns off/1/10/100 ≥ 1 V ≤ 2 ns

1-13

Page 26

5820A

Service Manual

1-17. Trigger Signal Specif ications (Edge Function)

Table 1-11. Trigger Signal Specifications (Edge Function)

Edge Signal

Frequency

1 kHz to 10 MHz off/1 ≥ 1 V ≤ 2 ns 40 ns

Division

Ratio

Typical Amplitude

into 50 Ω (p-p) Typical Rise Time Typical Lead Time

1-18. Trigger Signal Specif ications (Square Wave Voltage Function)

Table 1-12. Trigger Signal Specifications (Square Wave Voltage Function)

Edge Signal

Frequency

10 Hz to 10 kHz off/1 ≥ 1 V ≤ 2 ns 2 µs

Division

Ratio

Typical Amplitude

into 50 Ω (p-p) Typical Rise Time Typical Lead Time

1-19. Trigger Signal Specif ications (TV)

Table 1-13. TV Trigger Signal Specifications

Trigger Signal Type Parameters

Frame Formats Selectable NTSC, SECAM, PAL, PAL-M

Polarity Positive or negative

Amplitude into 50 Ω (p-p) Adjustable 0 to 1.5 V p-p into 50 ohm load, (±7 % accuracy)

Line Marker Selectable Line Video Marker

1-20. Tunnel Diode Drive Capability

Table 1-14. Tunnel Diode Drive Capability

TD Pulse Drive Square wave at 100 Hz to 100 kHz with variable amplitude of 60 to 100 V p-p

