Page 1

Temperature

calibration equipment:

A technician’s guide

Have you ever been brought a new thermometer to calibrate, and asked yourself,

“What am I going to need to calibrate this?” This guide is intended to help you work

out the kind of equipment you need for your particular calibration situation. Of course,

there are many considerations—including accuracy, temperature range, automation

requirements and budget. This guide covers the main points, but you’ll probably want

to speak with an experienced Fluke application specialist before you make a nal

decision; as always, we stand ready to help keep you up and running.

Getting started

Most often, thermometer type

determines the kind of equipment needed. Some of the most

common items that need to be

calibrated are listed in Table 1.

The equipment types shown in

the Needed equipment column

should not be considered

definitive. For example, the

same equipment used to calibrate an RTD or an SPRT could

also be used to calibrate a PRT,

but this is a good guide to

what you would most likely

use. In addition, choice of

equipment may depend on

where the calibration is

performed. For example, you

might use a calibration bath

and temperature standard to

calibrate an RTD in a laboratory, but a portable calibrator

would be more appropriate for

on-site calibrations. More about

the equipment needed will be

explained below.

Calibration method

No matter what your temperature calibration application,

you’re going to need a temperature source to heat or cool

your thermometers to a known

temperature. During the calibration, the thermometers are

Application Note

placed into a heat transfer

medium in the temperature

source. The heat transfer

medium might be a stirred fluid,

a metal block, or a fixed point

cell. The heat transfer medium

maintains a constant and

uniform temperature environment that allows the reading

of the thermometer under test

to be compared to a more

accurate known temperature.

The known temperature

value is going to come from

one of two places:

Naturally occurring

•

phenomena, such as

the triple point of water

(0.010 °C)

A temperature measure-

•

ment, made by a

temperature standard

These two different methods

of getting the more accurate

known temperature lead to two

distinct methods of calibration:

comparison calibration and

fixed point calibration.

Comparison calibration is the

most common type.

