Page 1

5700A/5720A

Series II Multi-Function Calibrator

Operator Guide

PN 601648

May 1996

© 1996 Fluke Corporation, Inc.

All rights reserved. Printed in U.S.A.

®

Page 2

Page 3

Contents

What is in this Guide? ................................ 2

Safety Summary......................................... 2

P Fuse and Line Voltage .......................... 4

Basic Operation.......................................... 5

A Short Calibration Exercise....................... 5

Warming up the Calibrator ..................... 5

Exercise: Running dc Zero Calibration........ 6

Connecting a Meter................................ 6

Applying a dc Voltage ............................ 7

Checking the Calibrator Uncertainty.......7

Exercise: Activating Error Mode ............. 8

Checking the Meter’s Higher and Lower

Exercise: Applying an ac Voltage........... 9

Front Panel Features.................................. 10

Output Display (Left Side)...................... 10

Control Display (Right Side)................... 10

Display Screen Saver............................. 11

Front Panel Keys ................................... 12

Front Panel Connectors ......................... 21

Rear Panel Features .................................. 23

Rear Panel Connectors.......................... 23

Switches and Fuse Holder...................... 26

Cable Recommendations............................ 27

Connecting to a UUT (Unit Under Test) ...... 28

Using Error Mode....................................... 35

Operating in Remote .................................. 37

RS-232-C Interface Parameters.................. 38

Ranges..................................... 8

1

Page 4

What is in this Guide?

The

Operator Guide

information, a short meter calibration exercise for

new users, then continues with a condensation of

information from the

complete information about the Calibrator’s

features, functions, and operating procedures,

refer to the

Operator Manual

begins with safety

Operator Manual

.

. For

Safety Summary

Warning

[

Lethal voltage may be present on the

terminals. Observe all safety

precautions in this guide.

To avoid electrical shock hazard, the operator

should not electrically contact the OUTPUT HI or

SENSE HI binding posts. During operation, lethal

voltages of up to 1100V ac or dc may be present

on these terminals.

Whenever possible, keep one hand away from the

equipment to reduce the hazard of current flowing

through vital organs of the body.

Symbols Marked on Equipment

[

P

To avoid fire hazard, use only the fuse specified

on the line voltage selection switch label.

Warning - Risk of electric shock.

Q

Ground Protective ground (earth) terminal.

Attention Refer to the manual for

information about this feature. This symbol

appears on the rear panel ground terminal

and by the fuse holder.

Use the Proper Fuse

2

Page 5

Safety Summary (cont.)

[Grounding the Calibrator

The Calibrator is a Safety Class I (grounded

enclosure) instrument. The enclosure is grounded

through the grounding conductor of the power

cord. To avoid electrical shock, plug the power

cord into a properly wired earth grounded

receptacle before making any connections to the

Calibrator terminals. A protective ground

connection by way of the grounding conductor in

the power cord is essential for safe operation.

[Do Not Remove the Cover

To avoid personal injury, do not remove the

Calibrator cover. Do not operate the Calibrator

without the cover properly installed. There are no

user-serviceable parts inside the Calibrator, so

there is no need to ever remove the cover.

3

Page 6

P

Fuse and Line Voltage

The correct fuse type for each voltage selection is

indicated on the rear panel as shown in the

following figure.

CAUTION

FOR FIRE PROTECTION REPLACE ONLY

WITH A 250V FUSE OF INDICATED RATING.

VOLTAGE

SELECTION

S2 S3 S4

100V

110V

115V

120V

FUSE-F1

T 125A

250V

(SB)

VOLTAGE

SELECTION

S2 S3 S4

200V

220V

230V

240V

FUSE-F1

T 125A

250V

(SB)

CAUTION

FOR FIRE PROTECTION REPLACE ONLY

WITH A 250V FUSE OF INDICATED RATING.

VOLTAGE

VOLTAGE

FUSE-F1

SELECTION

S2 S3 S4

100V

110V

115V

120V

FUSE-F1

SELECTION

S2 S3 S4

200V

T 125A

T 125A

220V

250V

250V

230V

(SB)

(SB)