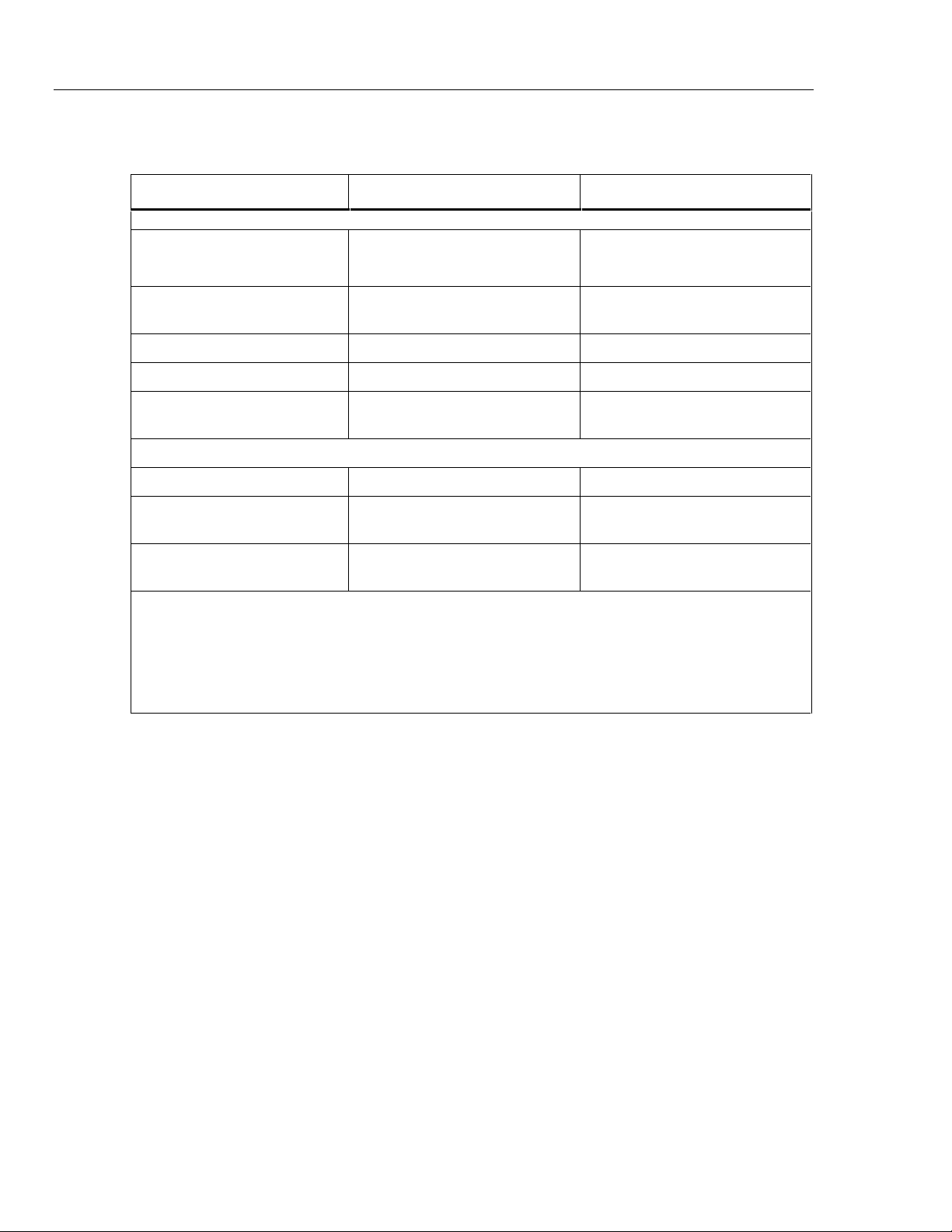

1-21. Oscilloscope I nput Resistance Measurement Specifications

Table 1-15. Oscilloscope Input Resistance Measurement Specifications

Scope Input Selected 50 Ω 1 MΩ

Measurement Range 40 Ω to 60 Ω 500 kΩ to 1.5 MΩ

Uncertainty 0.1 % 0.1 %

1-22. Oscilloscope I nput Capacitance Measurement Specifications

Table 1-16. Oscilloscope Input Capacitance Measurement Specifications

Scope Input Selected 1 MΩ

Measurement Range 5 pF to 50 pF

Uncertainty ± (5 % of input + 0.5 pF) [1]

[1] Measurement made within 30 minutes of capacitance zero reference.

1-14

Page 27

1-23. Overload Measurement Speci f ications

The Overload test function applies dc or ac (1 kHz square wave) power into the 50 Ω

oscilloscope input and monitors the current. A time measurement counter indicates the

time duration of the applied overload signal. When the input protection circuit reacts and

opens up the 50 Ω load, the calibrator indication is set to ‘off’ on the right hand display.

In order to prevent front end damage to the oscilloscope, a limited amount of energy is

applied by a user selectable time limit.

Table 1-17. Overload Measurement Specifications

Introduction and Specifications

General Specifications

1

Source

Voltage

5 V to 9 V 100 mA to 180 mA 10 mA setable 5 to 60 sec

Typical ‘On’ current

indication

Typical ‘Off’ current

indication

Maximum Time Limit DC or

AC (1 kHz)

1-24. External Reference Input Speci f ications

The External Reference Input selection allows the user to provide their own high

stability 10 MHz reference clock for the 5820A for all functions except the Wave

Generator function. For all other modes, the frequency stability is determined by the

external reference stability. The external reference input must be between 1 to 5 V p-p.

1-25. Auxiliary Input Specifications

Maximum input voltage into the auxiliary input is 40 V p-p.

Table 1-18. Auxiliary Input Performance

Channel Configuration Frequency Typical Loss Typical VSWR

1-Channel < 600 MHz ≤ 1.1 dB ≤ 1.2:1

1-Channel 600 MHz to 1 GHz ≤ 1.3 dB ≤ 1.4:1

1-Channel 1 GHz to 2.0 GHz ≤ 2.0 dB ≤1.7:1

1-Channel 2 GHz to 3 GHz ≤ 3.0 dB ≤ 2.0:1

5-Channel < 600 MHz ≤ 1.1 dB ≤ 1.2:1

5-Channel 600 MHz to 1 GHz ≤ 1.3 dB ≤ 1.4:1

5-Channel 1 GHz to 2.0 GHz ≤ 2.0 dB ≤ 1.7:1

5-Channel 2 GHz to 3 GHz ≤ 3.0 dB ≤ 2.0:1

1-26. Current Output Speci f i cations

Table 1-19. Current Output Specifications

DC Squarewave

Amplitude (compliance voltage 2 V max) ± 100 µA to ± 100 mA 100 µAp-p to 100 mAp-p

Accuracy ± (0.25% + 0.5 µA) ± (0.25% + 0.5 µA) [1]

Frequency Range N/A 10 Hz to 100 KHz

Accuracy 2.5 ppm +5 µHz

Steps 1,2,5 or continuous

[1] Amplitude uncertainty for frequency range 45 Hz to 1 kHz at < 120 mV compliance voltage.

