Page 1

5800A

®

Oscilloscope Calibrator

Operators Manual

PN 686318

January 1998 Rev.1, 12/98

© 1998 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies.

Page 2

LIMITED WARRANTY & LIMITATI O N OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under

normal use and service. The warranty period is one year and begins on the date of shipment.

Parts, product repairs and services are warranted for 90 days. This warranty extends only to the

original buyer or end-user customer of a Fluke authorized reseller, and does not apply to fuses,

disposable batteries or to any product which, in Fluke’s opinion, has been misused, altered,

neglected or damaged by accident or abnormal conditions of operation or handling. Fluke

warrants that software will operate substantially in accordance with its functional specifications for

90 days and that it has been properly recorded on non-defective media. Fluke does not warrant

that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user

customers only but have no authority to extend a greater or different warranty on behalf of Fluke.

Warranty support is available if product is purchased through a Fluke authorized sales outlet or

Buyer has paid the applicable international price. Fluke reserves the right to invoice Buyer for

importation costs of repair/replacement parts when product purchased in one country is submitted

for repair in another country.

Fluke’s warranty obligation is limited, at Fluke’s option, to refund of the purchase price, free of

charge repair, or replacement of a defective product which is returned to a Fluke authorized

service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center or send the

product, with a description of the difficulty, postage and insurance prepaid (FOB Destination), to

the nearest Fluke authorized service center. Fluke assumes no risk for damage in transit.

Following warranty repair, the product will be returned to Buyer, transportation prepaid (FOB

Destination). If Fluke determines that the failure was caused by misuse, alteration, accident or

abnormal condition of operation or handling, Fluke will provide an estimate of repair costs and

obtain authorization before commencing the work. Following repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and return

transportation charges (FOB Shipping Point).

THIS WARRANTY IS BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, WHETHER

ARISING FROM BREACH OF WARRANTY OR BASED ON CONTRACT, TORT, RELIANCE OR

ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or

exclusion or limitation of incidental or consequential damages, the limitations and exclusions of

this warranty may not apply to every buyer. If any provision of this Warranty is held invalid or

unenforceable by a court of competent jurisdiction, such holding will not affect the validity or

enforceability of any other provision.

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090 P.O. Box 1186

Everett, WA 98206-9090 5602 BD Eindhoven

U.S.A. The Netherlands

5/94

Page 3

SAFETY TERMS IN THIS MANUAL

This instrument has been designed and tested in accordance with IEC publicat ion

1010-1 (1992-1), Safety Requirements for Electrical Measuring, Control and Labor atory

Equipment, and ANSI/ISA-S82.01-1994, and CAN/CSA-C22.2 No. 1010.1-92. This User

Manual contains information, warning, and caut ions t hat must be followed to ensure

safe operation and to maintain the instrument in a safe condition. Use of this equipment

in a manner not specified herein may impair the pr ot ection provided by the equipment.

This instrument is designed for IEC 1010-1 Inst allation Category II use. It is not

designed for connection to circuits rated over 4800 VA.

WARNING statements identify condit ions or practices that could result in personal injury

or loss of life.

CAUTION statements identify conditions or pr act ices t hat could result in damage to

equipment.

SYMBOLS MARKED ON EQUIPMENT

WARNING Risk of electric shock. Refer to the manual (see the Index for

references).

GROUND Ground terminal to chassis (earth).

Attention Refer to the manual (s ee t he Index for references). This

symbol indicates that information about usage of a feature is contained in

the manual.

AC POWER SOURCE

The instrument is intended to operate from an ac power source that will not apply more

than 264V ac rms between the supply conductors or bet ween eit her supply conductor

and ground. A protective ground connection by way of the grounding conductor in the

power cord is required for safe operation.

USE THE PROPER FUSE

To avoid fire hazard, for fuse replacement use only t he specified unit: 100 or 120 V

operation, 2 ampere/250 volt time delay; 200 or 240 V oper ation, 1 ampere/250 volt time

delay.

GROUNDING THE INSTRUMENT

The instrument utilizes controlled overvoltage techniques that require the instrument to

be grounded whenever normal mode or common mode ac volt ages or t r ansient voltages

may occur. The enclosure must be grounded through t he gr ounding conductor of the

power cord, or through the rear panel gr ound binding post .

Page 4

USE THE PROPER POWER CORD

Use only the power cord and connector appropriate for the voltage and plug

configuration in your country.

Use only a power cord that is in good condition.

Refer power cord and connector changes to qualified service personnel.

DO NOT OPERATE IN EXPLOSIVE ATM O SPHERES

To avoid explosion, do not operate the instrument in an atmosphere of explosive gas.

DO NOT REMOVE COVER DURING OPERATION

To avoid personal injury or death, do not remove the instrument cover without first

removing the power source connected to the rear panel. Do not operate the instrument

without the cover properly installed. Norm al calibration is accomplished with the cover

closed. Access procedures and the warnings for such procedures ar e cont ained both in

this manual and in the Service Manual. Service procedur es ar e f or qualified service

personnel only.

DO NOT ATTEMPT TO OPERATE IF PROTECTION MAY BE IMPAIRED

If the instrument appears damaged or operates abnormally, protection may be impair ed.

Do not attempt to operate t he inst r um ent under these conditions. Refer all questions of

proper instrument operation to qualif ied service personnel.

Page 5

Table of Contents

Chapter Title Page

1 Introduction and Specifications........................................................ 1-1

1-1. Introduction.......................................................................................... 1-3

1-2. Operation Overview............................................................................. 1-4

1-3. Local Operation ............................................................................... 1-4

1-4. Remote Operation (RS-232) ............................................................ 1-4

1-5. Remote Operation (IEEE-488)......................................................... 1-5

1-6. Where To Go from Here ...................................................................... 1-5

1-7. Instruction Manuals.............................................................................. 1-6

1-8. 5800A Operators Manual................................................................. 1-6

1-9. 5800A Service Manual..................................................................... 1-6

1-10. Specifications....................................................................................... 1-6

1-11. General Specifications..................................................................... 1-8

1-12. Voltage Output Specifications......................................................... 1-9

1-13. Edge Specifications.......................................................................... 1-10

1-14. Leveled Sine Wave Specifications................................................... 1-11

1-15. Time Marker Specifications............................................................. 1-12

1-16. Wave Generator Specifications........................................................ 1-13

1-17. Pulse Generator Specifications........................................................ 1-14

1-18. Trigger Signal Specifications (Pulse Function)............................... 1-14

1-19. Trigger Signal Specifications (Time Marker Function) .................. 1-15

1-20. Trigger Signal Specifications (Edge Function)................................ 1-15

1-21. Trigger Signal Specifications (Square Wave Voltage Function)..... 1-15

1-22. Trigger Signal Specifications........................................................... 1-15

1-23. Tunnel Diode Drive Capability........................................................ 1-15

1-24. Oscilloscope Input Resistance Measurement Specifications........... 1-15

1-25. Oscilloscope Input Capacitance Measurement Specifications........ 1-16

1-26. Overload Measurement Specifications............................................ 1-16

1-27. External Reference Input Specifications.......................................... 1-16

1-28. Auxiliary Input/Output Specifications............................................. 1-16

2 Preparing for Operation..................................................................... 2-1

2-1. Introduction.......................................................................................... 2-3

2-2. Unpacking and Inspection.................................................................... 2-3

2-3. Replacing The Fuse.............................................................................. 2-3

i

Page 6

5800A

Operators Manual

2-4. Selecting Line Voltage......................................................................... 2-4

2-5. Connecting To Line Power................................................................... 2-4

2-6. Service Information.............................................................................. 2-6

2-7. Placement and Rack Mounting............................................................. 2-7

2-8. Cooling Considerations........................................................................ 2-7

3 Features.............................................................................................. 3-1

3-1. Introduction.......................................................................................... 3-3

3-2. Front Panel Features............................................................................. 3-3

3-3. Rear Panel Features.............................................................................. 3-3

3-4. Setup Softkey Menu Trees................................................................... 3-10

4 Front Panel Operation ....................................................................... 4-1

4-1. Introduction.......................................................................................... 4-3

4-2. Turning on the Calibrator..................................................................... 4-3

4-3. Warming up the Calibrator................................................................... 4-4

4-4. Using the Softkeys................................................................................ 4-4

4-5. Using the Setup Menu.......................................................................... 4-4

4-6. Using the Instrument Setup Menu ................................................... 4-5

4-7. Utility Functions Menu.................................................................... 4-5

4-8. Using the Format EEPROM Menu.............................................. 4-6

4-9. Resetting the Calibrator........................................................................ 4-6

4-10. Using the Operate and Standby Modes................................................ 4-7

4-11. Connecting the Calibrator to the UUT................................................. 4-7

4-12. Starting the Calibrator.......................................................................... 4-7

4-13. The Output Signal............................................................................ 4-8

4-14. Editing and Error Output Settings........................................................ 4-8

4-15. Adjusting the Output Signal............................................................. 4-9

4-16. Keying in a Value........................................................................ 4-9

4-17. Adjusting Values with the Rotary Knob ..................................... 4-9

X

and

D

4-18. Using

.................................................................. 4-10

4-19. Displaying the Output Error............................................................. 4-10

4-20. Resetting the Calibrator................................................................... 4-11

4-21. Calibrating the Voltage Amplitude on an Oscilloscope....................... 4-11

4-22. The VOLTAGE Function ................................................................ 4-11

4-23. The V/DIV Menu............................................................................. 4-12

4-24. Shortcuts for Setting the Voltage Amplitude................................... 4-12

4-25. The TRIG (Trigger) Menu............................................................... 4-13

4-26. Oscilloscope Amplitude Calibration Procedure .............................. 4-13

4-27. Calibrating the Pulse and Frequency Response on an Oscilloscope.... 4-14

4-28. The Edge Function........................................................................... 4-14

4-29. The TRIG (Trigger) Menu............................................................... 4-15

4-30. Oscilloscope Pulse Response Calibration Procedure....................... 4-16

4-31. Pulse Response Calibration Using a Tunnel Diode Pulser.............. 4-17

4-32. The Leveled Sine Wave Function.................................................... 4-18

4-33. Shortcuts for Setting the Frequency and Voltage............................ 4-19

4-34. The MORE OPTIONS Menu........................................................... 4-19

4-35. Sweeping Through a Frequency Range........................................... 4-20

4-36. Oscilloscope Frequency Response Calibration Procedure.............. 4-21

4-37. Calibrating the Time Base of an Oscilloscope..................................... 4-22

4-38. The Time Marker............................................................................. 4-23

4-39. The TRIG (Trigger) Menu............................................................... 4-24

4-40. Time Base Marker Calibration Procedure for an Osciloscope........ 4-24

4-41. Testing the Trigger............................................................................... 4-25

ii

Page 7

Contents

4-42. Testing Video Triggers......................................................................... 4-26

4-43. Verifying Pulse Capture....................................................................... 4-27

4-44. The TRIG (Trigger) Menu............................................................... 4-29

4-45. Measuring Input Impedance and Capacitance...................................... 4-29

4-46. Input Impedance Measurement........................................................ 4-30

4-47. Input Capacitance Measurement...................................................... 4-30

4-48. Testing Overload Protection................................................................. 4-31

4-49. Using Auxiliary Input (AUXIN).......................................................... 4-32

4-50. Setting the Output Channel.................................................................. 4-33

4-51. Using an External Reference................................................................ 4-33

5 Remote Operation.............................................................................. 5-1

5-1. Introduction.......................................................................................... 5-4

5-2. Setting up the IEEE-488 Port for Remote Control............................... 5-4

5-3. IEEE-488 Port Setup Procedure....................................................... 5-7

5-4. Testing the IEEE-488 Port............................................................... 5-8

5-5. Setting up the RS-232 Host Port for Remote Control.......................... 5-11

5-6. RS-232 Host Port Setup Procedure.................................................. 5-11

5-7. Testing the RS-232 Host Port.......................................................... 5-13

5-8. Testing RS-232 Host Port Operation using a Terminal............... 5-13

5-9. Testing RS-232 Host Port Operation using Visual Basic............ 5-15

5-10. Setting up the RS-232 UUT Port for Remote Control ......................... 5-16

5-11. RS-232 UUT Port Setup Procedure................................................. 5-16

5-12. Testing the RS-232 UUT Port via RS-232 Host Port ...................... 5-17

5-13. Testing RS−232 UUT Port Operation via a Terminal................. 5-19

5-14. Testing RS-232 UUT Port Operation using Visual Basic........... 5-20

5-15. Testing the RS-232 UUT Port via IEEE-488 Port........................... 5-21

5-16. Changing between Remote and Local Operation................................. 5-23

5-17. Local State ....................................................................................... 5-23

5-18. Local with Lockout State................................................................. 5-23

5-19. Remote State.................................................................................... 5-23

5-20. Remote with Lockout State.............................................................. 5-23

5-21. RS-232 Interface Overview.................................................................. 5-24

5-22. IEEE-488 Interface Overview.............................................................. 5-25

5-23. Using Commands................................................................................. 5-28

5-24. Types of Commands ........................................................................ 5-28

5-25. Device−Dependent Commands................................................... 5-28

5-26. Common Commands ................................................................... 5-29

5-27. Query Commands........................................................................ 5-29

