Page 1

287/289

True-rms Digital Multimeters

Users Manual

®

June 2007, Rev. 1, 7/08

© 2007, 2008 Fluke Corporation. All rights reserved. Specifications subject to change without notice.

All product names are trademarks of their respective companies.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

Lifetime Limited Warranty

Each Fluke 20, 70, 80, 170, 180 and 280 Series DMM will be free from defects in material and workmanship for its lifetime. As used herein,

“lifetime” is defined as seven years after Fluke discontinues manufacturing the product, but the warranty period shall be at least ten years from

the date of purchase. This warranty does not cover fuses, disposable batteries, damage from neglect, misuse, contamination, alteration, accident or abnormal conditions of operation or handling, including failures caused by use outside of the product’s specifications, or normal wear

and tear of mechanical components. This warranty covers the original purchaser only and is not transferable.

For ten years from the date of purchase, this warranty also covers the LCD. Thereafter, for the lifetime of the DMM, Fluke will replace the LCD

for a fee based on then current component acquisition costs.

To establish original ownership and prove date of purchase, please complete and return the registration card accompanying the product, or

register your product on

product purchased through a Fluke authorized sales outlet and at the applicable international price. Fluke reserves the right to charge for

importation costs of repair/replacement parts if the product purchased in one country is sent for repair elsewhere.

If the product is defective, contact your nearest Fluke authorized service center to obtain return authorization information, then send the

product to that service center, with a description of the difficulty, postage and insurance prepaid (FOB Destination). Fluke assumes no risk

for damage in transit. Fluke will pay return transportation for product repaired or replaced in-warranty. Before making any non-warranty

repair, Fluke will estimate cost and obtain authorization, then invoice you for repair and return transportation.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER WARRANTIES, SUCH AS FITNESS FOR A PARTICULAR PURPOSE, ARE

EXPRESSED OR IMPLIED. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY. AUTHORIZED RESELLERS ARE NOT

AUTHORIZED TO EXTEND ANY DIFFERENT WARRANTY ON FLUKE’S BEHALF. Since some states do not allow the exclusion or limitation of an implied warranty or of incidental or consequential damages, this limitation of liability may not apply to you. If any provision of this

warranty is held invalid or unenforceable by a court or other decision-maker of competent jurisdiction, such holding will not affect the validity

or enforceability of any other provision.

. Fluke will, at its option, repair at no charge, replace or refund the purchase price of a defective

5/07

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

Table of Contents

Title Page

Lifetime Limited Warranty............................................................................................... ii

Introduction .................................................................................................................... 1

Contacting Fluke ............................................................................................................ 1

Safety Information .......................................................................................................... 1

Hazardous Voltage......................................................................................................... 3

Symbols ......................................................................................................................... 4

Features ......................................................................................................................... 5

Understanding the Push Buttons ............................................................................... 5

Using Auto Repeat .................................................................................................... 6

Understanding the Display ........................................................................................ 7

Bar Graph ............................................................................................................. 8

Status Bar Elements ............................................................................................. 8

Page Area............................................................................................................. 9

Softkey Labels ...................................................................................................... 9

Adjusting Display Contrast.................................................................................... 9

Understanding the Rotary Switch .............................................................................. 10

Using the Input Terminals.......................................................................................... 11

i

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

287/289

Users Manual

Controlling Meter Power ................................................................................................ 12

Powering the Meter On and Off Manually ................................................................. 12

Battery Level Indicator .............................................................................................. 12

Automatic Power-Off ................................................................................................. 12

Battery Saver Mode .................................................................................................. 12

Controlling the Backlight ........................................................................................... 13

Selecting the Range ...................................................................................................... 13

Understanding Function Menus ..................................................................................... 13

Input Alert™ Feature...................................................................................................... 15

Using the Info Button ..................................................................................................... 15

Hold and AutoHold Mode............................................................................................... 15

Measuring Crest Factor ................................................................................................. 16

Capturing Minimum and Maximum Values .................................................................... 16

Capturing Peak Values .................................................................................................. 18

Low Pass Filter (Model 289 only)................................................................................... 20

Making Relative Measurements..................................................................................... 21

Making Measurements................................................................................................... 22

Measuring AC Voltage .............................................................................................. 22

Using LoZ for Voltage Measurements (Model 289 only) ........................................... 23

Making dB Measurements ........................................................................................ 23

Measuring DC Voltage .............................................................................................. 25

Measuring AC and DC Signals ................................................................................. 26

Measuring Temperature............................................................................................ 28

Using the Y Function (Model 289 Only) ............................................................... 31

Testing for Continuity ................................................................................................ 31

Using Conductance for High Resistance Tests......................................................... 34

Measuring Capacitance ............................................................................................ 35

Testing Diodes .......................................................................................................... 36

ii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

Contents

Measuring Current..................................................................................................... 38

Measuring Frequency................................................................................................ 42

Measuring Duty cycle ................................................................................................ 43

Measuring Pulse Width.............................................................................................. 45

Changing Meter Setup Options ...................................................................................... 47

Resetting Meter Setup Options.................................................................................. 47

Setting Display Contrast ............................................................................................ 47

Setting the Meter’s Language.................................................................................... 47

Setting Date and Time............................................................................................... 48

Setting Backlight and Auto Off Timeouts ................................................................... 48

Setting a Custom dBm Reference ............................................................................. 48

Disabling and Enabling the Beeper ........................................................................... 48

Enabling and Disabling the Smoothing Mode ............................................................ 49

Using Other Setup Options........................................................................................ 49

Using Memory ................................................................................................................ 49

Storing Individual Measurement Data........................................................................ 49

Naming Saved Data .................................................................................................. 49

Viewing Memory Data ............................................................................................... 50

Viewing Snapshot and Summary Data ................................................................. 50

Viewing Trend Data .............................................................................................. 50

Zooming in on Trend Data .................................................................................... 51

Deleting Stored Measurement Data .......................................................................... 51

Recording Measurement Data ....................................................................................... 52

Setting up a Recording Session ................................................................................ 53

Setting the Event Threshold Value ............................................................................ 54

Starting a Recording Session .................................................................................... 54

Stopping a Recording Session .................................................................................. 54

Using Communications .................................................................................................. 55

(continued)

iii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

287/289

Users Manual

Error Messages ............................................................................................................. 56

Maintenance .................................................................................................................. 57

General Maintenance................................................................................................ 57

Testing the Fuses...................................................................................................... 57

Replacing the Batteries ............................................................................................. 59

Replacing the Fuses ................................................................................................. 59

Test Lead Storage..................................................................................................... 59

In Case of Difficulty........................................................................................................ 61

Service and Parts .......................................................................................................... 62

General Specifications ................................................................................................... 66

Detailed Specifications................................................................................................... 67

AC Voltage Specifications......................................................................................... 68

AC Current Specifications ......................................................................................... 69

DC Voltage Specification .......................................................................................... 70

DC Current Specifications......................................................................................... 71

Resistance Specifications ......................................................................................... 72

Temperature Specifications ...................................................................................... 72

Capacitance and Diode Test Specifications .............................................................. 73

Frequency Counter Specifications ............................................................................ 74

Frequency Counter Sensitivity .................................................................................. 75

MIN MAX, Recording, and Peak Specifications ........................................................ 76

Input Characteristics ................................................................................................. 77