1-15

Page 28

5820A

Service Manual

1-16

Page 29

Chapter 2

Theory of Operation

Title Page

2-1. Introduction........................................................................................... 2-3

2-2. Voltage Mode................................................................................... 2-7

2-3. Edge Mode........................................................................................ 2-7

2-4. Leveled Sine Wave Mode ................................................................ 2-7

2-5. Time Marker Mode .......................................................................... 2-7

2-6. Wave Generator Mode ..................................................................... 2-8

2-7. Pulse Generator ................................................................................ 2-8

2-8. Input DC Voltage Measurement Mode ............................................ 2-8

2-9. Input Impedance Mode (Resistance)................................................ 2-8

2-10. Input Impedance Mode (Capacitance).............................................. 2-8

2-11. Current Module ................................................................................ 2-9

2-12. Overload Mode................................................................................. 2-9

2-13. Trigger.............................................................................................. 2-9

2-14. High Frequency Switching............................................................... 2-9

2-15. 5 Channel Option.............................................................................. 2-9

2-16. GHz Option Module......................................................................... 2-9

2-1

Page 30

5820A

Service Manual

2-2

Page 31

2-1. Introduction

The following discussion provides a brief overview of the following 5820A operating

modes:

• Voltage

• Edge

• Leveled sine wave

• Time marker

• Wave generator

• Video

• Pulse generator

• Input impedance

• Overload

• Current

• 5 Channel Option

Theory of Operation

Introduction

2

• DC Volts Measure

• GHz Option (2.1 GHz Leveled Sine and Fast Edge).

This discussion will allow you to identify which of the main plug-in boards of the

Calibrator Mainframe are defective. Figure 2-1 shows a block diagram of the 5820A.

Note that while ac power is filtered on the A3 Mother Board, most supply voltages are

derived on the A80 Voltage Board.

The components in the scope module are shown in Figure 2-2. A signal diagram is

shown in Figure 2-3. The scope module consists of the following:

• The A55 Main Scope Board, which generates leveled sine, marker, capacitance

measurement, and trigger.

• The A51 Voltage/Video Board, which generates precision dc and ac low frequency

square wave, video, overload measurement and resistance measurement.

• The A90 Attenuator/Edge Attenuator, which attenuates the signal by 0 to -48 dB and

generates the < 300 ps edge.

• The A52 Pulse Board, which generates pulse generator signals.

2-3

Page 32

5820A

Service Manual

Mother

Board

A03

Guard Processor

Board

A2

Front Panel

Processor Board

A9

Protection

Isolation

Relays

Control

Power

Direct Digital

Synthesis

Wave Gen

Function

Scope Board

Power Board

Current Board

A6

A55

Relay Control

A80

A81

Output

Optional

5 Channel

Trigger

Switch

Matrix

Single Trigger Channel

C1

C2

C3

C4

C5

Aux In

Output

Sense Bd

5 Channel

Chan 1

2

3

4

5

Aux in

Current

Loop

Outlet

Single Channel

Out

NC

NC

NC

Trigger

2-4

Figure 2-1. Signal Diagram of Chassis

yu068f.eps

Page 33

Power

Control

Main

Scope

Board

Control

Voltage Bd

A51

Theory of Operation

Introduction

2

Clock From

DDS A6

Ext Ref

Clock

Pulse Bd

A52

Trigger Out

Attenuator Bd

Signal Out

A90

A55

5820 Scope Module

Figure 2-2. Block Diagram of Scope Module

yu070f.eps

2-5

Page 34

5820A

Service Manual

LF PWB

50Ω

A6

DDS

Time Mark I

50 ms to 10 ns

Leveled Sine Wave

and Time Mark II

10 ns to 2 ns

Unleveled

Leveled

PLLs

Pwr Amp.