240V

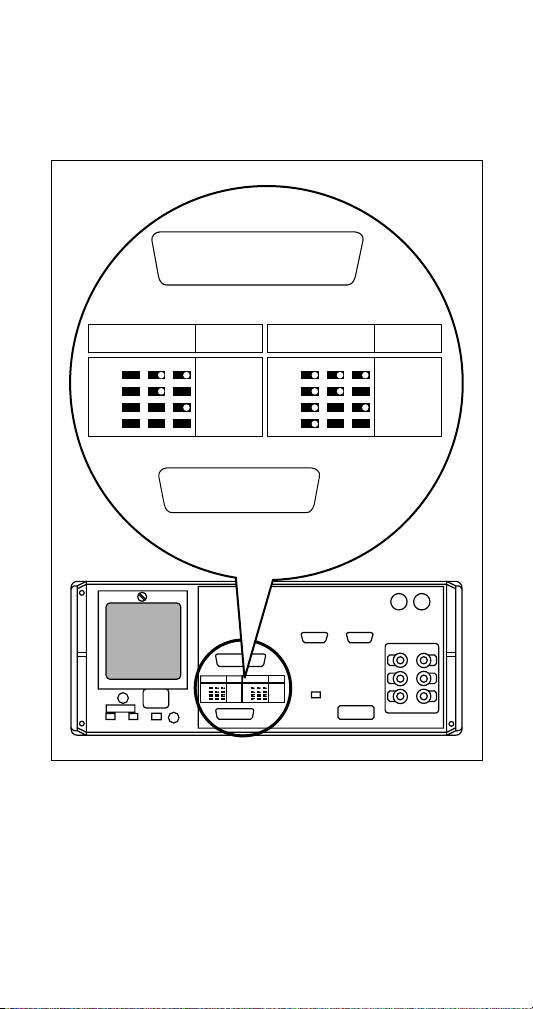

Line Power Label and Switch Locations

4

Page 7

Basic Operation

To set the output, simply press the following

sequence of keys to select an output function and

amplitude:

[numeric keys] [multiplier] [function] E O

For example, to set the output to 10 mV dc, press:

1 0 m V E O

To set an ac output, press the following additional

keys:

[numeric keys] [multiplier] H E

For example, to change the present 10 mV dc to

10 mV ac @ 1.8 kHz, press:

1 . 8 K H E

To change the output back to dc, press:

0 H E

or

+ E

A Short Calibration Exercise

If you are not familiar with the Calibrator, you will

find that the following exercise quickly teaches you

some important front panel operations.

Warming up the Calibrator

When you first turn the Calibrator on, you should

let it warm up for 30 minutes. This ensures that the

Calibrator meets or exceeds its specifications.

5

Page 8

Exercise: Running dc Zero Calibration

DC Zero is a brief internal process that removes

offset errors. The specifications require that you

run dc Zero at least every 30 days.

To run dc Zero, press the following sequence of

softkeys:

Setup Menus Cal Zero

Press any key, then press P twice to return to

normal operation.

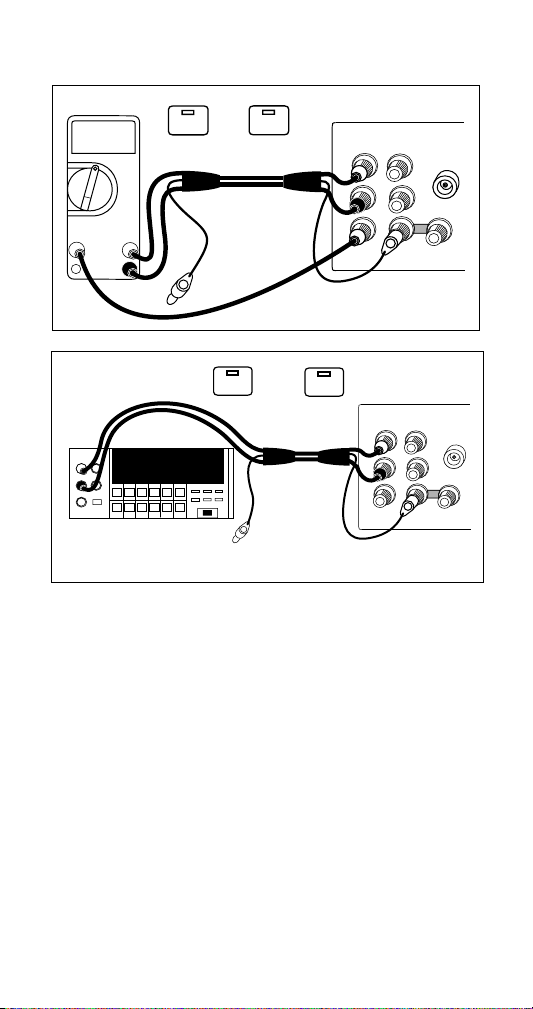

Connecting a Meter

Typical connections for handheld and benchtop

meters are shown on the next page. The diagrams

show the use of Fluke Model 5440-7002 Low

Thermal Cables. Other types of cable may be used

for this exercise. To connect either type of meter,

proceed as follows:

1. Verify that the Calibrator is on, and is in

standby mode (STANDBY indicator lit). If the

Calibrator is not in standby, press r.

2. Set the meter to the lowest range that reads

10V dc.