Burden Voltage (A, mA, μA)...................................................................................... 78

iv

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

List of Tables

Table Title Page

1. Symbols................................................................................................................................. 4

2. Push Buttons ......................................................................................................................... 5

3. Display Features ................................................................................................................... 7

4. Rotary Switch Positions......................................................................................................... 10

5. Input Terminals...................................................................................................................... 11

6. Battery Level Indicator........................................................................................................... 12

7. Trend Data Display................................................................................................................ 51

8. Recording Display ................................................................................................................. 53

9. Stopped Recording Display ................................................................................................... 55

10. Error Messages ..................................................................................................................... 56

11. Replacement Parts................................................................................................................ 62

12. Accessories ........................................................................................................................... 65

v

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

List of Figures

Figure Title Page

1. Push Buttons ......................................................................................................................... 5

2. Display Features ................................................................................................................... 7

3. Rotary Switch ........................................................................................................................ 10

4. Input Terminals...................................................................................................................... 11

5. Function Menu....................................................................................................................... 14

6. MIN MAX Record Display...................................................................................................... 17

7. Peak Record Display............................................................................................................. 18

8. Low Pass Filter...................................................................................................................... 20

9. Relative Mode Functions ....................................................................................................... 21

10. AC Voltage Measurements.................................................................................................... 22

11. dBm Display .......................................................................................................................... 23

12. DC Voltage Measurements ................................................................................................... 25

13. AC and DC Display................................................................................................................ 26

14. Temperature Measurement ................................................................................................... 28

15. Resistance Measurement...................................................................................................... 30

16. Continuity Indicator................................................................................................................ 31

17. Continuity Testing.................................................................................................................. 32

vii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

287/289

Users Manual

18. Conductance Measurement .................................................................................................. 34

19. Capacitance Measurement ................................................................................................... 35

20. Diode Testing........................................................................................................................ 37

21. Current Measurement Setup................................................................................................. 40

22. Current Measurement Circuit Connection............................................................................. 41

23. Functions Allowing Frequency Measurement ....................................................................... 42

24. Frequency Display ................................................................................................................ 43

25. Duty Cycle Measurements.................................................................................................... 44

26. Duty Cycle Display................................................................................................................ 45

27. Pulse Width Measurements .................................................................................................. 46

28. Testing the Current Fuses..................................................................................................... 58

29. Test Lead Storage ................................................................................................................ 59

30. Replacing Batteries and Fuses ............................................................................................. 60

31. Replaceable Parts................................................................................................................. 64

viii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

Introduction

XWWarning

Read “Safety Information” before using this Meter.

The descriptions and instructions in this manual apply to the

model 289 and model 287 True-rms Digital Multimeters

(hereafter referred to as the Meter). The model 289 appears in all

illustrations.

Safety Information

The Meter complies with:

• ANSI/ISA 82.02.01 (61010-1) 2004

• UL 61010B (2003)

• CAN/CSA-C22.2 No. 61010-1-04

• IEC/EN 61010-1 2

• EMC EN 61326-1

• Measurement Category III, 1000V, Pollution Degree 2

• Measurement Category IV, 600 V, Pollution Degree 2

In this manual, a Warning identifies hazardous conditions and

actions that could cause bodily harm or death. A Caution

identifies conditions and actions that could damage the Meter,

the equipment under test, or cause permanent loss of data.

To avoid possible electric shock or personal

injury, follow these guidelines:

• Use this Meter only as specified in this

manual or the protection provided by the

Meter might be impaired.

• Do not use the Meter if it is damaged. Before

you use the Meter, inspect the case. Look for

cracks or missing plastic. Pay particular

attention to the insulation surrounding the

connectors.

nd

Edition Pollution Degree 2

XWWarning

1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

287/289

Users Manual

• Make sure the battery door is closed and

latched before operating the Meter.

• Remove test leads from the Meter before

opening the battery door.

• Inspect the test leads for damaged insulation

or exposed metal. Check the test leads for

continuity. Replace damaged test leads before

you use the Meter.

• Do not apply more than the rated voltage, as

marked on the Meter, between the terminals or

between any terminal and earth ground.

• Never operate the Meter with the cover

removed or the case open.

• Use caution when working with voltages above

30 V ac rms, 42 V ac peak, or 60 V dc. These

voltages pose a shock hazard.

• Use only the replacement fuses specified by

the manual.

• Use the proper terminals, function, and range

for measurements.

• Avoid working alone.

• When measuring current, turn off circuit power

before connecting the Meter in the circuit.

Remember to place the Meter in series with the

circuit.

• When making electrical connections, connect

the common test lead before connecting the

live test lead; when disconnecting, disconnect

the live test lead before disconnecting the

common test lead.

• Do not use the Meter if it operates abnormally.

Protection may be impaired. When in doubt,

have the Meter serviced.

• Do not operate the Meter around explosive

gas, vapor, or dust.

• Use only 1.5 V AA batteries, properly installed

in the Meter case, to power the Meter.

• When servicing the Meter, use only specified

replacement parts.

• When using probes, keep fingers behind the

finger guards on the probes.

• Do not use the Low Pass Filter option to verify

the presence of hazardous voltages. Voltages

greater than what is indicated may be present.

First, make a voltage measurement without the

filter to detect the possible presence of

hazardous voltage. Then select the filter

function.

• Only use test leads that have the same voltage,

category, and amperage ratings as the meter

and that have been approved by a safety

agency.

2

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

True-rms Digital Multimeters

Hazardous Voltage

• Use proper protective equipment, as required

by local or national authorities when working

in hazardous areas.

• Comply with local and national safety

requirements when working in hazardous

locations.

WCaution

To avoid possible damage to the Meter or to the

equipment under test, follow these guidelines:

• Disconnect circuit power and discharge all

high-voltage capacitors before testing

resistance, continuity, diodes, or capacitance.

• Use the proper terminals, function, and range

for all measurements.

• Do not remove batteries while the Meter is

turned on or a signal is applied to the Meter’s

input jacks.

• Before measuring current, check the Meter's

fuses. (See "Testing the Fuses" in the Users

Manual on the accompanying CD.)

• Do not use the LoZ mode to measure voltages

in circuits that could be damaged by this

mode’s low impedance (≈3 kΩ). (Model 289

only)

Hazardous Voltage

To alert you to the presence of a potentially hazardous voltage,

when the Meter detects a voltage ≥30 V or a voltage overload

(OL), the

Ysymbol is displayed.

3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

287/289

Users Manual

Symbols

Table 1 lists and describes the symbols used on the Meter and in this manual.

Table 1. Symbols

Symbol Description Symbol Description

B

F

X

E

R

P

t

CAT III

~

AC (Alternating Current or Voltage)

DC (Direct Current or Voltage)

Hazardous voltage

Battery (Low battery when shown on the

display)

Continuity test or continuity beeper tone

Conforms to European Union directives

Underwriters Laboratory listed product

IEC Measurement Category III – CAT III

equipment is designed to protect against

transients in equipment in fixed equipment

installations, such as distribution panels,

feeders and short branch circuits, and

lighting systems in large buildings.

Do not dispose of this product as unsorted municipal waste. Go to Fluke’s website for recycling

information.

I

T

W

J

$

;

N10140

s

CAT IV

Fuse

Double Insulated

Important Information; refer to manual

Earth ground

Conforms to relevant Canadian and US

standards

Conforms to relevant Australian standards

Inspected and licensed by TÜV Product

Services

IEC Measurement Category IV – CAT IV

equipment is designed to protect against

transients from the primary supply level,

such as an electricity meter or an overhead

or underground utility service.