Page 2

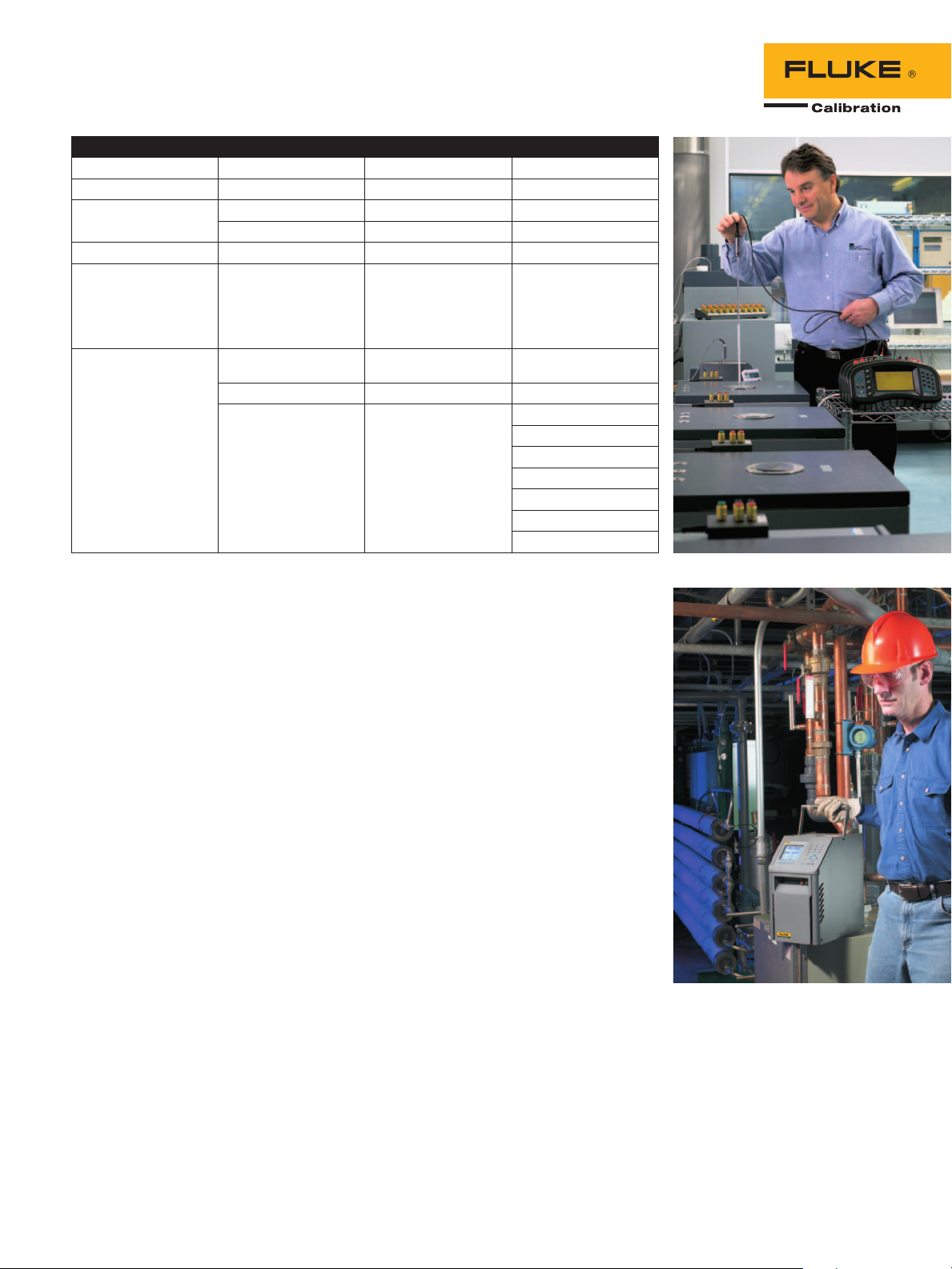

Table 1. Common thermometers that need to be calibrated

Workload Where calibrating? Needed equipment

Dial thermometer On-site A portable temperature calibrator

Liquid in glass Laboratory Cali bration bath, f luid level adapter, magnifier, carousel, and

RTD On-site A portable temperature calibrator and (optional) temperature

Laboratory Cali bration bath and temperature standard

PRT On-site A portable temperature calibrator and (optional) temperature

Laboratory Cali bration bath and temperature standard

Thermocouple On-site A portable temperature calibrator and (optional) temperature

Laboratory Cali bration furnace and temperature standa rd

Thermistor Laboratory Calibration bath and temperature standard

SPRT Laboratory Fixed point cells, maintenance furnaces /baths, a standard

Infrared

thermometer

On-site Radiometrically calibrated infrared calibrator

Laboratory Radiometrically calibrated infrared calibrator, or an infrared

temperature standard

standard

standard

standard

resistor, and a resistance bridge

calibrator (plate) and a reference radiometer, or an infrared

blackbody (cav ity)

Comparison

calibration

For contact thermometer

comparison calibrations, you

will need:

A temperature source to heat

•

or cool the thermometer(s)

under test

A temperature standard to

•

provide the accurate known

temperature that is compared

with the thermometer under

test

(Optional) Measuring devices

•

to read the temperature standard and/or thermometer(s)

under test

As the name implies, during

a comparison calibration, a

thermometer under test is

compared to a more accurately calibrated temperature

standard, while both are maintained at the same constant

temperature in the temperature

source. Typically the standard

is four times more accurate

than the thermometer under

test. Any thermometer can be

calibrated by comparison, and

comparison calibrations can

take place either in a laboratory or on-site.

For non-contact thermometer

comparisons you will need:

A radiance source to gener-

•

ate the known radiance

observed by the infrared

thermometer

A radiometric temperature

•

standard to provide the

accurate known temperature

that is compared with the

thermometer under test

The radiance source can be

either a painted surface or a

blackbody cavity. Good blackbody cavities have a well

known emissivity value (i.e.

0.95 ±0.001). The key performance indicator of a radiance

source is its spectral emissivity. The spectral emissivity

depends on wavelength, the

geometry of the surface, the

finish of the surface, and the

types of plate material and

paint used. The emissivity of a

painted surface is different for

each wavelength; therefore, its

radiance is only known if it is

measured over the same wavelengths used by the infrared

thermometers being calibrated.