Leveling Loop

LF Mux.

HF Mux.

Trigger

%1,10,100,1000

HF PWB

Step Attenuator Module

HF Mux.

pp Detect

Oscilloscope

Calibrator

Trigger BNC

SCOPE

Output BNC

2-6

External

Clock In

Edge

Level

10 MHz Clock

A55 Main Scope Board

aag031f.eps

Figure 2-3. Signal Diagram of Scope Module

Page 35

Theory of Operation

Introduction

Other than the scope module, the A81 Current Board, the A6 Direct Digital Synthesis

Board, and the A3 Mother Board, provide the other functions in the 5820A. Digital

controls are provided by the 5520A-4002 for the front panel display and by 5520A-4009

Out-Guard CPU on the rear panel for all external and internal communication.

The A6 provides low frequency marker frequencies, the wave generator functions and

also contains the acquisition circuitry used in the dc voltage measurement. In addition,

the main voltage reference signals are generated on this board.

TheA3 is used to provide the routing for all control signals from the guard processor and

the signal path for all low frequency signals including the voltage sense signals. An

auxiliary input, Auxin, is a feature that allows a signal to be routed from the front panel

to the output port.

Optional features for the 5820A include 5-channel multiplexing capability and GHz

extended frequency capability. The 5-channel option allows the output signals to be

routed to one of five output ports. The GHz (gigahertz) option provides a 2.1 GHz

leveled sine and 150 ps fast edge. Information about the optional feature can be found in

the “Options” chapter of this manual.

Note

In the following discussion, the circuit boards are generally referenced by

their last two digits. As an example, the 5820A-4055 Main Scope Board is

referred to as the A55.

2

2-2. Voltage Mode

All ac and dc voltage function signals are generated from the A51 Voltage/Video Board,

a daughter card to the A55 Main Scope Board. A dc reference voltage is supplied to A51

from the A6 Direct Digital Synthesis Board; this reference is used for all dc and ac

amplitudes. All frequency signals (clock) are generated on the A55. The output of the

A51 is passed to the A55 board, which then passes through the A90 Edge/Attenuator

Board. The signal is then passed to the front panel high frequency switch. The dc

reference signal is used to generate both positive (+) and negative (-) dc and ac signals

that are amplified or attenuated to provide the complete range of output voltage signals.

Output trigger capability is available with the ac voltage signal.

2-3. Edge Mode

The edge clock originates on A55 and is used on A90 to generate the < 300 ps edge

signal. The edge signal is passed through the attenuator section of A90 and then, like all

of the signals, is passed to the front panel high frequency switch. Output trigger

capability is available with this signal.

2-4. Leveled Sine Wave Mode

Leveled sine wave signals from 50 kHz to 600 MHz are produced on A55. The leveled

sine wave signal is passed from A55 to the A90. The A90 provides range attenuation and

also contains a power detector that maintains the amplitude flatness across the frequency

range. The signal is then passed to the front panel high frequency switch. Output trigger

capability is not available with this signal.

2-5. Time Marker Mode

There are 4 primary “ranges” of time marker operation: 5 s to 50 ms, 20 ms to 2 µs, 1 µs

to 20 ns and 10 ns to 2 ns.

2-7

Page 36

5820A

Service Manual

2-6. Wave Generator Mode

The 5 s to 50 ms markers are generated on A6 and are passed to A55 for filtering and

shaping. The 20 ms to 2 µs markers are derived from a square wave signal that is

generated on A55 and passed through wave shaping and external trigger generation. The

1 µs to 20 ns periods are derived from leveled sine or square wave signals.

The 10 ns to 2 ns sine markers are generated from the leveled sine wave generator on

A55. This signal is also split to drive the external trigger circuits. If the trigger is turned

on, the signal is then connected to the Trig Out on the front panel. The other path routes

the signal to the marker circuits on A55, where the signal is shaped into the other marker

waveforms. The marker signals are passed from A55 to the A90 and on to the front panel

high frequency switch.