4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

True-rms Digital Multimeters

Features

Features

Tables 2 through 5 briefly describe the Meter’s features.

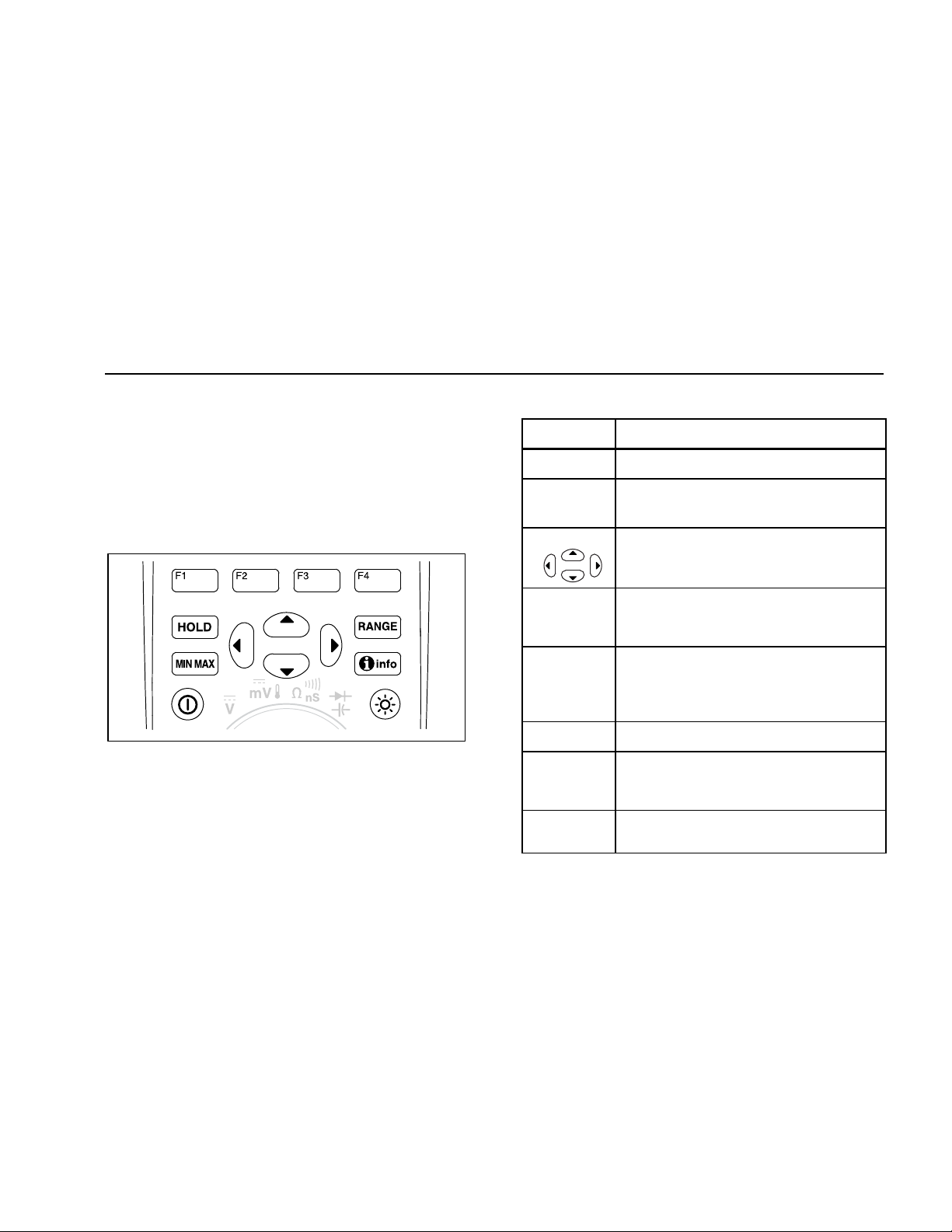

Understanding the Push Buttons

The 14 push buttons on the front of the Meter activate features

that augment the function selected using the rotary switch,

navigate menus or control power to Meter circuits. The buttons

shown in Figure 1 are described in Table 2.

est02.emf

Figure 1. Push Buttons

Table 2. Push Buttons

Button Function

O

12

34

H

R

M

I

G

Turns the Meter on or off.

Selects sub-functions and modes related

to the rotary switch function.

Cursor buttons select an item in a menu,

adjust display contrast, scroll through

information, and perform data entry.

Freezes the present reading in the

display and allows the display to be

saved. Also accesses AutoHold.

Switches the Meter range mode to

manual and then cycles through all

ranges. To return to autoranging, press

the button for 1 second.

Starts and stops MIN MAX recording.

Displays information about the present

function or items on the display at the

moment the info button is pressed.

Switches the display backlight between

off, low, and high.

5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

287/289

Users Manual

Using Auto Repeat

For some menu selections, holding down a softkey or cursor

button will continuously change (or advance) a selection until the

button is released. Normally, each press of a button causes the

selection to change once. During some selections, the selections

will change faster if the button is held for two or more seconds.

This is helpful when scrolling through a list of selections, such as

a list of stored measurements.

6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

True-rms Digital Multimeters

Features

Understanding the Display

Display features shown in Figure 2 are described in Table 3 and

the following sections.

9

87 11 12

6

8:10pm

5

4

123.45

3

2

AutoHOLD

1

Figure 2. Display Features

10

123.45 VAC

100 200 300 400

Save Setup

06/13/07

AutoSAVEHOLDREL

mVAC

Crest Factor

5 mVDC

Auto Range

500 VAC0

Hz60.000

13

14

15

16

est01.eps

Table 3. Display Features

Item Function Indication

A

Softkey labels Indicates the function of the button

B

Bar graph Analog display of the input signal

C

Relative Indicates the displayed value is

D

Minus sign Indicates a negative reading.

E

Lightning bolt Indicates hazardous voltage present

F

Remote

communication

G

Battery level Indicates the charge level of the six

H

Time Indicates the time set in the internal

I

Mode

annunciators

just below the displayed label.

(See the “Bar Graph” section for

more information).

relative to a reference value.

at the Meter’s input.

Indicates activity over the

communication link.

AA batteries.

clock.

Indicates the Meter’s mode.

7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

287/289

Users Manual

Table 3. Display Features (cont.)

Item Function Indication

J

Minimeasurement

K

Date Indicates the date set in the internal

L

Beeper Indicates the Meter’s beeper is

M

Units Indicates the units of measure.

N

Auxiliary Units Indicates unitless measurements

O

Range indicator Indicates the range the Meter is in

P

Secondary display Displays secondary measurement

Displays the lightning bolt (when

necessary) and the input value

when the primary and secondary

displays are covered by a menu or

pop-up message.

clock.

enabled (not associated with the

continuity beeper).

like Crest Factor.

and the ranging mode (auto or

manual).

information about the input signal.

Bar Graph

The analog bar graph functions like the needle on an analog

meter, but without the overshoot. The bar graph updates 30

times per second. Because the graph updates faster than the

digital display, it is useful for making peak and null adjustments

and observing rapidly changing inputs. For frequency, duty cycle,

pulse width, dBm, and crest factor functions, the bar graph

represents the amplitude of the input signal (volts or amps) and

not the value in the primary display. The bar graph is not shown

for capacitance, temperature, LoZ, AC+DC, AC over DC, peak,

or min max functions.