For example, measurements of

surface by a radiometer over

the band of wavelengths from

2 Fluke Calibration Temperature calibration equipment: A technicians guide

Page 3

8 to 14 microns will be good

for calibrating thermometers of

the same bandwidth (8 to 14

microns).

Surfaces used to calibrate

infrared thermometers should

be calibrated radiometrically

over the correct bandwidth, or

else a radiometric temperature

standard (radiometer) with the

correct bandwidth needs to

be compared with the thermometers under test during

calibration. For example, the

Fluke, Hart Scientific 4181

Precision Infrared Calibrator is

calibrated radiometrically from

8 to 14 microns and does not

require a separate radiometric

temperature standard over that

bandwidth. Alternatively, the

Hart 9132 Infrared Calibrator is

not radiometrically calibrated

and does require a separate radiometer for infrared

traceability.

Fixed point

calibration

For the most accurate thermometers under test, the only

sufficiently accurate temperature standard is a primary

standard. Fixed point cells are

the primary standards used

in temperature calibration. In

a primary standards laboratory, SPRTs are placed in fixed

point cells and given ITS-90

calibrations. The ITS-90 is

the international temperature

scale used by the International

System of Units (SI) to define

Kelvin and Celsius temperature

values for the world.

Fixed point cells rely on the

intrinsic properties of nature

to provide a very precisely

known temperature. Extremely

pure substances (i.e. tin, zinc

or water) under the right

conditions of temperature

and pressure become very

precise and reliable temperature standards. Thermometers

are calibrated by placing

them inside the cell so that

the thermometer and the

fixed point cell are resting at

the same temperature. This

means a fixed point cell is

both a temperature source

and a temperature standard.

Fixed point cells are the most

accurate type of temperature

calibration equipment but they

are also the most difficult to

use and are found mainly in

primary standards laboratories.

For fixed point calibrations,

you will need:

A fixed point cell (tempera-

•

ture source)

A device to maintain the

•

temperature surrounding the

cell (i.e. bath or furnace)

A resistance bridge to

•

measure the SPRT being

calibrated

Choosing a temperature

source

When choosing a temperature source, you often need to

choose the best compromise

between accuracy and some

other technical requirement.

Table 2 compares various

types of temperature sources

against some common technical requirements.