3. Connect the shield lead (if your cables are

shielded) to V GUARD on the Calibrator.

4. Verify that both X and x are off. Press

them if they are lit.

5. Connect the meter input LO to the Calibrator

OUTPUT LO.

6. Connect the meter input HI to the Calibrator

OUTPUT HI.

6

Page 9

Exercise: Connecting a Meter (cont.)

INPUT

DMM

10A

300mA

V

COM

Ω

NC

DMM

EX SNS

: OFF

EX SNS

NC

EX GRD

: OFF

: OFF

EX GRD

Calibrator

OUTPUT

Ω

V A

HI

LO

HI

AUX

CURRENT

: OFF

OUTPUT

HI

LO

HI

CURRENT

SENSE

Calibrator

ΩΩ

V A

AUX

Applying a dc Voltage

Apply 10V dc to the meter by pressing the

following sequence of keys:

1 0 V E O

Ω

V

GUARD

SENSE

GUARD

WIDEBAND

HI

LO

GROUND

V

WIDEBAND

HI

LO

GROUND

Checking the Calibrator Uncertainty

Press s. The total uncertainty for the 10V you

are applying to the meter is displayed on the

Control Display (the large dot-matrix display on the

right side of the front panel). This number depends

on the setting of the calibration cycle and

specification confidence level in a setup menu.

Press P to clear the uncertainty display.

7

Page 10

Exercise: Activating Error Mode

Chances are the meter reads something other than

exactly 10V. To quickly check the error of the

meter, turn the rotary knob to obtain a meter

reading of exactly 10V, and read the error off the

Control Display.

Turning the knob is all it takes to activate error

mode. When you turn the knob, the least

significant digit is highlighted. This digit changes

as you turn the knob. To change a higher order

digit, thereby speeding up the adjustment rate,

press <.

The error on the Control Display is a combination

of offset, scale, and linearity errors. You can view

component parts of the error by pressing o and

S.

Checking the Meter’s Higher and Lower Ranges

To check the meter error at 100V dc, first set the

meter range (if applicable) to the lowest range that

reads 100V. Press Y O. This sets a new

reference equal to ten times the previous

reference of 10V dc. (Pressing O was necessary

because the Calibrator goes into standby when it

crosses the safety threshold from below 22V to

over 22V.) Turn the rotary knob to re-activate error

mode and determine the meter error at 100V.

Now press Z Z. Set the meter range switch (if

applicable) to the lowest range that reads 1V.

To end the error mode session, press E.

This recalls the reference value and exits error

mode.

Press r

to set the output to 0 mV dc in standby.

8

Page 11

Exercise: Applying an ac Voltage

There is no “ac mode” switch on the Calibrator.

You change a dc output to ac by entering a

frequency through the keypad and pressing

E.

To test the meter at 10V at 1 kHz, set the meter to

read 10V ac, press 1 0 V, then 1 K

HEO. Adjust the rotary knob for a

reading on the meter of exactly 10V.

To test the mete r’s f lat ne ss, pre ss a. The 0.1 Hz

digit is highlighted. Press < four times. Turn the

knob to change the 1 kHz digit until the Calibrator

is set to 10 kHz. P ress a and turn the knob

again to check the meter’s accuracy at 10 kHz.

Each time you change the frequency, you need to

wait for the Calibrator output to settle (the “u”

annunciator will go out).

This ends the front panel exercise. To zero the

output and go to standby, press r.

9

Page 12

Front Panel Features

Following is a brief description of the Calibrator’s

front panel features.

Output Display (Left Side)

Shows output amplitude and frequency. The top

line shows the active output value in up to eight

digits, plus a polarity sign. The bottom line shows

output frequency in five digits. Annunciators below

the amplitude line on the output display indicate

the following active conditions:

OPERATE Lit when an output is active at the

STANDBY Lit when the Calibrator is in standby.

ADDR Lit when the Calibrator is addressed

ØLCK Lit when the Calibrator output is

ØSHF Lit when the Calibrator output has a

u (Unsettled) Lights when the output is

binding posts or auxiliary amplifier.

over the IEEE-488 interface.

phase locked to a signal at the rear

panel PHASE LOCK connector.

programmed phase difference with a

signal at the real panel VARIABLE

PHASE OUT connector.

changed, and remains lit until the

output settles to within specification.

Control Display (Right Side)

Shows data entries, UUT error adjustments,

softkey labels, and other prompts and messages.

Each softkey label identifies the functions of the

softkey that appears directly below it. All of the

softkey labels that appear on the display at once

are referred to as a menu. When you access the

function provided through the softkeys, you open

up other menus, containing new softkey labels.

10

Page 13

Display Screen Saver

Both the Output and Control displays blank

automatically after 30 minutes of inactivity, unless

the Calibrator is in one of the operating states that

overrides the screen saver.