For dc voltage, dc current, and all relative percent modes, a

zero-centered bar graph is displayed. For dc voltage and current,

the bar graph range is the maximum of the selected range. For

relative percent mode, the bar graph goes to ±10 %.

The number of lit segments indicates the measured value and is

relative to the full-scale value of the selected range. In the 50

Vac range, for example, the major divisions on the scale

represent 0, 5, 10, 15, 20, 25, 30, 35, 40, 45, and 50 Vac. An

input of 25 Vac turns on segments up to the middle of the scale.

For off-scale values, f appears to the right of the normal bar

graph. For the zero-center bar graph, a e appears at the left end

of the bar graph for negative off-scale values and fappears on

the right end for positive off-scale values.

Status Bar Elements

The status bar at the top of the Meter’s display contains

indicators for battery level, time of day, mini-measurement

display, present date, and beeper on/off icon.

8

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

True-rms Digital Multimeters

Features

The mini-measurement display shows the measurement value of

the primary function, if it is not already shown in the page area of

the display. For example, when the display is frozen for a HOLD,

the mini-measurement display continues to show the input signal

(Live) measurement and a mini z. In addition, the minimeasurement display will flash, if z (for inputs above 30 volts)

would normally appear in the primary display but is obscured. To

warn of the possibility of blowing a current fuse, the minimeasurement display also flashes when current measurements

exceed the maximum continuous current levels (see

specifications).

Page Area

The page area of the display is where the main meter content is

displayed. The primary display (upper half of the page area) is

where the most important value of the selected function is

shown. The secondary display contains the bar graph and values

that may be measured in addition to the primary function value.

For example, with frequency measurement selected in Vac, the

frequency value will appear in the primary display with the ac

voltage value in the secondary display.

Softkey Labels

Labels for the four function softkeys (F1 through F4) appear in

the bottom row of the display. These labels will change based on

the function and/or menu selection.

Adjusting Display Contrast

When not selecting items on a menu or inputting data, pressing

7 increases display contrast and pressing 8 decreases it.

9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

287/289

Users Manual

Understanding the Rotary Switch

Select a primary measurement function by positioning the rotary

switch to one of the icons around its perimeter. For each

function, the Meter presents a standard display for that function

(range, measurement units, and modifiers). Button choices made

in one function do not carry over into another function. The

model 289 offers two additional functions: low ohms (Y) and

low impedance (LoZ) ac volts. Each position shown in Figure 3 is

described in Table 4.

est03.emf

Figure 3. Rotary Switch

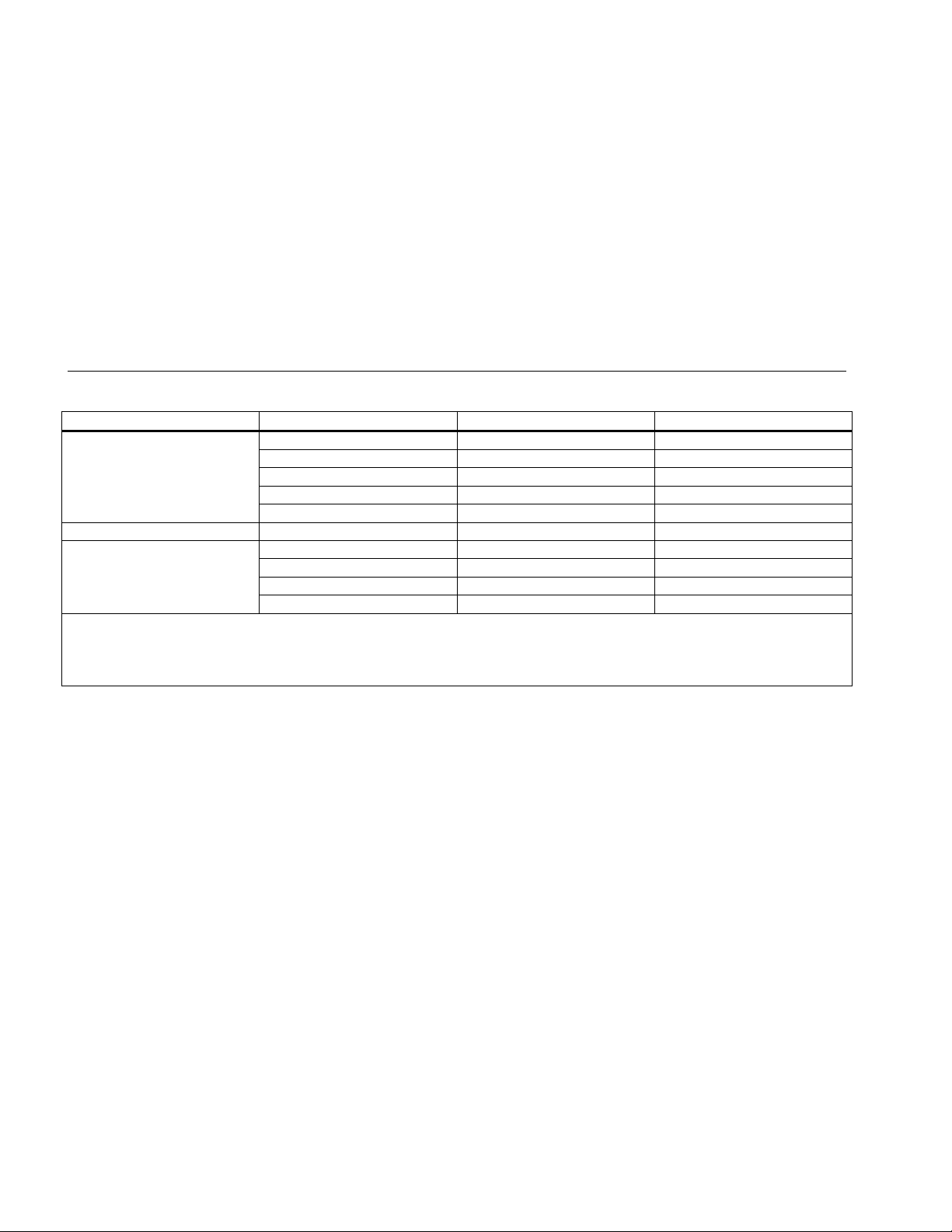

Table 4. Rotary Switch Positions

Switch

Position

L

V

T

U

N

S

P

A

X

Y

AC voltage measurement using a low input

impedance (model 289 only)

AC voltage measurements

AC millivolt measurements

DC and ac+dc voltage measurements

DC millivolts, ac+dc millivolt, and

temperature measurements

Resistance, continuity, and conductance

measurements

Diode test and capacitance measurements

AC, dc and ac+dc amps and milliamps

measurements

AC, dc and ac+dc microampere

measurements up to 5,000 μA

Resistance measurements with 50e range

(model 289 only)

Function

10

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

True-rms Digital Multimeters

Features

Using the Input Terminals

All functions except current use the W and COM input

terminals. The two current input terminals (A and mA/μA) are

used as follows:

Current from 0 to 400 mA, use the

Current between 0 and 10 A use the A and COM terminals.

Figure 4. Input Terminals

€ and COM terminals.

est04.emf

Table 5. Input Terminals

Terminal Description

Input for 0 A to 10.00 A current (20VA

A

€

COM

overload for 30 seconds on, 10 minutes off),

frequency, and duty-cycle measurements.