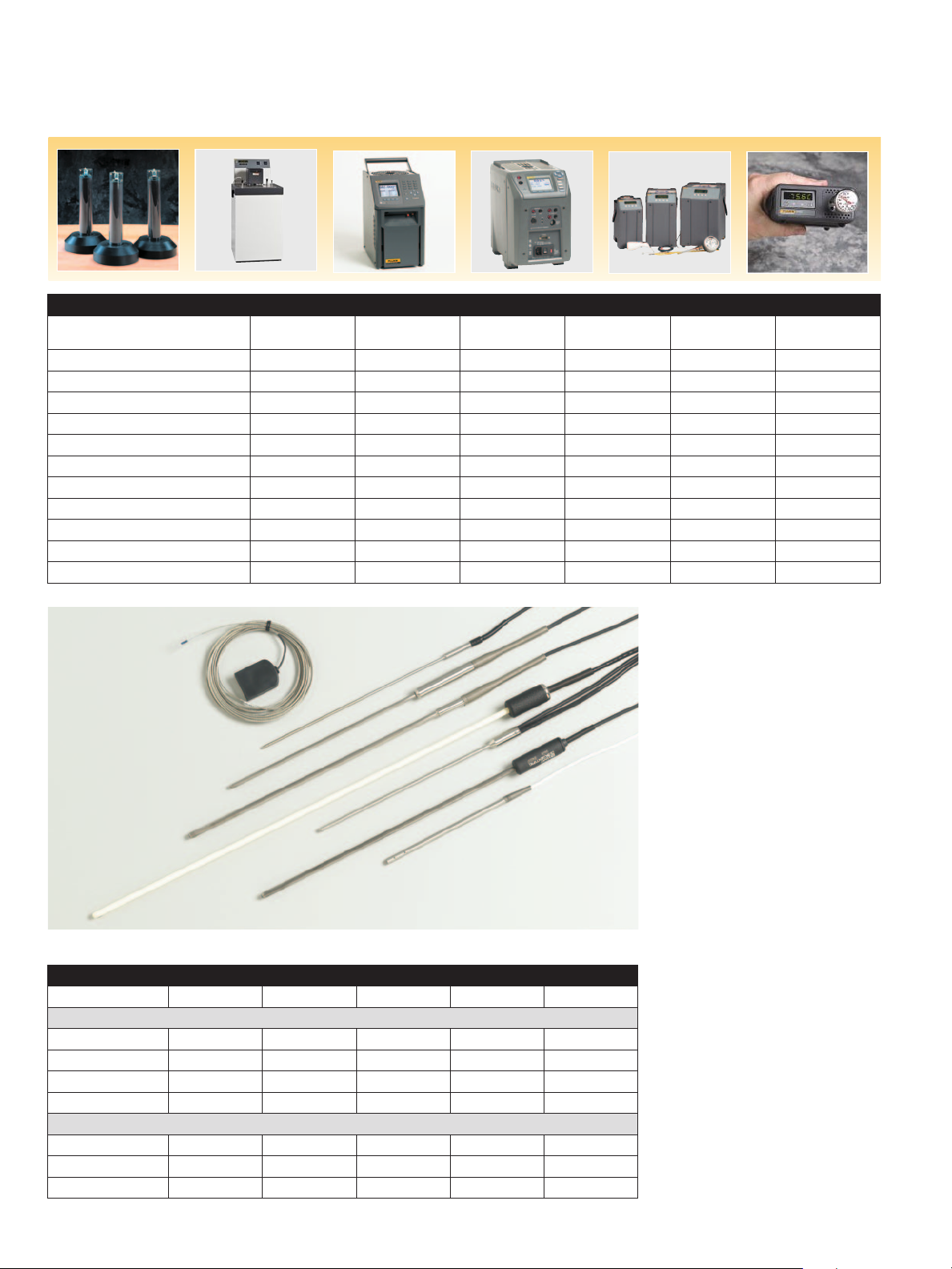

Choosing a calibrated

thermometer

(temperature standard)

For comparison calibrations,

you need to choose a calibrated thermometer for your

temperature standard. There

are several types to choose

from. Your choice depends

on your temperature range

and the required accuracy of

your measurements. Table 3

provides a guide for finding the

right type of thermometer for

your application. Other conditions that should be considered

are degree of ruggedness,

and needed probe dimensions

such as length and diameter.

A general rule for resistance

thermometers such as PRTs,

SPRTs, and HTSPRTs is that the

more rugged the instrument,

the less accurate it becomes.

3

Page 4

Table 2. Temperat ure sources

Techn ical need s Fixed points Baths Metrology wells Field metrology

Accu racy ±0.001 °C to ±0.01 °C

Accu racy ±0.01 °C to ± 0.1 °C

Accu racy ±0.1 °C to ±1.0 °C

Cali brate on-site

Elim inate fluids

Get to temperature fast

Cali brate multiple sizes and shapes

Automate calibration

Use fewer tools

Learn in less than 15 minutes

Use easily

Caption to go here

Table 3. Thermometer types

Techn ical need s Thermistor PRT SPRT HTSP RT Thermocouple

Range

0 °C to 100 °C

–200 °C to 660 °C

0 °C to 961 °C

0 °C to 1450 °C

Accuracy

±0.001 to ±0.01

±0.01 to ± 0.10

±0.1 to ±2.5

• • •

• • •

•

• •

• • • •

• • • •

• • • •

• •

• • • • • •

• • • • •

• •

• •

•

wells

• • •

•

•

•

Micro-baths Dry-wells

•

Once you have chosen the

type of thermometer probe you

will use as the temperature

standard, you need to choose

a device to measure it. This

device could be a specialized thermometer readout, or

it could be a general purpose

instrument like a digital multimeter. Thermometer readouts

deliver the best results because

their ranges, current settings

and firmware are designed

for temperature measurement.