If the screen saver has activated, you can restore

the display by pressing C. Pressing another key

or turning the knob restores the display and

performs the command sent by the key or knob.

The screen saver does not operate:

• if any part of the Setup menu is displayed.

• during remote operation.

• during calibration or diagnostics.

• when an error message is displayed.

11

Page 14

Front Panel Keys

O

Toggles the Calibrator between operate and

standby modes. In standby mode, the OUTPUT

binding posts are internally disconnected from the

Calibrator. The Calibrator powers up in standby

mode.

The Calibrator automatically switches to standby

mode when:

• r is pressed.

• the Calibrator is sourcing an ac or dc voltage

below 22V, and a voltage greater than 22V is

selected.

• the output function is changed, e.g., from dc

current to ac current.

• the output location is changed.

The Calibrator does not switch to standby when

the voltage is switched from any ac or dc voltage

to an ac or dc voltage less than 22V.

12

Page 15

Front Panel Keys (cont.)

X

Opens and closes an internal connection between

the SENSE and OUTPUT binding posts. The

Calibrator powers up with these two binding posts

connected internally (the SENSE binding posts are

open circuited), and the X indicator off. Toggling

X on (so it lights) disconnects the sense lines

from the OUTPUT binding posts.

External sensing should be used in the following

function under the stated conditions.

• In the dc voltage function when the UUT

draws enough current to produce a significant

voltage drop in the cables.

• In the resistance function when the UUT has a

four-wire input and the Calibrator is set to 100

kΩ or less.

• External sensing can also be used in the two-

wire ohms function to activate two-wire

compensation circuitry to the UUT terminals.

13

Page 16

Front Panel Keys (cont.)

x

Opens and closes an internal connection between

the V GUARD (voltage guard) and OUTPUT LO.

The Calibrator powers up with the V GUARD

internally connected to OUTPUT LO and the x

indicator off. Toggling x on (so it lights)

disconnects OUTPUT LO from the V GUARD.

The V GUARD binding post provides an external

connection point for the voltage internal guard. For

a UUT with ungrounded inputs, the V GUARD

should be connected to LO internally. (The EX

GRD key is toggled off.) For a UUT with a

grounded input, the GUARD may be externally

connected to the grounded UUT input. (The EX

GRD key is toggled on.)

w

Enables and disables the -03 Wideband AC option

and sets the Calibrator to standby mode. When

enabled, the ac voltage output over the range of

10 Hz to 30 MHz is available at the front panel

WIDEBAND connector. The wideband function is

disabled whenever w is toggled off, or when

another function (such as current) is selected.

14

Page 17

Front Panel Keys (cont.)

B

Enables or disables output from an amplifier, when

it would not otherwise be automatically selected.

Sets the Calibrator to standby if this selection

moves the output location.

When available, an amplifier is automatically

selected for output settings that exceed Calibrator

capabilities, but fall within the limits of the selected

amplifier. The B key is only needed to activate

an amplifier for an output setting that is available

from either the Calibrator or from the amplifier.

This allows you to take advantage of amplifier

capabilities other than extended range (i.e. higher

compliance voltage).

For both voltage and current, the amplifier is

assumed to be a 5725A unless another model is

designated in the Setup menus.

P

Aborts the current operation of the Calibrator and

recalls the previous menu. Some menus display a

more specific label for this key, such as “DONE

setting up.”

Softkeys

The functions of the five unlabeled softkeys are

provided through each menu in the Control

Display, with each function located directly above

the softkey that activates that function. Many of

these functions access new menus that contain a

new set of functions for the softkeys, providing

access to many capabilities and configuration

options through the menu tree.

POWER switch

Turns the power on and off.

u

15

Page 18

Front Panel Keys (cont.)

<a>

These keys are the output adjustment controls. If

any of these keys are pressed, or if the knob is

turned, a digit on the Output Display becomes

highlighted. Turning the knob adjusts the output

value. An error display appears on the Control

Display, showing the difference between the

original (reference) output and the new (adjusted)

output.

The < and > keys move the highlight to the

digit you wish to change. In the ac functions, the

a key allows you to move amongst voltage,

current, and frequency. In practice, for voltage and

current outputs, the knob and arrow keys are used

to adjust output until the UUT reads correctly. The

error display shows the UUT deviation from the

reference.

r

During local operation, pressing r aborts the

current operating state of the Calibrator and

returns the Calibrator to the power-up default

state. (This key is not effective during remote

operation.)

S

Identifies a UUT full-scale endpoint for checking

linearity, and does not change the output. If the

output was adjusted with the rotary knob,

subsequent keyed-in output values are multiplied

by a scale factor. Scaling is deactivated by

pressing S again, or by selecting another

function. Scaling is not available for resistance

outputs.