Input for 0 A to 400 mA current

measurements, frequency, and duty cycle.

Return terminal for all measurements.

Input for voltage, continuity, resistance,

diode test, conductance, capacitance,

frequency, temperature, period, and dutycycle measurements.

11

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

287/289

Users Manual

Controlling Meter Power

The Meter is powered by six AA batteries and controlled through

a front panel power switch and internal circuits designed to help

conserve battery power. The following sections describe several

techniques for controlling Meter power.

Powering the Meter On and Off Manually

With the Meter off, press O to turn on the Meter. Pressing O

while the Meter is on causes it to turn off.

Note

Collected data is retained when the Meter is turned off

while in record, MIN MAX record, or Peak record

modes. When the Meter is next turned on, the dispay

shows the collected data in stopped mode. Pressing

the softkey labeled Save will save the data.

Battery Level Indicator

The battery level indicator in the upper left-hand corner of the

display indicates the relative condition of the batteries. Table 6

describes the various battery levels the indicator represents.

Table 6. Battery Level Indicator

Indication Battery Capacity

B

C

D

E

F

[1] When critically low, a “Replace batteries” pop-up message

appears 15 seconds before the Meter shuts down.

The Meter will display a “Batteries low” message whenever the

battery level will not support a selected function.

Full capacity

¾ capacity

½ capacity

¼ capacity

[1]

Almost empty (less than one day)

Automatic Power-Off

The Meter automatically turns off if the rotary switch is not moved

or a button is not pressed for 15 minutes (default). Pressing O

will turn the Meter back on after it is powered off automatically.

To change the timeout period or completely disable automatic

power-off, refer to “Setting Backlight and Auto Off Timeouts” later

in this manual.

Battery Saver Mode

If Auto off is enabled (set to a time period), and MIN MAX record,

Peak record, Recording, or AutoHold is enabled, the Meter will

enter a battery-saver mode if a push-button is not pressed or the

rotary switch is not moved for a set period of time. For the

12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

True-rms Digital Multimeters

Selecting the Range

recording mode, the time period is five minutes. For MIN MAX,

Peak and AutoHold modes, the time period is the same time the

Auto Off feature is set for. See the “Setting Backlight and Auto

Off Timeouts” section later in this manual. Battery saver mode

conserves battery power by shutting down circuits not necessary

for the selected function, including the display. However, the LED

surrounding the power button (O) will continue to flash to

indicate the Meter is still collecting data.

The Meter “wakes up” from battery-save mode under the

following conditions:

• A button is pressed

• The rotary knob is moved

• A lead is removed or inserted into a current input jack.

• The Meter changes range

• IR Communications begin

These condictions only awaken the Meter and does not change

the Meter’s function or mode of operation.

Controlling the Backlight

If viewing the display becomes difficult in low-light conditions,

press G to activate the LCD backlight. The backlight button

cycles the backlight through three states: low, high, and off. The

Meter displays a message if the battery level will not support the

backlight operation.

To conserve battery life, a user-adjustable timeout controls how

long the backlight stays on. The default timeout is 5 minutes. To

change the timeout, refer to “Setting Backlight and Auto Off

Timeouts” later in this manual.

Selecting the Range

The Meter’s selected range is always displayed above the righthand end of the bar graph, as the range indicator. Pressing R

switches the Meter between manual and autoranging. It also

cycles through the Meter ranges when manual ranging is

enabled.

Note

You cannot use R in conductance, diode test, LoZ,

Low Ohms, and temperature functions. These

functions all use a fixed range.

In autorange, the Meter selects the lowest range to display the

highest available precision (resolution) for the input signal. If

Manual range is already enabled, press and hold R for one

second to enter the autoranging mode.

If autorange is enabled, press R to enter manual ranging.

Each additional press of R sets the Meter to the next higher

range, unless it is already in the highest range, at which point the

range switches to the lowest range.

Understanding Function Menus

Each primary measurement function (rotary switch position) has

a number of optional sub-functions or modes accessed by

pressing the softkey labeled Menu (F1). A typical menu is shown

in Figure 5.

13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

287/289

Users Manual

Menu

VAC

REL

Peak, CF

Hz, %, mS

dBm

dBV

REL REL% Close

Figure 5. Function Menu

est05.eps

Menu selection is indicated by the filled-in black square

(hereafter the menu selector) to the left of a menu item. Use the

four front-panel cursor buttons (5 6 7 8) to position the menu

selector next to a menu item. As the menu selector moves

between menu items, the four softkeys and their labels change to

reflect the available functions and/or modes available for the

selection menu item.

The example menu in Figure 5 shows the REL (Relative)

function as the current selection. The function selected when the

menu opens is the function selected the last time the menu was

used. To get to the Hz menu item from the REL item, press 6

once, followed by one press of 7. As the menu selector moves

between the menu items, the softkey labels change to indicate

each softkey’s function. Once the desired function or mode

appears in one of the softkey labels, press the appropriate

softkey to activate it. The pop-up menu closes and the display

changes to reflect the selection just made. Pressing the softkey

labeled Close closes the pop-up menu, leaving the Meter in the

state it was in before pressing the Menu softkey.

In most cases, the softkeys revealed by the menu selection act

like toggles. The example menu shown in Figure 5 shows REL,

REL%, and Close softkeys. In this example, the Meter is not in

the relative mode, so pressing the softkey labeled REL would

activate, or toggle, the relative mode. If, on the other hand the

Meter is already in the relative mode, pressing the same softkey

would disable the relative function.

In some cases, pressing a function that can not be used with

other functions appearing in the menu turns off the previously

selected function. For example, in Figure 5, if the Meter is

already in the relative function, pressing REL% causes the Meter

to turn off relative and display relative percent.

In cases where multiple modes have been selected, selecting the

first (top-left) menu item always turns off all other functions and

modes, and returns the Meter to the primary function selected by

the rotary switch. For example, assume that the Meter is setup

for frequency (Hz) and is displaying in relative mode as selected

through the menu in Figure 5. Moving the menu selector to the

menu item labeled VAC and pressing the softkey labeled VAC,

clears both frequency and relative selections, leaving the Meter

in volts ac only.

Menu selections are remembered for each rotary switch position.

For example, selecting REL for the volts ac position causes REL

to be selected the next time the menu is opened in volts ac, even

though in the interim, Hz,%,ms was selected from a similar menu

for the millivolts ac function.

Up to two columns of four items each are displayed at any one

time. If more than eight menu items are available for a primary

function, g appears in the lower right-hand corner of the page

area of the display, indicating more menu items are available.

With the menu selector on one of the items in the left column,

14

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

True-rms Digital Multimeters

Input Alert™ Feature

press 5 to scroll the screen horizontally and reveal the off-screen

menu items. Conversely, with the menu selector on an item in

the right-hand column, press 6 to reveal the off-screen menu

items.

Input Alert™ Feature

XW Warning

To avoid circuit damage and possibly blowing the

Meter’s current fuse, do not place the probes

across (in parallel with) a powered circuit when a

lead is plugged into a current terminal. This

causes a short circuit because the resistance

through the Meter's current terminals is very low.