5-28. Interface Messages (IEEE-488)................................................... 5-29

5-29. Compound Commands................................................................. 5-31

5-30. Coupled Commands..................................................................... 5-31

5-31. Overlapped Commands................................................................ 5-32

5-32. Sequential Commands................................................................. 5-32

5-33. Commands that Require the Calibration Switch to be Enabled.. 5-32

5-34. Commands for RS-232 Only....................................................... 5-32

5-35. Commands for IEEE-488 Only.................................................... 5-33

5-36. Command Syntax............................................................................. 5-34

5-37. Parameter Syntax Rules............................................................... 5-34

5-38. Extra Space or Tab Characters .................................................... 5-35

5-39. Terminators.................................................................................. 5-36

5-40. Incoming Character Processing................................................... 5-36

5-41. Response Message Syntax........................................................... 5-37

5-42. Checking 5800A Status........................................................................ 5-38

(continued)

iii

Page 8

5800A

Operators Manual

5-43. Serial Poll Status Byte (STB) .......................................................... 5-38

5-44. Service Request (SRQ) Line........................................................ 5-40

5-45. Service Request Enable Register (SRE)...................................... 5-40

5-46. Programming the STB and SRE.................................................. 5-41

5-47. Event Status Register (ESR)............................................................ 5-41

5-48. Event Status Enable (ESE) Register............................................ 5-41

5-49. Bit Assignments for the ESR and ESE........................................ 5-41

5-50. Programming the ESR and ESE.................................................. 5-42

5-51. Instrument Status Register (ISR)..................................................... 5-43

5-52. Instrument Status Change Registers............................................ 5-43

5-53. Instrument Status Change Enable Registers................................ 5-43

5-54. Bit Assignments for the ISR, ISCR, and ISCE............................ 5-43

5-55. Programming the ISR, ISCR, and ISCE...................................... 5-45

5-56. Output Queue................................................................................... 5-45

5-57. Error Queue...................................................................................... 5-46

5-58. Remote Program Examples.................................................................. 5-46

5-59. Guidelines for Programming the Calibrator..................................... 5-46

5-60. Writing an SRQ and Error Handler ................................................. 5-47

5-61. Using *OPC?, *OPC, and *WAI..................................................... 5-48

5-62. Taking an Impedance Measurement................................................ 5-48

5-63. Using the RS-232 UUT Port to Control an instrument.................... 5-49

5-64. Input Buffer Operation..................................................................... 5-49

6 Remote Commands........................................................................... 6-1

6-1. Introduction.......................................................................................... 6-3

6-2. Command Summary by Function......................................................... 6-3

6-3. Summary of Commands and Queries................................................... 6-8

7 Maintenance....................................................................................... 7-1

7-1. Introduction.......................................................................................... 7-3

7-2. Replacing the Line Fuse....................................................................... 7-3

7-3. Cleaning the Air Filter.......................................................................... 7-4

7-4. General Cleaning.................................................................................. 7-6

7-5. Verification Tables............................................................................... 7-6

7-6. DC Voltage Verification.................................................................. 7-6

7-7. AC Voltage Amplitude Verification................................................ 7-7

7-8. AC Voltage Frequency Verification................................................ 7-8

7-9. Wave Generator Amplitude Verification: 1 MΩ Output Impedance 7-8

7-10. Wave Generator Amplitude Verification: 50Ω Output Impedance. 7-9

7-11. Wave Generator Frequency Verification: 1 MΩ Output Impedance 7-10

7-12. Leveled Sinewave Verification: Amplitude..................................... 7-10

7-13. Leveled Sinewave Verification: Frequency..................................... 7-10

7-14. Leveled Sinewave Verification: Harmonics.................................... 7-11

7-15. Leveled Sinewave Verification: Flatness ........................................ 7-12

7-16. Edge Verification: Amplitude.......................................................... 7-18

7-17. Edge Verification: Frequency.......................................................... 7-18

7-18. Edge Verification: Duty Cycle......................................................... 7-18

7-19. Edge Verification: Rise Time .......................................................... 7-19

7-20. Tunnel Diode Pulser Verification.................................................... 7-19

7-21. Marker Generator Verification ........................................................ 7-19

7-22. Pulse Generator Verification: Period............................................... 7-20

7-23. Pulse Generator Verification: Pulse Width...................................... 7-20

7-24. Input Impedance Verification: Resistance....................................... 7-20

7-25. Input Impedance Verification: Capacitance..................................... 7-20

iv

Page 9

Contents

8 Options...............................................................................................8-1

8-1. Introduction..........................................................................................8-3

8-2. 5800A-5 Option....................................................................................8-3

9 Accessories........................................................................................9-1

9-1. Introduction .........................................................................................9-3

9-2. Rack Mount Kit ....................................................................................9-3

9-3. IEEE-488 Interface Cables ..................................................................9-4

9-4. RS-232 Null-Modem Cables ..............................................................9-4

9-5. RS-232 Modem Cables ........................................................................9-4

Appendices

AGlossary......................................................................................................A-1

BASCII and IEEE-488 Bus Codes................................................................B-1

CZiatech ZT-1444A Jumper and DIP Switch Positions................................C-1

DRS-232/IEEE-488 Cables and Connectors.................................................D-1

E Creating a Visual Basic Test Program........................................................E-1

F Error Message.............................................................................................F-1

Index

(continued)

v

Page 10

5800A

Operators Manual

vi

Page 11

List of Tables

Table Title Page

1-1. Voltage Output Specifications............................................................................... 1-9

1-2. Edge Specifications............................................................................................... 1-10

1-3. Leveled Sine Wave Specifications ........................................................................ 1-11

1-4. Time Marker Specifications.................................................................................. 1-12

1-5. Wave Generator Specifications............................................................................. 1-13

1-6. Pulse Generator Specifications.............................................................................. 1-14

1-7. Trigger Signal Specifications (Pulse Function)..................................................... 1-14

1-8. Trigger Signal Specifications (Time Marker Function)........................................ 1-15

1-9. Trigger Signal Specifications (Edge Function)..................................................... 1-15

1-10. Trigger Signal Specifications (Square Wave Voltage Function).......................... 1-15

1-11. TV Trigger Signal Specifications.......................................................................... 1-15

1-12. Tunnel Diode Drive Capability ............................................................................. 1-15

1-13. Oscilloscope Input Resistance Measurement Specifications................................. 1-15

1-14. Oscilloscope Input Capacitance Measurement Specifications.............................. 1-16

1-15. Overload Measurement Specifications.................................................................. 1-16

1-16. Auxiliary Input Performance................................................................................. 1-16

2-1. Standard Equipment............................................................................................... 2-3

2-2. Line Power Cord Types Available from Fluke...................................................... 2-6

3-1. Front Panel Features.............................................................................................. 3-4

3-2. Rear Panel Features............................................................................................... 3-9

3-3. Factory Default Settings for the SETUP Menus ................................................... 3-20

4-1. Factory Defaults for SETUP.................................................................................. 4-6

4-2. Keys That Exit Error Mode................................................................................... 4-8

5-1. Operating State Transitions................................................................................... 5-24

5-2. RS-232 Interface Wiring........................................................................................ 5-24

5-3. RS-232 Emulation of IEEE-488 Messages............................................................ 5-25

5-4. IEEE-488 Interface Messages (Receive ).............................................................. 5-30

5-5. Interface Messages (Send)..................................................................................... 5-31

5-6. Commands for RS-232 Only.................................................................................. 5-33

5-7. Commands for IEEE-488 Only.............................................................................. 5-33

5-8. Units Accepted in Parameters and Used in Responses.......................................... 5-34

5-9. Terminator Characters........................................................................................... 5-36

5-10. Response Data Types............................................................................................. 5-37

5-11. Status Register Summary....................................................................................... 5-38

6-1. Command Summary by Function .......................................................................... 6-3

vii

Page 12

5800A

Operators Manual

6-2. SCOPE Command Parameters............................................................................... 6-32

7-1. Replacement Fuses ................................................................................................ 7-3

7-2. DC Voltage Verification........................................................................................ 7-6

7-3. AC Voltage Amplitude Verification...................................................................... 7-7

7-4. AC Voltage Frequency Verification...................................................................... 7-8

7-5. Wave Generator Amplitude Verification (into 1 MΩ output impedance)............ 7-8

7-6. Wave Generator Amplitude Verification (into 50 Ω impedance)......................... 7-9

7-7. Wave Generator Frequency Verification (into 1 MΩ Impedance)........................ 7-10

7-8. Leveled Sinewave Verification: Amplitude .......................................................... 7-10

7-9. Leveled Sinewave Verification: Frequency........................................................... 7-10

7-10. Leveled Sinewave Verification: Harmonics.......................................................... 7-11

7-11. Leveled Sinewave Verification: Flatness.............................................................. 7-12

7-12. Edge Verification: Amplitude................................................................................ 7-18

7-13. Edge Verification: Frequency................................................................................ 7-18

7-14. Edge Verification: Duty Cycle.............................................................................. 7-18

7-15. Edge Verification: Rise Time................................................................................ 7-19

7-16. Tunnel Diode Pulser Verification.......................................................................... 7-19

7-17. Marker Generator Verification.............................................................................. 7-19

7-18. Pulse Generator Verification: Period..................................................................... 7-20

7-19. Pulse Generator Verification: Pulse Width ........................................................... 7-20

7-20. Input Impedance Verification: Resistance............................................................. 7-20

7-21. Input Impedance Verification: Capacitance .......................................................... 7-20

9-1. Options and Accessories........................................................................................ 9-3

D-1. IEEE-488 Connection Cables................................................................................ D-1

D-2. Serial Port Connection Cables............................................................................... D-2

F-1. Error Message Format ........................................................................................... F-1

viii

Page 13

List of Figures

Figure Title Page

1-1. 5800A Multi-Product Calibrator............................................................................ 1-3

1-2. RS-232 Remote Connections................................................................................. 1-5

1-3. 5800A Calibrator Dimensional Outline................................................................. 1-7

2-1. Accessing the Fuse and Selecting Line Voltage.................................................... 2-5

2-2. Line Power Cord Types Available from Fluke...................................................... 2-6

3-1. Front Panel View................................................................................................... 3-4

3-2. Rear Panel View.................................................................................................... 3-9

3-3. SETUP Softkey Menu Tree................................................................................... 3-11

3-4. SETUP Softkey Menu Displays ............................................................................ 3-12

4-1. Oscilloscope connection: channel ......................................................................... 4-7

4-2. Tunnel Diode Pulser Connections......................................................................... 4-17

5-1. Typical IEEE-488 Remote Control Connections................................................... 5-5

5-2. Typical RS-232 Remote Control Connections...................................................... 5-6

5-3. Testing the IEEE-488 Port..................................................................................... 5-8

5-4. Testing the RS-232 Host Port................................................................................ 5-13

5-5. Testing the RS-232 UUT Port via the RS-232 Host Port...................................... 5-18

5-6. Testing the RS-232 UUT Port via IEEE-488 Port................................................. 5-21

5-7. IEEE-488 Remote Message Coding ...................................................................... 5-27

5-8. Status Register Overview....................................................................................... 5-39

5-9. Serial Poll Status Byte (STB) and Service Request Enable (SRE) ....................... 5-40

5-10. Event Status Register (ESR) and Event Status Enable (ESE)............................... 5-42

5-11. Bit Assignments for the ISR, ISCEs and ISCRs.................................................... 5-44

7-1. Accessing the Fuse ................................................................................................ 7-4

7-2. Accessing the Air Filter......................................................................................... 7-5

C-1. IEEE-488 Single-Board Configuration (non-MET/CAL) ..................................... C-2

C-2. IEEE-488 Dual-Board Configuration, Port 0, Electronic Key .............................. C-3

C-3. IEEE-488 Dual Board Configuration, Port 0, No Electronic Key......................... C-3

C-4. IEEE-488 Dual Board Configuration, Port 1, Electronic Key............................... C-4

C-5. IEEE-488 Dual Board Configuration, Port 1, No Electronic Key......................... C-4

D-1. IEEE-488 Connector Pinout (connection side)...................................................... D-1

D-2. SERIAL 1 FROM HOST Port Connector Pinout.................................................. D-2

D-3. SERIAL 2 TO UUT Port Connector Pinout (connection side) ............................. D-2

D-4. Serial Port Connections (DB-9/DB-9)................................................................... D-3

D-5. Serial Port Connections (DB-9/DB-25)................................................................. D-4

ix

Page 14

5800A

Operators Manual

x

Page 15

Chapter 1

Introduction and Specifications

Title Page

1-1. Introduction.......................................................................................... 1-3

1-2. Operation Overview............................................................................. 1-4

1-3. Local Operation ............................................................................... 1-4

1-4. Remote Operation (RS-232) ............................................................ 1-4

1-5. Remote Operation (IEEE-488)......................................................... 1-5

1-6. Where To Go from Here ...................................................................... 1-5

1-7. Instruction Manuals.............................................................................. 1-6

1-8. 5800A Operators Manual................................................................. 1-6

1-9. 5800A Service Manual..................................................................... 1-6

1-10. Specifications....................................................................................... 1-6

1-11. General Specifications..................................................................... 1-8

1-12. Voltage Output Specifications......................................................... 1-9