Selection criteria for thermometer readouts include the type of

thermometer and level of accuracy required and other factors

like need for battery power,

number of inputs, and whether

data can be recorded for future

retrieval. See Table 4.

Don’t forget that if you are

calibrating temperature sensors

like RTDs and thermocouples,

you will need thermometer

readouts for them too. A multichannel thermometer readout

can be used to measure your

temperature standard and your

thermometers under test at the

same time.

4 Fluke Calibration Temperature calibration equipment: A technicians guide

Page 5

Table 4. Thermometer readouts from Fluke, Hart Scientific

Techn ical need s 1523 1524 1502A 1504 1529 1560 1595

Measure RTDs

Measure PRTs

Measure SPRTs

Measure HTSPRTS

Measure

thermistors

Measure

Thermocouples

Measure

transmitters

Measure thermal

switches

Cali brate on-site

Batter y powered

Use fewer tools

Single channel

Multi channel

Record data

Automated data

logging

Graphing

Fixed point

calibration

• • • • • • • •

• • • • • • • •

• •

• •

• • • • • •

• • • • •

• • • • • • • •

• • •

• • •

• • • • •

• • • • •

• • •

• • • •

•

914X 917X

Use two probes and the 1524 to read, log,

graph, and calibrate twice as much.

•

• •

• •

Calibrators wit h measurement capability

The 914X-P can act as the indicator for transmitters, thermocouples and RTDs and even a

reference PRT to improve accuracy.

5

Page 6

Table 5. ITS-90 fixed point calibration equipment

Temperature Needed equip ment

–196 °C Boiling Point of Liquid Nitrogen with 7196-4 Vacuum Flask Dewar

–38.8344 °C 5900 Triple Point of Mercury (TpHg) Cell and 7341 Mercury Maintenance Bath

0.010 °C 5901-D-Q T riple Point of Water (TPH20) Cell and 7312 TPW Maintena nce Bath

29.7646 °C 5943 Melting Point of Gal lium (MPGa) Cell and 9230 Ga llium Maintenance

156.5985 °C 5904 Freezing Point of I ndiu m (FPIn) Cell and 9114 Freeze Point Furnace

231.928 °C 5905 Freezing Point of Tin (FPSn) Cell and 9114 Freeze Point Furnace

419.527 °C 5906 Freezing Point of Zinc (FPZn ) Cell and 9114 Freeze Point Furnace

660.323 °C 5907 Freezing Point of A lum inum (FPAl) Cell and 9114 Freeze Point Fur nace

961.78 °C 5908 Freezing Point of Silver (FPAg) Cell and 9115A Freeze Point Furnace

–196 °C to 961 °C 5581 Primary Standard Automated Resistance Bridge

–196 °C to 660 °C 5430-10 10-Ohm Resistance Standard and 7108 Resistor Maintenance Bath

0 °C to 961 °C 5430-1 1-Ohm Resistance Standard and 7108 Resistor Maintenance Bath

Apparatus

5313-002 10 Channel Scanner for Automated Resistance Bridge ( optional)

5313-004 Software for Automated Resistance Bridge

As mentioned earlier, fixed

point calibration is a little

different from comparison calibration and requires different

equipment. Table 5 shows the

kind of equipment used in a

primary standards laboratory

that performs fixed point calibrations on SPRTs.

There is at least one fixed

point cell that is used in

almost all temperature calibration laboratories around

the world. The triple point of

water cell is the backbone of

the temperature calibration

laboratory, even if comparisons

are the only type of calibration performed. The triple point

of water is not just required

for calibrating SPRTs, it’s also

required for maintaining their

accuracy after calibration.

So if you own an SPRT, you

should also own a triple point

of water cell. Even secondary

reference PRTs used as calibration temperature standards are

also checked regularly at the

triple point of water to ensure

their continued reliability. Mini

triple point of water cells are

available to make this more

convenient and economical.