If a test lead is plugged into the mA/μA or A terminal, but the

rotary switch is not set to the correct current position, the beeper

warns you by making a chirping sound and displays “Leads

connected incorrectly”. This warning is intended to stop you from

attempting to measure voltage, continuity, resistance,

capacitance, or diode values when the leads are plugged into a

current terminal.

Using the Info Button

While operating the Meter, more information about a selected

function, a front-panel button, or a menu item may be necessary.

Press I to open an information window that lists topics

covering the functions and modifiers that are available at the time

the button is pressed. Each topic provides a brief explanation on

a Meter function or feature.

The information revealed through I is not meant to replace

the more detailed information found in this manual. Function and

feature explanations are brief and only meant to refresh a

person’s memory.

The number of information topics displayed at any one time may

exceed the display area. Use the softkeys labeled Next and Prev

to move from topic to topic. Use the softkey labeled More or 7

and 8 to scroll through the information a full screen at a time.

Pressing the softkey labeled Close, or I will close the

information window.

Hold and AutoHold Mode

To freeze the display for any function, press H. Only the minimeasurement display and hazardous voltage icon (z) continue to

indicate the actual input. The battery level indicator is also active.

The Meter’s softkeys are relabeled for saving the frozen reading

or activating the AutoHold mode.

If H is pressed while MIN MAX record, peak record, or a

recording session is in progress, the display freezes but the data

acquisition continues in the background. Pressing H again

updates the display to reflect data that was acquired during the

hold.

Pressing the softkey labeled AutoHOLD activates AutoHold if

the Meter is not in the Peak, MIN MAX, or Record modes.

AutoHold operation monitors the input signal and updates the

display and, if enabled, sounds the beeper, whenever a new

stable measurement is detected. A stable measurement is one

that does not vary more than a selected adjustable percentage

(AutoHold threshold) for at least one second. The Meter filters

15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

287/289

Users Manual

out open lead conditions so the Meter leads can be moved

between test points without triggering a display update.

Note

For temperature measurements, the AutoHold

threshold is a percent of 100 degrees. The default

AutoHold threshold is 4% of 100 degrees, or 4 degrees

Celsius or Fahrenheit.

Pressing H while in AutoHold mode, forces the Meter’s

display to update with the present measurement, just as if a

stable measurement had been detected.

To set the AutoHOLD Threshold Value, press the softkey labeled

Setup to access the setup menu. Using the cursor buttons, move

the menu selector next to the menu item labeled Recording and

press the softkey labeled Recording to open the recording setup

screen. Using the cursor buttons, move the menu selector next

to the menu item labeled Event Threshold for AutoHOLD and

then press the softkey labeled Edit. Press 7 or 8 to scroll

through the AutoHold threshold values. With the desired value

selected, press the softkey labeled Close.

Measuring Crest Factor

Crest factor is a measure of signal distortion and is calculated as

a signal’s peak value over its rms value. This is an important

measurement when looking at power quality issues.

The Meter’s crest factor function is only available for the ac

measurements: Vac, mVac, Aac, mAac, and μAac. With the

Meter in one of the ac measurement functions, press the softkey

labeled Menu. Next, move the menu selector next to the menu

item labeled Peak,CF and press the softkey labeled CF. The

crest factor value is displayed in the primary display while the ac

measurement appears in the secondary display. Frequency, duty

cycle, and pulse width are not allowed during crest factor

measurements.

Capturing Minimum and Maximum Values

The MIN MAX Record mode captures minimum, average, and

maximum input values. When the input goes below the recorded

minimum value or above the recorded maximum value, the Meter

beeps and records the new value. The Meter stores the elapsed

time since the recording session was started at the same time.

The MIN MAX mode also calculates an average of all readings

taken since the MIN MAX mode was activated.

This mode is for capturing intermittent readings, recording

minimum and maximum readings unattended, or recording

readings while equipment operation precludes watching the

Meter. The MIN MAX mode is best for recording power supply

surges, inrush currents, and finding intermittent failures.

Response time is the length of time an input must stay at a new

value to be captured as a possible new minimum or maximum

value. The Meter has a 100 millisecond MIN MAX response time.

For example, a surge lasting 100 milliseconds would be captured

but one lasting only 50 milliseconds may not be captured at its

actual peak value. See the MIN MAX specification for more

information.

The true average value displayed is the arithmetic mean of all

readings taken since the start of recording (overloads are

discarded). The average reading is useful for smoothing out

unstable inputs, calculating power consumption, or estimating

the percentage of time a circuit is active.

16

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

True-rms Digital Multimeters

Capturing Minimum and Maximum Values

Note

For input signals that are noisy or change rapidly, turn

on the Smoothing mode to display a steadier reading.

See the “Enabling and Disabling the Smoothing Mode”

section later in this manual.

To extend battery life during MIN MAX recording, the Meter will

enter a battery saver mode. See the “Setting Backlight and Auto

Off Timeouts” section for more information on the battery saver

mode.

To activate the MIN MAX mode, press M. As shown in

Figure 6, the Meter displays e at the top of the

measurement page, and the MIN MAX start date and time along

the bottom of the page. In addition, the recorded maximum,

average, and minimum values appear in the secondary display

with their respective elapsed times.

8:10pm

06/07/07

Min Max

VAC

119.81

Maximum

Average

Minimum

Restart

Figure 6. MIN MAX Record Display

To stop a MIN MAX recording session, press M or the softkey

labeled Stop. The summary information in the display freezes,

and the softkeys change function to allow saving the collected

data. Pressing M again or the softkey labeled Close exits the

MIN MAX record session without saving the collected data.

Turning the rotary switch before saving the MIN MAX

recording data will cause all the accumulated data to

be lost.

To save the MIN MAX screen data, the MIN MAX session must

be ended by pressing the softkey labeled Stop. Next, press the

softkey labeled Save. A dialog box opens where the default

saved name can be selected or another name assigned. Press

127.09

119.50

110.23

Start : 06/07/07 7:00 pm

Note

VAC

VAC

VAC

Auto Range

500 VAC

00:03:17

01:10:09

00:59:59

Stop

est42.eps

17

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

287/289

Users Manual

the softkey labeled Save to store the MIN MAX screen data. MIN

MAX can not be continued at this point. Press the softkey labeled

Close to exit the MIN MAX mode.

Pressing the softkey labeled Restart while MIN MAX is running

stops the MIN MAX session, discards all MIN MAX data, and

immediately starts a new MIN MAX recording session.

Capturing Peak Values

Peak record is almost the same as MIN MAX record explained

earlier in this manual. The significant difference between the two

recording functions is the shorter response time for peak

recording: 250 μs. With this short response time, the actual peak

values of a sinusoidal signal are measurable. Transients are

more accurately measured using the peak record feature.

To activate the peak mode, press the softkey labeled Menu.

Move the menu selector next to the menu item labeled Peak,CF

or Peak. Press the softkey labeled Peak to start the peak

recording session.

8:10pm

06/07/07

Peak

VAC

119.8

Peak Max

Average

Peak Min

Restart

As shown in Figure 7, the primary display shows the “live”

measurement present on the Meter’s inputs. In the secondary

area of the display, the maximum and minimum peak values as

well as the average value are shown along with their respective

time stamps. The time stamp next to the average value indicates

the elapsed time of the peak recording session. The peak

recording session start time is shown along the bottom of the

page area of the display.

When the peak value of the input signal goes below the recorded

minimum value or above the recorded maximum value, the Meter

beeps and records the new value. At the same time, the elapsed

time since the peak recording session was started is stored as

the recorded value’s time stamp.