1-13. Edge Specifications.......................................................................... 1-10

1-14. Leveled Sine Wave Specifications................................................... 1-11

1-15. Time Marker Specifications............................................................. 1-12

1-16. Wave Generator Specifications........................................................ 1-13

1-17. Pulse Generator Specifications........................................................ 1-14

1-18. Trigger Signal Specifications (Pulse Function)............................... 1-14

1-19. Trigger Signal Specifications (Time Marker Function) .................. 1-15

1-20. Trigger Signal Specifications (Edge Function)................................ 1-15

1-21. Trigger Signal Specifications (Square Wave Voltage Function)..... 1-15

1-22. Trigger Signal Specifications........................................................... 1-15

1-23. Tunnel Diode Drive Capability........................................................ 1-15

1-24. Oscilloscope Input Resistance Measurement Specifications........... 1-15

1-25. Oscilloscope Input Capacitance Measurement Specifications........ 1-16

1-26. Overload Measurement Specifications............................................ 1-16

1-27. External Reference Input Specifications.......................................... 1-16

1-28. Auxiliary Input/Output Specifications............................................. 1-16

1-1

Page 16

5800A

Operators Manual

1-2

Page 17

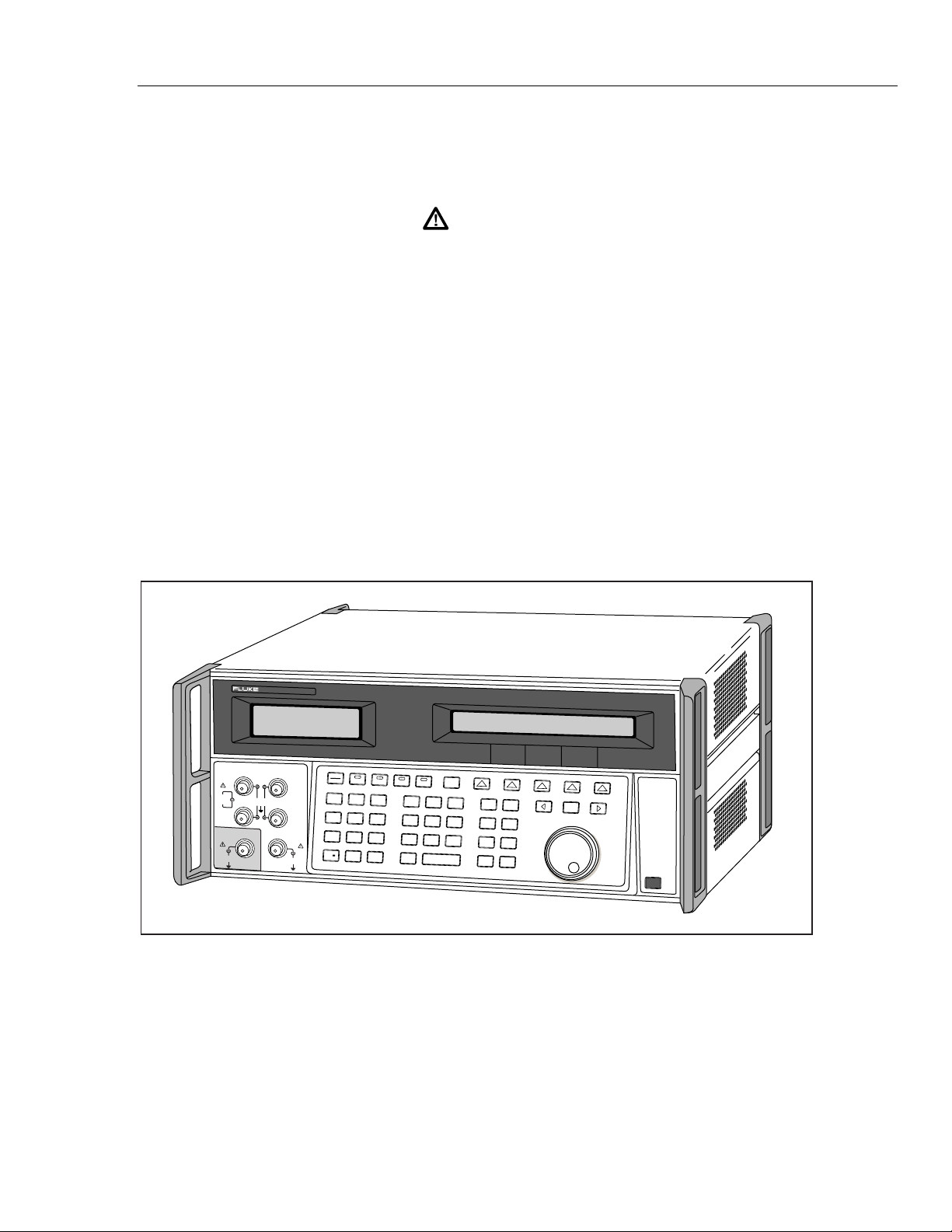

1-1. Introduction

The Fluke Model 5800A Oscilloscope Calibrator (Figure 1-1) is a precise instrument that

calibrates analog and digital oscilloscopes. Specifications are provided in this chapter.

To prevent electric shock or other possible injuries, t he 5800A

Calibrator must be operated in the way specif ied by this manual

or other documentation provided by Fluke. To avoid personal

injury and equipment damage, do not apply signal s t o any

output terminal.

Features of the 5800A Calibrator include the following:

• Automatic meter error calculation.

• X and D keys that change the output value to pre-determined cardinal values

for various functions.

• Programmable entry limits that prevent invalid amounts from being entered.

• Edge, Leveled Sine, Pulse, Marker, and Wave Generation modes.

Warning

Introduction and Specifications

Introduction

1

• Accurate oscilloscopic input impedance measurement.

• Tunnel Diode Pulse compatibility.

5800A

CALIBRATOR

OUTPUT

CHAN 1

EXT TRIG

130V

PEAK

20V PK

MAX

MAX

CHAN 1-5

CHAN 3

AUX

INPUT

20V PK

MAX

CHAN 2

CHAN 4

EXT TRIG

CHAN 5

20V PK

MAX

OPR

STBY

VOLT

EDGE

789

456

123

+

/

0•

LEVSINE

PREV

MARKER

MENU

NEW

µ

V

REF

m

n

dBm

k

sec

Hz

M

ENTER

MORE

MODES

CHAN

MULT

RESETCE

SETUP

AUX

INPUT

DIV

x

÷

EDIT

FIELD

Figure 1-1. 5800A Oscilloscope Calibrator

POWER

OQ001F.EPS

1-3

Page 18

5800A

Operators Manual

1-2. Operation Overview

• External reference.

• Auxiliary input.

• 5-channel output (5-channel option). The 5-channel option allows you to calibrate up

to five oscilloscope channels simultaneously without changing cables.

• Simultaneous output of a signal and a trigger signal.

• 600 MHz, Leveled Sine wave output.

• Standard IEEE-488 (GPIB) interface, complying with ANSI/IEEE Standards

488.1-1987 and 488.2-1987.

• EIA Standard RS-232-C serial data interface for printing, displaying, or transferring

internally stored calibration constants, and for remote control of the 5800A.

• Pass-through RS-232-C serial data interface for communicating with the Unit Under

Test (UUT).

• Extensive automatic internal self testing and diagnostics of analog and digital

functions.

The 5800A Calibrator may be operated at the front panel in the local mode, or remotely

using RS-232 or IEEE-488 ports. For remote operations, several software options are

available to integrate 5800A operation into a wide variety of calibration requirements.

1-3. Local Operation

Typical local operations include front panel connections to the Unit Under Test (UUT),

and then manual keystroke entries at the front panel to place the calibrator in the desired

output mode. The front panel layout facilitates hand movements from left to right, and

multiply and divide keys make it easy to step up or down at the press of a single key.

The backlit liquid crystal display is easy to read from many different viewing angles and

lighting conditions, and the large, easy-to-read keys are color-coded and provide tactile

feedback when they are pressed.

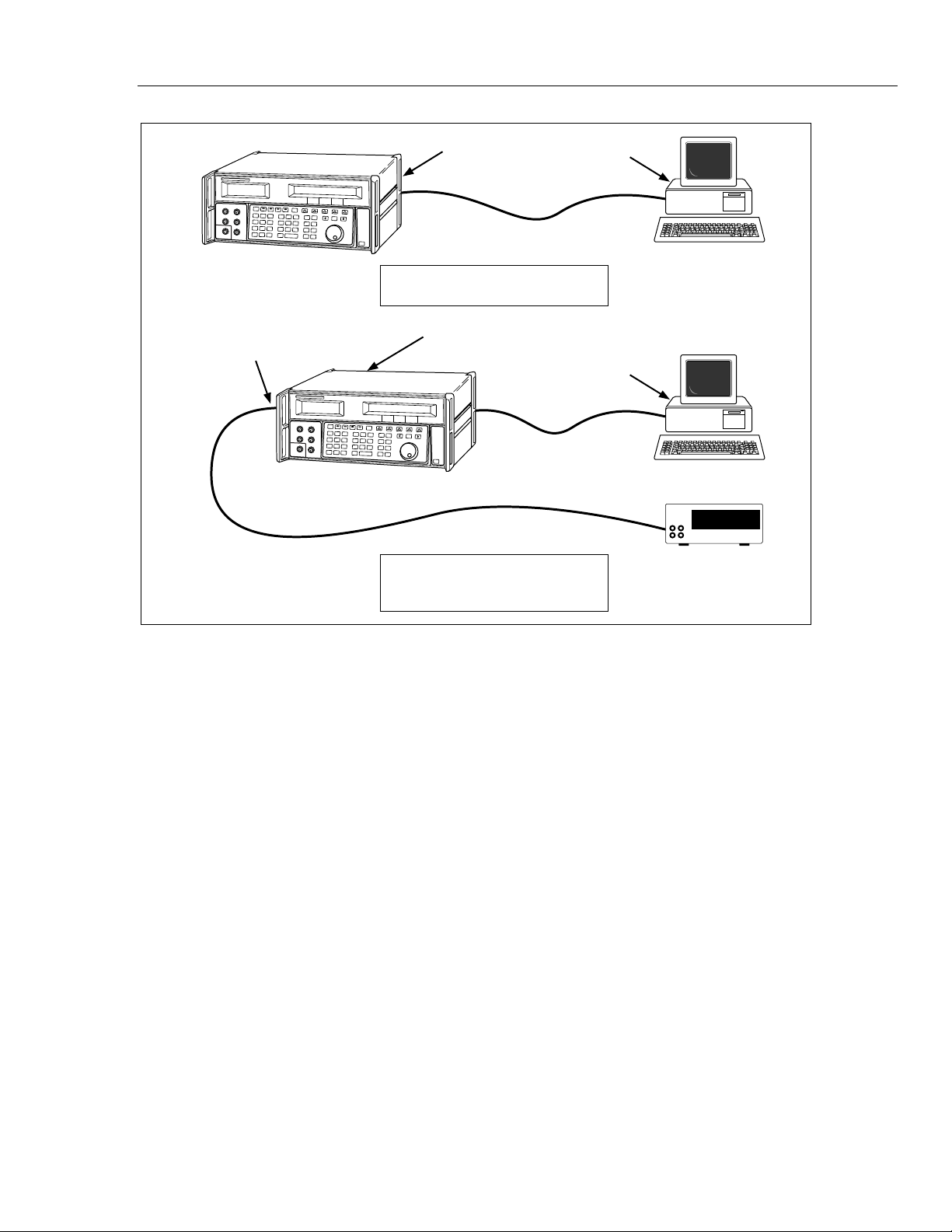

1-4. Remote Operation (RS-232)

The Calibrator has two rear-panel serial data RS-232 ports: SERIAL 1 FROM HOST,

and SERIAL 2 TO UUT (Figure 1-2). Each port is dedicated to serial data

communications for operating and controlling the 5800A during calibration procedures.

For complete information on remote operations, see Chapter 5.

The SERIAL 1 FROM HOST serial data port connects a host terminal or personal

computer to the 5800A. You have several choices for sending commands to the 5800A:

you can enter commands from a terminal (for example, using the Terminal accessory

from Windows using a PC), you can write your own programs using BASIC, or you can

run optional Windows-based software such as 5500/CAL or MET/CAL. The 5500/CAL

software includes more than 200 example procedures covering a wide range of test tools

the 5800A can calibrate. (See Chapter 6 for a discussion of the RS-232 commands.)

The SERIAL 2 TO UUT serial data port connects a UUT to a PC or terminal via the

5800A (see Figure 1-2). This “pass-through” configuration eliminates the requirement

for two COM ports at the PC or Terminal. A set of four commands control the operation

of the SERIAL 2 TO UUT serial port. See Chapter 6 for a discussion of the UUT_*

commands.