Filters on A55 shape the signal into spike and 20% pulse. The marker signal passing

through A55 is connected to the A90 assembly. The signal is then passed to the front

panel high frequency switch. Output trigger capability is available with these signals.

All amplitude and frequency for the Wavegen function are generated on A6 and the

signals are routed through A55. The signals are then sent to the A90 assembly, where

range attenuation occurs. Wavegen signals are then sent to front panel high frequency

switch. Output trigger capability is not available with these signals.

2-7. Pulse Generator

Pulse Gen (Pulse Generator Modes) signals are derived from A52. While the maximum

pulse period is 20 ms or 50 Hz, the minimum is 200 ns. The pulse width can be set to

less than 1 ns or set as wide as 500 ns. The pulse can be skewed with the output trigger

so that it leads or lags the trigger in 250 ps increments. Output trigger capability is

available with this signal.

2-8. Input DC Voltage Measurement Mode

The dc voltage measurement mode is provided through A6. The input signal to be

measured is filtered on A3. The DCV reference signal and measuring signals are on A6.

Maximum input voltage is 10 V dc.

Caution

Input voltages above 30 V dc may cause damage to the unit.

2-9. Input Impedance Mode (Resistance)

The reference resistors for input resistances are on A51, while the actual measurement

takes place on A6.

2-10. Input Impedance Mode (Capacitance)

Capacitance measurement circuits are contained on A55. Signals from the leveled sine

signals are used in the measurement.

2-8

Page 37

2-11. Current Module

For the A81 Current Board, A55 supplies the reference signal. This signal is inverted

with respect to polarity of the output current (a negative voltage results in a positive

current output). A81 has three ranges: 100 µA to 1.0999 mA, 1.1 mA to 10.999 mA and

11 mA to 100 mA. The board limits the compliance to 2 V.

2-12. Overload Mode

The source voltage for the overload mode is generated on the A51 Voltage/Video Board.

The voltage is applied to the external 50 Ω load, and the circuit current is monitored by

A6.

2-13. Trigger

The A55 marker clock signal is used to generate the trigger signals. There are two trigger

output SMB connectors on A55. The right angle SMB should be used to route the trigger

signal to the front panel. The vertical connector should be used to route the trigger signal

to the optional GHz module, if installed.

2-14. High Frequency Switchi ng

For the standard single channel calibrator, output signals, except for current and trigger,

are routed to a high frequency switch. From the switch, the signals are cabled to the

5820A-4096 output block. For the single channel unit, the trigger signal and current

signal are cabled directly to the output block and current loop, respectively. A high

frequency relay is used to select between the auxiliary input signal, Auxin, and the

output signal. The selected signal is cabled to connectors on the front panel. In five

channel units, additional high frequency switches are used to route the trigger signal out

channel 1 or channel 5.

Theory of Operation

Introduction

2

2-15. 5 Channel Option

This option multiplexes the output to one of the 5 channels. All signals, except for

current, are routed through this switch system.

2-16. GHz Option Module

The GHz option extends leveled sine from 600 MHz to 2.1 GHz and adds a 150 ps, 250

mV fast edge signal. For more information on the GHz Option Module, see the Options

Chapter.

2-9

Page 38

5820A

Service Manual

2-10

Page 39

Chapter 3

Calibration and Verification

Title Page

3-1. Introduction........................................................................................... 3-3

3-2. Equipment Required for Calibration and Verification......................... 3-3

3-3. Calibration Setup.................................................................................. 3-6

3-4. Calibration and Verification of Square Wave Voltage Functions........ 3-6

3-5. Overview of HP3458A Operation.................................................... 3-6

3-6. Setup for Scope Calibrator Voltage Square Wave Measurements... 3-6

3-7. Setup for Scope Calibrator Edge and Wave Gen Square Wave

Measurements.................................................................................. 3-8

3-8. DC Voltage Calibration........................................................................ 3-9

3-9. AC Voltage Calibration........................................................................ 3-10

3-10. DC Measurement Calibration............................................................... 3-11

3-11. Current Calibration............................................................................... 3-11

3-12. DC Current Calibration.................................................................... 3-11