168.2

118.9

-173.9

Start : 06/07/07 7:00 pm

Figure 7. Peak Record Display

V

VAC

V

Auto Range

500 VAC

00:03:17

01:10:59

01:10:09

Stop

est43.eps

18

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 28

True-rms Digital Multimeters

Capturing Peak Values

Pressing the softkey labeled Stop ends the peak recording

session. The summary information in the display freezes and the

softkeys change function to allow saving the collected data.

Pressing the softkey labeled Close exits the peak recording

session without saving the collected data.

Note

Turning the rotary switch before saving the peak

recording data will cause all the accumulated data to

be lost.

To save peak screen data, the peak capture session must be

ended by pressing the softkey labeled Stop. Next press the

softkey labeled Save. A dialog box opens where the default

saved name can be selected or another name assigned. Press

the softkey labeled Save to store the Peak screen data. Peak

capture can not be continued at this point. Press the softkey

labeled Close to exit the Peak capture mode.

Pressing the softkey labeled Restart while the peak recording

session is running stops the session, discards all peak recorded

data, and immediately starts a new peak record session.

When viewing saved records, snapshot peak records look the

same as a stopped peak records. Therefore, use the elapsed

time (average value time stamp) to identify one record from

another.

To extend battery life during peak record, the Meter enters a

battery-saver mode after a period of time set for the Auto Off

feature. See the “Setting Backlight and Auto Off Timeouts”

section for more information on the battery saver mode.

19

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 29

287/289

Users Manual

Low Pass Filter (Model 289 only)

The Meter is equipped with an ac low pass filter. When

measuring ac voltage, or Vac frequency, press the softkey

labeled Menu to open the function menu, and move the menu

selector to the l item. Next, press the softkey labeled

l to toggle the low pass filter mode on (l displayed)

and off.

XWWarning

To avoid possible electric shock or personal

injury, do not use the Low Pass Filter option to

verify the presence of hazardous voltages.

Voltages greater than what is indicated may be

present. First, make a voltage measurement

without the filter to detect the possible presence of

hazardous voltage. Then select the filter function.

The Meter continues measuring in the chosen ac mode, but now

the signal passes through a filter that blocks unwanted voltages

above 1 kHz, as shown in Figure 8. The low pass filter can

improve measurement performance on composite sine

waves that are typically generated by inverters and variable

frequency motor drives.

Note

In Low Pass Mode, the Meter goes to manual mode.

Select ranges by pressing R. Autoranging is not

available when the Low Pass Filter is enabled.

100 Hz

1 kHz

Figure 8. Low Pass Filter

aom11f.eps

20

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 30

True-rms Digital Multimeters

Making Relative Measurements

Making Relative Measurements

The Meter displays calculated values that are based on a stored

value when set to relative and relative percent mode. Figure 9

shows the functions for which the two relative modes are

available. In addition, the two relative modes are available in

frequency, duty cycle, pulse width, crest factor, and dB.

est29.eps

Figure 9. Relative Mode Functions

To activate the relative or relative percent modes while in one of

the functions shown in Figure 9, press the softkey labeled Menu.

Move the menu selector to the menu item labeled REL. Next,

press either the softkey labeled REL or REL%. The

measurement value at the time that either Rel or Rel % is

enabled, is stored as the reference value and displayed in the

secondary display. The present or “Live” measurement moves to

the secondary display and the primary display indicates the

difference between the present measurement and the reference

value in measurement units for REL and as a percentage for

REL %.

When relative percent is enabled, the bar graph is a zerocentered bar graph that indicates the percentage difference. The

bar graph’s range is limited to ±10 %, but the display goes to

±999.9 %. At 1000 % or more, the display indicates OL. When

the reference value is 0, the Meter displays OL.

With the exception of dB measurements, ranging is set to

manual and can not be changed. Both auto and manual ranging

is possible when making relative dB measurements.

When relative is enabled during dBm or dBV measurements, the

displayed units change to dB.

In relative or relative percent mode, the softkey label for F3

indicates REL or REL%, depending on which of the two modes

is not presently selected. The F3 button acts as a toggle,

switching the Meter between the two modes. Moving the rotary

switch between V and mV while in relative dBm or dBv mode

does not disable the dB measurement. This allows continuous

measurements over a wide range of input voltage.

21

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 31

287/289

Users Manual

Making Measurements

The following sections describe how to take measurements with

the Meter.

Measuring AC Voltage

The Meter displays ac voltage measurements as rms (root mean

square) readings. The rms value is the equivalent dc voltage that

would produce the same amount of heat in a resistance as the

measured voltage. True-rms readings are accurate for sine

waves and other wave forms (with no dc offset) such as square

waves, triangle waves, and staircase waves. For ac with dc

offset, refer to the “Measuring AC and DC Signals” section later

in this manual.

Rotate the Meter’s rotary switch to V or T and set up the Meter

to measure ac volts as shown in Figure 10.

The Meter’s ac volts function offers a number of modes to

provide more details about an ac signal. Pressing the softkey

labeled Menu opens a menu of items that can be used to modify

the basic ac voltage measurement. Refer to the appropriate

section in this manual to learn more about each menu item.

To clear all modes and return to the basic volts ac measurement,

press the softkey labeled Menu. Move the menu selector to the

item labeled VAC. Press the softkey labeled VAC to clear all

functions and modes.

08:10pm

123.45

100 200 300 400

Menu

Save Setup

03 / 13/ 06

VAC

Auto Range

500 VAC0

Switch

Box

est07.eps

Figure 10. AC Voltage Measurements

22

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 32

True-rms Digital Multimeters

Making Measurements

Using LoZ for Voltage Measurements (Model 289 only)

W Caution

Do not use the LoZ mode to measure voltages in

circuits that could be damaged by this mode’s low

impedance (≈3 kΩ).

To eliminate ghost voltages, the Meter’s LoZ function presents a

low impedance across the leads to obtain a more accurate

measurement.

To make a LoZ measurement, set the rotary switch to L. The

Meter displays the ac voltage in the primary display and the dc

voltage in the secondary display. During LoZ measurements, the

Meter’s range is set to 1000 volts in the manual ranging mode.

In LoZ, both R and M are disabled. There are no additional

modes for this function and the softkey labeled Menu is therefore

disabled as well.

Making dB Measurements

The Meter is capable of displaying voltage as a dB value, either

relative to 1 milliwatt (dBm), a reference voltage of 1 volt (dBV)

or a user-selectable reference value. See the “Setting a Custom

dBm Reference” section later in this manual.

8:10pm

06/13/07

dBm

41.83

123.45

1000 Reference

Menu

To set the Meter to display values in dBm, set the rotary switch

to V or T and press the softkey labeled Menu. Move the menu

selector to the menu item labeled dBm. Press the softkey

labeled dBm. The dBm, Hz menu selection replaces the

secondary display (123.45 VAC in Figure 11) with the frequency

measurement. All voltage measurements are displayed as a

dBm value, as shown in Figure 11.

A dBm measurement must use a reference impedance

(resistance) to calculate a dB value based on 1 milliwatt. When

set to 600 Ω (default), the reference impedance is not displayed

during a dBm measurement. When set to something other than

600 Ω, the reference impedance is displayed just above the

softkey labels.