1-4

Page 19

Introduction and Specifications

Where To Go from Here

1

SERIAL 1 FROM HOST port

5800A

SERIAL 2

TO UUT port

RS-232 Remote Operation using the

SERIAL 1 FROM HOST port

SERIAL 1 FROM HOST port

5800A

RS-232 Remote Operation using the

SERIAL 1 FROM HOST and

SERIAL 2 TO UUT ports

Figure 1-2. RS-232 Remote Connections

COM port

PC or Terminal

COM port

PC or Terminal

Unit Under Test

oq002f.eps

1-5. Remote Operation (IEEE-488)

The 5800A rear panel IEEE-488 port is a fully programmable parallel interface bus

meeting standard IEEE-488.1 and supplemental standard IEEE-488.2. Under the remote

control of an instrument controller, the 5800A Calibrator operates exclusively as a

“talker/listener.” You can write your own programs using the IEEE-488 command set or

run the optional Windows-based MET/CAL software. (See Chapter 6 for a discussion of

the commands available for IEEE-488 operation.)

1-6. Where To Go from Here

To locate specific information concerning the installation and operation of the 5800A

calibrator, refer to the following list:

• Unpacking and setup: see Chapter 2

• Installation and rack mounting: see Chapter 2 and the rack mount kit instruction

sheet

• AC line power and interface cabling: see Chapter 2,

• Controls, indicators, and displays: see Chapter 3

• Front panel operation: see Chapter 4

• Cabling to a UUT (Unit Under Test): see Chapter 4

• Using the auxiliary amplifier: see Chapter 4

1-5

Page 20

5800A

Operators Manual

1-7. Instruction Manuals

1-8. 5800A Operators Manual

• Remote operation (IEEE-488 or serial): see Chapter 5

• Accessories to the 5800A Calibrator: see Chapter 9

• Instrument specifications: see Chapter 1

The 5800A Manual Set provides complete information for operators and service or

maintenance technicians. The set includes:

• 5800A Operators Manual (PN 686318)

• 5800A Service Manual (PN 689411)

The operator manual ships with the instrument. The 5800A Service Manual is optional.

Order additional copies of the manuals separately using the part number provided. For

ordering instructions, refer to the Fluke Catalog, or ask a Fluke sales representative (see

Chapter 2 for more information).

This 5800A Operators Manual provides complete information for installing the 5800A

Oscilloscope Calibrator and operating it from the front panel keys and in remote

configurations. This manual also provides a glossary of calibration, specifications, and

error code information. The 5800A Operators Manual includes the following topics:

• Installation

• Operating controls and features, including front panel operation

• Remote operation (IEEE-488 bus or serial port remote control)

• Serial port operation (printing, displaying, or transferring data, and setting up for

serial port remote control)

• Operator maintenance, including verification procedures and calibration approach

for the 5800A

• Accessories

• Error Messages

1-9. 5800A Service Manual

The 5800A Service Manual can be ordered through your local Fluke Sales or Service

representative (see Chapter 2 for more information). The 5800A Service Manual

includes: appropriate theory of operation, performance testing, maintenance, calibration,

parts lists, and schematic diagrams.

1-10. Specifications

The following paragraphs describe the details for the 5800A specifications. All

specifications are valid after allowing a warm-up period of 30 minutes, or twice the time

the 5800A has been turned off. (For example, if the 5800A has been turned off for 5

minutes, the warm-up period is 10 minutes.)

1-6

All specifications apply for the temperature and time period indicated. For temperatures

outside of tcal + 5 °C (tcal is the ambient temperature when the 5800A was calibrated),

the temperature coefficient is less than 0.1 times the 1-year specification per °C (limited

to 0 °C - 50 °C).

Page 21

Introduction and Specifications

Specifications

If you ordered the GHz Option, the following specification tables are superseded by the

tables with the same headings in Chapter 8:

• Voltage Output Specifications

• Edge Specifications

• Leveled Sine Wave Specifications

• Pulse Generator Specifications

• Oscilloscope Input Capacitance Measurement Specifications

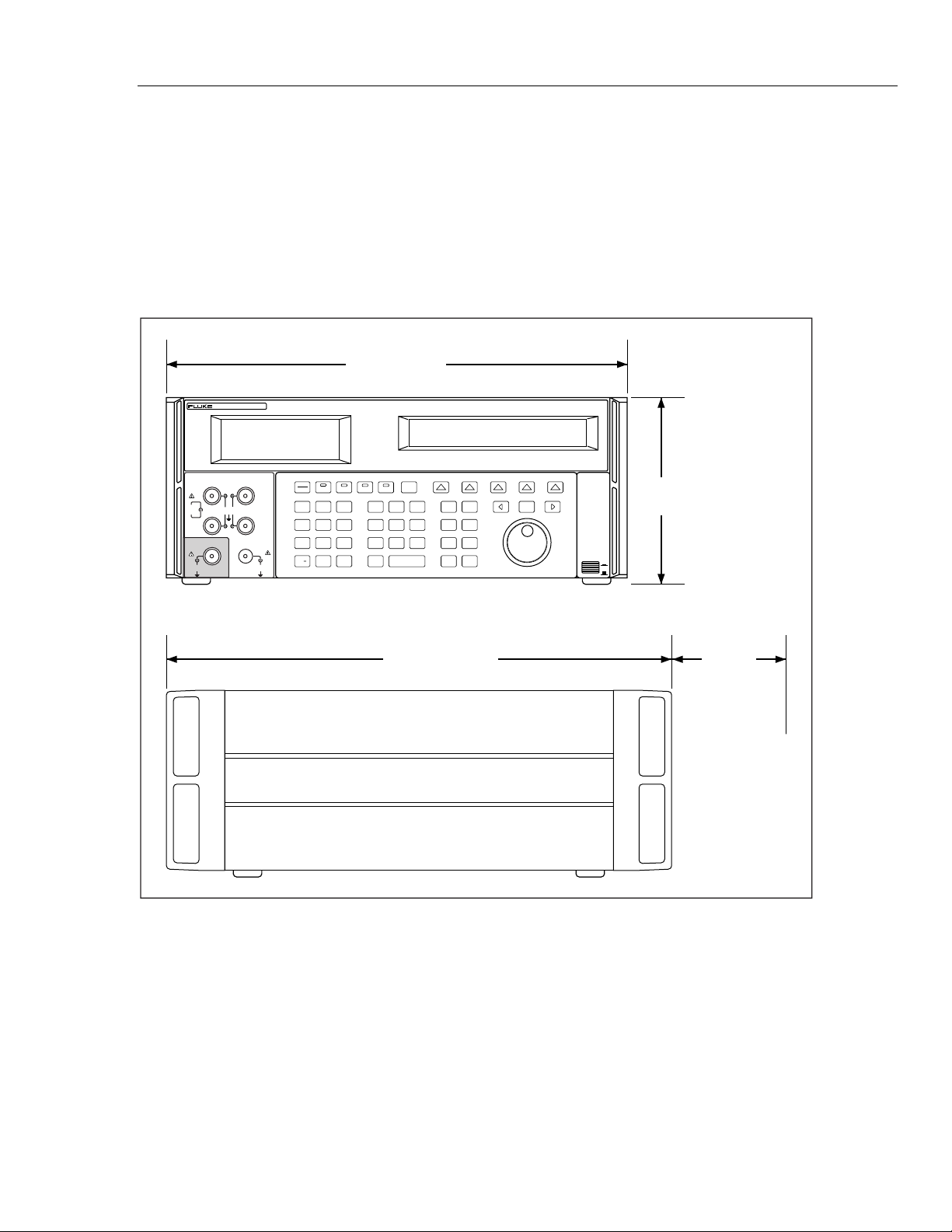

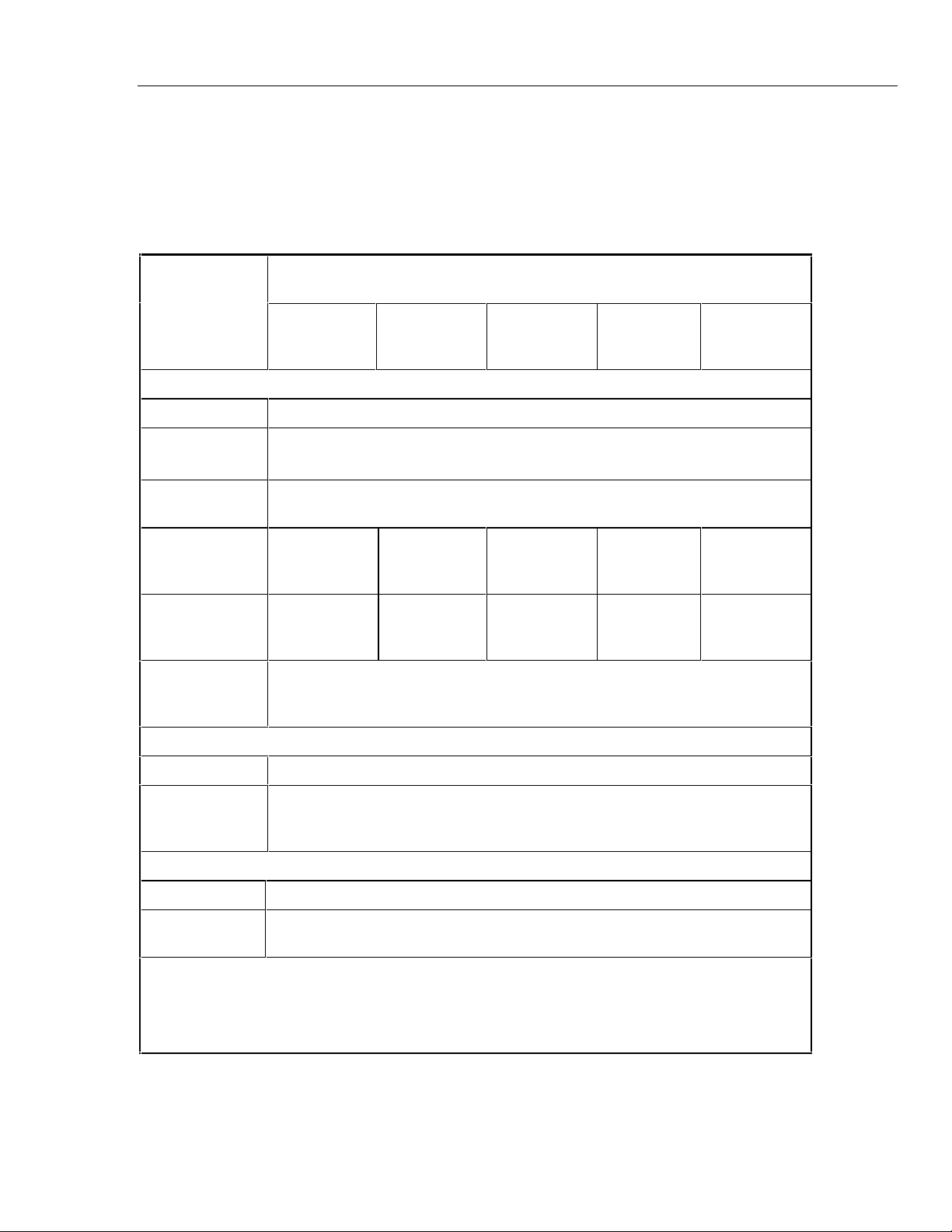

Refer to Figure 1-3 for the dimensional outline of the 5800A Calibrator.

43.2 cm (17 in)

CALIBRATOR

5800A

1

CHAN 1

EXT TRIG

130V

PEAK

MAX

CHAN 1-5

CHAN 3

AUX

INPUT

OUTPUT

20V PK

MAX

20V PK

MAX

EXT TRIG

20V PK

CHAN 2

CHAN 4

CHAN 5

MAX

OPR

STBY

VOLT EDGE LEVSINE MARKER

789

456

123

+

0•

/

µ

m

k sec

M

PREV

MENU

NEW

V

REF

dBm

n

Hz

ENTER

CE

MORE

MODES

CHAN

MULTxDIV

RESET

SETUP

INPUT

AUX

÷

EDIT

FIELD

POWER

I

O

17.8 cm

(7 in)

47.0 cm (18.5 in) 6.4 cm

(2.5 in)