16

Page 19

Front Panel Keys (cont.)

L

Calls up a menu that allows you to specify limits

beyond which the Calibrator will not operate. This

can be used to set limits that protect both

operators and equipment.

Z

Changes the output to one tenth the reference

value (which is not necessarily the same as the

present output value). The value only changes if

the new value is within performance limits.

Y

Changes the output to ten times the reference

value (which is not necessarily the same as the

present output value). The value only changes if

the new value is within performance limits. This

key sets the Calibrator to standby if this change is

made from a value less than 22V to one that is

greater than or equal to 22V.

s

Causes the Calibrator to compute and display its

uncertainty for the present output setting for the

calibration interval and specification confidence

level selected in the setup menus.

o

Identifies a UUT zero-scale endpoint and does not

change the output. Subsequent keyed-in output

values have the offset value (the Calibrator output

value when o was pressed) added to them.

Offset mode is deactivated by pressing o again,

or by selecting another function. Offsets are

available for dc outputs only.

17

Page 20

Front Panel Keys (cont.)

C

Clears a partially completed keypad entry from the

Control Display, or clears an error message that

required acknowledgment, If there is a partially

completed entry when C is pressed, the output is

unaffected.

N

This key is only active during error mode

operation. It establishes the present output value

as a new reference for meter error computation.

D

When in the ac volts, or wideband function, and if

no entry is in progress, the D key shows the

equivalent dBm output on the Control Display. For

the ac voltage function, dBm is calculated for a

600Ω load. (For ac outputs less than 220 mV, the

Calibrator output impedance is always

50Ω because the output is resistively divided.) For

the wideband function, dBm is calculated for a

50Ω resistive termination at the end of a three-foot

50Ω coaxial cable.

Note

The formula to compute dBm is:

dBm = 10 log (power in mW)

Examples:

For 3.0V into a 600Ω load:

dBm = 10 log (15.000) = 11.7609 dBm

for 3.0V into a 50Ω load:

dBm = 10 log (180.000) = 22.5527 dBm

18

Page 21

Front Panel Keys (cont.)

E

Loads a newly keyed-in output value showing on

the Control Display into the Calibrator. If you press

E without identifying the units for the entry,

the Calibrator keeps the units (except Hz) that

were last used. This allows you to alter values for

a function without keying in the units every time.

The multipliers are not retained, for example, you

can enter 1 mV, and then later simply enter 10 to

obtain 10V.

In addition to these functions, the E key

recalls the currently programmed reference value

during error mode operation.

D V A Q H

(Output Function Keys)

These keys select the output function as follows:

D Decibels relative to 1 mW

V Voltage

A Current

Q Resistance

H Frequency

When a value, then H are selected, the

Calibrator automatically switches to ac. To change

back to dc, enter 0 H or enter a signed (+ or amplitude).

U m K M

(Multiplier Keys)

These keys select output value multipliers. For

example, if you enter 33, then m, then V, then

ENTER, the Calibrator output value is 33 mV.

U micro (10

m milli (10

K kilo (10

M Mega(10

-6

or 0.000001)

-3

or 0.001

3

or 1000)

6

or 1,000,000)

19

Page 22

Front Panel Keys (cont.)

0 - 9 (Numeric Keypad)

Used to enter the digits of the output amplitude

and frequency, as well as other data such as the

time and date. The proper sequence for entering a

value is to enter the digits, then any necessary

multipliers, an output function key, then E.

For example, to obtain an output of 20 mV, you

would press the following sequence of keys:

2 0 m V E. The . key is

available for decimal places.

+

If the output function is dc voltage, current, ac

voltage entered in dBm, or a wideband output

entered in dBm, pressing + E toggles the

polarity of the output. If the output function is ac

voltage or current, pressing + E changes

the output to dc.

20

Page 23

Front Panel Connectors

WIDEBAND Connector

A type “N” connector that provides a connection

point for output from the -03 Wideband AC option.

Wideband output specifications are stated for

output levels present at the end of its three-foot

50Ω coaxial cable terminated into a 50Ω purely

resistive load. The connector shell is connected to

chassis ground.

GND Binding Post

If the Calibrator is the location of the ground

reference point in a system, the GND binding post

can be used for connecting other instruments to

earth ground. (The chassis is normally connected

to earth ground through the three-conductor line

cord instead of through the earth ground binding

post.)

V GUARD Binding Post

Provides an external connection point for the

internal voltage guard. For a UUT with floating

(ungrounded) inputs, the C GUARD should be

connected to LO internally (x key toggled off).