Save Setup

Figure 11. dBm Display

Ref

Auto Range

500 VAC0 100 200 300 400

VAC

est08.eps

23

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 33

287/289

Users Manual

To select another reference value, press the softkey labeled Ref

to display a message box with the current reference value.

Pressing 7 or 8, scrolls through the nine predefined references:

4, 8, 16, 25, 32, 50, 75, 600, and 1000. Set the reference by

pressing the softkey labeled OK. To add a custom reference

impedance, see the “Setting a Custom dBm Reference” section

later in this manual.

A dBV measurement uses a 1 volt reference voltage to compare

the present measurement against. The difference between the

two ac signals is displayed as a dBV value. The reference

impedance setting is not part of a dBV measurement.

To make a dBV measurement, position the rotary switch to V or

T and place the Meter leads on the voltage to be measured.

Next, press the softkey labeled Menu. Move the menu selector

to the menu item labeled dBV and press the softkey labeled

dBV. The Meter displays the voltage in dBV.

To exit the dBV or dBm function, press the softkey labeled Menu

followed by the softkey labeled dBV or dBm, respectively.

Selecting one of the other modifiers such as ms, %, or CF also

cancels dBV or dBm.

24

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 34

True-rms Digital Multimeters

Making Measurements

Measuring DC Voltage

The Meter displays dc volts values as well as their polarity. The

bar graph for dc voltage measurements is a zero-centered bar

graph. Positive dc voltages cause the bar graph to fill to the right

of center while negative dc voltages fill left of center.

To measure a dc voltage with the Meter, rotate the rotary switch

to the U or N position as shown in Figure 12.

The Meter’s dc volts function offers a number of modes to

provide more details about a dc signal. Pressing the softkey

labeled Menu opens a menu of items that can be used to modify

the basic dc voltage measurement. Refer to the appropriate

section in this manual to learn more about each menu item.

To clear all modes and return to the basic volts dc measurement,

press the softkey labeled Menu. Move the menu selector to the

item labeled VDC. Press the softkey labeled VDC to clear all

functions and modes.

8:10pm

9.752

Save Setup

Menu

06/13/07

VDC

Auto Range

50 VDC3020100-10-20-30-40-50 40

VV

est09.eps

Figure 12. DC Voltage Measurements

25

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 35

287/289

Users Manual

Measuring AC and DC Signals

The Meter is capable of displaying both ac and dc signal

components (voltage or current) as two separate readings or one

AC+DC (rms) value combined. As shown in Figure 13, the Meter

displays ac and dc combinations three ways: ac displayed over

dc (AC,DC), dc displayed over ac (DC,AC), and ac combined

with dc (AC+DC). Select one of these three displays using the

Function and Mode menu.

With the rotary switch set to U, N, A, or X, press the

softkey labeled Menu. Move the menu selector to the menu item

labeled AC+DC. At this point, three different softkey labels

AC over DC DC over AC AC + DC

8:10pm

06/13/07

8:10pm

VAC

123.45

23.45

Menu

Save Setup

Auto Range

500 VAC

VDC

23.45

Menu

Figure 13. AC and DC Display

Save Setup

indicate AC+DC (F1), AC,DC (F2), and DC,AC (F3). Press the

softkey that presents these two signals as needed.

While in any of the three AC+DC modes, peak measurements,

frequency, duty cycle, and period measurements are not

allowed. In addition to these modes, MIN MAX, relative, and

relative % are not allowed in AC,DC or DC,AC modes.

123.45

Note

The bar graph is not displayed while the Meter is in

any of the three AC+DC modes.

06/13/07

VDC

Auto Range

500 V

VAC

8:10pm

125.66

23.45

Menu

Save Setup

06/13/07

V

AC + DC

Auto Range

VDC

500 V

est30.eps

Both manual and autoranging is available when using the ac+dc

modes. The same range is used for both ac and dc signals.

However, while in autorange, up-ranging occurs when either the

ac or dc signal exceeds the present range. Down-ranging occurs

26

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 36

True-rms Digital Multimeters

Making Measurements

only when both the ac and dc signals drop below 10% of the

present range. For AC+DC, ranging is controlled by the

underlying values of the ac and dc signals and not by the sum of

the AC+DC calculation.

To exit the AC+DC mode, press the softkey labeled Menu and

select the default mode for the selected function. For dc volts

and dc millivolts functions, move the menu selector to VDC and

press the softkey labeled VDC. For the current functions, move

the menu selector to the AC,DC menu item and press either the

AC or DC softkey.

27

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 37

287/289

Users Manual

Measuring Temperature

XW Warning

To avoid the potential for fire or electric shock, do

not connect the thermocouple to electrically live

circuits.

The Meter uses an 80BK-A Integrated DMM Temperature Probe

or other type-K temperature probe for measuring temperature.

To measure temperature, set up the Meter as shown in

Figure 14. Press the softkey labeled Menu and move the menu

selector to the menu item labeled Temp. Press the softkey

labeled F for temperature in Fahrenheit or C for Celsius.

Note

A Meter classified as “SI” will not have an F selection.

The primary display normally shows temperature or the message

“Open Thermocouple”. The open thermocouple message may be

due to a broken (open) probe or because no probe is installed

into the input jacks of the Meter. Shorting the W terminal to

the COM terminal will display the temperature at the Meter

terminals.

Note

R is disabled when the Meter is in the Temperature

function.

8:10pm

Menu

06/13/07

26.5

+8.0 Offset

Save Offset Setup

C

80BK Type K

Thermocouple

Probe

Figure 14. Temperature Measurement

Vent

or

Pipe

est17.eps

28

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 38

True-rms Digital Multimeters

Making Measurements

To input a temperature offset value, press the softkey labeled

Offset to open a message box with the present offset value. Use

6 and 5 to position the cursor over one of the digits or the polarity

sign. Use 7 and 8 to scroll through the numbers for each digit

in the offset or switch between a + or – offset. With the desired

value displayed, press the softkey labeled OK to set the

temperature offset. When set to something other than 0.0, the

offset value is shown in the secondary display.

Measuring Resistance

W Caution

To avoid possible damage to the meter or to the

equipment under test, disconnect circuit power

and discharge all high-voltage capacitors before

measuring resistance.

The Meter measures resistance (opposition to current flow) in

ohms (Ω). This is accomplished by sending a small current out

through the test leads to the circuit under test.

To measure resistance, set the Meter’s rotary switch to

set up the Meter as shown in Figure 15.

S and

Keep the following in mind when measuring resistance.

Because the meter’s test current flows through all possible paths

between the probe tips, the measured value of a resistor in a

circuit is often different from the resistor’s rated value.

The test leads can add 0.1 Ω to 0.2 Ω of error to resistance

measurements. To test the leads, touch the probe tips together

and read the resistance of the leads. To remove lead resistance

from the measurement, hold the test lead tips together and press

the softkey labeled Menu. Next, move the menu selector to the

menu item labeled REL and press the softkey labeled REL. Now

all future displayed readings indicate the resistance at the probe

tips.

The Meter’s resistance function includes modes to help with

resistance measurements. Pressing the softkey labeled Menu

opens a menu of items that can be used to modify the basic

resistance measurement. Refer to the appropriate section in this

manual to learn more about each menu item.

29

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 39

287/289

Users Manual

8:10pm

Menu

06/13/07

5.67

Auto Range

Save Setup

In-Circuit Resistance Measurements

Isolating a Potentiometer

Circuit Power