For Cable

Access

oq003f.eps

Figure 1-3. 5800A Calibrator Dimensional Outline

1-7

Page 22

5800A

Operators Manual

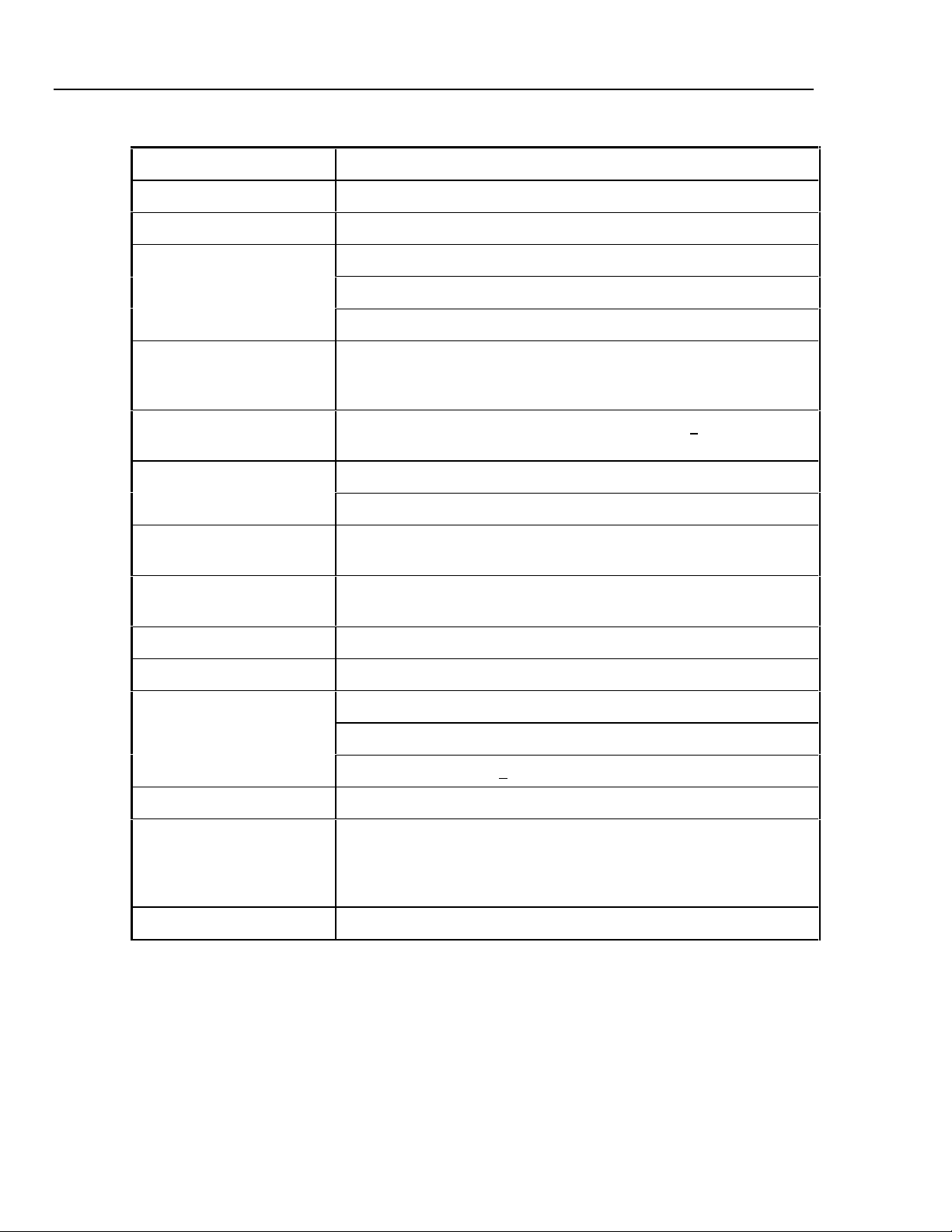

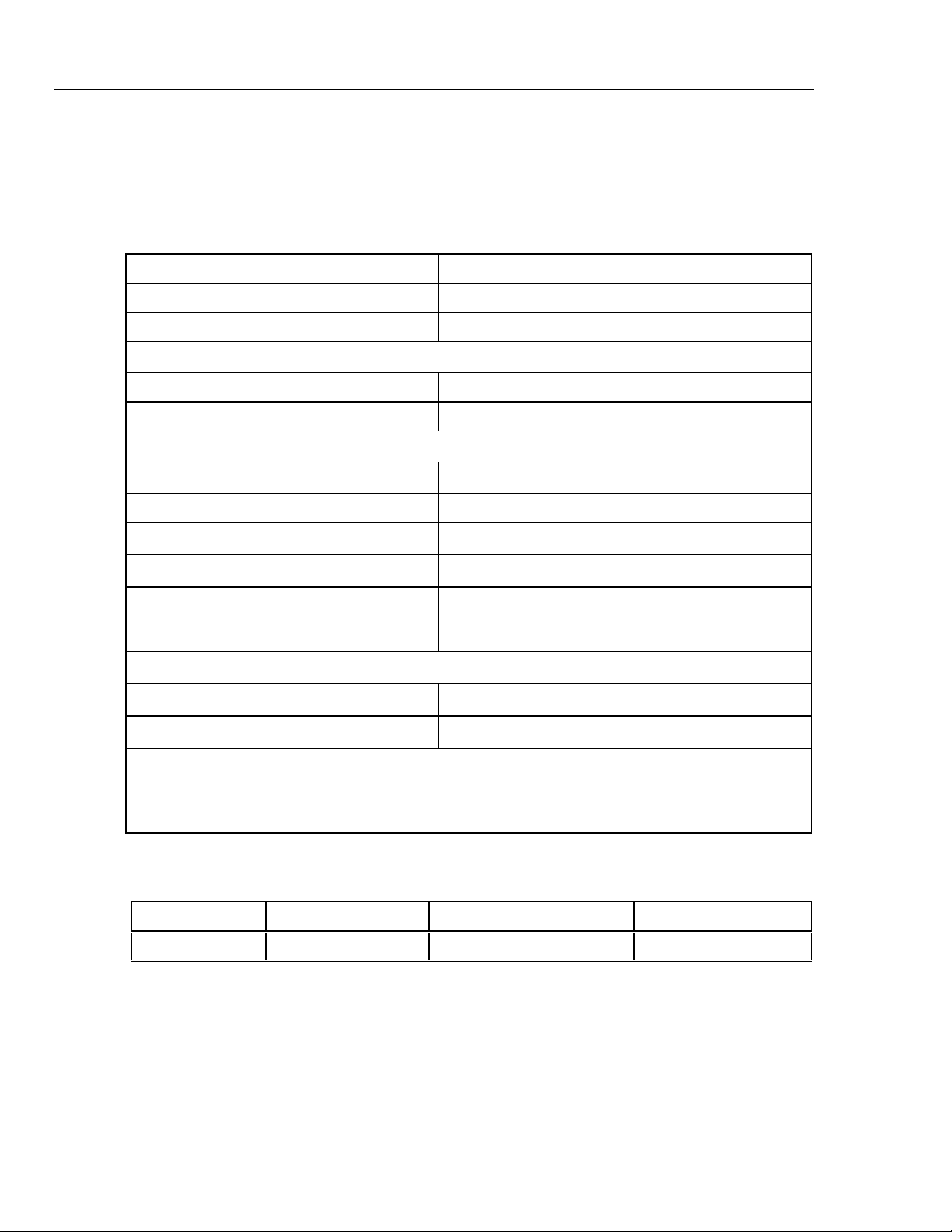

1-11. General Specifications

Warmup Time Twice the time since last warmed up, to a maximum of 30 minutes

Settling Time 5 seconds or faster for all functions and ranges

Standard Interfaces IEEE-488 (GPIB), RS-232

Temperature Performance Operating: 0 °C to 50 °C

Calibration (tcal): 15 °C to 35 °C

Storage: -20 °C to 70 °C

Electromagnetic

Compatibility

Temperature Coefficient Temperature Coefficient for temperatures outside tcal +5 °C is 0.1X/°C of

Relative Humidity Operating: <80 % to 30 °C, <70 % to 40 °C,<40 % to 50 °C

Altitude Operating: 3,050 m (10,000 ft) maximum

Safety Designed to comply with IEC 1010-1 (1992-1); ANSI/ISA-S82.01-1994;

Analog Low Isolation 20 V

EMC Complies with EN 61326-1

Line Power Line Voltage (selectable): 100 V, 120 V, 220 V, 240 V

Power Consumption 250 VA

Designed to operate in Standard Laboratory environments where the

Electromagnetic environment is highly controlled. If used in areas with

Electromagnetic fields >1 V/m, there could be errors in output values.

1-year specification.

Storage: <95 %, noncondensing

Nonoperating: 12,200 m (40,000 ft) maximum

CAN/CSA-C22.2 No. 1010.1-92

Line Frequency: 47 to 63 Hz

Line Voltage Variation: +10 % about line voltage setting

1-8

Dimensions Height: 17.8 cm (7 inches), standard rack increment, plus 1.5 cm

(0.6 inch) for feet on bottom of unit;

Width: 43.2 cm (17 inches), standard rack width

Depth: 47.3 cm (18.6 inches) overall.

Weight 20 kg (44 pounds)

Page 23

Introduction and Specifications

1-12. Voltage Output Specifications

Note

If you ordered the GHz Option, the following specification table is

superseded by the table with the same heading in Chapter 8.