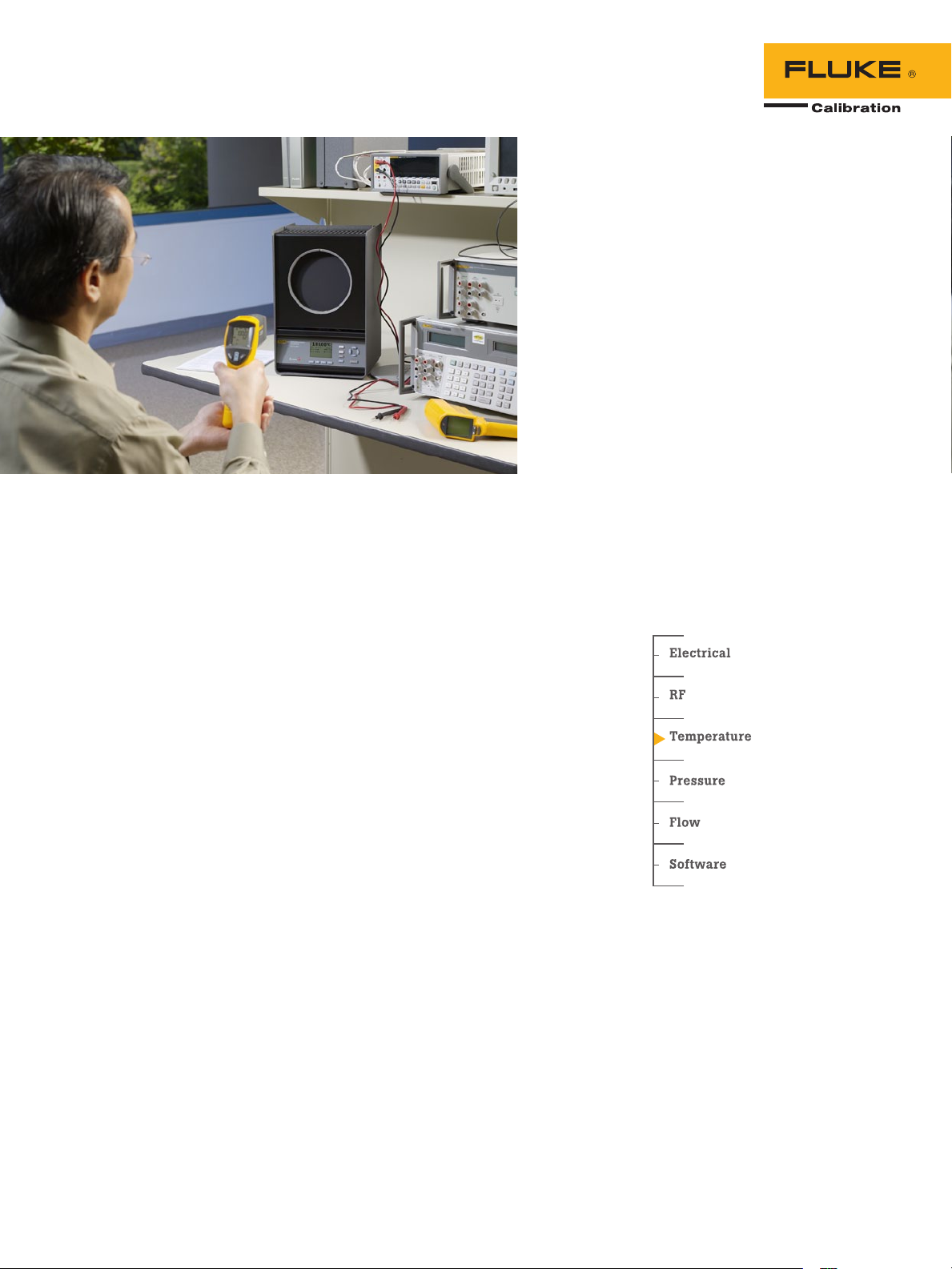

A few examples

To reinforce this discussion,

a few examples arranged in a

good, better, and best format

are summarized in table 6.