For a UUT with a grounded input, the V GUARD

must be externally connected to the grounded UUT

input (x key toggled on). The maximum

allowable potential between the V GUARD

connector and chassis ground is 20V peak.

21

Page 24

Front Panel Connectors (cont.)

SENSE Binding Posts

Used in the resistance and voltage functions for

sensing at the UUT after you have selected

external sense by toggling the X key on, or by

remote command.

External sensing should be used in the dc voltage

function when the UUT draws enough current to

produce a significant voltage drop in the cables,

and in the resistance function when the UUT has a

four-wire ohms input and the Calibrator is set to

100 kΩ or less. External sensing can also be used

in the two-wire ohms function to allow the two-wire

compensation circuitry to the UUT terminals. Refer

to the connection diagrams for examples of usage.

OUTPUT Binding Posts

Provide connection points for ac and dc current

and voltage output, as well as for resistance. The

function of each OUTPUT binding post is defined

below:

LO The common binding post for all

HI The active binding post for all output

AUX

CURRENT

OUTPUT

output functions including Calibrator

amplified voltage output, but not for

Option -03 Wideband AC or auxiliary

amplifier output.

functions, including 5725A amplified

voltage output; does not include

Option -03 Wideband AC or auxiliary

amplifier output.

An optional active binding post for

current. This output is convenient for

calibrating UUTs that have a

separate current input terminal.

22

Page 25

Rear Panel Features

The following list provides descriptions of the

connectors and switches on the Calibrator’s rear

panel.

Rear Panel Connectors

5725A AMPLIFIER Connector

Provides the analog and digital interface for the

Fluke 5725A Amplifier.

5205A AMPLIFIER Connector

Provides the analog and control interface for either

the Fluke 5205A or 5215A Precision Power

Amplifier.

5220A AMPLIFIER Connector

Provides the analog and control interface for the

Fluke 5220A Transconductance Amplifier.

VARIABLE PHASE OUT BNC Connector

Provides access to a variable-phase nominal 2.5V

rms sine wave signal. The phase of this signal can

be adjusted using the arrow keys and rotary knob

(or by remote commands) to lead or lag the main

Calibrator output signal by up to 180°. The

connector shell is not connected directly to chassis

ground; it is connected internally to the OUTPUT

LO binding post. The maximum allowable potential

between the connector shell and chassis ground is

20V peak.

23

Page 26

Rear Panel Connectors (cont.)

PHASE LOCK IN BNC Connector

Provides the input for an external signal onto

which the Calibrator can be phase locked (1V to

10V rms, 10 kΩ input impedance). The connector

shell is not connected directly to chassis ground; it

is connected internally to the OUTPUT LO binding

post. The maximum allowable potential between

the connector shell and chassis ground is 20V

peak.

IEEE-488 CONNECTOR

This is a standard interface connector for

operating the Calibrator in remote control as either

a Talker or a Listener of the IEEE-488 Bus.

RS 232C Connector

A male (DTE) serial port connector for transmitting

internal calibration constant data to a printer,

monitor, or host computer. This connector is also

used for remote control of the Calibrator.

24

Page 27

Rear Panel Connectors (cont.)

The OUTPUT, SENSE, and V GUARD binding

posts on the rear panel are alternative connections

to the UUT. An internal cable enables either the

front or rear binding posts. The procedure to

disable the front panel binding posts and enable

the rear panel binding posts involves opening the

cover of the Calibrator, which should only be done

by authorized service personnel.

The I GUARD binding post provides an external

connection point for the internal current guard. The

current guard is used when the Calibrator is

supplying low-level ac current through a long cable

to remove errors introduced by leakage through

the cable capacitance.

Refer to the connection diagrams for examples of

usage.

AUX CURRENT OUTPUT

This output is not available on the rear panel

binding posts.

CHASSIS GROUND Binding Post

A binding post that is internally grounded to the

chassis. If the Calibrator is the location of the

ground reference point in a system, this binding

post can be used for connecting other instruments

to earth ground. (The chassis is normally

connected to earth ground through the threeconductor line cord instead of through the earth

ground binding post.)

25

Page 28

Switches and Fuse Holder

CALIBRATION SWITCH

A slide switch that enables and disables the

capability to write to nonvolatile memory. This

switch is used for recording and then storing

calibration constants, dates, and parameter

settings. When this switch is in the ENABLE

position, you can write to memory; when in the

NORMAL position, the data in the memory is

protected from being overwritten. The switch is

recessed in order to allow the metrologist to cover

it with a calibration sticker to guarantee calibrator

integrity.

F1 Fuse Holder

This holds the line power fuse. See “Fuse and Line

Voltage” at the beginning of this guide for the

location of the correct ratings.

Line Voltage Selection Switches

Select the operating line voltage. See “Fuse and

Line Voltage” at the beginning of this guide for the

location of the label that shows the correct ratings.