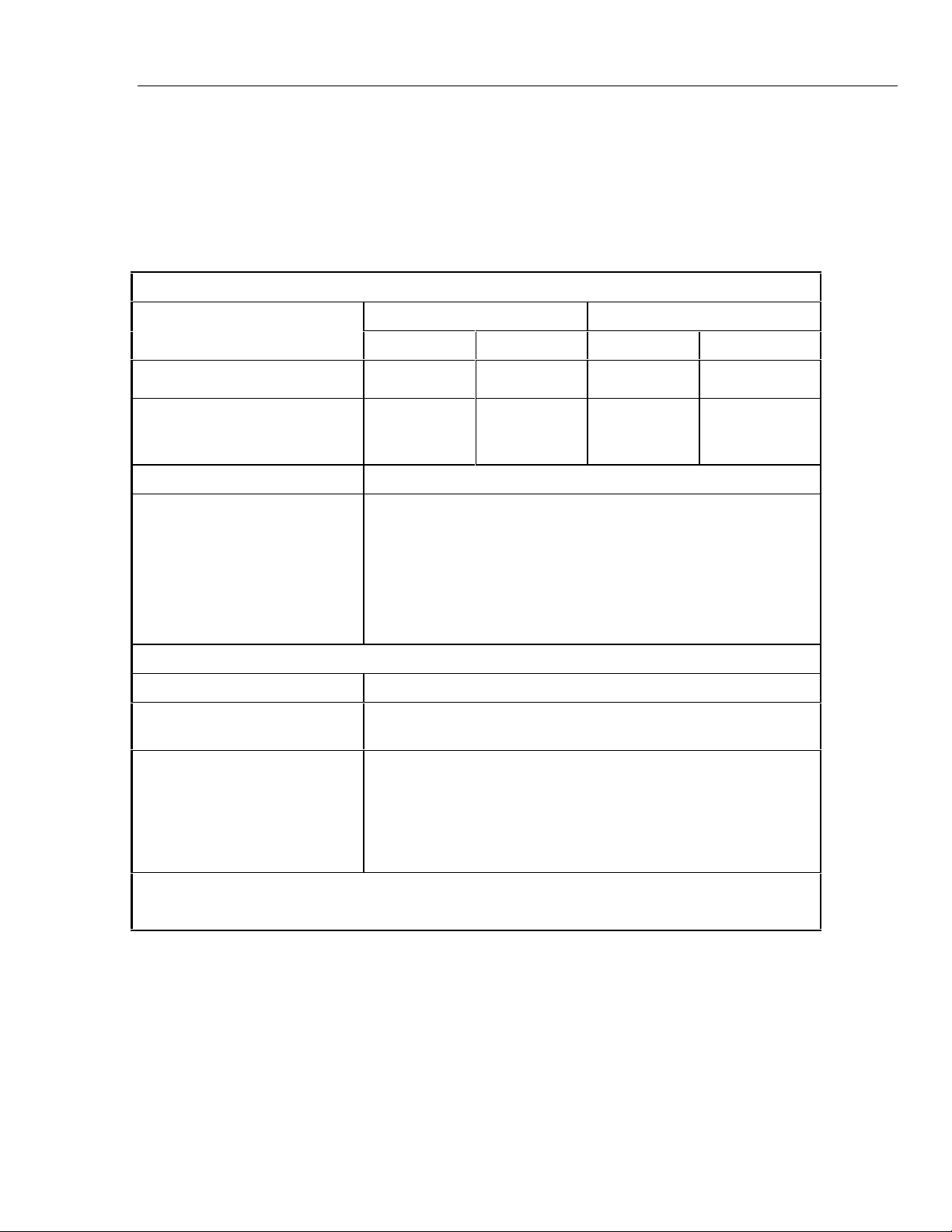

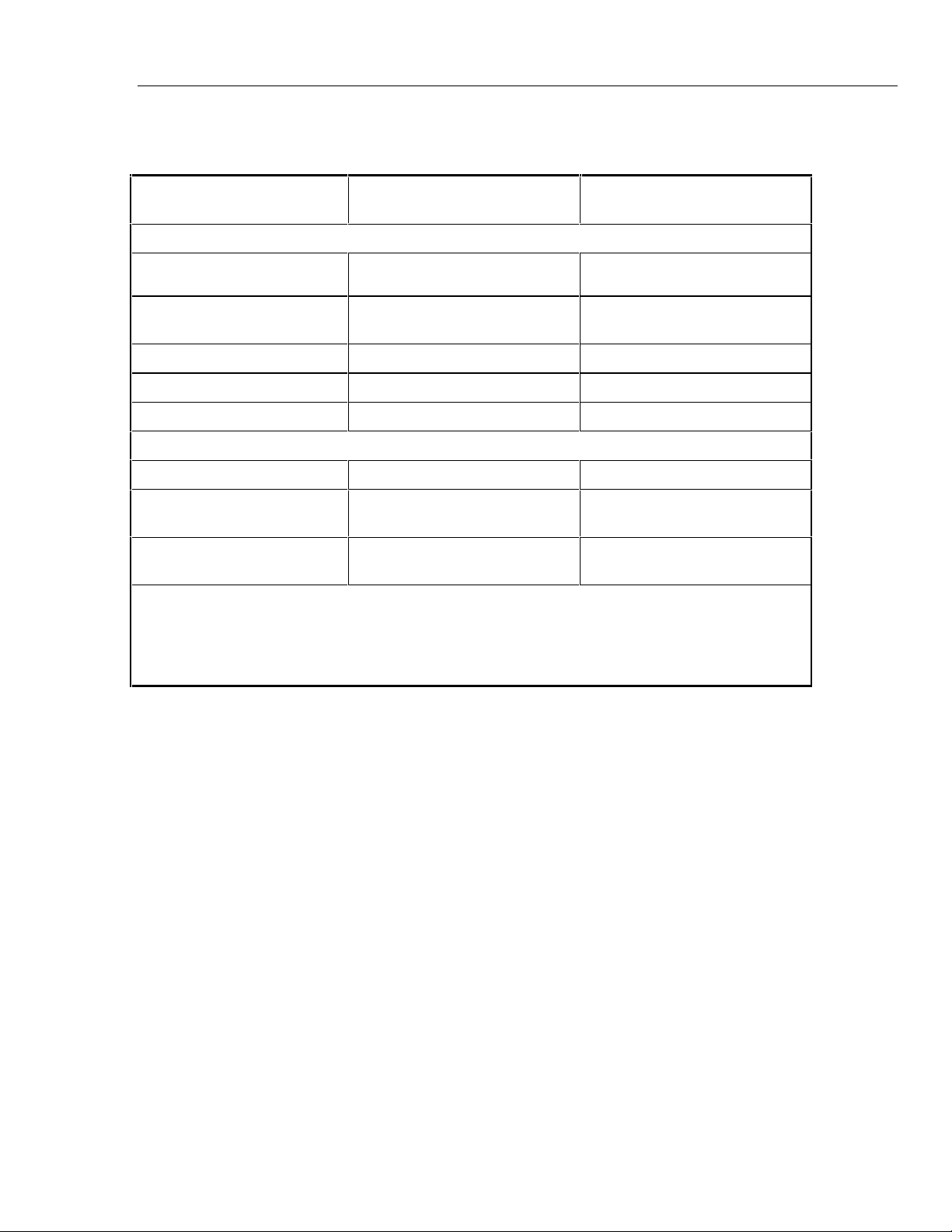

Table 1-1. Voltage Output Specifications

Amplitude Characteristics

DC Signal Square Wave Signal [1]

50 Ω Load 1 MΩ Load 50 Ω Load 1 MΩ Load

Adjustment Range (continuous)

1-Year Absolute Uncertainty,

tcal ± 5 °C

Adjustment Sequence 1-2-5 (e.g., 10 mV, 20 mV, 50 mV)

0 V to ±6.6 V 0 V to ±130 V ±1 mV to

±6.6 V p-p

± (0.25 %

of output +

40 µV)

± (0.025 %

of output +

25 µV)

± (0.25 %

of output +

40 µV)

Specifications

±1 mV to

±130 V p-p

± (0.05 %

of output +

5 µV) [2]

1

Resolution

1 mV to 24.999 mV

25 mV to 109.99 mV

110 mV to 2.1999 V

2.2 V to 10.999 V

11 V to 130 V

Square Wave Frequency Characteristics

Range 10 Hz to 10 kHz

1-Year Absolute Uncertainty,

tcal ± 5 °C

Typical Aberration (from 50 %

of leading/trailing edge)

25 mV to 130 V: within 4 µs

10 mV to 25 mV: within 8 µs

1 mV to 10 mV: within 14 µs

[1] Positive or negative, zero-referenced square wave.

[2] Above 1 kHz, ± (0.25 % of output + 40 µV).

< (0.5 % of output + 100 µV)

1 µV

10 µV

100 µV

1 mV

10 mV

± (1 ppm of setting)

1-9

Page 24

5800A

Operators Manual

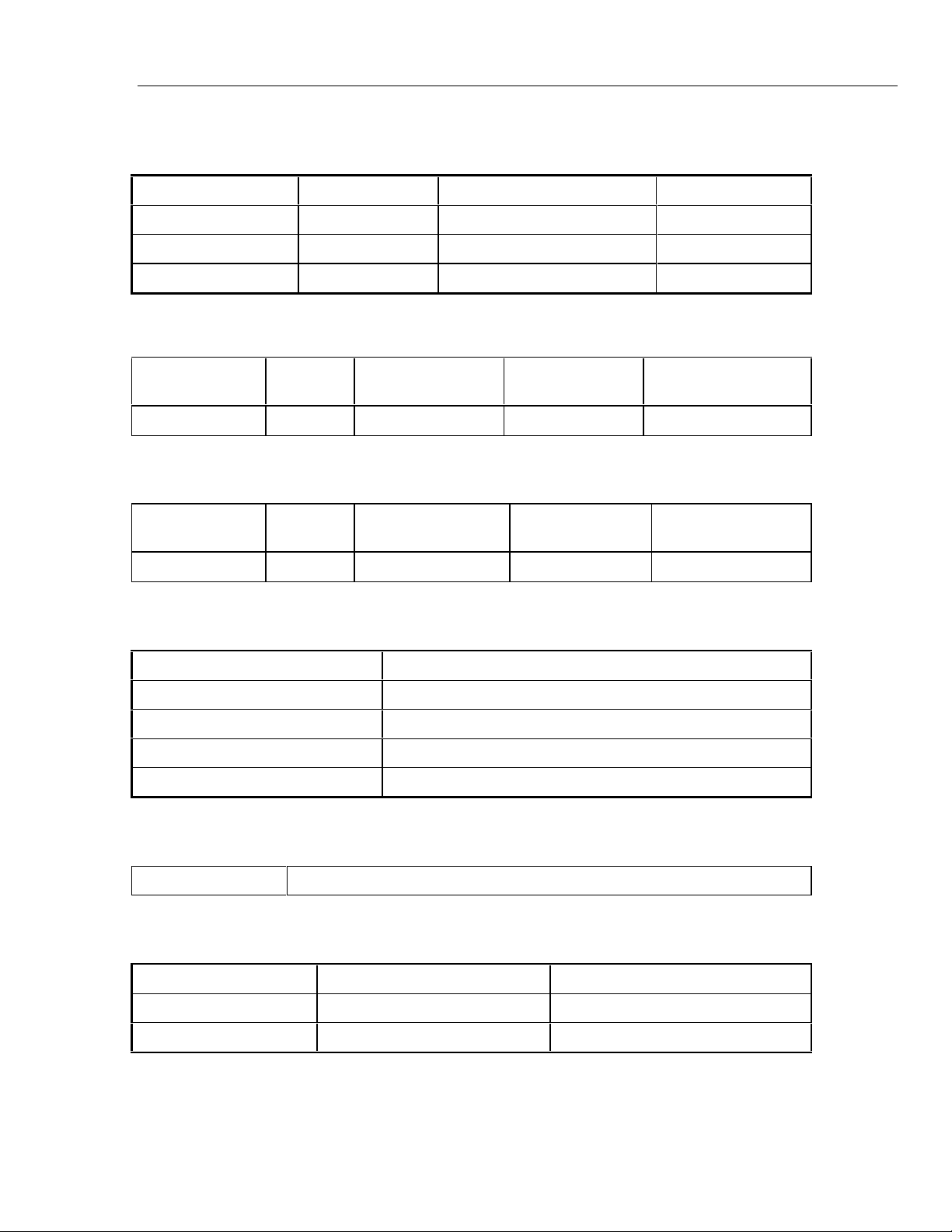

1-13. Edge Specifications

Note

If you ordered the GHz Option, the following specification table is

superseded by the table with the same heading in Chapter 8.

Table 1-2. Edge Specifications

Edge Characteristics into 50 Ω Load

Rise Time 250 ps [1] ± 50 ps

Amplitude Range (p-p) 4.0 mV to 2.5 V ± (2 % of output + 200 µV)

Resolution 4 digits

Adjustment Range ± 10 % around each sequence

value (indicated below)

Sequence Values 5 mV, 10 mV, 25 mV, 50 mV,

60 mV, 80 mV, 100 mV, 200 mV,

250 mV, 300 mV, 500 mV, 600 mV,

1 V, 2.5 V

Frequency Range 1 kHz to 10 MHz ± (1 ppm of setting)

Typical Jitter, edge to trigger < 5 ps (p-p)

Leading Edge Aberrations[2] within 2 ns from 50 % of rising

edge

2 to 5 ns

5 to 15 ns < (1 % of output + 2 mV)

after 15 ns < (0.5 % of output + 2 mV)

1-Year Absolute

Uncertainty, tcal ± 5 °C

< (3 % of output + 2 mV)

< (2 % of output + 2 mV)

1-10

Typical Duty Cycle 45 % to 55 %

[1] Frequency range above 2 MHz has rise time specification 300 ps typical.

[2] Below 250 mV, the leading edge aberrations are typical. All readings are referenced to a Tek

TDS820 8 GHz scope or a Tek 11801 mainframe with an SD26 or SD22 option.

Page 25

1-14. Leveled Sine Wave Specifications

Note

If you ordered the GHz Option, the following specification table is

superseded by the table with the same heading in Chapter 8.

Table 1-3. Leveled Sine Wave Specifications

Introduction and Specifications

Specifications

1

Leveled Sine

Wave

Characteristics

into 50 Ω

Amplitude Characteristics

Range (p-p) 5 mV to 5.5 V

Resolution < 100 mV:3 digits

Adjustment

Range

1-Year Absolute

Uncertainty,

tcal ± 5 °C

Flatness [1]

(relative to

50 kHz)

Short-Term

Amplitude

Stability

50 kHz

(reference)

≥ 100 mV:4 digits

continuously adjustable

± (2 % of

output +

300 µV)

not applicable ± (1.5 % of

50 kHz to

100 MHz

± (3.5 % of

output +

300 µV)

output +

100 µV)

Frequency Range

100 MHz to

300 MHz

± (4 % of

output +

300 µV)

± (2 % of

output+

100 µV)

≤ 1 %[2]

300 MHz

to 500

MHz

± (5.5 % of

output +

300 µV)

± (3.5 % of

output +

100 µV)

500 MHz to

600 MHz

± (6 % of

output +

300 µV)

± (4 % of

output +

100 µV)

Frequency Characteristics

Resolution 10 kHz

1-Year Absolute

Uncertainty,

tcal ± 5 °C

Distortion Characteristics [3]

2nd Harmonic ≤ -33 dBc

3rd and Higher

Harmonics

[1] As measured near Oscilloscope bandwidth frequency.

[2] Within one hour after reference amplitude setting, provided temperature varies no more than ± 5 °C.

[3] Harmonics above 500 MHz are typical.

± 1 ppm

≤ -38 dBc

1-11

Page 26

5800A

Operators Manual

1-15. Time Marker Specifications

Note

If you ordered the GHz Option, the following specification table is

superseded by the table with the same heading in Chapter 8.

Table 1-4. Time Marker Specifications

Time Marker into 50 Ω 5 s to

50 ms

Wave Shape spike or

square

Typical Output Level > 1 V pk [1] > 1 V pk [1] > 1 V pk [1] >1 V pk [1] > 1 V p-p

Typical Jitter (p-p) <10 ppm < 1 ppm < 1 ppm <1 ppm <1 ppm

Sequence 5-2-1 from 5 s to 2 ns (e.g., 500 ms, 200 ms, 100 ms )

Adjustment Range At least ± 10 % around each sequence value indicated above.

Amplitude Resolution 4 digits

1-Year Absolute

Uncertainty, tcal ± 5 °C [3]

[1] Typical rise time of square wave and 20%-pulse (20 % duty cycle pulse) is < 1.5 ns.

[2] With 10 MHz external reference selected, the uncertainty becomes that of the external clock plus

5 µHz.