A good solution for performing calibrations on-site is a

dry-well. If you are new to

on-site temperature calibration,

a handheld dry-well like the

9100S or 9102S is a good place

to start. You can learn to use

these in less than 15 minutes,

they can be taken just about

anywhere you need to calibrate

something, and they are very

reasonably priced.

A better solution would be a

field dry-well with an external reference thermometer for

improved accuracy. A 1523 is

a great choice for the readout

because it graphs temperature

in real-time, letting you know

exactly when it’s time to take a

reading, and it measures PRTs,

thermistors and thermocouples.

6 Fluke Calibration Temperature calibration equipment: A technicians guide

Page 7

Table 6. Examples of calibration solutions

Good Better Best

Accu racy 1.0 °C to 0.1 °C 0.1 °C to 0.01 °C 0.01 °C to .001 °C

Workload Dial ther mometers RTDs/PRTs PRTs

Thermocouples Liquid in glass SPRTs

Typical environment Mostly on-site Lab or on-site Lab

Entry-level solution Handheld dry-well:

Premium solution

9100S or 9102S

Handheld readout: 1523

or 1524

PRT : 5616 5699 SPRT 5901D-Q TPW cell

Field dry-well: 9103 or

9141

Field Metrology Well:

914X-P

5626 reference PRT

1560 with 256X Module 7012 TPW Maintenance

70XX or 60XX bath 9114 fixed point furnace

9210 mini Tpw

Maintenance Apparatus

5901B mini TPW cel l

9260 Mini Furnace

594X Fixed Point Cells

7196 LN2 comparator

Bath

590X fixed point cells

7341 TPHg bath

5900A TpHg cell

7196 LN2 Comparator

5681 SPRT

5581 Resistance bridge

More accurate thermometers

like RTDs and LIGs (liquid in

glass thermometers) require

more accurate equipment to

calibrate them. The equipment

used to calibrate RTDs and LIGs

often bridge the gap between

on-site and laboratory calibration work and could be used

in either location. For example,

914X Field Metrology Wells

can be carried on-site in one

hand and are great for speed

and versatility. 917X Metrology

Wells are portable and yet are

sufficiently accurate for laboratory calibration work. On the

other hand, certain calibration

baths, are sufficiently compact

to, be taken on-site (i.e. 6102

or 7102 Micro-Baths), but most

calibration baths are used

exclusively in the laboratory,

because of their size.

For best results, SPRTs and

better PRTs can be calibrated

by fixed point. Entry-level fixed

point calibration is usually

done with mini-fixed point

cells for high-end PRTs. The

maintenance apparatus for

these are significantly less

expensive than maintenance

apparatus for large cells, and

the smaller dimensions make

it easier to calibrate PRTs than

SPRTs (i.e. 9 in to 15 in) and

would not be long enough for

calibration in the large fixed

point cells. Fixed point calibrations do not require a reference

thermometer, unless a comparison at the normal boiling point

of liquid nitrogen (–197 °C) is

substituted for the triple point

of Argon (–189.3442 °C).

7

Page 8

Conclusion

If you have a new type of thermometer to calibrate, hopefully you

now have a better idea of what you are going to need to calibrate

it. If you have SPRTs, you are going to need the equipment for

fixed point calibration, and if you are doing comparison calibrations of other types of thermometers, your choice of equipment

may hinge largely on where you have to go to calibrate them. If

it’s in the laboratory, you’ll probably use baths and SPRTs with

thermometer readouts, and if you’re calibrating on-site you’ll

be using a calibrator like a Field Metrology Well or Micro-Bath.

Whichever way you decide to go, don’t forget to talk to the

experts; we’ll help you get started and keep you up and running.

8 Fluke Calibration Temperature calibration equipment: A technicians guide

Fluke Calibration.

Precision, performance, confidence.

Fluke Calibration

PO Box 9090, Everett, WA 98206 U.S.A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2010 Fluke Corporation.

Specifications subject to change without notice.

Printed in U.S.A. 8/2010 3592831A A-EN-N

Modification of this document is not permitted without

written permission from Fluke Corporation.

Pub-ID 11667-eng

™

Loading...

Loading...