26

Page 29

Cable Recommendations

Output Function Cable Recommendations

DC Voltage

AC Voltage ≤10 kHz

AC Current ≤2A, ≤10

kHz

DC Current ≤2A

Resistance

AC Voltage > 10 kHz SENSE/GUARD: Triaxial cable or

AC Current with Guard Triaxial cable

Wideband AC 3 feet (1m) 50Ω coaxial cable with

Voltage-Boosted

Output, 5205A or 5215A

Voltage-Boosted

Output, 5725A

Current-Boosted Output,

5725A, 5220A

Low Thermal EMF Test Leads

(5440A-7002) or twisted shielded pair

Twinax (e.g., Alpha 2829/2).

OUTPUT: Coaxial

Or: SENSE: Coaxial, OUTPUT:

Coaxial GUARD Lead: Separate wire

Type “N” male connector supplied

with the option. A 50Ω feedthrough

terminator is also supplied for

connecting to meters with impedance

higher than 50Ω.

Use the cable supplied with the

amplifier.

Low Thermal EMF Test Leads

(5440A-7002). (Output is at the

Calibrator front panel.)

16-gauge or heavier twisted-pair

insulated wire, as short as possible to

minimize resistance and inductance.

(Output is at the amplifier terminals.)

27

Page 30

Connecting to a UUT (Unit Under Test)

EX SNS

: OFF

A.

UUT

SENSE

INPUT

4-WIRE

Ω

GUARD

B.

HI

LO

: ON

EX SNS

HI

LO

A

UUT

INPUT

DC

AC

C.

SHIELDED TWISTED

SHIELDED TWISTED

: OFF

EX SNS

PAIR

PAIR

UUT

LOHI

EX GRD

EX SNS

EX GRD

: OFF

OUTPUT

HI

LO

HI

AUX

CURRENT

: ON

OUTPUT

V A

HI

LO

HI

AUX

CURRENT

: ON

OUTPUT

HI

LO

HI

CURRENT

Calibrator

SENSE

Ω

V A

V

GUARD

Calibrator

SENSE

Ω

V

GUARD

Calibrator

SENSE

Ω

V A

AUX

GUARD

Ω

Ω

HI

LO

V

Ω

HI

LO

GROUND

WIDEBAND

GROUND

WIDEBAND

WIDEBAND

HI

LO

GROUND

DC Voltage, AC Voltage ≤10 kHz

28

Page 31

Connecting to a UUT (cont.)

A.

EX SNS

: ON

EX GRD

: OFF

UUT

HI

LO

INPUT

A

SENSE

4-WIRE

Ω

GUARD

B.

HI

LO

EX SNS

TRIAXIAL CABLE

TRIAXIAL CABLE

: OFF

EX GRD

HI

LO

HI

CURRENT

: OFF

UUT

OUTPUT

HI

LO

HI

CURRENT

HI

LO

INPUT

A

SENSE

4-WIRE

Ω

GUARD

TRIAXIAL CABLE

HI

LO

NOTE

Keep the SENSE leads as short as possible.

Calibrator

OUTPUT

V A

Ω

AUX

V-GUARD

Calibrator

V A

Ω

AUX

V-GUARD

SENSE

V

SENSE

V

Ω

Ω

WIDEBAND

HI

LO

GROUND

WIDEBAND

HI

LO

GROUND

Be careful not to exceed the capacitive load limit of

1000 pF up to 220V, 600 pF 220 to 1100V. (1000 pF

with 5725A Amplifier.)

AC Voltage >10 kHz

29

Page 32

Connecting to a UUT (cont.)

HI

LO

HI

LO

INPUT

A

INPUT

A

UUT

SENSE

4-WIRE

Ω

UUT

SENSE

4-WIRE

Ω

GUARD

GUARD

A.

EX SNS

HI

LO

B.

EX SNS

TRIAXIAL CABLE

HI

LO

NC

AC Current ≤2A

: OFF

: OFF

EX GRD

EX GRD

: OFF

Calibrator

OUTPUT

SENSE

V A

Ω

HI

LO

HI

AUX

GUARDGROUND

CURRENT

: OFF

Calibrator

OUTPUT

SENSE

V A

Ω

HI

LO

I-GUARD

V-GUARD

(FRONT)

V

Ω

WIDEBAND

HI

LO

(REAR)

V

Ω

HI

LO

30

Page 33

Connecting to a UUT (cont.)

HI

LO

A

INPUT

UUT

10A

300mA

UUT

SENSE

4-WIRE

Ω

Ω

V

COM

A.

GUARD

UUT

B.