[3] Time marker uncertainty is ±50 ppm when measured off of cardinal points:

5 s, 2 s, 1 s, 500 ms, 200 ms, 100 ms, 50 ms, 20 ms, 10 ms, 5 ms, 2 ms, 1 ms, 500 µs, 200 µs,

100 µs, 50 µs, 20 µs, 10 µs, 5 µs, 2 µs, 1 µs, 500 ns, 200 ns, 100 ns, 50 ns, 20 ns, 10 ns, 5 ns,

2 ns

± (2.5 ppm

+ 5 µHz) [2]

20 ms to

100 ns

spike, square,

or 20%-pulse

± 1 ppm ± 1 ppm ± 1 ppm ± 1 ppm

50 ns to

20 ns

spike or

square

10 ns 5 ns to

square or

sine

sine

2 ns

1-12

Page 27

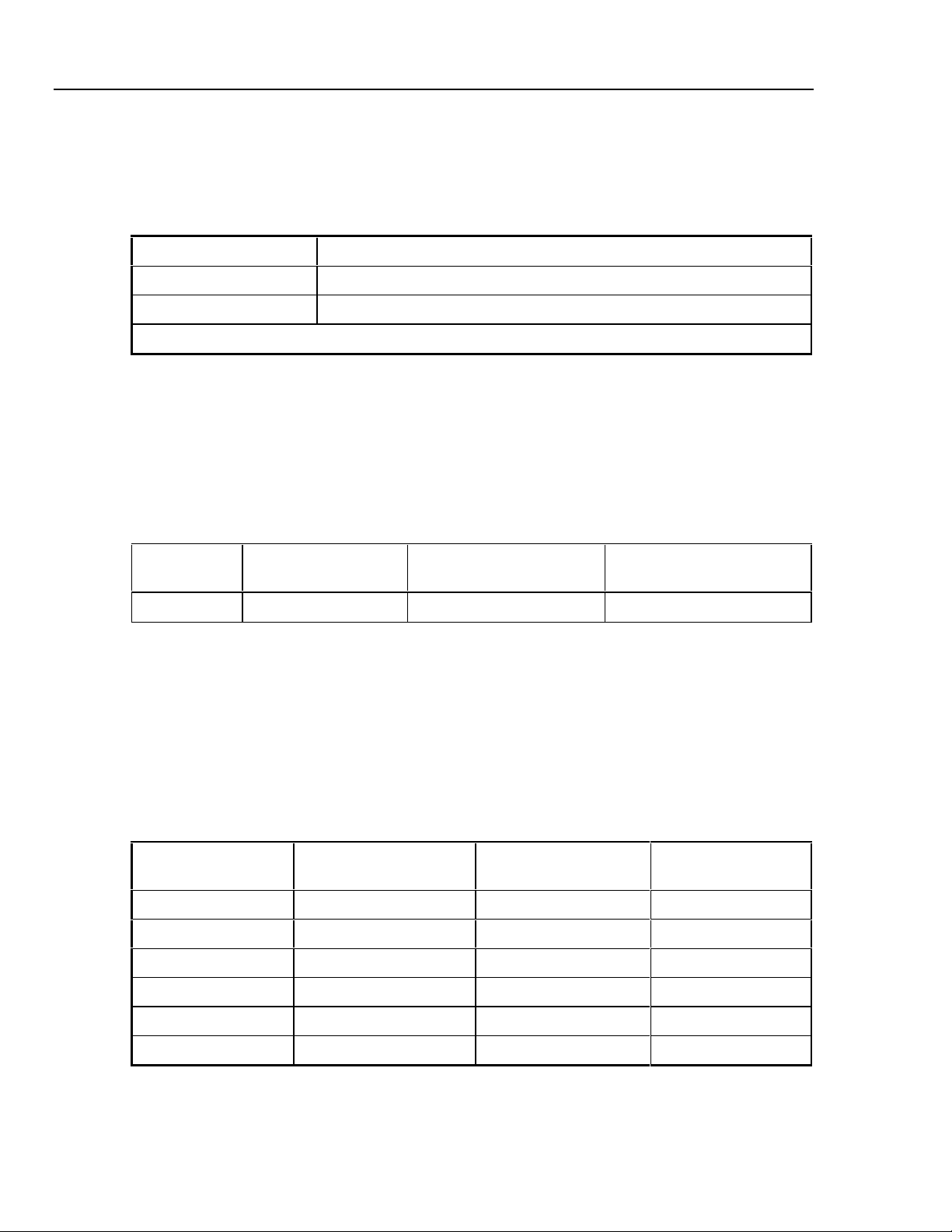

1-16. Wave Generator Specifications

Table 1-5. Wave Generator Specifications

Introduction and Specifications

Specifications

1

Wave Generator

Characteristics

Amplitude

Range into 1 MΩ: 1.8 mV to 55 V p-p

1-Year Absolute Uncertainty,

tcal ± 5 °C, 10 Hz to 10 kHz

Sequence 1-2-5 (e.g., 10 mV, 20 mV, 50 mV) 1-2-5 (e.g., 10 mV, 20 mV, 50 mV)

Typical DC Offset Range 0 to ± (≥40 % of p-p amplitude) [1] 0 to ± (≥40 % of p-p amplitude) [1]

Ramp Linearity [2] better than 0.1 % 10 Hz to 10 kHz

Frequency

Range 0.01 Hz to 100 kHz 0.01 Hz to 100 kHz

Resolution 4 or 5 digits depending upon

1-Year Absolute Uncertainty,

tcal ± 5 °C [3]

[1] The DC offset plus the wave signal must not exceed 30 V rms.

[2] Applies to the 10 % to 90 % of the triangle waveform 500 mV p-p to 10 V p-p.

[3] Uncertainty below 10 Hz is typical.

[4] With 10 MHz external reference selected, the uncertainty becomes that of the external clock plus 5

µHz.

Square Wave and Sine Wave

into 50 Ω or 1 MΩ

into 1 MΩ: 1.8 mV to 55 V p-p

into 50 Ω: 1.8 mV to 2.5 V p-p

± (3 % of p-p output + 100 µV) ± (3 % of p-p output + 100 µV)

frequency

± (2.5 ppm + 5 µHz) [4] ± (2.5 ppm + 5 µHz) [4]

into 50 Ω: 1.8 mV to 2.5 V p-p

4 or 5 digits depending upon

frequency

Triangle Wave

into 50 Ω or 1 MΩ

1-13

Page 28

5800A

Operators Manual

1-17. Pulse Generator Specifications

Pulse Generator Characteristics Positive pulse into 50 Ω

Rise Time 500 ps typical

Available Amplitudes (typical) 1.5 V, 600 mV, 150 mV, 60 mV, 15 mV

Pulse Width

Range [1] 1 ns to 500 ns

Uncertainty 5 % ±200 ps

Pulse Period

Pulse width 1 ns 20 ms to 200 ns

Note

If you ordered the GHz Option, the following specification table is

superseded by the table with the same heading in Chapter 8.

Table 1-6. Pulse Generator Specifications

1 ns = Pulse width = 9.9 ns 20 ms to 200 ns

10 ns = Pulse width = 79.9 ns 20 ms to 1 µs

80 ns = Pulse width = 500 ns 20 ms to 10 µs

Resolution 4 or 5 digits depending upon frequency and width

1-Year absolute Uncertainty, tcal ± 5°C ± 1 ppm

Pulse Skew with Trigger [3]

Range [2] +30 ns to -10 ns with 250 ps resolution

Uncertainty ± 500 ps

[1] May generate pulses below 1 ns but pulse width accuracy is not specified.

[2] Assumes that trigger used in divide by 1 mode. Other divide modes are not specified.

[3] Pulse skew measured from 30% of trigger signal amplitude to 30% of pulse amplitude range.

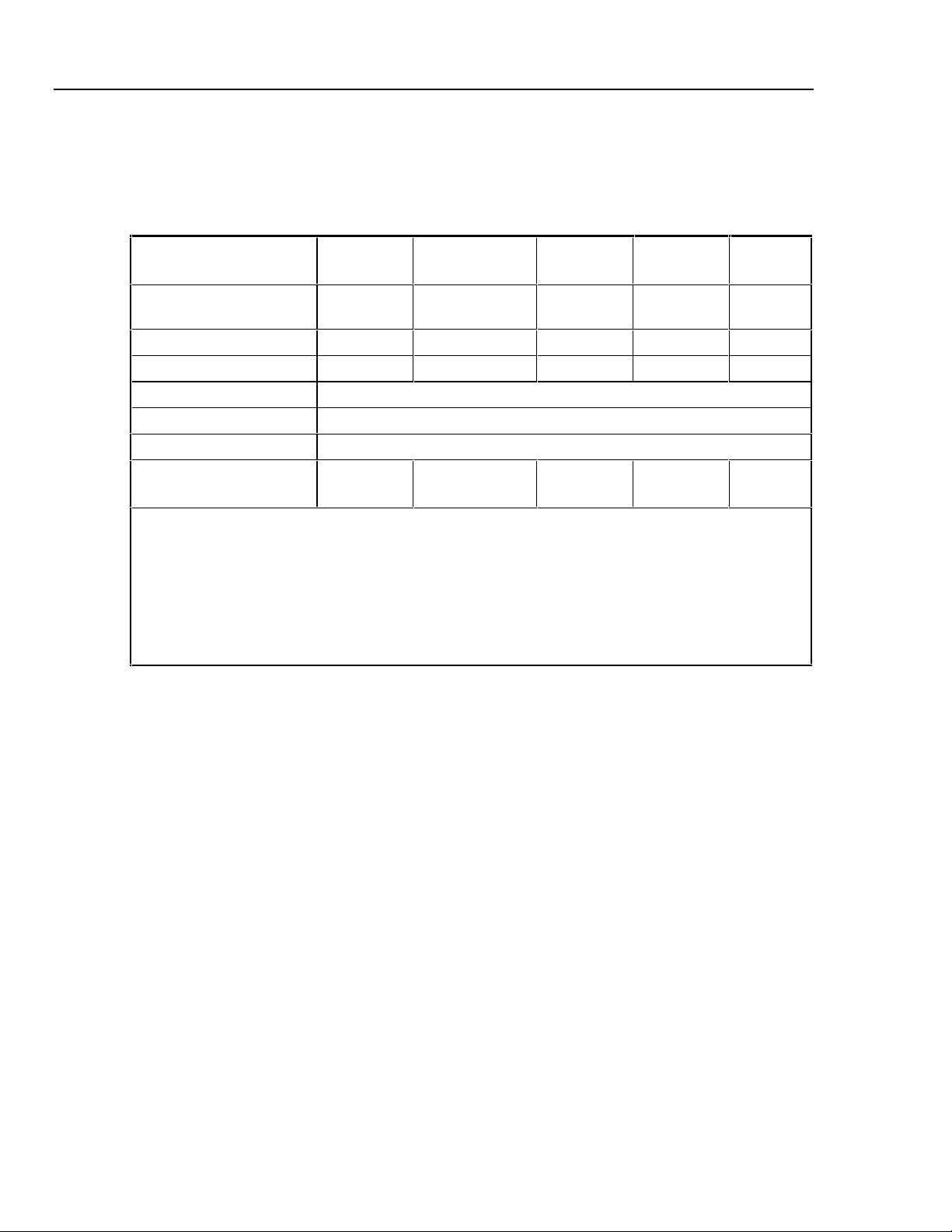

1-18. Trigger Signal Specifications (Pulse Funct ion)

Table 1-7. Trigger Signal Specifications (Pulse Function)

Pulse Period Division Ratio Amplitude into 50 Ω (p-p) Typical Rise Time

20 ms to 200 ns off/1/10/100 ≥ 1 V ≤ 2 ns

1-14

Page 29

Introduction and Specifications

1-19. Trigger Signal Specifications (Ti me Marker Function)

Table 1-8. Trigger Signal Specifications (Time Marker Function)

Time Marker Period Division Ratio Amplitude into 50 Ω (p-p) Typical Rise Time

5 s to 750 ns off/1 ≥ 1 V ≤ 2 ns

34.9 ms to 7.5 ns off/1/10 ≥ 1 V ≤ 2 ns

34.9 ms to 2 ns off/1/10/100 ≥ 1 V ≤ 2 ns

1-20. Trigger Signal Specifications (Edge Functi on)

Table 1-9. Trigger Signal Specifications (Edge Function)

Specifications

1

Edge Signal

Frequency

1 kHz to 10 MHz off/1 ≥ 1 V ≤ 2 ns 40 ns

Division

Ratio

Typical Amplitude

into 50 Ω (p-p)

Typical Rise Time Typical Lead Time

1-21. Trigger Signal Specifications (Square Wave Volt age Function)

Table 1-10. Trigger Signal Specifications (Square Wave Voltage Function)

AC Voltage

Frequency

10 Hz to 10 kHz off/1 ≥ 1 V ≤2 ns 1 µs

Division

Ratio

Typical Amplitude

into 50 Ω (p-p)

Typical Rise Time Typical Lead Time

1-22. Trigger Signal Specifications

Table 1-11. TV Trigger Signal Specifications

Trigger Signal Type Parameters

Frame Formats Selectable NTSC, SECAM, PAL, PAL-M

Polarity Positive or negative

Amplitude into 50 Ω (p-p) Adjustable 0 to 1.5 V p-p into 50 ohm load, (±7 % accuracy)

Line Marker Selectable Line Video Marker

1-23. Tunnel Diode Drive Capability

Table 1-12. Tunnel Diode Drive Capability

TD Pulse Drive Square wave at 100 Hz to 100 kHz with variable amplitude of 60 V to 100 V p-p

1-24. Oscilloscope Input Resistance Measurement Specifications

Table 1-13. Oscilloscope Input Resistance Measurement Specifications

Scope Input Selected 50 Ω 1 MΩ

Measurement Range 40 Ω to 60 Ω 500 kΩ to 1.5 MΩ

Uncertainty 0.1 % 0.1 %

1-15

Page 30

5800A

Operators Manual

1-25. Oscilloscope Input Capacitance Measurement Specifications

Scope Input Selected 1 MΩ

Measurement Range 5 pF to 50 pF

Uncertainty ± (5 % of input + 0.5 pF) [1]

[1] Measurement made within 30 minutes of capacitance zero reference.

1-26. Overload Measurement Specifications

Note

If you ordered the GHz Option, the following specification table is

superseded by the table with the same heading in Chapter 8.

Table 1-14. Oscilloscope Input Capacitance Measurement Specifications

The Overload test function applies dc or ac (1 kHz square wave) power into the 50 Ω

oscilloscope input and monitors the current. A time measurement counter indicates the

time duration of the applied overload signal. When the input protection circuit reacts and

opens up the 50 Ω load, the calibrator indication is set to ‘off’ on the right hand display.

In order to prevent front end damage to the oscilloscope, a limited amount of energy is

applied by a user selectable time limit.

Table 1-15. Overload Measurement Specifications

Source

Voltage

5 V to 9 V 100 mA to 180 mA 10 mA setable 1 s to 60 s

Typical ‘On’ current

indication

Typical ‘Off’ current

indication

Maximum Time Limit DC or

(1 kHz)

1-27. External Reference Input Specifications

The External Reference Input selection allows the user to provide their own high

stability 10 MHz reference clock for the 5800A for all functions except the Wave

Generator function. For all other modes, the frequency stability is determined by the

external reference stability. The external reference input must be between 1 to 5 V p-p

1-28. Auxiliary Input/Output Specifications

Maximum input voltage into the auxiliary input is 40 V p-p.

Table 1-16. Auxiliary Input Performance

Channel

Configuration

1-Channel < 600 MHz ≤ 1.1 dB ≤ 1.2:1

1-Channel 600 MHz to 1 GHz ≤ 1.3 dB ≤ 1.4:1

1-Channel 1 GHz to 2.0 GHz ≤ 2.0 dB ≤1.7:1

Frequency Typical Loss Typical VSWR

1-16

5-Channel < 600 MHz ≤ 1.1 dB ≤ 1.2:1

5-Channel 600 MHz to 1 GHz ≤ 1.3 dB ≤ 1.4:1

5-Channel 1 GHz to 2.0 GHz ≤ 2.0 dB ≤1.7:1

Page 31

Chapter 2

Preparing for Operation

Title Page

2-1. Introduction.......................................................................................... 2-3

2-2. Unpacking and Inspection.................................................................... 2-3

2-3. Replacing The Fuse.............................................................................. 2-3

2-4. Selecting Line Voltage......................................................................... 2-4

2-5. Connecting To Line Power................................................................... 2-4

2-6. Service Information.............................................................................. 2-6

2-7. Placement and Rack Mounting............................................................. 2-7

2-8. Cooling Considerations........................................................................ 2-7

2-1

Page 32

5800A

Operators Manual

2-2

Page 33

Warning

To avoid electric shock, read this chapter and follow the

instructions given. The 5800A Calibrator can supply lethal

voltage. If any output channel is energized with a hazardous

voltage, always treat the unused channel s as i f there are

hazardous live voltages present.

2-1. Introduction

This chapter provides instructions for unpacking and installing the 5800A, selecting the

line voltage, replacing the fuse, and connecting to line power. For instructions for cable

connections other than line power, refer to the following chapters:

• UUT (Unit Under Test) connections: Chapter 4

• IEEE-488 parallel interface connection: Chapter 5

• RS-232-C serial interface connection: Chapter 5

• Auxiliary amplifier connections: Chapter 4

2-2. Unpacking and Inspection

Inspect the calibrator carefully for damage and immediately report any damage to the

shipper. The shipping container includes instructions for inspection and claims.

Preparing for Operation

Introduction

2

When you unpack the calibrator, check for all the standard equipment listed in Table 2-1

and check the shipping order for any additional items ordered. Refer to Chapter 9 for

more information. Report any shortage to the place of purchase or to the nearest Fluke

Technical Service Center (see “Service Information” in this chapter). For a performance

test, refer to Chapter 7.

If reshipping the calibrator, use the original container. If it is not available, you can order

a new container from Fluke by indicating the calibrator's model and serial number.

Table 2-1. Standard Equipment

Item Model or Part Number

Calibrator

Line Power Cord

5800A Operator Manual

Certificate of Calibration

Cable assembly, COAX, N(M), BNC (M), 1M

2 EA with 5800A, 5 EA with 5800A-5

Soft Case for storage of output cables

2-3. Replacing The Fuse

To avoid fire, be sure to install the proper fuse and to set the

voltage select switch to the proper vol tage. For 100 V and

120 V, use 2A/250V SB (time delay). For 220 V and 240 V, use

1A/250V SB (time delay).

5800A

See Table 2-2 and Figure 2-2

686318

Form G749

P/N 688960

P/N 603115

Warning

The line power fuse is accessible on the rear panel. The fuse rating is 2A/250V time

delay fuse for the 100V/120V line voltage setting; 1A/250V time delay fuse for the

2-3

Page 34

5800A

Operators Manual

2-4. Select ing Line Voltage

220V/240V line voltage setting. For fuses that are not user replaceable, refer to Chapter

7 for a list.

To check or replace the fuse, refer to Figure 2-1 and proceed as follows:

1. Disconnect line power.

2. Open the fuse compartment by inserting a screwdriver blade in the tab located at the

left side of the compartment and gently pry until it can be removed with the fingers.

3. Remove the fuse from the compartment for replacement or verification. Be sure the

correct fuse is installed.

4. Reinstall the fuse compartment by pushing it back into place until the tab locks.

The calibrator arrives from the factory configured for the line voltage normally

appropriate for the country of purchase, or as specified at the time of your purchase

order. You can operate the 5800A Calibrator from one of four line voltage settings:

100 V, 120 V, 200 V, and 240 V (47 to 63 Hz). To check the line voltage setting, note

the voltage setting visible through the window in the power line fuse compartment cover

(Figure 2-1). The allowed line voltage variation is 10 % above or below the line voltage

setting.

To change the line voltage setting, complete the following procedure:

1. Disconnect line power.

2. Open the fuse compartment by inserting a screwdriver blade in the tab located at the

left side of the compartment and gently pry until it can be removed with the fingers.

3. Remove the line voltage selector assembly by gripping the line voltage indicator tab

with pliers and pulling it straight out of its connector.

4. Rotate the line voltage selector assembly to the desired voltage and reinsert.

5. Verify the appropriate fuse for the selected line voltage and reinstall the fuse

compartment by pushing it back into place until the tab locks.

2-5. Connecting To Line Power

Warning

To avoid shock hazard, connect the factory supplied threeconductor line power cord to a properly grounded power outlet.

Do not use a two-conductor adapter or extension cord; this will

break the protective ground connection.

Use the rear-panel ground terminal for a protective grounding

wire if there is any question as t o i nstrument earth grounding.

The calibrator is shipped with the appropriate line power plug for the country of

purchase. If you need a different type, refer to Table 2-2 and Figure 2-2 for a list and

illustration of the line power plug types available from Fluke.

2-4

After you verify that the line voltage selection is set correctly and that the correct fuse

for that line voltage is installed, connect the calibrator to a properly grounded threeprong outlet.

Page 35

MAINS SUPPLY

100V

220V

/120V

/240V

FUSE

T2.5A 250V

T1.25A 250V

CAUTION

(SB)

REPLACE ONLY WITH A 250V FUSE

OF INDICATED RATING

(SB)

FOR FIRE PROTECTION

47Hz

300VA MAX

/ 63Hz

Preparing for Operation

Connecting To Line Power

2

CHANGING LINE FUSE

240

120

CHANGING LINE VOLTAGE

LINE VOLTAGE

INDICATOR

0V

(SB)

120

Figure 2-1. Accessing the Fuse and Selecting Line Voltage

oq066f.eps

2-5

Page 36

5800A

Operators Manual

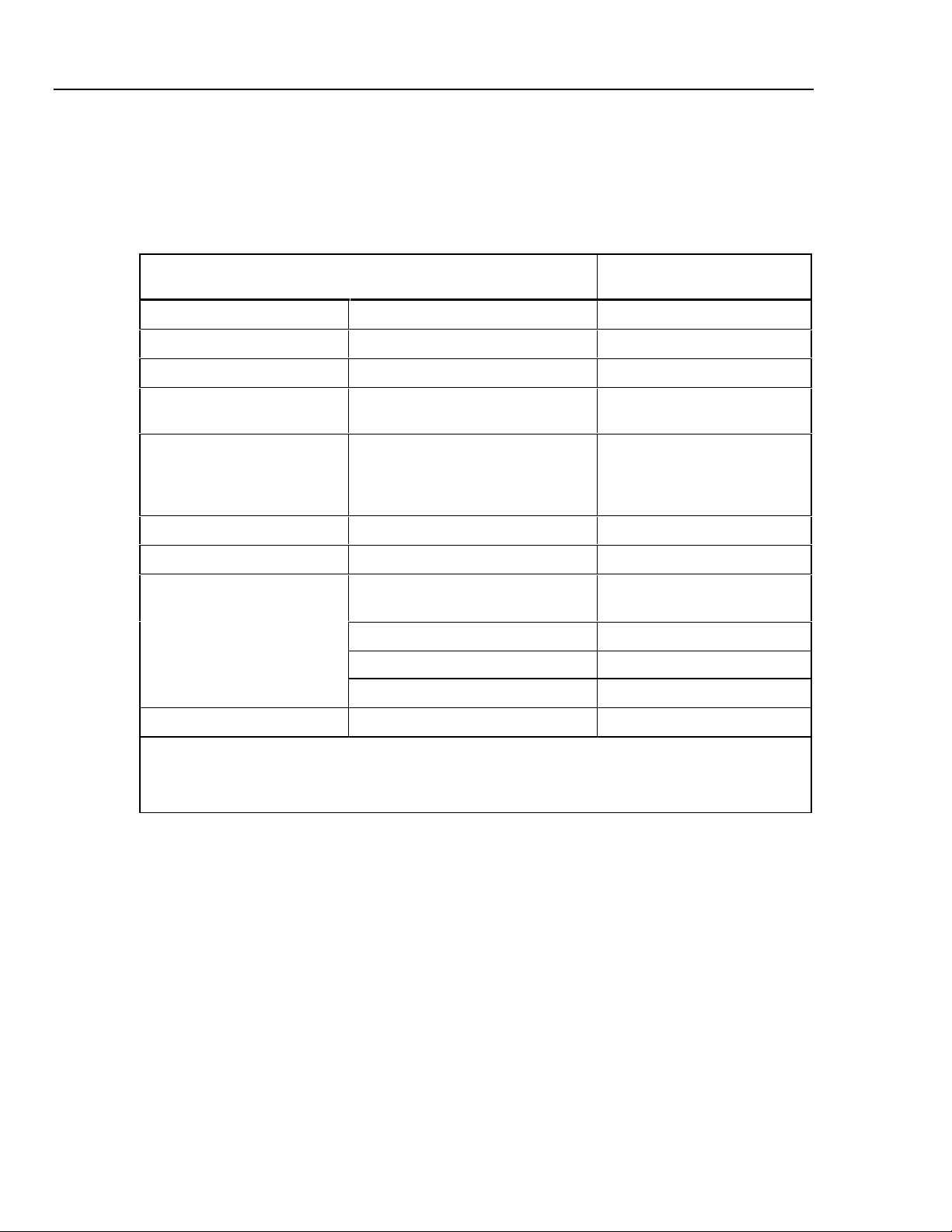

Table 2-2. Line Power Cord Types Available from Fluke

Type Voltage/Current Fluke Option Number

North America

North America

Universal Euro

United Kingdom

Switzerland

Australia

South Africa

LC-1 LC-2 LC-3 LC-4

120 V/15 A

240 V/15 A

220 V/16 A

240 V/13 A

220 V/10 A

240 V/10 A

240 V/5 A

LC-1

LC-2

LC-3

LC-4

LC-5

LC-6

LC-7

LC-5 LC-6 LC-7

Figure 2-2. Line Power Cord Types Available from Fluke

2-6. Service Information

The warranty for the original purchaser of each Model 5800A Calibrator is 1 year

beginning on the date received. The warranty is located at the front of this manual.

To contact Fluke, call:

USA and Canada: 1-888-99-FLUKE (1-888-993-5853)

Europe: +31 402-678-200

Japan: +81-3-3434-0181

Singapore: +65-7385655

Anywhere in the world: +1-425-356-5500

For additional information about Fluke, its products, and services, visit Fluke’s web site

at:

www.fluke.com

Refer to the Fluke catalog or contact a Technical Service Center representative for the

module exchange procedure.

oq009.eps

2-6

Page 37

2-7. Placement and Rack Mounting

You may place the calibrator on a bench top or mount it in a standard-width, 24-inch

(61-cm) deep equipment rack. For bench-top use, the calibrator has non-slipping, nonmarring feet. To mount the calibrator in an equipment rack, use the 5800A Rack Mount

Kit, Model Y5537. The rack mount kit has instructions for rack mounting the calibrator.

2-8. Cooling Considera tions

Warning

To avoid risk of injury, never operate or power the 5800A

Calibrator without the fan fil t er i n pl ace.

Caution

To avoid damage to the calibrator, make sure the calibrator i s

kept at the coolest possible temperature and ai r f low is not

restricted. Damage caused by overheating may occur if the

area around the air intake is restricted, the int ake ai r i s t oo

warm, or the air filter becomes clogged.

Preparing for Operation

Placement and Rack Mounting

2

Baffles direct cooling air from the fan throughout the chassis to internally dissipate heat

during operation. The accuracy and dependability of all internal parts of the calibrator

are enhanced by maintaining the coolest possible internal temperature. You can lengthen

the life of the calibrator and enhance its performance by observing the following rules:

• The area around the air filter must be at least 3 inches from nearby walls or rack

enclosures.

• The exhaust perforations on the sides of the calibrator must be clear of obstructions.

• The air entering the instrument must be at room temperature: make sure the exhaust

air from another instrument is not directed into the fan inlet.

Clean the air filter every 30 days or more frequently if you operate the calibrator in a