NC

EX SNS

: ON

EX GRD

: OFF

2-WIRE

COMP

OFF

Calibrator

SENSE

OUTPUT

V

Ω

V A

HI

LO

SENSE

SOURCE

SOURCE

SENSE

: OFF

EX SNS

EX GRD

Ω

HI

LO

HI

AUX

CURRENT

: OFF

WIDEBAND

HI

LO

GUARD

GROUND

Calibrator

2-WIRE

COMP

OFF

Calibrator

OUTPUT

SENSE

Ω

V A

Ω

V

WIDEBAND

GUARD

HI

LO

GROUND

HI

LO

HI

AUX

CURRENT

UUT

Calibrator

Resistance

31

Page 34

Connecting to a UUT (cont.)

EX SNS

: ON

C.

UUT

Ω

V

10A

COM

300mA

Use Connections With Exposed Plug Tips

For The Ohms Function Only.

Caution

NC

NC

EX GRD

: OFF

OUTPUT

V A

Ω

HI

LO

HI

AUX

CURRENT

COMP

2-WIRE

COMP

ON

Calibrator

SENSE

Ω

V

WIDEBAND

HI

LO

GUARD

GROUND

UUT

10A

COM

300mA

UUT

D.

EX SNS

: OFF

EX GRD

COMP

: OFF

Calibrator

2-WIRE

COMP

ON

Calibrator

OUTPUT

SENSE

Ω

V A

V

Ω

WIDEBAND

HI

LO

HI

Ω

V

NC

CURRENT

COMP

AUX

UUT

COMP

HI

LO

GUARD

GROUND

Calibrator

Resistance (cont.)

32

Page 35

Connecting to a UUT (cont.)

50Ω Feedthrough Terminator

Supplied With Option -03

LO

CURRENT

OUTPUT

V A

HI

HI

AUX

Ω

Calibrator

SENSE

Ω

V

HI

LO

GUARD

GROUND

WIDEBAND

Cable Supplied With

Option -03

Cable Supplied With

Option -03

NOTE

For wideband meters with higher than 50Ω input impedance,

use the 50Ω feedthrough terminator at the meter connection

end. For all wideband applications, take care to achieve a

good 50Ω impedance match (use cable and connectors with

a characteristic input impedance of 50Ω).

Wideband AC Voltage Output

(Option -03)

33

Page 36

Connecting to a UUT (cont.)

5725A

HI

LO

UUT

INPUT

HI

LO

A

SENSE

4-WIRE

Ω

GUARD

HI

LO

5725A Amplified Current Output

34

Page 37

Using Error Mode

Activate error mode by turning the rotary knob,

pressing an arrow key, or pressing a. When you

enter error mode, the starting value is the

reference from which errors are computed. A new

reference is established when you exit and reenter

error mode. The following table lists the actions

that cause the Calibrator to exit error mode.

35

Page 38

Using Error Mode (cont.)

Keys Action

E Returns to the previous reference

+, then E Establishes a new reference.

A keypad entry, then

E

N Establishes the present output as a

Y Sets the Calibrator to ten times the

Z Sets the Calibrator to one-tenth the

o Identifies the present output as a zero-

S Identifies the present output as a full-

r Returns to the power-up state.

The “Setup Menus”

softkey

value.

Establishes a new reference.

new reference.

reference value and establishes a new

reference.

reference value and establishes a new

reference.

scale endpoint for scaling, and

establishes 0.0 as the new reference.

scale endpoint for scaling and causes

the display to show scale error.

Opens the setup menu.

36

Page 39

Operating in Remote

To operate the Calibrator remotely, proceed as

follows:

1. Turn off the Calibrator power.

2. Connect a remote interface to either the RS232C or IEEE-488 connector on the Calibrator

rear panel.

3. Turn on the Calibrator power.

4. Choose the correct remote parameters using

the softkey menus:

a. Setup Menus Instmt Setup Remote Port

Setup

b. Select Remote Port type (GPIB = IEEE-

488), Remote lang (NORMAL or emulation

mode)

c. Select either GPIB Port Setup or RS-232

Port Setup.

d. If GPIB: select the address.

e. If RS-232: select the parameters in the

next table.

37

Page 40

RS-232-C Interface Parameters

Parameter Choices Default Setting

Data Bits 7 or 8 8

Stop Bits 1 or 2 1

Flow Control Ctrl S/Ctrl Q

(XON/XOFF), RTS,

or none

Parity Checking Odd, even, or none none

Baud Rate 110,300,600,1200,

2400,4800,9600, or

19200

Time-out Period 0 to 30 seconds 0 (no time-out)

EOL (End of Line) CR, LF, or CR LF CR LF

EOF (End of File) Any two ASCII

characters

Ctrl S/Ctrl Q

9600

no characters

38

Loading...

Loading...